Research and Development of the Oxy-Fuel Combustion Power Cycles with CO2 Recirculation

Abstract

1. Introduction

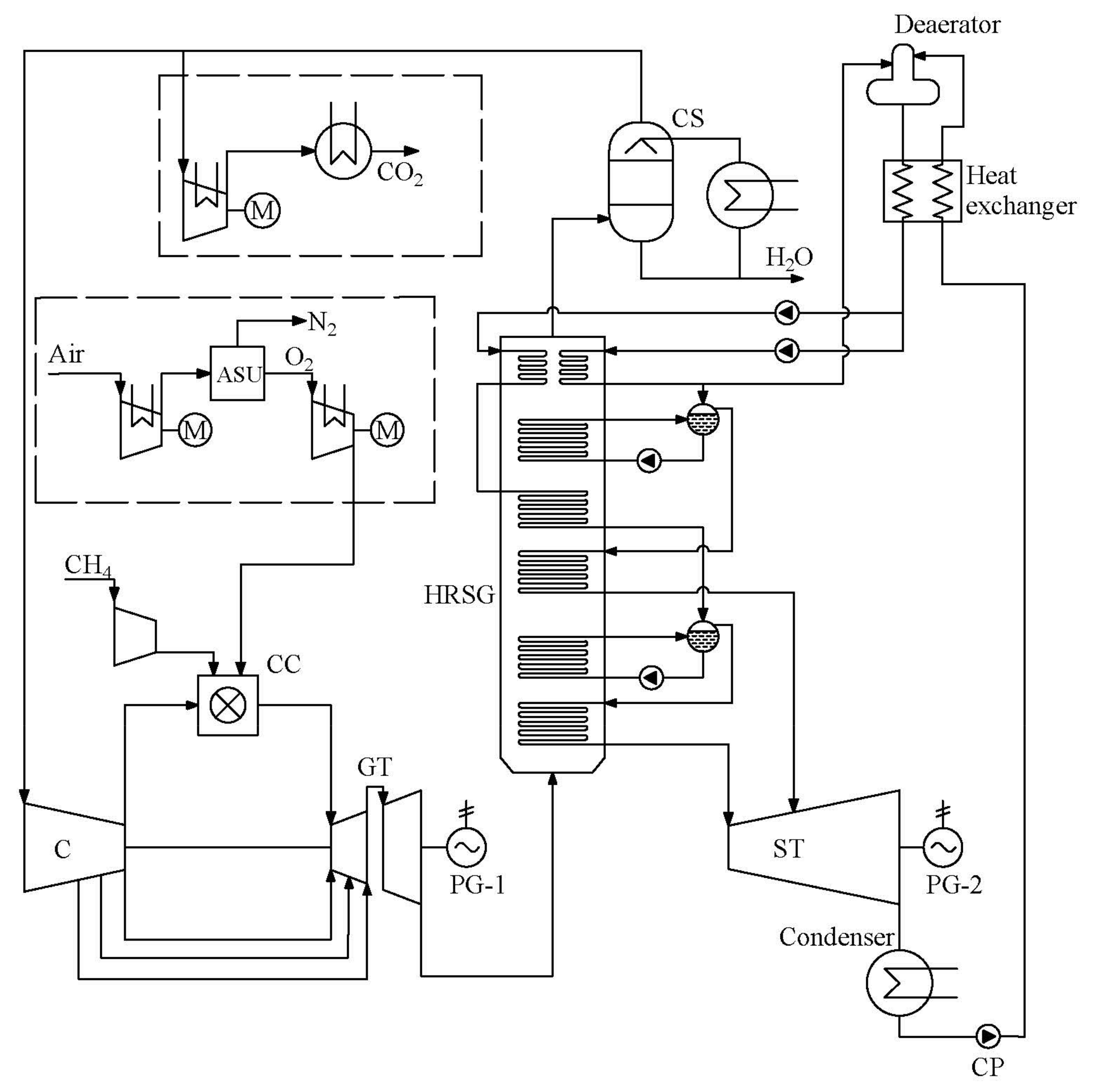

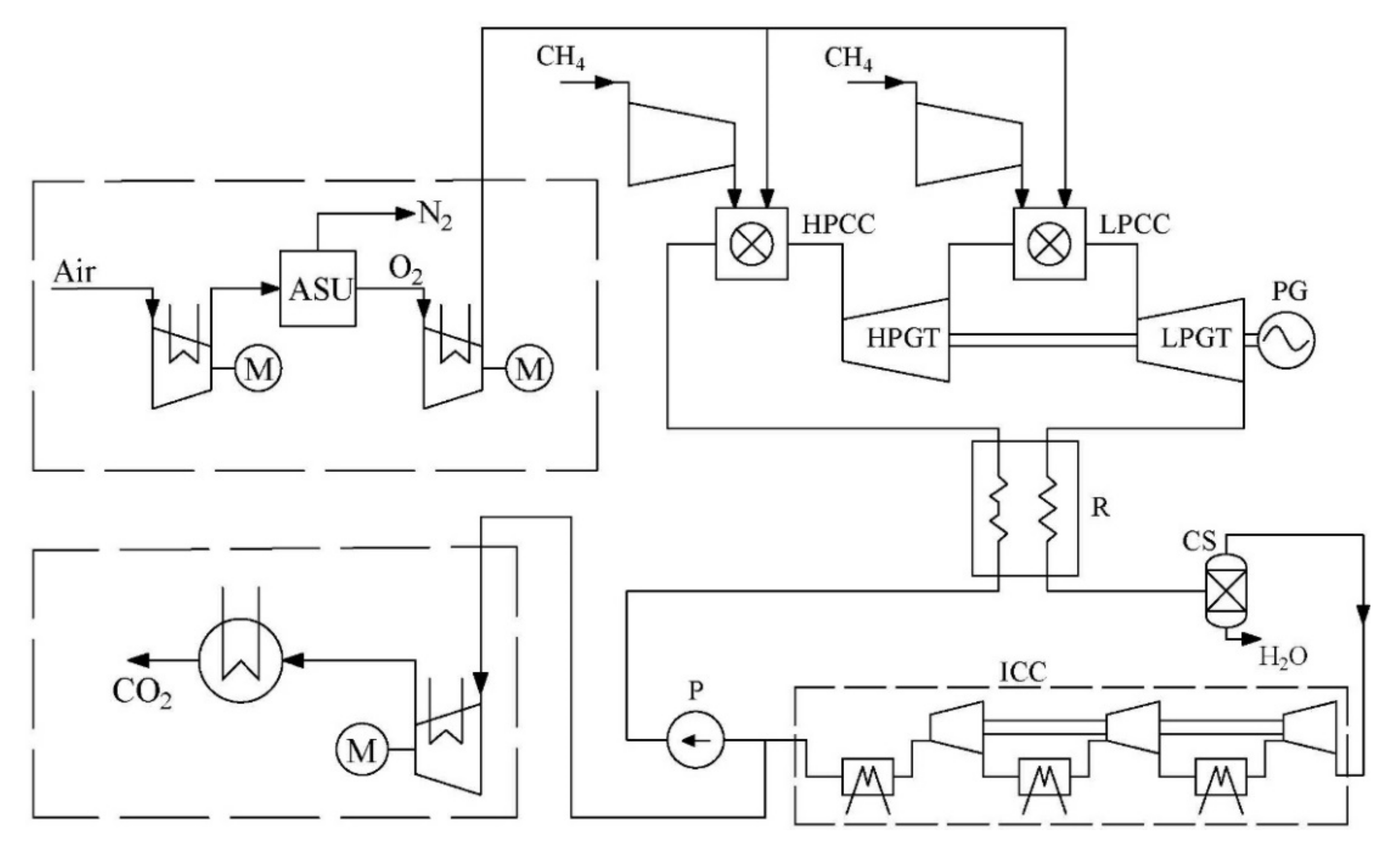

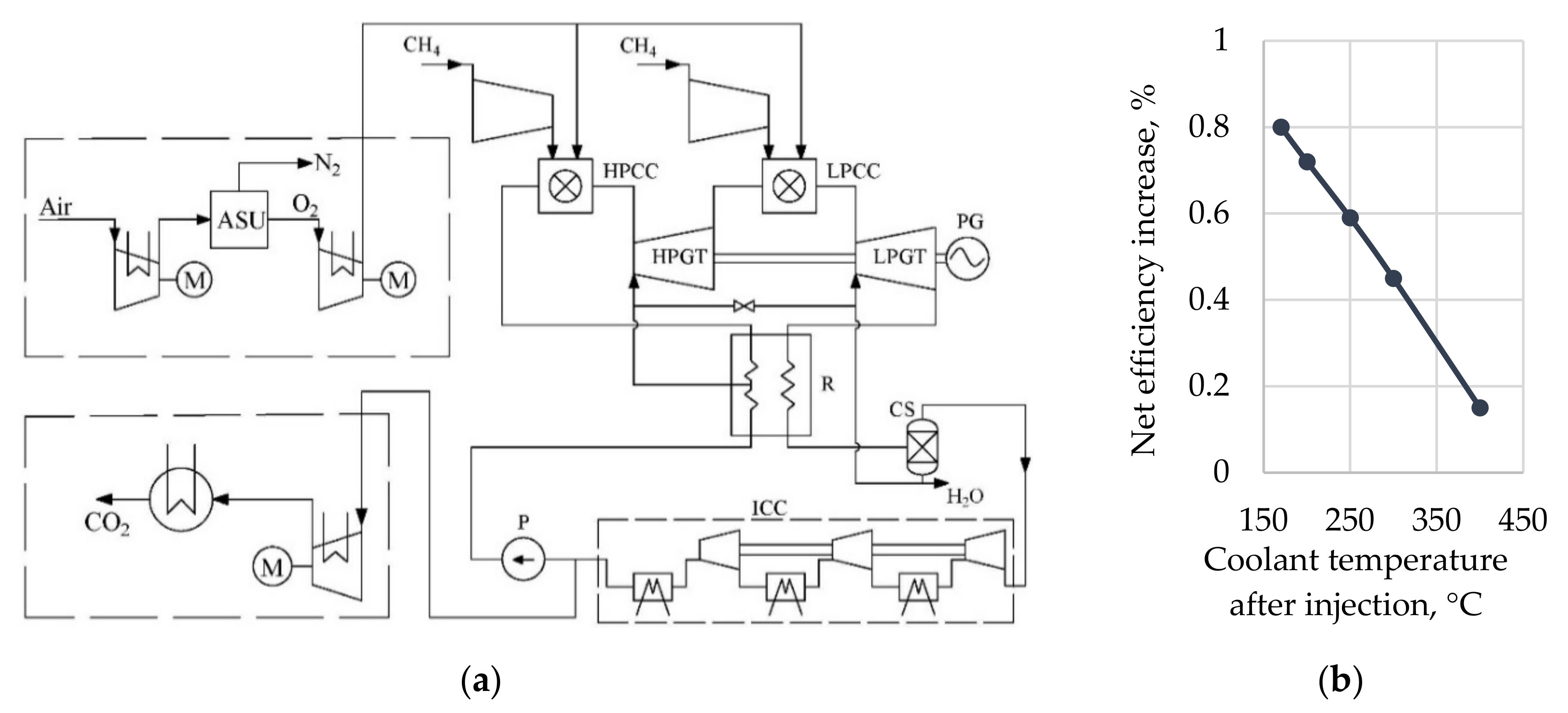

2. Basic Schemes and Initial Parameters for Simulation of the Oxy-Fuel Combustion Power Cycles

3. Methodology

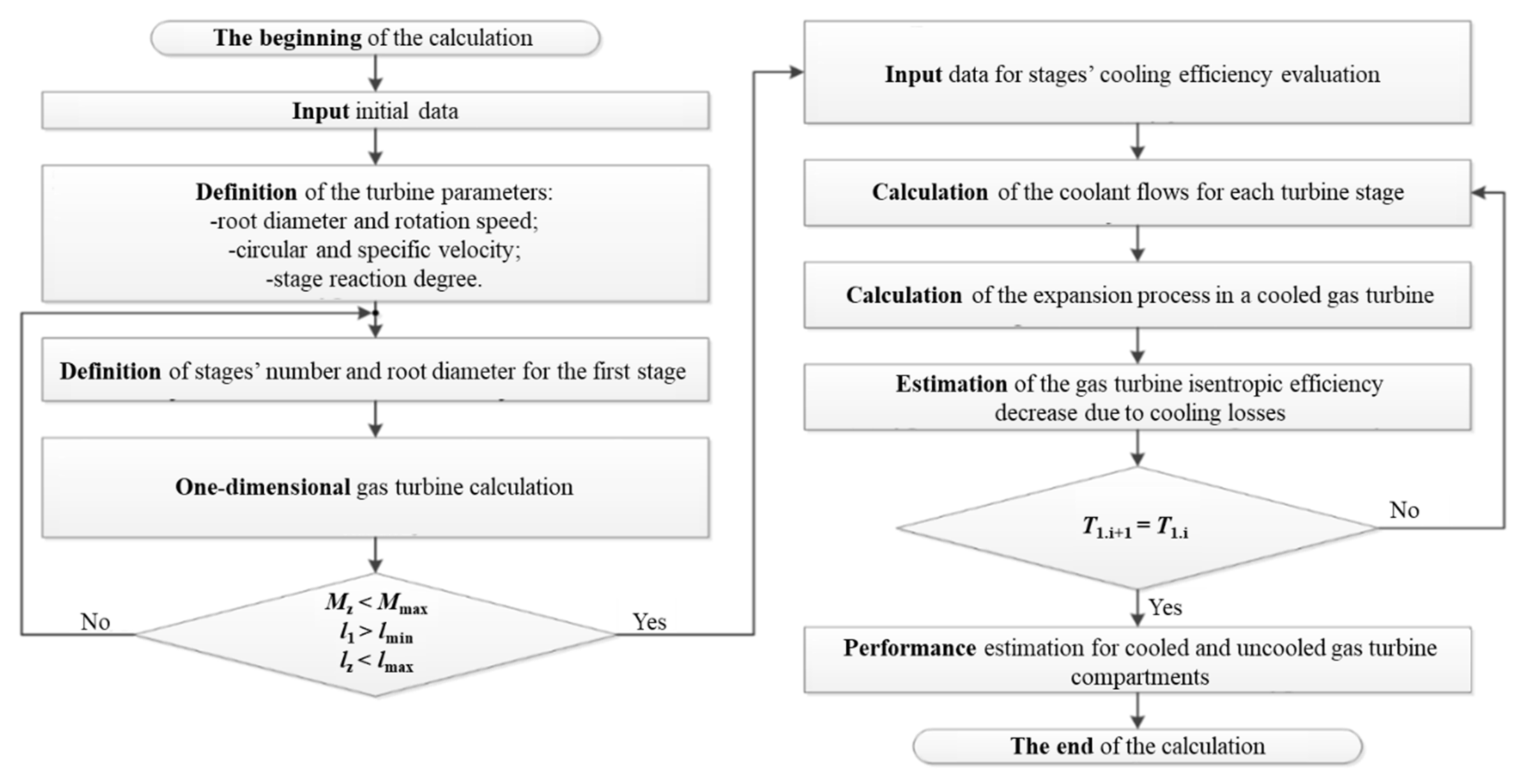

3.1. Mathematical Model and Calculation Algorithm for the Investigation of the Oxy-Fuel Combustion Power Cycle

- An air separation unit that produces high purity oxygen (mathematical model of ASU was developed using MATLAB software [24]).

- A semiclosed gas turbine cycle (SCGTC) producing electricity (mathematical models of cycles were developed using AspenONE [25] and MATLAB software).

- A multistaged intercooled compressor that compresses carbon dioxide before storage (mathematical model of ICC was developed using AspenONE software).

3.2. Mathematical Model of the Air Separation Unit

3.3. Mathematical Model of the Cooled Carbon Dioxide Gas Turbine

- Turbine inlet/exit thermodynamic parameters.

- The noncooled turbine flowpath specific internal efficiency ηoi.

- Main fluid massflow at the turbine inlet D0 or the turbine electric power Ne.

- Selection of the cooling system scheme.

- Selection of the cooling system type, open or closed.

- Maximal acceptable blade surface temperature.

