Combined Effect of Superabsorbent Polymers and Cellulose Fibers on Functional Performance of Plasters

Abstract

:1. Introduction

2. Experimental

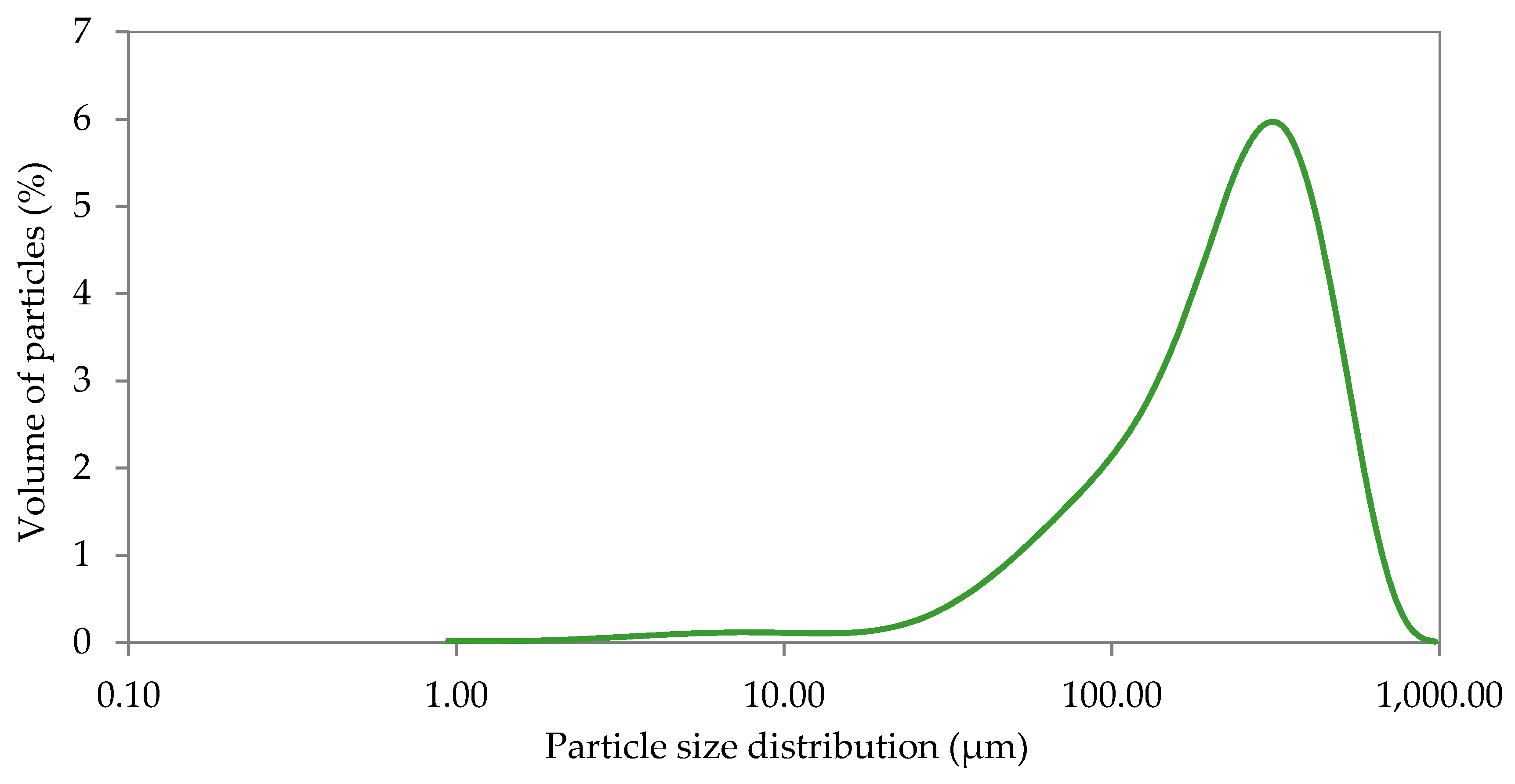

2.1. Used Materials

2.2. Determination Methods

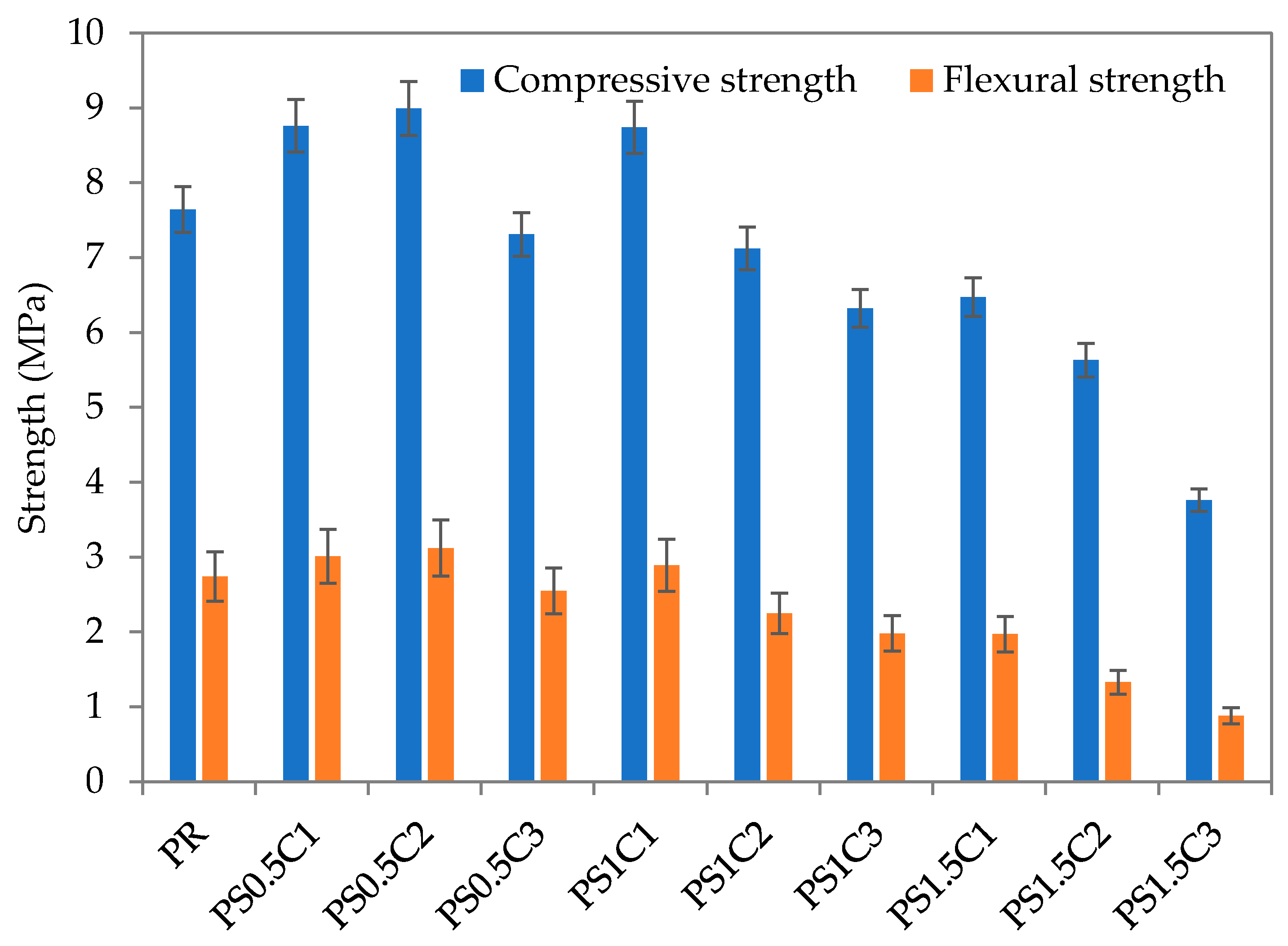

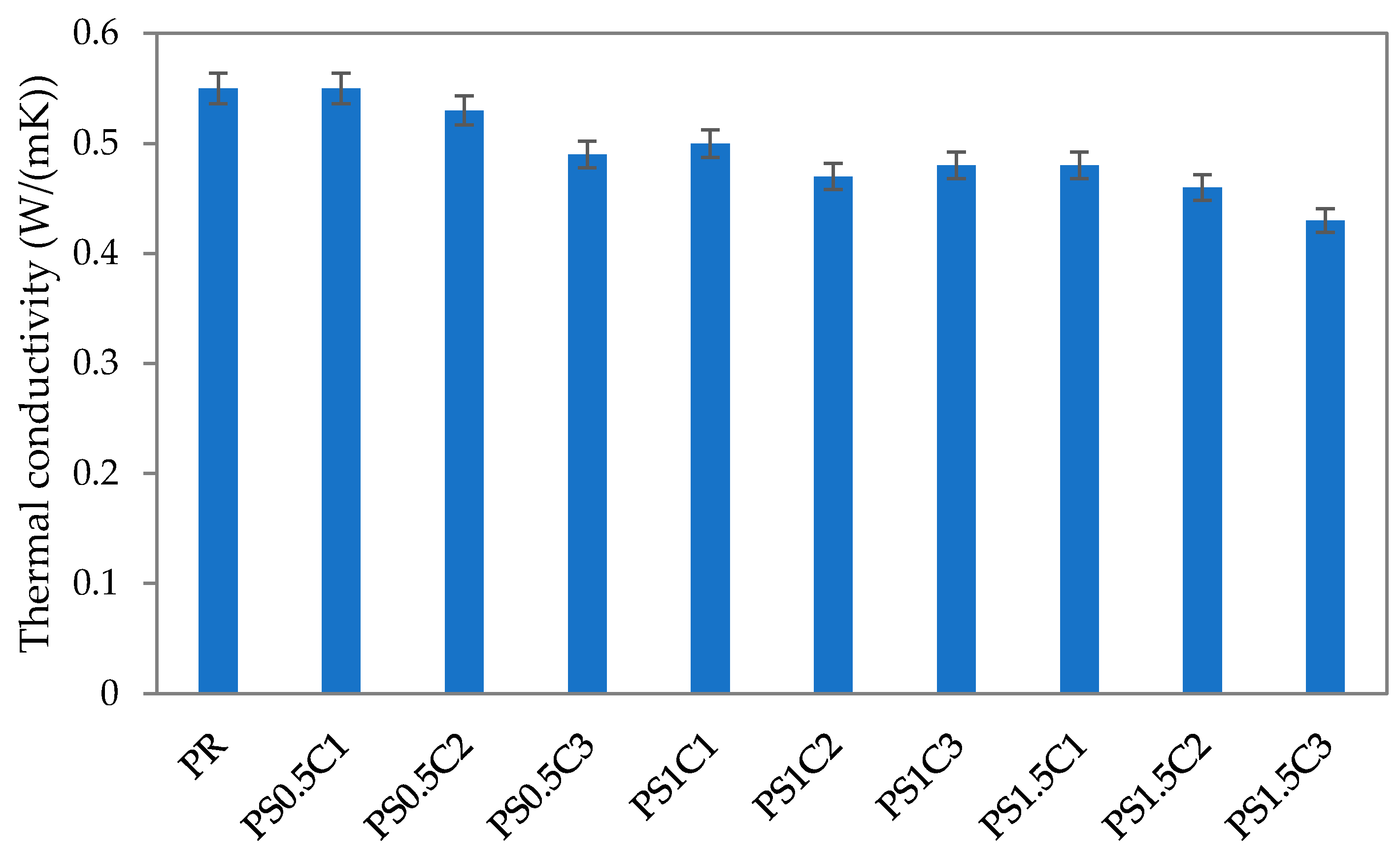

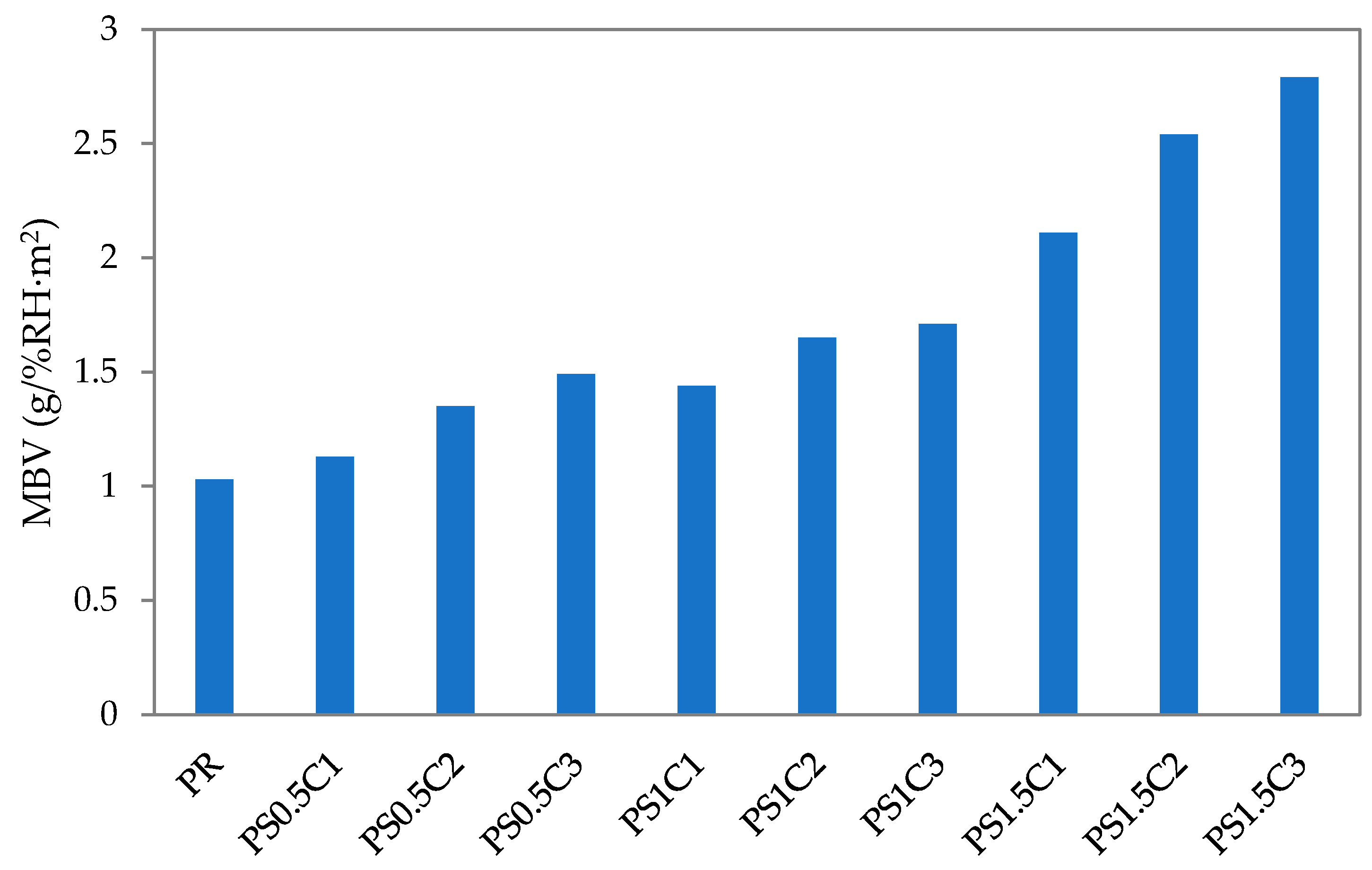

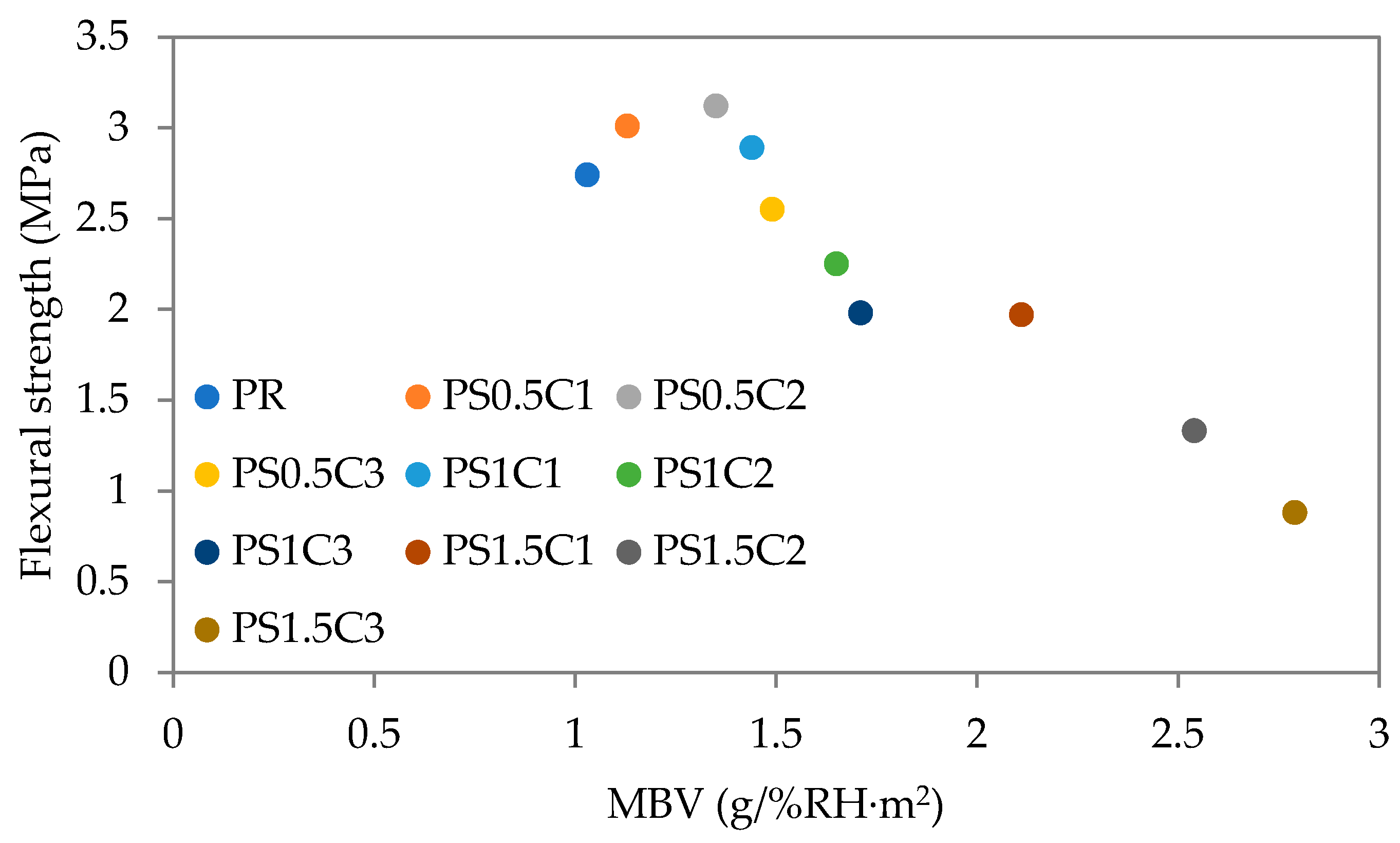

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Walker, R.; Pavia, S. Thermal