Designing a Smart Gateway for Data Fusion Implementation in a Distributed Electronic System Used in Automotive Industry

Abstract

1. Introduction

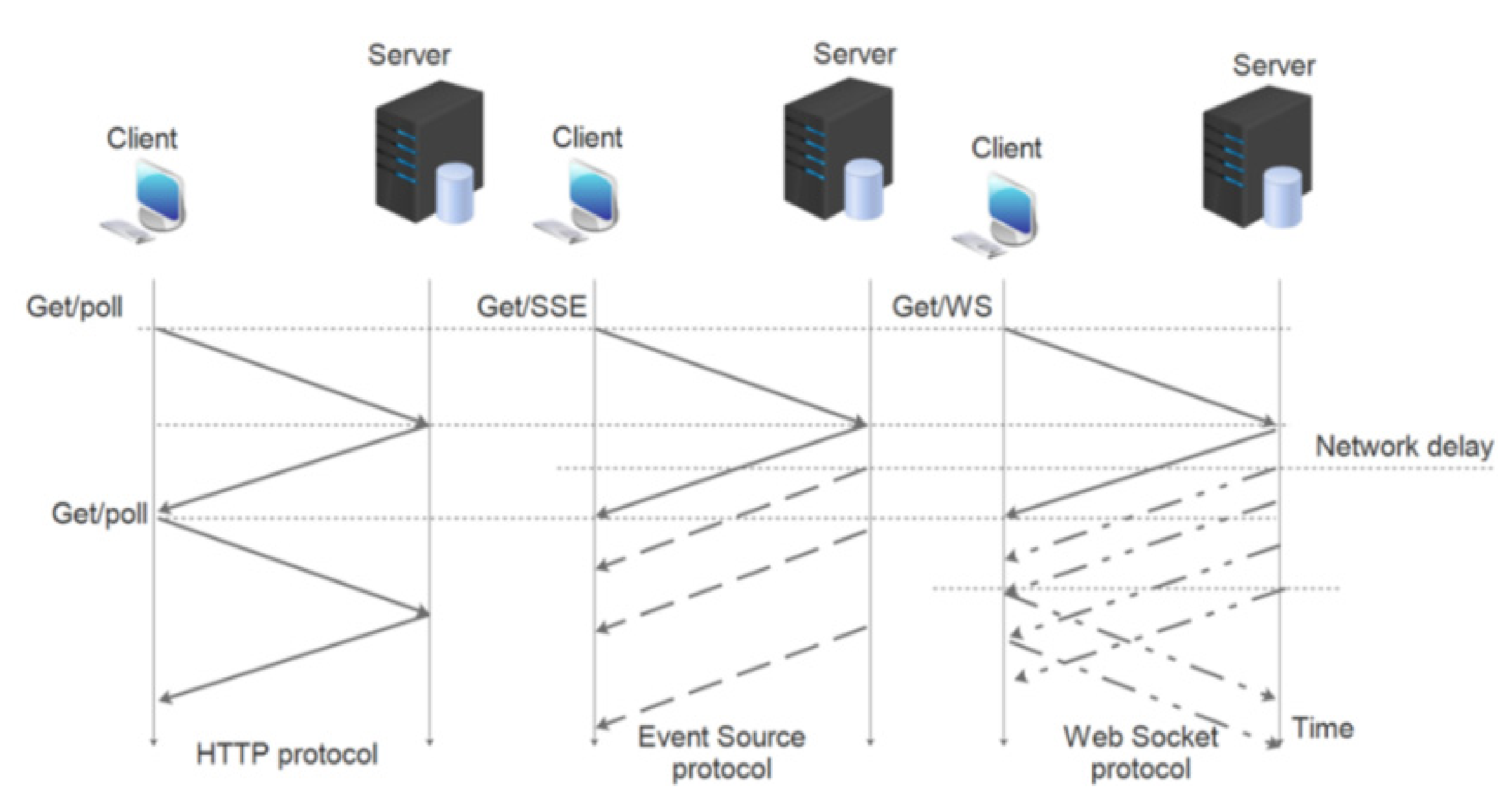

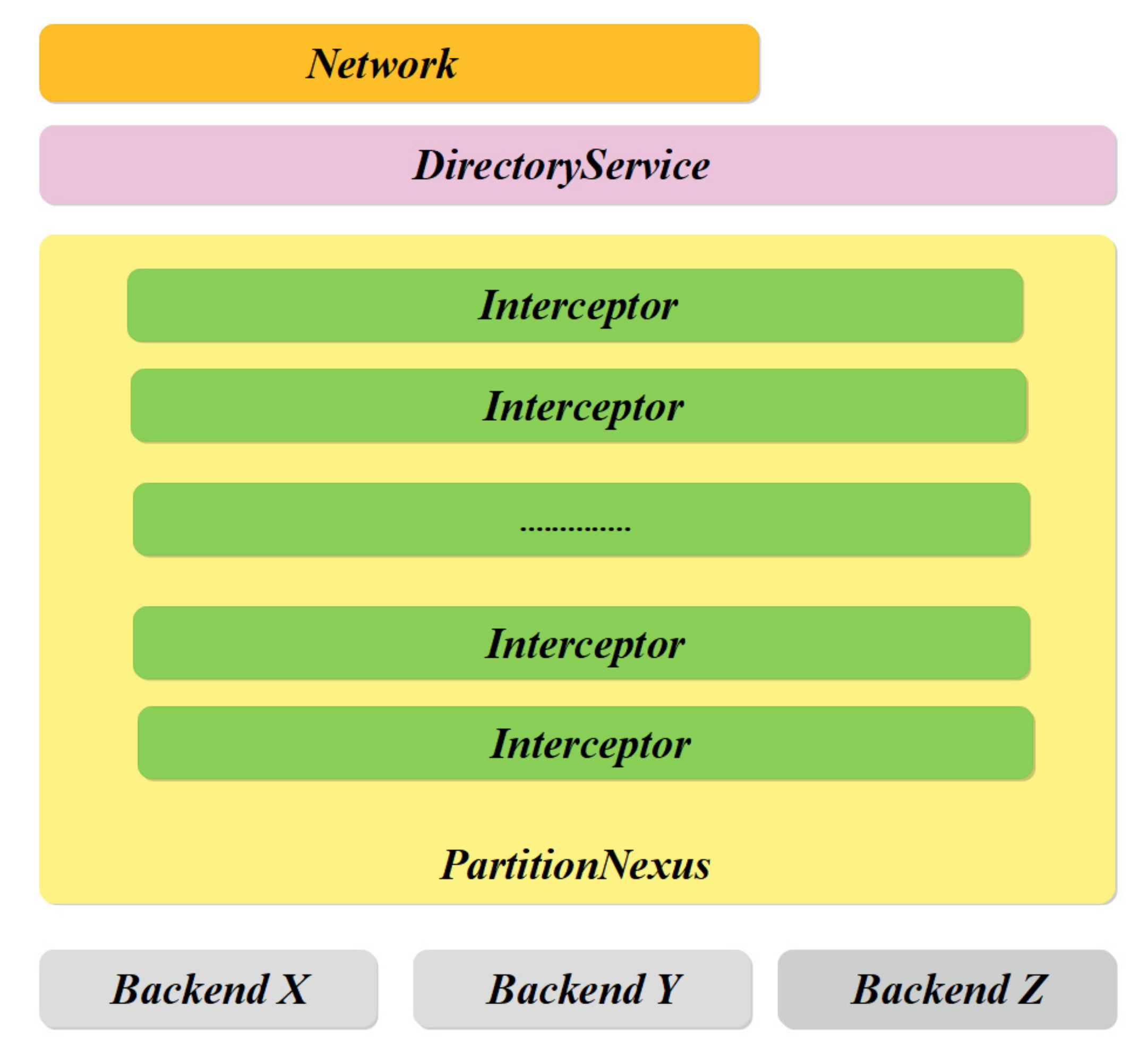

Related Work