4. Results and Discussion

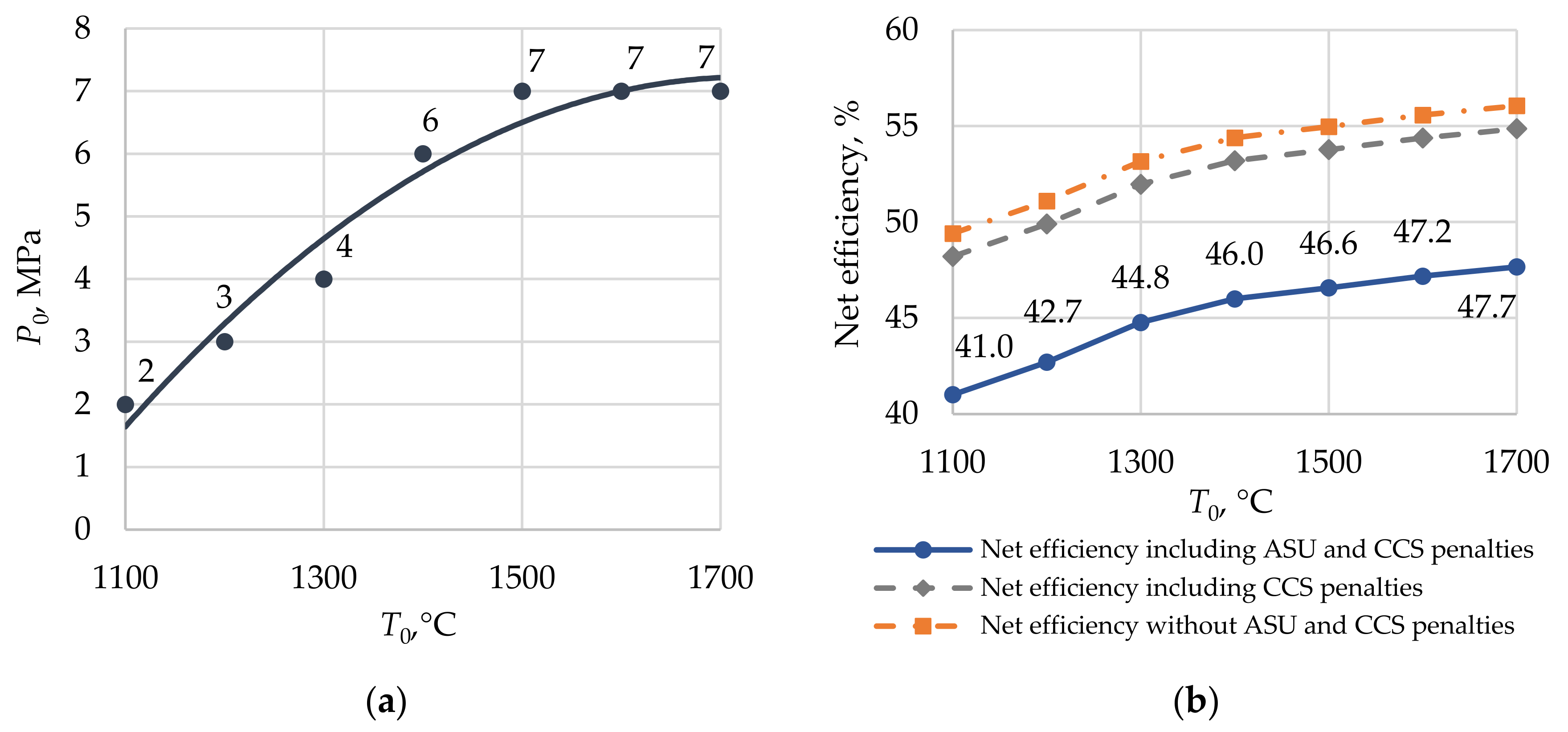

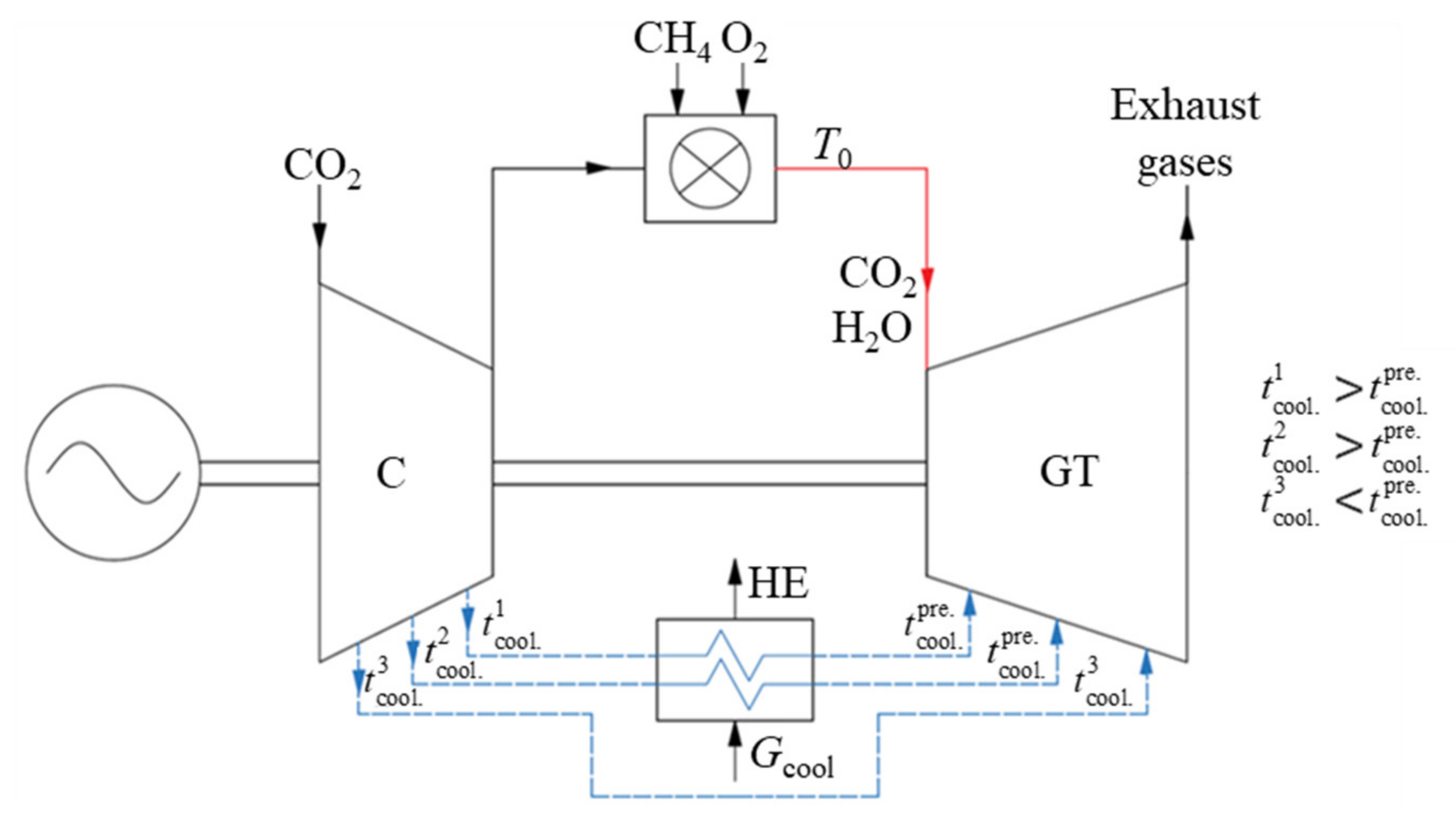

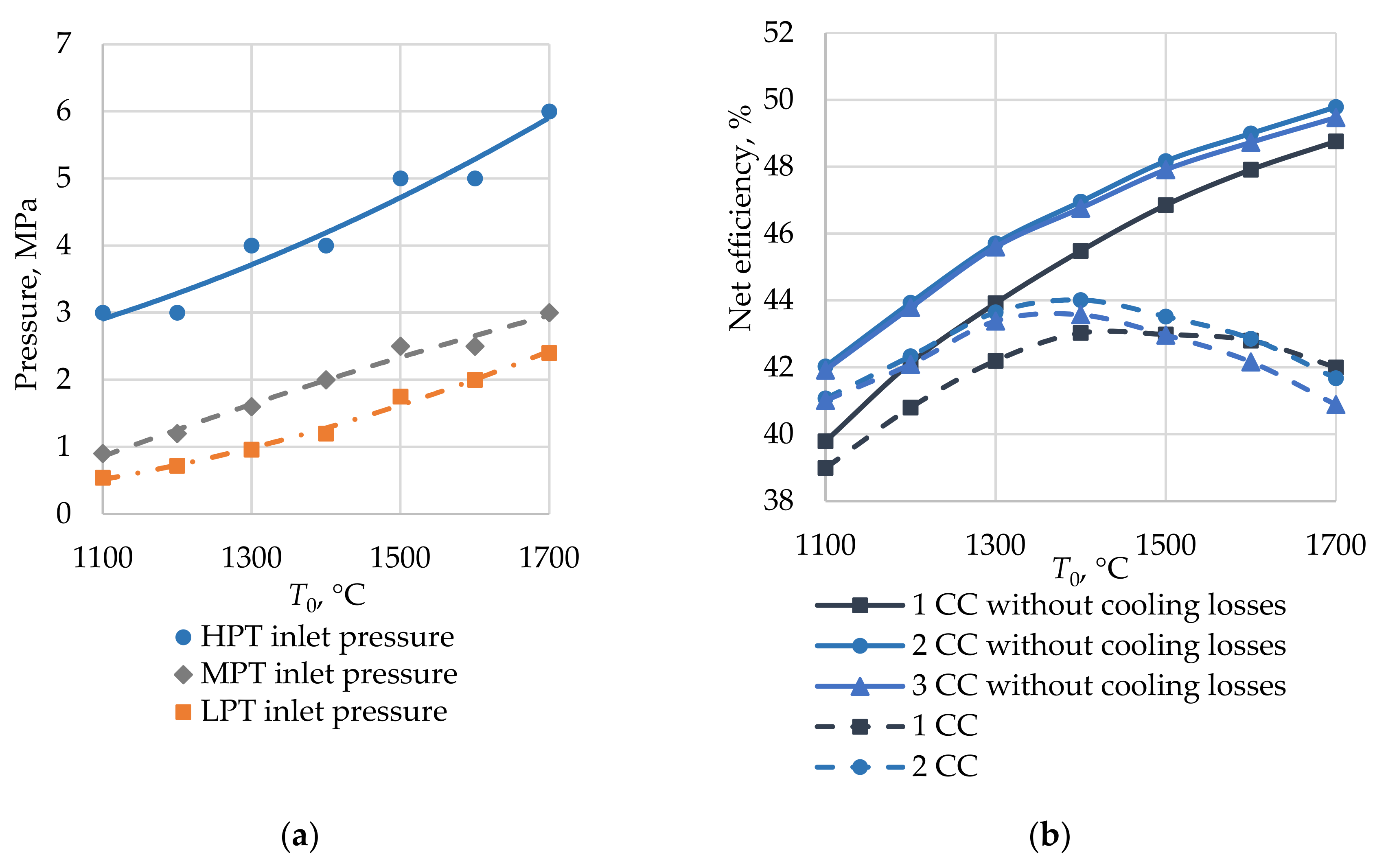

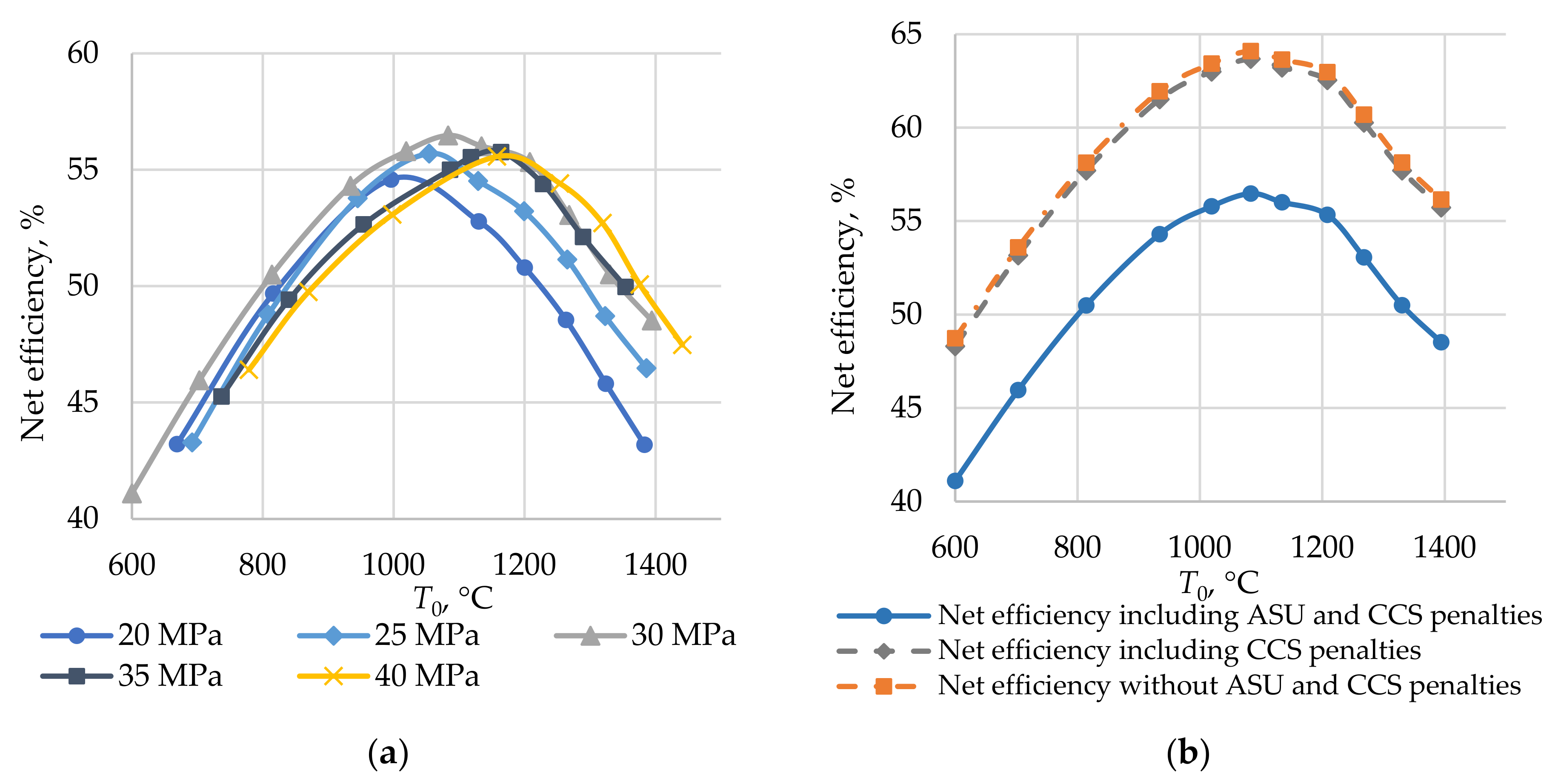

4.1. Structural and Parametric Optimization of the Semiclosed Oxy-Fuel Combustion Combined Cycle

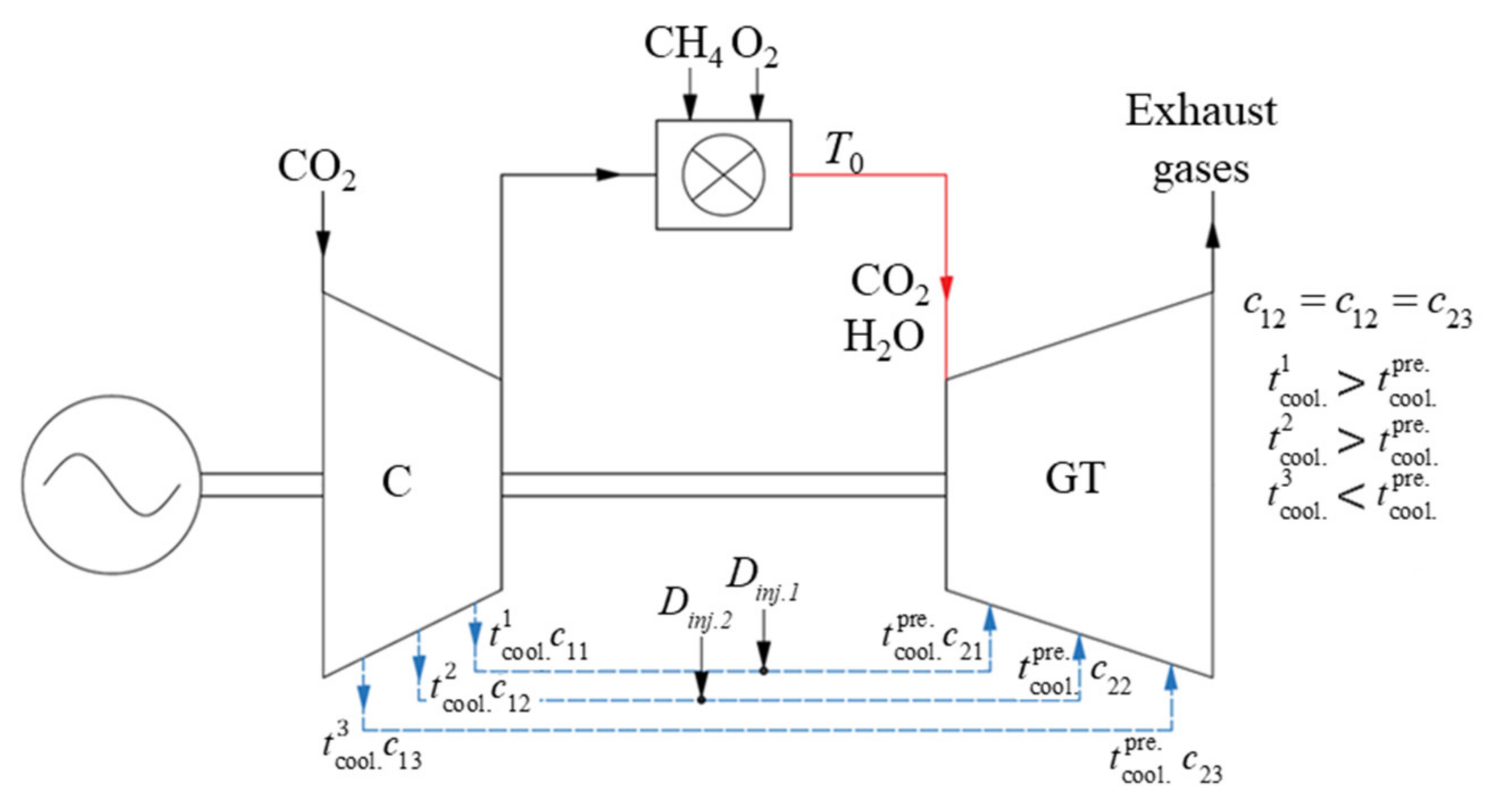

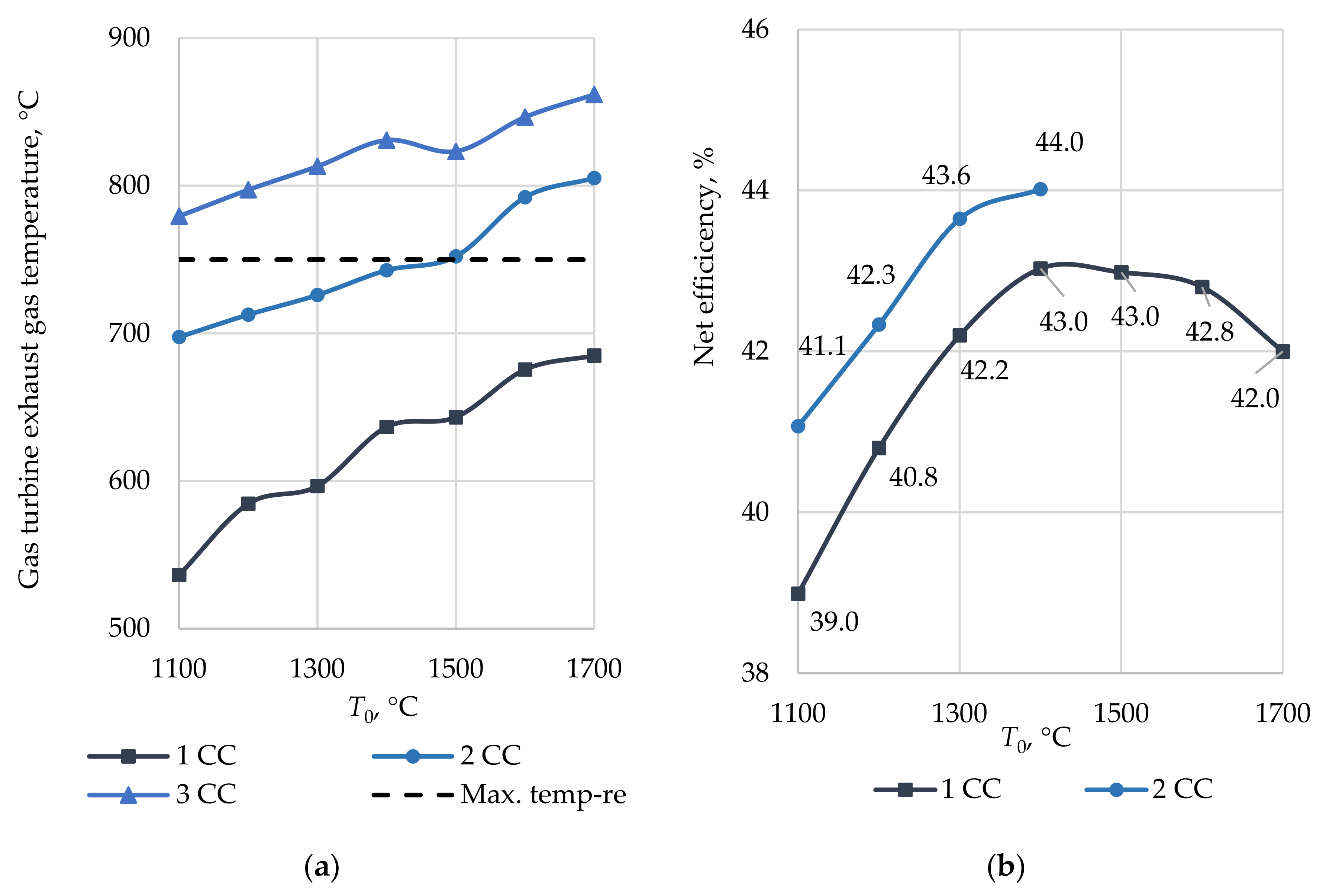

4.2. Structural and Parametric Optimization of the E-MATIANT Cycle

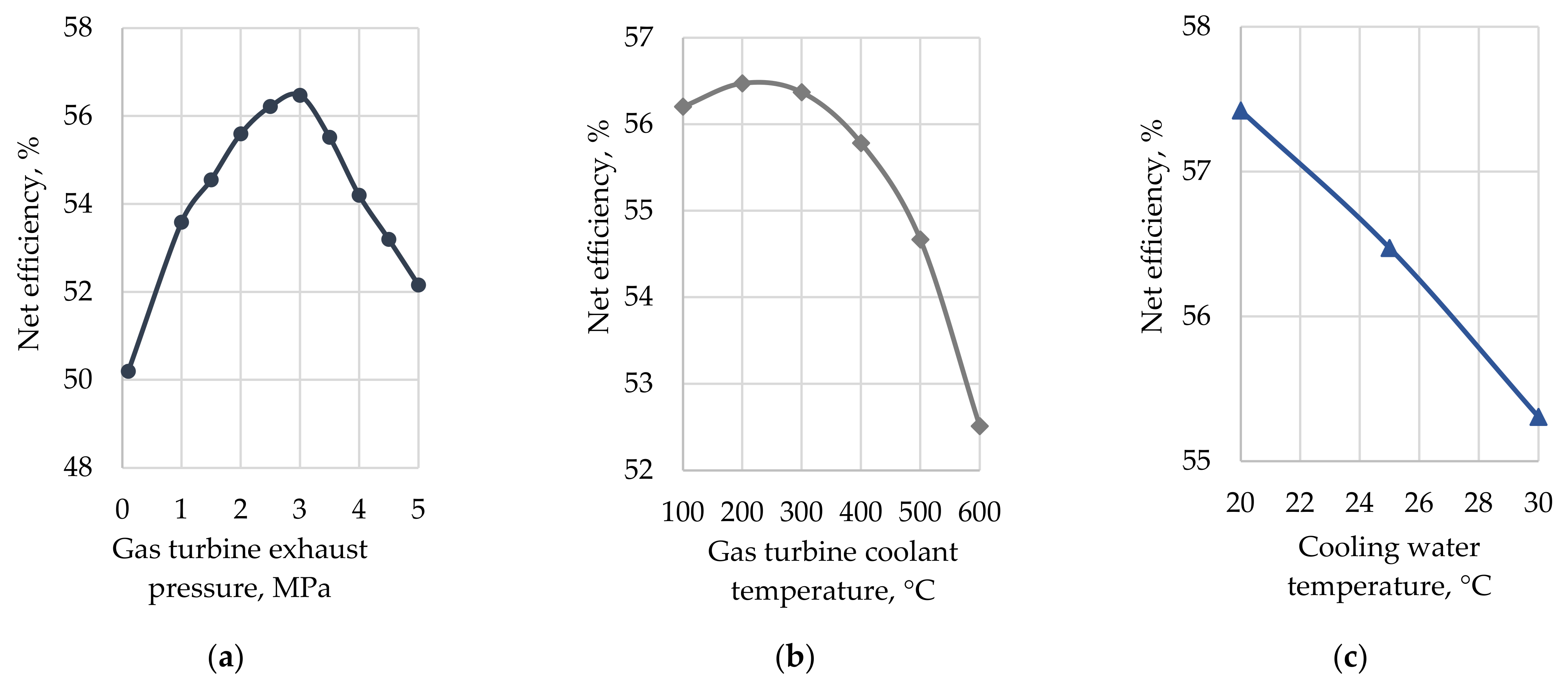

4.3. Parametric Optimization of the Allam Cycle

- Initial temperature of 1083 °C

- Initial pressure of 30 MPa

- Gas turbine exit pressure of 3 MPa

- Coolant temperature of 200 °C

- Coolant specific massflow of 7.7%

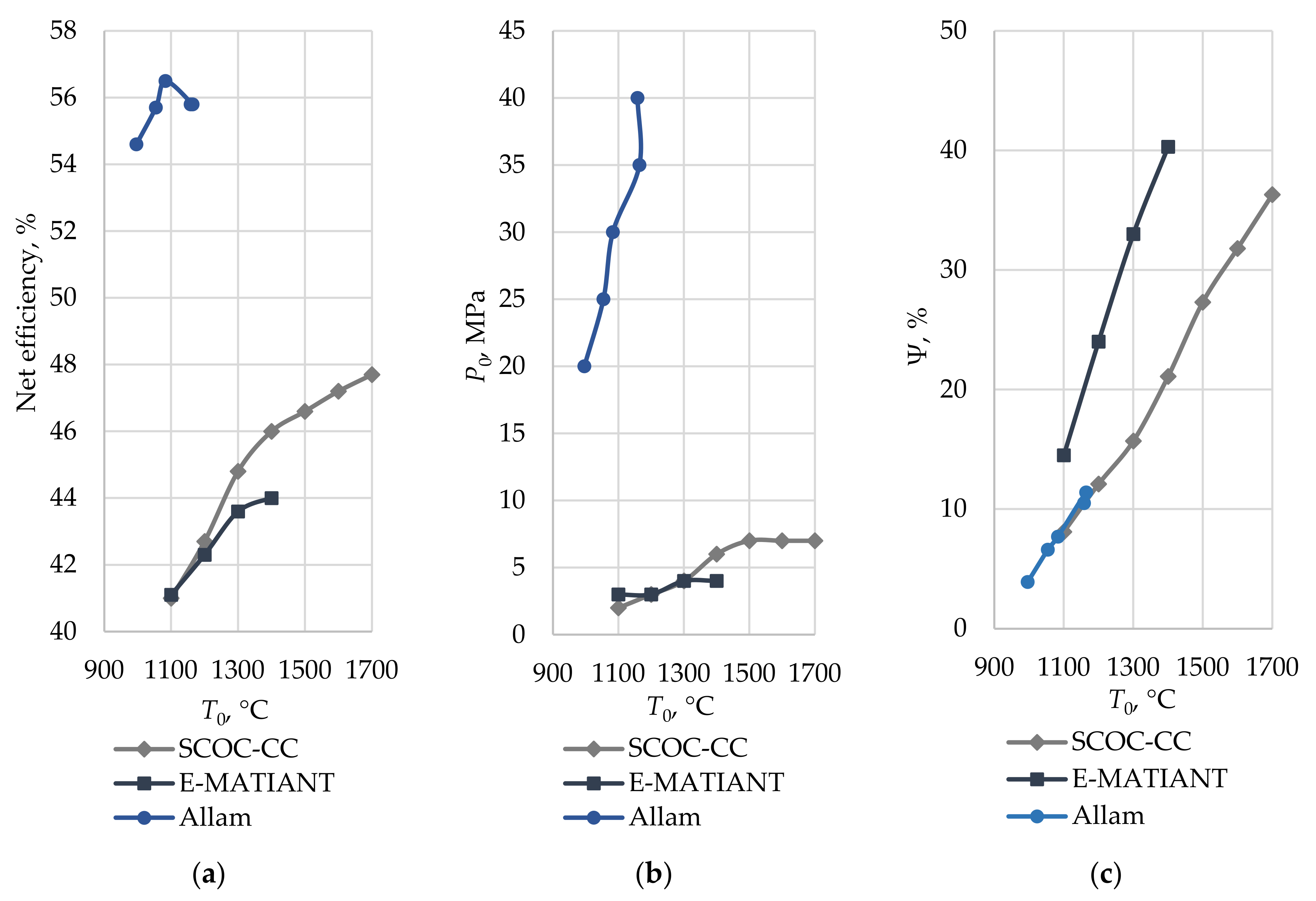

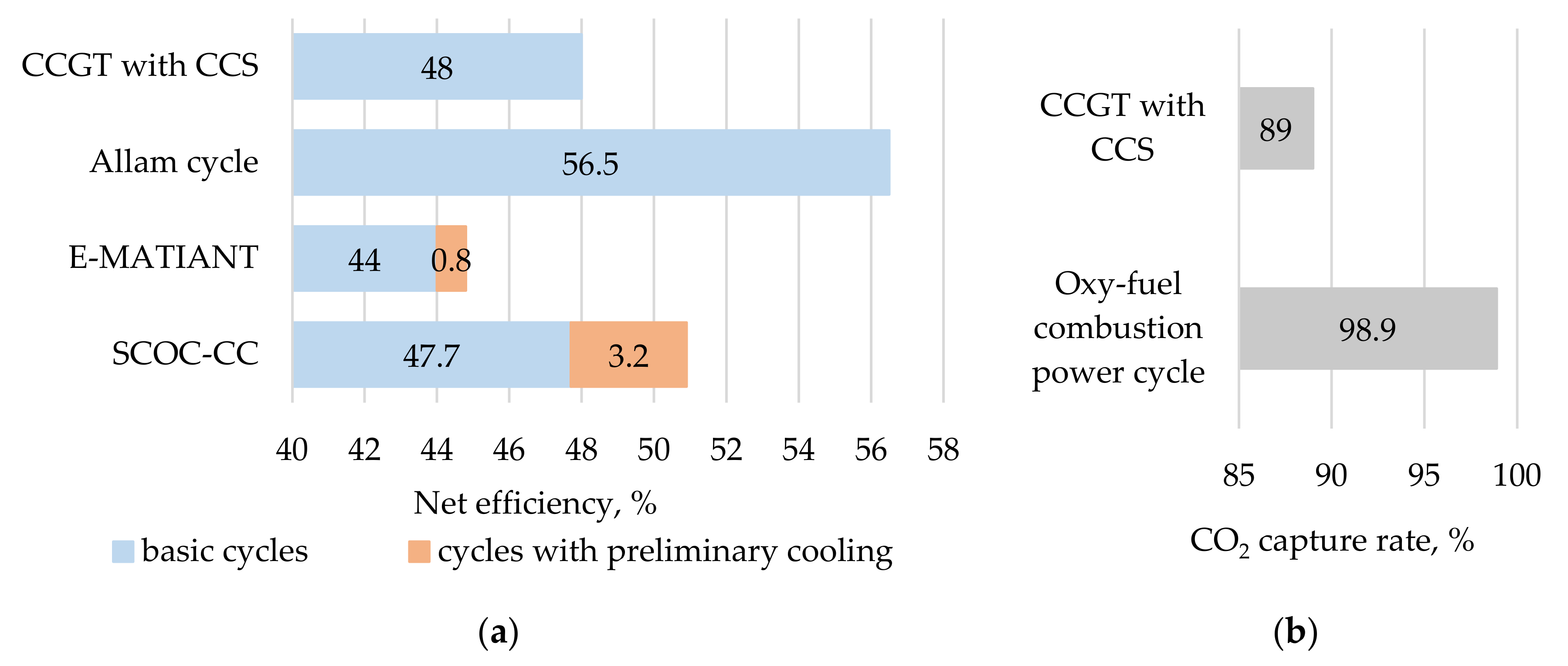

4.4. Oxy-Fuel and Combined Cycle with CO2 Storage Facilities Parameters Comparison

- An increase of the SCOC-CC initial temperature from 1100 to 1700 °C causes the optimal pressure to increase from 2 to 7 MPa, the coolant massflow to increase from 8.1 to 36%, and results in the net efficiency to increase from 41.0 to 47.7%.

- An increase of the E-MATIANT cycle initial temperature from 1100 to 1400 °C causes the optimal pressure increase from 3 to 4 MPa, the coolant massflow to increase from 14.5 to 40.3%, and causes the results in the net efficiency to increase from 41.1 to 44.0%.

- An increase of the Allam cycle initial temperature from 1000 to 1100 °C causes the optimal pressure increase from 20 to 31 MPa, coolant massflow increase from 3.9 to 8.5%, and results in the net efficiency increase from 54.6 to 56.3%.

- SCOC-CC working fluid initial parameters of 1700 °C/7 MPa.

