Metrics for Measuring Sustainable Product Design Concepts

Abstract

1. Introduction

2. Related Work

2.1. Sustainable Product Design

2.2. Concept Assessment Methods

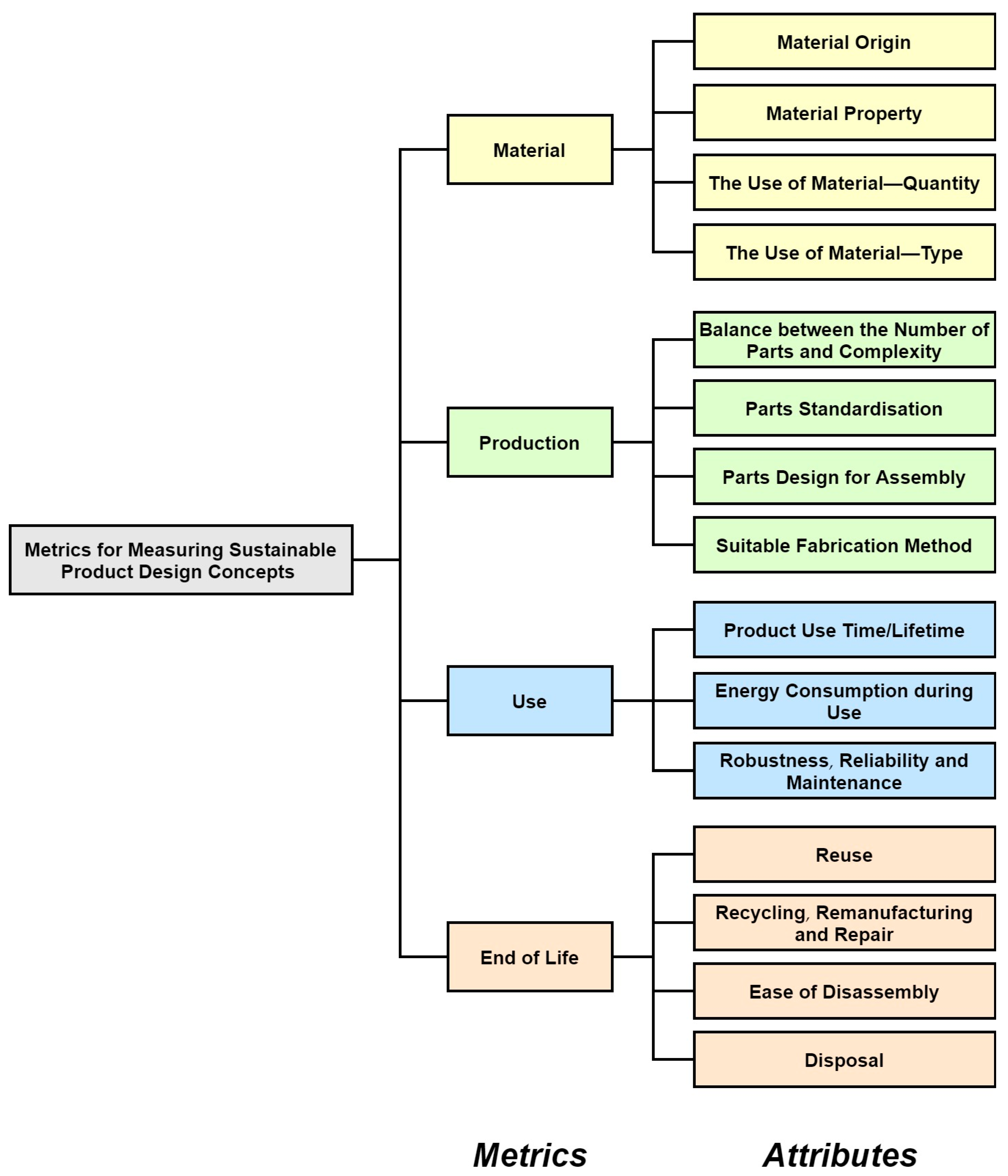

3. Metrics for Measuring Sustainable Product Design Concepts

3.1. Material

Measurement of Material

3.2. Production (Manufacturing and Assembly)

Measurement of Production

3.3. Use

