Abstract

Heat production from a geothermal energy source is gaining increasing attention due to its potential contribution to the decarbonization of the European energy sector. Obtaining representative results of the environmental performances of geothermal systems and comparing them with other renewables is of utmost importance in order to ensure an effective energy transition as targeted by Europe. This work presents the outputs of a Life Cycle Assessment (LCA) performed on the Rittershoffen geothermal heat plant applying guidelines that were developed within the H2020 GEOENVI project. The production of 1 kWhth from the Rittershoffen heat plant was compared to the heat produced from natural gas in Europe. Geothermal heat production performed better than the average heat production in climate change and resource use, fossil categories. The LCA identified the electricity consumption during the operation and maintenance phase as a hot spot for several impact categories. A prospective scenario analysis was therefore performed to assess the evolution of the environmental performances of the Rittershoffen heat plant associated with the future French electricity mixes. The increase of renewable energy shares in the future French electricity mix caused the impact on specific categories (e.g., land use and mineral and metals resource depletion) to grow over the years. However, an overall reduction of the environmental impacts of the Rittershoffen heat plant was observed.

1. Introduction

Geothermal energy refers to the thermal energy stored in the Earth’s underground. Several applications exist for geothermal energy. Among the numerous examples, one could cite the possibility to avoid ice formation on street pavements [1], coupling heat pumps with heat exchangers included into pile foundations to improve heating and cooling of buildings [2,3], or recreational purposes such as the Blue Lagoon Resort in Iceland [4]. Still, the most common applications remain the production of heat and/or electricity. In Europe, the potential use of geothermal energy for power or heat production is increasingly gaining attention. In fact, European geothermal power generation capacity has increased in 2019 to 3.3 GWe, thus representing a 5% growth compared to 2018. Similarly, 5.5 GWth geothermal district heating and cooling capacity was installed in Europe in 2019 and the planned projects foresee a rapid growth of this type of geothermal resource exploitation [5]. Technological developments have further increased the deployment potential of geothermal energy. For example, Enhanced Geothermal Systems (EGS) make non-accessible geothermal resources useable by injecting water and/or chemicals into the underground to improve its permeability.

Advantages of producing heat and/or power from geothermal energy include the continuous nature of the supplied energy, the large amount of geothermal resource, low operating costs, and the expected contribution to the decarbonization of the European energy sector [6]. In fact, in opposition to other energy generating technologies, geothermal energy systems emit few greenhouse gases (GHG) into the environment during their operation phase [7]. However, other life cycle stages, such as the construction or end-of-life, might imply emissions of GHG into the environment. In addition, building and operating a geothermal plant can involve other environmental impacts such as acidification or human toxicity impacts [8]. The same rationale applies to other energy generating technologies, thus calling for a method to estimate the potential environmental impacts of any energy generating technology and so allow for comparisons and support decision-making processes. Life Cycle Assessment (LCA) represents such a method, since it is a widely accepted and standardized methodology within which the resources, material, and energy flows necessary for the entire life cycle of a system are translated into a series of potential environmental impacts [9,10]. Despite the standardization of LCA in international norms, its application to specific processes, such as energy generating systems, still leaves the LCA practitioner with several choices. Choices related to, for example, the system boundaries, the functional unit, the allocation procedure, the system’s lifetime, or the impact assessment method, which can lead to large differences in the final LCA results. In fact, for power generation from geothermal plants, the IPCC reports variations in the climate change impact ranging from 5 to 45 g CO2-eq/kWh for flash steam plants and 22 to 80 g CO2-eq/kWh for EGS. To help LCA practitioners to reduce this large variability and conduct reproducible and comparable LCAs, Parisi et al. [11] published guidelines for the LCA of geothermal energy projects, based on the outcomes of the European H2020 GEOENVI project [12]. These guidelines provide recommendations for harmonised methodological choices on each of the four steps of LCA. First, during the goal and scope definition, where guidance on the functional unit and system boundaries definition is, for example, given. Second, during the inventory analysis, where LCA practitioners are encouraged to use installation-specific data as much as possible but are provided with alternative default values in the guidelines. Third, during the impact assessment phase, where the use of the Environmental Footprint v3.0 method is recommended, and seven impact categories are classified as of high relevance. Finally, in the interpretation phase where the guidelines state which results to generate and how they should be reported.

The publication of these guidelines should facilitate the application of LCA in the geothermal context and so increase the number of available LCA results while ensuring their comparability. In fact, only few complete LCAs of geothermal energy systems are available thus far. In 2012, the review of the IPCC on electricity from geothermal energy only reported eight LCA studies. More recently, in 2017, Tomasini-Montenegro et al. [13] reviewed a total of 19 studies for the different types of geothermal energy technologies. Reliable and comprehensive estimates of the environmental impacts of geothermal energy systems, also accounting for potential future developments, is however essential to satisfy the needs of regulatory bodies, for example within the European sustainable financing scheme [14].