and moisture monitoring of an internally insulated historic brick wall. Build. Environ. 2018, 133, 178–186. [Google Scholar] [CrossRef]

- Ibrahim, O.M.O.; Tayeh, B.A. Combined effect of lightweight fine aggregate and micro rubber ash on the properties of cement mortar. Adv. Concr. Constr. 2020, 10, 537–546. [Google Scholar]

- Maleki, B.; Khadang, A.; Maddah, H.; Alizadeh, M.; Kazemian, A.; Ali, H.M. Development and thermal performance of nanoencapsulated PCM/plaster wallboard for thermal energy storage in buildings. J. Build. Eng. 2020, 32, 10. [Google Scholar]

- Boccarusso, L.; Durante, M.; Iucolano, F.; Mocerino, D.; Langella, A. Production of hemp-gypsum composites with enhanced flexural and impact resistance. Constr. Build. Mater. 2020, 260, 18. [Google Scholar] [CrossRef]

- Fort, J.; Novotny, R.; Trnik, A.; Cerny, R. Preparation and Characterization of Novel Plaster with Improved Thermal Energy Storage Performance. Energies 2019, 12, 3318. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.H.; Phelipot-Mardele, A.; Collet, F.; Lanos, C.; Lemke, M.; Ansell, M.; Hussain, A.; Lawrence, M. Moisture buffer, fire resistance and insulation potential of novel bio-clay plaster. Constr. Build. Mater. 2020, 244, 10. [Google Scholar] [CrossRef]

- Pedreno-Rojas, M.A.; De Brito, J.; Flores-Colen, I.; Pereira, M.F.C.; Rubio-de-Hita, P. Influence of gypsum wastes on the workability of plasters: Heating process and microstructural analysis. J. Build. Eng. 2020, 29, 101143. [Google Scholar] [CrossRef]

- Mazhoud, B.; Collet, F.; Pretot, S.; Chamoin, J. Hygric and thermal properties of hemp-lime plasters. Build. Environ. 2016, 96, 206–216. [Google Scholar] [CrossRef]

- Pavlik, Z.; Fort, J.; Pavlikova, M.; Pokorny, J.; Trnik, A.; Cerny, R. Modified lime-cement plasters with enhanced thermal and hygric storage capacity for moderation of interior climate. Energy Build. 2016, 126, 113–127. [Google Scholar] [CrossRef]