Measurement of Use

3.4. End of Life

Measurement of End of Life

3.5. The Four Metrics

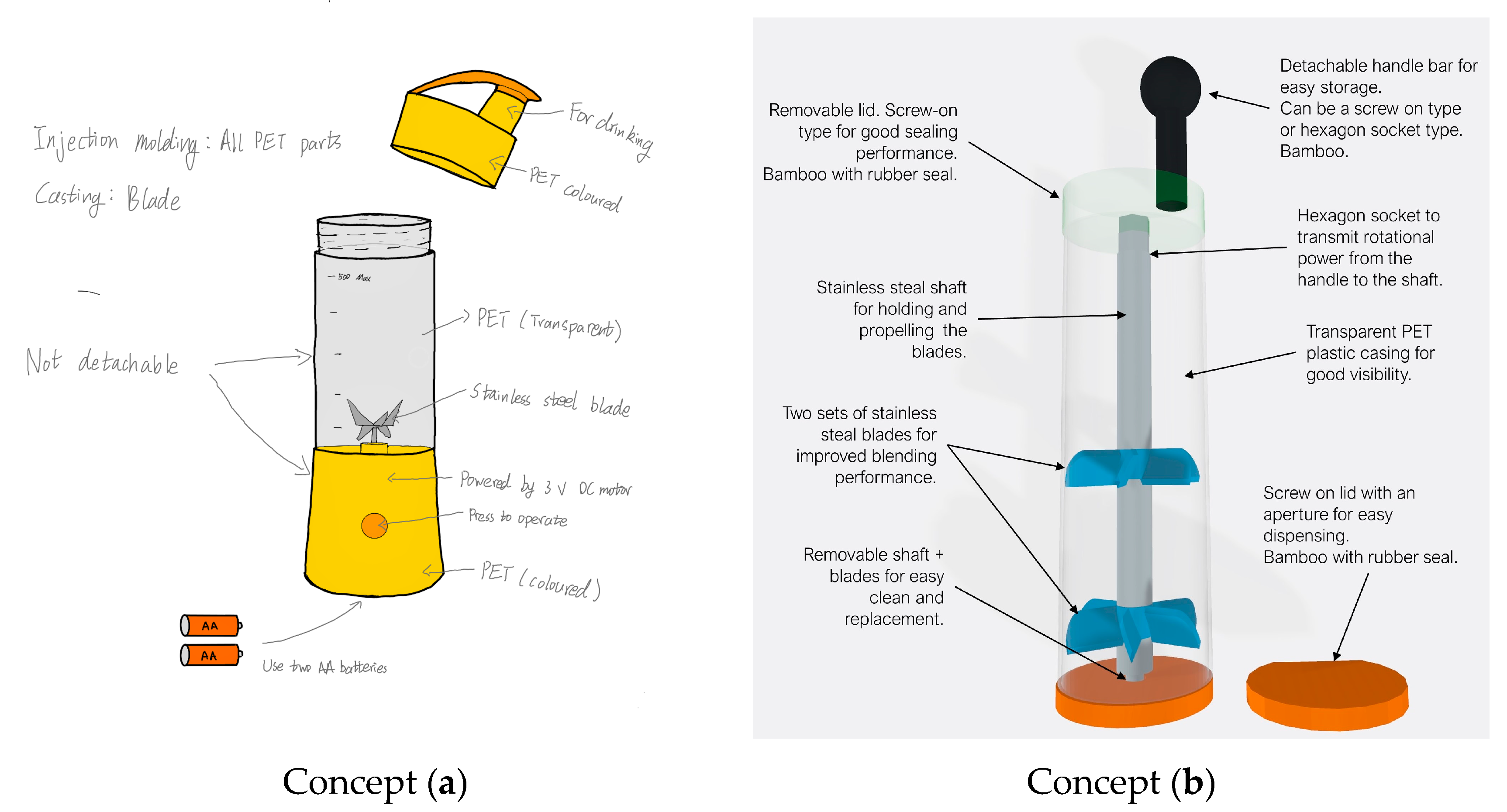

4. Case Study

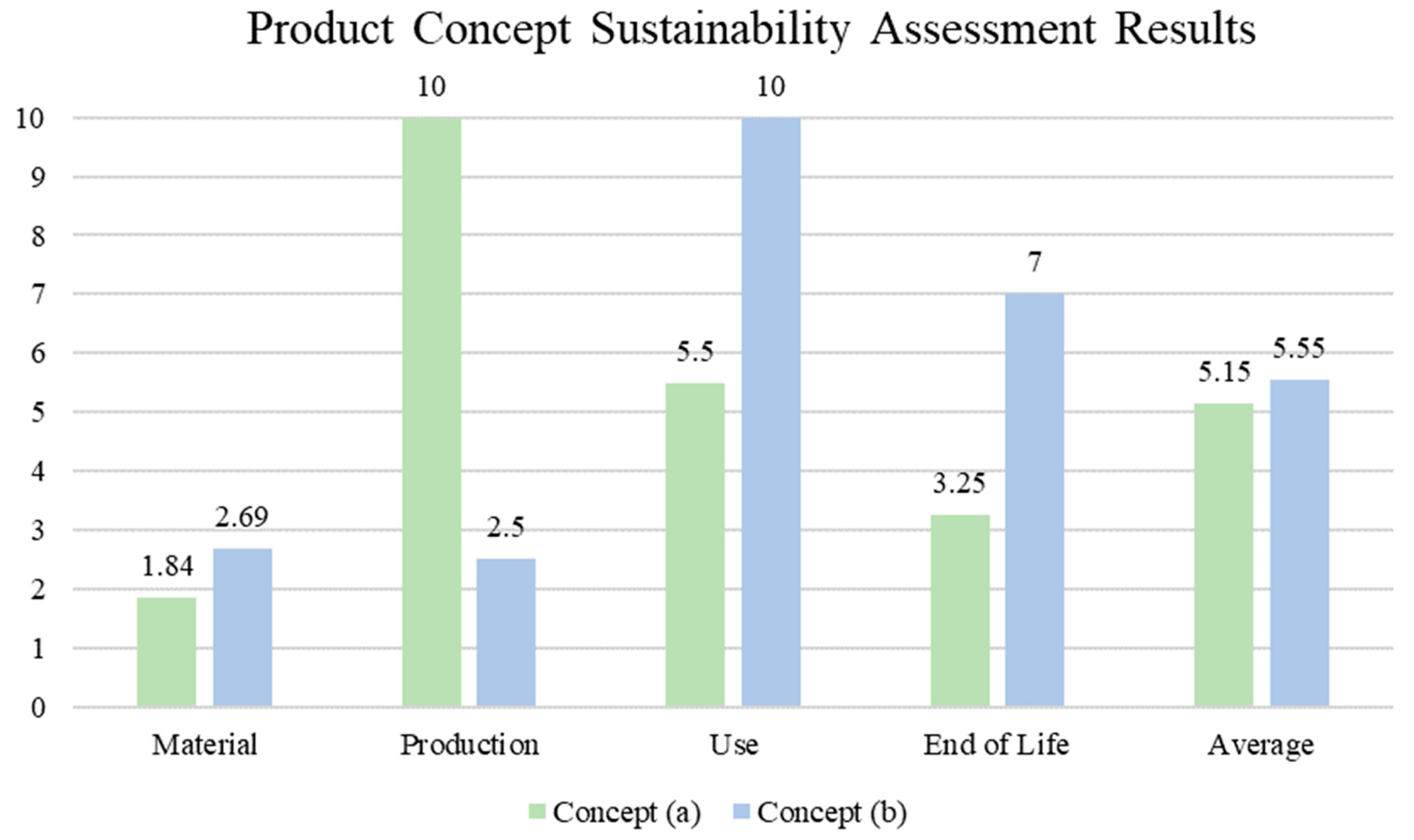

Evaluation and Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Parker, J.; Simpson, G.D. A Theoretical Framework for Bolstering Human-Nature Connections and Urban Resilience via Green Infrastructure. Land 2020, 9, 252. [Google Scholar] [CrossRef]

- Vollset, S.E.; Goren, E.; Yuan, C.-W.; Cao, J.; Smith, A.E.; Hsiao, T.; Bisignano, C.; Azhar, G.S.; Castro, E.; Chalek, J.; et al. Fertility, mortality, migration, and population scenarios for 195 countries and territories from 2017 to 2100: A forecasting analysis for the Global Burden of Disease Study. Lancet 2020, 396, 1285–1306. [Google Scholar] [CrossRef]

