1. Introduction

Recently, in Poland, one may have observed a slight improvement in the air quality. This is influenced by the widely propagated education programs and domestic heating upgrade schemes such as the introduction of modern heating boilers including solid fuel heating boilers compliant with the Ecodesign Directive [

1]. Unfortunately, domestic heating, due to the inappropriate combustion of solid fuels, still remains the main source of air pollution in Poland. One of the methods of reducing smog is the introduction of a database of domestic heating boilers and increasingly frequent monitoring of the air quality based on sensing of the concentration of particles in the air. These actions do not directly impact the air quality improvement. They are used strictly for monitoring and information purposes. This can be confirmed by four reports on the air quality in Poland as well as the high number of Polish cities in the European statistics having the worst air quality [

2]. According to the work of [

3], about of 90% of the total emission of PM2.5 and PM10 comes from individual heating sector. Particulate matter emission has a big impact for respiratory and cardiovascular morbidity [

4]. The problem of air pollution is also observed in China, where the amount of solid fuels used for heating purposes is very high. In China, approx. 67% of the households are heated with low quality coal [

5]. It is estimated that the low air quality in China is responsible for approx. 400,000 fatalities per annum [

6]. Researchers also focus on the reduction of energy consumption used for the heating of buildings.

For many years, the authors of this paper have been researching the improvement of the emission and energy-related parameters in modern solid fuel heating boilers [

7,

8,

9,

10,

11]. Unfortunately, the recently changing requirements as to the parameters of newly designed equipment do not result in a significant improvement of the air quality. In 2018, according to Polish Office of Statistics (GUS), almost 36% of Polish households were heated with solid fuel heating boilers [

12]. In China, when analyzing the effectiveness of different modernization schemes, no significant improvement of the air quality was observed when substituting low quality fossil fuels with high-energy coal [

13]. In Lithuania, this problem was solved when a successful transformation was implemented based on substituting fossil fuels with renewable energy sources. In the 1990s, in Lithuania, approx. 25% of the households were still using coal as their main fuel [

14]. In 2012, the use of coal in Lithuania was approx. 4% of the total used energy and the dominating heating method was solid biofuels, with a share of approx. 35% [

15].

The analysis of the heating boiler actual operation in Poland is based on the analysis of the power output, at which these appliances operate throughout the year and on the pollutant emissions to the environment during their operation. An optimum situation would be if all heating boilers operating in Poland worked at their nominal power, i.e., the maximum for a given appliance. As has been widely analyzed by Barma [

16], the operation of a heating boiler at its nominal power ensures its highest efficiency and lowest unit emission of pollutants. The actual conditions, under which the heating boilers are operated, are far from those assumed for the nominal power outputs of a given appliance. These deviations are influenced by the weather conditions, the fuel quality, the adjustment of the combustion setting and its precision, as well as the technical and operational parameters of the heating boilers. In reality, a variety of different parameters jointly influencing the heating boiler operation cause majority of the heating devices to operate on a sub-optimum level. This translates into low operating parameters of the heating boilers, such as high emission of pollutants and increased consumption of fuel. The currently known methods of reduction of particle emissions from the combustion of solid fuels in heating in the form of particle filters [

17] allow a reduction of the emissions to the admissible level, but they do not act on the cause of the emission lying in the combustion process under actual conditions of operation.

One of the elements that could actively improve the air quality in Poland, influencing the actual operating conditions of low power heating boilers are automatic combustion adjustment systems. These systems are based on self-learning artificial neural networks governing the operation of an appliance based on the data collected in real time [

18,

19]. Some of the system components are state-of-the-art combustion quality analyzers. The main idea behind these analyzers is direct and continuous monitoring of the basic thermodynamic parameters responsible for the combustion process (the content of oxygen and carbon dioxide, the temperature of the flue gas and the content of particles in the flue gas, etc.) and a simultaneous control of the heating boiler with a view to making its work fall in the stoichiometric range (full and complete combustion). Combustion quality analyzers, in combination with the heating boiler control systems, adapt the combustion process to make it environment friendly and economical within the assumed range of power outputs and temperatures of the heating water. One of the methods of improvement in the air quality in Poland related to the optimization of the actual heating boiler operation is the enforcement of additional monitoring-optimization systems such as combustion quality analyzers.