- Mlakar, J.; Strancar, J. Temperature and humidity profiles in passive-house building blocks. Build. Environ. 2013, 60, 185–193. [Google Scholar] [CrossRef]

- Nakayama, Y.; Nakaoka, H.; Suzuki, N.; Tsumura, K.; Hanazato, M.; Todaka, E.; Mori, C. Prevalence and risk factors of pre-sick building syndrome: Characteristics of indoor environmental and individual factors. Environ. Health Prev. Med. 2019, 24, 10. [Google Scholar] [CrossRef] [PubMed]

- Marincioni, V.; Marra, G.; Altamirano-Medina, H. Development of predictive models for the probabilistic moisture risk assessment of internal wall insulation. Build. Environ. 2018, 137, 257–267. [Google Scholar] [CrossRef]

- Alev, U.; Kalamees, T. Avoiding mould growth in an interiorly insulated log wall. Build. Environ. 2016, 105, 104–115. [Google Scholar] [CrossRef]

- Lee, H.; Ozaki, A.; Lee, M.; Yamamoto, T. Humidity control effect of vapor-permeable walls employing hygroscopic insulation material. Indoor Air 2020, 30, 346–360. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 22. [Google Scholar] [CrossRef]

- Zhao, H.T.; Ding, J.; Li, S.H.; Wang, P.G.; Chen, Y.Z.; Liu, Y.; Tian, Q. Effects of porous shale waste brick lightweight aggregate on mechanical properties and autogenous deformation of early-age concrete. Constr. Build. Mater. 2020, 261, 9. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, X.J.; Zhao, Y.; Zhang, X.B. A Novel Passive Method for Regulating Both Air Temperature and Relative Humidity of the Microenvironment in Museum Display Cases. Energies 2019, 12, 3768. [Google Scholar] [CrossRef] [Green Version]

- Fort, J.; Sal, J.; Koci, J.; Cerny, R. Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes. Energies 2020, 13, 2012. [Google Scholar] [CrossRef] [Green Version]

- Brzyski, P.; Suchorab, Z. Capillary Uptake Monitoring in Lime-Hemp-Perlite Composite Using the Time Domain Reflectometry Sensing Technique for Moisture Detection in Building Composites. Materials 2020, 13, 1677. [Google Scholar] [CrossRef] [Green Version]

- Fenoglio, E.; Fantucci, S.; Serra, V.; Carbonaro, C.; Pollo, R. Hygrothermal and environmental performance of a perlite-based insulating plaster for the energy retrofit of buildings. Energy Build. 2018, 179, 26–38. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L.; Vieira, N.; Raupp-Pereira, F.; Senff, L.; Labrincha, J.A. The influence of porogene additives on the properties of mortars used to control the ambient moisture. Energy Build. 2014, 74, 61–68. [Google Scholar] [CrossRef]

- Vieira, J.; Senff, L.; Goncalves, H.; Silva, L.; Ferreira, V.M.; Labrincha, J.A. Functionalization of mortars for controlling the indoor ambient of buildings. Energy Build. 2014, 70, 224–236. [Google Scholar] [CrossRef]

- Fort, J.; Koci, J.; Pokorny, J.; Cerny, R. Influence of Superabsorbent Polymers on Moisture Control in Building Interiors. Energies 2020, 13, 2009. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L.; Raupp-Pereira, F.; Senff, L.; Labrincha, J.A. Development of porogene-containing mortars for levelling the indoor ambient moisture. Ceram. Int. 2014, 40, 15489–15495. [Google Scholar] [CrossRef]

- He, Z.M.; Shen, A.Q.; Guo, Y.C.; Lyu, Z.H.; Li, D.S.; Qin, X.; Zhao, M.; Wang, Z.L. Cement-based materials modified with superabsorbent polymers: A review. Constr. Build. Mater. 2019, 225, 569–590. [Google Scholar] [CrossRef]

- Senff, L.; Ascensao, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Assessment of the single and combined effect of superabsorbent particles and porogenic agents in nanotitania-containing mortars. Energy Build. 2016, 127, 980–990. [Google Scholar] [CrossRef]

- Iucolano, F.; Caputo, D.; Leboffe, F.; Liguori, B. Mechanical behavior of plaster reinforced with abaca fibers. Constr. Build. Mater. 2015, 99, 184–191. [Google Scholar] [CrossRef]

- Fort, J.; Keppert, M.; Cerny, R. Application of cellulose fiber reinforcement in lime plasters. Cem. Wapno Beton 2018, 23, 433. [Google Scholar]

