Thermally Accelerated Aging of Insulation Paper for Transformers with Different Insulating Liquids

Abstract

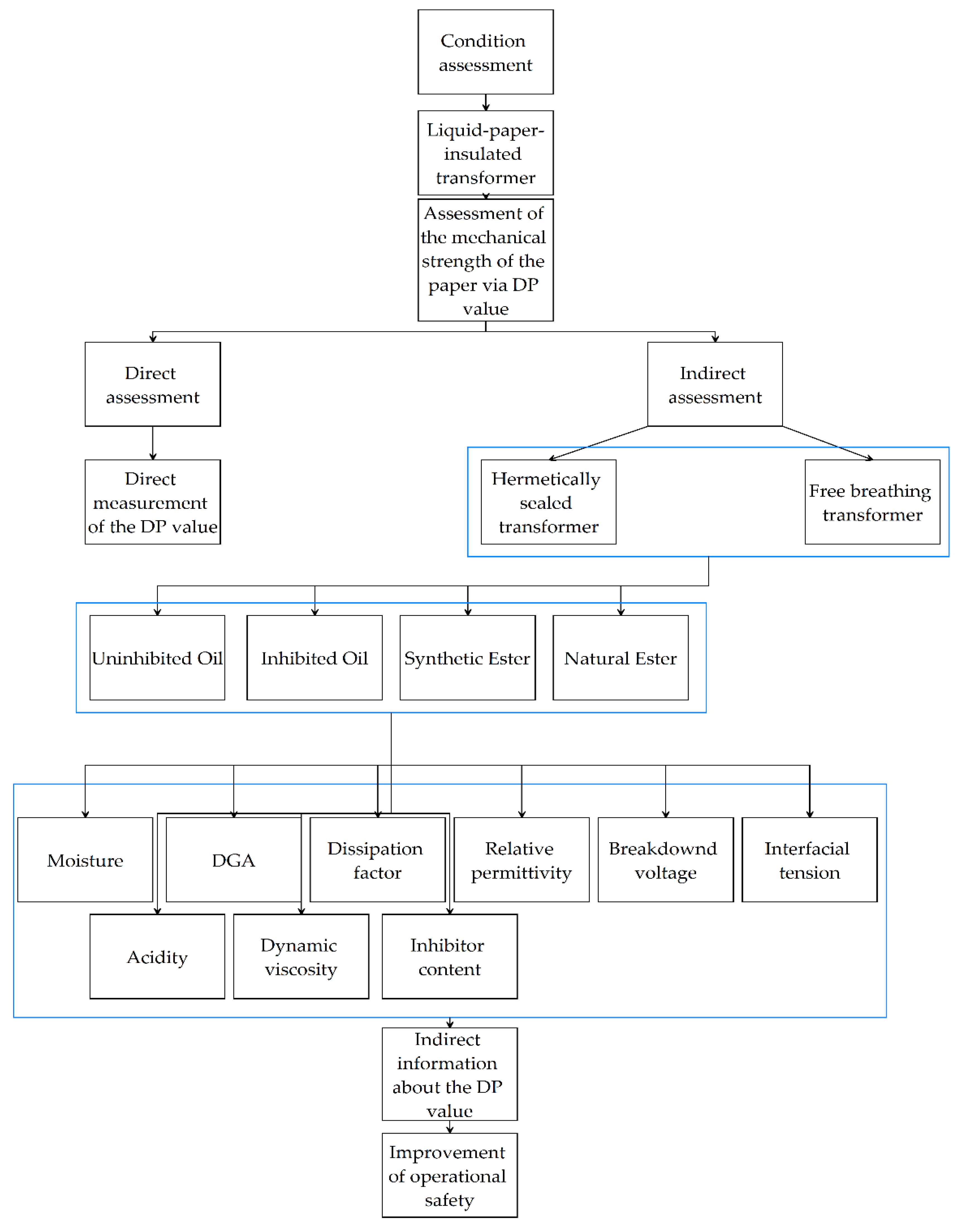

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Preparation

2.3. Aging Process

2.4. Sampling

2.5. Measurement Methods

3. Results and Discussion

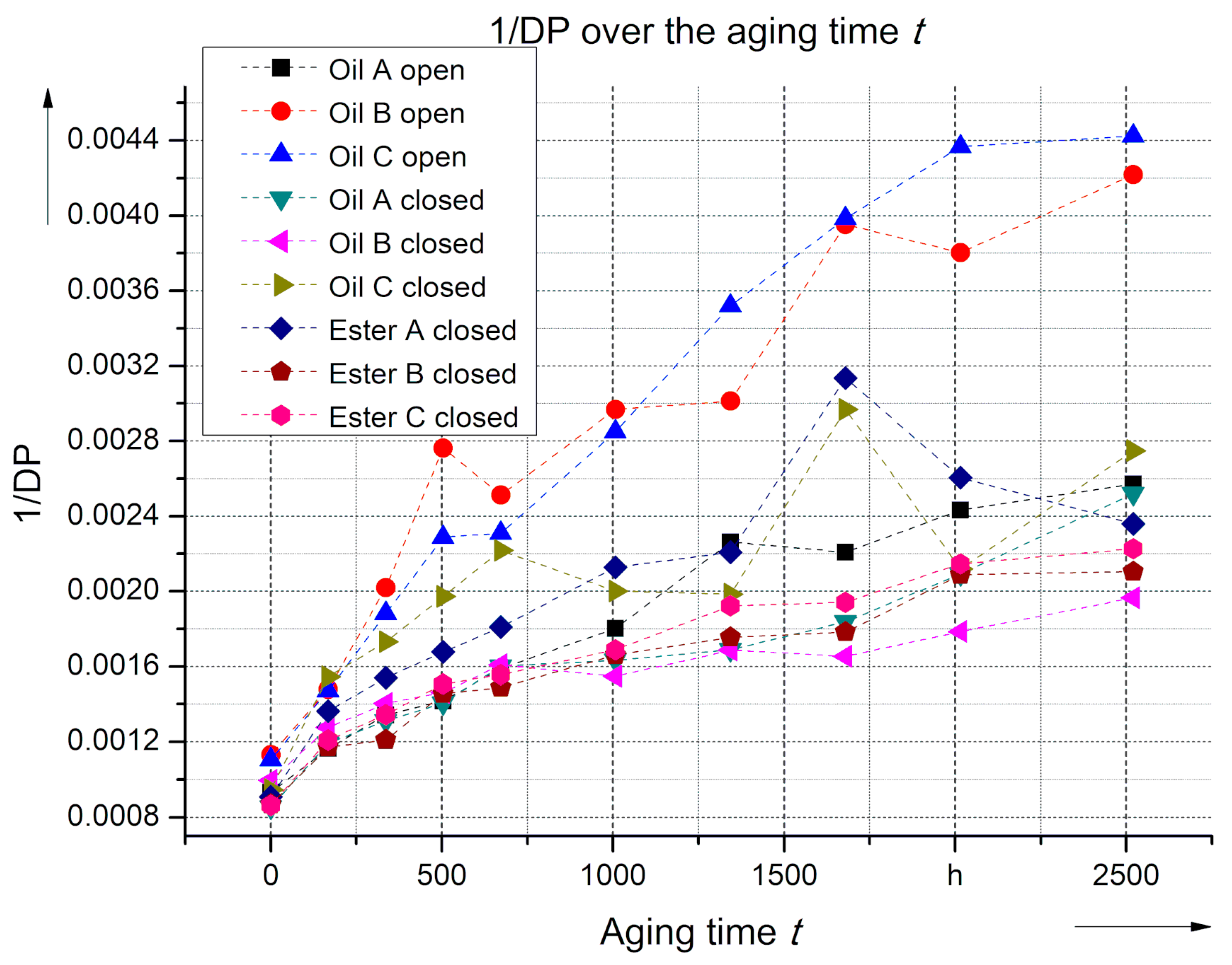

3.1. Degree of Polymerization

3.2. Oil Aging Marker

3.2.1. Moisture

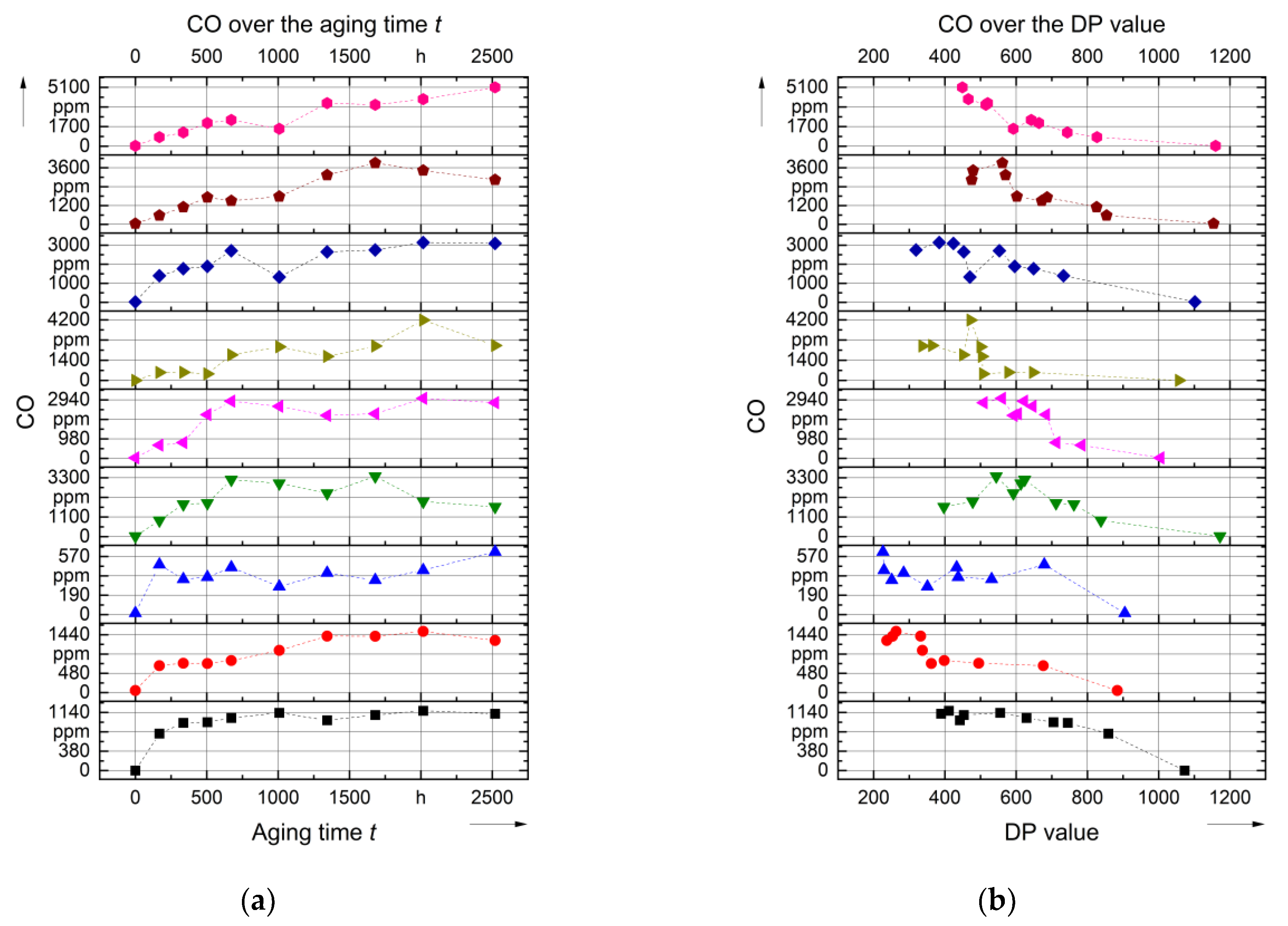

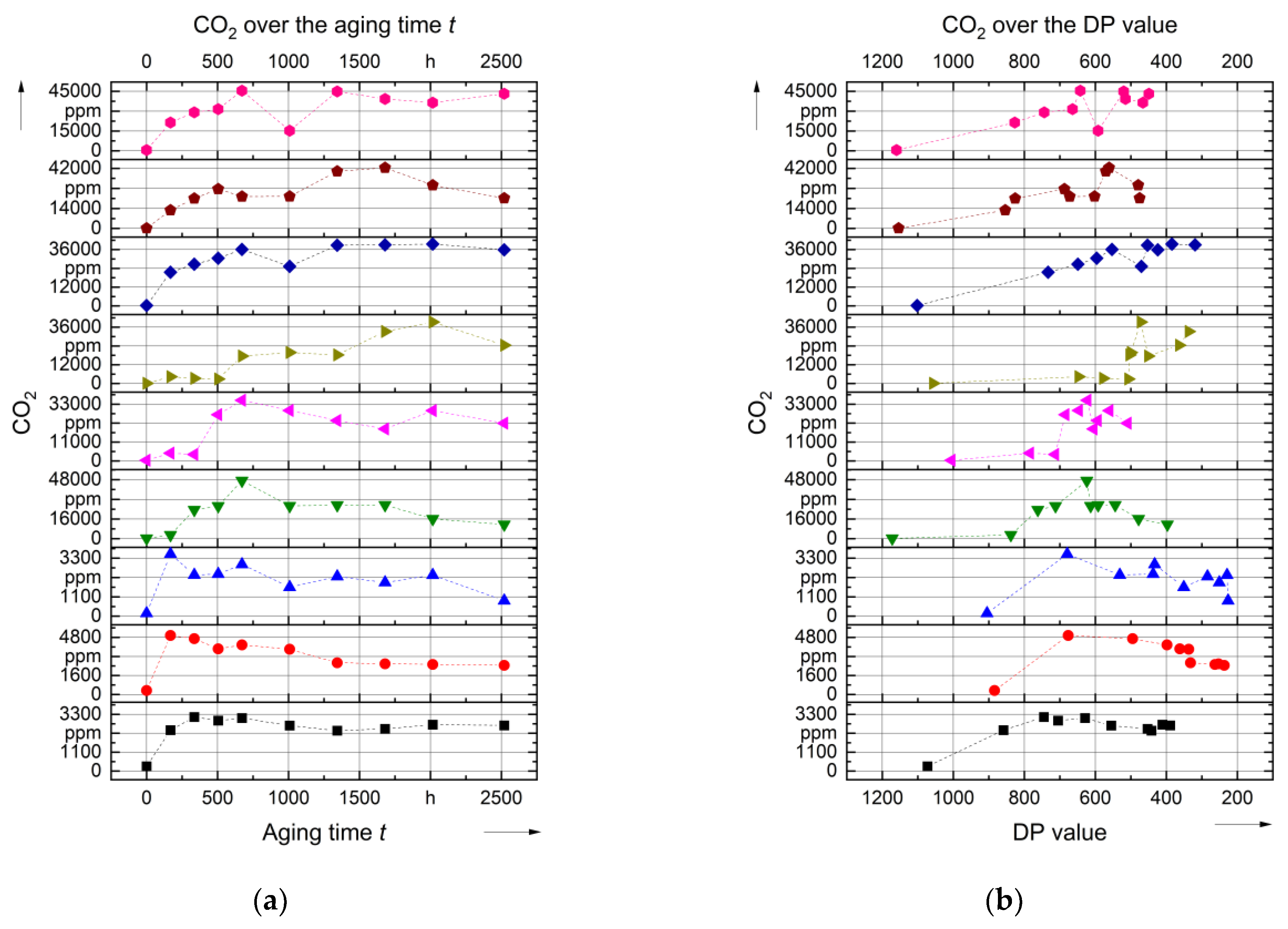

3.2.2. CO and CO2

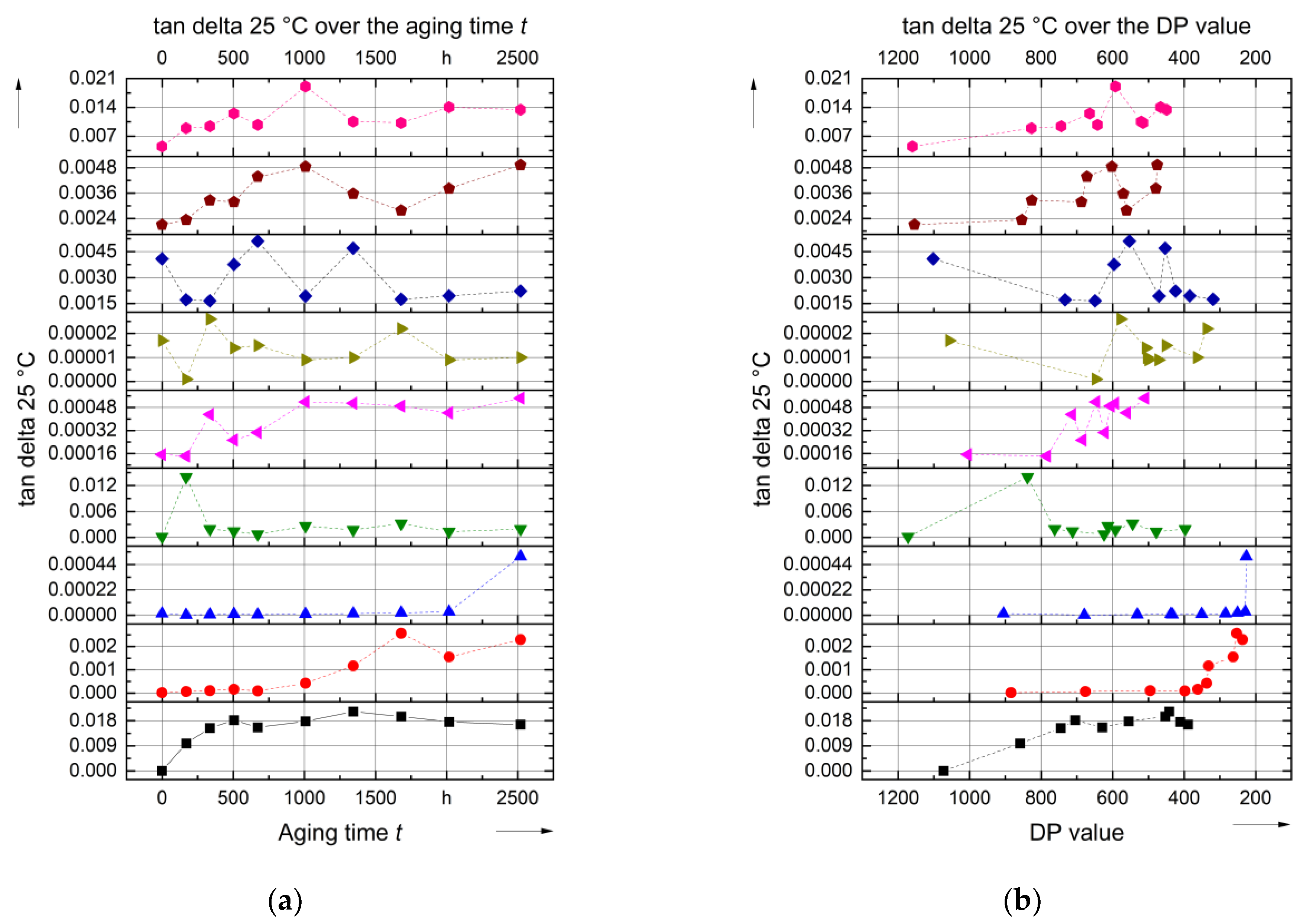

3.2.3. Dissipation Factor tan δ and Relative Permittivity εr

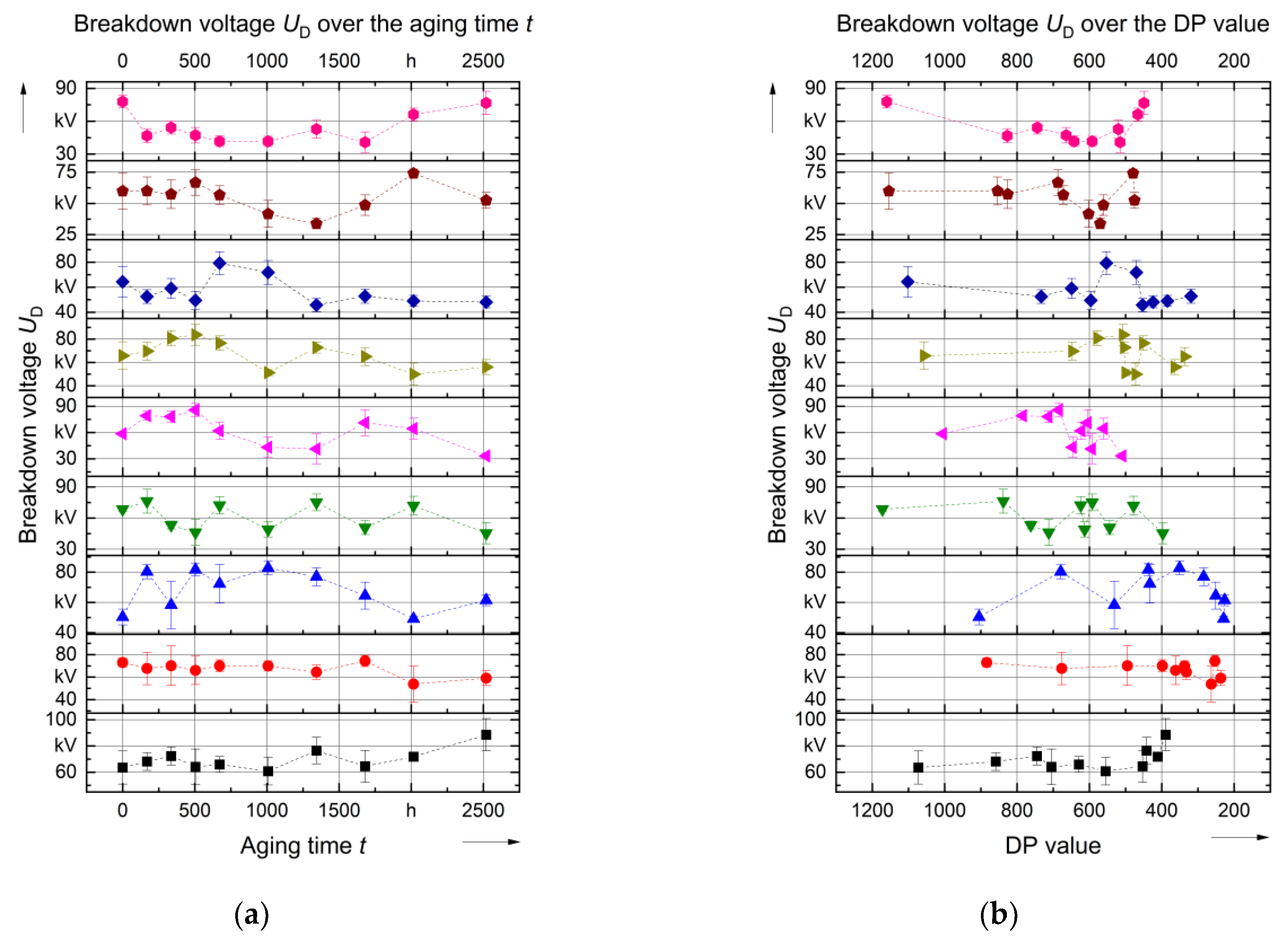

3.2.4. Breakdown Voltage UD

3.2.5. Interfacial Tension σ

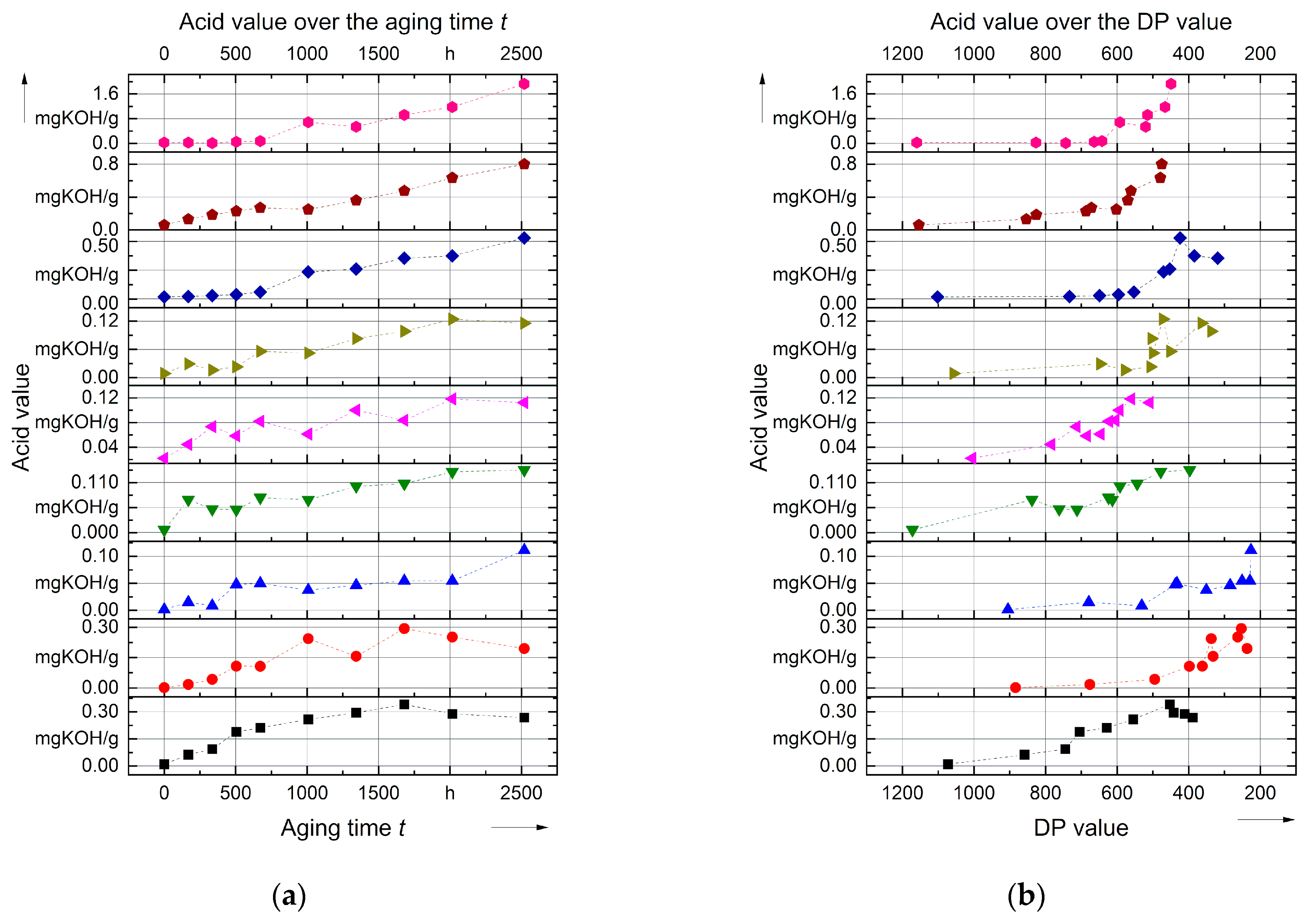

3.2.6. Acidity

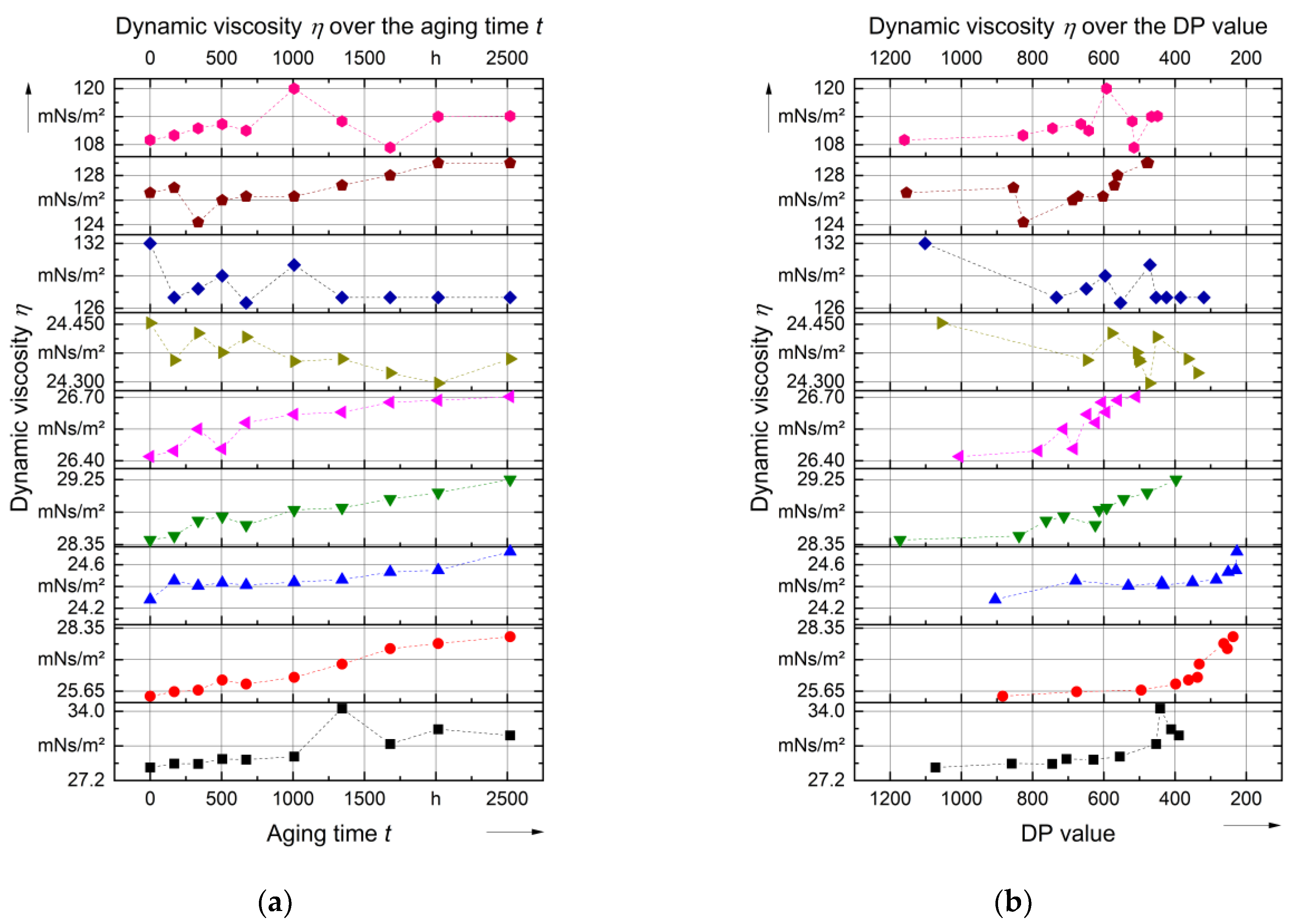

3.2.7. Dynamic Viscosity η

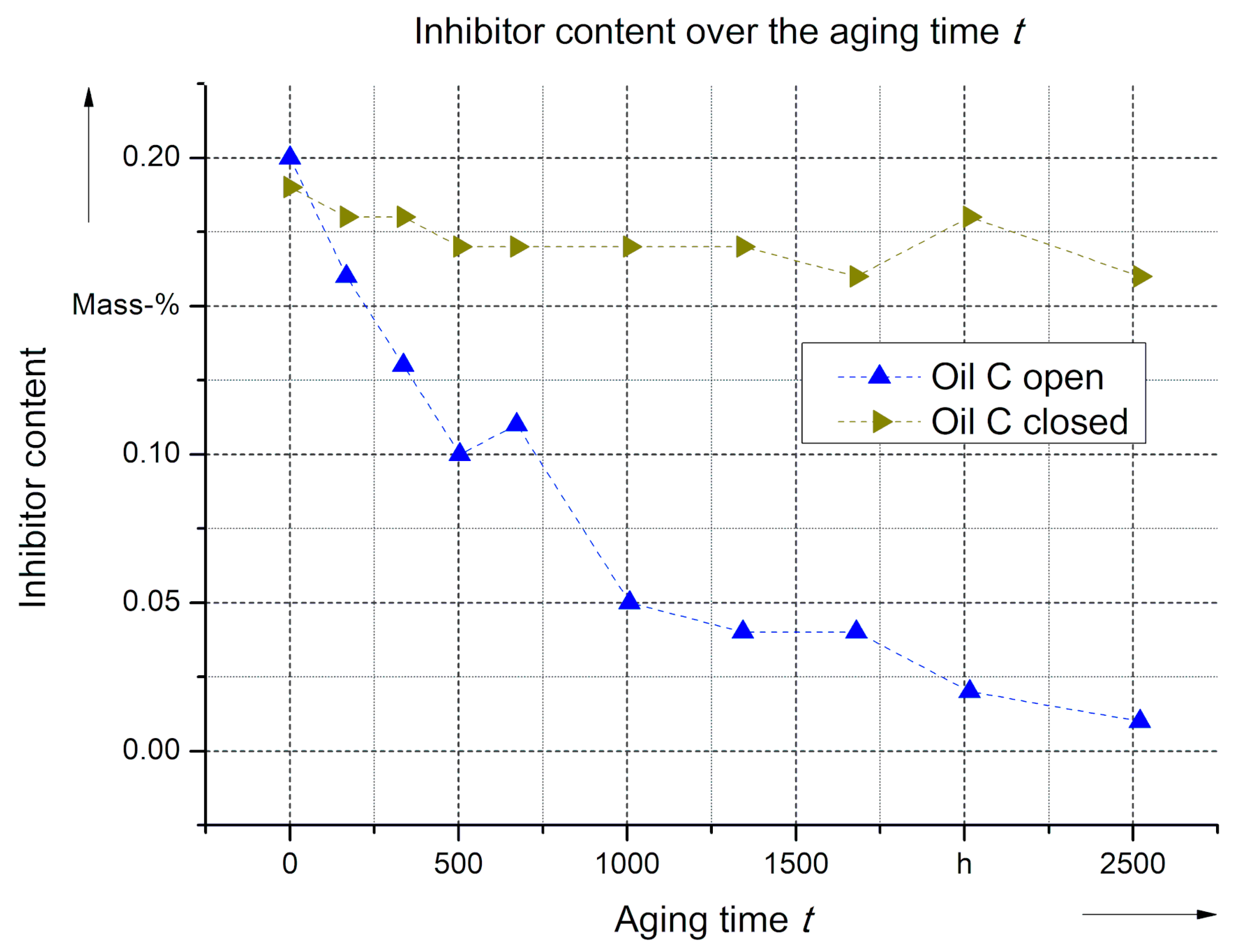

3.3. Inhibitor Content