The aim of this paper was therefore to apply the LCA guidelines for geothermal energy systems to the Rittershoffen geothermal heat plant and compare the outcomes to a traditional heat source, i.e., natural gas. Furthermore, the influence on the LCA results of the evolutions in the electricity grid mix supplied to the installation were also assessed. This paper presents one of the first applications of the geothermal LCA guidelines to an EGS plant producing heat [15,16]. It further advances current knowledge by providing a full overview of the environmental profile and describing its potential changes based on the evolution of the supplied electrical grid mix [17].

2. Materials and Methods

In this Section, a brief description of the Rittershoffen geothermal heat plant is given. Then, the LCA phases as mentioned in the ISO standards are described. The LCA was performed according to the approach described in the LCA guidelines [11]. Instead of describing each methodological choice, only the most critical steps of this LCA are reported here with the intention to provide a reference case study for future work aiming to follow the LCA guidelines. Finally, details on the comparison to heat production from natural gas and the evaluation of prospective electricity mixes to feed into the Rittershoffen geothermal heat plan are provided. Even though such comparison is not covered by the LCA guidelines, it is included here to put the geothermal heat production in context and quantify the potential environmental advantages of using geothermal energy instead of traditional fossil-based sources.

2.1. Plant Description

The geothermal heat plant of Rittershoffen has been developed to supply heat to the industrial processes of a starch plant. This industrial user is placed in Beinheim, France, and its demand amounts to 100 MWth. The Ritthershoffen heat plant has an installed capacity of 27.5 MWth, and it has been providing an average of 22.5 MWth and 180 GWh/year of heat to the starch plant since June 2016.

The Ritthershoffen heat plant reservoir is a Triassic sandstone and the top of a fractured carboniferous granite basement located at 2500 m depth. The heat plant relies on two wells. The first well, GRT-1, 2580 m Measured Depth (MD), was drilled in 2012. After drilling of the GRT-1, an initial testing resulted in a low productivity index. A stimulation program, including thermal, chemical, and hydraulic stimulation, was therefore performed in 2013 [18]. The second well, GRT-2, 3196 m MD, was drilled in 2014. The total drilled length for GRT-2 is 3938 m, because a part of this well was cemented for consolidation and redrilled. On the contrary to GRT-1, the test performed after drilling on GRT-2 showed a good productivity index. The Rittershoffen geothermal heat plant is classified as an EGS due to the stimulation activity performed on GRT-1 and because of the total reinjection of the discharged geothermal fluids in the reservoir.

The geothermal brine is a Na-Ca-K-Cl dominated brine with a Total Dissolved Solids content of approximately 100 g/L. Non-Condensable Gas (NCG) content is 0.24% in weight mass and it is composed mainly of CO2 [19]. Due to the nature of the reservoir, the heat plant was designed with a pressurized geothermal loop. The loop consists of a downhole Line Shaft Pump (LSP) which works to pressurize the geothermal brine in the surface equipment to exceed the gas break-out pressure. This pressure level allows to maintain the gas dissolved in the liquid phase and prevents any NCG emission during operation.

Figure 1 shows a schematic representation of the Rittershoffen geothermal heat plant supplying heat to the industrial user. The production temperature at the wellhead of the GRT-2 reaches 170 °C and the flowrate is regulated at 75–85 kg/s. This is necessary to satisfy the starch plant’s heat demand. The geothermal heat is transferred to a secondary loop by means of tubular heat exchangers. The brine is then fully reinjected back into the injection well, GRT-1, without any additional pumps at a temperature of 85 °C. This secondary loop that carries freshwater, is then connected to a 15 km long transport loop to transfer the heat to the starch plant.

Figure 1.

View of the Rittershoffen geothermal plant and schematic representation of the plant suppling heat to the industrial user (credits: ES group).

2.2. Goal and Scope of the Study

The goal of the LCA presented in this study was to assess the environmental impacts related to heat production from the Rittershoffen geothermal heat plant.

2.2.1. Functional Unit Definition

The Rittershoffen plant produces only heat. Therefore, the functional unit selected was 1 kWhth produced at the plant and no allocation procedure was needed.

