Influence of Properties of Hydraulic Fluid on Pressure Peaks in Axial Piston Pumps’ Chambers

Abstract

1. Introduction

- density;

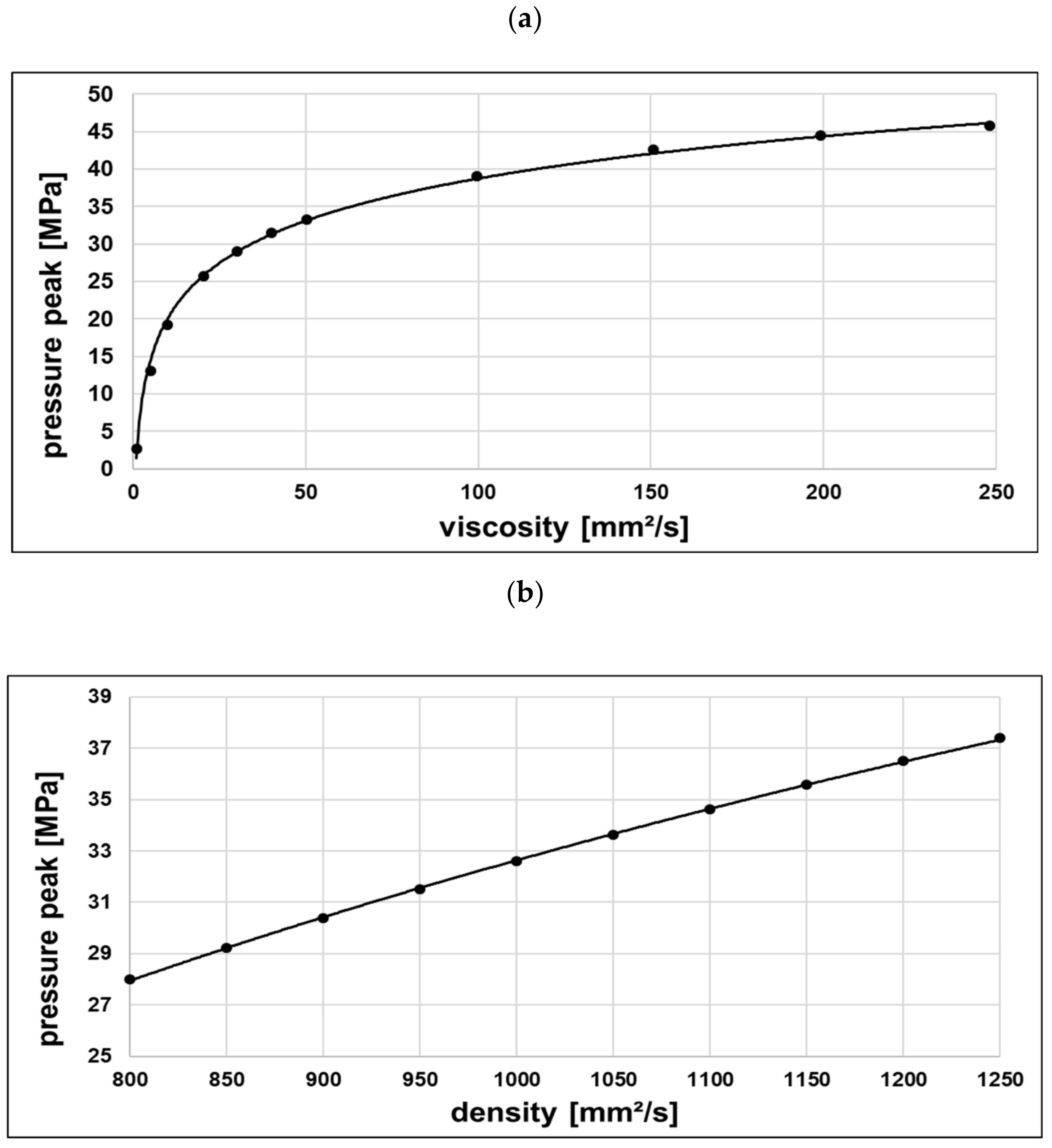

- viscosity;

- compressibility;

- aeration.

