Use of Environmental Management Systems and Renewable Energy Sources in Selected Food Processing Enterprises in Poland

Abstract

1. Introduction

- Have the examined companies made modifications to their areas of operation in order to implement sustainable production principles?

- Have the examined companies implemented environmental management systems?

- Have the examined companies used renewable energy sources in their operations?

2. Materials and Methods

2.1. Sample and Procedure

- -

- Running food processing activity according to Polish Classification of Activities (PKD 2007/year);

- -

- Site in the country;

- -

- Active business operations;

- -

- Processing and production capacity (t/week), number of full-employed workers, income value (PLN/year).

2.2. Measures

- The electronic form allows the results of the survey to be viewed while it is in progress;

- It is low cost due to there being no need to hire interviewers;

- Questionnaires in electronic form are easier to correct in case a mistake is noticed after they have been prepared, and they do not require financial outlays connected with printing them;

- There is quick access to the obtained data and possibility of quick analysis;

- It eliminates the “pollster effect”, i.e., the influence of the person conducting the survey on the answers given and the participants can remain more anonymous;

3. Results and Discussion

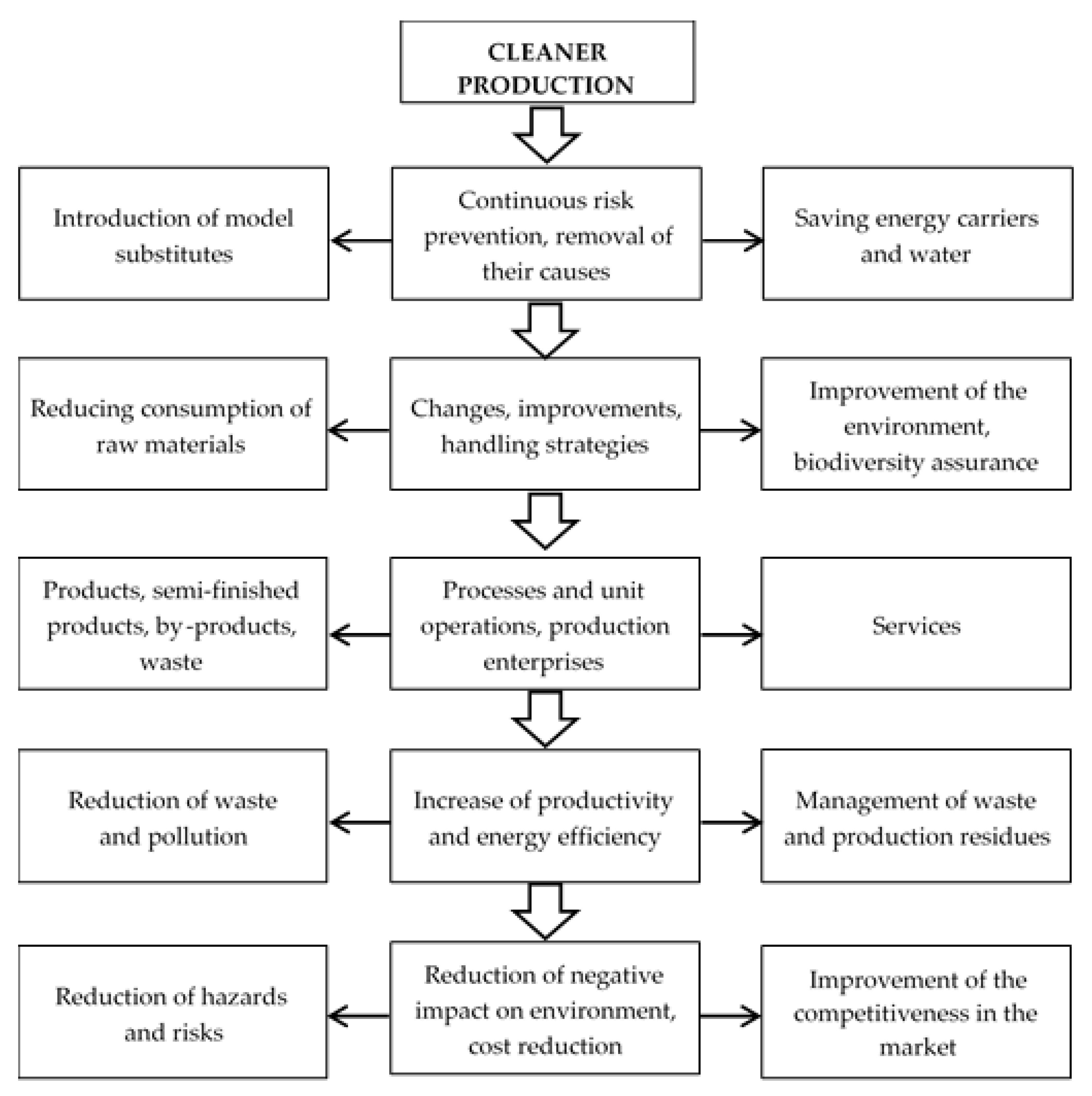

- Minimizing the amount of raw materials needed for production, usually by using new technologies and recycling;

- Minimizing the amount of pollution and waste generated during production, by using closed circuits;

- Manufacturing of products or parts of products with a long service life, so that the use of new raw materials for production is shifted in time;

- Designing and organizing all stages of the production process for environmental protection.