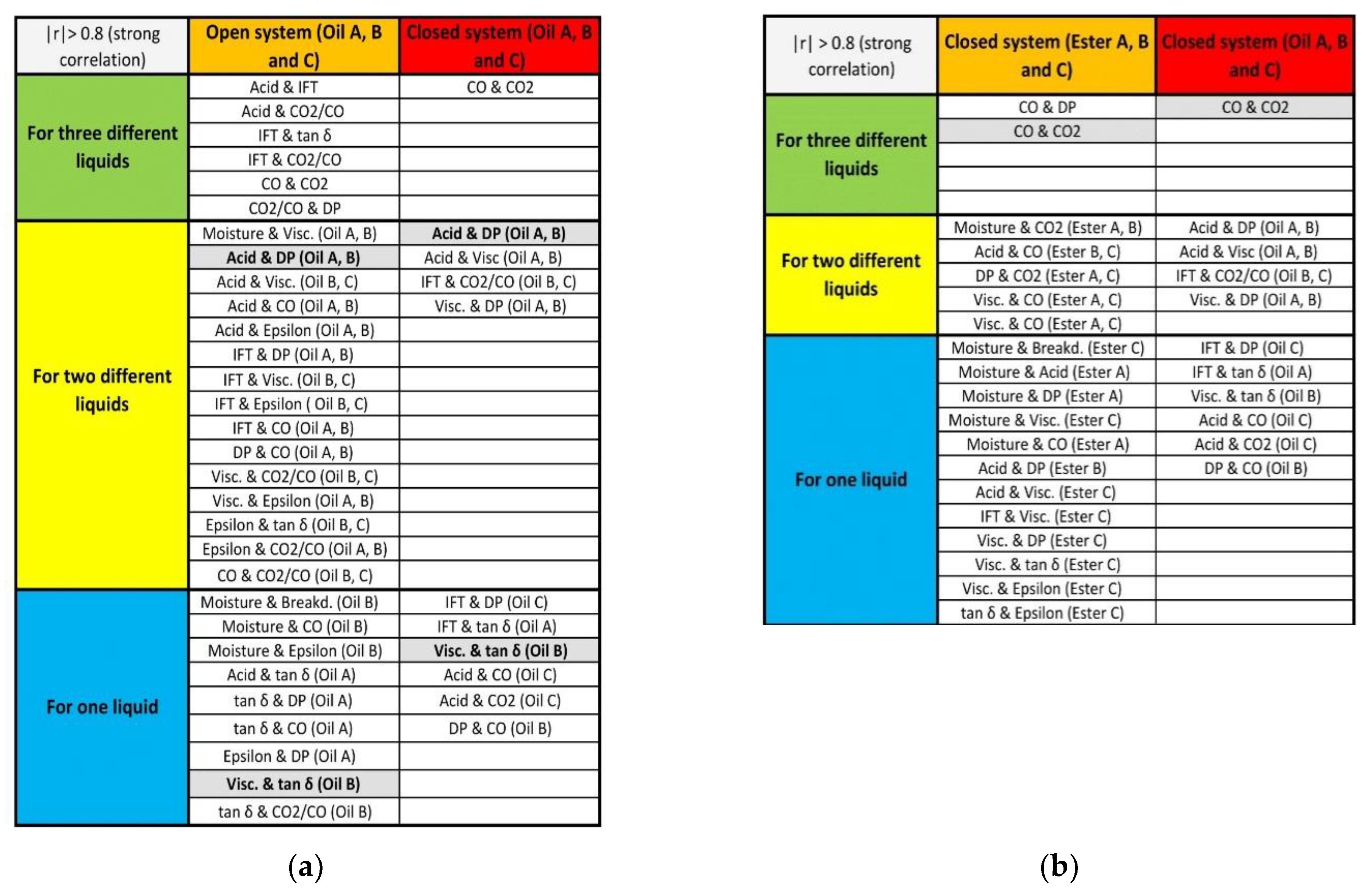

3.4. Correlation Analysis

3.5. Threshold Values for Paper Aging

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ageing of Liquid Impregnated Cellulose for Power Transformers: Study Committee: D1, WG (TF): WG D1.53; Cigré: Paris, France, 2018.

- Okabe, S.; Ueta, G. Partial discharge criterion in AC test of oil-immersed transformer and gas-filled transformer in terms of harmful partial discharge level and signal transmission rate. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1431–1439. [Google Scholar] [CrossRef]

- Wang, Y.; Chang, D.; Fan, Y.; Zhang, G.; Zhan, J.; Shao, X.; He, W. Acoustic localization of partial discharge sources in power transformers using a particle-swarm-optimization-route-searching algorithm. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3647–3656. [Google Scholar] [CrossRef]