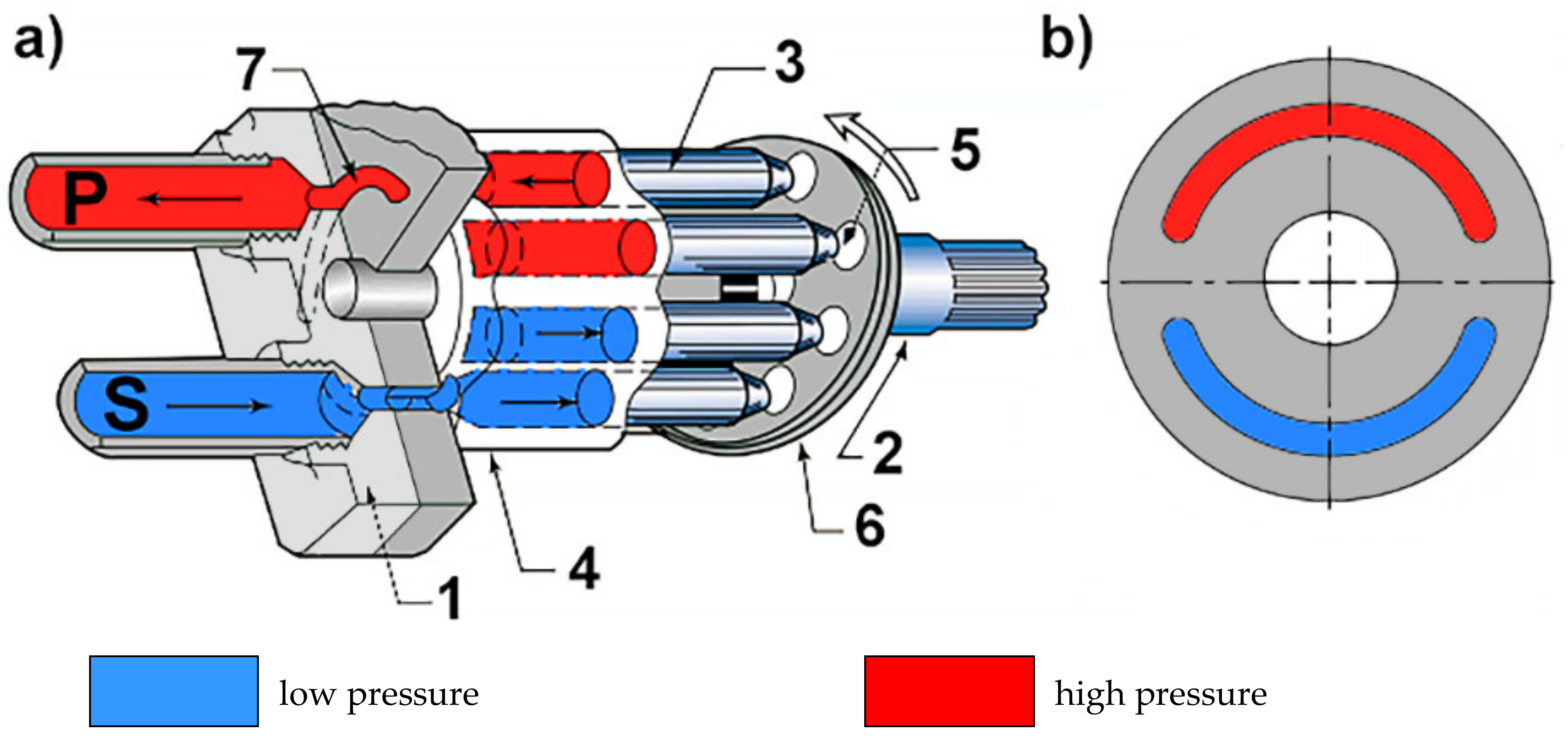

2. Methods and Models

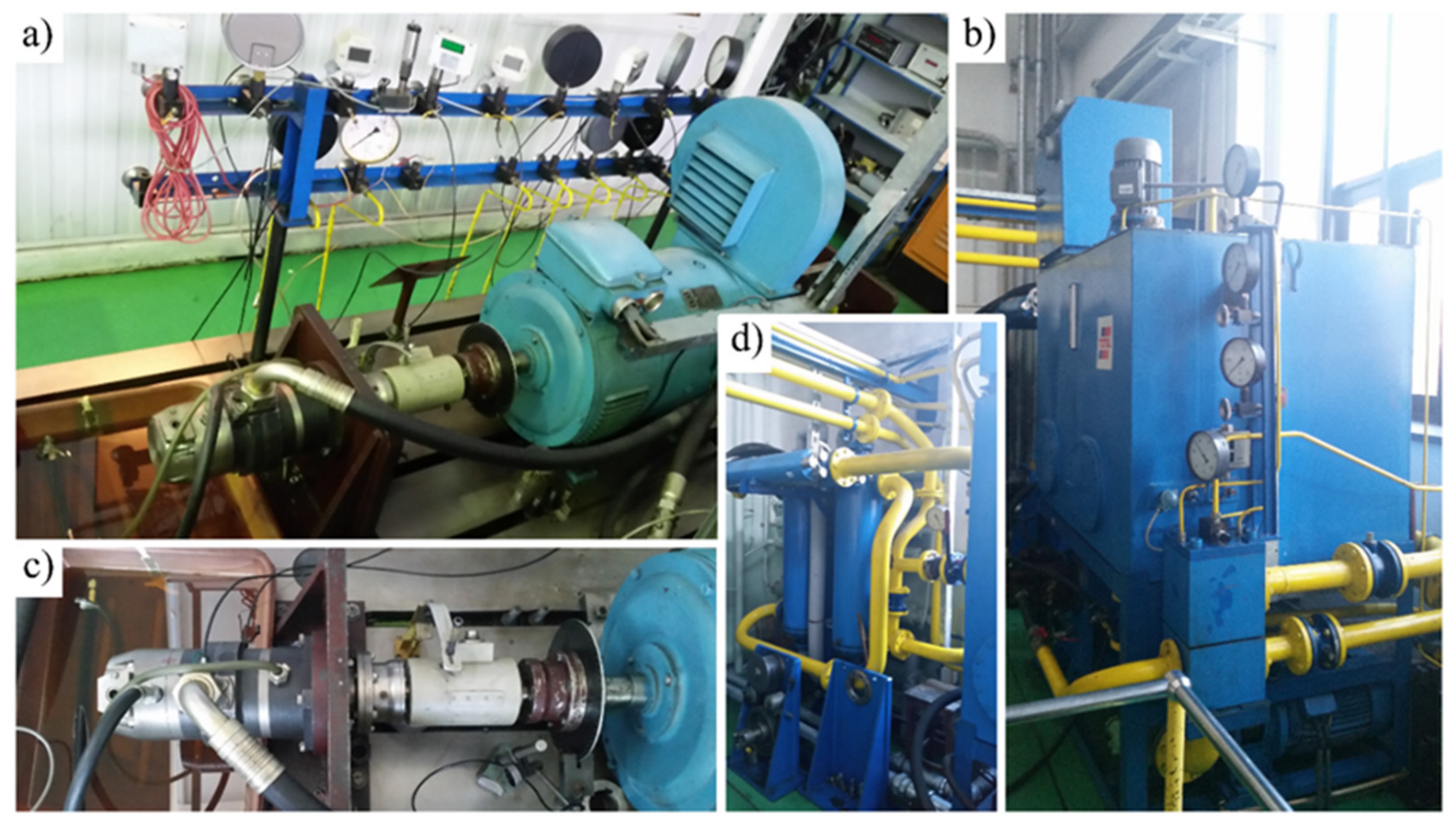

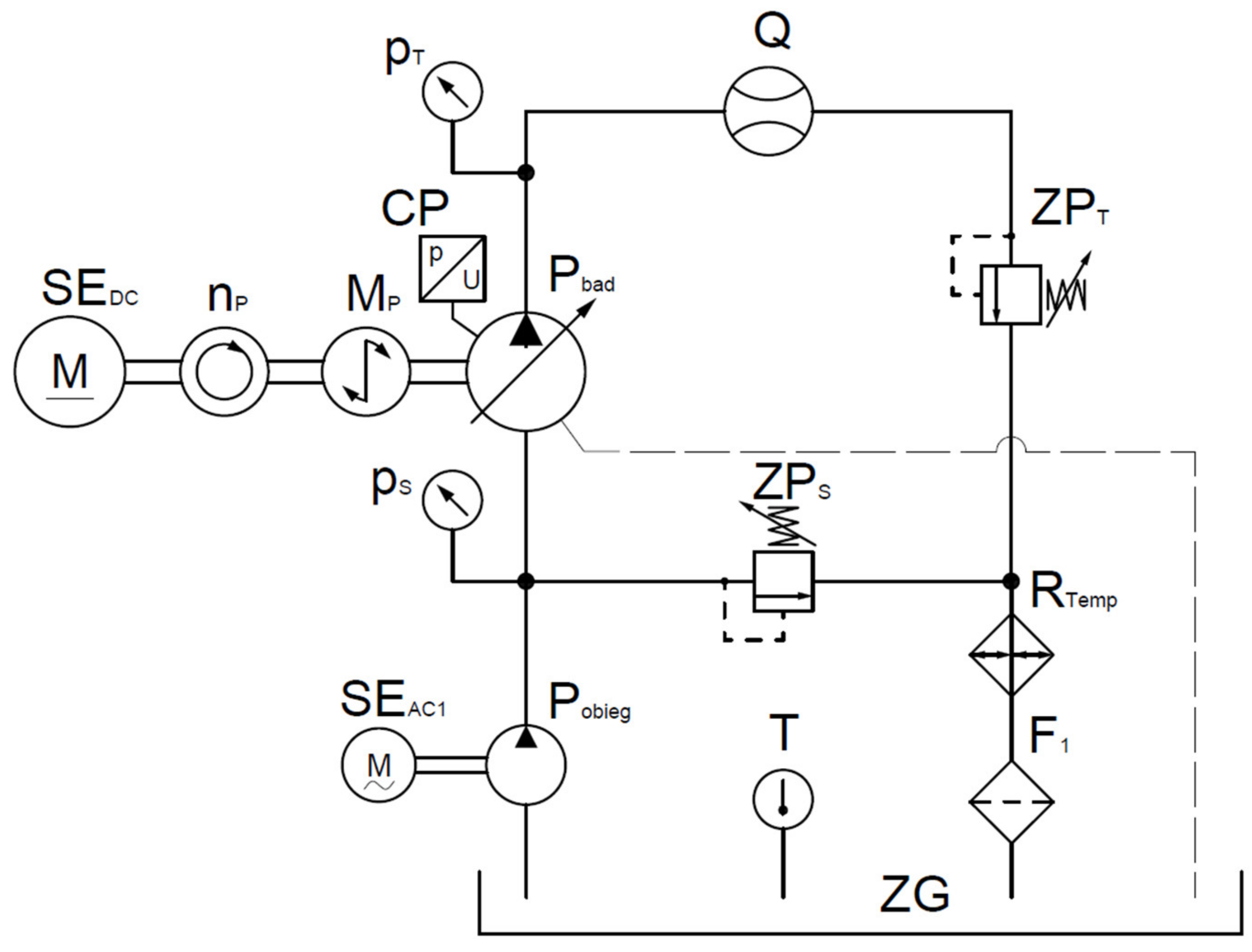

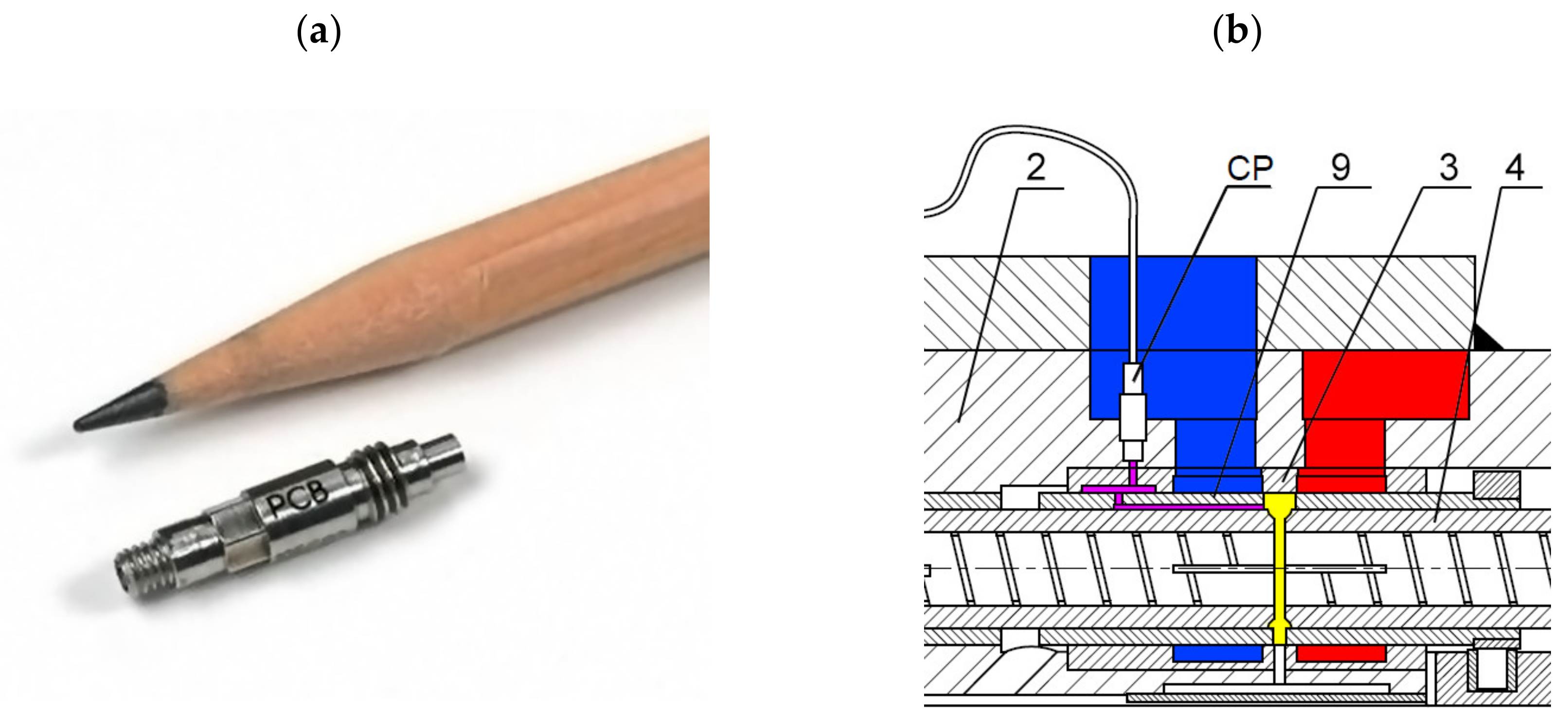

2.1. Experiment Description

2.2. Mathematical and Partial CFD Models

