Some Key Issues in Hypersonic Propulsion

Abstract

:1. Introduction

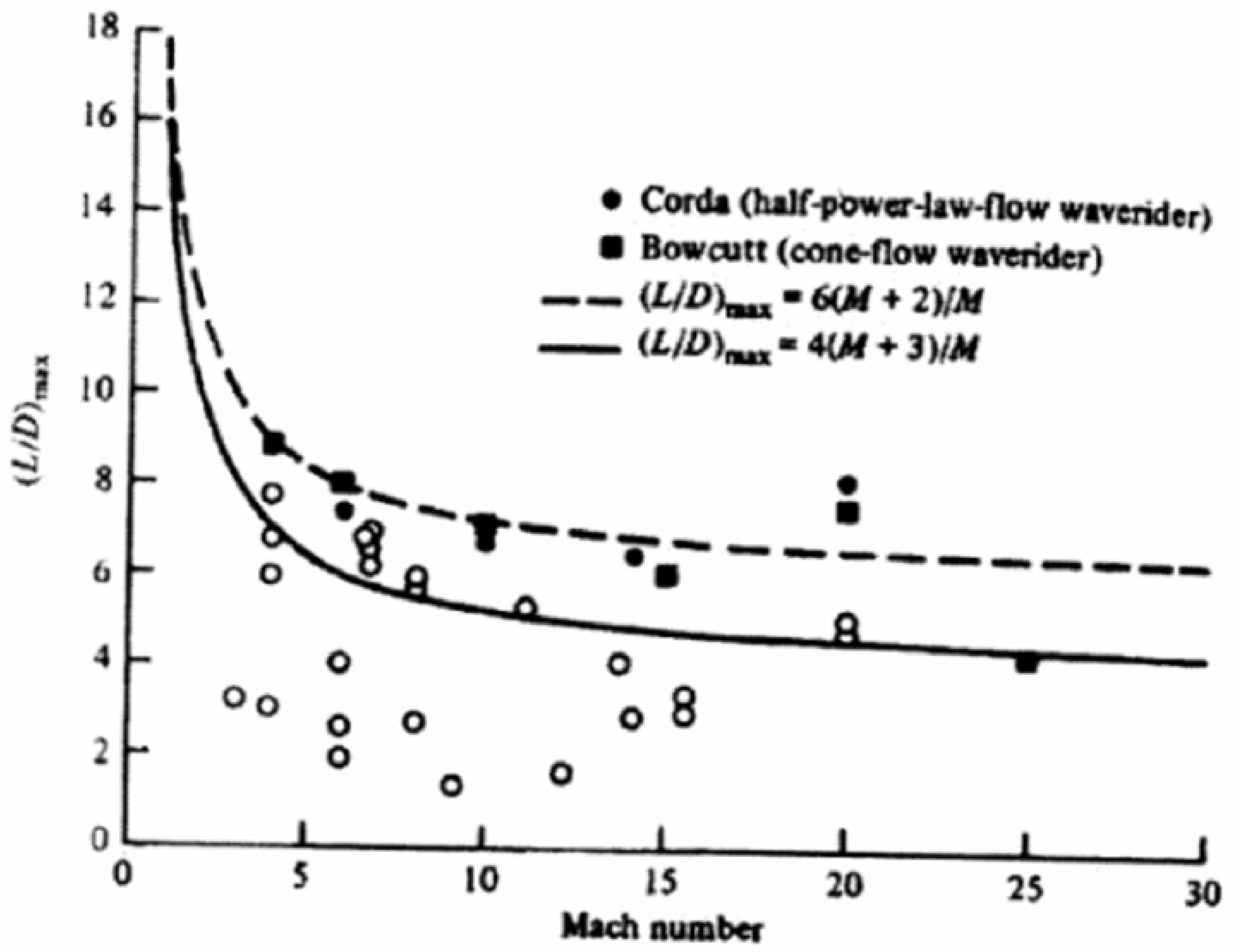

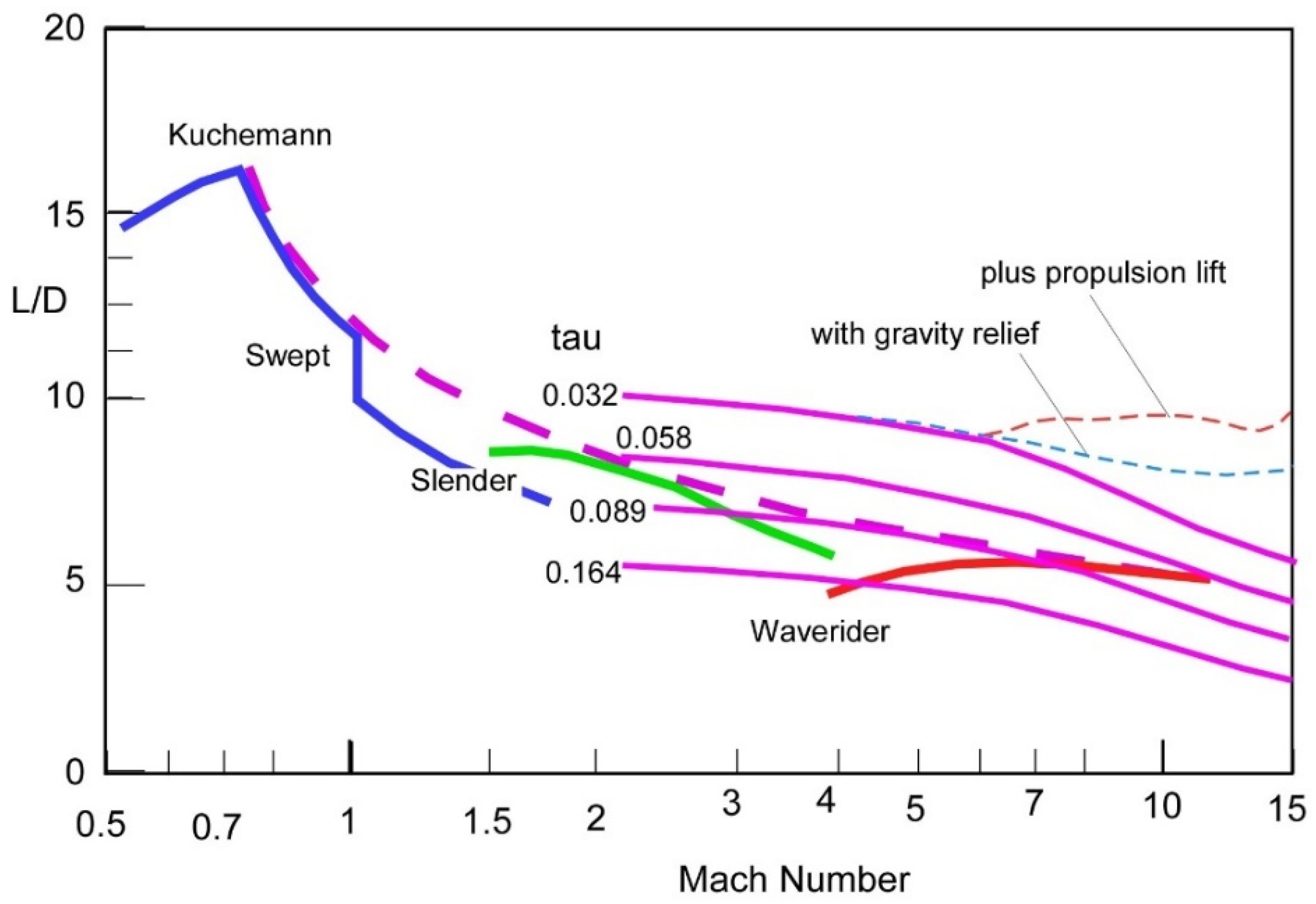

1.1. Cruisers

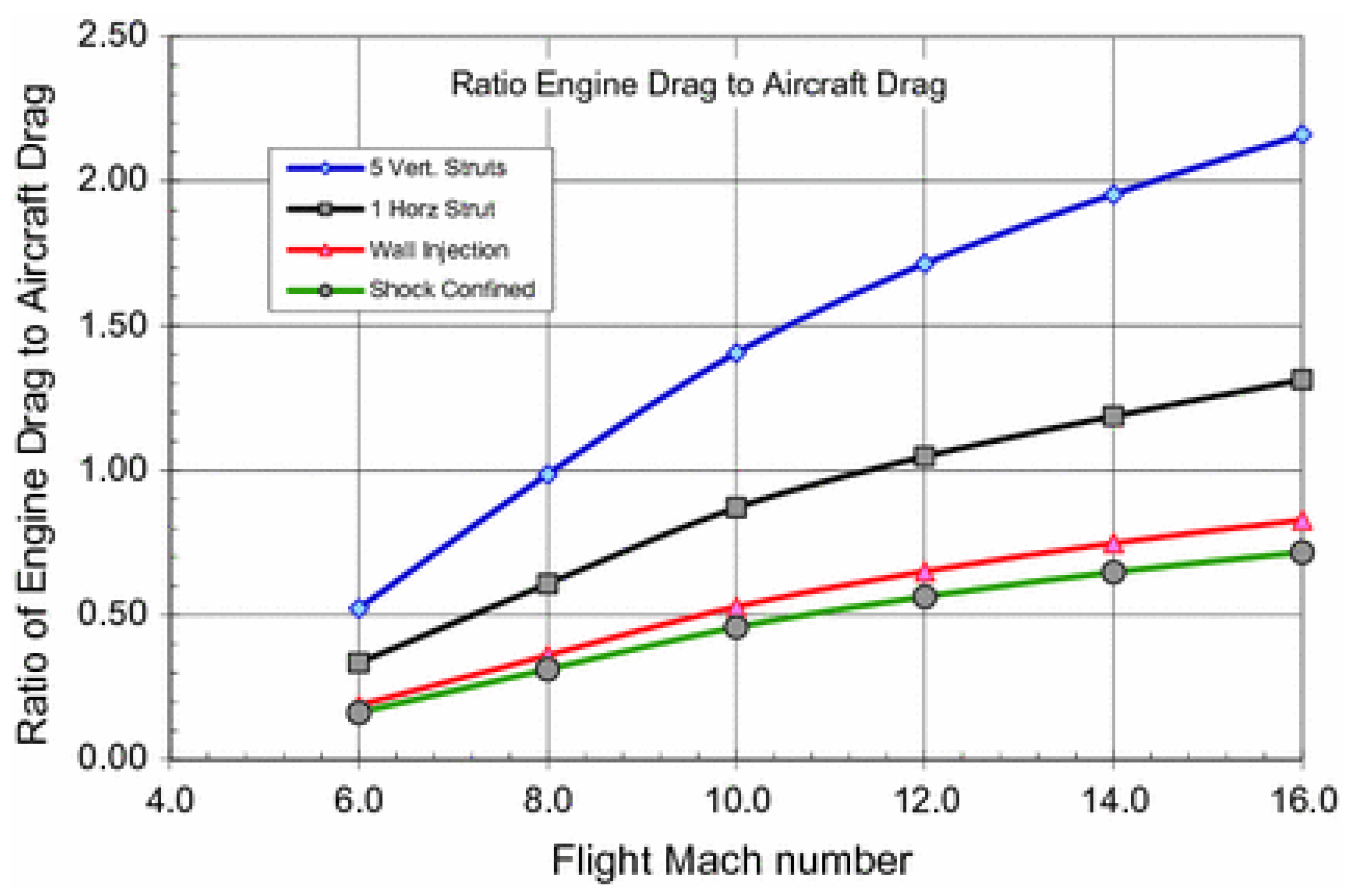

1.2. Accelerators

2. Energy and Propulsion

