Co-Combustion Studies of Low-Rank Coal and Refuse-Derived Fuel: Performance and Reaction Kinetics

Abstract

:1. Introduction

2. Materials and Methods

3. Kinetic Modelling

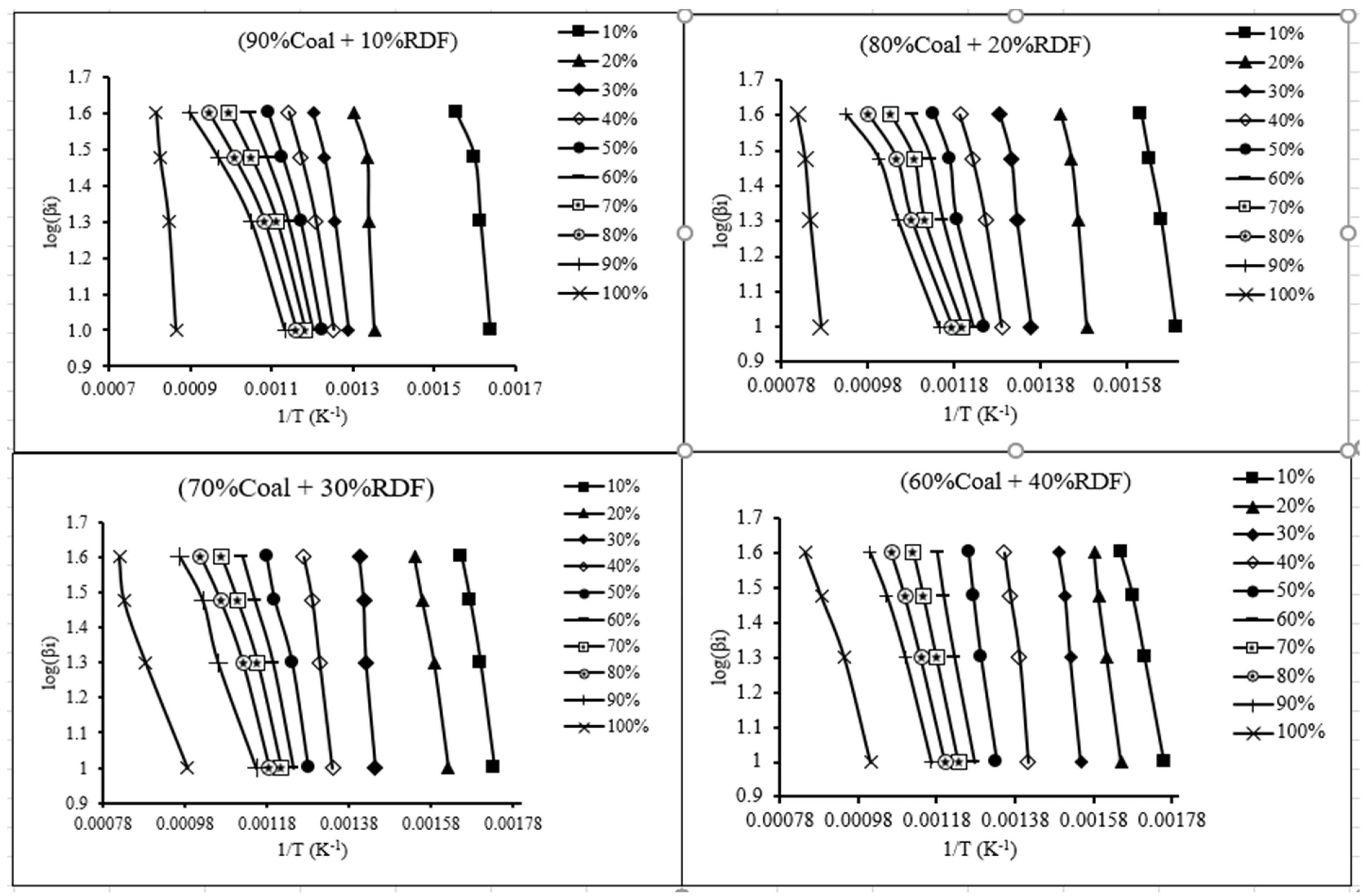

3.1. Kissinger–Akahira–Sunnose Method (KAS)

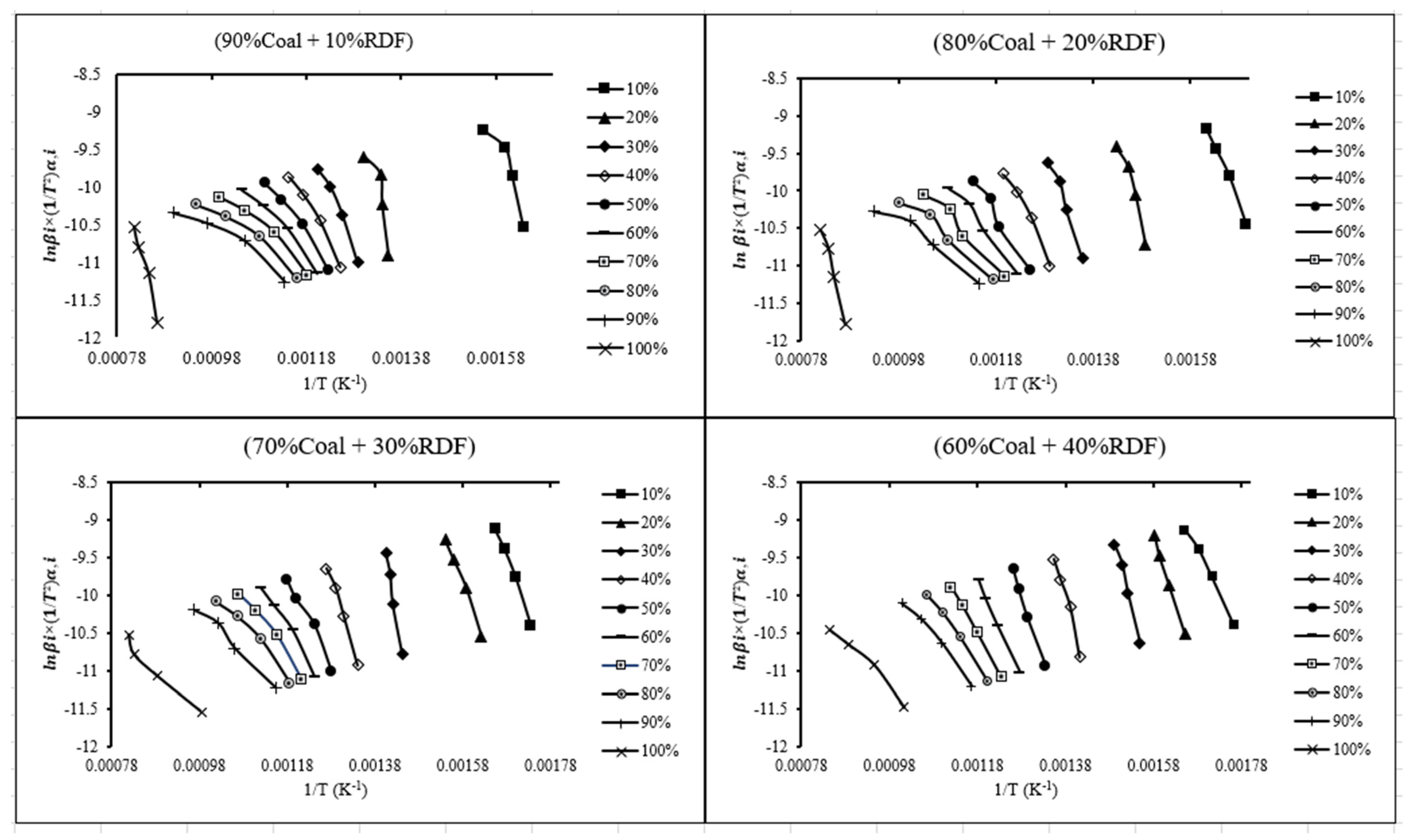

3.2. Flynn–Wall–Ozawa Method (FWO)

4. Results and Discussion

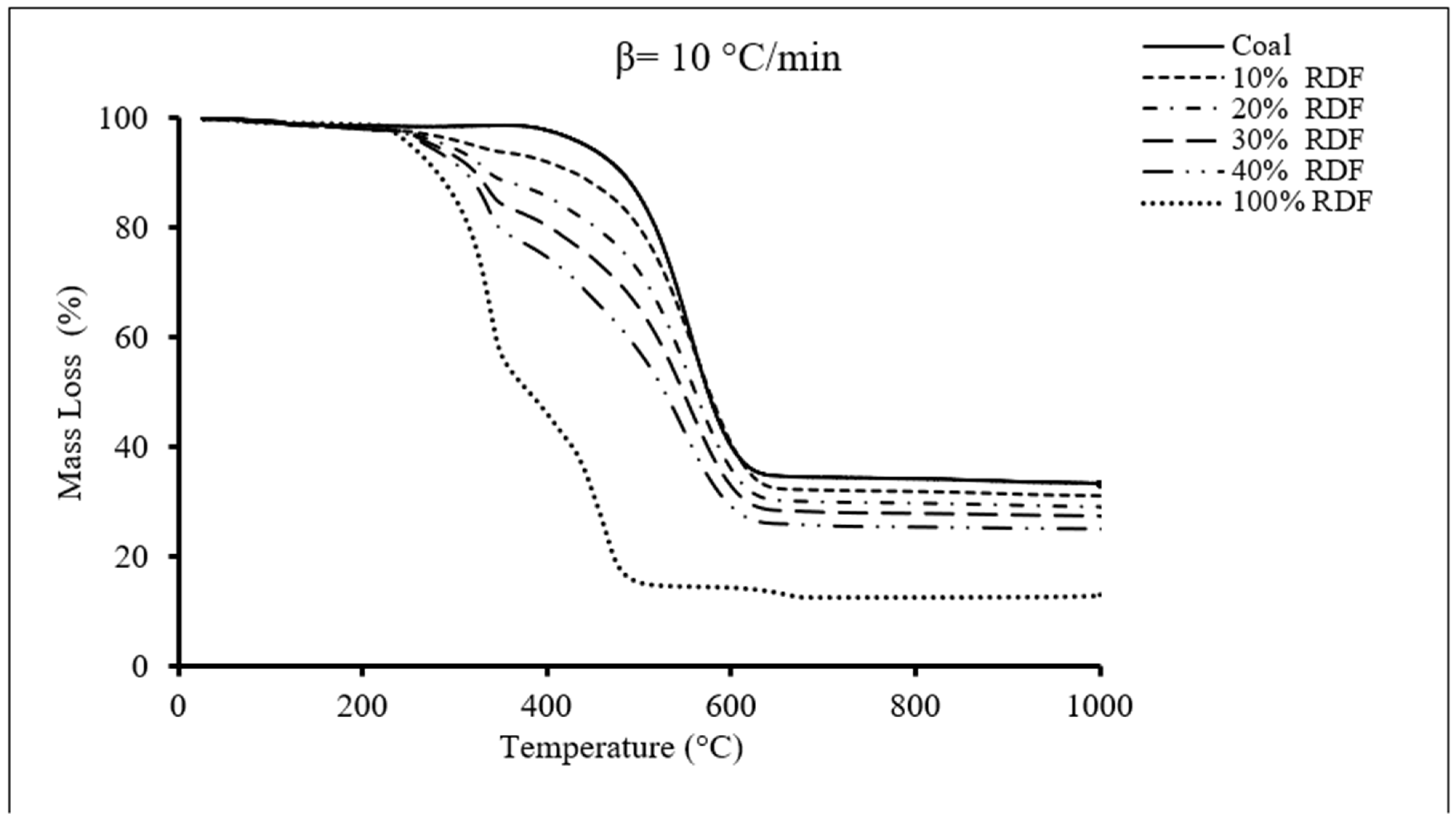

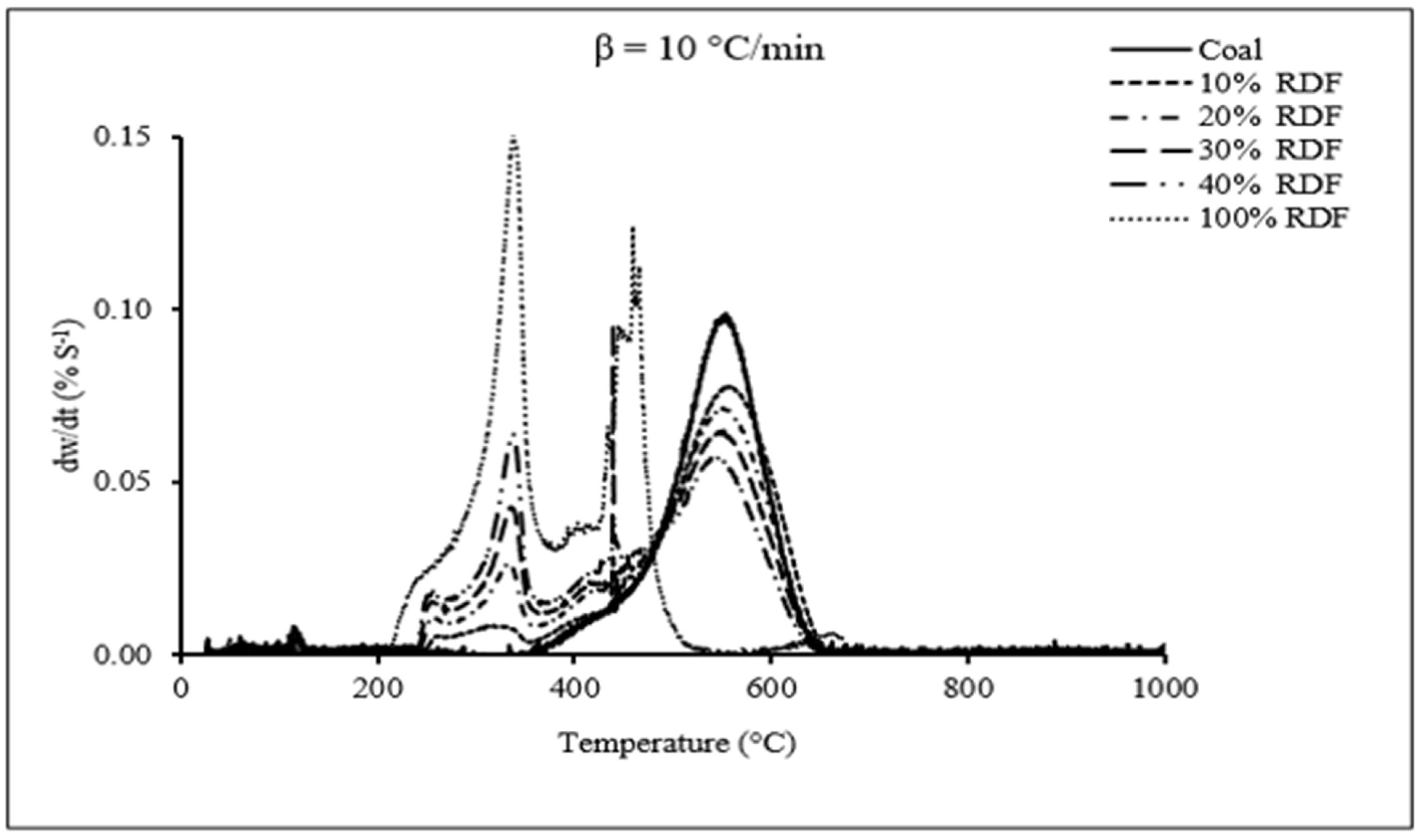

4.1. Thermal Decomposition

4.2. Effect of Blending of Coal with RDF

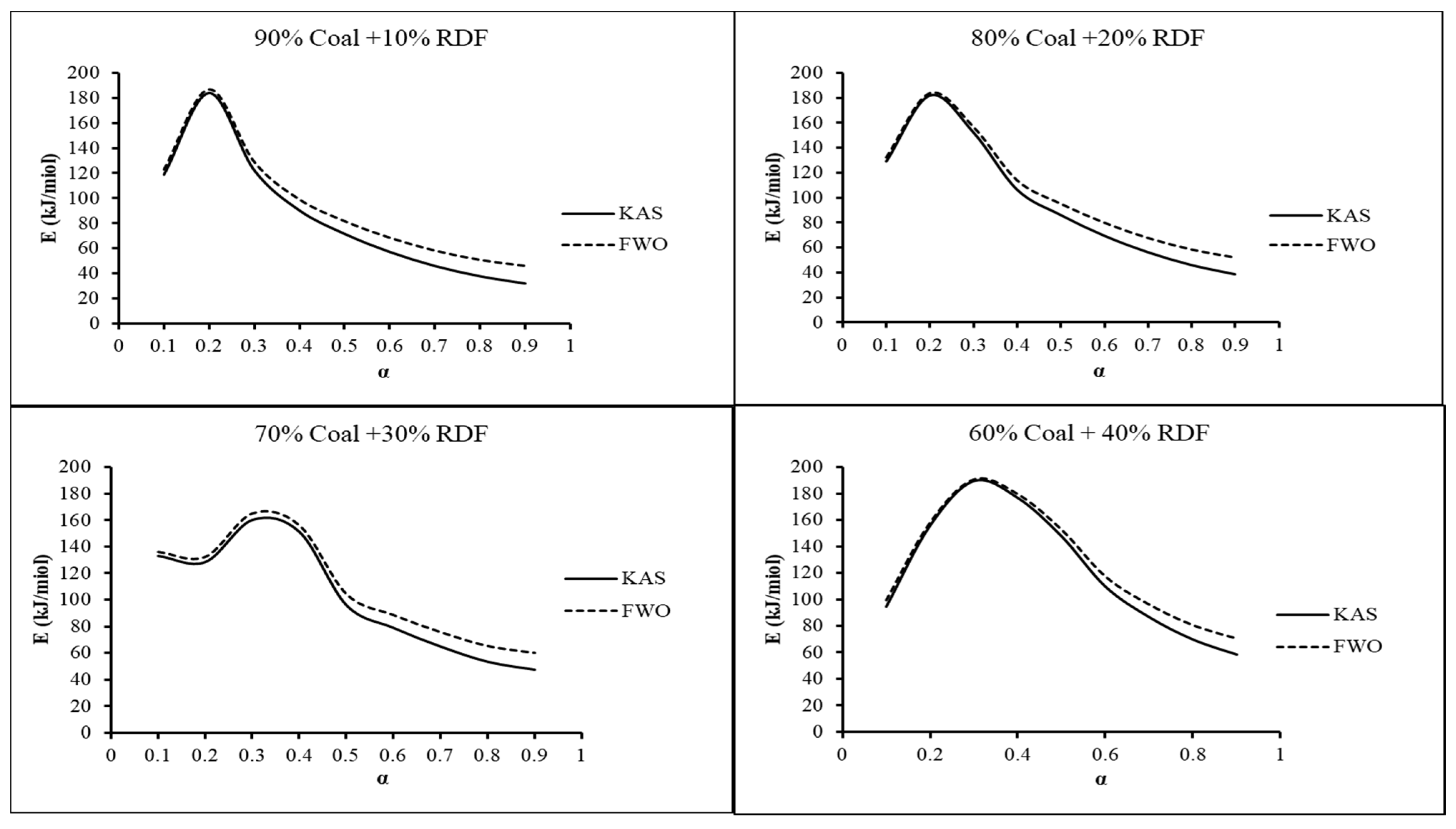

4.3. Kinetic Analyses

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| TGA | Thermogravimetric Analysis |

| MC | Moisture Content |

| FC | Fixed Carbon |

