Techno-Economic Assessment of Calcium Looping for Thermochemical Energy Storage with CO2 Capture

Abstract

1. Introduction

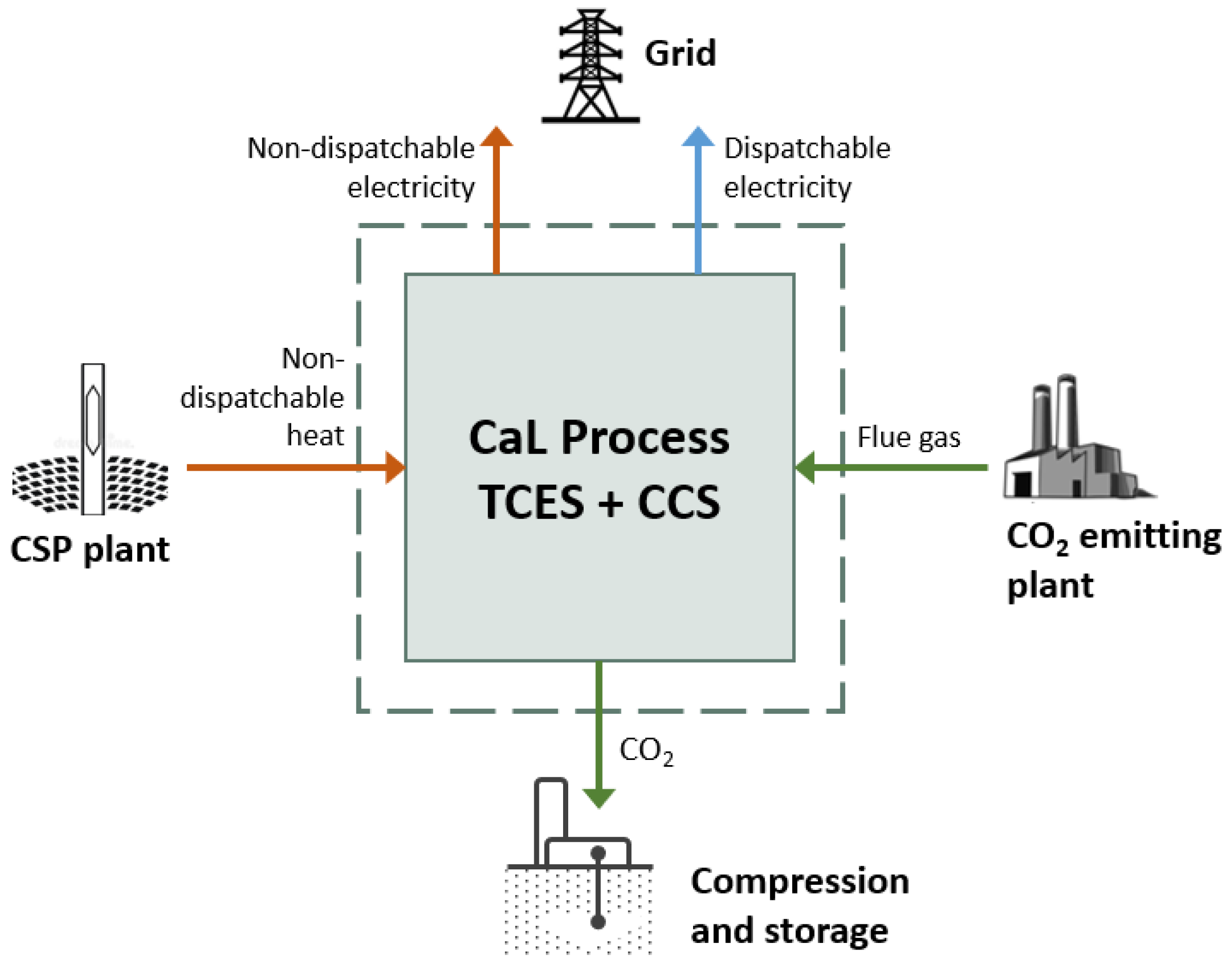

2. Process Description

3. Methodology

3.1. Mass and Energy Balances

3.2. Economic Assessment

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Ahx | Heat exchanger area |

| C | Capital cost |

| Csteel | Cost of steel |

| C0 | Cost of reference |

| CFi | Cash flow in year i |

| Heat capacity of compound i | |

| Db | Diameter of the bed |

| Dcyc | Cyclone diameter |

| f | Scaling parameter |

| Mass flow of compound i entering the reactor | |

| Mass flow of compound i leaving the reactor | |

| IncomeCC | Carbon capture-derived income |

| Mass flow of steam | |

| Pel: | Electrical power |

| Pfluid | Fluid pressure |

| Pgas | Gas pressure |

| Qcalc | Available heat input to the calciner |

| Qin | Net heat input into the process |

| Qout | Heat output |

| r | Discount rate |

| S | Equipment size |

| S0 | Size of reference |

| tcharge | Charging time |

| Treactor | Temperature in the reactor |

| ug | Gas velocity |

| Stoichiometric coefficient of reactant i | |

| Vsteel | Volume of steel |

| Wnet,charge | Net power in charging mode |

| Wnet,dis | Net power in discharging-only mode |

| Wturb | Turbine work |

| xcalc | Degree of solids conversion in the calciner |

| xcarb | Degree of solids conversion in the carbonator |

| Reaction enthalpy | |

| Φ | Solids porosity, External heat flow |

| ηis | Isentropic efficiency |

| ηT | Total efficiency |

| Extent of reaction |

Abbreviations

| BESP | Breakeven electricity selling price |

| CaL | Calcium looping |

| CCS | Carbon capture and storage |

| CEPCI | Chemical engineering plant cost index |

| CFB | Circulating fluidized bed |

| ESP | Electricity selling price |

| G-S | Gas-solids |

| HX | Heat exchanger |

| LCOE | Levelized cost of electricity |

| NPV | Net present value |

| O&M | Operation and maintenance |

| PBP | Payback period |

| S-S | Solids-solids |

| TCES | Thermochemical energy storage |

| USD | United States dollar |

| VRE | Variable renewable energy |

References

- Stocker, T.F.; Quin, D. IPCC 2013: Climate Change 2013—The Physical Science Basis; Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- International Renewable Energy Agency, IRENA. Global Energy Transformation: A Roadmap to 2050. 2019. Available online: https://www.irena.org/publications/2019/Apr/Global-energy-transformation-A-roadmap-to-2050-2019Edition (accessed on 7 February 2021).