2.2.2. System Boundaries

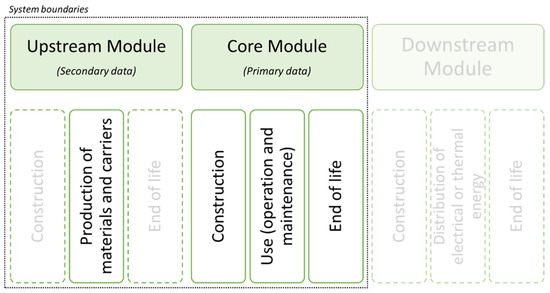

According to the LCA guidelines [11] and as reported in Figure 2, the system boundaries of the LCA were divided into two modules namely upstream and core modules. The upstream module included the production processes for materials and energy consumed by the core module (i.e., background system). Generally, these are secondary data which are taken from existing LCA databases. To meet the recommendations of the LCA guidelines, the Environmental Footprint (EF) database as provided by the openLCA developers was used as source of background processes [20]. The core module is represented by the construction of the infrastructure, operation, maintenance, and End of Life (EoL) phases of a geothermal energy conversion plant. The core module must be included in any LCA study of geothermal systems [11]. The core module should be modelled using primary data directly measured or collected from reports or questionnaires and representative of the geothermal plant (site and technology specific). In the case of the Ritthershoffen heat plant, the core module entails:

Figure 2.

Graphical representation of the system boundaries adopted in the LCA of Rittershoffen heat plant.

- -

- Construction: the exploration activity, drilling of the wells and stimulations, wellheads, collection pipelines, power plant building, and all the necessary plant machinery/equipment items. The construction of the district heat network was excluded from this phase.

- -

- Operation & Maintenance: the energy requirements for the geothermal fluid exploitation, scaling and corrosion prevention agent as well as equipment replacement.

- -

- End of life: procedures for the correct closure of the wells, and the treatment of wastes produced from all previous phases.

2.2.3. Data Quality

The Life Cycle Inventory (LCI) developed by Pratiwi et al. [17] was used as an initial source of data and complemented by new information in collaboration with the plant operator. In some cases, mathematical relationships were used to determine the input amount of some processes. Further information can be found in Douziech et al. [21]. However, since primary data, based on real drilling, building and operation, were used for most activities, the overall data confidence index is considered high.

2.2.4. Software and Database Adopted

The modelling of the Rittershoffen geothermal heat plant and the calculations were performed with the openLCA V1.10.3 software [22]. The database used to model the background processes is the Environmental Footprint database version 2 (EF2) as provided by Green Delta and designed to be uploaded in the openLCA software.

2.3. Life Cycle Inventory

The detailed inventory of the Rittershoffen geothermal heat plant has been provided as supplementary material to this article and can be accessed with the link reported in the specific Section of this manuscript.

The electricity mixes used in the study were modelled based on [23] and adapted to the background dataset available. Table 1 reports the relative composition of the electricity mix by sources. The relative composition calculated in the report refers to the net energy produced. Therefore, the efficiency of power plants and network losses are included.

Table 1.

Share of the electricity mix composition by sources used to perform the study.

Table 2 reports the specific names of the processes used to build the French (FR) energy mix as provided by the EF dataset.

Table 2.

Processes used for each energy source as retrieved from the EF2 dataset.

2.4. Life Cycle Impact Assessment Method

The life cycle impact assessment adopted was the Environmental Footprint 2 (EF2). The guidelines recommend the use of the EF version 3 due to the most updated characterization factors for substances especially concerning (eco)toxicity related impact categories. However, for the time being, the openLCA software does not support the EF3, and the conversion procedure from EF2 to EF3 is very time consuming and error prone. Therefore, we opted for calculating LCA results by adopting the EF2 method which is embedded in the openLCA software. Following the guidelines’ indication, the impact categories were classified according to their level of priority: (1) indicators with a high priority to be applied for any type of geothermal systems (2) indicators with a moderate priority and (3) indicators with a low priority but worth to be considered depending on the type of geothermal system and the specificity of its local environmental. High priority categories, namely Acidification (ACI), Climate Change (CC), Resource use, minerals and metals (RMi), Resource use, fossil (REn), Human toxicity, carcinogenic (HTC), Human toxicity non-carcinogenic (HTN) and Ecotoxicity (Eto), are considered as such because of their relevance in the geothermal context as highlighted by the available literature and expert opinions.