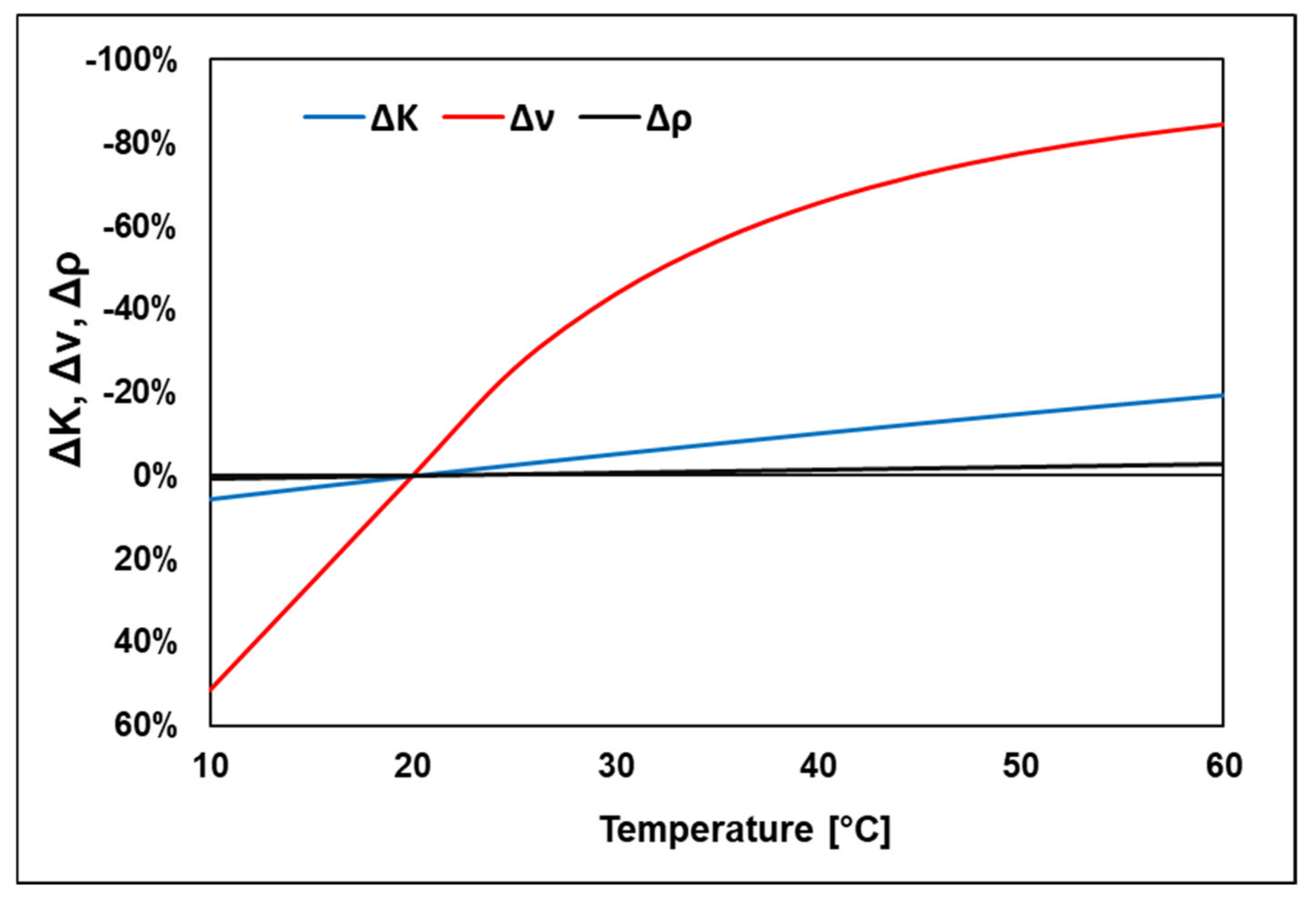

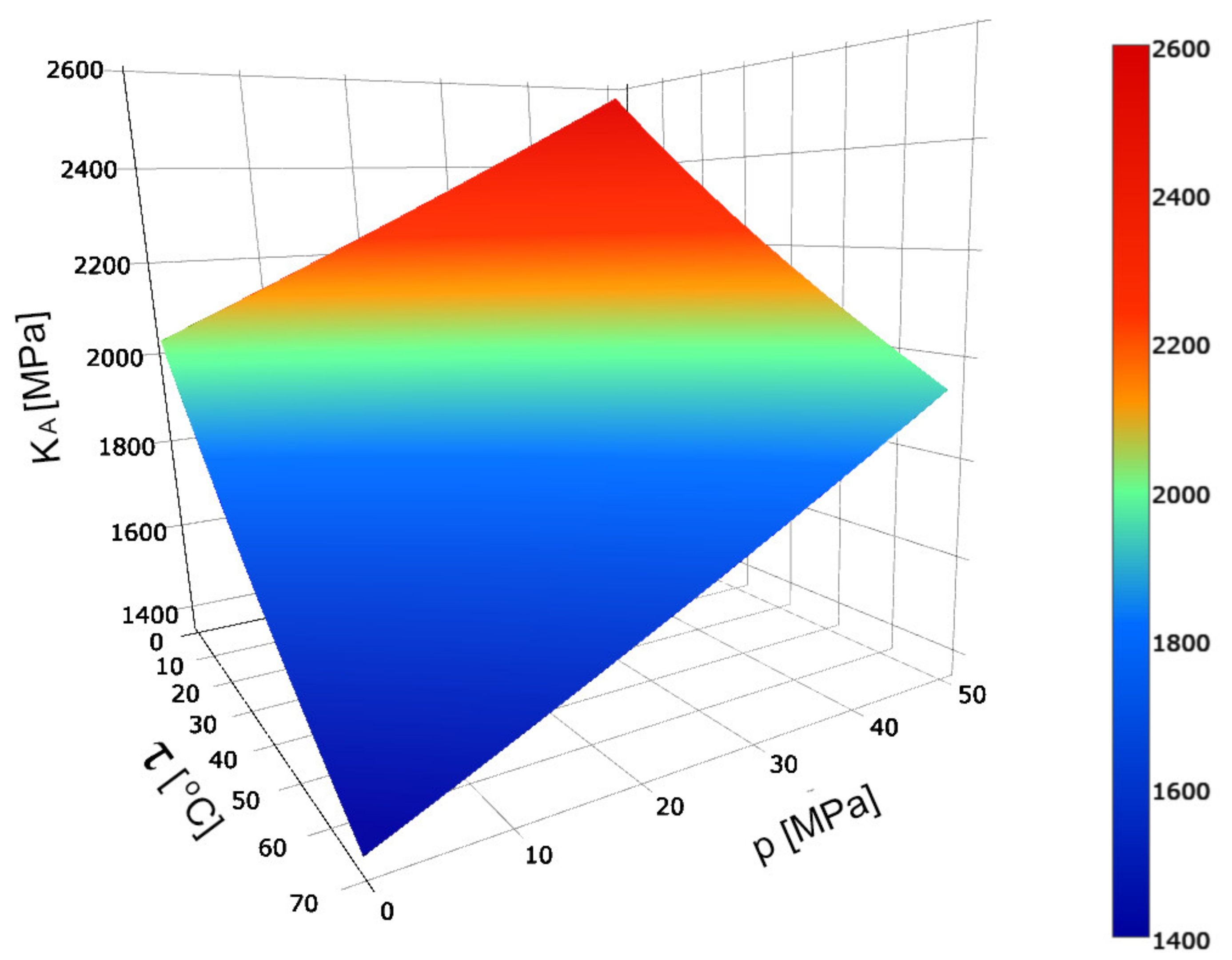

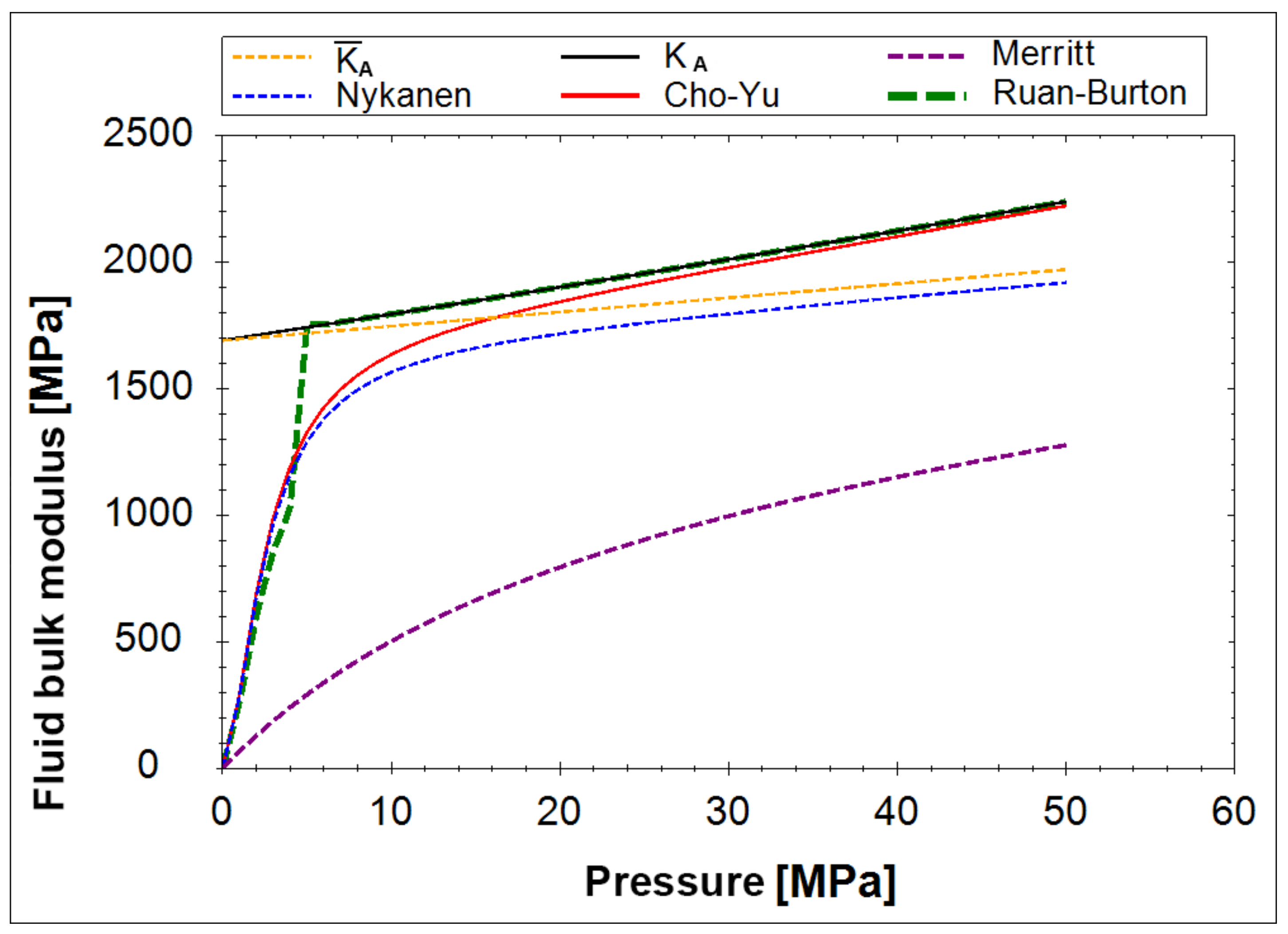

2.2.1. Fluid Bulk Modulus and Aeration

- Merritt model;

- Nykanen model;

- Cho and Feldman models (each gives the same result).

- Yu model;

- Ruan–Burton model.

