A Multiple Criteria Decision Making Method to Weight the Sustainability Criteria of Equipment Selection for Surface Mining

Abstract

1. Introduction

2. Materials and Methods

- Construction of the decision maker’s model of preferences with regard to particular criteria, including the definition of the respective weights and threshold values.

- Derivation of the valued outranking relationship—S.

- Variant ranking according to outranking relationships.

- Final ranking of variants.

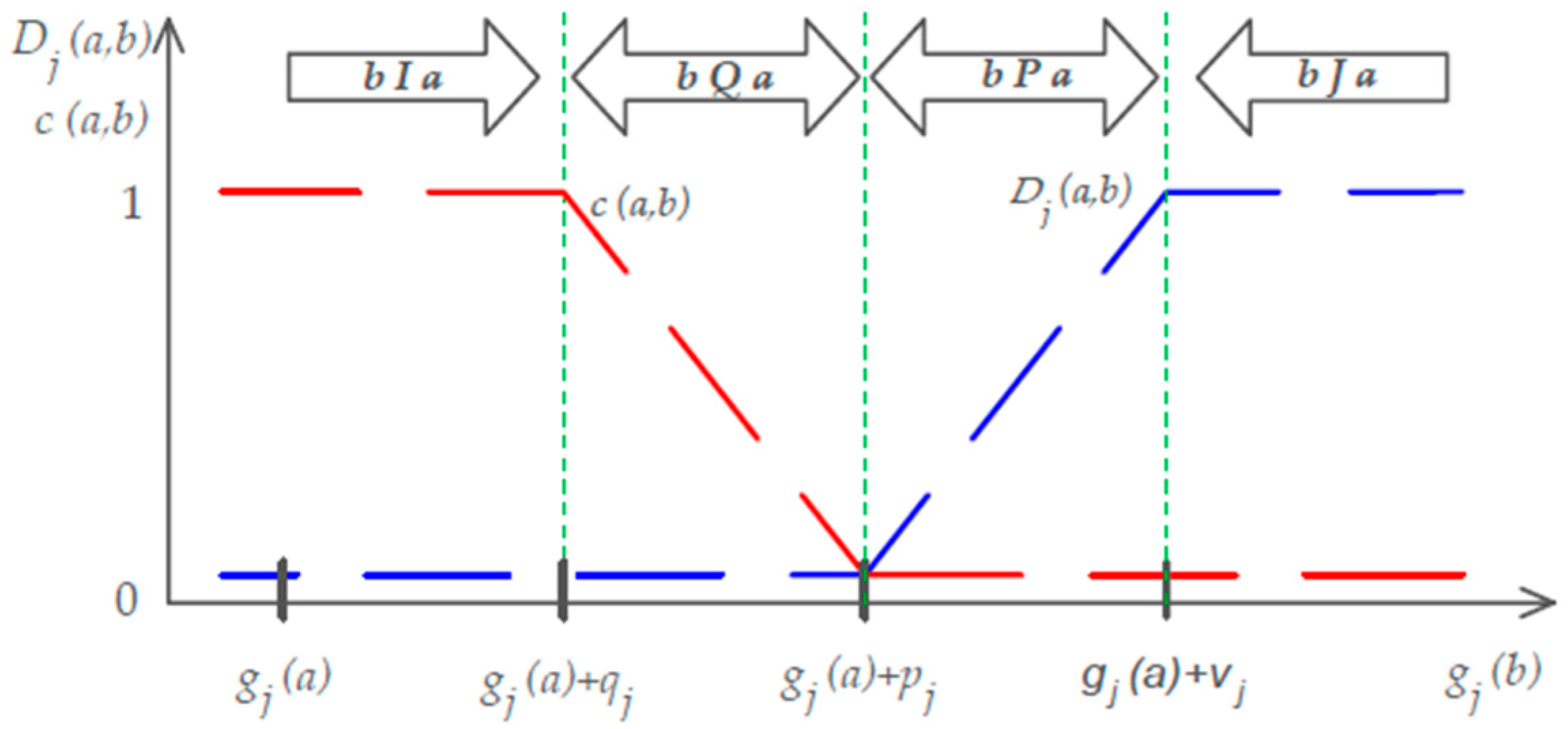

- Indifference, denoted by aIb.

- Weak preference for variant a over variant b, denoted by aQb.

- Strong preference for variant a over variant b, denoted by aPb.

- Incomparability of variants a and b, denoted by aJb.

3. Results

- Complexity and intricate nature o of evaluation criteria.