- Jaroszewski, M.; Rakowiecki, K. Partial discharge inception voltage in transformer natural ester liquid—Effect of the measurement method in the presence of moisture. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2477–2482. [Google Scholar] [CrossRef]

- Garcia, B.; Burgos, J.C.; Alonso, A.M. Transformer Tank Vibration Modeling as a Method of Detecting Winding Deformations—Part II: Experimental Verification. IEEE Trans. Power Deliv. 2006, 21, 164–169. [Google Scholar] [CrossRef]

- Bagheri, M.; Zollanvari, A.; Nezhivenko, S. Transformer Fault Condition Prognosis Using Vibration Signals over Cloud Environment. IEEE Access 2018, 6, 9862–9874. [Google Scholar] [CrossRef]

- Nurmanova, V.; Bagheri, M.; Zollanvari, A.; Aliakhmet, K.; Akhmetov, Y.; Gharehpetian, G.B. A New Transformer FRA Measurement Technique to Reach Smart Interpretation for Inter-Disk Faults. IEEE Trans. Power Deliv. 2019, 34, 1508–1519. [Google Scholar] [CrossRef]

- Hashemnia, N.; Abu-Siada, A.; Islam, S. Improved power transformer winding fault detection using FRA diagnostics–part 1: Axial displacement simulation. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 556–563. [Google Scholar] [CrossRef]

- Tenbohlen, S.; Jagers, J.; Bastos, G.; Desai, B.; Diggin, B.; Fuhr, J.; Gebauer, J.; Krueger, M.; Lapworth, J.; Mański, P.; et al. Development and Results of a Worldwide Transformer Reliability Survey. In Proceedings of the CIGRE SC A2 Colloquium, Shanghai, China, 20–25 September 2015. [Google Scholar]

- Li, S.; Ge, Z.; Abu-Siada, A.; Yang, L.; Li, S.; Wakimoto, K. A New Technique to Estimate the Degree of Polymerization of Insulation Paper Using Multiple Aging Parameters of Transformer Oil. IEEE Access 2019, 7, 157471–157479. [Google Scholar] [CrossRef]

- Emsley, A.M.; Ali, M.; Xiao, X.; Heywood, R.J. Degradation of cellulosic insulation in power transformers. Part 4: Effects of ageing on the tensile strength of paper. IEEE Proc. Sci. Meas. Technol. 2000, 147, 285–290. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Linhjell, D. Ageing and Restoration of Transformer Windings; SINTEF Energy Research: Trondheim, Norway, 2001; EBL-K EBL-K-43-2001. [Google Scholar]

- Liland, K.; Kes, M.; Glomm Ese, M.-H.; Lundgaard, L.; Christensen, B. Study of oxidation and hydrolysis of oil impregnated paper insulation for transformers using a microcalorimeter. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 2059–2068. [Google Scholar] [CrossRef]

- Vasovic, V.; Lukic, J.; Mihajlovic, D.; Pejovic, B.; Radakovic, Z.; Radoman, U.; Orlovic, A. Aging of transformer insulation—experimental transformers and laboratory models with different moisture contents: Part I—DP and furans aging profiles. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1840–1846. [Google Scholar] [CrossRef]