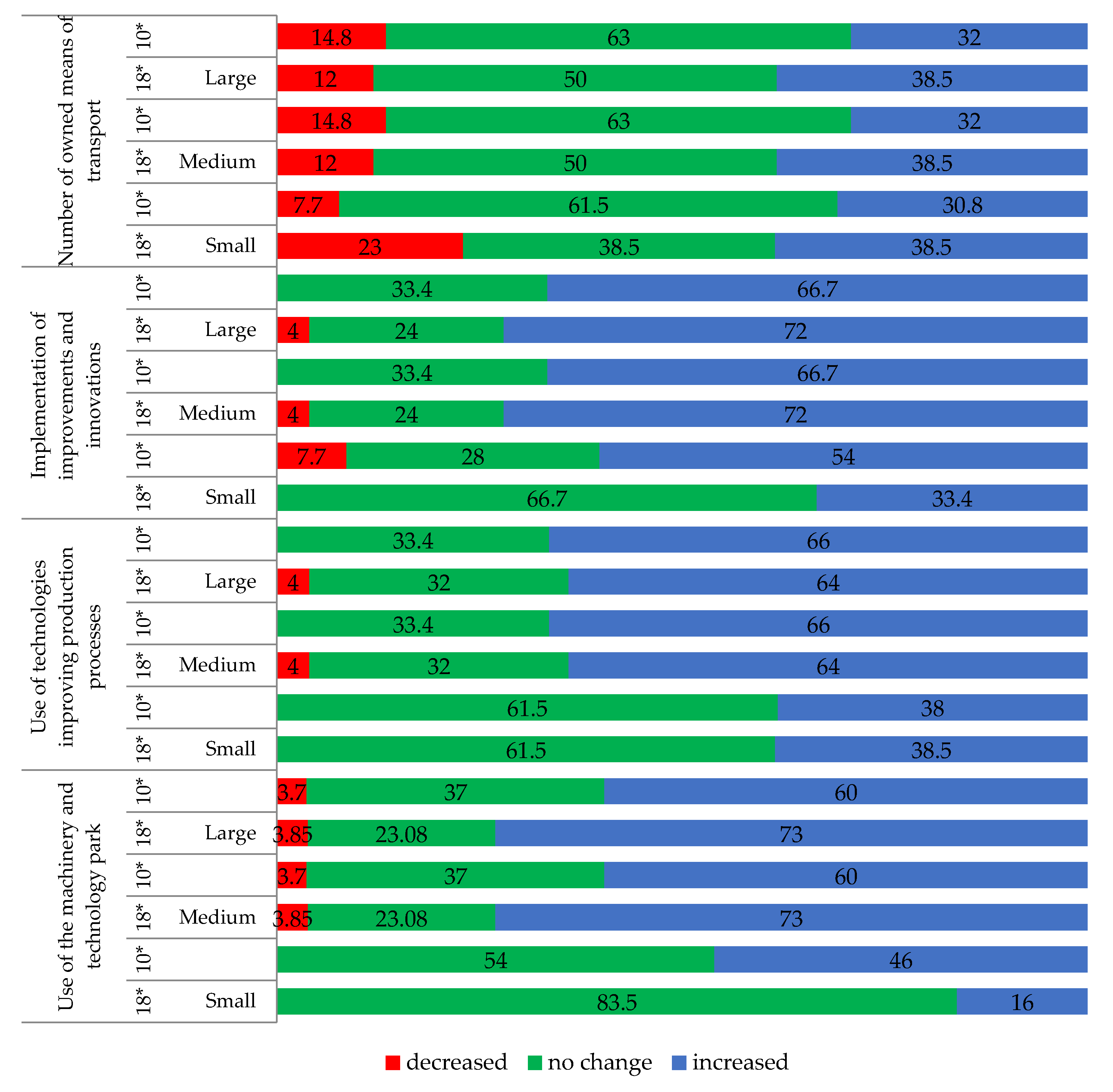

3.1. The Validity of Structure of Modified Areas of Activities

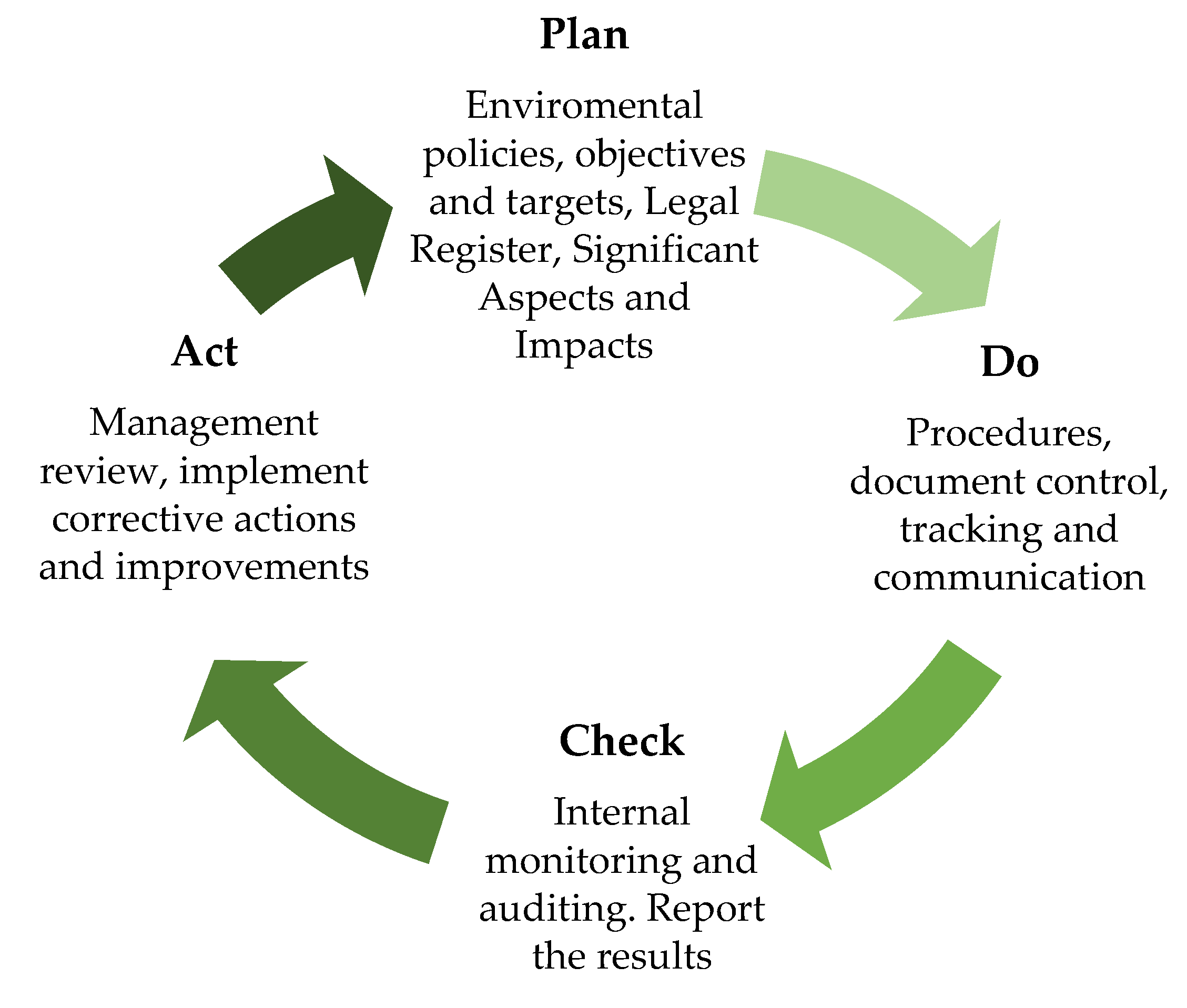

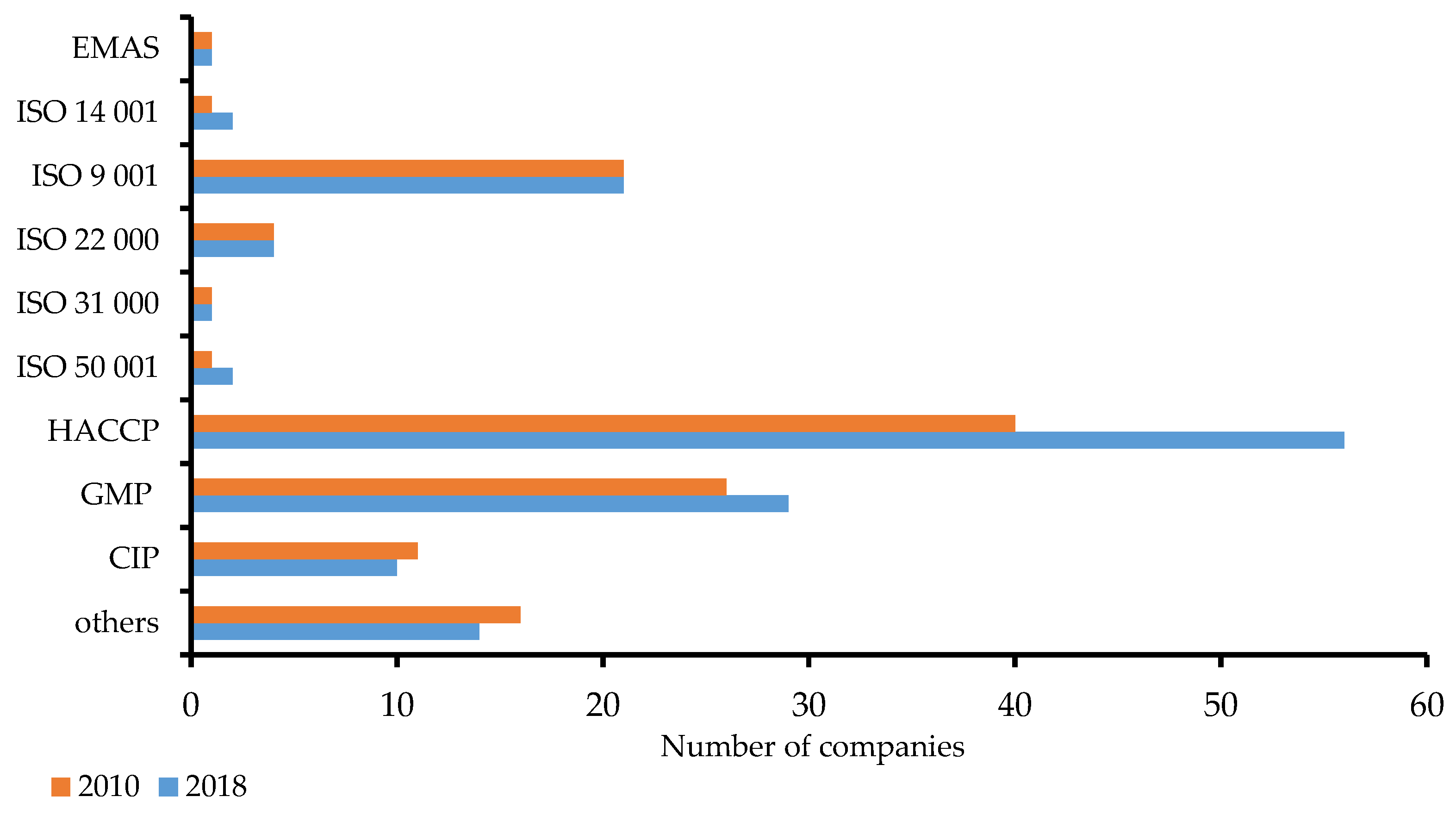

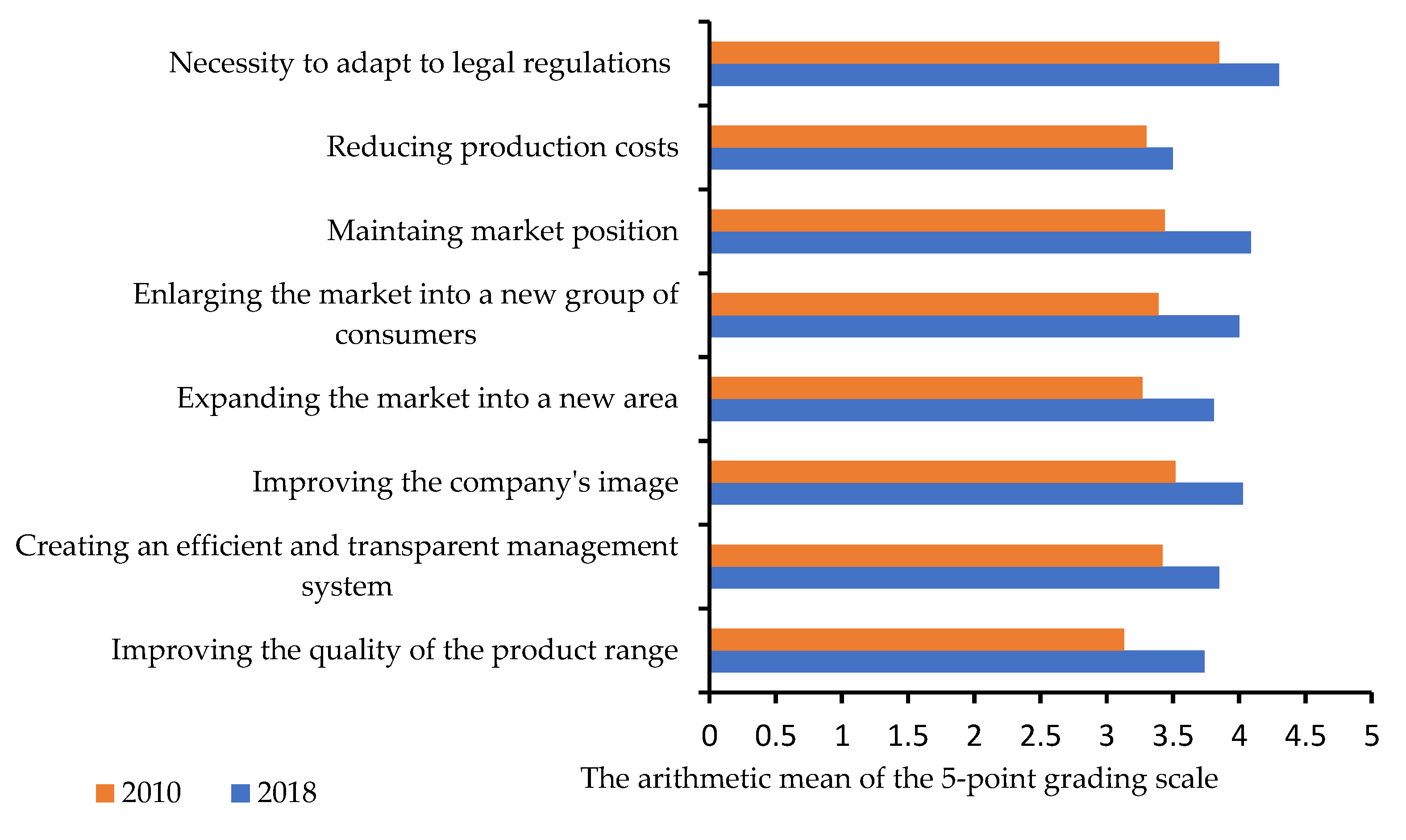

3.2. The Declarations of Respondents Concerning the Implementation of Management Systems in Examined Food Processing Enterprises in Poland

3.3. Cross-Case-Studies on the Use of Renewable Energy Sources in Food Processing Enterprises in Poland

4. Conclusions

- Enterprises as key factors influencing the improvement of functioning recognize the implementation of improvements and innovations, and the introduction of new or ‘knowledge-intensive’ technologies. Attention has been drawn to the need for more efficient use of the machinery and technology park.

- The main factors motivating companies to implement measures is the need to comply with the legal provisions in terms of environmental protection.

- All analyzed food processing enterprises strongly referred to environmental aspects of their operations. A total of 80% of the analyzed enterprises stressed an impact on the public.

- The examined food processing enterprises should focus on measures to improve the environmental performance through:

- -

- Shaping the potential and development of areas for the implementation of environmental measures;

- -

- Seeking solutions to further reduce pollution levels in the atmosphere by installing gas boilers and filters, reducing emissions of pollutants into the atmosphere.