- Johnsson, F.; Kjärstad, J.; Rootzén, J. The threat to climate change mitigation posed by the abundance of fossil fuels. Clim. Policy 2019, 19, 258–274. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook (2020), Paris. 2020. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 23 February 2021).

- IEA. CCUS in Clean Energy Transitions, Paris. 2020. Available online: https://www.iea.org/reports/ccus-in-clean-energy-transitions (accessed on 23 February 2021).

- Boot-Handford, M.E.; Abanades, J.C.; Anthony, E.J.; Blunt, M.; Brandani, S.; Mac Dowell, N.; Fernández, J.R.; Ferrari, M.-C.; Gross, R.; Hallett, J.P.; et al. Carbon capture and storage update. Energy Environ. Sci. 2014, 7, 130–189. [Google Scholar] [CrossRef]

- Hirth, L. The market value of variable renewables. Energy Econ. 2013, 38, 218–236. [Google Scholar] [CrossRef]

- Steen, D.; Goop, J.; Lisa, G.; Shemsedin, N.; Brolin, M. Challenges of Integrating Solar and Wind into the Electricity Grid. 2014. pp. 94–107. Available online: http://publications.lib.chalmers.se/publication/210515-challenges-of-integrating-solar-and-wind-into-the-electricity-grid (accessed on 1 April 2021).

- Prasad, J.S.; Muthukumar, P.; Desai, F.; Basu, D.N.; Rahman, M.M. A critical review of high-temperature reversible thermochemical energy storage systems. Appl. Energy 2019, 254, 113733. [Google Scholar] [CrossRef]

- Pardo, P.; Deydier, A.; Anxionnaz-Minvielle, Z.; Rougé, S.; Cabassud, M.; Cognet, P. A review on high temperature thermochemical heat energy storage. Renew. Sustain. Energy Rev. 2014, 32, 591–610. [Google Scholar] [CrossRef]

- Carrillo, A.J.; González-Aguilar, J.; Romero, M.; Coronado, J.M. Solar Energy on Demand: A Review on High Temperature Thermochemical Heat Storage Systems and Materials. Chem. Rev. 2019, 119, 4777–4816. [Google Scholar] [CrossRef] [PubMed]

- Matthews, L.; Lipiński, W. Thermodynamic analysis of solar thermochemical CO2 capture via carbonation/calcination cycle with heat recovery. Energy 2012, 45, 900–907. [Google Scholar] [CrossRef]

- Tregambi, C.; Salatino, P.; Solimene, R.; Montagnaro, F. An experimental characterization of Calcium Looping integrated with concentrated solar power. Chem. Eng. J. 2018, 331, 794–802. [Google Scholar] [CrossRef]