- E-MATIANT cycle working fluid parameters at high and low pressure turbine inlets of 1400 °C/4/2 MPa, and the temperature of the working fluid bleeding from the regenerator for the turbine cooling of 400 °C.

- The Allam cycle working fluid initial parameters of 1083 °C/30 MPa, the turbine exhaust pressure of 3 MPa, and the temperature of working fluid bleeding from the regenerator for the turbine cooling of 200 °C.

- SCOC-CC with cooling in the surface heat exchanger, where the cooling agent is a part of the steam turbine condensate and improves the net efficiency by 3.2%, which is reasonable to apply for the coolant to cool down to 150–250 °C.

- SCOC-CC with cooling by the water injection: the water is bled from the gas cycle cooler-separator and is injected into the coolant flow to reduce its temperature down to 250 °C. The net efficiency increase is up to 1.5%.

- The E-MATIANT cycle with the low pressure turbine coolant taken from the regenerator and cooled by injection of the water bleed from the cooler-separator. The net efficiency grows by 0.8%.

- The working fluid is compressed near the CO2 saturation line, which reduces the compressor drive power consumption.

- The useful utilization in the regenerator of low potential heat reduces heat losses in the cold source.

- Minimal gas turbine coolant flow caused by the moderate initial temperature.

- Minimal power consumption for the compression of the separated content due to the high final pressure.

5. Conclusions

- The developed set of algorithms, methods, and recommendations for oxy-fuel combustion power cycle simulation allow for the calculation of thermal efficiency, including cooling losses in a high temperature turbine, and the power and fluid flow transition between the power production compartment and the air separation unit.