- Mesa, J.; Maury, H.; Arrieta, R.; Corredor, L.; Bris, J. A novel approach to include sustainability concepts in classical DFMA methodology for sheet metal enclosure devices. Res. Eng. Des. 2018, 29, 227–244. [Google Scholar] [CrossRef]

- Fargnoli, M.; de Minicis, M.; Tronci, M. Design Management for Sustainability: An integrated approach for the development of sustainable products. J. Eng. Technol. Manag. 2014, 34, 29–45. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Chu, C.-H. Review of sustainable product design from life cycle perspectives. Int. J. Precis. Eng. Manuf. 2012, 13, 1259–1272. [Google Scholar] [CrossRef]

- WCED. Our Common Future; Oxford University Press: Oxford, UK, 1987; Available online: https://archive.org/details/ourcommonfuture00worl/page/n5/mode/2up (accessed on 8 June 2021).

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- He, B.; Gu, Z. Sustainable design synthesis for product environmental footprints. Des. Stud. 2016, 45, 159–186. [Google Scholar] [CrossRef]

- Vallet, F.; Eynard, B.; Millet, D.; Mahut, S.G.; Tyl, B.; Bertoluci, G. Using eco-design tools: An overview of experts’ practices. Des. Stud. 2013, 34, 345–377. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, J.; Yu, J.-Y.; Noori, H. A new methodology for evaluating sustainable product design performance with two-stage network data envelopment analysis. Eur. J. Oper. Res. 2012, 221, 348–359. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Howarth, G.; Hadfield, M. A sustainable product design model. Mater. Des. 2006, 27, 1128–1133. [Google Scholar] [CrossRef]

- Tiwari, V.; Jain, P.K.; Tandon, P. Product design concept evaluation using rough sets and VIKOR method. Adv. Eng. Inform. 2016, 30, 16–25. [Google Scholar] [CrossRef]

- Shidpour, H.; Da Cunha, C.; Bernard, A. Group multi-criteria design concept evaluation using combined rough set theory and fuzzy set theory. Expert Syst. Appl. 2016, 64, 633–644. [Google Scholar] [CrossRef]

- Zhu, G.-N.; Hu, J.; Qi, J.; Gu, C.-C.; Peng, Y.-H. An integrated AHP and VIKOR for design concept evaluation based on rough number. Adv. Eng. Inform. 2015, 29, 408–418. [Google Scholar] [CrossRef]

- Wang, L.; Shen, W.; Xie, H.; Neelamkavil, J.; Pardasani, A. Collaborative conceptual design—State of the art and future trends. Comput. Aided Des. 2002, 34, 981–996. [Google Scholar] [CrossRef]

- Hsu, W.; Liu, B. Conceptual design: Issues and challenges. Comput. Aided Des. 2000, 32, 849–850. [Google Scholar] [CrossRef]

- Marcinkowski, A.; Zych, K. Environmental Performance of Kettle Production: Product Life Cycle Assessment. Manag. Syst. Prod. Eng. 2017, 25, 255–261. [Google Scholar] [CrossRef]

- WRAP. Environmental Assessment of Consumer Electronic Products. Available online: http://archive.wrap.org.uk/sites/files/wrap/Environmental%20assessment%20of%20consumer%20electronic%20products.pdf (accessed on 25 May 2021).

- Lewis, H.; Gertsakis, J.; Grant, T.; Morelli, N.; Sweatman, A. Design+ Environment: A Global Guide to Designing Greener Goods; Routledge: London, UK, 2017. [Google Scholar]

- Ramani, K.; Ramanujan, D.; Bernstein, W.Z.; Zhao, F.; Sutherland, J.; Handwerker, C.; Choi, J.-K.; Kim, H.; Thurston, D. Integrated Sustainable Life Cycle Design: A Review. J. Mech. Des. 2010, 132, 091004. [Google Scholar] [CrossRef]

- Birch, A.; Hon, K.K.B.; Short, T. Structure and output mechanisms in Design for Environment (DfE) tools. J. Clean. Prod. 2012, 35, 50–58. [Google Scholar] [CrossRef]

- Ruy, M.; Alliprandini, D.; Scur, G. Environmental assessment in the conceptual design phase of new product development. Int. J. Sustain. Des. 2019, 3, 182–204. [Google Scholar] [CrossRef]

- Hallstedt, S.I. Sustainability criteria and sustainability compliance index for decision support in product development. J. Clean. Prod. 2017, 140, 251–266. [Google Scholar] [CrossRef]