- El-Aal, R.A.A.; Helal, K.; Hassan, A.M.M.; Dessouky, S.S. Prediction of Transformers Conditions and Lifetime Using Furan Compounds Analysis. IEEE Access 2019, 7, 102264–102273. [Google Scholar] [CrossRef]

- Leibfried, T.; Jaya, M.; Majer, N.; Schafer, M.; Stach, M.; Voss, S. Postmortem Investigation of Power Transformers—Profile of Degree of Polymerization and Correlation with Furan Concentration in the Oil. IEEE Trans. Power Deliv. 2013, 28, 886–893. [Google Scholar] [CrossRef]

- Feng, D.; Yang, L.; Zhou, L.; Liao, R. Influential Factors and Correction Method of Furfural Content in Transformer Oil. IEEE Access 2019, 7, 53487–53495. [Google Scholar] [CrossRef]

- Feng, D.; Yang, L.; Zhou, L.; Liao, R.; Chen, X. Effect of oil–paper–pressboard mass ratio on furfural content in transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1308–1315. [Google Scholar] [CrossRef]

- Fernandez, O.H.A.; Fofana, I.; Jalbert, J.; Gagnon, S.; Rodriguez-Celis, E.; Duchesne, S.; Ryadi, M. Aging characterization of electrical insulation papers impregnated with synthetic ester and mineral oil: Correlations between mechanical properties, depolymerization and some chemical markers. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 217–227. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Aging of Oil-Impregnated Paper in Power Transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Emsley, A.M. The kinetics and mechanisms of degradation of cellulosic insulation in power transformers. Polym. Degrad. Stab. 1994, 44, 343–349. [Google Scholar] [CrossRef]

- Lessard, M.C.; van Nifterik, L.; Masse, M.; Penneau, J.F.; Grob, R. Thermal aging study of insulating papers used in power transformers. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena-CEIDP ‘96, Millbrae, CA, USA, 23 October 1996; Volume 2, pp. 854–859. [Google Scholar]

- Tokunaga, J.; Koide, H.; Mogami, K.; Hikosaka, T. Comparative studies on the aging of thermally upgraded paper insulation in palm fatty acid ester, mineral oil, and natural ester. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 258–265. [Google Scholar] [CrossRef]

- Trnka, P.; Hornak, J.; Prosr, P.; Michal, O.; Wang, F. Various Aging Processes in a Paper-Natural Ester Insulation System in the Presence of Copper and Moisture. IEEE Access 2020, 8, 61989–61998. [Google Scholar] [CrossRef]

- R&S International Holding AG. The 1000th Power Transformer. Available online: https://the-rsgroup.com/the-1000th-power-transformer/ (accessed on 4 May 2021).

- Boerstn Electric Co. Ltd. Hermetically Sealed Three Phase Oil Immersed Power Transformer. Available online: http://www.boerstn.com/hermetically-sealed-3-phase-oil-immersed-power-transformer-15913446741093711.html (accessed on 4 May 2021).

- Tenbohlen, S.; Koch, M. Aging Performance and Moisture Solubility of Vegetable Oils for Power Transformers. IEEE Trans. Power Deliv. 2010, 25, 825–830. [Google Scholar] [CrossRef]

- Muenster, T.; Kinkeldey, T.; Werle, P.; Haemel, K.; Preusel, J. Investigation on the Accelerated Ageing Behaviour of Oil-Paper-Insulation Using Different Insulating Oils. In Proceedings of the VDE High Voltage Technology 2018, ETG-Symposium, Berlin, Germany, 12–14 November 2018; pp. 1–6. [Google Scholar]

- Münster, T.; Kinkeldey, T.; Werle, P.; Hämel, K.; Preusel, J. Investigation on Ageing Parameters of a Thermally Accelerated Aged Paper-Oil-Insulation in a Hermetically Sealed System. In Proceedings of the 2018 Condition Monitoring and Diagnosis (CMD), Bentley, Australia, 23–26 September 2018; pp. 1–6. [Google Scholar]

- Münster, T.; Kinkeldey, T.; Werle, P.; Hämel, K.; Preusel, J. Comparison of a Thermally Accelerated Aged Oil-Paper Insulation of an Open and Hermetically Sealed System. In Proceedings of the 21st International Symposium on High Voltage Engineering; Németh, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1, pp. 777–787. ISBN 978-3-030-31675-4. [Google Scholar]

- Münster, T.; Kinkeldey, T.; Werle, P.; Hämel, K.; Preusel, J. Investigation on the Ageing Behaviour of Ester Impregnated Insulating Paper in a Hermetically Sealed System. In Proceedings of the 2019 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Washington, DC, USA, 20–23 October 2019; pp. 134–137, ISBN ISBN 2576-2397. [Google Scholar]

- Deutsche Institut für Normung e.V. Electrical Insulation Systems (EIS)-Thermal Evaluation of Combined Liquid and Solid Components-Part 2: Simplified Test; Beuth GmbH: Berlin, Germany, 2014; 62332-2:2014-12; Available online: https://www.beuth.de/de/vornorm/din-iec-ts-62332-2/222906506 (accessed on 16 February 2021).

- Brinkmann, C. Die Isolierstoffe der Elektrotechnik; Springer: Berlin/Heidelberg, Germany, 1975; ISBN 9783642809224. [Google Scholar]

- Deutsches Institut für Normung e.V. Method of Sampling Insulating Liquids (IEC 60475:2011); German Version EN 60475:2011; Beuth GmbH: Berlin, Germany, 2012; EN 60475:2012-07; Available online: https://www.beuth.de/de/norm/din-en-60475/152891057 (accessed on 16 February 2021).

- Küchler, A. Hochspannungstechnik: Grundlagen, Technologie, Anwendungen, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 3540784128. [Google Scholar]

- Ese, M.; Liland, K.; Lundgaard, L. Oxidation of paper insulation in transformers. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 939–946. [Google Scholar] [CrossRef]

- Lelekakis, N.; Martin, D.; Wijaya, J. Ageing rate of paper insulation used in power transformers Part 1: Oil/paper system with low oxygen concentration. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1999–2008. [Google Scholar] [CrossRef]

- Oxidation Stability of Insulating Fluids: TECHNICAL BROCHURES; Study Committee: D1, WG D1.30; Cigré: Paris, France, 2013.

- Du, Y.; Mamishev, A.V.; Lesieutre, B.C.; Zahn, M.; Kang, S.H. Moisture solubility for differently conditioned transformer oils. IEEE Trans. Dielect. Electr. Insul. 2001, 8, 805–811. [Google Scholar] [CrossRef]

- Hao, J.; Liao, R.; Chen, G.; Ma, Z.; Yang, L. Quantitative analysis ageing status of natural ester-paper insulation and mineral oil-paper insulation by polarization/depolarization current. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 188–199. [Google Scholar] [CrossRef] [Green Version]

- Matharage, S.Y.; Liu, Q.; Wang, Z.D.; Wilson, G.; Krause, C. Aging assessment of synthetic ester impregnated thermally non-upgraded kraft paper through chemical markers in oil. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 507–515. [Google Scholar] [CrossRef]

- Frimpong, G.; Oommen, T.; Asano, R. A survey of aging characteristics of cellulose insulation in natural ester and mineral oil. IEEE Electr. Insul. Mag. 2011, 27, 36–48. [Google Scholar] [CrossRef]

- Kachler, A.J.; Hohlein, I. Aging of cellulose at transformer service temperatures. Part 1: Influence of type of oil and air on the degree of polymerization of pressboard, dissolved gases, and furanic compounds in oil. IEEE Electr. Insul. Mag. 2005, 21, 15–21. [Google Scholar] [CrossRef]

- Mandlik, M.; Ramu, T.S. Moisture Aided Degradation of Oil Impregnated Paper Insulation in Power Transformers. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 186–193. [Google Scholar] [CrossRef]

- Life Management Techniques for Power Transformers: Technical Brochures; Study Committee: A2, WG A2.18; Cigré: Paris, France, 2013.

- Teymouri, A.; Vahidi, B. CO2/CO concentration ratio: A complementary method for determining the degree of polymerization of power transformer paper insulation. IEEE Electr. Insul. Mag. 2017, 33, 24–30. [Google Scholar] [CrossRef]

- Deutsche Institut für Normung e.V. Mineral Oil-Filled Electrical Equipment in Service-Guidance on the Interpretation of Dissolved and Free Gases Analysis; Beuth GmbH: Berlin, Germany, 2016; EN 60599:2016-10; Available online: https://www.beuth.de/de/norm/din-en-60599/253359747 (accessed on 16 February 2021).