- Structural and parametric optimization of the oxy-fuel combustion power cycles with carbon dioxide working fluid was carried out for the initial temperature ranges from 1100 to 1700 °C. An influence of the initial temperature and pressure on cycles’ performance was estimated. Optimal parameter combinations providing maximum net efficiency were identified. Significant values of the coolant massflow were identified for the SCOC-CC and E-MATIANT cycles working at initial temperatures higher than 1200 °C.

- Several new technical solutions improving oxy-fuel combustion power cycles’ efficiency were suggested consisting in preliminary cooling of the coolant flow in the surface heat exchanger and by the water injection. The calculation results confirmed the possibility to increase cycles’ efficiency by 0.8–3.2% by reducing gas turbine cooling losses.

- The analysis results show that the Allam cycle is one of the most effective oxy-fuel technologies. The cycle net efficiency is 8.5% higher than the combined cycle with carbon dioxide capturing, the carbon dioxide emission is 11–12 times smaller, and the installed power cost is 46% lower. However, the Allam cycle design efficiency remarkably depends on the simulation conditions of a multiflow regenerative heat exchanger. The efficiency estimations disclosed here may be applied when the regenerator is considered as a united heat exchanging device. In further studies, it is reasonable to design, in detail, the multiflow heat exchanging system, and to re-evaluate the thermal efficiency of the prospective oxy-fuel combustion power cycle operating with supercritical carbon dioxide.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Energy Outlook 2018; IEA: Paris, France, 2018.