- Implementation of several decision-makers’ preference models, the decision-makers acting as independent experts.

- Preference models giving the relative weight of each criterion, as well as the relationship between the weak and strong preference, and indifference between the alternatives being evaluated.

- Uncertainty on the part of decision makers as to whether the analyzed variants and preference thresholds should be regarded as incomparable.

- The significance of modelling of the decision-making processes, requiring a repeated reliability analysis.

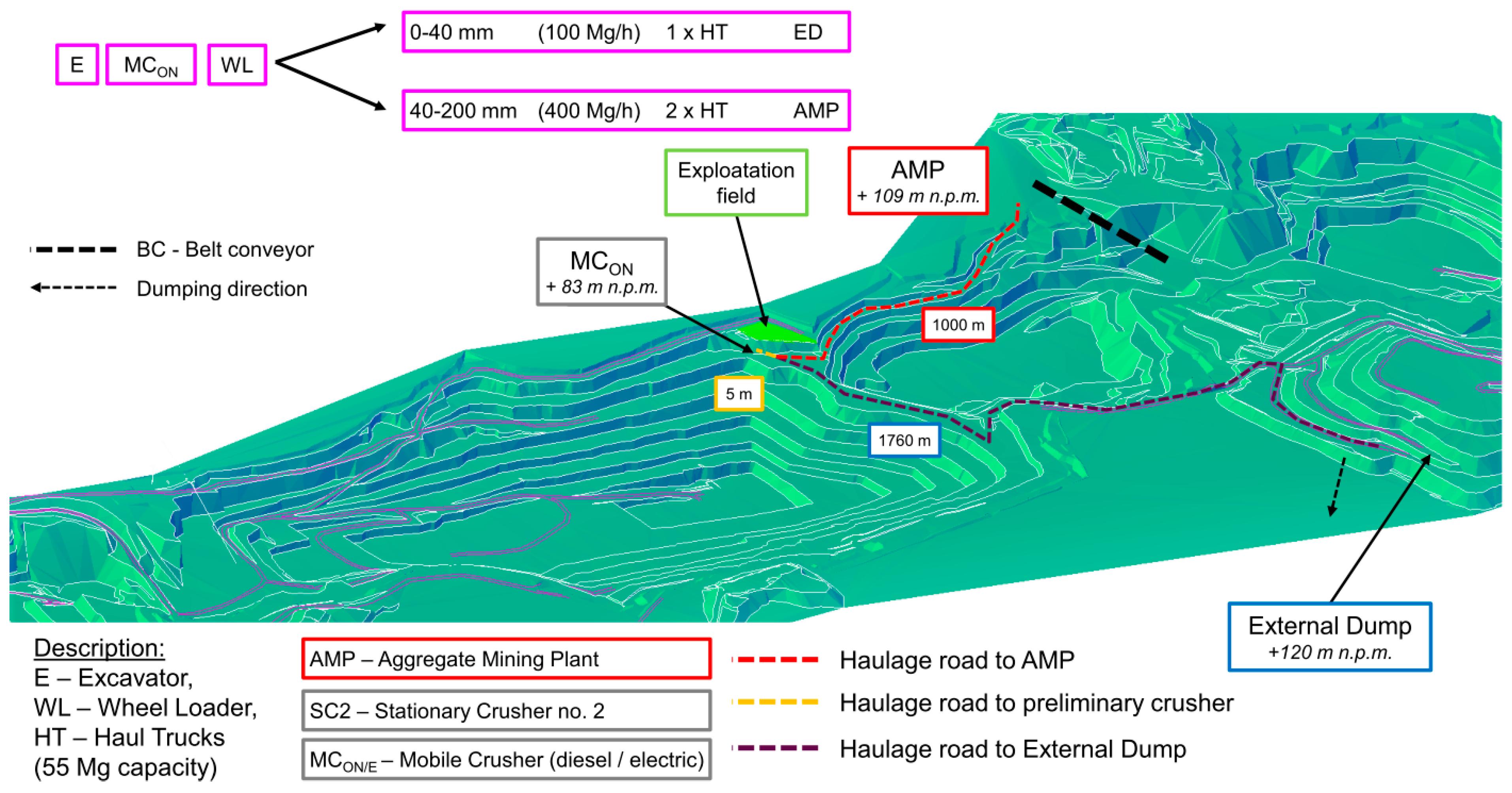

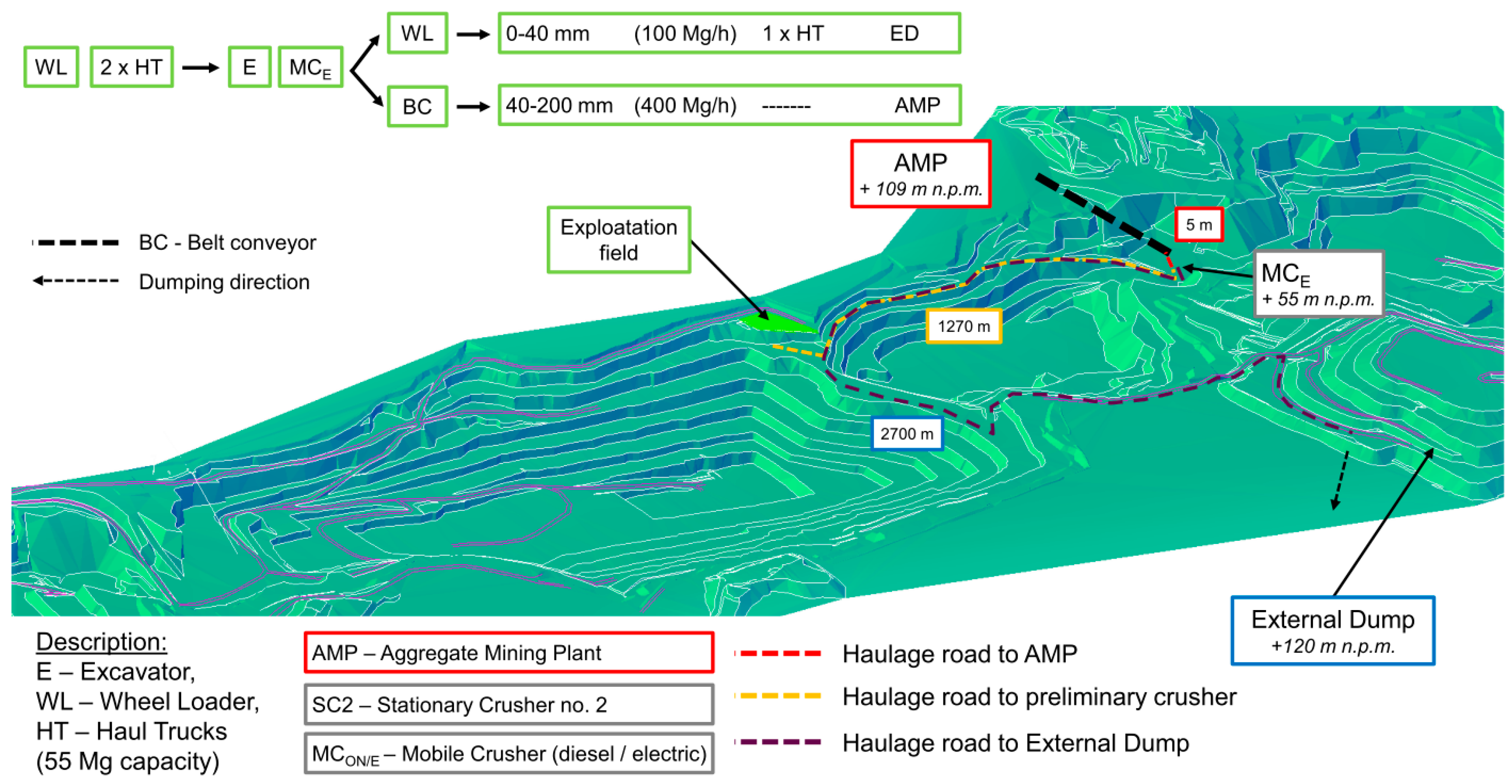

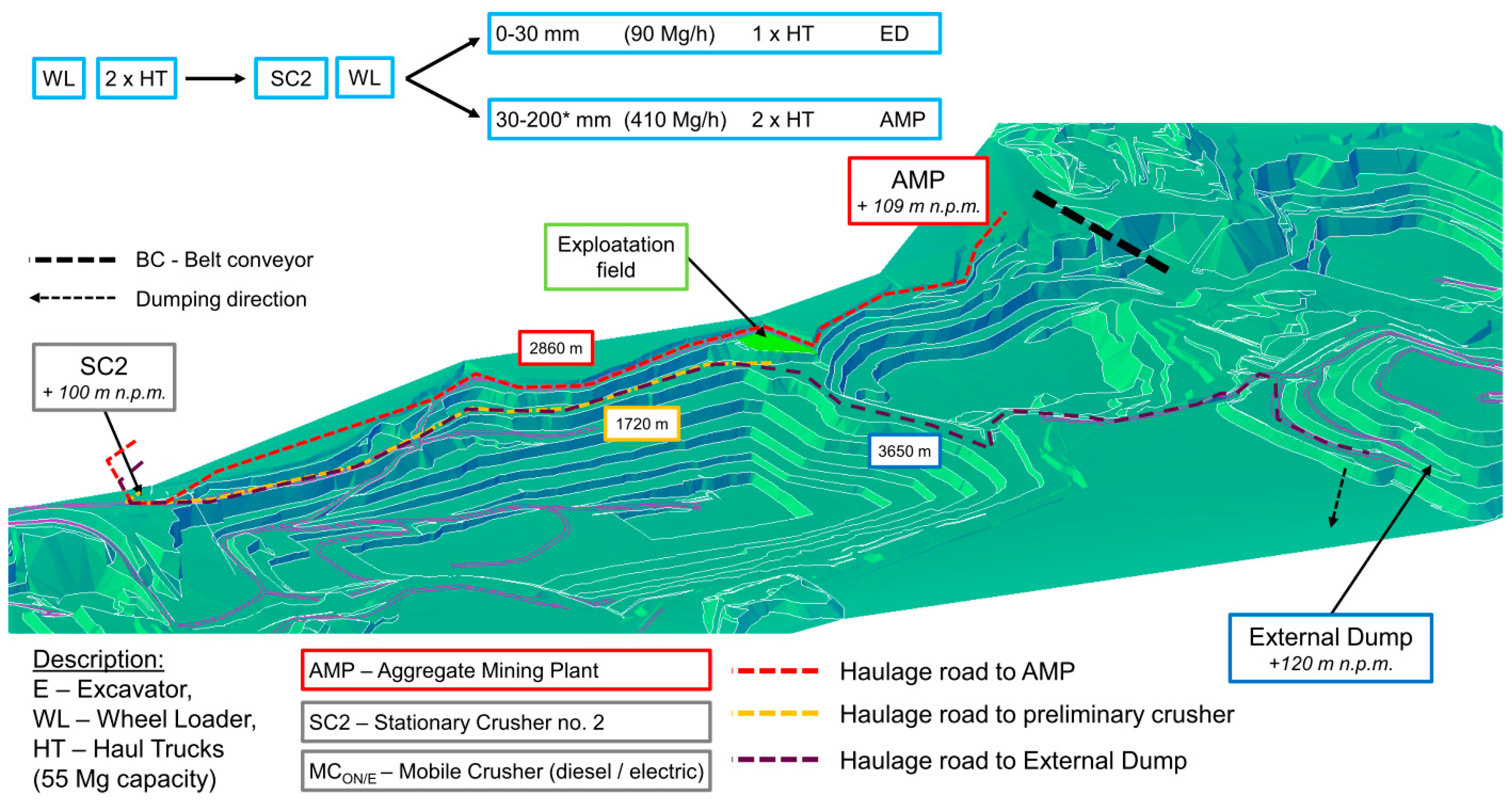

3.1. Designing Decision Variants

- Transport the excavated to the primary crusher (SC2 or MC).

- Transport excavated material to Aggregate Mining Plant (AMP).

- Transport the extracted rock to the external dump (ED).

3.2. Criteria for Selection and Evaluation of Mining Equipment in Open Pit Rock Mines

- K1—length of transport routes.

- K2—machine fleet size.

- K3—reliability index.

- K4—distance of the crushing unit from residential buildings.

- K5—energy consumption by the mining equipment.

- K6—CO emissions from the mining equipment.

- K7—size of external dump.

- K8—process-related costs.