- Zhao, M.; Minett, A.I.; Harris, A.T. A review of techno-economic models for the retrofitting of conventional pulverised-coal power plants for post-combustion capture (PCC) of CO2. Energy Environ. Sci. 2013, 6, 25–40. [Google Scholar] [CrossRef]

- Ortiz, C.; Valverde, J.; Chacartegui, R.; Perez-Maqueda, L.; Giménez, P. The Calcium-Looping (CaCO3/CaO) process for thermochemical energy storage in Concentrating Solar Power plants. Renew. Sustain. Energy Rev. 2019, 113, 109252. [Google Scholar] [CrossRef]

- Khosa, A.A.; Xu, T.; Xia, B.; Yan, J.; Zhao, C. Technological challenges and industrial applications of CaCO3/CaO based thermal energy storage system—A review. Sol. Energy 2019, 193, 618–636. [Google Scholar] [CrossRef]

- Ortiz, C.; Valverde, J.M.; Chacartegui, R.; Pérez-Maqueda, L.A.; Gimenez-Gavarrell, P. Scaling-up the Calcium-Looping Process for CO2 Capture and Energy Storage. KONA Powder Part. J. 2021, 38, 189–208. [Google Scholar] [CrossRef]

- Bayon, A.; Bader, R.; Jafarian, M.; Fedunik-Hofman, L.; Sun, Y.; Hinkley, J.; Miller, S.; Lipiński, W. Techno-economic assessment of solid–gas thermochemical energy storage systems for solar thermal power applications. Energy 2018, 149, 473–484. [Google Scholar] [CrossRef]

- Muto, A.; Hansen, T. Demonstration of High-Temperature Calcium-Based Thermochemical Energy Storage System for Use with Concentrating Solar Power Facilities. 2018. Available online: https://www.osti.gov/servlets/purl/1523643 (accessed on 5 March 2021).

- Socratces Project. 2021. Available online: https://socratces.eu/ (accessed on 5 March 2021).

- Flamant, G.; Benoit, H.; Jenke, M.; Santos, A.F.; Tescari, S.; Moumin, G.; Rodriguez, A.; Azapagic, A.; Stamford, L.; Baeyens, J.; et al. Solar processing of reactive particles up to 900 °C, the SOLPART project. AIP Conf. Proc. 2018, 2033. [Google Scholar] [CrossRef]

- Fenell, P.; Anthony, B. Calcium and Chemical Looping Technology for Power Generation and Carbon Dioxide (CO2) Capture, 1st ed.; Woodhead Publishing Series: Cambridge, UK, 2015; ISBN 9780857092434. [Google Scholar]

- Michalski, S.; Hanak, D.P.; Manovic, V. Techno-economic feasibility assessment of calcium looping combustion using commercial technology appraisal tools. J. Clean. Prod. 2019, 219, 540–551. [Google Scholar] [CrossRef]

- Mantripragada, H.C.; Rubin, E.S. Calcium Looping Cycle for CO2 Capture: Performance, Cost and Feasibility Analysis. Energy Procedia 2014, 63, 2199–2206. [Google Scholar] [CrossRef]

- Chacartegui, R.; Alovisio, A.; Ortiz, C.; Valverde, J.; Verda, V.; Becerra, J. Thermochemical energy storage of concentrated solar power by integration of the calcium looping process and a CO2 power cycle. Appl. Energy 2016, 173, 589–605. [Google Scholar] [CrossRef]

- Padula, S.; Tregambi, C.; Solimene, R.; Chirone, R.; Troiano, M.; Salatino, P. A novel fluidized bed “thermochemical battery” for energy storage in concentrated solar thermal technologies. Energy Convers. Manag. 2021, 236, 113994. [Google Scholar] [CrossRef]

- Champagne, S.; Lu, D.Y.; Macchi, A.; Symonds, R.T.; Anthony, E.J. Influence of Steam Injection during Calcination on the Reactivity of CaO-Based Sorbent for Carbon Capture. Ind. Eng. Chem. Res. 2013, 52, 2241–2246. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, K.; Clough, P.T.; Anthony, E.J. Developments in calcium/chemical looping and metal oxide redox cycles for high-temperature thermochemical energy storage: A review. Fuel Process. Technol. 2020, 199, 106280. [Google Scholar] [CrossRef]

- Scala, F. Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Woods, R.D. Rules of Thumb in Engineering Practice; Wiley-VCH: Weinheim, Germany, 2007. [Google Scholar]