- Hroudova, J.; Korjenic, A.; Zach, J.; Mitterbock, M. Development of a thermal insulation plaster with natural fibres and the investigation of its heat and moisture behaviour. Bauphysik 2017, 39, 261–271. [Google Scholar]

- Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete block. Part II: Hygric properties. J. Build. Eng. 2019, 24, 11. [Google Scholar] [CrossRef]

- Palomar, I.; Barluenga, G. A multiscale model for pervious lime-cement mortar with perlite and cellulose fibers. Constr. Build. Mater. 2018, 160, 136–144. [Google Scholar] [CrossRef]

- EN 1015-10:1999, Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar; Czech Standardization Institute: Prague, Czech Republic, 1999.

- EN 1015-11:2019, Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; Czech Standardization Institute: Prague, Czech Republic, 2019.

- Pavlik, Z.; Jerman, M.; Fort, J.; Cerny, R. Monitoring Thermal Performance of Hollow Bricks with Different Cavity Fillers in Difference Climate Conditions. Int. J. Thermophys. 2015, 36, 557–568. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementitious materials. Part II: Essential tool for assessment of transport properties and for durability prediction. Cem. Concr. Res. 2007, 37, 438–454. [Google Scholar] [CrossRef]

- Hall, C. Water Sorptivity of Mortars and Concretes—A Review. Mag. Concr. Res. 1989, 41, 51–61. [Google Scholar] [CrossRef]

- Rode, C.; Grau, K. Moisture buffering and its consequence in whole building hygrothermal modeling. J. Build. Phys. 2008, 31, 333–360. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Siddique, R.; Klimek, B.; Franus, M. The use of zeolite, lightweight aggregate and boiler slag in restoration renders. Constr. Build. Mater. 2017, 142, 162–174. [Google Scholar] [CrossRef]

- van der Wel, G.K.; Adan, O.C.G.; Bancken, E.L.J. Towards an ecofriendlier control of fungal growth on coated plasters? Prog. Org. Coat. 1999, 36, 173–177. [Google Scholar] [CrossRef]

- Senff, L.; Ascensao, G.; Ferreira, V.M.; Seabra, M.P.; Labrincha, J.A. Development of multifunctional plaster using nano-TiO2 and distinct particle size cellulose fibers. Energy Build. 2018, 158, 721–735. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Neto, A.R.S.; Silva, F.D.; de Souza, F.G.; Toledo, R.D. The influence of carboxylated styrene butadiene rubber coating on the mechanical performance of vegetable fibers and on their interface with a cement matrix. Constr. Build. Mater. 2020, 262, 10. [Google Scholar] [CrossRef]

- Guardia, C.; Barluenga, G.; Palomar, I. PCM Cement-Lime Mortars for Enhanced Energy Efficiency of Multilayered Building Enclosures under Different Climatic Conditions. Materials 2020, 13, 4043. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.O.; Medina, M.A.; Sun, X.Q.; Jin, X. Thermal performance of phase change materials (PCM)-enhanced cellulose insulation in passive solar residential building walls. Sol. Energy 2018, 163, 113–121. [Google Scholar] [CrossRef]

- Nindiyasari, F.; Griesshaber, E.; Zimmermann, T.; Manian, A.P.; Randow, C.; Zehbe, R.; Fernandez-Diaz, L.; Ziegler, A.; Fleck, C.; Schmahl, W.W. Characterization and mechanical properties investigation of the cellulose/gypsum composite. J. Compos. Mater. 2016, 50, 657–672. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.S.; Yu, K.Y.; Gao, X.J.; Ren, M.; Jia, M.J.; Yang, Y.Z. Enhanced thermal properties of hydrate salt/poly (acrylate sodium) copolymer hydrogel as form-stable phase change material via incorporation of hydroxyl carbon nanotubes. Sol. Energy Mater. Sol. Cells 2020, 208, 10. [Google Scholar] [CrossRef]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibres on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793–803. [Google Scholar] [CrossRef]

- Fort, J.; Migas, P.; Cerny, R. Effect of Absorptivity of Superabsorbent Polymers on Design of Cement Mortars. Materials 2020, 13, 5503. [Google Scholar] [CrossRef] [PubMed]

- Zu, K.; Qin, M.H.; Rode, C.; Libralato, M. Development of a moisture buffer value model (MBM) for indoor moisture prediction. Appl. Therm. Eng. 2020, 171, 9. [Google Scholar] [CrossRef]