3.2.1. Technology-Related Criteria

3.2.2. Exploitation and Reliability Criterion

3.2.3. Environmental Criteria

3.2.4. Economic Criteria

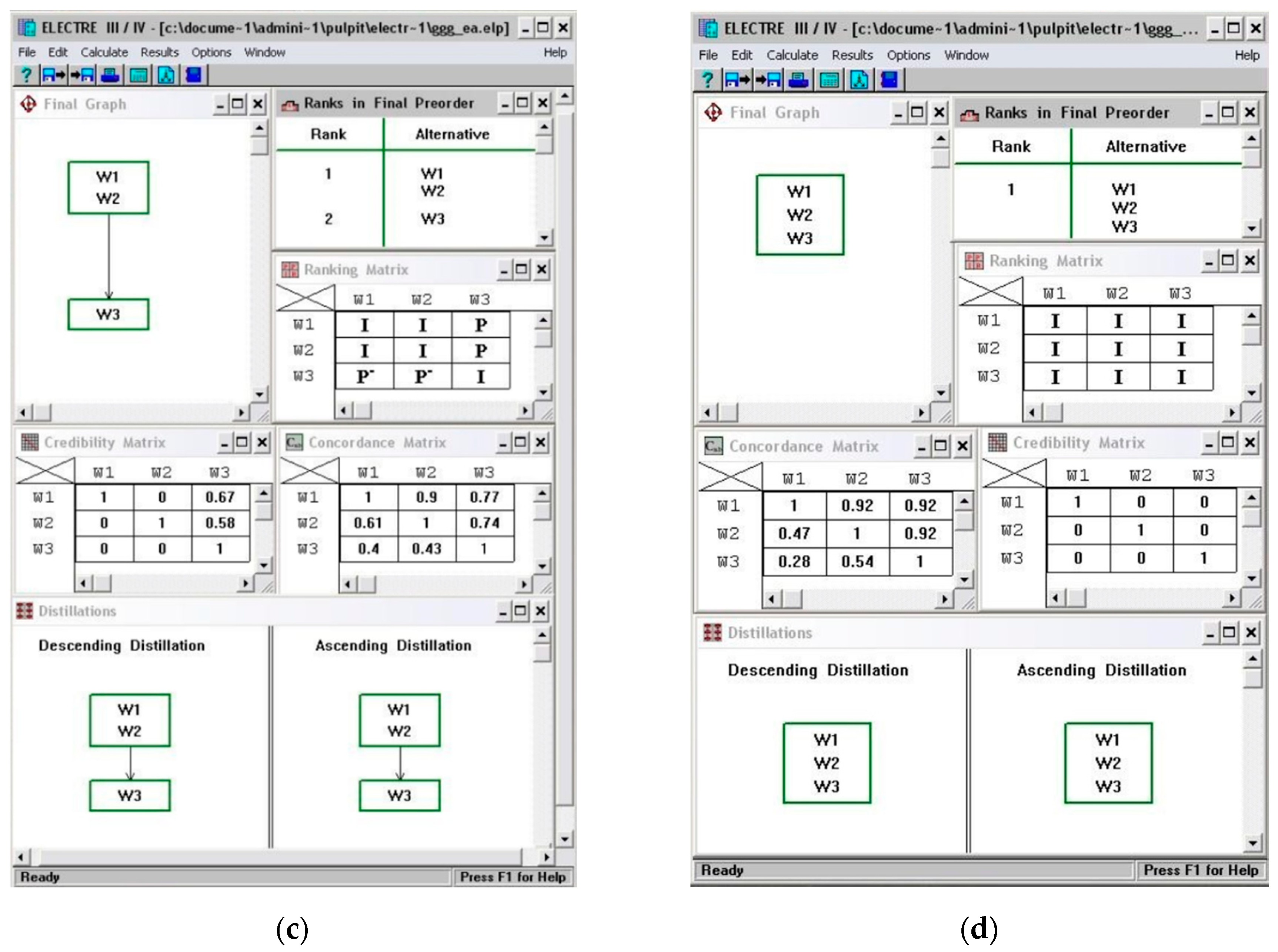

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bodziony, P.; Kasztelewicz, Z.; Sawicki, P. The Problem of Multiple Criteria Selection of the Surface Mining Haul Trucks. Arch. Min. Sci. 2016, 61, 223–243. [Google Scholar] [CrossRef]

- Stevanović, D.; Lekić, M.; Kržanović, D.; Ristović, I. Application of MCDA in selection of different mining methods and solutions. Adv. Sci. Technol. Res. J. 2018, 12, 171–180. [Google Scholar] [CrossRef]

- Bazzazi, A.A.; Osanloo, M.; Karimi, B. A new fuzzy multi criteria decision making model for open pit mines equipment selection. Asia-Pac. J. Oper. Res. 2011, 28, 279–300. [Google Scholar] [CrossRef]

- Burt, C.N.; Caccetta, L. Equipment Selection for Surface Mining: A Review. Interfaces 2014, 44, 143–162. [Google Scholar] [CrossRef][Green Version]

- Voronov, Y.; Voronov, A.; Voronov, A. Quality criterion of the loading and transport system operation at open-pit mines. E3S Web Conf. 2019, 105. [Google Scholar] [CrossRef]

