A Preliminary Techno-Economic Analysis on the Calcium Looping Process with Simultaneous Capture of CO2 and SO2 from a Coal-Based Combustion Power Plant

Abstract

1. Introduction

2. Description of Plant Configurations

- Case 1 (Base Case): PF power plant without CaL system;

- Case 2: PF power plant with CaL system; and

- Case 3: PF power plant with CaL system for simultaneous capture of CO2 and SO2.

3. Assessment of Economic Performance

3.1. Estimation of Plant Capital Costs

- C is the capital cost of the single unit with capacity Q;

- C0 is the capital cost of the single unit with capacity Q0; and

- m is the constant depending on the equipment type.

3.2. Estimation of O&M Costs, LCOE, and CO2 Capture Costs.

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IEA. Energy and Climate Change, World Energy Outlook Special Report; IEA: Paris, France, 2015.

- Coppola, A.; Scala, F.; Salatino, P.; Montagnaro, F. Fluidized bed calcium looping cycles for CO2 capture under oxy-firing calcination conditions: Part 2. Assessment of dolomite vs. limestone. Chem. Eng. J. 2013, 231. [Google Scholar] [CrossRef]

- Zhao, C.; Chen, X.; Anthony, E.J.; Jiang, X.; Duan, L.; Wu, Y.; Dong, W.; Zhao, C. Capturing CO2 in flue gas from fossil fuel-fired power plants using dry regenerable alkali metal-based sorbent. Prog. Energy Combust. Sci. 2013, 39, 515–534. [Google Scholar] [CrossRef]

- Cormos, C.C. Economic evaluations of coal-based combustion and gasification power plants with post-combustion CO2 capture using calcium looping cycle. Energy 2014, 78, 665–673. [Google Scholar] [CrossRef]

- Pathi, S.K.; Lin, W.; Illerup, J.B.; Dam-Johansen, K.; Hjuler, K. Performance of a bench-scale fast fluidized bed carbonator. Energy Fuels 2014, 28, 5259–5269. [Google Scholar] [CrossRef]

- Ströhle, J.; Junk, M.; Kremer, J.; Galloy, A.; Epple, B. Carbonate looping experiments in a 1 MWth pilot plant and model validation. Fuel 2014, 127, 13–22. [Google Scholar] [CrossRef]

- Erans, M.; Manovic, V.; Anthony, E.J. Calcium looping sorbents for CO2 capture. Appl. Energy 2016, 180, 722–742. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Li, Z.; Li, M.; Xu, K.; Liu, W.; Luo, G.; Yao, H. Limestone Decomposition in an O2/CO2/Steam Atmosphere Integrated with Coal Combustion. Energy Fuels 2016, 30, 5092–5100. [Google Scholar] [CrossRef]

- Perejón, A.; Romeo, L.M.; Lara, Y.; Lisbona, P.; Martínez, A.; Valverde, J.M. The Calcium-Looping technology for CO2 capture: On the important roles of energy integration and sorbent behavior. Appl. Energy 2016, 162, 787–807. [Google Scholar] [CrossRef]

- Salaudeen, S.A.; Acharya, B.; Dutta, A. CaO-based CO2 sorbents: A review on screening, enhancement, cyclic stability, regeneration and kinetics modelling. J. CO2 Util. 2018, 23, 179–199. [Google Scholar] [CrossRef]

- Tregambi, C.; Montagnaro, F.; Salatino, P.; Solimene, R. A model of integrated calcium looping for CO2 capture and concentrated solar power. Sol. Energy 2015, 120, 208–220. [Google Scholar] [CrossRef]

- Tregambi, C.; Salatino, P.; Solimene, R.; Montagnaro, F. An experimental characterization of Calcium Looping integrated with concentrated solar power. Chem. Eng. J. 2018, 331, 794–802. [Google Scholar] [CrossRef]

- Coppola, A.; Esposito, A.; Montagnaro, F.; De Tommaso, G.; Scala, F.; Salatino, P. Effect of exposure to SO2 and H2O during the carbonation stage of fluidised bed calcium looping on the performance of sorbents of different nature. Chem. Eng. J. 2019, 377, 120626. [Google Scholar] [CrossRef]

- IEA-GHG. Improvements in Power Generation with Post-Combustion Capture of CO2. Report PH4/33, Nov. 2004; IEA Greenhouse Gas R&D Programme: Cheltenham, UK, 2004.