3. Results

3.1. Environmental Impacts and Contribution Analysis of the Rittershoffen Geothermal Heat Plant

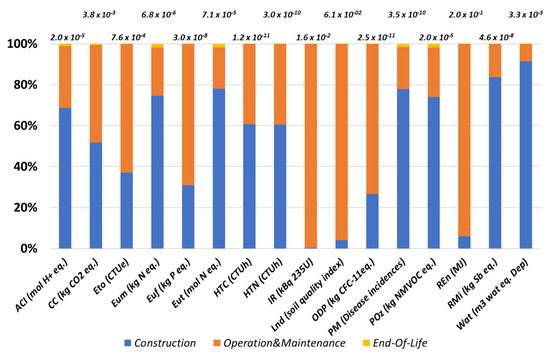

This Section reports the LCA results of the Rittershoffen power plant. The results are divided according to categories’ priority as suggested in the LCA guidelines [11]. Therefore, the seven impact categories with high priority are discussed in detail and process contributions are given, whereas general trends are described for all other impact categories. Figure 3 shows the characterized results for all impact categories along with, for each impact category, the contributions of the main phases of the life cycle to the total impact.

Figure 3.

Percentages of contribution of main life cycle phases to the total impact in all impact categories selected. The total characterized impact for each category is reported at the top of the corresponding columns. Geothermal source type: liquid, energy conversion technology: direct heat use, load factor: 77%, annual energy output decay: <0.1%, lifetime installation: 30 years, installed capacity: 27 MWth, number of wells: 2 (GRT-1: 2580 mMD, GRT-2: 3938 m total drilled).

- Climate Change (CC)

The major contribution to the total impact on CC is represented by the Construction phase that covers 52% of the total impact. In this phase, the process that has a significant influence on CC is the drilling (about 35% of the impact on CC). As expected, 99% of the impact from the drilling activity is linked to the direct emissions of CO2 due to diesel combustion to operate the drilling rigs. Concerning the powerplant construction, the main influence on CC is due to the construction of the heat exchanger (i.e., 10% of the construction phase) and of the downhole production pumps (13% of the construction phase). In this case, the indirect emissions of CO2 from background production processes are responsible for most of the impact of these two processes. The second contribution is due to the operation and maintenance phase which amounts to about 47% of the total impact on CC. Within this phase, the impact is dominated by the internal electricity (i.e., French national mix) consumption that accounts for 38% of the total impact on CC.

- Acidification (ACI)

The main contributor to the ACI category is the construction phase (about 70% of the total impact on ACI). Well drilling, production pumps and heat exchanger construction play the major role in determining the impact from the construction phase with a contribution of 47, 13 and 6% to the total impact of construction phase, respectively. Direct emissions of sulphur and nitrogen dioxides to air from diesel combustion during drilling activities contribute the most to the impact. The operation and maintenance phase’s contribution is dominated by electricity requirements.

- Resource use, minerals and metals (RMi)

The impact on the use of mineral and metal resources is dominated by the contruction phase, with about 80% of the total contribution. Within this phase, the use of steel is by far the most influencing process. Next to the construction phase, the operation and maintenance phase contributes 16% to the total impact on the resource use mineral and metals category because of equipment replacement during operation and the electricity consumption.

- Resource use, fossil (REn)

The impact on the use of fossil resources is determined by the electricity requirement from the operation and maintenance phase (95% of the total impact on this category).

- Human Toxicity, carcinogenic (HTC)

The construction phase has the largest contribution (i.e., 60%) to the total impact on the HTC category. The processes that contribute the most are the construction of the power plant machineries (i.e., 36% of the total impact on HTC), because of steel requirement, and more specifically the construction process of the heat exchanger and production pumps. The well drilling process is responsible for 25% of the total impact on HTC.

The operation and maintenance phase registered a contribution of about 40% to the total impact on HTC. Internal electricity consumption determines the impact of this phase. The emissions that determined the impact on HTC are chromium, nickel and mercury to air and chromium to water from the steel production process.

- Human Toxicity, non-carcinogenic (HTN)

The impact on HTN from the commissioning phase is determined by the well drilling activity (i.e., 31% of the total impact on HTN) and the production pumps’ construction (12% of the total impact on HTN) followed by the construction of the heat exchanger (9% of the total impact on HTN). Concerning the operation and maintenance phase (i.e., 40% of the total impact on HTN), the internal electricity consumption contributes the most to the impact of this phase.

The elementary flow contributing to the HTN impact is the indirect emission of lead (Pb) to air during the steel production process.

- Ecotoxicity (Eto)

The impact on the Eto category is determined to 62% by the operation and maintenance phase. Within this phase, the electricity consumption plays a major part of the impact. The emission of Vanadium to water has a significant influence on the final impact on ETo. The remaining part of the impact to Eto (i.e., about 36%) is due to the well drilling, production of the heat exchanger and production pumps during the construction phase.

Impact categories with moderate and low priority show a similar trend compared to high priority ones where construction and operation and maintenance phases determine most of the impacts. The process contributions are also very similar to the ones already described for high priority categories. It is worth to mention that the anticorrosion agent used during the operation and maintenance of Ritthershoffen heat plant has a significant impact on the freshwater eutrophication (EUf) category.