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sust. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Dutka, M.; Ditaranto, M.; Løvås, T. Application of a central composite design for the study of NOx emission performance of a low NOx burner. Energies 2015, 8, 3606–3627. [Google Scholar] [CrossRef]

- Volchyn, I.A.; Haponych, L.S. Estimate of the sulfur dioxide concentration at thermal power plants fired by Donetsk coal. Power Technol. Eng. 2014, 48, 218–221. [Google Scholar] [CrossRef]

- Jo, H.; Kang, K.; Park, J.; Ryu, C.; Ahn, H.; Go, Y. Optimization of air distribution to reduce NOx emission and unburned carbon for the retrofit of a 500 MWe tangential-firing coal boiler. Energies 2019, 12, 3281. [Google Scholar] [CrossRef]

- Loo, L.; Konist, A.; Neshumayev, D.; Pihu, T.; Maaten, B.; Siirde, A. Ash and flue gas from oil shale oxy-fuel circulating fluidized bed combustion. Energies 2018, 11, 1218. [Google Scholar] [CrossRef]

- Fuller, A.; Maier, J.; Karampinis, E.; Kalivodova, J.; Grammelis, P.; Kakaras, E.; Scheffknecht, G. Fly ash formation and characteristics from (co-) combustion of an herbaceous biomass and a Greek lignite (low-rank coal) in a pulverized fuel pilot-scale test facility. Energies 2018, 11, 1581. [Google Scholar] [CrossRef]

- Liu, H.; Yüksel, S.; Dinçer, H. Analyzing the criteria of efficient carbon capture and separation technologies for sustainable clean energy usage. Energies 2020, 13, 2592. [Google Scholar] [CrossRef]

- Cherednichenko, O.; Havrysh, V.; Shebanin, V.; Kalinichenko, A.; Mentel, G.; Nakonieczny, J. Local green power supply plants based on alcohol regenerative gas turbines: Economic and environmental aspects. Energies 2020, 13, 2156. [Google Scholar] [CrossRef]