- Samanta, B.; Sarkar, B.; Mukherjee, S.K. Selection of Opencast Mining Equipment by Multi-Criteria Decision-Making Process. Min. Technol. 2002, 111, 136–142. [Google Scholar] [CrossRef]

- Haldar, S.K. Chapter 12—Elements of Mining, Mineral Exploration (Second Edition). Princ. Appl. 2018, 229–258. [Google Scholar]

- Petlovanyi, M.V.; Lozynskyi, V.H.; Saik, P.B.; Sai, K.S. Modern experience of low-coal seams underground mining in Ukraine. Int. J. Min. Sci. Technol. 2018, 28, 917–923. [Google Scholar] [CrossRef]

- Pimentel, B.S.; Gonzalez, E.S.; Barbosa, G.N.O. Decision-support models for sustainable mining networks: Fundamentals and challenges. J. Clean. Prod. 2016, 112, 2145–2157. [Google Scholar] [CrossRef]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of mining waste as aggregates in fly ash-based geopolymers. J. Clean. Prod. 2019, 220, 65–73. [Google Scholar] [CrossRef]

- Segura-Salazar, J.; Tavares, L.M. Sustainability in the Minerals Industry: Seeking a Consensus on Its Meaning. Sustainability 2018, 10, 1429. [Google Scholar] [CrossRef]

- Patyk, M.; Bodziony, P.; Kasztelewicz, Z. Analysis of quarrying equipment operating cost structure. J. Pol. Miner. Eng. Soc. 2019, 21, 311–318. [Google Scholar]

- Mudd, G.M. The Environmental sustainability of mining in Australia: Key mega-trends and looming constraints. Resour. Policy 2010, 35, 98–115. [Google Scholar] [CrossRef]

- Moore, K.R.; Whyte, N.; Roberts, D.; Allwod, J.; Leal Ayala, D.; Bertrand, G.; Bloodworth, A.J. The re-direction of small deposit mining: Technological solutions for raw materials supply security in a whole systems context. Resour. Conserv. Recycl. X 2020, 7. [Google Scholar] [CrossRef]

- Siksnelyte-Butkiene, I.; Zavadskas, E.K.; Streimikiene, D. Multi-Criteria Decision-Making (MCDM) for the Assessment of Renewable Energy Technologies in a Household: A Review. Energies 2020, 13, 1164. [Google Scholar] [CrossRef]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Trojanowska, M.; Nęcka, K. Selection of the Multiple-Criiater Decision-Making Method for Evaluation of Sustainable Energy Development: A Case Study of Poland. Energies 2020, 13, 6321. [Google Scholar] [CrossRef]

- Hokkanen, J.; Salminen, P. ELECTRE III and IV Decision Aids in an Environmental Problem. J. Multi-Criteria Decis. Anal. 1997, 6, 215–226. [Google Scholar] [CrossRef]

- Mutlu, M.; Sari, M. Kullanimi multi-criteria decision making methods and use of in mining industry. Sci. Min. J. 2017, 4, 181–196. [Google Scholar]

- Sitorus, F.; Cilliers, J.; Brito-Parada, R. Multi-criteria decision making for the choice problem in mining and mineral processing: Applications and trends. Expert Syst. Appl. 2019, 121, 393–417. [Google Scholar] [CrossRef]

- De Sousa, W.T., Jr.; Souza, M.J.F.; Cabral, I.E.; Diniz, M.E. Multi-Criteria Decision Aid methodology applied to highway truck selection at a mining company. Rem. Rev. Esc. Minas 2014, 67, 285–290. [Google Scholar] [CrossRef]

- Stojanovic, C.; Bogdanovic, D.; Urosevic, S. Selection of the optimal technology for surface mining by multi-criteria analysis. Kuwait J. Sci. 2015, 42, 170–190. [Google Scholar]

- Vujic, S.; Hudej, M.; Miljanovic, I. Results of the promethee method application in selecting the technological system at the majdan III open pit mine. Arch. Min. Sci. 2013, 58, 213–219. [Google Scholar]

- Hodgett, R.E. Comparison of Multi-Criteria Decision-Making Methods for Equipment Selection. Int. J. Adv. Manuf. Technol. 2016, 85, 1145–1157. [Google Scholar] [CrossRef]

- Figueira, J.R.; Greco, S.; Roy, B.; Slowinski, R. An overview of ELECTRE methods and their recent extensions. J. Multi-Criteria Decis. Anal. 2013, 20, 61–85. [Google Scholar] [CrossRef]