- Xu, G.; Yang Y ping Ding, J.; Li, S.; Liu, W.; Zhang, K. Analysis and optimization of CO2 capture in an existing coal-fired power plant in China. Energy 2013, 58, 117–127. [Google Scholar] [CrossRef]

- Petrescu, L.; Bonalumi, D.; Valenti, G.; Cormos, A.M.; Cormos, C.C. Life Cycle Assessment for supercritical pulverized coal power plants with post-combustion carbon capture and storage. J. Clean. Prod. 2017, 157, 10–21. [Google Scholar] [CrossRef]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis and Design of Chemical Processes; Pearson Education: London, UK, 2008. [Google Scholar]

- Cormos, C.C. Techno-economic and environmental evaluations of large scale gasification-based CCS project in Romania. Int. J. Hydrog. Energy 2014, 39, 13–27. [Google Scholar] [CrossRef]

- Romano, M.C.; Spinelli, M.; Campanari, S.; Consonni, S.; Cinti, G.; Marchi, M.; Borgarello, E. The calcium looping process for low CO2 emission cement and power. Energy Procedia 2013, 37, 7091–7099. [Google Scholar] [CrossRef]

- Cormos, C.C.; Vatopoulos, K.; Tzimas, E. Assessment of the consumption of water and construction materials in state-of-the-art fossil fuel power generation technologies involving CO2 capture. Energy 2013, 51, 37–49. [Google Scholar] [CrossRef]

- Yang, Y.; Zhai, R.; Duan, L.; Kavosh, M.; Patchigolla, K.; Oakey, J. Integration and evaluation of a power plant with a CaO-based CO2 capture system. Int. J. Greenh. Gas Control 2010, 4, 603–612. [Google Scholar] [CrossRef]

- Martínez, A.; Lara, Y.; Lisbona, P.; Romeo, L.M. Operation of a mixing seal valve in calcium looping for CO2 capture. Energy Fuels 2014, 28, 2059–2068. [Google Scholar] [CrossRef]

- Romano, M.C.; Martínez, I.; Murillo, R.; Arstad, B.; Blom, R.; Ozcan, D.C.; Ahn, H.; Brandani, S. Process simulation of Ca-looping processes: Review and guidelines. Energy Procedia 2013, 37, 142–150. [Google Scholar] [CrossRef]

- Mantripragada, H.C.; Rubin, E.S. Calcium looping cycle for CO2 capture: Performance, cost and feasibility analysis. Energy Procedia 2014, 63, 2199–2206. [Google Scholar] [CrossRef]

- Hanak, D.P.; Powell, D.; Manovic, V. Techno-economic analysis of oxy-combustion coal-fired power plant with cryogenic oxygen storage. Appl. Energy 2017, 191, 193–203. [Google Scholar] [CrossRef]

- Erans, M.; Hanak, D.P.; Mir, J.; Anthony, E.J.; Manovic, V. Process modelling and techno-economic analysis of natural gas combined cycle integrated with calcium looping. Therm. Sci. 2016, 20, S59–S67. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E.; Timmerhaus, K.; West, R. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 1968; Volume 4. [Google Scholar]

- Abanades, J.C.; Grasa, G.; Alonso, M.; Rodriguez, N.; Anthony, E.J.; Romeo, L.M. Cost structure of a postcombustion CO2 capture system using CaO. Environ. Sci. Technol. 2007, 41, 5523–5527. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Minett, A.I.; Harris, A.T. A review of techno-economic models for the retrofitting of conventional pulverised-coal power plants for post-combustion capture (PCC) of CO2. Energy Environ. Sci. 2013, 6, 25–40. [Google Scholar] [CrossRef]

| Unit | Parameters |

|---|---|

| Boiler | Pulverized fuel boiler |

| Air separation unit | 95% (vol.) oxygen purity (Consumption: 200 kWh per tons of oxygen) |

| Desulphurisation unit | Limestone Flue-gas desulfurization (SO2 abatement efficiency: 98–99%) |

| Calcium looping unit | Carbonation @650 °C–Calcination @940 °C Sorbent make-up ratio: 5% |

| Captured CO2 conditioning | Intercooled multi-stage compression @120 bar Dehydration by Tri-ethylene-glycol |