- Recent Developments on the Interpretation of Dissolved Gas Analysis in Transformers: Study Committee: A2, D1, JTF D1.02/A2.11; Cigré: Paris, France, 2006.

- Liao, R.; Guo, C.; Wang, K.; Yang, L.; Grzybowski, S.; Sun, H. Investigation on thermal aging characteristics of vegetable oil-paper insulation with flowing dry air. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1649–1658. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Z.; Grzybowski, S.; Liu, Y. Characteristics of moisture diffusion in vegetable oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1650–1656. [Google Scholar] [CrossRef]

- Ten, C.F.; Fernando, M.A.R.M.; Wang, Z.D. Dielectric properties measurements of transformer oil, paper and pressboard with the effect of moisture and ageing. In Proceedings of the 2007 Annual Report-Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007; pp. 727–730, ISBN 0084-9162. [Google Scholar]

- Darma, I.S. Dielectric properties of mixtures between mineral oil and natural ester. In Proceedings of the 2008 International Symposium on Electrical Insulating Materials (ISEIM 2008), Yokkaichi, Japan, 7–11 September 2008; pp. 514–517. [Google Scholar]

- Deutsche Institut für Normung e.V. Insulating Liquids-Determination of the Breakdown Voltage at Power Frequency-Test Method; Beuth GmbH: Berlin, Germany, 2017; EN 60156:2017-05; Available online: https://www.beuth.de/de/norm-entwurf/din-en-60156/271035585 (accessed on 16 February 2021).

- Shim, M. Comparative evaluation of aging of insulating, material in natural ester and mineral oil. In Proceedings of the 2010 International Conference on High Voltage Engineering and Application, New Orleans, LA, USA, 11–14 October 2010; pp. 393–396. [Google Scholar]

- Koch, M.; Tenbohlen, S.; Stirl, T. Diagnostic Application of Moisture Equilibrium for Power Transformers. IEEE Trans. Power Deliv. 2010, 25, 2574–2581. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Interfacial Tension of Insulating Liquids against Water by the Ring Method (D971-20). Available online: https://www.astm.org/Standards/D971.htm (accessed on 16 February 2021).

- Hadjadj, Y.; Fofana, I.; Sabau, J.; Briosso, E. Assessing insulating oil degradation by means of turbidity and UV/VIS spectrophotometry measurements. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2653–2660. [Google Scholar] [CrossRef]

- Forouhari, S.; Abu-Siada, A. Remnant life estimation of power transformer based on IFT and acidity number of transformer oil. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 552–555, ISBN 2160-9241. [Google Scholar]

- Deutsche Institut für Normung e.V. Insulating Liquids-Determination of acidity-Part 1: Automatic potentiometric titration; Beuth GmbH: Berlin, Germany, 2004; EN 62021-1:2004-06; Available online: https://www.beuth.de/de/norm/din-en-62021-1/71333782 (accessed on 16 February 2021).

- Deutsche Institut für Normung e.V. Insulating Liquids-Determination of Acidity-Part 3: Test Methods for Non Mineral Insulating Oils; Beuth GmbH: Berlin, Germany, 2015; EN 62021-3:2015-05; Available online: https://www.beuth.de/de/norm/din-en-62021-3/228589835 (accessed on 16 February 2021).

- Kouassi, K.; Fofana, I.; Cissé, L.; Hadjadj, Y.; Yapi, K.; Diby, K. Impact of Low Molecular Weight Acids on Oil Impregnated Paper Insulation Degradation. Energies 2018, 11, 1465. [Google Scholar] [CrossRef] [Green Version]

- Lundgaard, L.; Hansen, W.; Ingebrigtsen, S. Ageing of Mineral Oil Impregnated Cellulose by Acid Catalysis. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 540–546. [Google Scholar] [CrossRef]

- Azis, N.; Liu, Q.; Wang, Z.D. Ageing assessment of transformer paper insulation through post mortem analysis. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 845–853. [Google Scholar] [CrossRef]

- Yao, W.; Li, J.; Huang, Z.; Li, X.; Xiang, C. Acids generated and influence on electrical lifetime of natural ester impregnated paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1904–1914. [Google Scholar] [CrossRef]

- Singha, S.; Asano, R.; Frimpong, G.; Claiborne, C.C.; Cherry, D. Comparative aging characteristics between a high oleic natural ester dielectric liquid and mineral oil. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 149–158. [Google Scholar] [CrossRef]

- Deutsche Institut für Normung e.V. Mineralölerzeugnisse-Durchsichtige und undurchsichtige Flüssigkeiten-Bestimmung der kinematischen Viskosität und Berechnung der dynamischen Viskosität; Beuth GmbH: Berlin, Germany, 2021; EN ISO 3104:2021-01; Available online: https://www.beuth.de/de/norm/din-en-iso-3104/323356210 (accessed on 16 February 2021).

- Wilhelm, H.; Tulio, L.; Jasinski, R.; Almeida, G. Aging markers for in-service natural ester-based insulating fluids. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 714–719. [Google Scholar] [CrossRef]

- Deutsche Institut für Normung e.V. Detection and Determination of Specified Additives in Mineral Insulating Oils; Beuth GmbH: Berlin, Germany, 2011; EN 60666:2011-03; Available online: https://www.beuth.de/de/norm/din-en-60666/137571780 (accessed on 16 February 2021).

- Mehanna, N.A.; Jaber, A.; Oweimreen, G.A.; Abulkibash, A.M. Assessment of dibenzyl disulfide and other oxidation inhibitors in transformer mineral oils. IEEE Trans. Dielect. Electr. Insul. 2014, 21, 1095–1099. [Google Scholar] [CrossRef]

- Wada, J.; Ueta, G.; Okabe, S.; Amimoto, T. Inhibition technique of transformer insulating oil degradation-evaluation of the effectiveness of oxidation degradation inhibitors. IEEE Trans. Dielect. Electr. Insul. 2013, 20, 1641–1648. [Google Scholar] [CrossRef]

- Zou, K.H.; Tuncali, K.; Silverman, S.G. Correlation and simple linear regression. Radiology 2003, 227, 617–622. [Google Scholar] [CrossRef] [PubMed]

- Kinkeldey, T.; Muenster, T.; Werle, P.; Nasution, E.F.; Suwarno, S.; Haemel, K.; Preusel, J. Estimation of the Degree of Polymerization (DP) of Oil-Paper Insulated Transformers Using a Novel Fuzzy Logic Algorithm. In Proceedings of the VDE High Voltage Technology 2018, ETG-Symposium, Berlin, Germany, 12–14 November 2018; pp. 1–6. [Google Scholar]

- Kinkeldey, T.; Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Estimation of the Ageing Condition of Oil-Filled Transformers Based on the Oil Parameters Using a Novel Fuzzy Logic Algorithm. In Proceedings of the 21st International Symposium on High Voltage Engineering; Németh, B., Ed.; Springer: Cham, Germany, 2020; Volume 1, pp. 926–936. ISBN 978-3-030-31676-1. [Google Scholar]

- Deutsche Institut für Normung e.V. Measurement of the Average Viscometric Degree of Polymerization of New and Aged Cellulosic Electrically Insulating Materials; Beuth GmbH: Berlin, Germany, 2008; EN 60450:2008-03; Available online: https://www.beuth.de/de/norm/din-en-60450/104350320 (accessed on 16 February 2021).

- Schreiter, S.; Kinkeldey, T.; Lohmeyer, H.; Werle, P.; Münster, T.; Hämel, K.; Preusel, J. Anwendung eines Fuzzy-Logik-Algorithmus für die Lebensdauerabschätzung von Transformatoren im Betrieb: VDE Hochspannungstechnik, ETG-Fachtagung, 9–11 November 2020, Online-Veranstaltung; VDE GmbH: Berlin, Germany, 2020; ISBN 9783800753536. [Google Scholar]

- Kinkeldey, T.; Schreiter, S.; Lohmeyer, H.; Werle, P.; Münster, T.; Hämel, K.; Preusel, J. Furankonzentrationen vs. Fuzzy-Logik: Ein neuer Vorschlag zu Abschätzung des DP-Wertes von Leistungstransformatoren: VDE Hochspannungstechnik, ETG-Fachtagung, 9–11. November 2020, Online-Veranstaltung; VDE GmbH: Berlin, Germany, 2020; ISBN 9783800753536. [Google Scholar]

- SI Analytics GmbH. GEBRAUCHSANLEITUNG Originalversion OPERATING MANUAL: TitroLine® 7500 KF trace TITRATOR. Available online: https://www.xylemanalytics.com/de/File%20Library/Resource%20Library/SIA/01%20Manuals/INT/TL-7500KF_Operating%20Instructions_1.7-MB_German-English-PDF.pdf (accessed on 2 May 2021).