2. Materials and Methods

The first stage of the research works was the estimation of the pollutant emissions during the laboratory investigations for 15 heating boilers fueled with wood pellet and 15 heating boilers fueled with hard coal. For this purpose, the authors used data from the certification sheet of the selected appliances obtained during operation at a minimum power of 30% of the nominal power output and at the nominal power output. The aim of the analysis was to estimate the average emission related parameters of the heating boilers during their certification. The next step consisted in distinguishing four Polish towns located at a significant distance from one another in order to analyze the average annual amplitude of temperatures in the years 2018 and 2019 and analyze the air quality in this period. The analysis of the air quality was carried out based on generally available historic data from Chief Inspectorate of Environmental Protection (GIOŚ) [

20]. Based on the measurements of the average annual temperature, these were calculated for each month of the year, as well as the average annual emission of pollutants in the analyzed period. Within the analysis of the pollutant emissions, average emissions of CO, NO

x, PM and SO

2 were obtained. Within the four selected locations, a solid fuel heating boiler for a single household was selected for the investigations and its actual thermal load was analyzed for the period under investigation. The performance of the analysis enabled a determination of the relations between the actual operation of the heating boilers for different locations in Poland and their influence on the air quality in the said locations. Within the scope of the research, the authors carried out investigations of the pollutant emissions for three solid fuel heating boilers fueled with hard coal and wood pellet. For the investigations, the authors selected appliances that complied with the applicable standards and directives as well as the out-of-class ones. During the investigations, the authors measured the emission of pollutants (CO, NO

x and PM) for appliances operating at actual thermal loads determined during earlier stages of the research. The additionally obtained pollutant emissions were compared with the results obtained under laboratory conditions.

2.1. Heat and Associated Devices

The investigations were carried out on three low power heating boilers fueled with the most frequently used fuels in Poland: hard coal and wood pellet. The pellet-fueled heating boiler (Q Pellet GL 25 by Heiztechnik, Skarszewy, Poland) is a low-temperature heating boiler of the nominal power output of 25 kW complaint with class 5 (highest) of the environment protection requirements as per the PN-EN 303-5:2012 standard. Its design is based on a smoke tube heat exchanger and the range of obtainable thermal power is 8–25 kW. The heating boiler was fueled with wood pellet. The pellet supply was automatic and its combustion was realized using a chute burner (PellHard PLUS by Heiztechnik, Skarszewy, Poland) fitted in the front part of the heater. The heating boiler was controlled by HT-tronic 900 by Brager, Pleszew, Poland, allowing modulating the power output by selecting appropriate doses of fuel and the amount of air fed during the process of combustion.

The other two investigated heating boilers were Q EKO 20 by Heiztechnik, Skarszewy, Poland (automatic fuel supply) of the nominal power output of 20 kW. The heating boilers were fueled with hard coal of the grain size from 5 to 25 mm operating in the range of 6–20 kW. The fundamental difference in both heating boilers is the fact that one of them meets the class 5, PN-EN 303-5:2012 requirement [

21] and the other one is an out-of-class appliance. Both heating boilers differ in the design of their combustion chambers. A microchip controller governs the operation of both heating boilers.

The class 5 Q EKO 20 heating boiler was equipped with a cast iron rotary burner (DUO by PANCERPOL, Dąbrowa Górnicza, Poland) fitted in the combustion chamber. The heater had a weather compensator (HT Tronic 700 Sensor by Brager, Pleszew, Poland) allowing the adjustment of the thermal power by precise air and fuel dosage to the combustion chamber.