- Among the planned actions of the EC’s new package on a circular economy are [68]:

- -

- Development of environmental standards for secondary raw materials to facilitate their identification and increase their potential for use in the single market;

- -

- Implementation of a plastics strategy on recycling, biodegradability, and presence of hazardous substances in plastics;

- -

- Actions to reduce food waste, including the development of a common measurement methodology, improved labelling of expiration dates, and tools to achieve the sustainable development goal of halving food waste by 2030;

- -

- Amending the Fertilizer Ordinance to make it easier to identify organic and waste-based fertilizers in the single market and to promote the importance of biological nutrients;

- -

- Action on water recycling, including a legislative proposal on minimum requirements for secondary use of waste water.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Number of Question in a Questionnaire | Answer Options |

|---|---|

| 1. Number of modified areas of activities undertaken by chosen food processing enterprises classified as: (a) use of the machinery and technology park (b) use of technologies improving production processes (c) implementation of improvements and innovations (d) number of owned means of transport | Give answers to all answer options by assigning a score from 1 to 5, where: 1 is the most important and 5 is the least important. |

| 2. Implementation of chosen Management Systems by food processing enterprises: (a) EMAS (b) ISO 14 001 (c) ISO 9 001 (d) ISO 22 000 (e) ISO 31 000 (f) ISO 50 001 (g) HACCP (h) GMP (i) CIP (j) others | Give answers to all answer options by assigning those which are implemented. |

| 3. Declared reasons for implementing Management Systems in food processing enterprises: (a) necessity to adapt to legal regulations (b) reducing production costs (c) maintaining market position (d) enlarging the market into a new group of consumers (e) expanding the market into a new area (f) improving the company’s image (g) creating an efficient and transparent management (h) improving the quality of the product range | Give answers to all answer options by assigning a score from 1 to 5, where: 1 is the most important and 5 is the least important. |

| 4. Use of renewable energy sources in food processing enterprises: (a) processing of slaughterhouse waste (b) production of biogas (c) own heat and power plant (d) the purification and reuse of process water (e) own sewage treatment plant (f) distillery stillage (g) implementation of ISO 14 001 (h) expenditures on pro-environmental policy (i) expenditure on pro-environmental investments (j) innovations in food packaging | Give answers to all answer options by assigning those which are implemented. |