| RDF | Refuse Derived Fuel |

| HHV | High Heating Value |

| VM | Volatile Matter |

| MSW | Municipal Solid Waste |

| ad | air-dried basis |

| daf | dried ash-free basis |

| α | Fractional Conversion |

| Eα | Activation Energy (kJ/mol) |

| A | Pre-exponential Factor |

| Heating Rate (°C/min) | |

| R | General Gas Constant |

| Differential Form of Reaction Model | |

| Integral Form of Reaction Model | |

| R2 | Correlation Co-efficient |

References

- Lee, Z.H.; Sethupathi, S.; Lee, K.T.; Bhatia, S.; Mohamed, A.R. An overview on global warming in Southeast Asia: CO2 emission status, efforts done, and barriers. Renew. Sustain. Energy Rev. 2013, 28, 71–81. [Google Scholar] [CrossRef]

- Isaac, K.; Bada, S.O. The co-combustion performance and reaction kinetics of refuse derived fuels with South African high ash coal. Heliyon 2020, 6, e03309. [Google Scholar] [CrossRef] [PubMed]

- Zuberi, M.J.S.; Ali, S.F. Greenhouse effect reduction by recovering energy from waste landfills in Pakistan. Renew. Sustain. Energy Rev. 2015, 44, 117–131. [Google Scholar] [CrossRef]

- Matthews, E.; Themelis, N. Potential for reducing global methane emissions from landfills, 2000–2030. In Proceedings of the Eleventh International Waste Management and Landfill Symposium, Cagliari, Italy, 1 October 2007. [Google Scholar]

- Sajwan, K.S.; Alva, A.K.; Punshon, T.; Twardowska, I. Coal Combustion Byproducts and Environmental Issues; Springer: Berlin/Heidelberg, Germany, 2006; Volume 81. [Google Scholar]