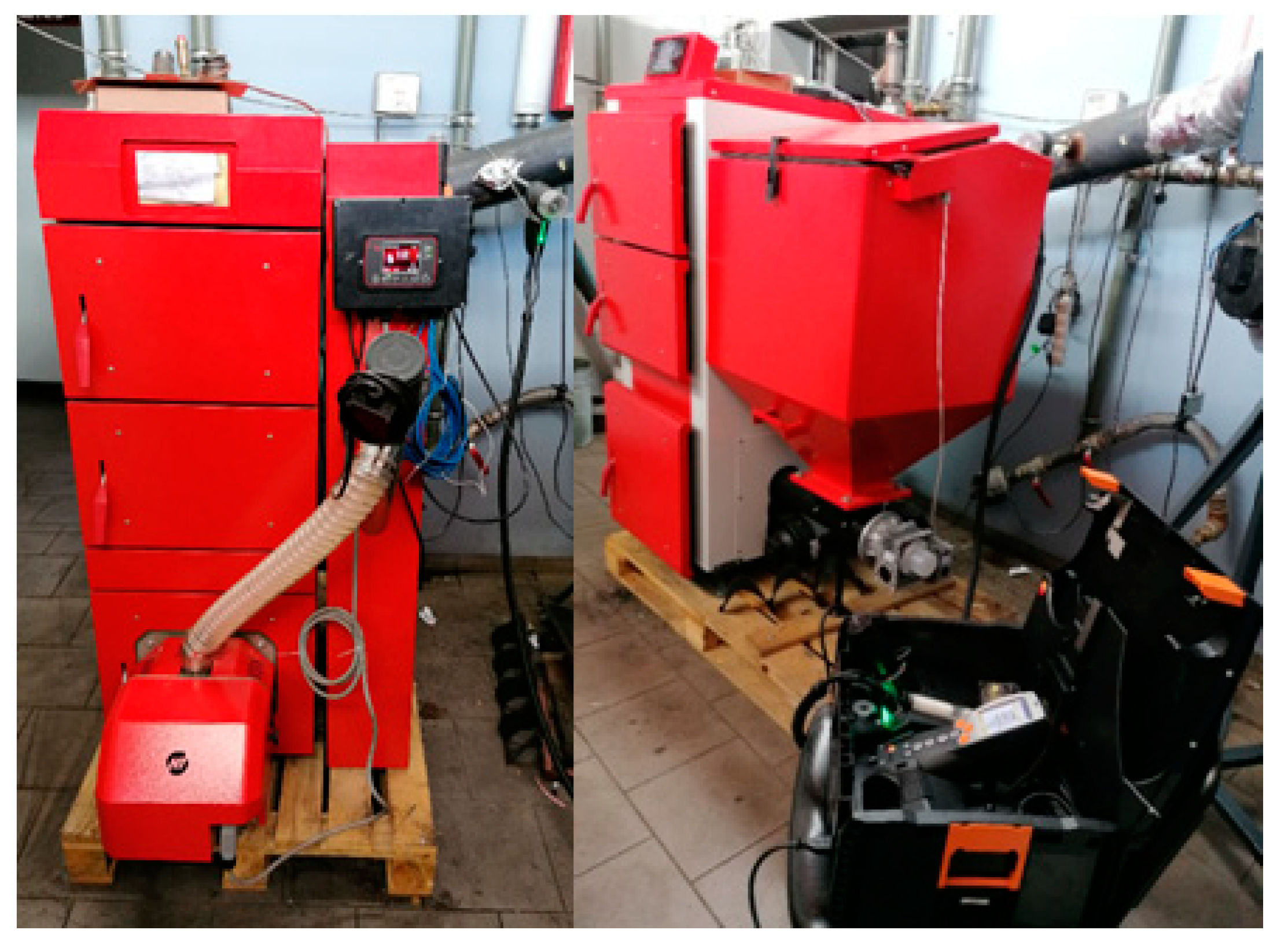

Figure 1 presents the pellet-fueled heater (left) and the hard coal fueled heater (right).

2.2. Chemical Parameters of Fuel

In the investigations, the authors used hard coal (eco-pea coal) and wood pellet. Both fuels were applied in the as-received condition and, for more accurate determination of their parameters, a prior technical analysis was performed as per the [

22] standard. The obtained results have been presented in

Table 1.

2.3. Heat Load Measurement

In order to ascertain the power, at which the heaters were operated under their actual operating conditions, the authors used data pulled from a heater control and monitoring system by eCoal [

23]. Upon consent, each user having the eCoal module installed in his/her heater can make the heater parameter data available directly on a server. The server allows each external user checking the parameters of a given heater in an analyzed time frame. Four heaters located in four towns in Poland (Bydgoszcz, Lublin, Zielona Góra and Warsaw, Poland) were selected. For the analysis, the authors used data related to the operating power on a given day. This information allowed us to obtain the average thermal powers of the heaters as divided into seasons of the year as well as their averaging on the annual scale.

According to the PN-EN 303-5:2012 standard, the thermal power is determined via a direct method, consisting in measurements of the thermal power in a water circulation system of the heating boiler or via an indirect method based on measurements of the thermal power in the water heat exchanger. According to the direct method, the usable thermal power on the side of the heating water is determined via the measurement (in the boiler circulation system) of the mass flow of cold water supplied to the heater circulation and the water temperature increment compared to the temperature at the outlet or via the measurement of the mass flow of water circulating in the heater system and its temperature increment. When investigating the heating boiler of the nominal power output, the average temperature value of water at the outlet should fall in the range from 70 °C to 90 °C and the average temperature difference between the outlet and return water should fall in the range from 10 K to 25 K.