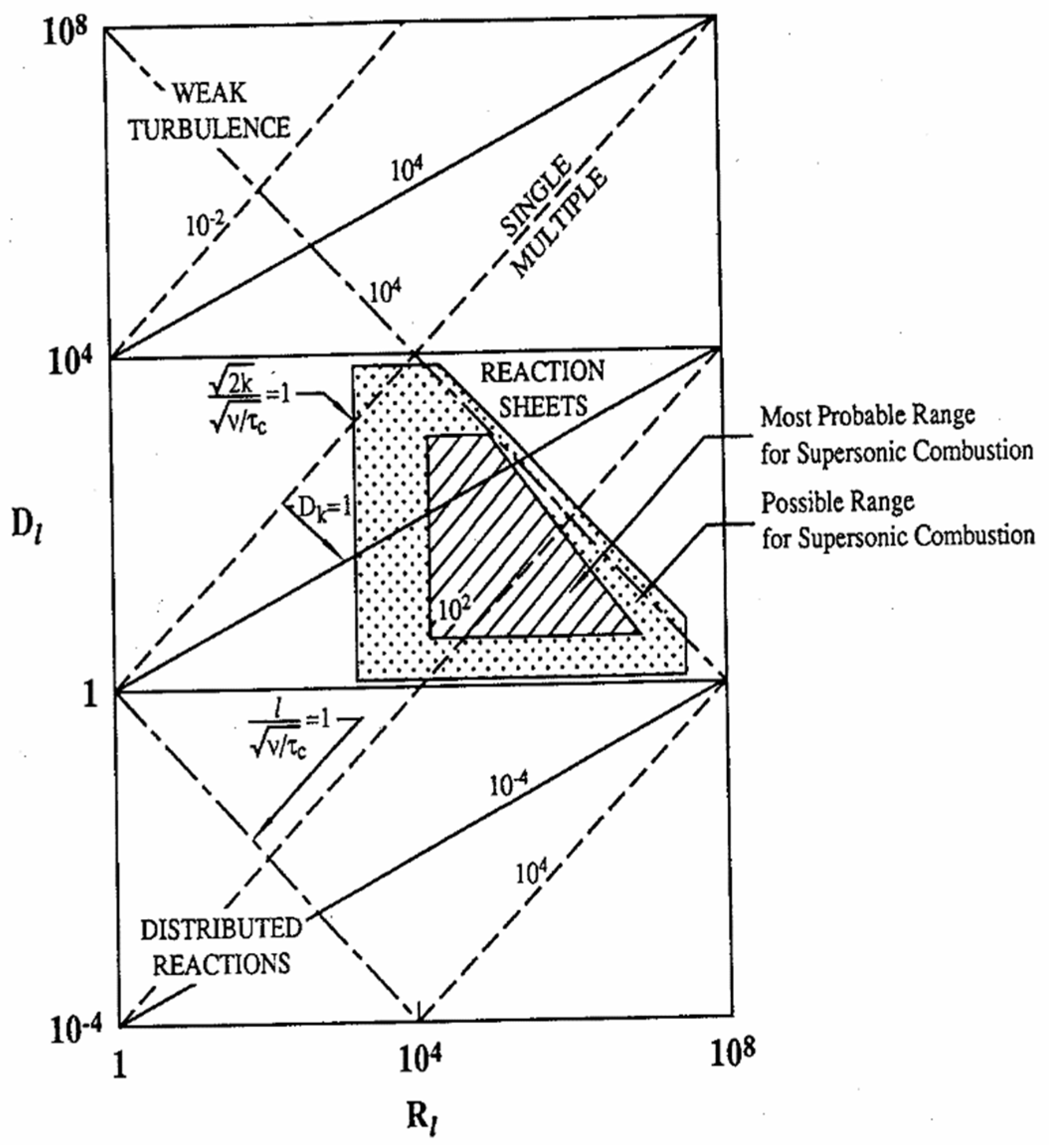

2.1. Turbulent Mixing

2.2. Combustion

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Sänger, E. Rocket Flight Engineering; National Aeronautics and Space Administration: Washington, DC, USA, 1965. [Google Scholar]

- Bréguet, L. Calcul du poids de combustible consommé par un avion en vol ascendant. In Comptes Rendus Hebdomadaires des Séances de l’Académie des Sciences; Académie des Sciences: Paris, France, 1923; pp. 870–872. [Google Scholar]

- Czysz, P.A.; Bruno, C.; Chudoba, B. Future Space Propulsion Systems and Integration; Springer/Praxis: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Ingenito, A.; Gulli, S.; Bruno, C.; Chudoba, B.; Czysz, P.A. Sizing of a fully integrated hypersonic commercial airliner. J. Aircr. 2011, 48, 2161–2164. [Google Scholar] [CrossRef]