- Munawer, M.E. Human health and environmental impacts of coal combustion and post-combustion wastes. J. Sustain. Min. 2018, 17, 87–96. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Hall, R.E.; Khan, S.; Culligan, K.; Lani, B.W. Nitrogen oxides emission control options for coal-fired electric utility boilers. J. Air Waste Manag. Assoc. 2005, 55, 1367–1388. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srivastava, R.K.; Jozewicz, W.; Singer, C. SO2 scrubbing technologies: A review. Environ. Prog. 2001, 20, 219–228. [Google Scholar] [CrossRef]

- Granite, E.J.; Pennline, H.W.; Senior, C. Mercury Control: For Coal-Derived Gas Streams; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Chang, Y.-H.; Chen, W.; Chang, N.B. Comparative evaluation of RDF and MSW incineration. J. Hazorduos Mater. 1998, 58, 33–45. [Google Scholar] [CrossRef]

- Çepelioğullar, Ö.; Haykırı-Açma, H.; Yaman, S. Kinetic modelling of RDF pyrolysis: Model-fitting and model-free approaches. Waste Manag. 2016, 48, 275–284. [Google Scholar] [CrossRef] [PubMed]

- Reza, B.; Soltani, A.; Ruparathna, R.; Sadiq, R.; Hewage, K. Environmental and economic aspects of production and utilization of RDF as alternative fuel in cement plants: A case study of Metro Vancouver Waste Management. Resour. Conserv. Recycl. 2013, 81, 105–114. [Google Scholar] [CrossRef]