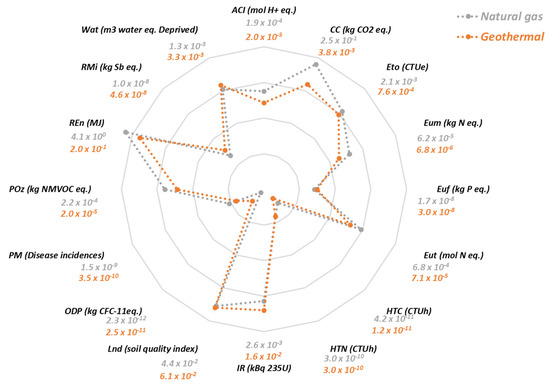

3.2. Comparison with Natural Gas

Figure 4 reports the characterized environmental impacts for the heat production from natural gas (European average EU28) and the heat produced by the Rittershoffen plant for all the impact categories considered in this study. The comparison shows that the geothermal heat production performed better on 9 out of the 16 impact categories selected. In particular, the geothermal heat production performed better on the climate change (CC) and resource use, fossil (REn) categories. On the contrary, the ionizing radiation (IR) and ozone depletion (ODP) categories showed a higher impact from geothermal heat production compared to natural gas. These impacts are linked to the current relatively high share of the nuclear resource in the French electricity mix. This picture is expected to change considering the future trends of the French electrical mix composition, as shown in Section 3.3.

Figure 4.

Comparison of the production of 1 kWhth from the most common heat source in Europe (Natural gas, grey dots in Figure 4) with the investigated heat production from the Rittershoffen power plant (Geothermal, orange dots in Figure 4). The characterized results of impacts from natural gas (in grey) and geothermal (in orange) are reported below the corresponding categories. Geothermal source type: liquid, energy conversion technology: direct heat use, load factor: 77%, annual energy output decay: <0.1%, lifetime installation: 30 years, installed capacity: 27 MWth, number of wells: 2 (GRT-1: 2580 m MD, GRT-2: 3938 m total drilled).

Regarding the categories EUf, Water depletion (Wat) and RMi, impacts associated with heat production from natural gas are lower than those from geothermal source.

3.3. Impacts of the Electrical Mix

Table 3 reports the LCA results of 1 kWhth produced by the Rittershoffen heat plant for the 2020 and 2050 electricity mixes that were modelled as described in Section 2.4. The different electric mixes employed in the model resulted in a small variation (i.e., <10%) of the total impact for the categories ACI, CC, Eto, marine eutrophication (EUm), terrestrial eutrophication (EUt), HTC, particulate matter (PM), photochemical ozone formation (POz) and Wat when the 2020 was compared to the future 2050 scenario. The impacts on the mentioned categories are namely determined by processes taking place during the construction phase (e.g., drilling activities and steel production) so that increasing the renewables share in the electricity mix did not affect such categories much. On the contrary, the composition of the future French electricity mix reduced the impacts in 2050 of the categories ionising radiation (IR), ozone depletion potential (ODP) and REn and increased the ones of EUf, HTN, land use (Lnd), RMi when compared to 2020.

Table 3.

Characterized impacts for the 2020 and 2050 electricity mixes. The variation between the 2020 and 2050 results is also reported as percentage. Geothermal source type: liquid, energy conversion technology: direct heat use, load factor: 77%, annual energy output decay: <0.1%, lifetime installation: 30 years, installed capacity: 27 MWth, number of wells: 2 (GRT-1: 2580 mMD, GRT-2: 3938 m total drilled).

4. Discussion

Among currently available studies, only the one by Pratiwi et al. [17] on the climate change impact of the Rittershoffen heat plant is to some extent comparable to our results. This comparison increases the confidence in the presented results and highlights how the LCA guidelines contribute to harmonising LCA practices in this sector. Pratiwi et al. [17] report 5.5 gCO2-eq/kWhth for the Rittershoffen heat plant excluding the transport pipes, which is close to the 3.7 gCO2-eq/kWhth reported here. The differences most likely relate to the different system lifetimes (25 years in Pratiwi et al. [17] compared to 30 years here), the different databases used for background processes (ecoinvent 3 in Pratiwi et al. [17] compared to EF here), and updates in the inventory flows. Karlsdottir et al. [24] characterized several environmental impacts for the geothermal district heating system of Stykkishólmur. The impact assessment results are however derived using the CML 2 baseline method, which leads to incomparable results for most of the impact categories (e.g., acidification, human and freshwater ecotoxicity). Further, the system boundaries include the district heating station and distribution system, making a comparison with the results presented here not appropriate.