- Ingenito, A. Subsonic Combustion Ramjet Design, SpringerBriefs in Applied Sciences and Technology; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Küchemann, D. The Aerodynamic Design of Aircraft; Pergamon Press: London, UK, 1978. [Google Scholar]

- Bruno, C. Hypersonic Propulsion—An Introduction; Springer: New York, NY, USA, 2021; in press. [Google Scholar]

- Hunt, J.L. Trade studies for hypersonic vehicles. In Proceedings of the 1st Joint Europe-US Short Course on Hypersonics, Paris, France, 7–11 December 1987. [Google Scholar]

- Oswatitsch, K. Gas Dynamics; Academic Press: Cambridge, MA, USA, 1956. [Google Scholar]

- Czysz, P.A.; Murthy, S.N.B. Energy management and vehicle synthesis. In Developments in High-Speed-Vehicle Propulsion Systems; Murthy, S.N.B., Curran, E.T., Eds.; AIAA: Reston, VA, USA, 1996; p. 587. [Google Scholar]

- Pan, L.; Scannapieco, E. Mixing in supersonic turbulence. Astrophys. J. 2010, 721, 1765–1782. [Google Scholar] [CrossRef]

- Ingenito, A.; Cecere, D.; Giacomazzi, E. Large Eddy simulation of turbulent hydrogen-fuelled supersonic combustion in an air cross-flow. Shock Waves 2013, 23, 481–494. [Google Scholar] [CrossRef]

- Nishioka, M.; Hiejima, T.; Sunami, T.; Sakaue, S. Streamwise Vortices as a Powerful Means for Supersonic Mixing Enhancement. In Proceedings of the International Symposium on Dynamics and Statics of Coherent Structures in Turbulence: Roles of Elementary Vortices; Kida, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2002; pp. 2017–2228. [Google Scholar]

- Barnes, F.W.; Segal, C. Cavity-Based Flameholding for Chemically-Reacting Supersonic Flows. Prog. Aerosp. Sci. 2015, 76, 24–41. [Google Scholar] [CrossRef]

- Schetz, J.A.; Cox-Stouffer, S.; Fuller, R. Integrated CFD and experimental studies of complex injectors in supersonic flows, Paper AIAA-1998-2780. In Proceedings of the 20th Advanced Measurement and Ground Testing Technology Conference, Albuquerque, NM, USA, 15–18 June 1989. [Google Scholar]

- Kolmogorov, A.N. On Degeneration (Decay) of Isotropic Turbulence in An Incompressible Viscous Liquid. Proc. Acad. Sci. USSR 1941, 31, 538–540. [Google Scholar] [CrossRef]

- Morkovin, M.V. Effects of Compressibility on Turbulent Flows. Mechanique de la Turbulence; Favre, A., Ed.; Gordon and Breach: New York, NY, USA, 1962; pp. 367–380. [Google Scholar]

- Batchelor, G.K. Kolmogoroff’s theory of locally isotropic turbulence. Proc. Camb. Phil. Soc. 1947, 43, 533–559. [Google Scholar] [CrossRef]

- Urzay, J. Propulsion systems for supersonic flight. In Annual Review of Fluid Mechanics; Annual Reviews: Palo Alto, CA, USA, 1989; Volume 50, pp. 593–627. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bruno, C.; Ingenito, A. Some Key Issues in Hypersonic Propulsion. Energies 2021, 14, 3690. https://doi.org/10.3390/en14123690

Bruno C, Ingenito A. Some Key Issues in Hypersonic Propulsion. Energies. 2021; 14(12):3690. https://doi.org/10.3390/en14123690

Chicago/Turabian StyleBruno, Claudio, and Antonella Ingenito. 2021. "Some Key Issues in Hypersonic Propulsion" Energies 14, no. 12: 3690. https://doi.org/10.3390/en14123690

APA StyleBruno, C., & Ingenito, A. (2021). Some Key Issues in Hypersonic Propulsion. Energies, 14(12), 3690. https://doi.org/10.3390/en14123690