References

- Sustainable Development. Available online: https://en.unesco.org/themes/education-sustainable-development/what-is-esd/sd (accessed on 8 May 2021).

- Florczak, W. Koncepcja zrównoważonego rozwoju w naukach społeczno-ekonomicznych (The concept of sustainable development in socio-economic sciences). Stud. Prawno Ekon. 2007, 75, 119–139. [Google Scholar]

- Kurowska, K.; Marks-Bielska, R.; Bielski, S.; Aleknavičius, A.; Kowalczyk, C. Geographic information systems and the sustainable development of rural areas. Land 2021, 10, 6. [Google Scholar]

- Moraine, M.; Duru, M.; Nicholas, P.; Leterme, P.; Therond, O. Farming system design for innovative crop-livestock integration in Europe. Animal 2014, 8, 1204–1217. [Google Scholar] [CrossRef]

- Wojdalski, J.; Niżnikowski, R.; Krajewski, K.; Żelaziński, T. Biogospodarka, przemysł rolno-spożywczy, zrównoważony rozwój—Wybrane zagadnienia (Bioeconomy, agri-food industry, sustainable development—Selected issues). Przegląd Hodowlany 2018, 4. Available online: http://ph.ptz.icm.edu.pl/wp-content/uploads/2018/07/7-Wojdalski.pdf (accessed on 1 February 2021).

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj (accessed on 8 May 2021).

- Waste Framework Directive (2008/98/EC) 5 Jul 2010). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098&rid=9 (accessed on 8 May 2021).

- Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions Closing the Loop—An EU Action Plan for the Circular Economy COM/2015/0614 Final. Available online: https://www.eea.europa.eu/policy-documents/com-2015-614-final-closing (accessed on 8 May 2021).

- Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions. A New Circular Economy Action Plan. For a Cleaner and More Competitive Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0098 (accessed on 8 May 2021).

- Closing the Loop—An EU Action Plan for the Circular Economy COM/2015/0614 Final. Available online: https://www.eea.europa.eu/policy-documents/com-2015-0614-final (accessed on 1 February 2021).

- Giacomarra, M.; Crescimanno, M.; Sakka, G.; Galati, A. Stakeholder engagement toward value co-creation in the F&B packaging industry. EuroMed J. Bus. 2019. [Google Scholar] [CrossRef]

- Marques, P.; Bernardo, M.; Presas, P.; Simon, A. Corporate social responsibility in a local subsidiary: Internal and external stakeholders’ power. EuroMed J. Bus. 2019. [Google Scholar] [CrossRef]

- Upward, A.; Jones, P. An ontology for strongly sustainable business models: Defining an enterprise framework compatible with natural and social science. Organ. Environ. 2016, 29, 97–123. [Google Scholar] [CrossRef]

- Lacy, P.; Long, J.; Spindler, W. How Can Businesses Accelerate the Transition to a Circular Economy? World Economic Forum: Cologny, Switzerland, 2020; Available online: https://www.weforum.org/agenda/2020/01/how-can-we-accelerate-the-transition-to-a-circular-economy/ (accessed on 1 May 2021).

- Boyle, G. Renewable Energy Power for a Sustainable Future, 2nd ed.; Oxford University Press: Oxford, UK, 2004. [Google Scholar]

- What are Environmental Management Systems (EMS)? Available online: http://www.asq.org/quality-resources/environmental-management-system (accessed on 1 February 2021).

- International Organization for Standardization. PN-EN ISO 14001. Zarządzanie Środowiskowe. Ocena Cyklu Życia. Zasady i Struktura (Environmental Management. Life Cycle Assessment. Principles and Structure); ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Poskrobko, B.; Poskrobko, T. Zarządzanie Środowiskiem w Polsce. Warszawa: PWE. Przemysł Spożywczy, Lata: 2018–2019 (Environmental Management in Poland. Food Industry, Years: 2018–2019); SIGMA-NOT: Warsaw, Poland, 2012. [Google Scholar]

- Sroufe, R. Effects on environmental management systems on environmental management practices and operations. Prod. Oper. Manag. 2003, 12, 287–431. [Google Scholar] [CrossRef]

- Czaplicka-Kolarz, K.; Kruczek, M.; Burchart-Korol, D. Koncepcja ekoefektywności w zrównoważonym zarządzaniu produkcją (The concept of eco-efficiency in sustainable production management). Zeszyty Nauk. Seria Org. Zarz. 2013, 63, 59–71. [Google Scholar]

- Zielińska-Chmielewska, A.; Olszańska, A.; Kaźmierczyk, J.; Andrianova, E.V. Advantages and constraints of eco-efficiency measures: The case of the polish food industry. Agronomy 2021, 11, 299. [Google Scholar] [CrossRef]

- Bhaskar, T.; Bhavya, B.; Singh, R.; Naik, D.V.; Kumar, A.; Goyal, H.B. Thermochemical conversion of biomass to biofuels. In Biofuels—Alternative Feedstocks and Conversion Processes; Pandey, A., Larroche, C., Ricke, S.C., Dussap, C.G., Gnansounou, E., Eds.; Academic Press: Oxford, UK, 2011; pp. 51–77. [Google Scholar]