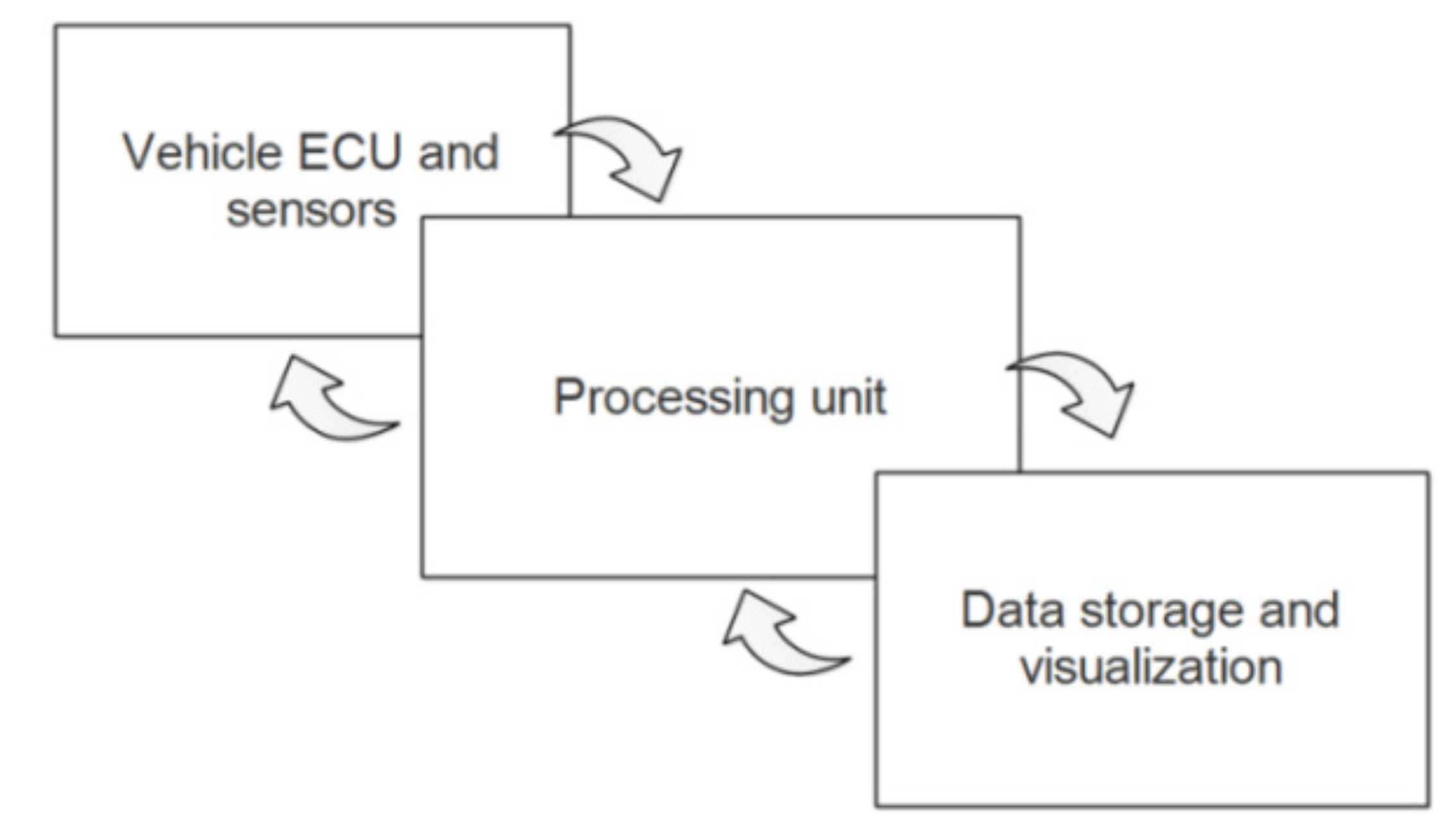

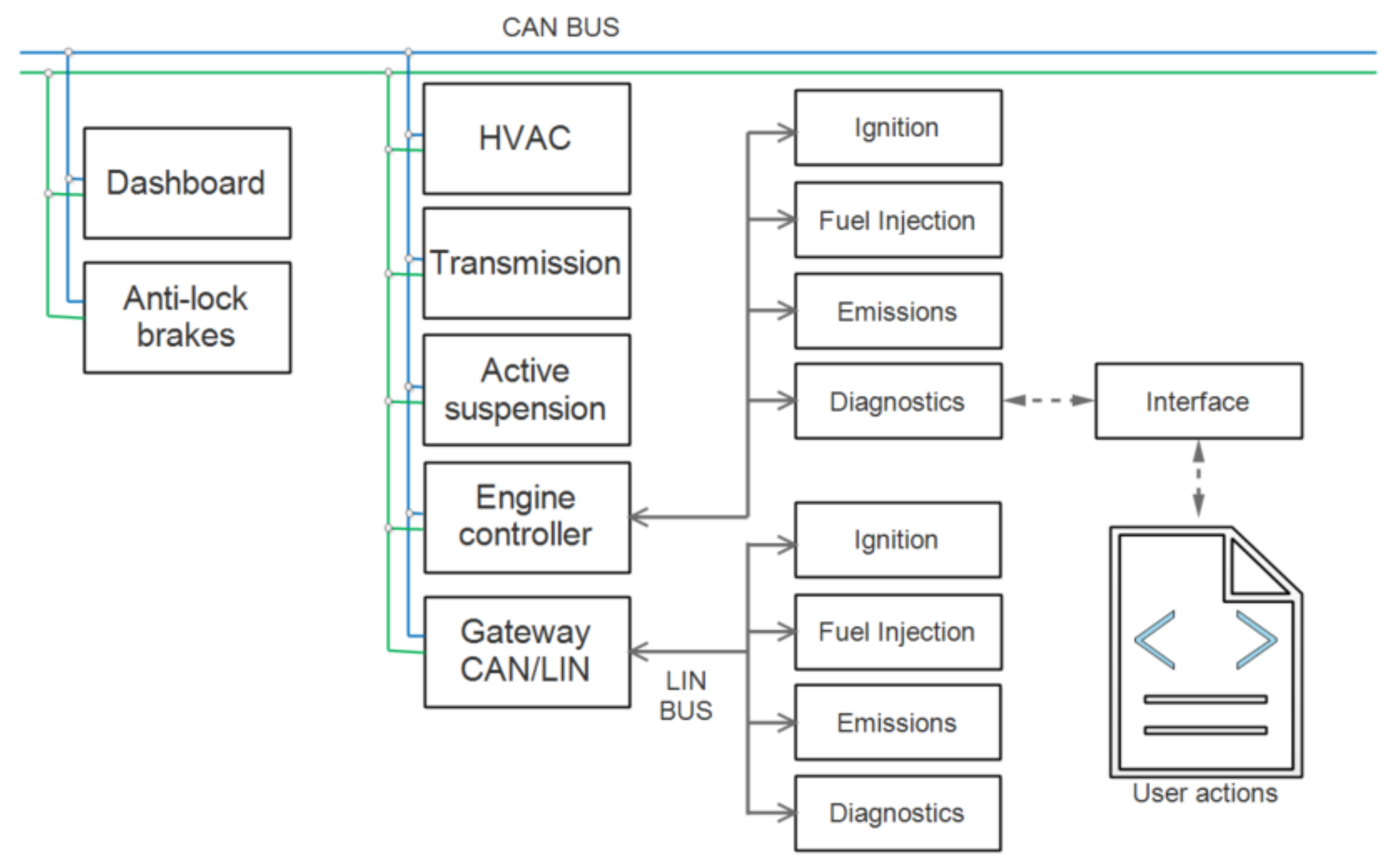

2. Process Representation—Conceptual Framework

2.1. Process Definition

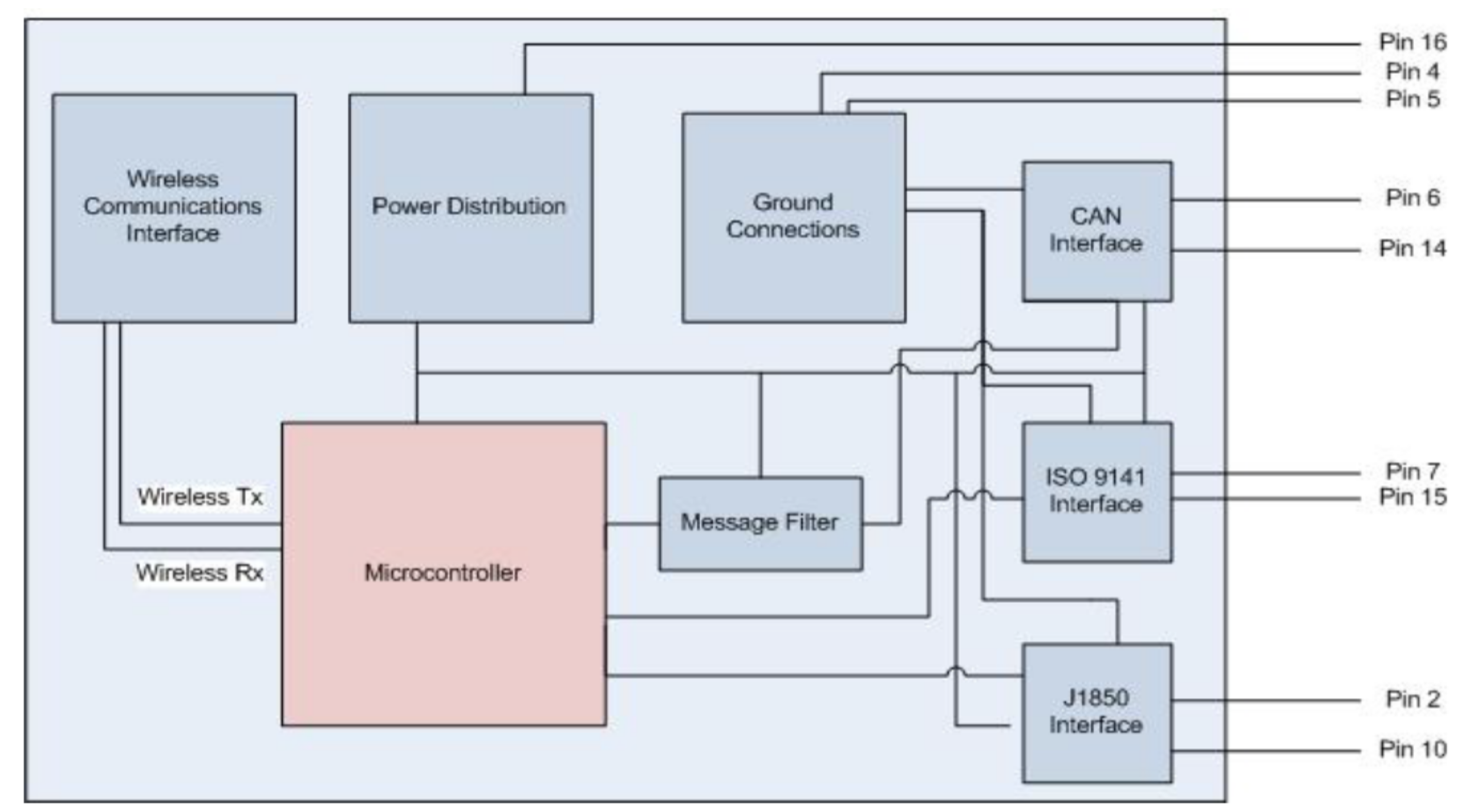

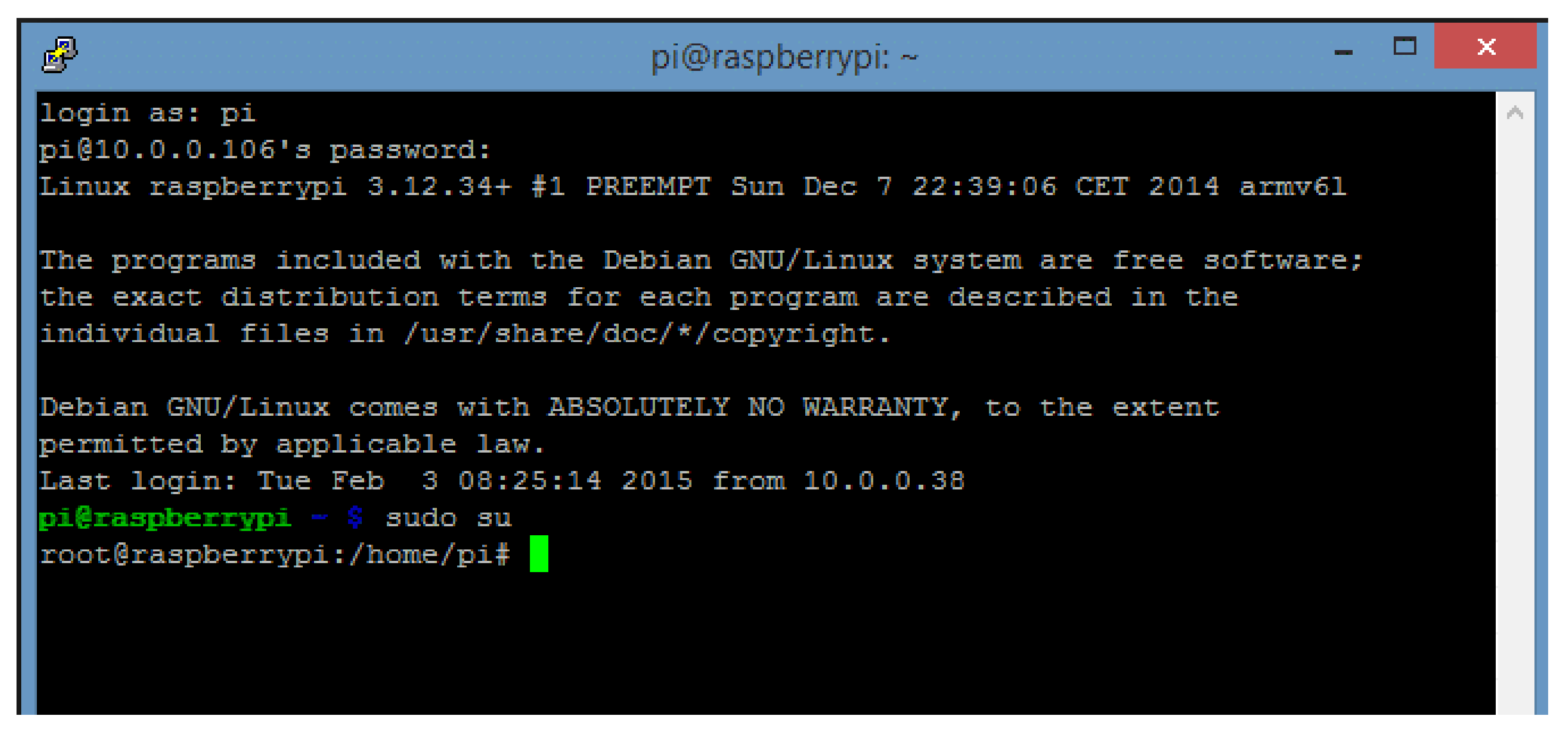

2.2. Process Model Design on ARM Cortex Controller