- Roy, B. The Outranking Approach and the Foundations of ELECTRE Methods. Readings in Multiple Criteria Decision Aid. Bana e Costa C.A.; Springer: Berlin, Germany, 1990; pp. 155–183. [Google Scholar]

- Roy, B. Decision Aid and Decision Making. Eur. J. Oper. Res. 1990, 45, 324–331. [Google Scholar] [CrossRef]

- Roy, B. Wielokryterialne Wspomaganie Decyzji; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 1990. [Google Scholar]

- Vincke, P. Multicriteria Decision–Aid; John Wiley & Sons: Chichester, UK, 1992. [Google Scholar]

- Vincke, P. Outranking Approach. In Multicriteria Decision Making; Gal, T., Stewart, T.J., Hanne, T., Eds.; International Series in Operations Research & Management Science; ISOR: Boston, MA, USA, 1999; Volume 21, pp. 305–333. [Google Scholar]

- Sawicki, P. Wielokryterialny dobór operatora usług logistycznych. Logistyka 2001, 4, 59–66. [Google Scholar]

- Govindan, K.; Brandt Jepsen, M. ELECTRE: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2016, 250, 1–29. [Google Scholar] [CrossRef]

- Bodziony, P.; Patyk, M.; Kasztelewicz, Z. Multi-criteria decision making for the choice equipment in mining with application of AHP method. New trends in production engineering: Monograph. Soc. Sci. 2019, 48–59. [Google Scholar]

- Caterpillar Performance Handbook; 48th ed.. Caterpillar Inc.: Peoria, IL, USA, 2018. Available online: https://wheelercat.com/wp-content/uploads/2018/07/SEBD0351_ED48.pdf (accessed on 1 March 2021).

- Specification @ application Handbook; Edition 31. Komatsu Ltd.: Komatsu, Japan, 2013. Available online: https://www.directminingservices.com/wp-content/uploads/2011/05/Edition31.pdf (accessed on 1 March 2021).

- Powerscreen 1180 Premiertrak Jaw Crusher Specification—Rev 6. 01/01/2015. Available online: http://csrpower.com.my/details/Powerscreen%201180%20Premiertrak.pdf (accessed on 1 March 2021).

- EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; EEA Report; EEA: Luxembourg, 2019; Volume 13.

| Machine Type | Name | W1 | W2 | W3 |

|---|---|---|---|---|

| haul truck | Komatsu HD 465 | 3 | 3 | 5 |

| excavator | CAT 34 | 1 | 1 | - |

| wheel loader | Komatsu WA600 HL | 1 | 2 | 2 |

| mobile crusher diesel | Powerscreen Premiertrak 1180 | 1 | - | - |

| mobile crusher electric | Powerscreen Premiertrak 1180 | - | 1 | - |

| stationary crusher | - | - | - | 1 |

| belt conveyor | - | - | 1 | 1 |

| total | - | 6 | 8 | 8 |

| Machine Type/Name | Power Installed (kW) | Av. Consumption of Energy Carriers | CO Emissions (g/kWh) |

|---|---|---|---|

| excavator/CAT 349 | 317 | 39 l/h | 6.5 |

| wheel loader/Komatsu WA600 HL | 393 | 40 l/h | 3.5 |

| haul trucks/Komatsu HD 465 | 551 | 38 l/h | 3.5 |

| mobile crusher plant (diesel)/Powerscreen Premiertrak 1180 | 205 | 28 l/h | 5.0 |

| mobile crusher plant (electric)/Powerscreen Premiertrak 1180 | 185 | 148 kW/h | zero emission |

| belt conveyor | 180 | 144 kW/h | zero emission |

| preliminary crushing + rectangular screen stationary Crusher no. 2 + stationary plant | 1300 | 1043 kW/h | zero emission |

| Criteria | K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 |

|---|---|---|---|---|---|---|---|---|

| Length of Transport Routes | Machine Fleet Size | Reliability Index | Distance of the Crushing Unit | Energy Consumption | CO Emissions | Size of External Dump | Process-Related Costs | |

| unit | km/day | pcs. | % | m | MJ/day | g/kWh | Mg | EUR/day |

| preference | min | min | max | max | min | min | min | min |

| W1 | 454 | 6 | 93.1 | 2192 | 103,194 | 90.70 | 1400 | 732 |

| W2 | 570 | 8 | 94.0 | 1190 | 125,925 | 95.67 | 1400 | 991 |

| W3 | 2181 | 8 | 93.6 | 1975 | 170,885 | 125.84 | 1260 | 1304 |

| No. | Preference Direction | Indifference Threshold | Preference Threshold | Veto Threshold | Relative Importance |