- Malat’ák, J.; Velebil, J.; Bradna, J. Specialty types of waste paper as an energetic commodity. Agron. Res. 2018, 16, 534–542. [Google Scholar]

- Yanik, J.; Duman, G.; Karlström, O.; Brink, A. NO and SO2 emissions from combustion of raw and torrefied biomasses and their blends with lignite. J. Environ. Manag. 2018, 227, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Vekemans, O.; Chaouki, J. Municipal solid waste Co-firing in coal power plants: Combustion performance. Dev. Combust. Technol. 2016, 118–142. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Lin, X.; Chen, Z.; Li, X.; Jiang, X.; Yan, J. Influence on gaseous pollutants emissions and fly ash characteristics from co-combustion of municipal solid waste and coal by a drop tube furnace. Waste Manag. 2018, 81, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Xie, J.; Mei, S.; He, F. NOx and SO2 Emissions during Co-Combustion of RDF and Anthracite in the Environment of Precalciner. Energies 2018, 11, 337. [Google Scholar] [CrossRef] [Green Version]

- Zabetta, E.C.; Barišić, V.; Peltola, K.; Hotta, A. Foster Wheeler Experience with biomass and waste in CFBs. In Proceedings of the 33rd International Technical Conference on Coal Utilization and Fuel Systems, Clearwater, FL, USA, 1–5 June 2008. [Google Scholar]

- Iordanidis, A.; Asvesta, A.; Vasileiadou, A. Combustion behaviour of different types of solid wastes and their blends with lignite. Therm. Sci. 2018, 22, 1077–1088. [Google Scholar] [CrossRef]

- Azam, M.; Jahromy, S.S.; Raza, W.; Raza, N.; Lee, S.S.; Kim, K.-H.; Winter, F. Status, characterization, and potential utilization of municipal solid waste as renewable energy source: Lahore case study in Pakistan. Environ. Int. 2020, 134, 105291. [Google Scholar] [CrossRef] [PubMed]

- Azam, M.; Jahromy, S.S.; Raza, W.; Jordan, C.; Harasek, M.; Winter, F. Comparison of the combustion characteristics and kinetic study of coal, municipal solid waste, and refuse-derived fuel: Model-fitting methods. Energy Sci. Eng. 2019, 7, 2646–2657. [Google Scholar] [CrossRef] [Green Version]

- Boumanchar, I.; Chhiti, Y.; Alaoui, F.E.M.h.; Elkhouakhi, M.; Sahibed-Dine, A.; Bentiss, F.; Jama, C.; Bensitel, M. Investigation of (co)-combustion kinetics of biomass, coal and municipal solid wastes. Waste Manag. 2019, 97, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Burnham, A.K.; Dinh, L. A comparison of isoconversional and model-fitting approaches to kinetic parameter estimation and application predictions. J. Therm. Anal. Calorim. 2007, 89, 479–490. [Google Scholar] [CrossRef] [Green Version]

- Burnham, A.K. How to Model Maturation and Pyrolysis. In Global Chemical Kinetics of Fossil Fuels; Springer International Publishing: New York, NY, USA, 2017. [Google Scholar]

- White, J.E.; Catallo, W.J.; Legendre, B.L. Biomass pyrolysis kinetics: A comparative critical review with relevant agricultural residue case studies. J. Anal. Appl. Pyrolysis 2011, 91, 1–33. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Ceylan, S.; Topçu, Y. Pyrolysis kinetics of hazelnut husk using thermogravimetric analysis. Bioresour. Technol. 2014, 156, 182–188. [Google Scholar] [CrossRef]

- Mishra, G.; Bhaskar, T. Non isothermal model free kinetics for pyrolysis of rice straw. Bioresour. Technol. 2014, 169, 614–621. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Wang, J.; Yang, Y.; Zhang, Y.; Zhao, C.; Yu, Y.; Wang, S. Comparison of the thermal degradation behaviors and kinetics of palm oil waste under nitrogen and air atmosphere in TGA-FTIR with a complementary use of model-free and model-fitting approaches. J. Anal. Appl. Pyrolysis 2018, 134, 12–24. [Google Scholar] [CrossRef]

- Budrugeac, P.; Homentcovschi, D.; Segal, E. Critical analysis of the isoconversional methods for evaluating the activation energy. I. Theoretical background. J. Therm. Anal. Calorim. 2000, 63, 457–463. [Google Scholar] [CrossRef]

- Šimon, P. Isoconversional methods. J. Therm. Anal. Calorim. 2004, 76, 123. [Google Scholar] [CrossRef]