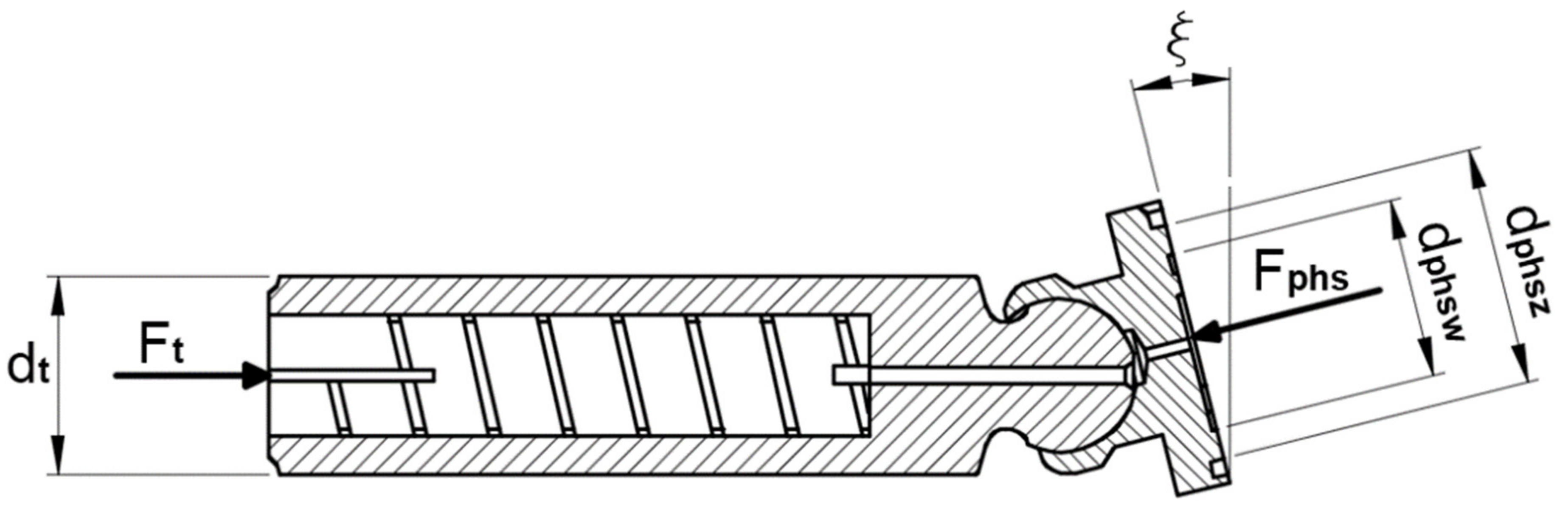

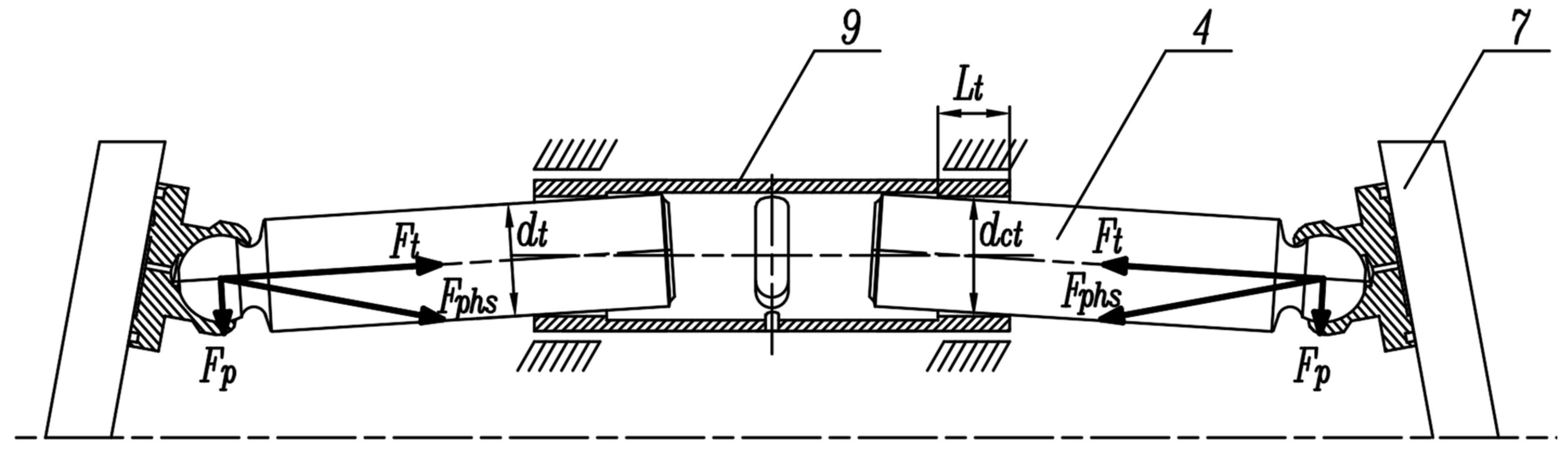

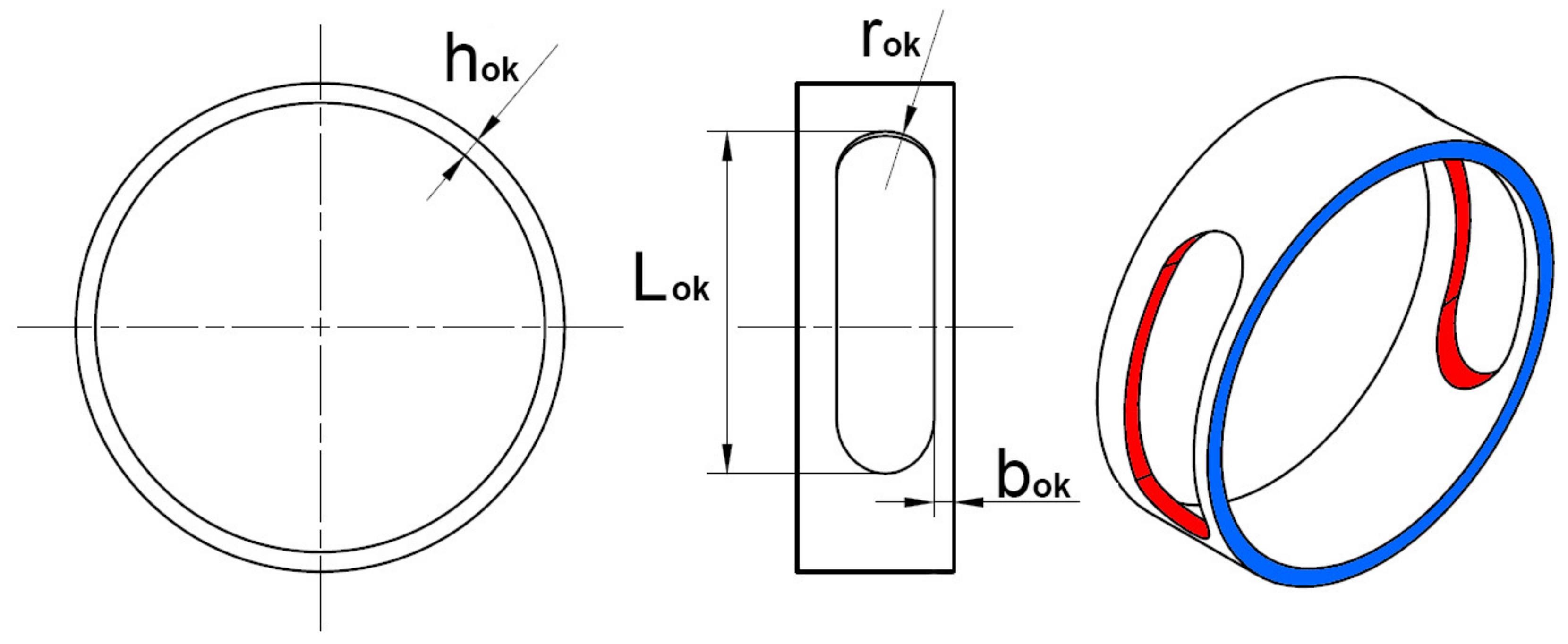

2.2.2. Leakage from the Working Chamber

- Flow through the piston hydrostatic supports, ;

- Flow through the annular gaps between the pistons and commutation tube, ;

- Flow through the gap in the commutation widow, .

- ν—kinematic viscosity;

- ρ—density;

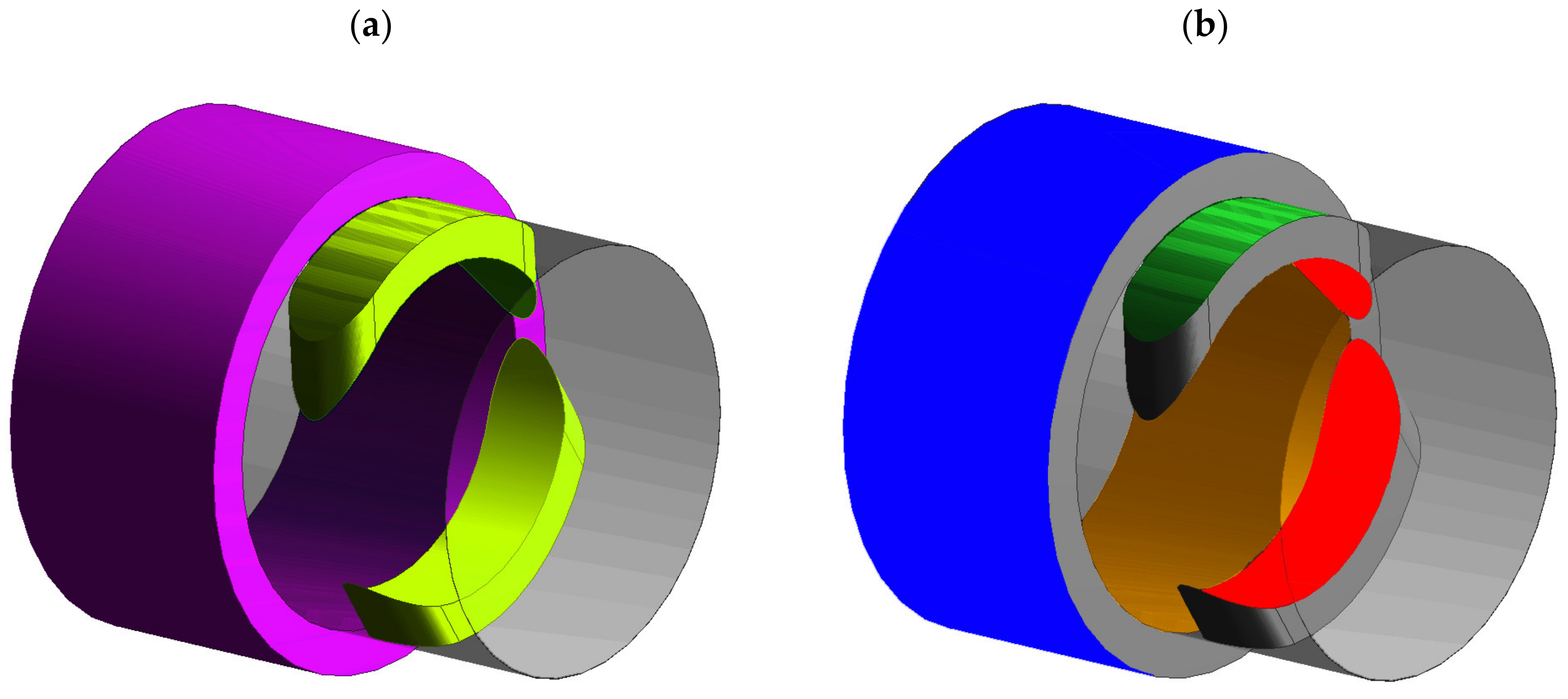

- peripheral channel (purple);

- gap between the commutation tube and the socket (transparent grey);

- two commutation windows (yellow).