- Rosales-Calderon, O.; Arantes, V. A review on commercial scale high value products that can be produced alongside cellulosic ethanol. Biotechnol. Biofuels 2019, 12. [Google Scholar] [CrossRef]

- Ministerstwo Aktywów Państwowych. Krajowy Plan na Rzecz Rozwoju Energii i Klimatu na Lata 2021–2030. Założenia i Cele Oraz Polityki Działania (National Plan for the Development of Energy and Climate for the Years 2021–2030. Assumptions, Goals and Policies); Ministerstwo Aktywów Państwowych: Warsaw, Poland, 2019. (In Polish) [Google Scholar]

- Marks-Bielska, R.; Bielski, S.; Pik, K.; Kurowska, K. The importance of renewable energy sources in Poland’s energy mix. Energies 2020, 13, 4624. [Google Scholar] [CrossRef]

- Bielski, S.; Marks-Bielska, R.; Zielińska-Chmielewska, A.; Romaneckas, K.; Šarauskis, E. Importance of agriculture in creating energy security—A case study of Poland. Energies 2021, 14, 2465. [Google Scholar] [CrossRef]

- Escobar, J.A.; Lora, E.E.; Venturini, O.J.; Yánez, E.; Castillo, E.F.; Almazán, O. Biofuels: Environment, technology and food security. Renew. Sustain. Energy Rev. 2009, 13, 1275–1287. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuś, M. Development of renewable energy sources in the context of threats resulting from low-altitude emissions in rural areas in Poland: A review. Energies 2019, 12, 3558. [Google Scholar] [CrossRef]

- Zawalińska, K.; Kinnunen, J.; Gradziuk, P.; Celińska-Janowicz, D. To whom should we grant a power plant? Economic Effects of investment in nuclear energy in Poland. Energies 2020, 13, 2687. [Google Scholar] [CrossRef]

- Zhai, R.; Hu, J.; Saddler, J.N. What are the major components in steam pretreated lignocellulosic biomass that inhibit the efficacy of cellulase enzyme mixtures? ACS Sustain. Chem. Eng. 2016, 4, 3429–3436. [Google Scholar] [CrossRef]

- Jefferson, M. Sustainable energy development: Performance and prospects. Renew. Energy 2006, 31, 571–582. [Google Scholar] [CrossRef]

- Wyman, C.E.; Dale, B.E. Producing Biofuels via the Sugar Platform. Chem. Eng. Prog. 2015, 111, 45–57. Available online: https://www.researchgate.net/profile/Bruce_Dale/publication/283872696_Producing_biofuels_via_the_sugar_platform/links/57504a0a08aefe968db72891/Producing-biofuels-via-the-sugar-platform.pdf (accessed on 27 February 2021).

- Ang, B.W.; Choon, W.L.; Ng, T.S. Energy security: Definitions, dimensions and indexes. Renew. Sustain. Energy Rev. 2015, 42, 1077–1093. [Google Scholar] [CrossRef]

- Winzer, C. Conceptualizing energy security. Energy Policy 2012, 46, 36–48. [Google Scholar] [CrossRef]

- Bielski, S.; Romaneckas, K.; Novikova, A.; Šarauskis, E. Are Higher Input Levels to Triticale Growing Technologies Effective in Biofuel Production System? Sustainability 2019, 11, 5915. [Google Scholar] [CrossRef]

- Central Statistical Office. GUS, 2018 (Główny Urząd Statystyczny) 2018, Warsaw. 2018. Available online: https://stat.gov.pl/ (accessed on 1 March 2021).

- Creswell, J. Projektowanie Badań Naukowych: Metody Jakościowe, Ilościowe i Mieszane (Design Research Projects: Quality and Quantity Assessment, and Mixed); Uniwersytet Jagielloński: Krakow, Poland, 2013. [Google Scholar]

- Finstad, K. Response interpolation and scale sensitivity: Evidence against 5-pont scales. J. Usabil. Stud. 2010, 5, 104–110. [Google Scholar]

- Firlej, K.; Olejniczak, J.; Pondel, H. Wyzwania Rozwojowe Obszarów Wiejskich (Development Challenges in Rural Areas); Wydawnictwo Naukowe Scholar: Warsaw, Poland, 2019; pp. 131–144. [Google Scholar]

- Hadryjańska, B. Ekologizacja Procesu Produkcji a Kształtowanie Konkurencyjności w Przedsiębiorstwach Przetwórstwa Mleczarskiego (Ecologization of the Production Process and Shaping Competitiveness in Dairy Processing Enterprises); Wydawnictwo PTE: Poznan, Poland, 2015; pp. 255–282. [Google Scholar]

- Kruk, H. Przyrodnicza Konkurencyjność Regionów (Natural Competitiveness of Regions); Wydawnictwo Dom Organizatora: Torun, Poland, 2010; pp. 78–80. [Google Scholar]

- Pondel, H. Środowisko Przyrodnicze w Procesie Zrównoważonego Rozwoju Obszarów Wiejskich na Przykładzie Wielkopolski (Natural Environment in the Process of Sustainable Rural Development on the Example of Wielkopolska); Wydawnictwo Uniwersytetu Ekonomicznego w Poznaniu: Poznan, Poland, 2013; pp. 263–289. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- TPI. Available online: http://www.ThePartneringInitiative.org/thecasestudyproject (accessed on 1 February 2021).

- Dobrzańska, B.; Dobrzański, G.; Kiełczewski, D. Ochrona Środowiska Przyrodniczego (Protection of Environment); PWN: Warsaw, Poland, 2008. [Google Scholar]

- Food and Nutrition Act of 2008 [Public Law 88–525; Enacted Aug. 31, 1964; 78 Stat. 703] [As Amended Through P.L. 116–94, Enacted December 20, 2019]. Available online: https://www.fns.usda.gov/snap/food-and-nutrition-act-2008-enacted-december-20-2018 (accessed on 8 January 2021).