- Özsin, G.; Pütün, A.E. Kinetics and evolved gas analysis for pyrolysis of food processing wastes using TGA/MS/FT-IR. Waste Manag. 2017, 64, 315–326. [Google Scholar] [CrossRef] [PubMed]

- Idris, S.S.; Abd Rahman, N.; Ismail, K.; Alias, A.B.; Abd Rashid, Z.; Aris, M.J. Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour. Technol. 2010, 101, 4584–4592. [Google Scholar] [CrossRef] [PubMed]

- Muthuraman, M.; Namioka, T.; Yoshikawa, K. A comparison of co-combustion characteristics of coal with wood and hydrothermally treated municipal solid waste. Bioresour. Technol. 2010, 101, 2477–2482. [Google Scholar] [CrossRef] [PubMed]

- Grammelis, P.; Basinas, P.; Malliopoulou, A.; Sakellaropoulos, G. Pyrolysis kinetics and combustion characteristics of waste recovered fuels. Fuel 2009, 88, 195–205. [Google Scholar] [CrossRef]

- Sørum, L.; Grønli, M.; Hustad, J. Pyrolysis characteristics and kinetics of municipal solid wastes. Fuel 2001, 80, 1217–1227. [Google Scholar] [CrossRef]

- Du, S.-W.; Chen, W.-H.; Lucas, J.A. Pretreatment of biomass by torrefaction and carbonization for coal blend used in pulverized coal injection. Bioresour. Technol. 2014, 161, 333–339. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.-J.; Chen, W.-H. Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl. Energy 2015, 160, 49–57. [Google Scholar] [CrossRef]

- Wu, T.; Gong, M.; Lester, E.; Hall, P. Characteristics and synergistic effects of co-firing of coal and carbonaceous wastes. Fuel 2013, 104, 194–200. [Google Scholar] [CrossRef]

- Cardozo, E.; Erlich, C.; Alejo, L.; Fransson, T.H. Combustion of agricultural residues: An experimental study for small-scale applications. Fuel 2014, 115, 778–787. [Google Scholar] [CrossRef]

- Sezer, S.; Kartal, F.; Özveren, U. The investigation of co-combustion process for synergistic effects using thermogravimetric and kinetic analysis with combustion index. Therm. Sci. Eng. Prog. 2021, 23, 100889. [Google Scholar] [CrossRef]

- Seo, M.W.; Kim, S.D.; Lee, S.H.; Lee, J.G. Pyrolysis characteristics of coal and RDF blends in non-isothermal and isothermal conditions. J. Anal. Appl. Pyrolysis 2010, 88, 160–167. [Google Scholar] [CrossRef]

- Hu, S.; Ma, X.; Lin, Y.; Yu, Z.; Fang, S. Thermogravimetric analysis of the co-combustion of paper mill sludge and municipal solid waste. Energy Convers. Manag. 2015, 99, 112–118. [Google Scholar] [CrossRef]

| Proximate Analysis ad | Ultimate Analysis daf | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Samples | H2O (%) | VM (%) | Ash (%) | FC d (%) | C (%) | H (%) | O d (%) | N (%) | S (%) | HHV (kJ/kg) |

| Textile | 2.94 | 81.23 | 5.01 | 10.82 | 58.4 | 4.98 | 35.7 | 0.6 | 0.16 | 20,392 |

| Nylon plastic bags | 0.02 | 93.71 | 5.52 | 0.741 | 78.7 | 12.4 | 8.7 | 0.12 | 0.02 | 40,416 |

| Paper | 3.44 | 75.85 | 18.82 | 1.89 | 50.5 | 6.41 | 42.3 | 0.22 | 0.55 | 16,239 |

| PET bottles | ND | 92.26 | 0.19 | 7.55 | 62.0 | 4.04 | 33.9 | 0.05 | 0.01 | 23,060 |

| RDF | 1.6 | 86.2 | 7.07 | 4.7 | 66.9 | 8.7 | 23.8 | 0.32 | 0.14 | 29,429 |

| Coal | 1.84 | 38.8 | 31.7 | 27.53 | 80.7 | 3.6 | 9.6 | 1.02 | 5.04 | 30,362 |

| Sample | Ti (°C) | Tf (°C) | Mf (%) | T1 (°C) | T2 (°C) | DTG1 (%/s) | DTG2 (%/s) |

