System Designs and Experimental Assessment of a Seven-Mode Vehicle-Oriented Hybrid Powertrain Platform

Abstract

1. Introduction

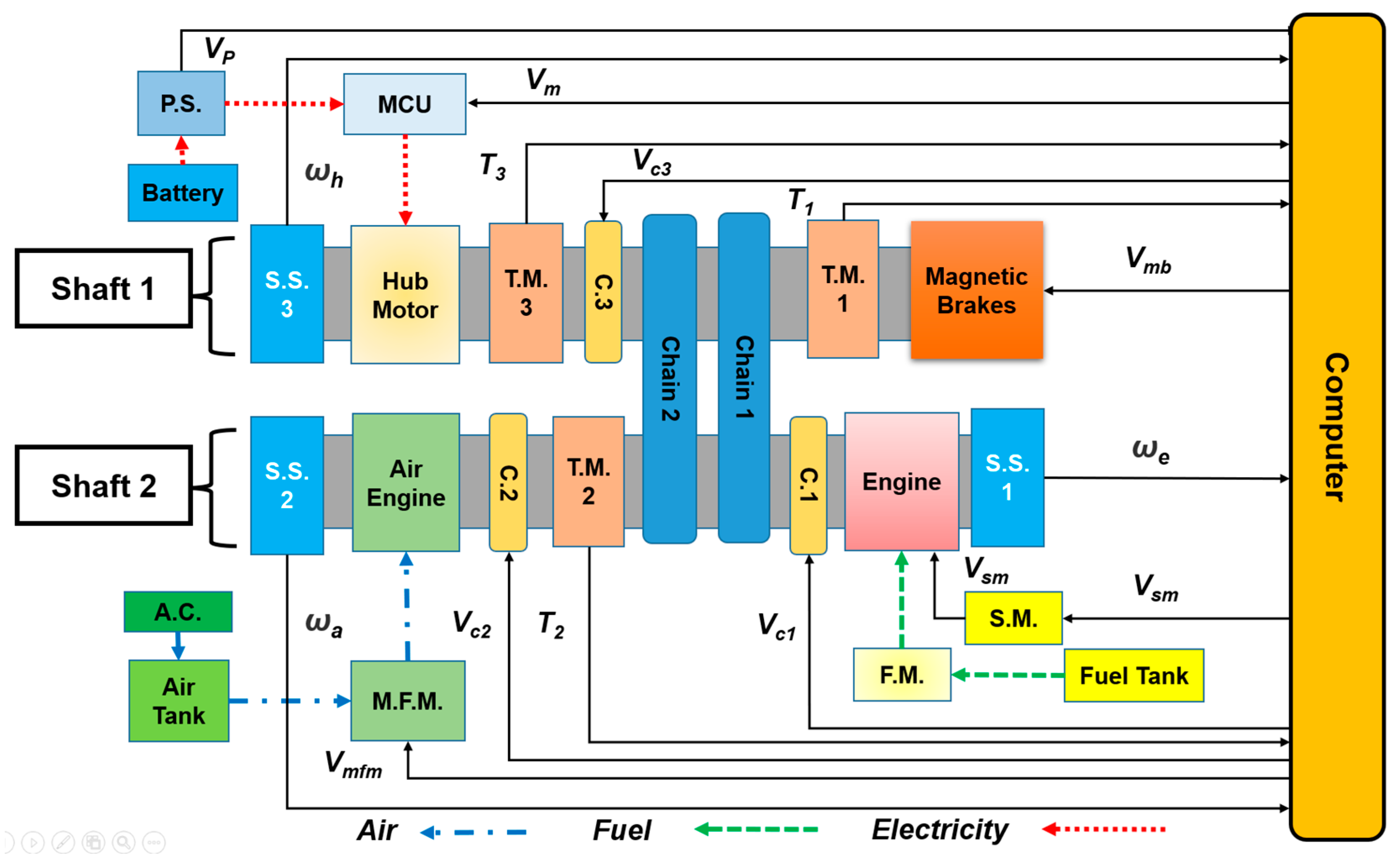

2. Experimental Platform Designs and Mode Control