While the developed guidelines are extremely useful to ensure the comparability of future geothermal LCAs, their application to this case study highlighted potential areas of improvement to increase their usefulness among LCA practitioners in the geothermal sector. The variety of the environmental impact categories makes a clear representation of the results difficult. In this regard, the application of normalization methods, such as the one recommended by the Joint Research Center [25] could be useful to guide the choice of the results to represent. Still, it is important that LCA practitioners keep the habit of reporting results for all impact categories, be it only in form of a table in the Supplementary Material. Further, as mentioned in the Methods’ Section, the recommendation of using the EF v3.0 method is currently difficult to apply. However, as this method becomes more widespread in LCA software, its use can be very beneficial to ensure uniformity in the inventory for different LCA studies. These recommendations, as well as other gathered during different stakeholder meetings with interested partners, were published recently [26].

The results of this paper clearly highlight the contribution of two life cycle phases to the environmental impact assessment of heat production from geothermal, namely the operation and maintenance and the construction phase. More specifically, the electricity grid mix used to power the pumps during the operation and maintenance phase and the material requirements (e.g., steel) during the construction phase were particularly influencing the environmental results. This is in line with the results published by Pratiwi et al. [17] for the greenhouse gas emissions of the Rittershoffen heat plant, except that in our study, as recommended in the guidelines, the transport pipes to and from the starch plant are not included within the system boundaries. Such a contribution analysis is particularly useful to identify hotspots in the environmental assessment of geothermal projects. The current finding shows the importance of including all the greenhouse gas emissions occurring over an installation’s life cycle since the climate change impact is due to nearly 50% to GHG occurring during the construction phase. Such findings are of particular importance for the assessment of “sustainable” projects and could feed into different carbon footprint methodologies, like the one of the European Investment Bank [27].

In this paper we further compared the results of heat production from geothermal energy to heat production from natural gas and put them in the perspective of future electricity mix evolutions. We showed that, in the case of Rittershoffen, producing heat from geothermal energy leads to a lower impact on climate change than using natural gas. Similarly, the lower impact in fossil resources use indicate that geothermal heat production can contribute to achieve the European objective concerning GHG reduction and the decarbonization of the energy and industrial sectors. For the ODP and IR impact categories, where heat production from geothermal shows larger impacts than natural gas, our analysis showed that the prospective developments of the electricity grid mix can help improve the environmental performances of geothermal heat. As for the impact categories for which geothermal heat showed larger impacts, namely EUf, RMi and Wat, the improvement of the environmental performance will require lower material uses during the construction phase, and particularly the anti-corrosion agents and steel.

Despite the consideration of different scenarios for the electricity mix input to the EGS, the presented case study neglects several sources of uncertainty and variability, that potentially influence the results. Variability in the power of the production or injection pumps during the 30 years of operation can for example greatly influence the electricity need and therefore the results of several impact categories. Besides uncertainty and variability in the inventory, the life cycle impact assessment methods also suffer from some uncertainty. For example, the high contribution of metals to the (eco)toxic impact categories calls for caution in the interpretation of the results. In fact, as highlighted in the guidelines, (eco)toxic results from metal emissions are very uncertain and their influence on the results can therefore only be interpreted as a flag mentioning their potential contribution to the results. A thorough sensitivity analysis was however not the aim of this paper but can be found elsewhere [21]. Finally, the importance of the reliability of the input inventory data should be highlighted as it conditions the reliability of the LCA results. In this study, the close collaboration with the plant operator represents one of the best guarantees of the representativity of the data used and therefore the LCA results.

5. Conclusions

The comparison of the results obtained in this study with those available in literature on the same geothermal heat plant clearly underlined the importance of developing dedicated energy-pathway LCA guidelines to ensure that reproducible, transparent, and comparable LCA results are published.

This study showed how the geothermal LCA guidelines developed within the GEOENVI project, can be applied to a specific case study. This application highlighted some areas where the guidelines can be improved but, more importantly, it showed their importance to ensure the publication of reproducible and comparable LCA studies of geothermal installations.

In addition, this study showed the potential of geothermal heat power plant to produce heat with lower or comparable environmental impacts than when using natural gas. The higher environmental impacts of geothermal heat relate to the large share of nuclear power in the French electricity mix powering the geothermal heat plant and the large steel requirements for the geothermal heat plant’s construction. Our results further support the role of geothermal heat plant in achieving the European objective concerning GHG reduction also in the future, building on the future electricity mix supply change.