| Steam cycle | Sub-critical: 170 bar@540 °C– One re-heat: 39 bar@540 °C |

| Main Plant Data | Units | Case 1 | Case 2 | Case 3 |

|---|---|---|---|---|

| Coal flowrate | t/h | 182.30 | 242.30 | 246.97 |

| Coal LHV | MJ/Kg | 25.17 | 25.17 | 25.17 |

| Fuel thermal energy | MWth | 1274.58 | 1694.08 | 1726.73 |

| Gross power output | MWe | 504.28 | 658.80 | 670.83 |

| ASU consumption | MWe | 0.00 | 25.76 | 26.23 |

| Boiler consumption | MWe | 6.37 | 8.47 | 8.63 |

| Ca-looping unit consumption | MWe | - | 56.00 | 57.02 |

| Power island consumption | MWe | 22.69 | 23.64 | 23.71 |

| Ancillary consumption | MWe | 29.07 | 113.87 | 115.60 |

| Net power output | MWe | 475.21 | 544.93 | 555.23 |

| Gross efficiency | % | 39.56 | 38.89 | 38.85 |

| Net efficiency | % | 37.28 | 32.17 | 32.15 |

| Carbon capture rate | % | - | 92.00 | 92.00 |

| CO2 specific emissions | Kg/MWh | 931.03 | 74.48 | 74.48 |

| Plant Sub-Units | Units | Case 1 | Case 2 | Case 3 | ||

|---|---|---|---|---|---|---|

| equipment cost (EC) | Solid handling facilities | M€ | 46.10 | 57.39 | 60.26 | [20] |

| Air separation unit | M€ | 0.00 | 102.65 | 107.78 | [20] | |

| Boiler | M€ | 180.16 | 180.16 | 180.16 | [20] | |

| CaL unit | M€ | 0.00 | 92.70 | 97.34 | [19] | |

| Sulphur removal unit | M€ | 78.16 | 100.38 | 0.00 | [20] | |

| CO₂ processing and drying | M€ | 0.00 | 33.14 | 33.14 | [20] | |

| Power island | M€ | 133.71 | 166.73 | 150.06 | [20] | |

| Utilities and offsite units (U&O) | M€ | 109.53 | 183.29 | 157.19 | 25% of EC | |

| Total installed costs (IC) | M€ | 547.66 | 916.44 | 785.93 | EC + U&O | |

| Owner’s costs and contingency (O&C) | M€ | 82.15 | 137.47 | 117.89 | 15% of IC | |

| Land, permitting, surveying, etc. (L) | M€ | 27.38 | 45.82 | 39.30 | 5% of IC | |

| Total investment costs (TIC) | M€ | 657.20 | 1099.73 | 943.11 | IC + O&C + L | |

| TIC per KW (gross) | €/kW | 1303.23 | 1620.51 | 1389.74 | ||

| TIC per KW (net) | €/kW | 1382.94 | 1957.12 | 1678.41 |

| Coal | 1.9 | €/GJ |

| Limestone (flux) | 20 | €/t |

| Natural gas cost | 5 | €/GJ |

| BFW and process water price | 0.1 | €/t |

| Cooling water price | 0.01 | €/t |

| Make up and water treatment chemicals | 0.0025 | €/t |

| Slag disposal cost | 10 | €/t |

| CO₂ transport and storage costs | 5 | €/t CO₂ |

| Carbon tax | 0 | €/t CO₂ |

| Direct labor | 100 | persons |

| Average annual direct labor costs | 50000 | €/y |

| Administrative, support, and overhead costs | 30% of the direct labor cost | 0.3 |