- Psarras, P.C.; Comello, S.; Bains, P.; Charoensawadpong, P.; Reichelstein, S.; Wilcox, J. Carbon Capture and Utilization in the Industrial Sector. Environ. Sci. Technol. 2017, 51, 11440–11449. [Google Scholar] [CrossRef]

- Criado, Y.A.; Arias, B.; Abanades, J.C. Calcium looping CO2 capture system for back-up power plants. Energy Environ. Sci. 2017, 10, 1994–2004. [Google Scholar] [CrossRef]

- Dixon, S.; Hall, C. Fluid Mechanics and Thermodynamics of Turbomachinery; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 978-0-12-415954-9. [Google Scholar]

- De Lena, E.; Spinelli, M.; Gatti, M.; Scaccabarozzi, R.; Campanari, S.; Consonni, S.; Cinti, G.; Romano, M.C. Techno-economic analysis of calcium looping processes for low CO2 emission cement plants. Int. J. Greenh. Gas Control. 2019, 82, 244–260. [Google Scholar] [CrossRef]

- Muschelknatuz, U.; Muschelknatuz, E. Abscheideleistung von Rückführzyklonen in Wirbelschichtfeuerungen. VGB Kraftwerkstechnik 1999, 79, 58–63. [Google Scholar]

- Manzolini, G.; Macchi, E.; Gazzani, M. CO2 capture in Integrated Gasification Combined Cycle with SEWGS—Part B: Economic assessment. Fuel 2013, 105, 220–227. [Google Scholar] [CrossRef]

- Cinti, G.; Anantharaman, R.; De Lena, E.; Fu, C.; Gardarsdottir, S.; Hoppe, H.; Jamali, A.; Romano, M.; Roussanaly, S.; Spinelli, M.; et al. Cost of Critical Components in CO2 Capture Processes. 2018. Available online: https://www.sintef.no/globalassets/project/cemcap/2018-11-14-deliverables/d4.4-cost-of-critical-components-in-co2-capture-processes.pdf (accessed on 1 May 2021).

- DOE/NETL. Cost and Performance for Low-Rank Pulverized Coal Oxycombustion Energy Plants. Technical Report. 2010. Available online: https://www.globalccsinstitute.com/archive/hub/publications/119786/cost-performance-low-rank-pulverized-coal-oxycombustion-energy-plants.pdf (accessed on 1 April 2021).

- Walas, S. Chemical Process Equipment; Elsevier: Amsterdam, The Netherlands, 1988. [Google Scholar] [CrossRef]

- Pizzolato, A.; Donato, F.; Verda, V.; Santarelli, M.; Sciacovelli, A. CSP plants with thermocline thermal energy storage and integrated steam generator—Techno-economic modeling and design optimization. Energy 2017, 139, 231–246. [Google Scholar] [CrossRef]

- European Commission. Guide to Cost-benefit Analysis of Investment Projects: Economic Appraisal Tool for Cohesion Policy 2014–2020; European Commission: Brussels, Belgium, 2014. [Google Scholar] [CrossRef]

- Hanak, D.P.; Manovic, V. Economic feasibility of calcium looping under uncertainty. Appl. Energy 2017, 208, 691–702. [Google Scholar] [CrossRef]

- US Geological Survey. 2021. Available online: https://www.usgs.gov/centers/nmic/iron-and-steel-statistics-and-information?qt-science_support_page_related_con=0# (accessed on 2 April 2021).

- EU. Eurostat Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_non-household_consumers (accessed on 1 May 2021).

- Ortiz, C.; Romano, M.; Valverde, J.; Binotti, M.; Chacartegui, R. Process integration of Calcium-Looping thermochemical energy storage system in concentrating solar power plants. Energy 2018, 155, 535–551. [Google Scholar] [CrossRef]

- Rodriguez, N.; Alonso, M.; Grasa, G.; Abanades, J.C. Heat requirements in a calciner of CaCO3 integrated in a CO2 capture system using CaO. Chem. Eng. J. 2008, 138, 148–154. [Google Scholar] [CrossRef]

- Santos, J.J.; Palacio, J.C.; Reyes, A.M.; Carvalho, M.; Freire, A.J.; Barone, M. Concentrating Solar Power. Adv. Renew. Energies Power Technol. 2018, 373–402. [Google Scholar] [CrossRef]

- Ho, C.K. A review of high-temperature particle receivers for concentrating solar power. Appl. Therm. Eng. 2016, 109, 958–969. [Google Scholar] [CrossRef]