- Yang, C.J.; Chen, J.L. Accelerating preliminary eco-innovation design for products that integrates case-based reasoning and TRIZ method. J. Clean. Prod. 2011, 19, 998–1006. [Google Scholar] [CrossRef]

- Brundage, M.P.; Bernstein, W.Z.; Hoffenson, S.; Chang, Q.; Nishi, H.; Kliks, T.; Morris, K.C. Analyzing environmental sustainability methods for use earlier in the product lifecycle. J. Clean. Prod. 2018, 187, 877–892. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.A.; McAloone, T.C. Developing A Tool to Support Decisions in Sustainability-Related Trade-Off Situations: Understanding Needs and Criteria. Proc. Des. Soc. 2020, 1, 265–274. [Google Scholar] [CrossRef]

- Gagnon, B.; Leduc, R.; Savard, L. From a conventional to a sustainable engineering design process: Different shades of sustainability. J. Eng. Des. 2012, 23, 49–74. [Google Scholar] [CrossRef]

- McAloone, T.C.; Pigosso, D.C.A. Ecodesign Implementation and LCA. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 545–576. [Google Scholar]

- Suhariyanto, T.T.; Wahab, D.A.; Rahman, M.N.A. Product Design Evaluation Using Life Cycle Assessment and Design for Assembly: A Case Study of a Water Leakage Alarm. Sustainability 2018, 10, 2821. [Google Scholar] [CrossRef]

- Harris, J.S. New product profile chart. Chemtech 1976, 6, 554–564. [Google Scholar]

- Amabile, T.M. Social psychology of creativity: A consensual assessment technique. J. Personal. Soc. Psychol. 1982, 43, 997–1013. [Google Scholar] [CrossRef]

- O’Quin, K.; Besemer, S.P. The development, reliability, and validity of the revised creative product semantic scale. Creat. Res. J. 1989, 2, 267–278. [Google Scholar] [CrossRef]

- Pugh, S.; Clausing, D. Creating Innovtive Products Using Total Design: The Living Legacy of Stuart Pugh; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1996. [Google Scholar]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Concept selection of car bumper beam with developed hybrid bio-composite material. Mater. Des. 2011, 32, 4857–4865. [Google Scholar] [CrossRef]

- Sarkar, P.; Chakrabarti, A. Assessing design creativity. Des. Stud. 2011, 32, 348–383. [Google Scholar] [CrossRef]

- Childs, P.R.N. Mechanical Design Engineering Handbook, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Yung, W.K.C.; Chan, H.K.; So, J.H.T.; Wong, D.W.C.; Choi, A.C.K.; Yue, T.M. A life-cycle assessment for eco-redesign of a consumer electronic product. J. Eng. Des. 2011, 22, 69–85. [Google Scholar] [CrossRef]

- Mestre, A.; Vogtlander, J. Eco-efficient value creation of cork products: An LCA-based method for design intervention. J. Clean. Prod. 2013, 57, 101–114. [Google Scholar] [CrossRef]

- Deng, C.; Wu, J.; Shao, X. Research on eco-balance with LCA and LCC for mechanical product design. Int. J. Adv. Manuf. Technol. 2016, 87, 1217–1228. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Voigt, S.; Walter, D.; Fullana-i-Palmer, P. Improving the production chain with LCA and eco-design: Application to cosmetic packaging. Resour. Conserv. Recycl. 2019, 151, 104475. [Google Scholar] [CrossRef]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- Wisthoff, A.; Ferrero, V.; Huynh, T.; DuPont, B. Quantifying the Impact of Sustainable Product Design Decisions in the Early Design Phase Through Machine Learning. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar]

- Millet, D.; Bistagnino, L.; Lanzavecchia, C.; Camous, R.; Poldma, T. Does the potential of the use of LCA match the design team needs? J. Clean. Prod. 2007, 15, 335–346. [Google Scholar] [CrossRef]

- Bereketli, I.; Erol Genevois, M. An integrated QFDE approach for identifying improvement strategies in sustainable product development. J. Clean. Prod. 2013, 54, 188–198. [Google Scholar] [CrossRef]

- Younesi, M.; Roghanian, E. A framework for sustainable product design: A hybrid fuzzy approach based on Quality Function Deployment for Environment. J. Clean. Prod. 2015, 108, 385–394. [Google Scholar] [CrossRef]