- Pfaff, I.; Oexmann, J.; Kather, A. Optimised integration of post-combustion CO2 capture process in greenfield power plants. Energy 2010, 35, 4030–4041. [Google Scholar] [CrossRef]

- Abu-Zahra, M.R.M.; Schneiders, L.H.J.; Niederer, J.P.M.; Feron, P.H.M.; Versteeg, G.F. CO2 capture from power plants: Part I. A parametric study of the technical performance based on monoethanolamine. Int. J. Greenh. Gas Con. 2007, 1, 37–46. [Google Scholar] [CrossRef]

- Adu, E.; Zhang, Y.D.; Liu, D.; Tontiwachwuthikul, P. Parametric process design and economic analysis of post-combustion CO2 capture and compression for coal- and natural gas-fired power plants. Energies 2020, 13, 2519. [Google Scholar] [CrossRef]

- Barba, F.C.; Sanchez, G.M.-D.; Segui, B.S.; Darabkhani, H.G.; Anthony, E.J. A technical evaluation, performance analysis and risk assessment of multiple novel oxy-turbine power cycles with complete CO2 capture. J. Clean. Prod. 2016, 133, 971–985. [Google Scholar] [CrossRef]

- Bolland, O.; Sæther, S. New concepts for natural gas fired power plants which simplify the recovery of carbon dioxide. Energy Convers. Manag. 1992, 33, 467–475. [Google Scholar] [CrossRef]

- Mathieu, P.; Nihart, R. Zero-emission MATIANT cycle. J. Eng. Gas. Turb. Power 1999, 121, 116–120. [Google Scholar] [CrossRef]

- Allam, R.; Martin, S.; Forrest, B.; Fetvedt, J.; Lu, X.; Freed, D.; Brown, G.W., Jr.; Sasaki, T.; Itoh, M.; Manning, J. Demonstration of the Allam cycle: An update on the development status of a high efficiency supercritical carbon dioxide power process employing full carbon capture. Energy Proced. 2017, 114, 5948–5966. [Google Scholar] [CrossRef]

- Oxy-Combustion Turbine Power Plants; IEAGHG: Cheltenham, UK, 2015.