- Ustawa Prawo Ochrony Środowiska (2001). (Dz. U. 2001, Nr 62, poz. 627 z Późn. Zm.). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20010620627 (accessed on 8 January 2021).

- EC Regulation, No. 852/2004. Available online: www.eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0852 (accessed on 1 February 2021).

- Przepisy Prawa Żywnościowego Obowiązujące w Polsce. Available online: http://www.food-safety.pl/polskie-prawożywnościowe/ustawy (accessed on 10 February 2021).

- Janowicz, L.; Wojdalski, J.; Janowicz, M.; Kupczyk, A. Zarządzanie energią w zakładach przemysłu spożywczego. (Energy management in food industry enterprises. Food industry). Przemysł Spożywczy 2017, 71, 16–22. [Google Scholar] [CrossRef]

- Walker, C.; Beretta, C.; Sanjuán, N.; Hellweg, S. Calculating the energy and water use in food processing and assessing the resulting impacts. Int. J. Life Cycle Assess. 2017, 23, 824–839. [Google Scholar] [CrossRef]

- Reed, G.; Hickey, G.M. Contrasting innovation networks in smallholder agricultural producer cooperatives: Insights from the Niayes region of Senegal. J. Co-Op. Organ. Manag. 2016, 4, 97–107. [Google Scholar] [CrossRef]

- Melnyk, S.A.; Sroufe, R.P.; Calantone, R.J. A model of site-specific antecedents of ISO 14001 certification. Prod. Oper. Manag. 2003, 12, 369–385. [Google Scholar] [CrossRef]

- Fiore, M.; Galati, A.; Gołębiewski, J.; Drejerska, N. Stakeholders’ involvement in establishing sustainable business models. The case of Polish dairy cooperatives. Br. Food J. 2020, 122, 1671–1691. [Google Scholar] [CrossRef]

- Staffas, L.; Gustavsson, M.; McCormick, K. Strategies and policies for the bioeconomny and bio-based economy: An analysis of official national approaches. Sustainability 2013, 5, 2571–2769. [Google Scholar] [CrossRef]

- Gołębiewski, J. Value chains within bioeconomy. Earth Biores. Life Qual. 2013, 4, 1–12. Available online: http://gchera-ejournal.nubip.edu.ua/index.php/ebql/article/view/138/104 (accessed on 1 March 2021).

- European Commission. Innovating for Sustainable Growth: A Bioeconomy for Europe. Communication from the Commission to the European Par-liament, the Council, The European Economic and Social Committee and the Committee of the Regions, Brussels, 13.2.2012 COM (2012) 60 Final. Available online: https://ec.europa.eu/research/bioeconomy/pdf/201202_innovating_sustainable_growth_en.pdf (accessed on 1 March 2021).

- Strategia Rozwoju Kraju 2020. Ministerstwo Infrastruktury i Rozwoju 2012. Available online: http://www.mir.gov.pl/strony/zadania/polityka-rozwoju-kraju/strategia-rozwoju-kraju/ (accessed on 1 March 2021).

- Drejerska, N.; Gołębiewski, J. The role of Poland’s primary sector in the development of the country’s bioeconomy. Riv. Econ. Agr. 2017, 3, 311–326. [Google Scholar] [CrossRef]

- Rynekbiogazu. Available online: http://www.rynekbiogazu.pl/tag/zakladymiesne-mroz (accessed on 1 August 2019).

- Zielińska-Chmielewska, A.; Malinowska, A. The importance and application examples of direct packaging units in Polish meat industry. Intercathedra 2015, 31, 117–122. Available online: http://www1.up.poznan.pl/intercathedra/files/Intercathedra%202015%20No%2031-4.pdf (accessed on 1 August 2019).

- FoodDrink Europe. Available online: http://www.fooddrinkeurope.eu/industry-in-focus/maximizing-food-resources (accessed on 1 August 2019).

- Halila, F.; Tell, J. Creating synergies between SMEs and universities for ISO 14001 certification. J. Clean. Prod. 2013, 48, 85–92. [Google Scholar] [CrossRef]

- European Environment Agency. Circular by Design. Products in the Circular Economy. 2017. Available online: https://circulareconomy.europa.eu/platform/sites/default/files/circular_by_design_-_products_in_the_circular_economy.pdf (accessed on 1 May 2021).

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 1 February 2021).

- Adhikari, G.C.; Vargas, P.; Zhu, H.; Grigoriev, A.; Zhu, P. Tetradic phosphor white light with variable CCT and superlative CRI through organolead halide perovskite nanocrystals. Nanoscale Adv. 2019, 1, 1791–1798. [Google Scholar] [CrossRef]

- Sgobba, V.; Guldi, D.M. Caron nanotubes—Electronic/electrochemical properties and application for nanoelectronics and photonics. Chem. Soc. Rev. 2009, 38, 165–184. [Google Scholar] [CrossRef]

- Stubbs, W.; Cocklin, C. Conceptualizing a sustainability business model. Organ. Environ. 2008, 21, 103–127. [Google Scholar] [CrossRef]

| Research Subject | Objects, Territorial and Temporal Scope | Measurement Methods and Tools | Current Application of Methods |

|---|---|---|---|

| Assessment of environmental-efficiency | Database on enterprises running business in food processing sector in Poland | Questionnaire: CAWI technique Case-studies Statistical methods | To deepen and widen the analyses of environmental efficiency in food processing sector |

| No. | The Implementation of the Bioeconomy Concept in Chosen Food Processing Enterprises in Poland | |

|---|---|---|

| 1. | Processing of slaughterhouse waste | A practical example of minimizing the cost of slaughterhouse waste processing is the use of so-called inedible byproducts in a biogas plant. The most common form of processing waste from industrial meat processing was the production of meat and bone meal, fat, and soil improvers. One of the alternative methods of utilization of slaughterhouse waste utilization, with a high content of organic matter, was to use the waste as a raw material for biogas production. |