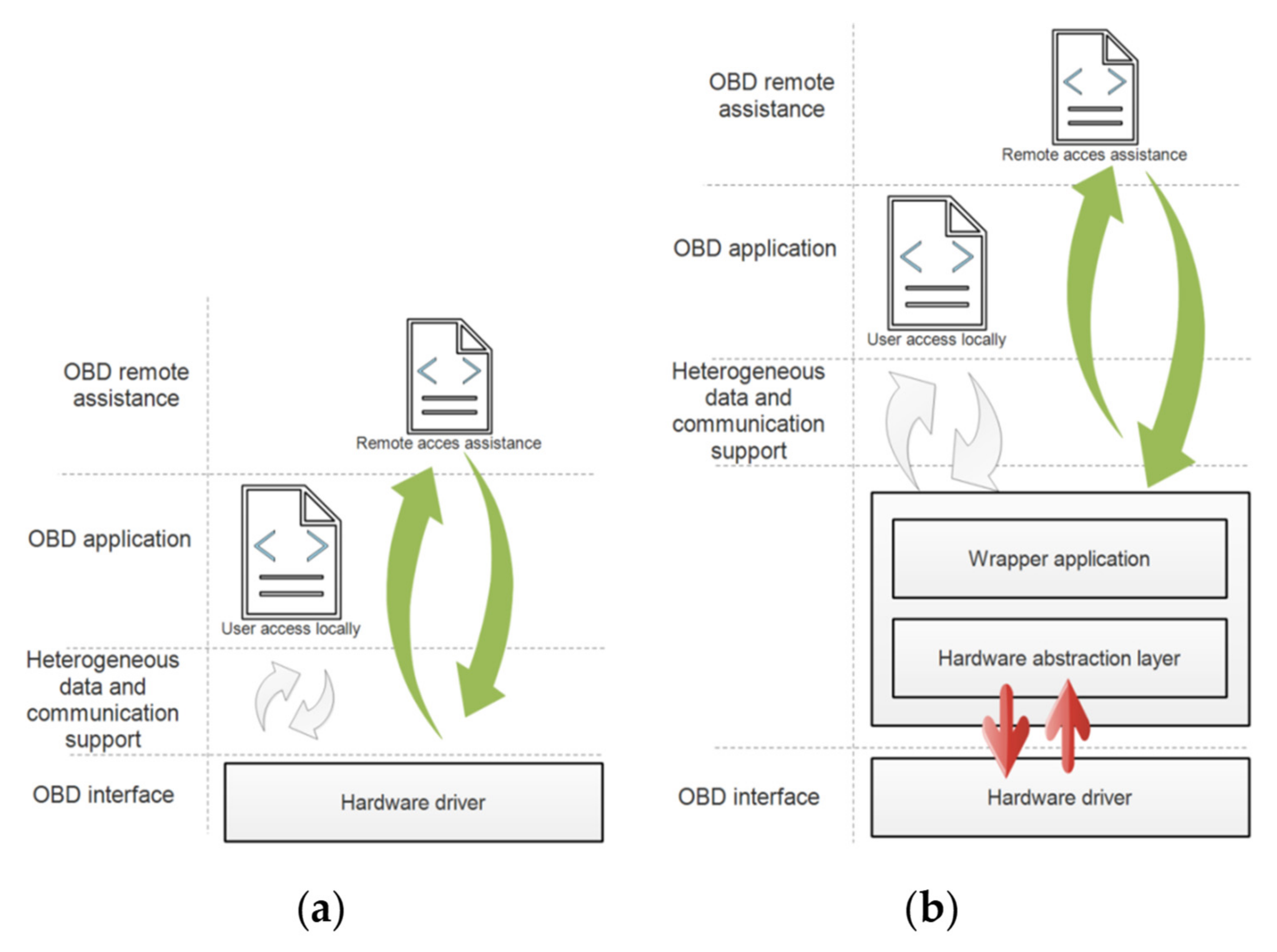

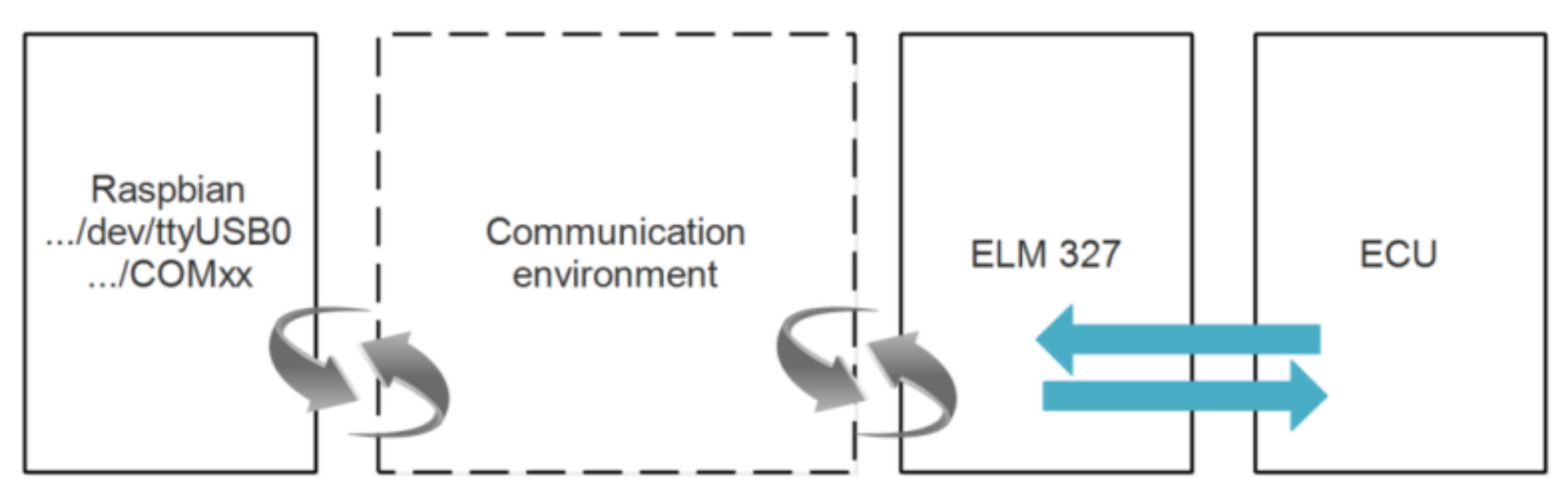

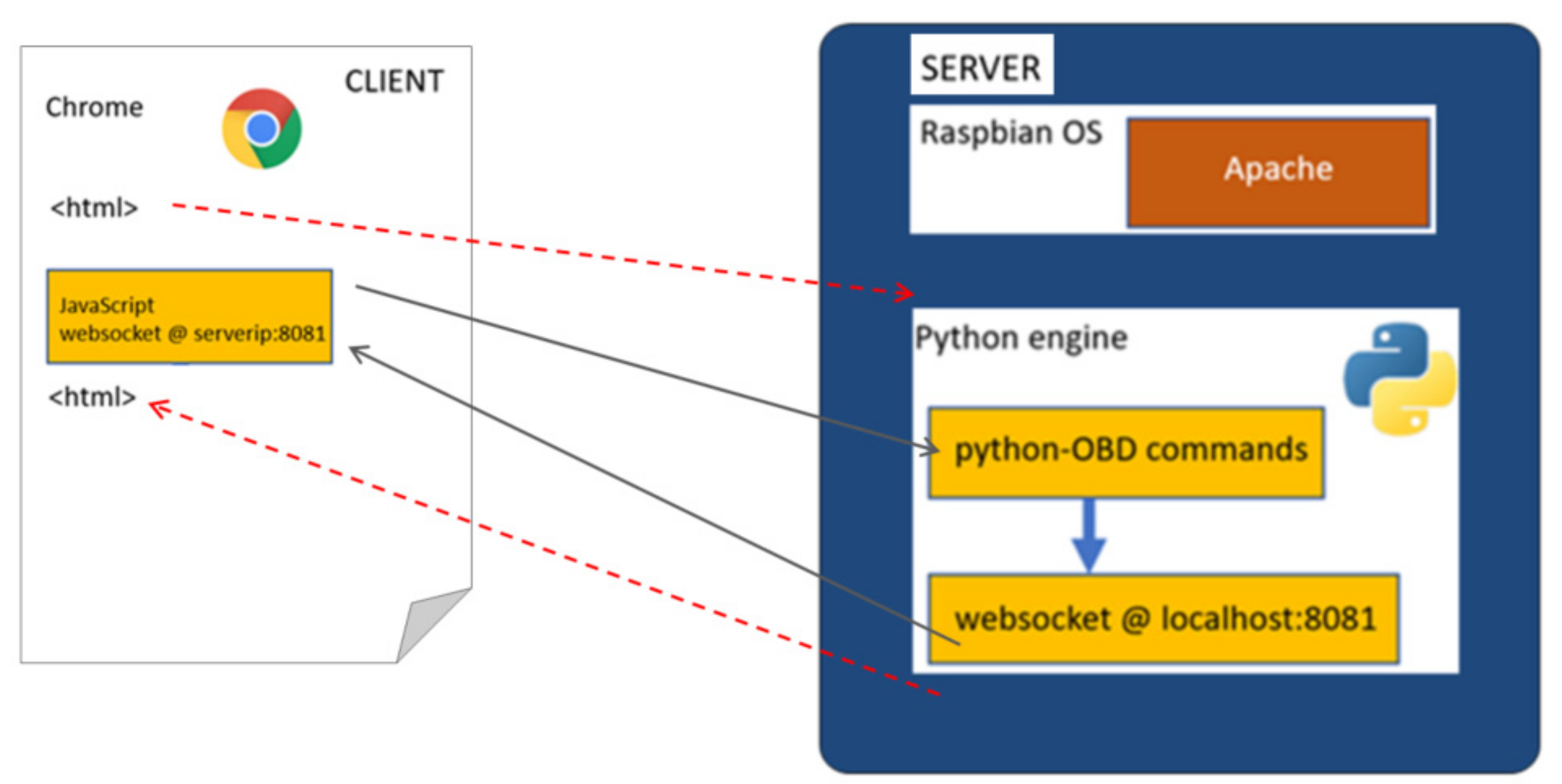

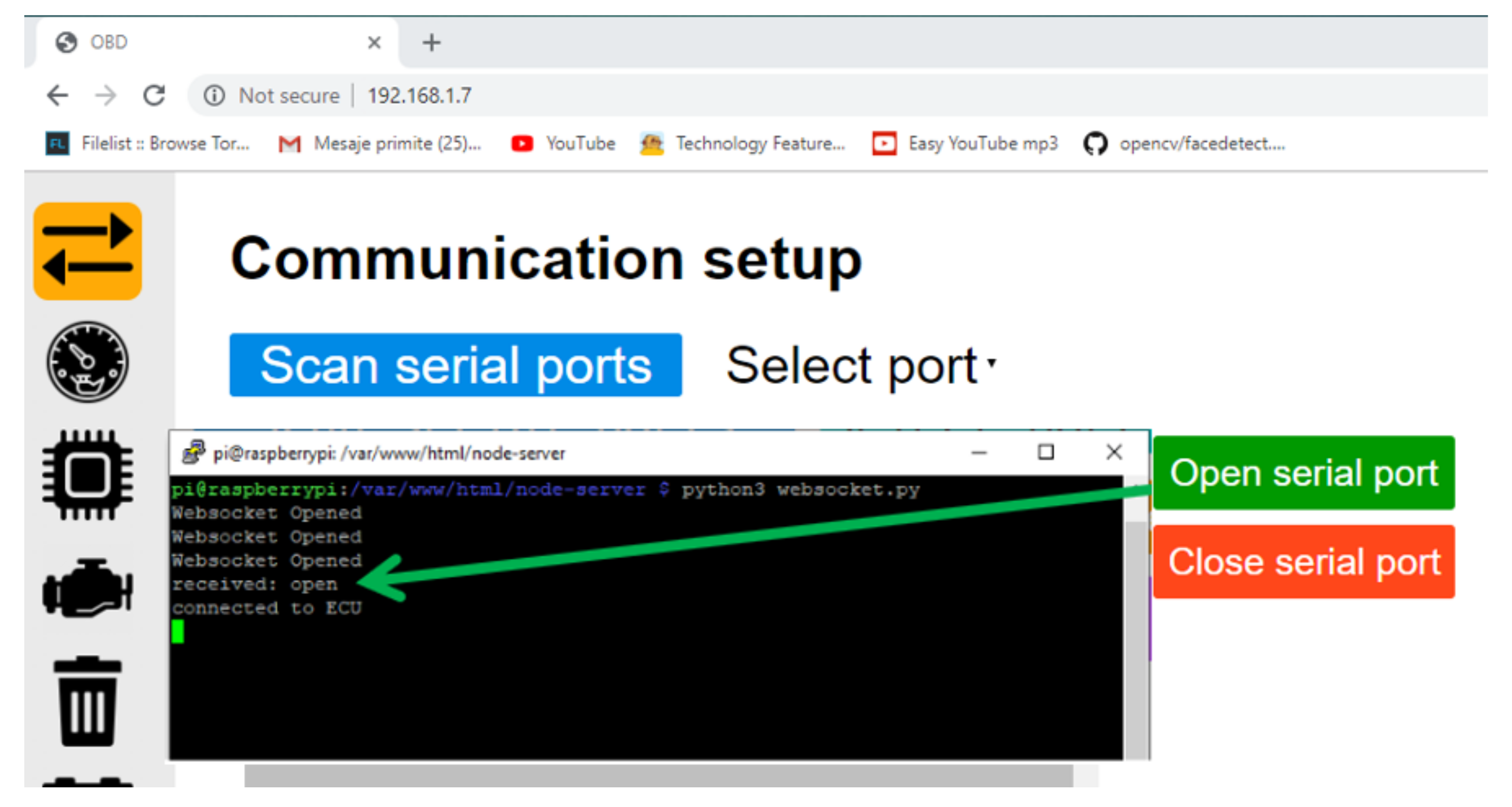

3. Software Design—Study Case

3.1. Algorithm Optimization

3.2. Hardware-Based Software Optimization