- Choi, B.; Kim, M.; Ahn, J.; Kim, T. Influence of a recuperator on the performance of the semi-closed oxy-fuel combustion combined cycle. Appl. Therm. Eng. 2017, 124, 1301–1311. [Google Scholar] [CrossRef]

- Sammak, M.; Thern, M.; Genrup, M. Performance of a Semi-Closed Oxy-Fuel Combustion Combined Cycle (SCOC-CC) with an Air Separation Unit (ASU). In Proceedings of the ASME Turbo Expo: Power for Land, Sea, and Air, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Zhao, Y.; Chi, J.; Zhang, S.; Xiao, Y. Thermodynamic study of an improved MATIANT cycle with stream split and recompression. Appl. Therm. Eng. 2017, 125, 452–469. [Google Scholar] [CrossRef]

- Zhu, Z.; Chen, Y.; Wu, J.; Zhang, S.; Zheng, S. A modified Allam cycle without compressors realizing efficient power generation with peak load shifting and CO2 capture. Energy 2019, 174, 478–487. [Google Scholar] [CrossRef]

- Mathieu, P.; Dubuisson, R.; Houyou, S.; Nihart, R. New concept of CO2 removal technologies in power generation, combined with fossil fuel recovery and long term CO2 sequestration. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000. [Google Scholar]

- Allam, R.J.; Palmer, M.; Brown, G.W., Jr. System and method for high efficiency power generation using a carbon dioxide circulating working fluid. U.S. Patent 0179799 A1, 31 August 2010. [Google Scholar]

- MATLAB 2020a; The MathWorks, Inc.: Natick, MA, USA, 2020.

- AspenONE 10; Aspen Technology, Inc.: Bedford, MA, USA, 2018.

- Rogalev, A.; Grigoriev, E.; Kindra, V.; Rogalev, N. Thermodynamic optimization and equipment development for a high efficient fossil fuel power plant with zero emissions. J. Clean. Prod. 2019, 236, 117592. [Google Scholar] [CrossRef]

- Jones, D.; Bhattacharyya, D.; Turton, R.; Zitney, S.E. Optimal design and integration of an air separation unit (ASU) for an integrated gasification combined cycle (IGCC) power plant with CO2 capture. Fuel Process. Technol. 2011, 92, 1685–1695. [Google Scholar] [CrossRef]

- Pfaff, I.; Kather, A. Comparative thermodynamic analysis and integration issues of CCS steam power plants based on oxy-combustion with cryogenic or membrane based air separation. Energy Proced. 2009, 1, 495–502. [Google Scholar] [CrossRef]

- Malkova, M.P. Physical and Technical Fundamentals of Cryogenics Handbook, 3rd ed.; Energoatomizdat: Moscow, Russia, 1985. [Google Scholar]

- Rogalev, A.; Kindra, V.; Osipov, S.; Rogalev, N. Thermodynamic analysis of the net power oxy-combustion cycle. In Proceedings of the 13th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics, Lausanne, Switzerland, 8–12 April 2019. [Google Scholar]

- Yang, X.; Liu, Z.; Zhao, Q.; Liu, Z.; Feng, Z.; Guo, F.; Ding, L.; Simon, T.W. Experimental and numerical investigations of overall cooling effectiveness on a vane endwall with jet impingement and film cooling. Appl. Therm. Eng. 2019, 148, 1148–1163. [Google Scholar] [CrossRef]

- Kindra, V.; Osipov, S.; Vegera, A. Structural and parametric investigations of oxy-fuel combustion cycles with the aim of increasing efficiency of electricity production. In Proceedings of the International Science and Technology Conference “EastConf”, Vladivostok, Russia, 1–2 March 2019. [Google Scholar]

- Zaryankin, A.; Rogalev, A.; Osipov, S.; Kindra, V. Supercritical carbon dioxide gas turbines for high-power generation. AIP Conf. Proc. 2018, 2047, 020026. [Google Scholar]

- Rogalev, A.N.; Kindra, V.O.; Rogalev, N.D.; Sokolov, V.P.; Milukov, I.A. Methods for efficiency improvement of the semi-closed oxy-fuel combustion combined cycle. J. Phys. Conf. Ser. 2018, 1111, 012003. [Google Scholar] [CrossRef]

- Scaccabarozzi, R.; Gatti, M.; Martelli, E. Thermodynamic analysis and numerical optimization of the NET Power oxy-combustion cycle. Appl. Energy 2016, 178, 505–526. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Ambient temperature/pressure/humidity, °C/MPa/% | 15/0.1013/60 |

| Fuel chemical contents | CH4 |

| Fuel combustion temperature/pressure/low heat production, °C/MPa/(kJ/kg) | 15/0.7/50025 |

| O2 produced by air separator temperature/pressure, °C/MPa | 30/1 |

| CO2 storage pressure, MPa | 10 |

| CO2 compressors and turbines internal specific efficiency besides cooling losses, % | 90 |

| Oxygen/fuel compressor internal specific efficiency, % | 85/88 |

| Steam turbine internal specific efficiency, % | 89 |

| Pumps internal specific efficiency, % | 75 |

| Compressors and turbines mechanical efficiency, % | 99 |

| Pumps mechanical efficiency, % | 95 |

| Power generator electric efficiency, % | 98.5 |

| Combustor pressure drop, % | 4 |

| Combustor exit O2 molar content, % | 1 |

| Cycle minimal temperature, °C | 30 |

| High pressure steam parameters, °C/MPa | 560/14 |

| Low pressure steam parameters, MPa | 0.7 |

| Steam turbine condenser/deaerator pressure, MPa | 0.0045/0.121 |

| Minimal high pressure steam under-heating at the gas turbine exit, °C | 20 |

| Heat recovery steam generator gas pressure losses, MPa | 0.002 |

| Pinch point temperature difference in multiflow regenerative heat exchanger, °C | 5 |

| Parameter | Value/Description |

|---|---|

| Rotation speed, rpm | 3000 |

| Root diameter configuration | dr = const |

| Number of stages | 6–8 |

| Mean heat drop in a stage, kJ/kg | 55–73 |

| Stage reaction degree | 0.2–0.3 |

| Velocity ratio | 0.35–0.4 |

| Relative stage airfoil efficiency without the cooling losses, % | 84–86 |

| Maximal absolute Mach number at the last stage exit | 0.75 |

| Minimal first stage blade length, mm | 15 |

| Maximal last stage blade length, mm | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogalev, A.; Rogalev, N.; Kindra, V.; Komarov, I.; Zlyvko, O. Research and Development of the Oxy-Fuel Combustion Power Cycles with CO2 Recirculation. Energies 2021, 14, 2927. https://doi.org/10.3390/en14102927

Rogalev A, Rogalev N, Kindra V, Komarov I, Zlyvko O. Research and Development of the Oxy-Fuel Combustion Power Cycles with CO2 Recirculation. Energies. 2021; 14(10):2927. https://doi.org/10.3390/en14102927

Chicago/Turabian StyleRogalev, Andrey, Nikolay Rogalev, Vladimir Kindra, Ivan Komarov, and Olga Zlyvko. 2021. "Research and Development of the Oxy-Fuel Combustion Power Cycles with CO2 Recirculation" Energies 14, no. 10: 2927. https://doi.org/10.3390/en14102927

APA StyleRogalev, A., Rogalev, N., Kindra, V., Komarov, I., & Zlyvko, O. (2021). Research and Development of the Oxy-Fuel Combustion Power Cycles with CO2 Recirculation. Energies, 14(10), 2927. https://doi.org/10.3390/en14102927