| Annual maintenance costs | 3.5% from capital expenditure (CAPEX) | 0.035 |

| Working capital | 30-day supply | |

| Power plant load factor | 7500 | h/y |

| Construction time | 3 | year |

| Economical plant life | 25 | year |

| Discount rate | 8.00 | % |

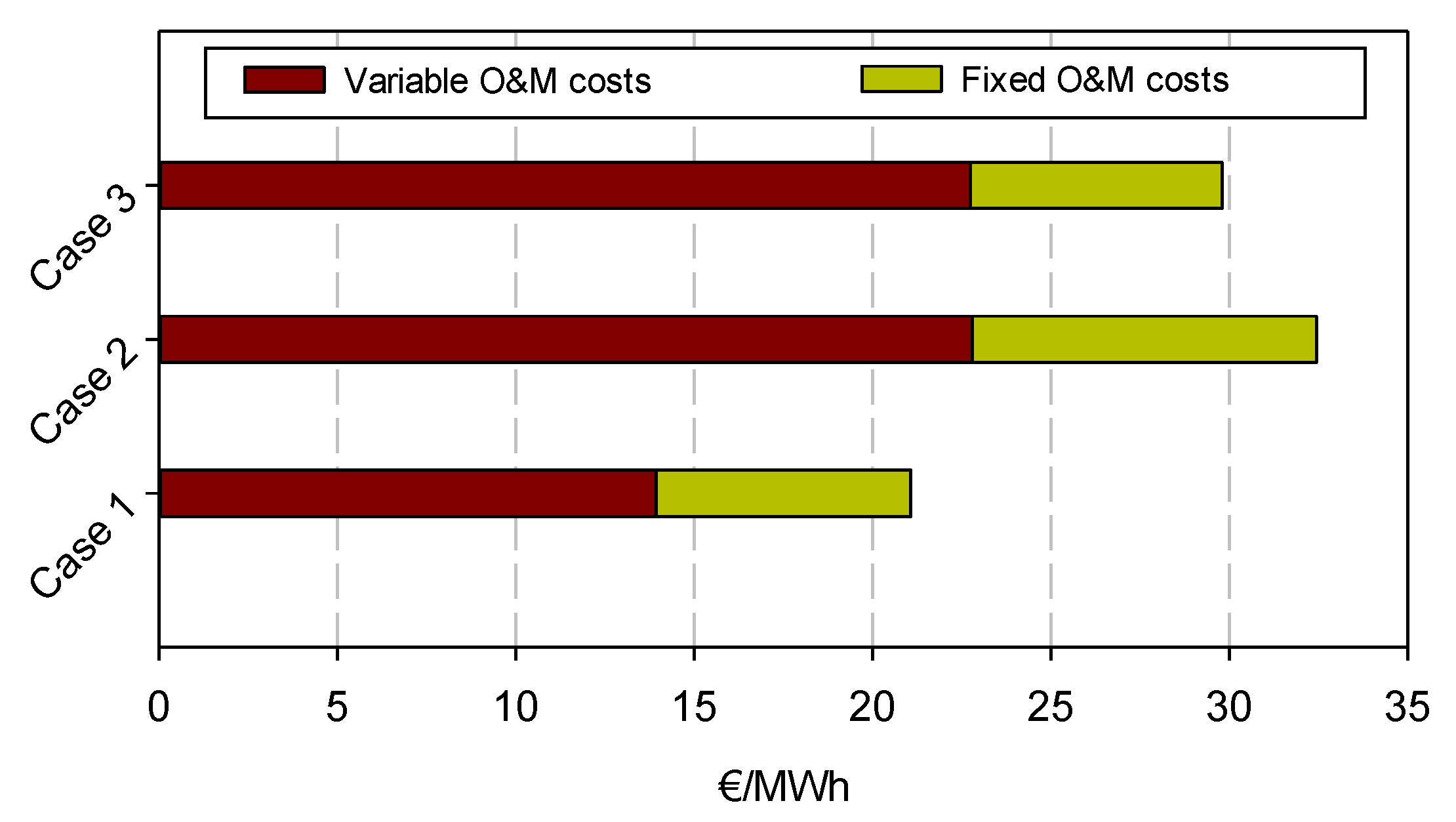

| Case 1 | Case 2 | Case 3 | |

|---|---|---|---|

| Supervision | 1.750 | 1.750 | 1.750 |

| Cost of direct labor | 5.000 | 5.000 | 5.000 |

| Maintenance | 25.297 | 34.995 | 30.000 |

| Taxes and insurance | 5.059 | 6.999 | 6.000 |

| Total Fixed Costs | 37.106 | 48.744 | 42.750 |

| Coal | 65.618 | 86.922 | 88.582 |

| Limestone make-up | 2.346 | 27.990 | 29.274 |

| Cooling water | 0.004 | 0.006 | 0.006 |

| Spent limestone disposal | 0.000 | 8.705 | 10.487 |

| Gypsum disposal | 0.695 | 0.880 | 0.000 |

| Ash disposal | 4.414 | 5.587 | 5.671 |

| CO₂ transport and storage | 0.000 | 21.919 | 22.733 |

| Total Variable Costs | 73.078 | 152.009 | 156.753 |

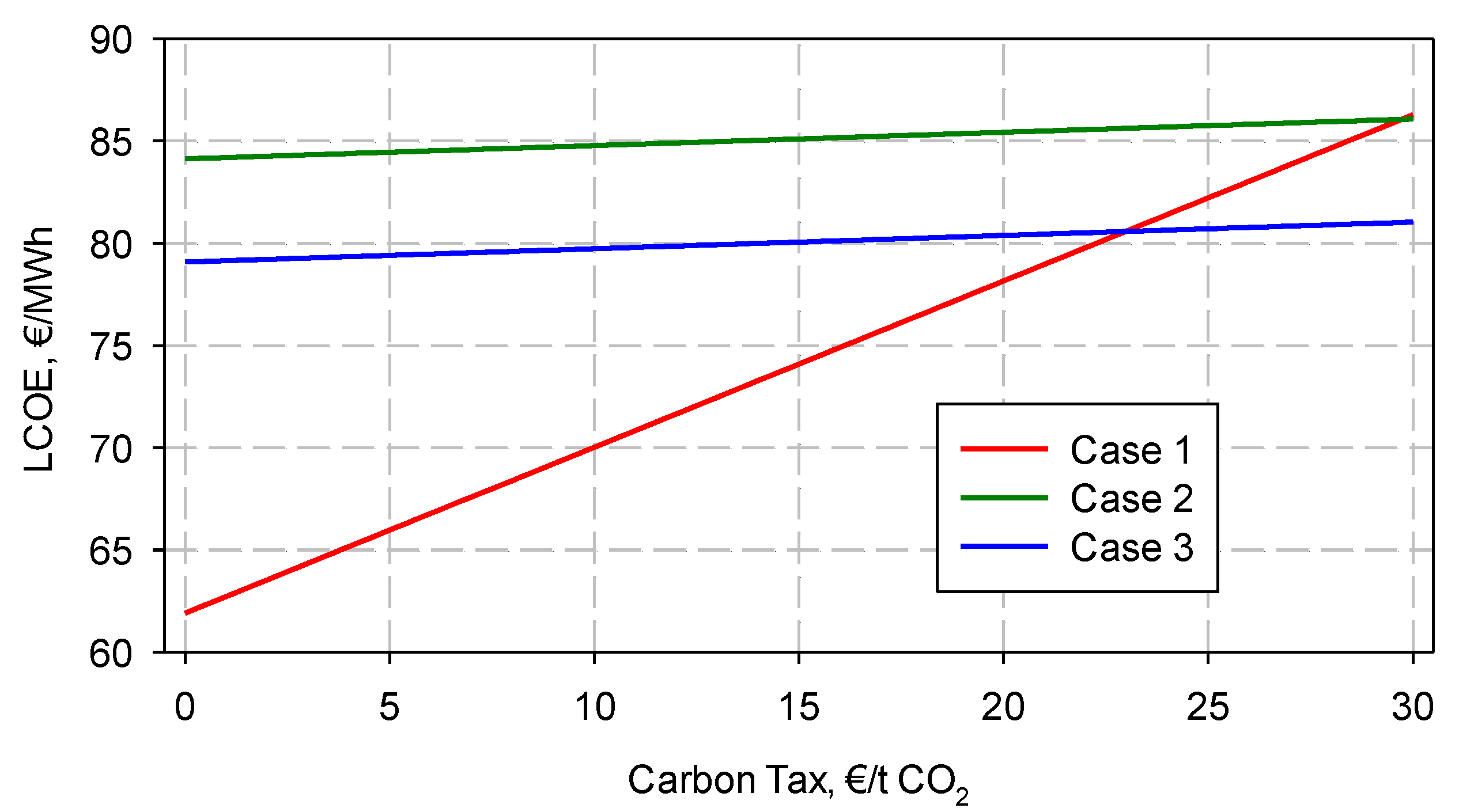

| Units | Case 1 | Case 2 | Case 3 | |

|---|---|---|---|---|

| LCOE | €/MWh | 61.90 | 84.13 | 79.09 |

| CO2 avoided cost | €/t CO2 | 0 | 25.95 | 20.06 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coppola, A.; Scala, F. A Preliminary Techno-Economic Analysis on the Calcium Looping Process with Simultaneous Capture of CO2 and SO2 from a Coal-Based Combustion Power Plant. Energies 2020, 13, 2176. https://doi.org/10.3390/en13092176

Coppola A, Scala F. A Preliminary Techno-Economic Analysis on the Calcium Looping Process with Simultaneous Capture of CO2 and SO2 from a Coal-Based Combustion Power Plant. Energies. 2020; 13(9):2176. https://doi.org/10.3390/en13092176

Chicago/Turabian StyleCoppola, Antonio, and Fabrizio Scala. 2020. "A Preliminary Techno-Economic Analysis on the Calcium Looping Process with Simultaneous Capture of CO2 and SO2 from a Coal-Based Combustion Power Plant" Energies 13, no. 9: 2176. https://doi.org/10.3390/en13092176

APA StyleCoppola, A., & Scala, F. (2020). A Preliminary Techno-Economic Analysis on the Calcium Looping Process with Simultaneous Capture of CO2 and SO2 from a Coal-Based Combustion Power Plant. Energies, 13(9), 2176. https://doi.org/10.3390/en13092176