- Wu, Y.-H.; Ho, C.C. Integration of green quality function deployment and fuzzy theory: A case study on green mobile phone design. J. Clean. Prod. 2015, 108, 271–280. [Google Scholar] [CrossRef]

- Ocampo, L.A.; Labrador, J.J.T.; Jumao-as, A.M.B.; Rama, A.M.O. Integrated multiphase sustainable product design with a hybrid quality function deployment—Multi-attribute decision-making (QFD-MADM) framework. Sustain. Prod. Consum. 2020, 24, 62–78. [Google Scholar] [CrossRef]

- Olewnik, A.; Lewis, K. Limitations of the House of Quality to provide quantitative design information. Int. J. Qual. Reliab. Manag. 2008, 25, 125–146. [Google Scholar] [CrossRef]

- Abu-Assab, S. Quality Function Deployment in New Product Development. In Integration of Preference Analysis Methods into Quality Function Deployment: A Focus on Elderly People; Abu-Assab, S., Ed.; Gabler Verlag: Wiesbaden, Germany, 2012; pp. 47–68. [Google Scholar]

- Han, J.; Forbes, H.; Schaefer, D. An exploration of how creativity, functionality, and aesthetics are related in design. Res. Eng. Des. 2021, 1–19. [Google Scholar] [CrossRef]

- Goswami, M.; Tiwari, M.K. A predictive risk evaluation framework for modular product concept selection in new product design environment. J. Eng. Des. 2014, 25, 150–171. [Google Scholar] [CrossRef]

- Rondini, A.; Bertoni, M.; Pezzotta, G. An IPA Based Method for PSS Design Concept Assessment. Procedia CIRP 2017, 64, 277–282. [Google Scholar] [CrossRef]

- Chulvi, V.; Sonseca, Á.; Mulet, E.; Chakrabarti, A. Assessment of the Relationships Among Design Methods, Design Activities, and Creativity. J. Mech. Des. 2012, 134, 111004. [Google Scholar] [CrossRef]

- García-García, C.; Chulvi, V.; Royo, M. Knowledge generation for enhancing design creativity through co-creative Virtual Learning Communities. Think. Ski. Creat. 2017, 24, 12–19. [Google Scholar] [CrossRef]

- Horn, D.; Salvendy, G. Measuring consumer perception of product creativity: Impact on satisfaction and purchasability. Hum. Factors Ergon. Manuf. Serv. Ind. 2009, 19, 223–240. [Google Scholar] [CrossRef]

- Chakrabarti, A.; Sarkar, P.; Leelavathamma, B.; Nataraju, B.S. A functional representation for aiding biomimetic and artificial inspiration of new ideas. Artif. Intell. Eng. Des. Anal. Manuf. 2005, 19, 113–132. [Google Scholar] [CrossRef]

- Chiu, I.; Shu, L.H. Investigating effects of oppositely related semantic stimuli on design concept creativity. J. Eng. Des. 2012, 23, 271–296. [Google Scholar] [CrossRef]

- Demirkan, H.; Afacan, Y. Assessing creativity in design education: Analysis of creativity factors in the first-year design studio. Des. Stud. 2012, 33, 262–278. [Google Scholar] [CrossRef]

- Lee, J.H.; Gu, N.; Ostwald, M.J. Creativity and parametric design? Comparing designer’s cognitive approaches with assessed levels of creativity. Int. J. Des. Creat. Innov. 2015, 3, 78–94. [Google Scholar] [CrossRef]

- Srinivasan, V.; Song, B.; Luo, J.; Subburaj, K.; Elara, M.R.; Blessing, L.; Wood, K. Does Analogical Distance Affect Performance of Ideation? J. Mech. Des. 2018, 140, 071101. [Google Scholar] [CrossRef]

- Starkey, E.M.; Menold, J.; Miller, S.R. When Are Designers Willing to Take Risks? How Concept Creativity and Prototype Fidelity Influence Perceived Risk. J. Mech. Des. 2019, 141, 031104. [Google Scholar] [CrossRef]

- Lindow, K.; Woll, R.; Stark, R. Developing Sustainable Products: An Interdisciplinary Challenge. In Proceedings of the 4th International Conference on Research into Design (ICoRD’13), Tamil Nadu, India, 7–9 January 2013; pp. 517–527. [Google Scholar]