3.3. Software Optimization

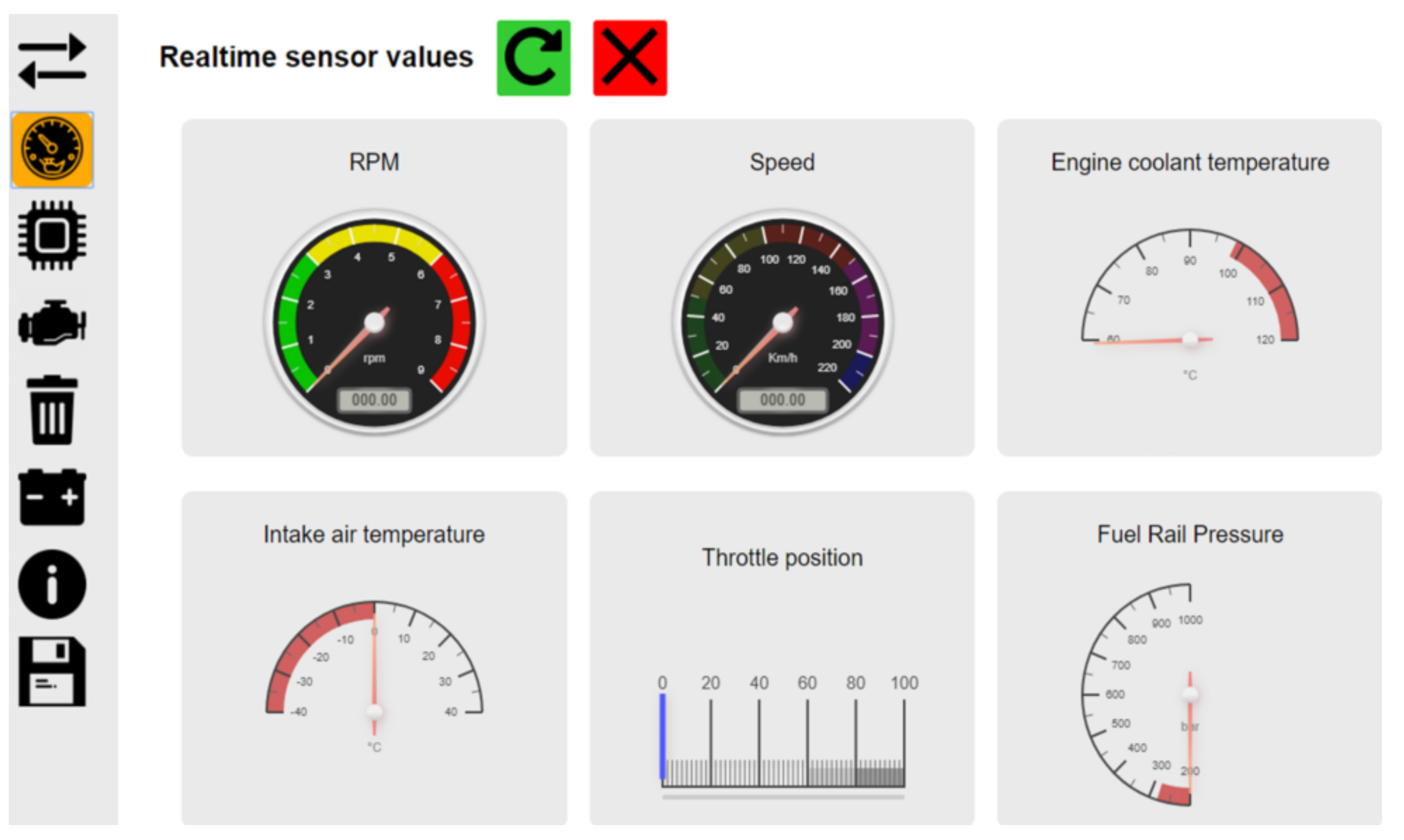

4. Tests Results

4.1. User Defined Standard-Based Tests

4.2. Compatibility Issue Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deloitte. Big Data and Analytics in the Automotive Industry. Automotive Analytics through Piece Report. Available online: https://www2.deloitte.com/content/dam/Deloitte/uk/Documents/manufacturing/deloitte-uk-automotive-analytics.pdf (accessed on 10 March 2019).

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing The Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-319-57869-9. [Google Scholar]

- Douaioui, K.; Fri, M.; Mabroukki, C.; Semma, E.A. The interaction between industry 4.0 and smart logistics: Concepts and perspectives. In Proceedings of the 2018 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Tangier, Morocco, 26–27 April 2018; pp. 128–132. [Google Scholar] [CrossRef]

- SAE J1930. Available online: https://law.resource.org/pub/us/cfr/ibr/005/sae.j1930.2002.pdf (accessed on 12 July 2019).