- Cormos, C.-C. Techno-economic implications of flexible operation for super-critical power plants equipped with calcium looping cycle as a thermo-chemical energy storage system. Fuel 2020, 280, 118293. [Google Scholar] [CrossRef]

- MacKenzie, A.; Granatstein, D.L.; Anthony, E.J.; Abanades, J.C. Economics of CO2 Capture Using the Calcium Cycle with a Pressurized Fluidized Bed Combustor. Energy Fuels 2007, 21, 920–926. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Plant size as net heat input to the process, Qin | 50, 100 (*), 500, 1000 | MW |

| Charging time, tcharge | 12 | h/day |

| Percentage of steam in the calciner (mol basis) | 50 [15,27] | % |

| Storage temperature | 20 | °C |

| Cooling water temperature | 20 | °C |

| Minimum temperature difference SS–HX | 20 | °C |

| Minimum temperature difference GS–HX | 15 | °C |

| Minimum temperature difference condensers | 15 | °C |

| S–G heat transfer coefficient | 480 [29] | W/m2K |

| Fluid–fluid heat transfer coefficient | 1500 [30] | W/m2K |

| Flue gas CO2 content | 15 [31,32] | %v |

| CO2 capture rate | 90 [31,32] | % |

| Available cooling water discharge temperature | 70 | °C |

| Cooling water pumping distance | 1000 | m |

| Solids porosity, Φ | 0.5 [18] | - |

| Turbomachinery isentropic efficiency, ηis | 0.89 [33] | - |

| Fraction of discharged solids preheated in the SS–HX | 0.85 [25] | - |

| Degree of conversion in the calciner, xcalc | 1 [25] | - |

| Degree of conversion in the carbonator, xcarb | 0.15, 0.25 (*), 0.5, 0.7 [17] | - |

| Solids conveying energy requirement | 10 [25] | MJ/t/100 m |

| Equivalent solids conveying length | 100 [25] | m |

| Equipment | Cost Function | Reference |

|---|---|---|

| Calciner | [38] | |

| Carbonator | [38] | |

| Gas–solids heat exchanger | [34] | |

| Solids–solids heat exchanger | [30] | |

| Gas–gas heat exchanger | [23] | |

| Cooler | [23] | |

| Solids Storage | [18] | |

| Steam turbine | [40] | |

| Electric generator | [23] | |

| Steam generator | [30] | |

| Pump | [23] |

| Parameter (Unit) | Value |

|---|---|

| Plant lifetime (years) | 20 [41] |

| Capacity factor (%) | 100 (*), 70, 80 [42] |

| Discount rate (%) | 4.75 (*), 6.75, 8.75 [41] |

| Limestone cost ($/t) | 10 (*), 20, 50 [42] |

| Steel cost (Csteel) ($/m3) | 5000 [43] |

| Carbon capture-derived income (IncomeCC) ($/t) | 10, 50 (*), 100 [31] |

| Electricity selling price (ESP) ($/MWh) | 20, 40 (*), 80 [44] |

| Parameter | Nominal | Variation 1 | Variation 2 |

|---|---|---|---|

| Capacity factor (100, 70, 80) [%] | 83 | 129 | 162 |

| Discount rate (4.75, 6.75, 8.75) [%] | 83 | 116 | 152 |

| Limestone cost (10, 50, 100) [$/t] | 83 | 83 | 84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez Castilla, G.; Guío-Pérez, D.C.; Papadokonstantakis, S.; Pallarès, D.; Johnsson, F. Techno-Economic Assessment of Calcium Looping for Thermochemical Energy Storage with CO2 Capture. Energies 2021, 14, 3211. https://doi.org/10.3390/en14113211

Martinez Castilla G, Guío-Pérez DC, Papadokonstantakis S, Pallarès D, Johnsson F. Techno-Economic Assessment of Calcium Looping for Thermochemical Energy Storage with CO2 Capture. Energies. 2021; 14(11):3211. https://doi.org/10.3390/en14113211

Chicago/Turabian StyleMartinez Castilla, Guillermo, Diana Carolina Guío-Pérez, Stavros Papadokonstantakis, David Pallarès, and Filip Johnsson. 2021. "Techno-Economic Assessment of Calcium Looping for Thermochemical Energy Storage with CO2 Capture" Energies 14, no. 11: 3211. https://doi.org/10.3390/en14113211

APA StyleMartinez Castilla, G., Guío-Pérez, D. C., Papadokonstantakis, S., Pallarès, D., & Johnsson, F. (2021). Techno-Economic Assessment of Calcium Looping for Thermochemical Energy Storage with CO2 Capture. Energies, 14(11), 3211. https://doi.org/10.3390/en14113211