2.1. Experimental Platform Designs

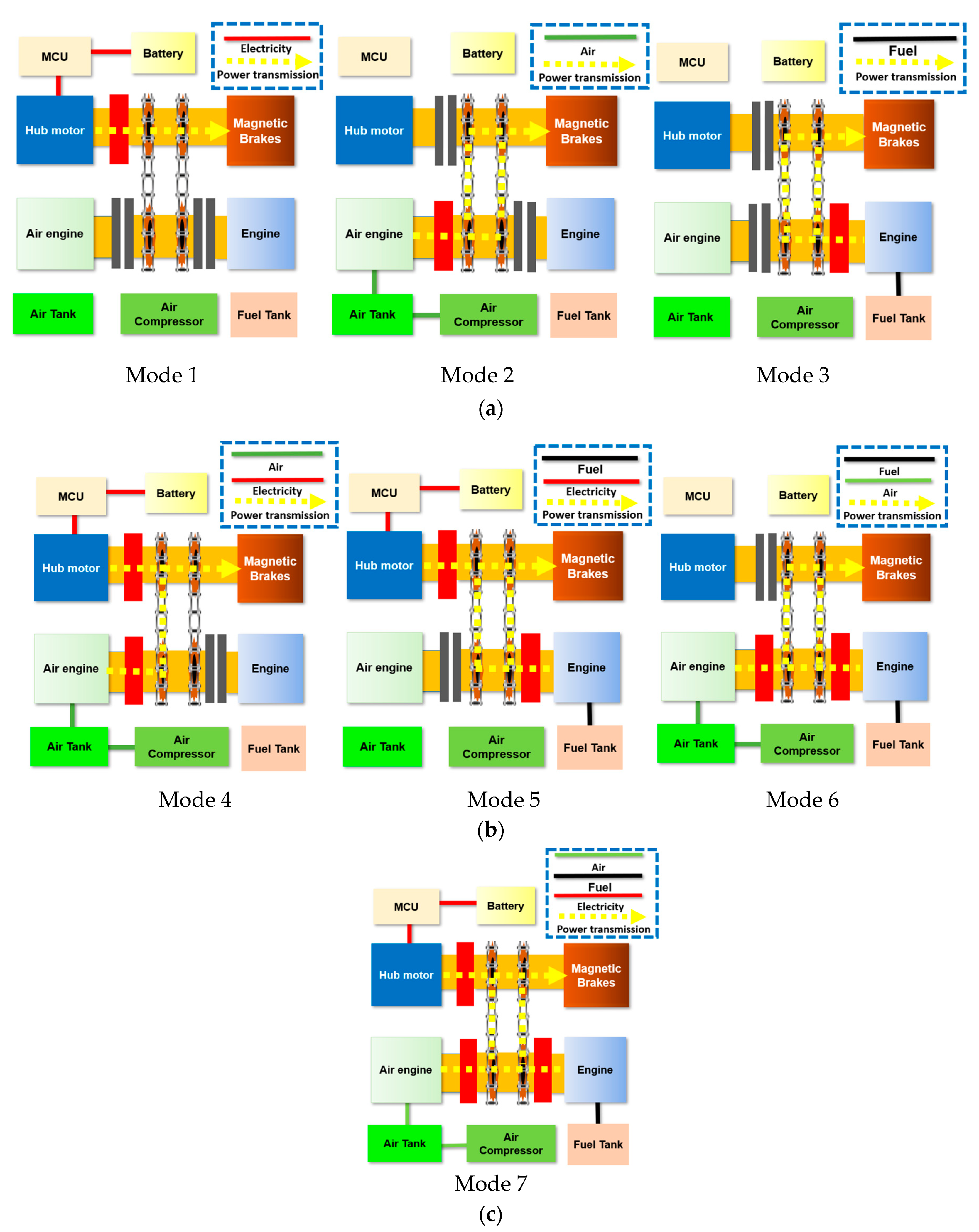

2.2. Seven Operation Modes