|---|---|---|---|---|---|---|---|

| Coal and RDF blends | |||||||

| 100% Coal | 460 | 620 | 32.9 | 561 | - | 0.10 | - |

| 90% Coal + 10% RDF | 423 | 618 | 31.3 | 340 | 567 | 0.01 | 0.08 |

| 80% Coal + 20% RDF | 390 | 626 | 28.7 | 347 | 559 | 0.02 | 0.07 |

| 70% Coal + 30% RDF | 340 | 610 | 27.1 | 350 | 547 | 0.04 | 0.06 |

| 60% Coal + 40% RDF | 298 | 608 | 24.8 | 351 | 536 | 0.06 | 0.05 |

| 100% RDF | 280 | 474 | 13 | 341 | 465 | 0.14 | 0.12 |

| Blending | 90% Coal + 10% RDF | 80% Coal + 20% RDF | 70% Coal + 30% RDF | 60% Coal + 40% RDF | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KAS | FWO | KAS | FWO | KAS | FWO | KAS | FWO | |||||||||

| (α) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) |

| 0.1 | 0.827 | 118.9 | 0.85 | 123 | 0.992 | 129.2 | 0.993 | 132.5 | 0.992 | 133.2 | 0.993 | 136 | 0.992 | 94.7 | 0.993 | 99.3 |

| 0.2 | 0.7198 | 183.8 | 0.745 | 186.7 | 0.934 | 182 | 0.941 | 184 | 0.992 | 128.6 | 0.993 | 132.3 | 0.996 | 155.8 | 0.997 | 158 |

| 0.3 | 0.967 | 122.3 | 0.974 | 129 | 0.966 | 152.4 | 0.971 | 156.9 | 0.982 | 160.3 | 0.984 | 165 | 0.988 | 189.5 | 0.99 | 190.7 |

| 0.4 | 0.98 | 90.4 | 0.985 | 99.15 | 0.973 | 106.6 | 0.979 | 114.1 | 0.987 | 151.3 | 0.989 | 156 | 0.974 | 176.7 | 0.977 | 179.5 |

| 0.5 | 0.979 | 71.74 | 0.986 | 81.9 | 0.974 | 86.3 | 0.98 | 95.3 | 0.979 | 96.14 | 0.984 | 104.3 | 0.995 | 147.7 | 0.995 | 152.6 |

| 0.6 | 0.971 | 57.37 | 0.983 | 68.7 | 0.982 | 69.7 | 0.998 | 80.1 | 0.984 | 79.1 | 0.989 | 88.6 | 0.998 | 109.8 | 0.998 | 117.2 |

| 0.7 | 0.96 | 46.2 | 0.979 | 58.5 | 0.968 | 56.5 | 0.98 | 67.8 | 0.979 | 65.1 | 0.987 | 75.8 | 1 | 86.8 | 1 | 96 |

| 0.8 | 0.947 | 38 | 0.975 | 51.1 | 0.964 | 46.2 | 0.981 | 58.6 | 0.971 | 53.7 | 0.983 | 65.4 | 0.995 | 69.9 | 0.997 | 80.4 |

| 0.9 | 0.93 | 32.24 | 0.972 | 46.3 | 0.947 | 38.8 | 0.976 | 52.1 | 0.981 | 47.7 | 0.991 | 60.2 | 0.984 | 58.6 | 0.991 | 70.3 |

| 0.99 | ||||||||||||||||

| Average | 97 | 106 | 108 | 116 | 95 | 103 | 114 | 121 | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azam, M.; Ashraf, A.; Setoodeh Jahromy, S.; Miran, S.; Raza, N.; Wesenauer, F.; Jordan, C.; Harasek, M.; Winter, F. Co-Combustion Studies of Low-Rank Coal and Refuse-Derived Fuel: Performance and Reaction Kinetics. Energies 2021, 14, 3796. https://doi.org/10.3390/en14133796

Azam M, Ashraf A, Setoodeh Jahromy S, Miran S, Raza N, Wesenauer F, Jordan C, Harasek M, Winter F. Co-Combustion Studies of Low-Rank Coal and Refuse-Derived Fuel: Performance and Reaction Kinetics. Energies. 2021; 14(13):3796. https://doi.org/10.3390/en14133796

Chicago/Turabian StyleAzam, Mudassar, Asma Ashraf, Saman Setoodeh Jahromy, Sajjad Miran, Nadeem Raza, Florian Wesenauer, Christian Jordan, Michael Harasek, and Franz Winter. 2021. "Co-Combustion Studies of Low-Rank Coal and Refuse-Derived Fuel: Performance and Reaction Kinetics" Energies 14, no. 13: 3796. https://doi.org/10.3390/en14133796

APA StyleAzam, M., Ashraf, A., Setoodeh Jahromy, S., Miran, S., Raza, N., Wesenauer, F., Jordan, C., Harasek, M., & Winter, F. (2021). Co-Combustion Studies of Low-Rank Coal and Refuse-Derived Fuel: Performance and Reaction Kinetics. Energies, 14(13), 3796. https://doi.org/10.3390/en14133796