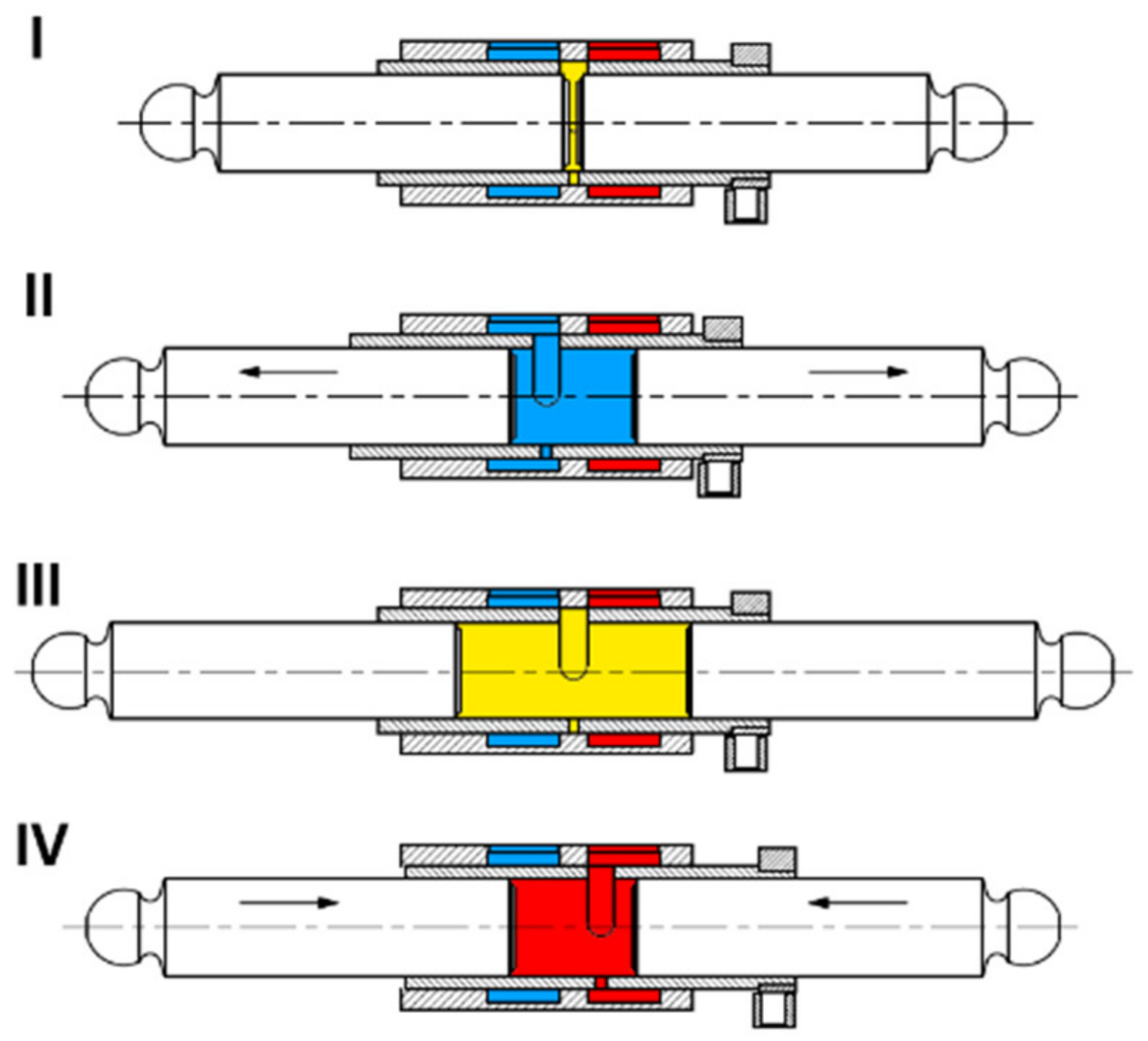

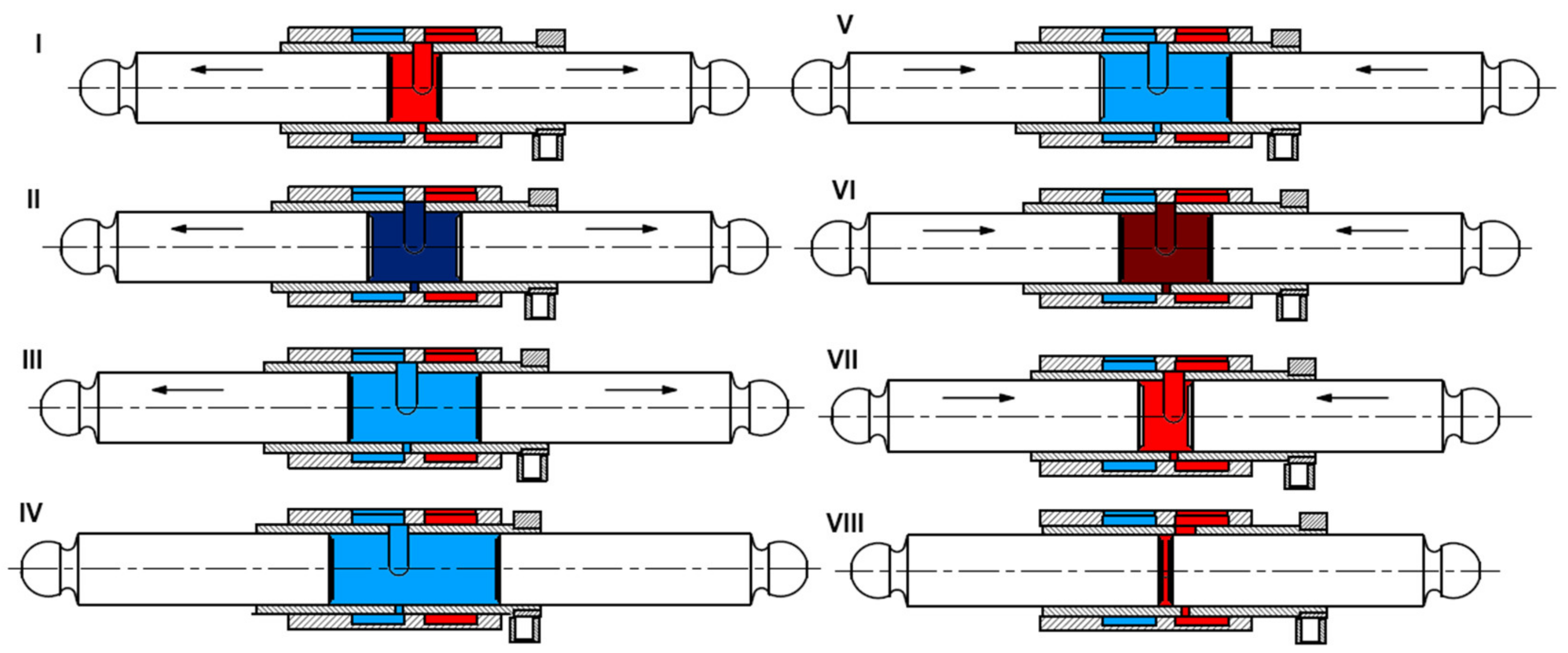

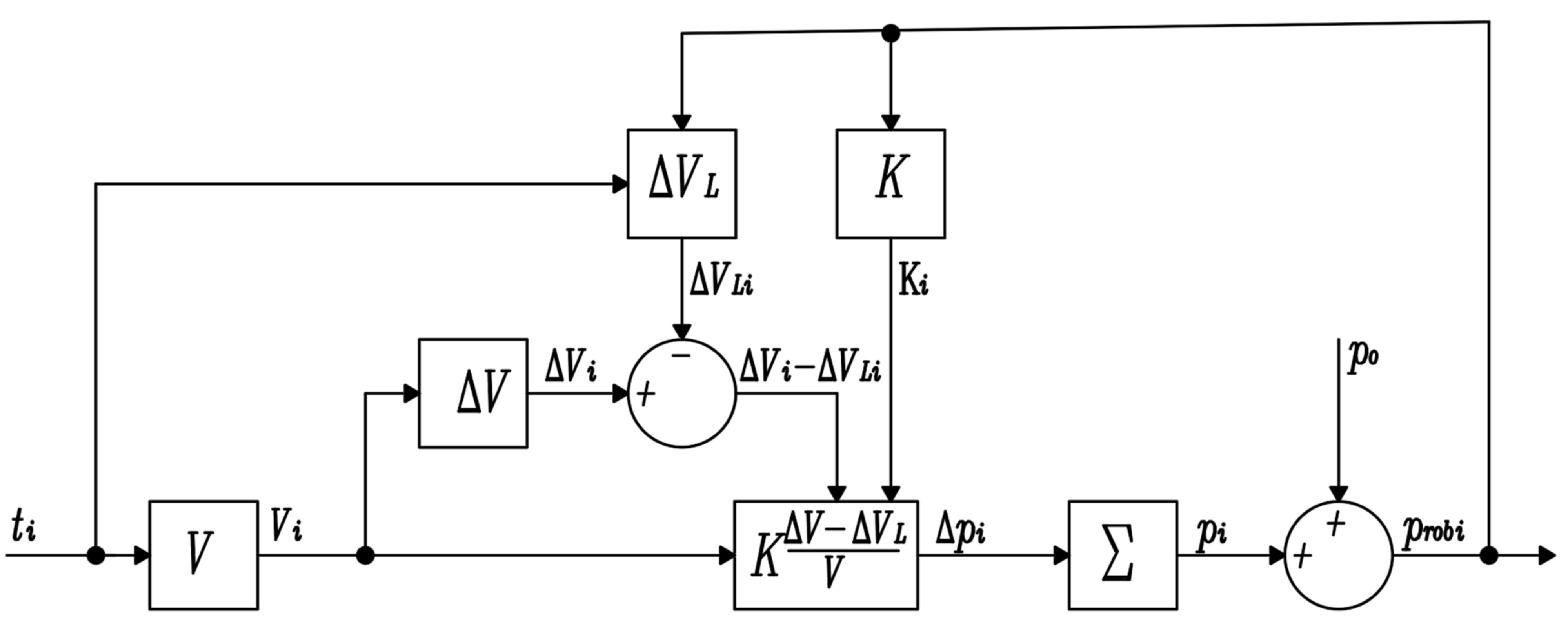

2.3. Discrete Model of the Compression Process

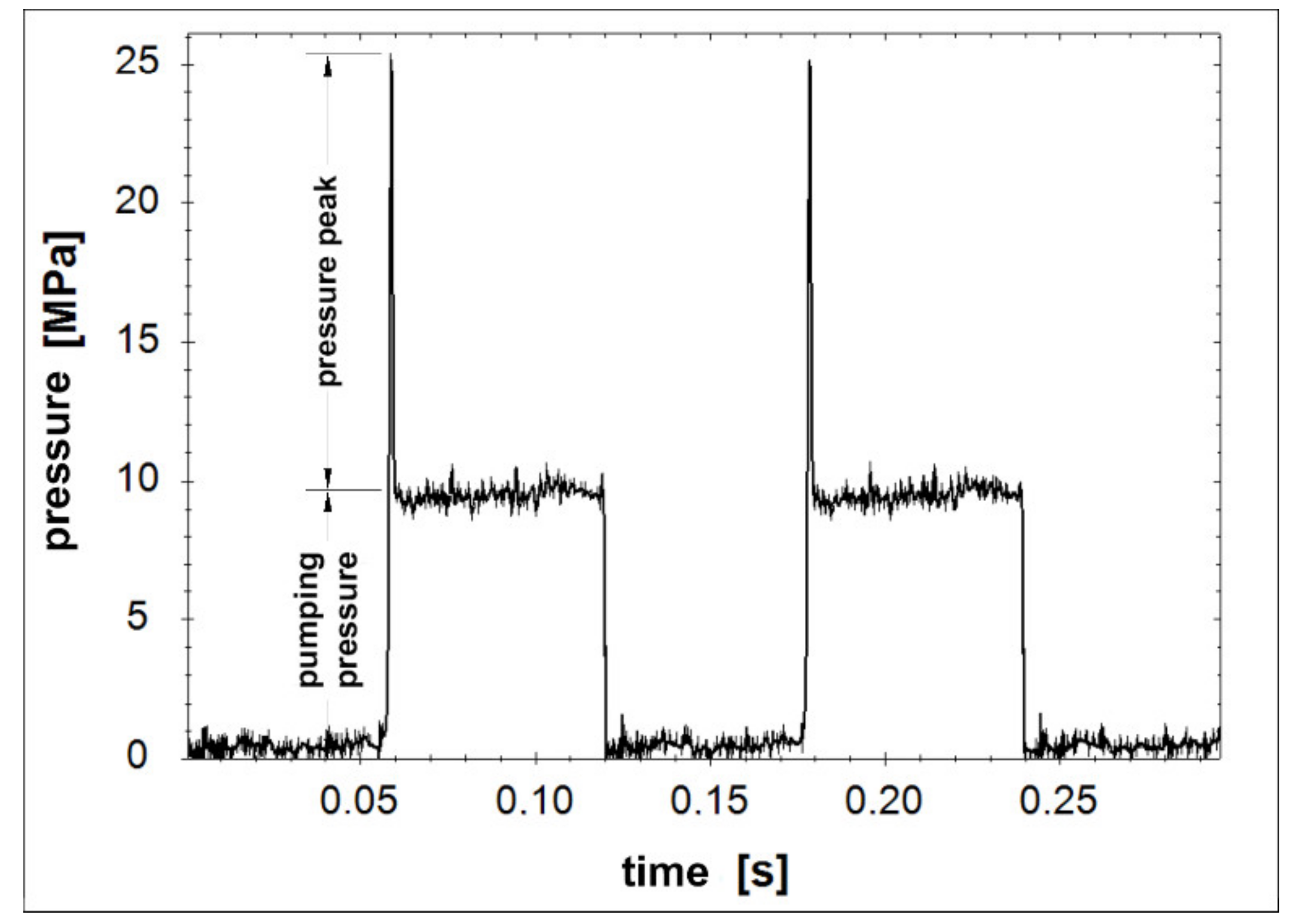

3. Results of the Experiment

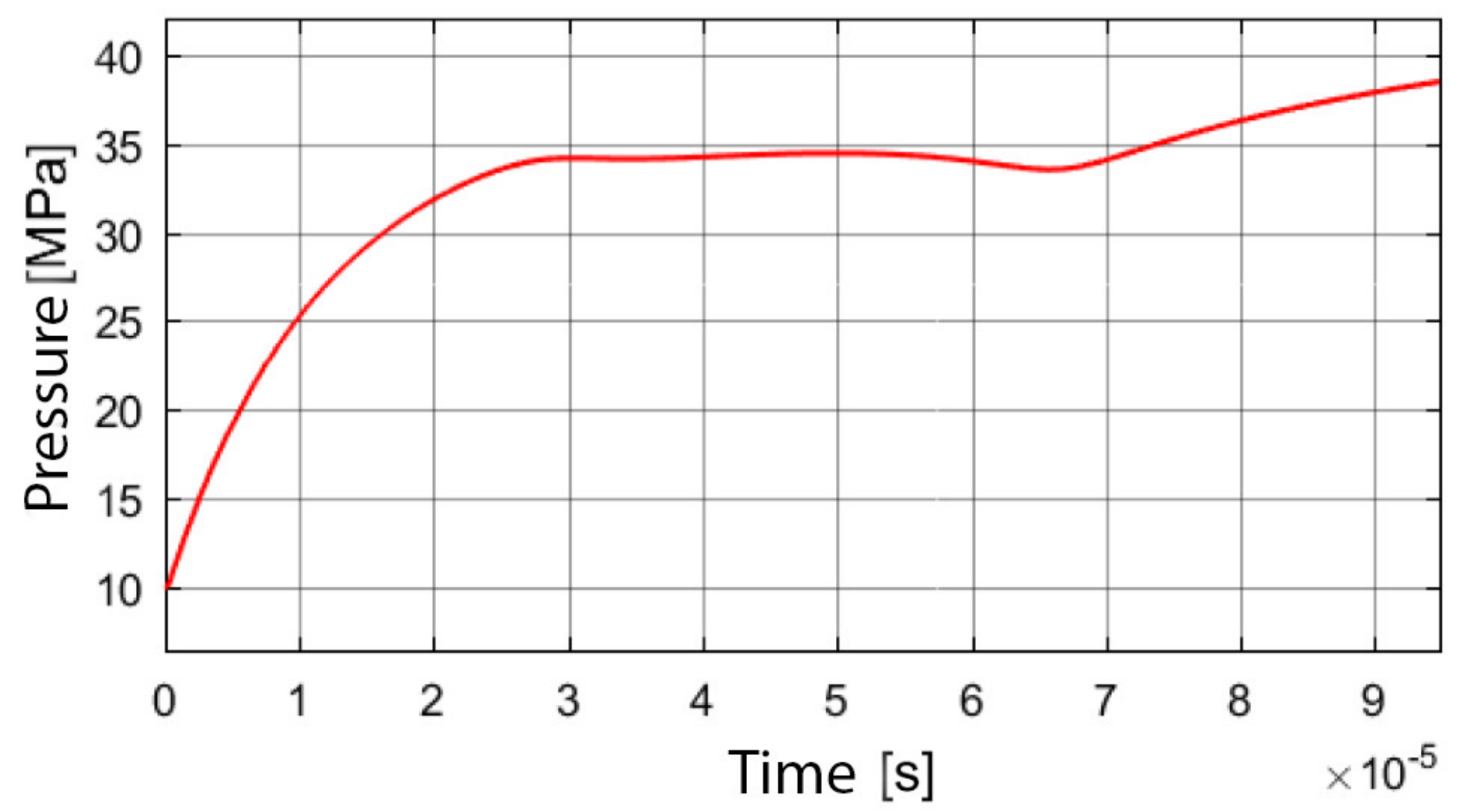

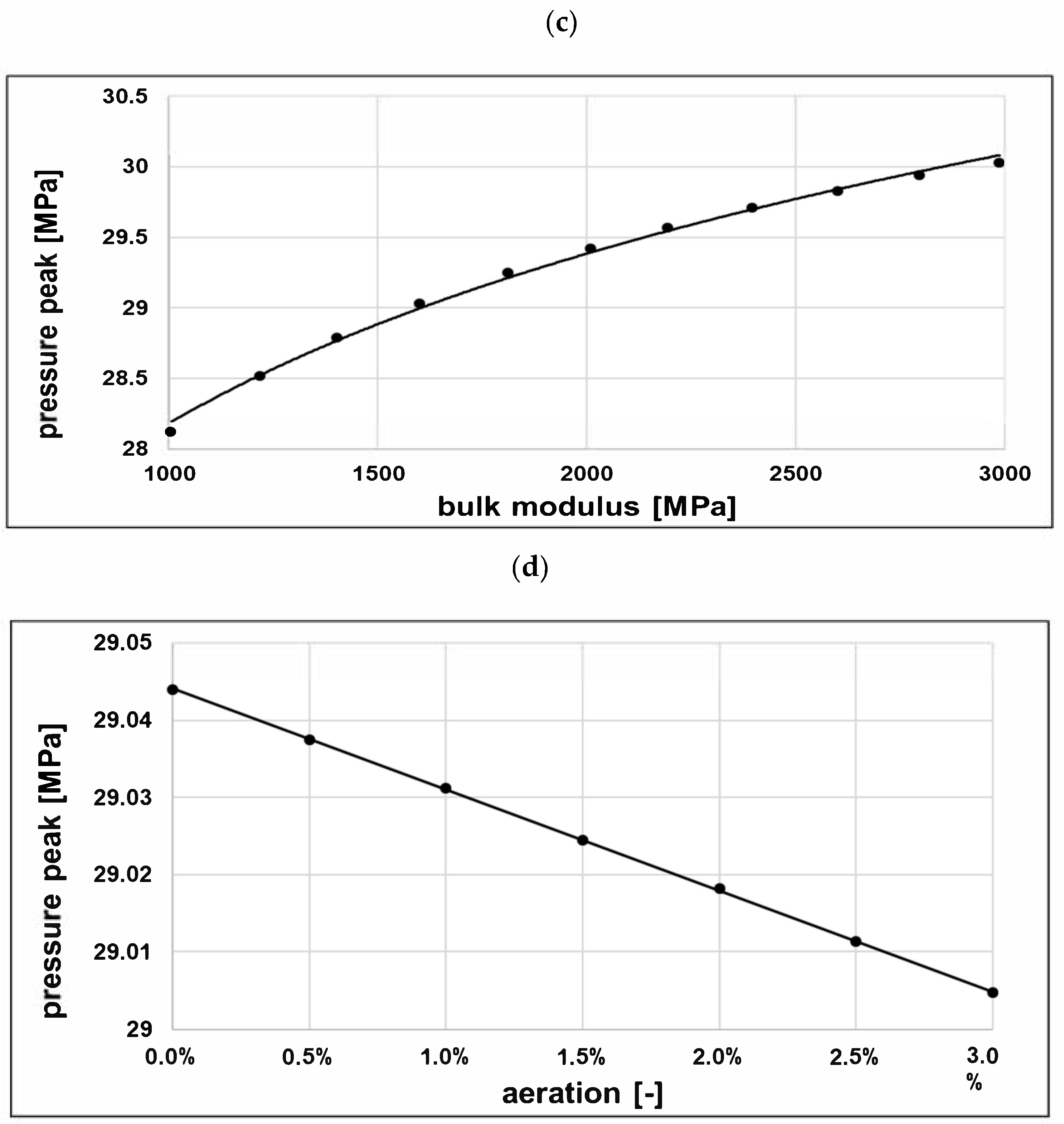

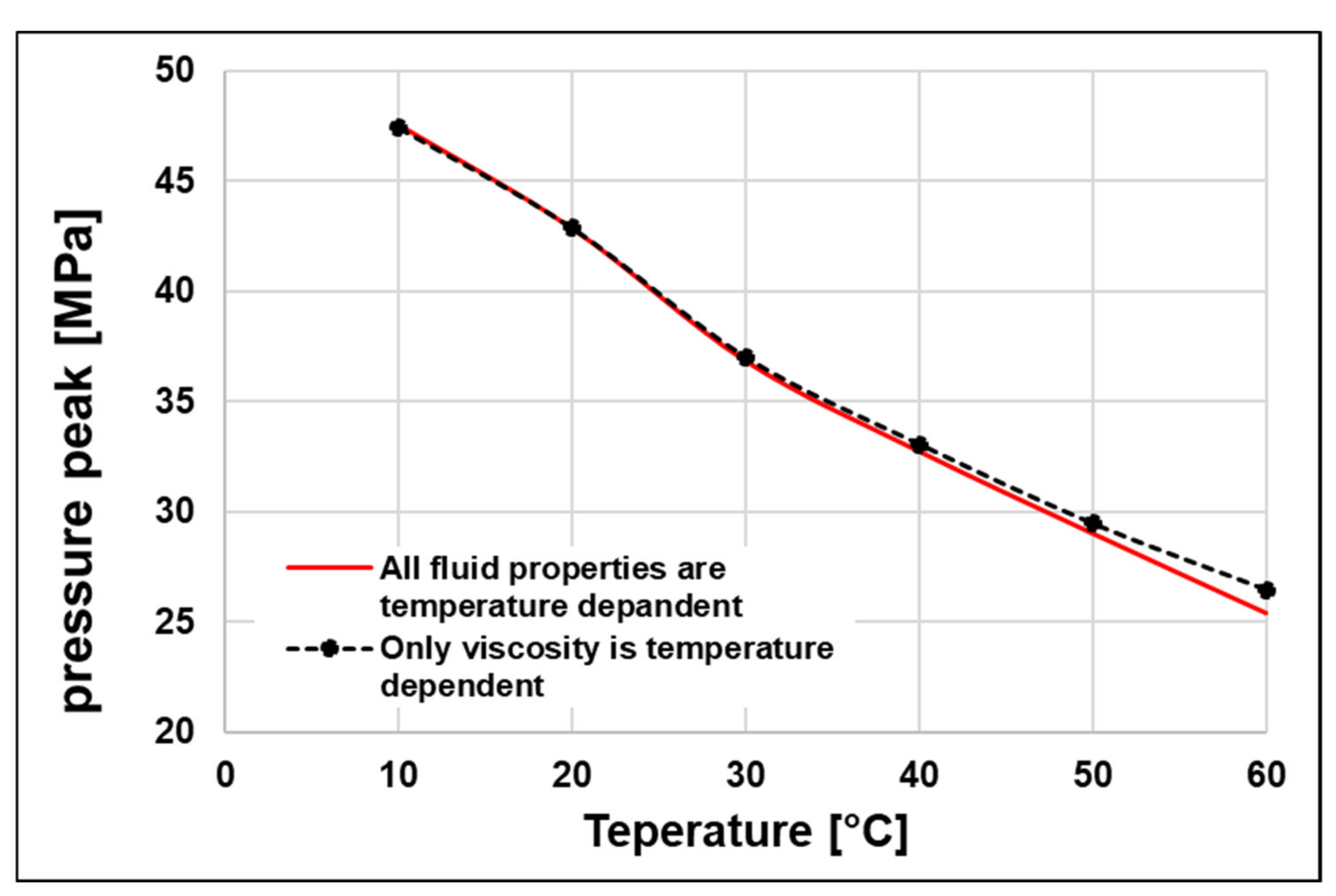

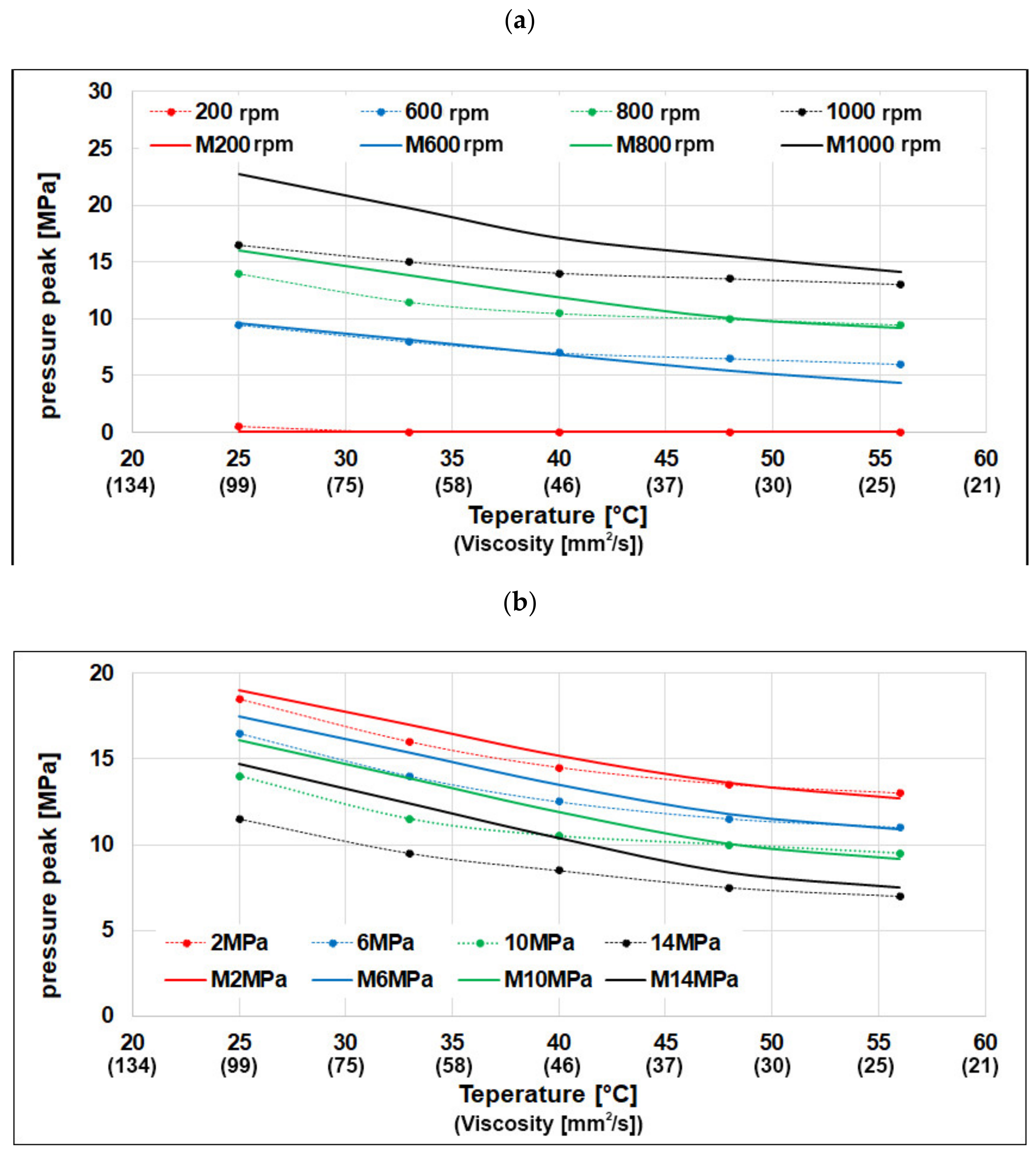

4. Results of the Simulation

5. Discussion and Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ivantysyn, J.; Ivantysynova, M.; Ivantysyn, J. Hydrostatic Pumps and Motors: Principles, Design, Performance, Modelling, Analysis, Control and Testing; Tech Books International: New Delhi, India, 2003; ISBN 978-81-85522-16-6. [Google Scholar]

- Guo, S.; Chen, J.; Lu, Y.; Wang, Y.; Dong, H. Hydraulic Piston Pump in Civil Aircraft: Current Status, Future Directions and Critical Technologies. Chin. J. Aeronaut. 2020, 33, 16–30. [Google Scholar] [CrossRef]

- Kumar, S. CFD Analysis of an Axial Piston Pump; Universitat Politècnica de Catalunya: Barcelona, Spain, 2010. [Google Scholar] [CrossRef]

- Cieślik, K.; Krogul, P.; Rubiec, A.; Spadło, K. Concept of a Vehicle for Collecting and Transporting Baled Biomass. In Proceedings of the 10th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, I℡MS, Panevesys, Lithuania, 21 May 2015; pp. 69–74. [Google Scholar]