- Snoeck, D.; Schrofl, C.; Mechtcherine, V. Recommendation of RILEM TC 260-RSC: Testing sorption by superabsorbent polymers (SAP) prior to implementation in cement-based materials. Mater. Struct. 2018, 51, 116. [Google Scholar] [CrossRef]

- Shi, C.N.; Zhang, H.B.; Xuan, Y.L. Experimental investigation of thermal properties and moisture buffering performance of composite interior finishing materials under different airflow conditions. Build. Environ. 2019, 160, 10. [Google Scholar] [CrossRef]

| Mixture | SAP (%) | Cellulose (%) |

|---|---|---|

| PR | - | - |

| PS0.5C1 | 0.5 | 1 |

| PS0.5C2 | 0.5 | 2 |

| PS0.5C3 | 0.5 | 3 |

| PS1C1 | 1 | 1 |

| PS1C2 | 1 | 2 |

| PS1C3 | 1 | 3 |

| PS1.5C1 | 1.5 | 1 |

| PS1.5C2 | 1.5 | 2 |

| PS1.5C3 | 1.5 | 3 |

| Mixture | Bulk Density (kg/m3) | Matrix Density (kg/m3) | Total Open Porosity (-) |

|---|---|---|---|

| PR | 1588 ± 25 | 2556 ± 11 | 0.38 |

| PS0.5C1 | 1546 ± 31 | 2543 ± 13 | 0.39 |

| PS0.5C2 | 1540 ± 26 | 2549 ± 11 | 0.40 |

| PS0.5C3 | 1433 ± 27 | 2561 ± 10 | 0.44 |

| PS1C1 | 1463 ± 30 | 2540 ± 15 | 0.42 |

| PS1C2 | 1408 ± 25 | 2539 ± 11 | 0.45 |

| PS1C3 | 1372 ± 19 | 2558 ± 12 | 0.46 |

| PS1.5C1 | 1377 ± 42 | 2562 ± 10 | 0.46 |

| PS1.5C2 | 1269 ± 27 | 2541 ± 14 | 0.50 |

| PS1.5C3 | 1185 ± 23 | 2550 ± 12 | 0.54 |

| Mixture | A (kg/m2s1/2) | Ƙ (m2/s) |

|---|---|---|

| PR | 0.164 | 4.94 × 10−7 |

| PS0.5C1 | 0.166 | 5.01 × 10−7 |

| PS0.5C2 | 0.174 | 5.22 × 10−7 |

| PS0.5C3 | 0.181 | 5.66 × 10−7 |

| PS1C1 | 0.176 | 5.25 × 10−7 |

| PS1C2 | 0.184 | 5.98 × 10−7 |

| PS1C3 | 0.192 | 6.13 × 10−7 |

| PS1.5C1 | 0.194 | 6.22 × 10−7 |

| PS1.5C2 | 0.204 | 6.63 × 10−7 |

| PS1.5C3 | 0.215 | 6.89 × 10−7 |

| Mixture | µ (-) |

|---|---|

| PR | 15.33 |

| PS0.5C1 | 14.76 |

| PS0.5C2 | 14.38 |

| PS0.5C3 | 13.76 |

| PS1C1 | 14.43 |

| PS1C2 | 13.98 |

| PS1C3 | 13.66 |

| PS1.5C1 | 12.45 |

| PS1.5C2 | 11.79 |

| PS1.5C3 | 11.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fořt, J.; Šál, J.; Žák, J. Combined Effect of Superabsorbent Polymers and Cellulose Fibers on Functional Performance of Plasters. Energies 2021, 14, 3679. https://doi.org/10.3390/en14123679

Fořt J, Šál J, Žák J. Combined Effect of Superabsorbent Polymers and Cellulose Fibers on Functional Performance of Plasters. Energies. 2021; 14(12):3679. https://doi.org/10.3390/en14123679

Chicago/Turabian StyleFořt, Jan, Jiří Šál, and Jaroslav Žák. 2021. "Combined Effect of Superabsorbent Polymers and Cellulose Fibers on Functional Performance of Plasters" Energies 14, no. 12: 3679. https://doi.org/10.3390/en14123679

APA StyleFořt, J., Šál, J., & Žák, J. (2021). Combined Effect of Superabsorbent Polymers and Cellulose Fibers on Functional Performance of Plasters. Energies, 14(12), 3679. https://doi.org/10.3390/en14123679