This study increases the current knowledge on the potential environmental impacts of deep geothermal heat producing plants. However, while LCA represents the currently most advanced methodology to conduct such assessments, it does not cover all aspects which influence decisions on the construction of deep geothermal projects. Potentially relevant environmental impacts are still missing from current life cycle impact assessment methodologies, such as noise or seismicity. In addition, the perception of such projects among different stakeholders also requires particular scrutiny, for example using approaches such as Social LCA (SLCA). Future research in these areas combining LCA and SLCA is therefore required to ensure a better understanding of the potential environmental and social impacts, topics particularly important to face the different social concerns linked with deep geothermal projects, and in general with the energy production sector.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/en14133820/s1.

Author Contributions

Conceptualization, M.D., L.T., N.F., M.L.P., P.P.-L. and G.R.; methodology, M.D., L.T., N.F., M.L.P., P.P.-L. and G.R.; software, M.D., L.T. and N.F.; validation, M.D., L.T., N.F., P.P.-L. and G.R.; formal analysis, M.D., L.T., N.F. and G.R.; investigation, M.D., L.T., N.F., M.L.P., P.P.-L. and G.R.; resources, G.R.; data curation, M.D., L.T., N.F., P.P.-L. and G.R.; writing—original draft preparation, M.D., L.T. and G.R.; visualization, M.D., L.T., G.R.; supervision, M.D., M.L.P., P.P.-L. and G.R.; project administration, M.D., M.L.P., P.P.-L. and G.R.; funding acquisition, M.L.P. and G.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union’s Horizon 2020 research and innovation program R, grant number 818242—GEOENVI.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors acknowledge ECOGI for the Rittershoffen geothermal site access and data use, as well as the ADEME and Electricité de Strasbourg for the previous LCA study performed in the framework of the EGS Alsace project. L.T. and M.L.P. acknowledge MIUR Grant—Department of Excellence 2018–2022 funding.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

LCA (Life Cycle Assessment), EGS (Enhanced Geothermal Heat), GHG (Greenhouse Gases), Measured Depth (MD), NCG (Non-Condensable Gases), LSP (Line Shaft Pump), EF (Environmental Footprint), EoL (End of Life), ACI (Acidification), CC (Climate Change), RMi (Resource use, minerals and metals), Ren (Resource use, fossil), HTC (Human toxicity, carcinogenic), HTN (Human toxicity non-carcinogenic) Eto (Ecotoxicity), IR (ionizing radiation), ODP (ozone depletion), Wat (Water use), EUm (marine eutrophication), EUt (terrestrial eutrophication), EUf (freshwater eutrophication), Lnd (land use), PM (particulate matter), POz (Photochemical ozone creation formation).

References

- Mauro, A.; Grossman, J.C. Street-Heat: Controlling Road Temperature via Low Enthalpy Geothermal Energy. Appl. Therm. Eng. 2017, 110, 1653–1658. [Google Scholar] [CrossRef]

- Adinolfi, M.; Maiorano, R.M.S.; Mauro, A.; Massarotti, N.; Aversa, S. On the Influence of Thermal Cycles on the Yearly Performance of an Energy Pile. Geomech. Energy Environ. 2018, 16, 32–44. [Google Scholar] [CrossRef]

- Li, Q.; Yin, Y.; Kong, L.; Qiao, L. Enhancing Heat Transfer in the Heat Exchange Medium of Energy Piles. J. Build. Eng. 2021, 40, 102375. [Google Scholar] [CrossRef]

- Gudmundsóttir, M.; Brynjólfsdóttir, Á.; Albertsson, A. The History of the Blue Lagoon in Svartsengi. In Proceedings of the World Geothermal Congress, Bali, Indonesia, 25–30 April 2010. [Google Scholar]

- EGEC. EGEC Geothermal Market Report 2019; EGEC—European Geothermal Energy Council: Brussels, Belgium, 2019. [Google Scholar]

- EGEC Media and Publications Archive. Available online: https://www.egec.org/media-publications/ (accessed on 4 May 2021).

- IPCC. Renewable Energy Sources and Climate Change Mitigation; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Bravi, M.; Basosi, R. Environmental Impact of Electricity from Selected Geothermal Power Plants in Italy. J. Clean. Prod. 2014, 66, 301–308. [Google Scholar] [CrossRef]

- ISO 14044. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Parisi, M.L.; Douziech, M.; Tosti, L.; Pérez-López, P.; Mendecka, B.; Ulgiati, S.; Fiaschi, D.; Manfrida, G.; Blanc, I. Definition of LCA Guidelines in the Geothermal Sector to Enhance Result Comparability. Energies 2020, 13, 3534. [Google Scholar] [CrossRef]

- Tackling the Environmental Concerns for Deploying Geothermal Energy in Europe. Available online: https://www.Geoenvi.Eu/ (accessed on 22 June 2021).