- Brando, G.; Dannier, A.; del Pizzo, A.; Rizzo, R. Power Electronic Transformer for advanced grid management in presence of distributed generation. Int. Rev. Electr. Eng. 2011, 6, 3009–3015. [Google Scholar]

- Rizzo, R.; Tricoli, P.; Spina, I. An innovative reconfigurable integrated converter topology suitable for distributed generation. Energies 2012, 5, 3640–3654. [Google Scholar] [CrossRef]

- Di Noia, L.P.; Genduso, F.; Miceli, R.; Rizzo, R. Optimal integration of hybrid supercapacitor and IPT system for a free-catenary tramway. IEEE Transa. Ind. Appl. 2019, 55, 794–801. [Google Scholar] [CrossRef]

- Eascy, Five Trends Transforming the Automotive Industry. Available online: www.pwc.com/auto (accessed on 22 July 2019).

- Morimoto, T. Connectivity and Big Data Analytics in Automotive; ICT Outlook Executive Briefing; Frost & Sullivan: New York, NY, USA, 2015. [Google Scholar]

- Malekian, R.; Moloisane, N.R.; Nair, L. Design and Implementation of a Wireless OBD II Fleet Management System. IEEE Sens. J. 2017, 17, 1154–1164. [Google Scholar] [CrossRef]

- Keenan, J. Creating A Wireless OBDII Scanner, Project Number: MQP-SJB-4C09. Available online: https://web.wpi.edu/Pubs/E-project/Available/E-project-043009-154526/unrestricted/JOHNKEENANIIIMQP2009.pdf (accessed on 15 February 2020).

- Risteiu, M.; Dobra, R. Designing Dedicated Electronic Systems—Mechatronics Embedded System; Universitas Publishing House: Petrosani, Romania, 2019; ISBN 978-973-741-618-6. [Google Scholar]

- Darwish, A.; Lakhtaria, K.I. The Impact of the New Web 2.0 Technologies in Communication, Development, and Revolutions of Societies. J. Adv. Inf. Technol. 2011, 2, 204–216. [Google Scholar] [CrossRef]

- Hayes, B. Cloud Computing. Commun. ACM 2008, 51, 9–11. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, X. Research of Web Real-Time Communication Based on Web Socket. Int. J. Commun. Netw. Syst. Sci. 2012, 5, 797–801. [Google Scholar] [CrossRef]

- Kiszka, J. The Real-Time Driver Model and First Applications. Available online: http://www.cs.ru.nl/lab/xenomai/RTDM-and-Applications.pdf (accessed on 22 July 2019).

- Grigorik, I. High Performance Browser Networking; O’Reilly Media, Inc.: Sevastopol, CA, USA, 2013; Available online: https://hpbn.co/ (accessed on 22 July 2019).

- Jennings, N. Socket Programming in Python (Guide). Available online: https://realpython.com/python-sockets/ (accessed on 23 July 2019).

- Nakamura, G. Why Hadoop Only Solves a Third of the Growing Pains for Big Data. Available online: https://www.wired.com/insights/2014/01/hadoop-solves-third-growing-pains-big-data/ (accessed on 23 July 2019).

- Apache Directory. Available online: https://directory.apache.org/apacheds/advanced-ug/1.5-backend.html (accessed on 20 May 2019).

- Raspberry Pi Architecture. Available online: https://www.macs.hw.ac.uk/~hwloidl/Courses/F28HS/slides_RPi_arch.pdf (accessed on 22 May 2019).

- BCM2835 Documentation. Available online: https://www.raspberrypi.org/documentation/hardware/raspberrypi/bcm2835/README.md (accessed on 20 May 2019).

- The MagPi Magazine. Available online: https://www.raspberrypi.org/magpi/tutorials/ (accessed on 2 September 2019).

- Nayyar, A.; Puri, V. Raspberry Pi-A Small, Powerful, Cost Effective and Efficient Form Factor Computer: A Review. Int. J. Adv. Res. Comput. Sci. Softw. Eng. 2015, 5, 720–737. [Google Scholar]

- Qutqut, M.H.; Al-Sakran, A. Comprehensive survey of the IoT open source Oss. IET Wirel. Sens. Syst. 2018, 8, 323–339. [Google Scholar] [CrossRef]

- Tuan, C.C.; Lu, C.H.; Wu, Y.C.; Yeh, W.L.; Chen, M.C.; Lee, T.F.; Chen, Y.-J.; Kao, H.-K. Development of a System for Real-Time Monitoring of Pressure, Temperature, and Humidity in Casts. Sensors 2019, 19, 2417. [Google Scholar] [CrossRef]

- Viel, F.; Augusto Silva, L.; Leithardt, V.R.Q.; De Paz Santana, J.F.; Celeste Ghizoni Teive, R.; Albenes Zeferino, C. An Efficient Interface for the Integration of IoT Devices with Smart Grids. Sensors 2020, 20, 2849. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rîșteiu, M.; Dobra, R.; Avram, A.; Samoilă, F.; Buică, G.; Rizzo, R.; Micu, D.D. Designing a Smart Gateway for Data Fusion Implementation in a Distributed Electronic System Used in Automotive Industry. Energies 2021, 14, 3300. https://doi.org/10.3390/en14113300

Rîșteiu M, Dobra R, Avram A, Samoilă F, Buică G, Rizzo R, Micu DD. Designing a Smart Gateway for Data Fusion Implementation in a Distributed Electronic System Used in Automotive Industry. Energies. 2021; 14(11):3300. https://doi.org/10.3390/en14113300

Chicago/Turabian StyleRîșteiu, Mircea, Remus Dobra, Alexandru Avram, Florin Samoilă, Georgeta Buică, Renato Rizzo, and Dan Doru Micu. 2021. "Designing a Smart Gateway for Data Fusion Implementation in a Distributed Electronic System Used in Automotive Industry" Energies 14, no. 11: 3300. https://doi.org/10.3390/en14113300

APA StyleRîșteiu, M., Dobra, R., Avram, A., Samoilă, F., Buică, G., Rizzo, R., & Micu, D. D. (2021). Designing a Smart Gateway for Data Fusion Implementation in a Distributed Electronic System Used in Automotive Industry. Energies, 14(11), 3300. https://doi.org/10.3390/en14113300