- Deutsche Institut für Normung e.V. Petroleum Products-Determination of Water Content Using Titration According to Karl Fischer; Beuth GmbH: Berlin, Germany, 2020; 51777:2020-04; Available online: https://www.beuth.de/de/norm/din-51777/315541277 (accessed on 2 May 2021).

- Energy Support GmbH. Bedienungsanleitung TOGA GC, Gaschromatograph für Gas-in-Öl-Analysen; Energy Support GmbH: Neuss, Germany, 2007. [Google Scholar]

- Deutsche Institut für Normung e.V. Insulating Liquids-Measurement of Relative Permittivity, Dielectric Dissipation Factor (tan δ) and d.c. Resistivity; Beuth GmbH: Berlin, Germany, 2005; EN 60247:2005-01; Available online: https://www.beuth.de/de/norm/din-en-60247/75943339 (accessed on 2 May 2021).

- BAUR GmbH. DTL C: BAUR Verlustfaktor- und Widerstandsmessgerät für Isolieröle. Available online: https://baur.at/XooWebKit/bin/download.php/cf3a7_d6a960c48d/DS_Oil%20tan%20delta%20resistivity%20tester_DTL%20C_BAUR_de-de.pdf (accessed on 2 May 2021).

- b2 electronic GmbH. BA100: Portable and Laboratory Based Oil Test Set. User Manual. Available online: http://www.b2hv.cn/wp-content/themes/b2hv_new/fileadmin/images_page/img_right/downloads/Datasheet-b2-BA100-DHV1207-Rev03.pdf (accessed on 2 May 2021).

- Biolin Scientific. Force Tensiometers: The Complete Range Of Du Noüy Ring and Wilhelmy Plate Tensiometers. Available online: https://www.strath.ac.uk/media/departments/mechanicalengineering/compositematerials/officedocuments/Sigma_force_701.pdf (accessed on 2 May 2021).

- SI Analytics GmbH. Gebrauchsanleitung Originalversion: TitroLine® 6000/7000 TITRATOR. Available online: https://www.xylemanalytics.com/en/File%20Library/Resource%20Library/SIA/01%20Manuals/GER/TitroLine-6000_7000_Deutsch.pdf (accessed on 2 May 2021).

- D02 Committee. Test Method for Low-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants Using a Rotational Viscometer; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Brookfield Engineering Laboratories, INC. Brookfield DV2T Viscometer: Operating Instructions. Manual No. M13-167-B0614. Available online: https://www.brookfieldengineering.com/-/media/ametekbrookfield/manuals/lab%20viscometers/dv2t%20instructions.pdf?la=en (accessed on 2 May 2021).

| Sample Number (per Oil and System) | Aging Time (Weeks) | Aging Time (Hours) |

|---|---|---|

| 1 | 0 | 0 |

| 2 | 1 | 168 |

| 3 | 2 | 336 |

| 4 | 3 | 504 |

| 5 | 4 | 672 |

| 6 | 6 | 1008 |

| 7 | 8 | 1344 |

| 8 | 10 | 1680 |

| 9 | 12 | 2016 |

| 10 | 15 | 2520 |

| Aging Marker | Measuring Device/Laboratory | Standard |

|---|---|---|

| Degree of polymerization (DP value) | Analysen Service GmbH Umwelt- und Öllabor Leipzig | IEC 60450 |

| Moisture wabs | TitroLine 7500 KF (SI Analytics GmbH) | DIN 51777 |

| CO and CO2 (DGA) | TOGA GC (Energy Support GmbH) | IEC 60475/IEC 60599 |

| Dissipation factor tan δ | BAUR DTL C (BAUR GmbH) | IEC 60247 |

| Relative permittivity εr | BAUR DTL C (BAUR GmbH) | IEC 60247 |

| Breakdown voltage UD | Breakdown Analyzer BA100 (b2 electronics GmbH) | IEC 60156 |

| Interfacial tension σ | Sigma 702ET (Biolin Scientific Ab) | ASTM D971 |

| Acidity | TitroLine 7000 (SI Analytics GmbH) | IEC 62021-1/IEC 62021-3 |

| Dynamic viscosity η | Brookfield DV2Textra (AMETEK Brookfield) | ASTM D2983 |

| Inhibitor content | Analysen Service GmbH Umwelt- und Öllabor Leipzig | IEC 60666 |

| Correlation Coefficient | Description |

|---|---|

| |r| < 0.2 | Very weak correlation |

| 0.2 ≤ |r| < 0.5 | Weak correlation |

| 0.5 ≤ |r| < 0.8 | Mean correlation |

| 0.8 ≤ |r| < 1.0 | Strong correlation |

| Parameter | Unit | Uninhibited Oil | Inhibited Oil | Synthetic Ester | Natural Ester | ||

|---|---|---|---|---|---|---|---|

| Open (≈700 h) | Closed (≈700 h) | Open (≈250 h) | Closed (≈250–700 h) | Closed (≈300 h) | Closed (≈700 h) | ||

| Acid value | mg KOH/g | 0.2 | 0.07 | 0.02 | 0.03–0.06 | 0.03 | 0.1 |

| IFT | mN/m | 21 | 35 | 40 | 37 | - | - |

| 42 | 44 | ||||||

| tan δ (25 °C) | 0.016 | 0.002 | 8 × 10−5 | 3 × 10−4 | 0.002 | 0.005 | |

| 4 × 10−6 | 1 × 10−6 | ||||||

| Rel. Permittivity (25 °C) | 2.2 | 2.18 | 2.18 | 2.18 | 3.18 | 3.11 | |

| - | 2.08 | ||||||

| CO | ppm | 1000 | 3000 | 700 | 2900 | 1800 | 1800 |

| 500 | 600 | ||||||

| CO2 | ppm | 2000 | 30,000 | 4000–5000 | 26,000 | 30,000 | 22,000 |

| 2500–3500 | 4000–8000 | ||||||

| CO2/CO | 3.25 | 12–15 | 7.00 | 7–12 | 12–14 | 14.00 | |

| Dyn. Viscosity (10 °C) | mNs/m² | 30 | - | - | - | - | - |

be exceeded

be exceeded  fallen short of

fallen short of  healthy range

healthy range  poor range

poor range| Parameter | Unit | Uninhibited Oil | Inhibited Oil | Synthetic Ester | Natural Ester | ||

|---|---|---|---|---|---|---|---|

| Open (>2500 h) | Closed (>2500 h) | Open (≈1000 h) | Closed (>2500 h) | Closed (>2500 h) | Closed (>2500 h) | ||

| Acid value | mg KOH/g | 0.35 | 0.15 | 0.15 | 0.15 | 0.37 | 0.8 |

| 0.03–0.06 | 0.09–0.13 | ||||||

| IFT | mN/m | 17.5 | 32 | 27.5 | 27.5 | -- | -- |

| 40 | 40 | ||||||

| tan δ (25 °C) | - | - | 0.04 | 0.06 | - | - | |

| 0.001 | 0.001 | ||||||

| Rel. Permittivity (25 °C) | 2.24 | 2.19 | - | - | 3.2 | - | |

| CO | ppm | 1250 | 3500 | 850 | 3250 | 3000 | 5000 |

| CO2 | ppm | 5000 | 50,000 | 2400–4000 | (2–4) × 104 | 40,000 | (2–4) × 104 |

| CO2/CO | 2–4 | 3–15 | 6–12.5 | 5–15 | 14–19 | 8–22 | |

| Dyn. Viscosity (10 °C) | mNs/m² | 31.6 | 29 | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Thermally Accelerated Aging of Insulation Paper for Transformers with Different Insulating Liquids. Energies 2021, 14, 3036. https://doi.org/10.3390/en14113036

Münster T, Werle P, Hämel K, Preusel J. Thermally Accelerated Aging of Insulation Paper for Transformers with Different Insulating Liquids. Energies. 2021; 14(11):3036. https://doi.org/10.3390/en14113036

Chicago/Turabian StyleMünster, Tobias, Peter Werle, Kai Hämel, and Jörg Preusel. 2021. "Thermally Accelerated Aging of Insulation Paper for Transformers with Different Insulating Liquids" Energies 14, no. 11: 3036. https://doi.org/10.3390/en14113036

APA StyleMünster, T., Werle, P., Hämel, K., & Preusel, J. (2021). Thermally Accelerated Aging of Insulation Paper for Transformers with Different Insulating Liquids. Energies, 14(11), 3036. https://doi.org/10.3390/en14113036