- Tomasini-Montenegro, C.; Santoyo-Castelazo, E.; Gujba, H.; Romero, R.J.; Santoyo, E. Life Cycle Assessment of Geothermal Power Generation Technologies: An Updated Review. Appl. Therm. Eng. 2017, 114, 1119–1136. [Google Scholar] [CrossRef]

- European Commission Overview of Sustainable Finance. Available online: https://ec.europa.eu/info/business-economy-euro/banking-and-finance/sustainable-finance/overview-sustainable-finance_en (accessed on 4 May 2021).

- Lacirignola, M.; Blanc, I. Environmental Analysis of Practical Design Options for Enhanced Geothermal Systems (EGS) through Life-Cycle Assessment. Renew. Energy 2013, 50, 901–914. [Google Scholar] [CrossRef]

- Lacirignola, M.; Meany, B.H.; Padey, P.; Blanc, I. A Simplified Model for the Estimation of Life-Cycle Greenhouse Gas Emissions of Enhanced Geothermal Systems. Geotherm. Energy 2014, 2, 8. [Google Scholar] [CrossRef] [Green Version]

- Pratiwi, A.; Ravier, G.; Genter, A. Life-Cycle Climate-Change Impact Assessment of Enhanced Geothermal System Plants in the Upper Rhine Valley. Geothermics 2018, 75, 26–39. [Google Scholar] [CrossRef]

- Baujard, C.; Genter, A.; Dalmais, E.; Maurer, V.; Hehn, R.; Rosillette, R.; Vidal, J.; Schmittbuhl, J. Hydrothermal Characterization of Wells GRT-1 and GRT-2 in Rittershoffen, France: Implications on the Understanding of Natural Flow Systems in the Rhine Graben. Geothermics 2017, 65, 255–268. [Google Scholar] [CrossRef] [Green Version]

- Mouchot, J.; Genter, A.; Cuenot, N.; Seibel, O.; Scheiber, J.; Bosia, C.; Ravier, G. First Year of Operation from EGS Geothermal Plants in Alsace, France: Scaling Issues. In Proceedings of the 43rd Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 12 February 2018. [Google Scholar]

- Green Delta. OpenLCA Nexus: The Source for LCA Data Sets. Available online: https://nexus.openlca.org/database/Environmental%20Footprints (accessed on 4 May 2021).

- Douziech, M.; Ravier, G.; Jolivet, R.; Pérez-López, P.; Blanc, I. How Far Can Life Cycle Assessment Be Simplified? A Protocol to Generate Simple and Accurate Models for the Assessment of Energy Systems and Its Application to Heat Production from Enhanced Geothermal Systems. Environ. Sci. Technol. 2021. [Google Scholar] [CrossRef] [PubMed]

- GreenDelta|OpenLCA.Org. Available online: https://www.openlca.org/greendelta/ (accessed on 22 June 2021).

- Capros, P.; De Vita, A.; Tasios, N.; Siskos, P.; Kannavou, M.; Petropoulos, A.; Evangelopoulou, S.; Zampara, M.; Papadopoulos, D.; Nakos, C.; et al. EU Reference Scenario 2016—Energy, Transport and GHG Emissions Trends to 2050; European Commission Directorate—General for Energy, Directorate—General for Climate Action and Directorate—General for Mobility and Transport: Luxembourg, 2016. [Google Scholar]

- Karlsdóttir, M.R.; Lew, J.; Pálsson, H.; Palsson, O. Geothermal district heating system in iceland: A life cycle perspective with focus on primary energy efficiency and CO2 emissions. In Proceedings of the 14th International Symposium on District Heating and Cooling, Stockholm, Sweden, 6–10 September 2014. [Google Scholar]

- Sala, S.; Crenna, E.; Secchi, M.; Pant, R. Global Normalisation Factors for the Environmental Footprint and Life Cycle Assessment, EUR (28984); Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-77213-9. JRC109878. [CrossRef]

- Douziech, M.; Blanc, I.; Damen, L.; Fiaschi, D.; Harcouët-Menou, V.; Manfrida, G.; Mendecka, B.; Parisi, M.L.; Perez Lopez, P.; Ravier, G.; et al. Harmonized Life Cycle Assessment Guidelines for Geothermal Installations. Feedback on the Use of the Harmonized Guidelines and the Protocol to Generate Simplified Models. Available online: https://www.geoenvi.eu/wp-content/uploads/2020/12/D-3.6-Harmonised-guidelines.pdf (accessed on 22 June 2021).

- European Investment Bank. EIB Project Carbon Footprint Methodologies; European Investment Bank: Luxembourg, 2020; 60p. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).