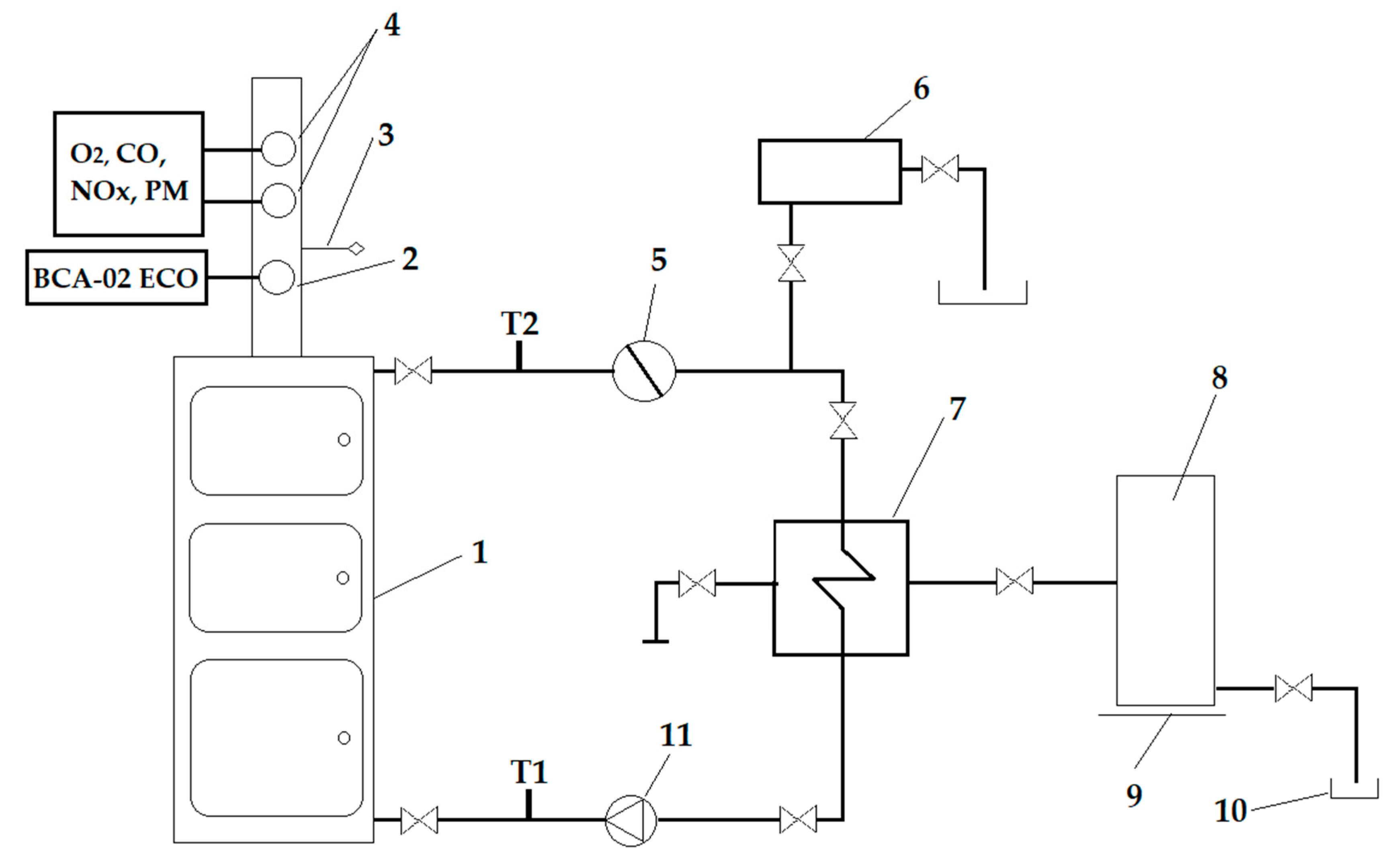

Figure 2 presents the diagram of the test stand.

2.4. Harmful Substances Emission Measurement

Within the realized research works, one measurement station for each town was selected. The location and type of stations have been presented in

Table 2.

All the above stations were stations that allow an automatic measurement and recording of the level of pollutants: CO, NOx, OGC and PM with a time step of one hour. In order to determine the emission of pollutants in the analyzed town, the results of the measurements of the emission of individual pollutants were averaged monthly and attributed to the heating seasons (seasons of the year).

For the performance of the measurements in the laboratory investigations of the actual operation of heating boilers, the authors used three types of measurement devices. Each device was responsible for the measurements of different thermodynamic and emission related parameters.

The first device was Testo 350-S (Testo SE & Co. KGaA, Titisee-Neustadt, Germany) in a two-component configuration—a controller and an analyzer. The analyzer was fitted with an O2 cell with a measurement range 0–25% vol. and error ±0.8%, which allowed recording the level of oxygen in the flue gas. Additionally, the temperature of the flue gas was measured with the accuracy of ±1 °C.

Another device was a Testo 380 particle analyzer (Testo SE & Co. KGaA, Titisee-Neustadt, Germany) together with a Testo 330-2 LL flue gas analyzer (Testo SE & Co. KGaA, Titisee-Neustadt, Germany) that served the purpose of controllers fitted with a display. Testo 380 served to measure the particulate matter within the range 0–300 mg/m

3 and the measurement error of ±5 mg/m

3. Thanks to the application of both devices at the same time as a joint unit, the authors could measure the concentration of carbon monoxide CO (0–8000 ppm) and nitrogen monoxide NO (0–3000 ppm) calculated to nitrogen oxides NO

x. The images of the measurement devices have been shown in

Figure 3.

2.5. Combustion Process Quality Analyzer

For the research part, the authors used a combustion quality analyzer (BCA-02 ECO) for the determination of the emission of pollutants when the analyzer was used and when it was not used.