- Hassan, M.F.; Saman, M.Z.M.; Sharif, S.; Omar, B. Sustainability evaluation of alternative part configurations in product design: Weighted decision matrix and artificial neural network approach. Clean Technol. Environ. Policy 2016, 18, 63–79. [Google Scholar] [CrossRef]

- Turan, F.M.; Johan, K.; Nor, N.H.M.; Omar, B. Sustainability Assessment Model in Product Development. IOP Conf. Ser. Mater. Sci. Eng. 2017, 226, 012021. [Google Scholar] [CrossRef]

- Tarne, P.; Traverso, M.; Finkbeiner, M. Review of life cycle sustainability assessment and potential for its adoption at an automotive company. Sustainability 2017, 9, 670. [Google Scholar] [CrossRef]

| Concept Assessment Methods | Year of Publication | Feasibility | Creativity | Sustainability |

|---|---|---|---|---|

| Harris [31] | 1976 | X | ||

| Amabile [32] | 1982 | X | ||

| O’Quin and Besemer [33] | 1989 | X | ||

| Pugh and Clausing [34] | 1996 | X | ||

| Horn and Salvendy [56] | 2009 | X | ||

| Davoodi et al. [35] | 2011 | X | ||

| Sarkar and Chakrabarti [36] | 2011 | X | ||

| Chiu and Shu [58] | 2012 | X | ||

| Chulvi et al. [54] | 2012 | X | ||

| Demirkan and Afacan [59] | 2012 | X | ||

| Lindow et al. [63] | 2013 | X | ||

| Goswami and Tiwari [52] | 2014 | X | ||

| Lee et al. [60] | 2015 | X | ||

| Zhu et al. [15] | 2015 | X | ||

| Hassan et al. [64] | 2016 | X | ||

| Shidpour et al. [14] | 2016 | X | ||

| Tiwari et al. [13] | 2016 | X | ||

| García-García et al. [55] | 2017 | X | ||

| Rondini et al. [53] | 2017 | X | ||

| Turan et al. [65] | 2017 | X | ||

| Childs [37] | 2018 | X | ||

| Srinivasan et al. [61] | 2018 | X | ||

| Starkey et al. [62] | 2019 | X |

| Attributes | Symbol | Low = 0 | Medium = 1 | High = 2 |

|---|---|---|---|---|

| Material origin | M1 | Nonrenewable (e.g., fossil-based plastics, metal, glass) | Hybrid (e.g., bioplastics, by-product waste materials) | Renewable (e.g., bamboo, wood, natural rubber) |

| Material property | M2 | Toxic, neither recyclable nor biodegradable | Either toxic or nontoxic, either recyclable or biodegradable | Nontoxic, can be easily reused or recycled |

| Use of material—quantity | M3 | Poor potential for material quantity reduction | Fair potential for material quantity reduction | Good potential for material quantity reduction |

| Use of material—type | N | Not Applicable | ||

| DFMA Considerations | Explanations |

|---|---|

| Minimum number of parts | The practical minimum number of parts for both manufacturing and assembly. |

| Parts/components standardisation | The number of standardised parts/components and unique parts/components. |

| Parts assembly | Parts presentation, handling, mistake proofing, and insertion for ease of assembly. |

| Suitable fabrication methods | Cost- and energy-effective technology/process for ease of manufacturing. |

| Attributes | Symbol | Low = 0 | Medium = 1 | High = 2 |

|---|---|---|---|---|

| Balance between number of parts and their complexity | P1 | Poor balance (e.g., contains too many parts or too complicated parts) | Fair balance (e.g., contains few parts but is complicated) | Good balance (e.g., contains few simple parts) |

| Parts standardisation | P2 | The concept requires a considerable degree of customisation | The concept has a reasonable degree of potential to be standardised | The concept can benefit significantly by using standardised components |

| Parts design for assembly | P3 | Poor potential for assembly optimisation | Fair potential for assembly optimisation | Good potential for assembly optimisation |

| Suitable fabrication method | P4 | Excessive operations needed (e.g., polishing, fine machining) | Partial excessive operations needed | No excessive operations needed |