| 2. | Production of biogas | In 2013, a biogas plant was launched at Zakłady Mięsne Mróz SA in Bo-rzęciczki in Wielkopolska. The fermenter is fed with slaughterhouse waste and corn silage from the company’s own crops. Every day, 30 tons of substrate is produced [60]. Reducing the cost of waste disposal, and for the local community—reducing the nuisance of fetor from the piggery is a component of a package of solutions for building a closed-circuit economy, including activities that reduce the negative impact of the product life cycle on the environment. |

| 3. | Own heat and power plant | The Piątnica Co-operative is the biggest producer of granular cheese worldwide. In 2011, the ecological dimension of the development enterprise of the Piątnica Dairy Co-operative started own heat and power plant, working on high-efficiency cogeneration. Electricity production is linked to heat production. The electricity demand of the plant is fully covered. The heat demand of the plant is covered to a large extent. The high energy efficiency of the equipment and the avoidance of transmission losses result in a high level (at least 75%) of use of the primary energy contained in the gas fuel [59]. |

| 4. | The purification and reuse of process water | The Piątnica Co-operative minimized the environmental effect of processing process by introducing the purification and reuse of process water. It led to significant reduction of water consumption approx. 240 m3/day. |

| 5. | Own sewage treatment plant | The Piątnica Co-operative cleans wastewater from the production in its own sewage treatment plant. After the modernization in 2012, the sewage treatment plant can clean up to 2500 m3 of sewage per day, which covers the needs of the production site for next years. |

| 6. | Distillery stillage | Distillers’ stillage is a waste from the production of bioethanol from various feed stocks, in particular, from grain. Distillers’ stillage can occur in dry, wet, liquid form. Its high nutritional value is due to its protein content. Nutritional value is high due to its protein content. Increasingly better processing technologies for grain broths have made them more consistent in composition and they are successfully used in swine feed. Individual farms working with meat processing companies choose to incorporate distillers’ stillage into pig feed. Depending on the type of grain used for fermentation, the metabolic energy of the distillery stillage varied from 10.5 to 14 MJ/kg. Studies have shown that the high insoluble fiber content of distillers’ broth in feed can benefit gut health and fattening pigs through changes in cell proliferation, digestive viscosity, and microbiome. Preliminary results suggest that, compared to soybean meal and corn, distillers’ broth has a lower risk of PED (porcine epidemic diarrhea) virus survival and does not appear to be a significant risk factor for ASF virus transmission. |

| Others | ||

| 7. | Implementation of ISO 14 001 | The Piątnica Co-operative implemented ISO 14 001 standards. |

| 8. | Expenditures on pro-environmental policy | Zakłady Mięsne Mielczarek sp. z o.o. sp. komandytowa actively participates in the environmental policy by developing and implementing the improved HACCP, GMP/GHP systems, which guarantee food health safety. In 2002, ZM Mielczarek was granted permission to trade with EU countries. The plant complied with the required environmental protection regulations. The expenses related to the protection of the environment and the surroundings of ZM Mielczarek include: - expenditures on pro-ecological investments, e.g.,: a modern plant not emitting harmful fumes, a modern car fleet, waste segregation, optimal use of bulk packaging, fixed costs incurred by the company for using the environment, paying monitoring costs, payments for waste management. |

| 9. | Expenditure on pro-environmental investments | The priority action of Delikatesy Mięsne Gzella Sp. z o.o. is to actively work on limiting the negative impact of the company on the environment and to rigorously comply with regulations in force in Poland concerning its protection. The scope of the company’s activities is related to production processes, which could have a negative impact on natural resources (water, air, soil). In Delikatesy mięsne Gzella, a key role is played by specialized Teams for Environmental Monitoring and Analysis and systematic work on introducing new even safer production and storage technologies. Expenses related to the protection of nature and surroundings of Delikatesy Mięsne Gzella sp. z o.o. can be divided into: expenditures on pro-ecological investments, e.g.,: modern plant not emitting harmful fumes, modern car fleet, waste segregation, optimal use of collective packaging, introduction of paper bags and cloth bags instead of plastic bags in the entire chain of Delikatesy Mięsne Gzella Sp. z o.o. |

| 10. | Innovations in food packaging | It is beneficial to introduce innovations in food packaging designed to increase barrier properties and extend shelf life of perishable products, i.e., meat [61]. It is important to reduce losses at the stage of industrial food production as a result of reliable verification of losses and setting plant standards at a minimum level [62]. Optimization of food production, storage, and transportation allows to minimalize the amount of unsold products, the only form of return of which is to undertake the “complaint process”. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bielski, S.; Zielińska-Chmielewska, A.; Marks-Bielska, R. Use of Environmental Management Systems and Renewable Energy Sources in Selected Food Processing Enterprises in Poland. Energies 2021, 14, 3212. https://doi.org/10.3390/en14113212

Bielski S, Zielińska-Chmielewska A, Marks-Bielska R. Use of Environmental Management Systems and Renewable Energy Sources in Selected Food Processing Enterprises in Poland. Energies. 2021; 14(11):3212. https://doi.org/10.3390/en14113212

Chicago/Turabian StyleBielski, Stanisław, Anna Zielińska-Chmielewska, and Renata Marks-Bielska. 2021. "Use of Environmental Management Systems and Renewable Energy Sources in Selected Food Processing Enterprises in Poland" Energies 14, no. 11: 3212. https://doi.org/10.3390/en14113212

APA StyleBielski, S., Zielińska-Chmielewska, A., & Marks-Bielska, R. (2021). Use of Environmental Management Systems and Renewable Energy Sources in Selected Food Processing Enterprises in Poland. Energies, 14(11), 3212. https://doi.org/10.3390/en14113212