The BCA-02 ECO combustion quality analyzer is an electronic device that allows a continuous measurement of the thermodynamic parameters that determine the combustion process. It can automatically select the heater operating parameters to optimize the combustion. The BCA-02 ECO analyzer is a compact device for the analysis of the parameters of combustion of solid fuels. The basic parameters measured by the device are the oxygen level % and the temperature °C of the flue gas. The device is compatible with all types of heating boilers and is fitted in the exhaust pipe immediately downstream of the flue. The BCA-02 ECO analyzer measures and calculates the concentration of oxygen % and carbon dioxide (calculated) %, the excess air coefficient λ (calculated), the flue gas temperature °C, the ambient temperature °C and the heat loss to the environment (calculated) %. The combustion quality analyzer is additionally equipped with an intelligent eco-indicator that sums up all the recorded parameters and continuously informs about the quality of the combustion process. The obtained parameters provide a feedback to the control system that allows the optimization of the combustion and increasing the heater energy efficiency. The operation of the device also leads to a reduction of the consumption of fuel as it optimizes the combustion process, which has impact on the rational use of fuel for the heating purposes and minimizes the workload of the user-operator. The image of the combustion quality analyzer has been shown in

Figure 4.

3. Results and Discussion

At the first stage, the authors performed an analysis of the pollutant emissions from 15 heating boilers fueled with wood pellet and 15 heating boilers fueled with hard coal. The analysis was based on the results of the official certification tests. The investigations were conducted according to the PN-EN 303-5:2012 standard [

21]. From the performed investigations, the authors obtained the emission parameters for 30% and 100% nominal power of the heating boiler. These values were collected and arithmetic averages were calculated. The obtained results have been shown in

Table 3 and

Table 4. For further laboratory tests, three boilers were selected from the analyzed boilers: an out-of-class boiler (fuelled by coal) and two boilers meeting the 5th class in accordance with the standard [

21] (fuelled by wood pellets and coal). The studies were carried out to compare emissions of harmful substances from boilers operated in domestic conditions with emissions of harmful substances obtained from these boilers in certification laboratory tests. Additionally, the selected boilers were used for research on the validity of using combustion process quality analyzers to reduce the amount of harmful substances emitted.