| Attributes | Symbol | Low = 0 | Medium = 1 | High = 2 |

|---|---|---|---|---|

| Product use time/lifetime | U1 | Product lifetime is significantly shorter/longer than product use time | Product lifetime is fairly shorter/longer than product use time | Product lifetime is almost identical to product use time |

| Energy consumption during use | U2 | The concept consumes a significant amount of energy | The concept consumes a fair amount of energy | The concept consumes a slight amount of energy |

| Robustness, reliability, and maintenance | U3 | The concept requires a significant amount of resource to maintain/service | The concept consumes a fair amount of resource to maintain/service | The concept consumes a slight amount of resource to maintain/service |

| Attributes | Symbol | Low = 0 | Medium = 1 | High = 2 |

|---|---|---|---|---|

| Reuse | E1 | Poor potential for reuse | Fair potential for reuse | Good potential for reuse |

| Recycling, remanufacturing, and repair | E2 | Poor potential for recycling and remanufacturing | Fair potential for recycling and remanufacturing | Good potential for recycling and remanufacturing |

| Disposal | E3 | Significant impact due to disposal | Moderate impact due to disposal | Little impact due to disposal |

| Ease of disassembly | E4 | Poor potential for disassembly optimisation | Fair potential for disassembly optimisation | Good potential for disassembly optimisation |

| Function |

|

| Performance |

|

| Safety |

|

| Purpose market |

|

| Quantity |

|

| Quality and reliability |

|

| Cost |

|

| Size and weight |

|

| Life span |

|

| Recycle |

|

| Environment |

|

| Metrics | Attributes | Concept (a) | Concept (b) |

|---|---|---|---|

| Material | Material origin (M1) |

|

|

| Material property (M2) |

|

| |

| Use of material—quantity (M3) |

|

| |

| Use of material—type (N) | 4 | 4 | |

| Material metric | |||

| Production | Balance between the number of parts and complexity (P1) | Simple design, only a few simple parts—2 | Simple design, only a few simple parts—2 |

| Parts standardisation (P2) | Motor, battery, and gearbox can benefit from standard components—2 | All components require customisation—0 | |

| Parts design for assembly (P3) | Good potential for assembly optimisation—2 | Good potential for assembly optimisation—2 | |

| Suitable fabrication method (P4) | No excessive operations needed—2 | Partial excessive operations needed—1 | |

| Production metric | |||

| Use | Product use time/lifetime (U1) | The design lifetime should be close to its use time—2 | The design lifetime should be close to its use time—2 |

| Energy consumption during use (U2) | Needs AA batteries to power—1 | Manually operated, no other energy required—2 | |

| Robustness, reliability, and maintenance (U3) | Internal components for the base (e.g., motor and gearbox will require a fair amount of resource to maintain/service)—1 | All components are easy to maintain—2 | |

| Use metric | |||

| End of Life | Reuse (E1) | Battery, motor, and gearbox have fair potential to be reused—1 | Poor potential for reuse as all components are custom-made—0 |

| Recycling, remanufacturing, and repair (E2) | PET plastic, steel blades, and batteries can be recycled (i.e., fair potential for recycling and remanufacturing)—1 | PET plastic, steel shaft, and blades can be recycled; bamboo can be remanufactured—2 | |

| Disposal (E3) | Batteries and motors will cause moderate impact due to disposal—1 | All components will have little impact due to disposal—2 | |

| Ease of disassembly (E4) | Blender base that contains battery, motor, and gearbox will be difficult to disassemble—1 | All components are easy to remove—2 | |

| End-of-Life metric | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; Jiang, P.; Childs, P.R.N. Metrics for Measuring Sustainable Product Design Concepts. Energies 2021, 14, 3469. https://doi.org/10.3390/en14123469

Han J, Jiang P, Childs PRN. Metrics for Measuring Sustainable Product Design Concepts. Energies. 2021; 14(12):3469. https://doi.org/10.3390/en14123469

Chicago/Turabian StyleHan, Ji, Pingfei Jiang, and Peter R. N. Childs. 2021. "Metrics for Measuring Sustainable Product Design Concepts" Energies 14, no. 12: 3469. https://doi.org/10.3390/en14123469

APA StyleHan, J., Jiang, P., & Childs, P. R. N. (2021). Metrics for Measuring Sustainable Product Design Concepts. Energies, 14(12), 3469. https://doi.org/10.3390/en14123469