|---|---|---|---|---|---|

| K1 | min | 25 | 50 | 100 | 8 |

| K2 | min | 0 | 1 | 2 | 4 |

| K3 | max | 0.5 | 0.75 | 1 | 5 |

| K4 | max | 100 | 200 | 500 | 9 |

| K5 | min | 1000 | 15,000 | 20,000 | 6 |

| K6 | min | 2 | 6 | 25 | 6 |

| K7 | min | 30 | 600 | 1000 | 7 |

| K8 | min | 120 | 240 | 600 | 8 |

| No. | Preference Direction | Indifference Threshold | Preference Threshold | Veto Threshold | Relative Importance |

|---|---|---|---|---|---|

| K1 | min | 200 | 500 | 1000 | 7 |

| K2 | min | 1 | 2 | 4 | 7 |

| K3 | max | 0.1 | 0.3 | 0.5 | 7 |

| K4 | max | 200 | 400 | 650 | 8 |

| K5 | min | 2500 | 20,000 | 50,000 | 5 |

| K6 | min | 10 | 15 | 20 | 2 |

| K7 | min | 60 | 100 | 200 | 5 |

| K8 | min | 30 | 60 | 120 | 9 |

| No. | Preference Direction | Indifference Threshold | Preference Threshold | Veto Threshold | Relative Importance |

|---|---|---|---|---|---|

| K1 | min | 100 | 300 | 500 | 5 |

| K2 | min | 1 | 3 | 5 | 3 |

| K3 | max | 0.2 | 0.5 | 0.7 | 5 |

| K4 | max | 1300 | 500 | 1000 | 5 |

| K5 | min | 3000 | 10,000 | 30,000 | 4 |

| K6 | min | 5 | 10 | 20 | 4 |

| K7 | min | 50 | 100 | 150 | 5 |

| K8 | min | 180 | 360 | 720 | 9 |

| No. | Preference Direction | Indifference Threshold | Preference Threshold | Veto Threshold | Relative Importance |

|---|---|---|---|---|---|

| K1 | min | 25 | 50 | 100 | 8 |

| K2 | min | 1 | 2 | 4 | 6 |

| K3 | max | 0.05 | 0.35 | 0.75 | 4 |

| K4 | max | 300 | 600 | 1200 | 8 |

| K5 | min | 3750 | 7500 | 15,000 | 4 |

| K6 | min | 5 | 10 | 25 | 9 |

| K7 | min | 30 | 60 | 120 | 8 |

| K8 | min | 60 | 120 | 240 | 2 |

| No. | Preference Direction | E1 | E2 | E3 | E4 | Average |

|---|---|---|---|---|---|---|

| K1 | min | 8 | 7 | 5 | 8 | 7 |

| K2 | min | 4 | 7 | 3 | 6 | 5 |

| K3 | max | 5 | 7 | 4 | 4 | 5.25 |

| K4 | max | 9 | 8 | 5 | 8 | 7.5 |

| K5 | min | 6 | 5 | 4 | 4 | 4.75 |

| K6 | min | 6 | 2 | 4 | 9 | 5.25 |

| K7 | min | 7 | 5 | 5 | 8 | 6.25 |

| K8 | min | 8 | 9 | 9 | 2 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patyk, M.; Bodziony, P.; Krysa, Z. A Multiple Criteria Decision Making Method to Weight the Sustainability Criteria of Equipment Selection for Surface Mining. Energies 2021, 14, 3066. https://doi.org/10.3390/en14113066

Patyk M, Bodziony P, Krysa Z. A Multiple Criteria Decision Making Method to Weight the Sustainability Criteria of Equipment Selection for Surface Mining. Energies. 2021; 14(11):3066. https://doi.org/10.3390/en14113066

Chicago/Turabian StylePatyk, Michał, Przemysław Bodziony, and Zbigniew Krysa. 2021. "A Multiple Criteria Decision Making Method to Weight the Sustainability Criteria of Equipment Selection for Surface Mining" Energies 14, no. 11: 3066. https://doi.org/10.3390/en14113066

APA StylePatyk, M., Bodziony, P., & Krysa, Z. (2021). A Multiple Criteria Decision Making Method to Weight the Sustainability Criteria of Equipment Selection for Surface Mining. Energies, 14(11), 3066. https://doi.org/10.3390/en14113066