- Przybysz, M.; Rubiec, A. Simulation Research of Kinematic Discrepancy in Multiaxis Hydrostatic Drive Systems. In Proceedings of the 11th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, I℡MS 2016, Panevezys, Lithuania, 28–29 April 2016; pp. 131–140. [Google Scholar]

- Sliwinski, P. The Basics of Design and Experimental Tests of the Commutation Unit of a Hydraulic Satellite Motor. Arch. Civ. Mech. Eng. 2016, 16. [Google Scholar] [CrossRef]

- Śliwiński, P. Influence of Water and Mineral Oil on the Leaks in Satellite Motor Commutation Unit Clearances. Pol. Marit. Res. 2017, 24. [Google Scholar] [CrossRef]

- Wu, X.; Chen, C.; Hong, C.; He, Y. Flow Ripple Analysis and Structural Parametric Design of a Piston Pump. J. Mech. Sci. Technol. 2017, 31, 4245–4254. [Google Scholar] [CrossRef]

- Xu, B.; Ye, S.; Zhang, J.; Zhang, C. Flow Ripple Reduction of an Axial Piston Pump by a Combination of Cross-Angle and Pressure Relief Grooves: Analysis and Optimization. J. Mech. Sci. Technol. 2016, 30, 2531–2545. [Google Scholar] [CrossRef]

- Hong, H.; Zhao, C.; Zhang, B.; Bai, D.; Yang, H. Flow Ripple Reduction of Axial-Piston Pump by Structure Optimizing of Outlet Triangular Damping Groove. Processes 2020, 8, 1664. [Google Scholar] [CrossRef]

- Osiecki, A.; Osiecki, L. Hydrostatic Axial Piston Machine. European Patent 0 742 870, 1999. [Google Scholar]

- Patrosz, P. Compensation of Pressure Peaks in Variable Displacement Piston Pump with Cam Driven Commutation, (Original title: Kompensacja Skoków Ciśnienia w Pompie Tłoczkowej z Rozrządem Krzywkowym). Ph.D. Thesis, Gdansk University of Technology, Gdansk, Poland, 2017. Available online: https://mostwiedzy.pl/pl/publication/download/1/kompensacja-skokow-cisnienia-w-pompie-tloczkowej-o-zmiennej-wydajnosci-z-rozrzadem-krzywkowym_32490.pdf (accessed on 10 June 2021). (In Polish).

- Załuski, P. Influence of the Position of the Swash Plate Rotation Axis on the Volumetric Efficiency of the Axial Piston Pumps. Sci. Tech. Union Mech. Eng. 2014, 11, 12–15. [Google Scholar]

- Załuski, P. Experimental Research of an Axial Piston Pump with Displaced Swash Plate Axis of Rotation. In Advances in Hydraulic and Pneumatic Drives and Control 2020; Stryczek, J., Warzyńska, U., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2021; pp. 135–145. ISBN 978-3-030-59508-1. [Google Scholar]

- Osiecki, L.; Patrosz, P.; Zawistowski, T.; Landvogt, B.; Piechna, J.; Żyliński, B. Compensation of Pressure Peaks in PWK-Type Hydraulic Pumps. Key Eng. Mater. 2011, 490, 33–44. [Google Scholar] [CrossRef]

- Osiecki, L.; Patrosz, P.; Landvogt, B.; Piechna, J.; Zawistowski, T.; Zylinski, B. Simulation of Fluid Structure Interaction in a Novel Design of High Pressure Axial Piston Hydraulic Pump. Arch. Mech. Eng. 2013, 60, 509–529. [Google Scholar] [CrossRef]

- Osiński, P.; Patrosz, P. Badania dynamicznych przebiegów ciśnienia w pompach wyporowych z wykorzystaniem czujników piezoelektrycznych. Napędy Sterow. 2016, 18, 110–114. [Google Scholar]

- Gholizadeh, H.; Burton, R.; Schoenau, G. Fluid Bulk Modulus: A Literature Survey. Int. J. Fluid Power 2011, 12, 5–15. [Google Scholar] [CrossRef]

- Hodges, P.K.B. Hydraulic Fluids; Arnold, J., Ed.; Wiley: London, UK; Wiley: New York, NY, USA, 1996; ISBN 978-0-340-67652-3. [Google Scholar]

- Gholizadeh, H. Modeling and Experimental Evaluation of the Effective Bulk Modulus for a Mixture of Hydraulic Oil and Air. Ph.D. Thesis, University of Saskatchewan, Saskatchewan, SK, Canada, 2013. [Google Scholar]

- Zastempowski, B. Badanie Przepływu Oleju Przez Dławik Śrubowy. Ph.D. Thesis, Gdansk University of Technology, Gdansk, Poland, 1981. [Google Scholar]

- Złoto, T. Modelowanie Odciążenia Hydrostatycznego i Analiza Zjawisk Przepływowych w Szczelinie Rozrządu Tarczowego Pompy Wielotłoczkowej Osiowej; Monografie/Politechnika Częstochowska; Wydawnictwa Politechn: Częstochowa, Poland, 2007; ISBN 978-83-7193-356-1. [Google Scholar]

- Złoto, T.; Kowalski, K. Load of the Slipper-Swash Plate Kinematic Pair of an Axial Piston Pump. MATEC Web Conf. 2018, 157, 08013. [Google Scholar] [CrossRef][Green Version]

- Osiecki, A. Hydrostatyczny Napęd Maszyn; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1998; ISBN 978-83-204-2296-2. [Google Scholar]

- Strmčnik, E.; Majdič, F. Comparison of Leakage Level in Water and Oil Hydraulics. Adv. Mech. Eng. 2017, 9, 168781401773772. [Google Scholar] [CrossRef]

- Patrosz, P. Influence of Gaps’ Geometry Change on Leakage Flow in Axial Piston Pumps. In Advances in Hydraulic and Pneumatic Drives and Control 2020; Stryczek, J., Warzyńska, U., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Swizerland, 2021; pp. 76–89. ISBN 978-3-030-59508-1. [Google Scholar]

- Edge, K.A.; Darling, J. Cylinder Pressure Transients in Oil Hydraulic Pumps with Sliding Plate Valves. Proc. Inst. Mech. Eng. Part B Manag. Eng. Manuf. 1986, 200, 45–54. [Google Scholar] [CrossRef]

- Ye, S.-G.; Zhang, J.-H.; Xu, B. Noise Reduction of an Axial Piston Pump by Valve Plate Optimization. Chin. J. Mech. Eng. 2018, 31, 57. [Google Scholar] [CrossRef]

- Bergada, J.M.; Kumar, S.; Davies, D.L.; Watton, J. A Complete Analysis of Axial Piston Pump Leakage and Output Flow Ripples. Appl. Math. Model. 2012, 36, 1731–1751. [Google Scholar] [CrossRef]

- Javalagi, S.; Singireddy, S. Hydraulic Fluid Properties and Its Influence on System Performance; Linkopings Universitet: Linkopings, Sweden, 2012. [Google Scholar]

- Rydberg, K.-E. Hydraulic Fluid Properties and Their Impact on Energy Efficiency. In Proceedings of the 13th Scandinavian International Conference on Fluid Power, Linköping, Sweden, 3–5 June 2013; Linköping University Electronic Press: Linköping, Sweden, 2013; pp. 447–453. [Google Scholar]

- Knight, G.C. Water Hydraulics. Tribol. Int. 1977, 10, 105–108. [Google Scholar] [CrossRef]

- Lim, G.H.; Chua, P.S.K.; He, Y.B. Modern Water Hydraulics—the New Energy-Transmission Technology in Fluid Power. Appl. Energy 2003, 76, 239–246. [Google Scholar] [CrossRef]

- Patrosz, P.; Osiecki, L. CFD Analysis of a Flow in Commutation Window in PWK pump [Data Set]. Gdańsk University of Technology. 2021. Available online: https://mostwiedzy.pl/pl/open-research-data/cfd-analysis-of-a-flow-in-commutation-window-in-pwk-pump,530084316516799-0 (accessed on 21 June 2021). [CrossRef]

| No. | Measured Value | Measuring Instrument | Class of the Instrument | Measuring Range | Precision/Sensitivity | Max Uncertainty |

|---|---|---|---|---|---|---|

| 1 | Pressure at suction channel | MPS-02 manometer | 0.2 | 2.4 MPa | 0.001 MPa | 0.006 MPa |

| 2 | Pressure at pumping channel | HBM manometer | 0.2 | 50 MPa | 0.05 MPa | 0.15 MPa |

| 3 | Pressure at pump’s chamber | M105C22 piezoelectric sensor | n/a | 34.47 MPa/4888 mV | 6.894 kPa/97.43 µV | 437.8 kPa/59.56 mV |

| PA-3000 signal amplifier | n/a | 20 V | n/a | 72.5 mV | ||

| NI-6210 DAQ module | n/a | −10÷10 V | 0.306 mV | 0.402 mV | ||

| 4 | Flow rate | PT-200 flowmeter | 0.2 | 200 dm3/min | 0.01 dm3/min | 0.41 dm3/min |

| 5 | Output torque | HBM torque meter | 0.2 | 500 Nm | 0.01 Nm | 1.01 Nm |

| 6 | Rotational velocity of pump shaft | Incremental encoder | n/a | 3000 RPM | 1 RPM | 1 RPM |

| 7 | Oil temperature | Thermocouple | 1.0 | 70 °C | 1 °C | 1.7 °C |

| 8 | Time | Quartz clock of NI-6210 DAQ module | n/a | 3 s | 50 ns | no data |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrosz, P. Influence of Properties of Hydraulic Fluid on Pressure Peaks in Axial Piston Pumps’ Chambers. Energies 2021, 14, 3764. https://doi.org/10.3390/en14133764

Patrosz P. Influence of Properties of Hydraulic Fluid on Pressure Peaks in Axial Piston Pumps’ Chambers. Energies. 2021; 14(13):3764. https://doi.org/10.3390/en14133764

Chicago/Turabian StylePatrosz, Piotr. 2021. "Influence of Properties of Hydraulic Fluid on Pressure Peaks in Axial Piston Pumps’ Chambers" Energies 14, no. 13: 3764. https://doi.org/10.3390/en14133764

APA StylePatrosz, P. (2021). Influence of Properties of Hydraulic Fluid on Pressure Peaks in Axial Piston Pumps’ Chambers. Energies, 14(13), 3764. https://doi.org/10.3390/en14133764