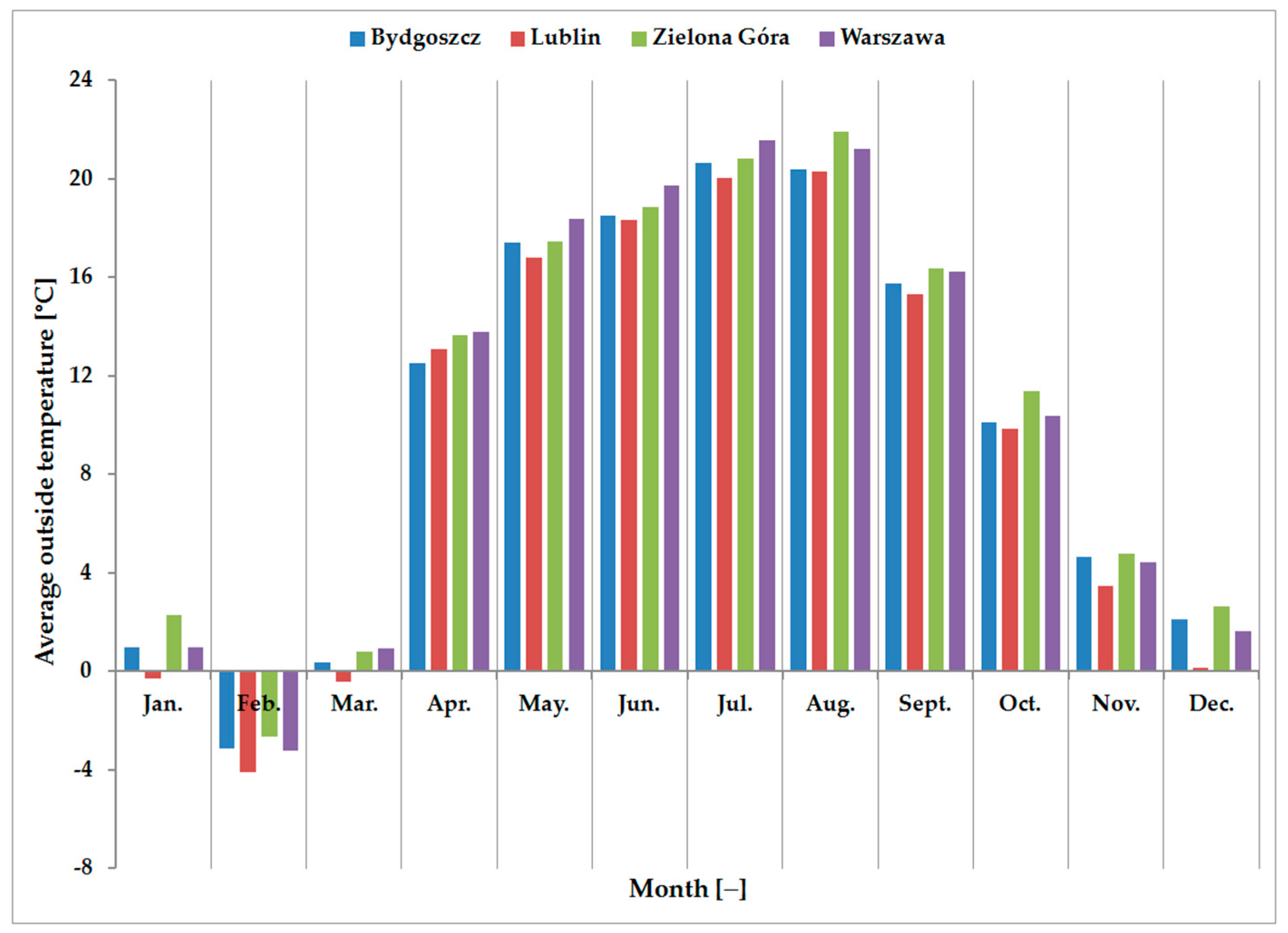

Figure 5 presents the distribution of average annual temperatures for the four discussed locations. For the analyses, the authors used the data from national meteorological stations [

25]. All selected locations, despite significant distance from one another, remain in the same climate zone.

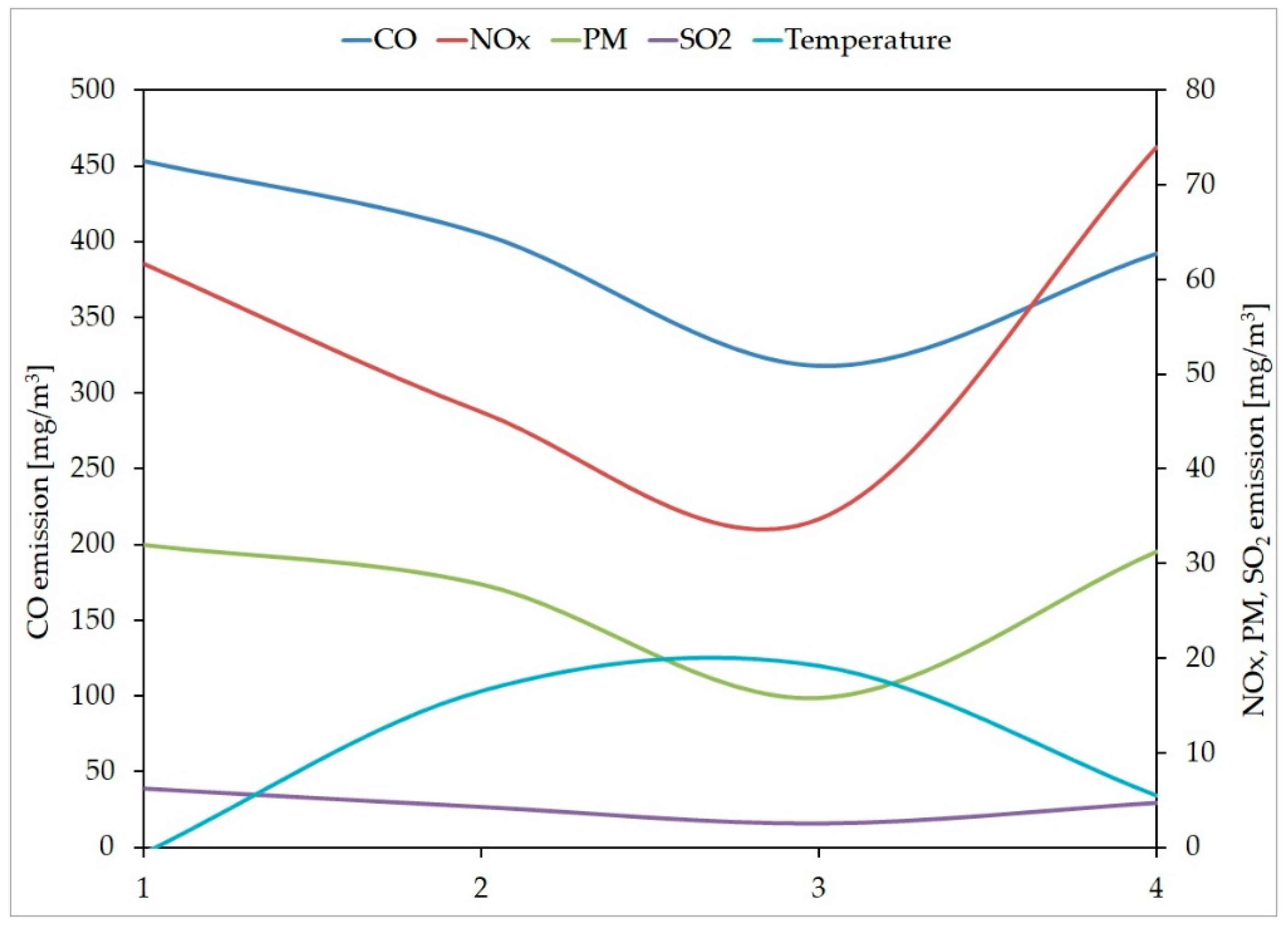

Figure 6 presents averaged emissions of pollutants from the four discussed locations divided into seasons of the year.

The analyzed results were composed into average annual emissions of individual emission components for the years 2018 and 2019 in the discussed locations. The obtained results have been presented in

Table 5.

From the performed analyses, the results show that the main share in the emissions had CO and particulate matter. The values obtained for these two components, at a relatively low content of NO

x in the flue gas, confirm that the main impact on the air pollution in the analyzed regions had the heating boilers that burned fuel on a sub-optimum level. The low content of nitrogen oxides at a significantly higher emission of CO and particulate matter confirm that the combustion process was characterized by oxygen starvation, which resulted in a non-full and incomplete combustion. In the conducted analysis, attention was paid to substance important from the point of view of air protection-sulfur dioxide SO

2. According to the data developed by Statistics Poland [

26] above 500,000 tons of this substance are emitted annually as a result of burning fossil fuels. In the case of insufficient air supplied to the combustion process (λ < 1), additional amounts of sulfur-related substances are formed: CS2—carbon disulphide and COS—carbon oxysulphide. The problem is particularly noticeable in the heating season in Poland [

27], because this period of time achieves emission approximately twice as high as in the summer period, when the boilers are operated at several times lower power.

When analyzing the results of the smog analyzers and certified heating boilers, one can observe that the actual pollutant emissions from the heating boilers in typical operation are several times higher and for the low-emission heaters, are far from the original assumptions of their designers and manufacturers of the boilers.

When analyzing the measurement data, the authors observed that the highest power outputs were obtained by the heating boilers in the winter period and their thermal power fell in the range from approx. 26% to approx. 56% of the nominal power output. Another part of the year under analysis was fall and here the thermal power of this season fell in the range from approx. 14% to approx. 34% of the heater nominal power output. In spring, the thermal power of the heaters fell in the range from approx. 12% to approx. 30% of the nominal power output. The data confirm similar heating trends in the fall and spring periods. This is also supported by the analysis of the amplitude of temperatures for these seasons of the year. The average temperatures in these periods are similar, which forces the users-operators to perform similar operation related routines. The lowest share of thermal power was observed for the summer and, in this time of year, the percent share of the thermal power against the nominal power output was approx. 4% to 12%. The power calculation divided into seasons of the year has been presented in

Table 6.

Based on the analyses of the thermal power, previously performed for the four heaters in different regions of Poland, the authors carried out the analyses of the actual operation of low power solid fuel heaters. Based on the analysis of the thermal power of the heaters in individual seasons, the following relations were observed:

in the winter, the season of the lowest temperatures, the heaters were adjusted in such a way that their thermal power was the highest compared to other seasons of the year, but they did not reach the power greater than approx. 50% (approx. 40% on average) of the nominal power output, which confirms an incorrect matching of the appliance to the thermal expectations of the users (an overrated heater),

the periods of fall and spring were characterized by coherent and similar thermal powers of the heaters and their power outputs did not exceed approx. 30% (approx. 20% on average) of the nominal power output. Additionally, when analyzing the curves of the thermal power in these periods, the authors observed that when temperatures lower than approx. 15 °C occurred, steplike, short lasting power peaks appeared, which may confirm the start of the house reheating process and the occurrence of the phenomenon referred to as overheating, which had impact on the periodic surge of the smog effect in these regions (September–October and April–May),

the summer was a period of the lowest thermal power of the heaters. Often, the heaters did not operate and their power was 0%, yet, the average power fell in the range of approx. 10% of the nominal power output.

When analyzing the actual operation of the solid fuel heaters for several locations, the authors attempted to develop an equation to calculate the season-related emissions [

1] that could be adapted in order to accurately and properly calculate the emissions from low-power solid fuel heaters (throughout the year).

The developed Equation (1) was based on analytical investigations of the thermal power outputs in the calendar year (actual operation) as well as on the smog effect analysis in the same period.

The efficiency of the reproduction of the emissions calculated based on the above equation was obtained following the iterative calculations and a reproduction of approx. 90% was obtained in the investigations of the pollutant emissions (CO, NO

x i PM) for all the analyzed cases (certification tests and actual operation). The currently applicable equation for the calculation of the emissions of individual pollutants [

24] assumes that the heaters operate at 30% of their power output for 85% of the year and at their nominal power output for 15% of the year. From on the performed investigations, it results that the heaters never reach their nominal power throughout the year and their operation at 30% of their power output occurs for approx. 50% of the year at the most. A certain generalization and lack of precision of the equation indexes in the applicable directive renders the average annual emission of pollutants from heaters inaccurate; hence, some corrections in the EU legislation are recommended.

Based on the obtained results from the combustion quality analyzer, the authors distinguished particle reduction indexes. For the particle reduction indexes, the average results from individual stages of the investigations were obtained in

Table 7. The reduction was referred to the heaters that were not fitted with the analyzer:

The effect of the performed analyses was the obtainment of an average reduction of the particle emission for the out-of-class heating boiler compliant with the applicable standards and directives and fitted with the BCA-02 combustion quality analyzer. Identical analyses were carried out in order to reduce the emission of CO

2 (results obtained based on the oxygen level in the flue gas). A change in the settings of the blower fan was observed, which influenced the amount of air fed to the combustion chamber so as to ensure stoichiometric combustion. The continuation of the stoichiometric combustion process resulted in a stable combustion in the entire volume of the fuel and a lack of visible loss of the unburned fuel. The obtained CO

2 reduction results (BCA-02 analyzer fitted) have been presented in

Table 8.

Another stage of the performed investigations was a validation of the improvement of the combustion following the installation of the combustion quality analyzer (whether it improves the heater emission level and the consumption of fuel). Tests were carried out to ascertain whether there would be a change on the side of the consumed fuel and whether the application of the analyzer would impact the consumption of fuel. At first, the authors determined the amount of consumed fuel by the heater in its actual operation (for the previously obtained power outputs) without the combustion quality analyzer and then an analogical trial was performed after fitting the combustion-optimizing device. The determination of the amount of consumed fuel was performed according to generally applied standards: a volumetric and mass measurement of the residual fuel in the container. The obtained differences among individual trials allowed calculating the residual fuel in the container and based on this information, estimating the reduction of the consumption of fuel with the installed analyzer. The obtained results have been presented in

Table 9.

4. Conclusions

Based on the performed research works, one may observe that the air quality in Poland is heavily influenced by the domestic heating sector. We may risk a statement that actual operation of a low power heating boiler significantly influences the air quality. This is related to the emission of pollutants from the combustion of solid fuels. From the performed analyses of the relation between the emissions of pollutants during certification and the quality of air, we may observe a lack of coherence, which confirms that the operation of heating boilers under actual conditions is different from their operation under laboratory conditions. The differences are observed through varied levels of emissions, which deteriorates the quality of air in Poland. The situation indicates that the government upgrade schemes of the heating infrastructure do not materially impact the quality of air in Poland, which forces the need to further improve advanced optimization technologies for the heating boilers and implement them in their daily operation. The main conclusion from the analysis of the pollutant emissions, as regards combustion quality analyzers, is that despite the technological upgrades of the heating boilers, the process of their operation is still far from that characteristic of the certification procedures, which has a clear impact on the continuous emissions suspended 40 m above the ground level (low level emissions) in the heating season in Poland.

Supported with the performed investigations, the authors proposed a new equation for the calculation of the average annual emissions from solid fuel heating boilers. The individual members of the equations are based on the percent share of the averaged thermal power for a given season of the year. The enforcement of the analysis of the emission of pollutants from heating boilers for the calculated thermal power outputs and the determination of the average annual emissions based on the equation will allow validating the emissions generated by the heaters in the laboratory conditions as compared to those obtained under actual thermal loads. The further trends in research and legislation converging the emissions obtained under laboratory conditions with those obtained under actual operation will hopefully reduce the significant differences that are currently the case given the unreal laboratory results.

Based on the performed investigations on the pollutant emissions from heating boilers operated under laboratory and actual conditions, the authors observed that the adjustment of the combustion process is influenced by a variety of technological aspects, which has impact on its precision. The lack of precision in the adjustment of the combustion process is connected to the fact that the only information used in the adjusting process is the thermal power requested by the user or the temperature of water in the heating systems. Failing to use the information on the quality of the combustion process in the adjustment procedure results in a high level of pollutant emissions and increased consumption of fuel. The feedback regarding the required thermal power of the heater and information on the quality of the combustion process allows reaching the emission parameters of the heaters similar to those obtained under laboratory conditions, which, in the case of actual heater operation, may result in their significant improvement. From the analysis of the obtained results of investigations on the rationality of application of combustion quality analyzers, one may observe a promising reduction of the emission of particulate matter, carbon dioxide and the consumption of fuel. All the effects were achieved maintaining the same thermal power of the heating boilers, which confirms that the analyzer does optimize the combustion and improves the consumption of fuel. The conclusion of the realized research work is the necessity of an obligatory introduction of combustion quality analyzers in low power heating boilers with a view to improving the air quality.