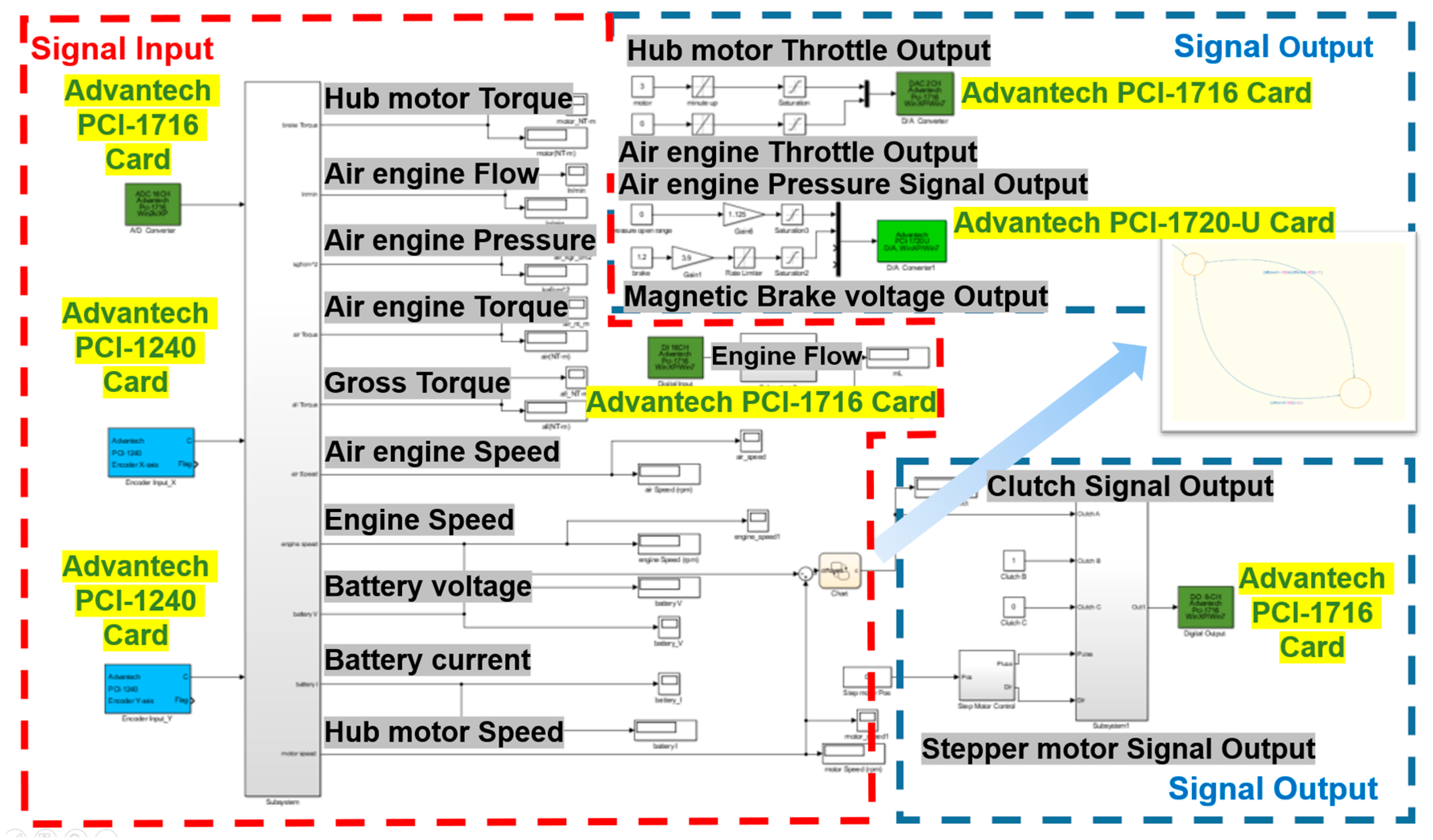

2.3. Control Strategies

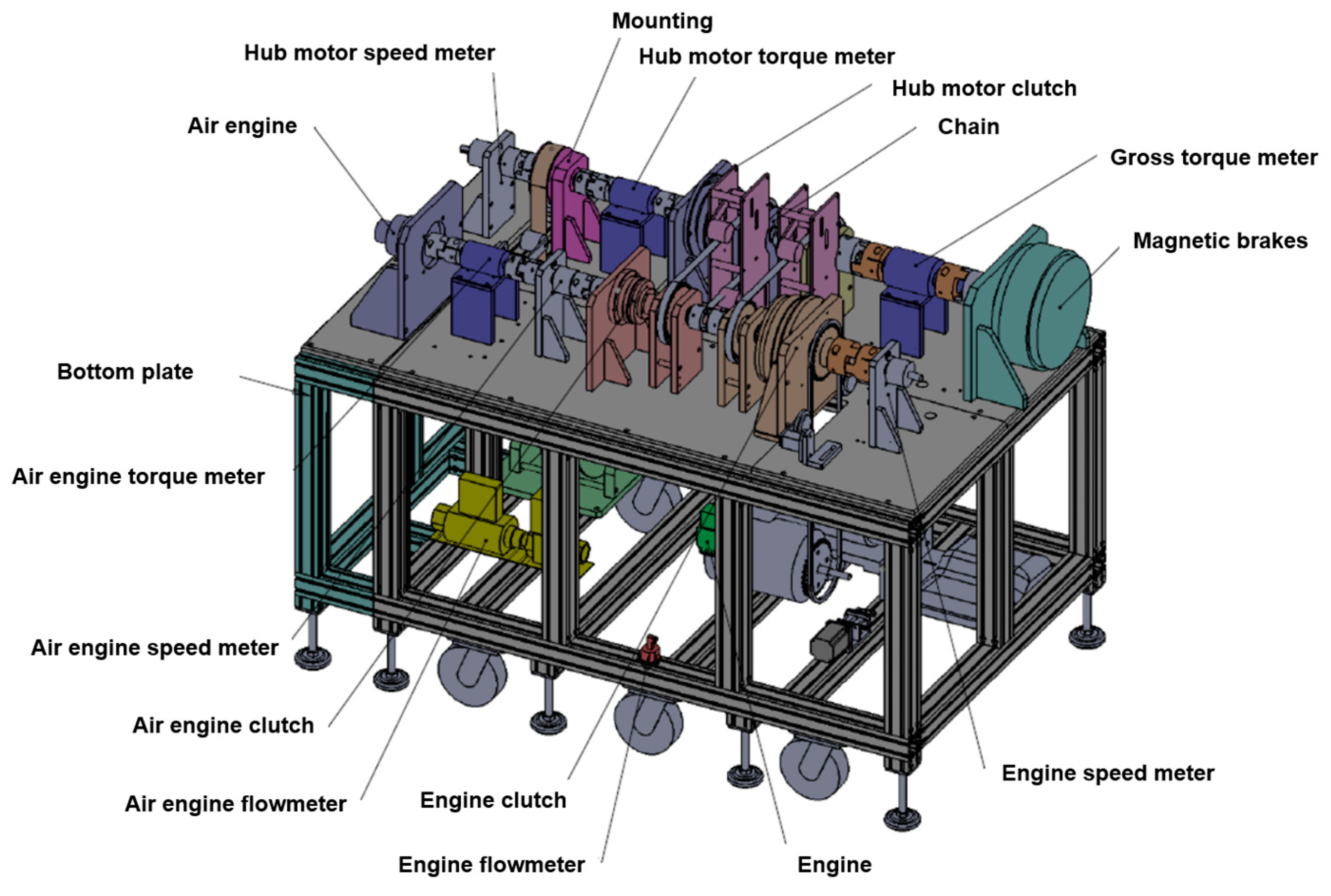

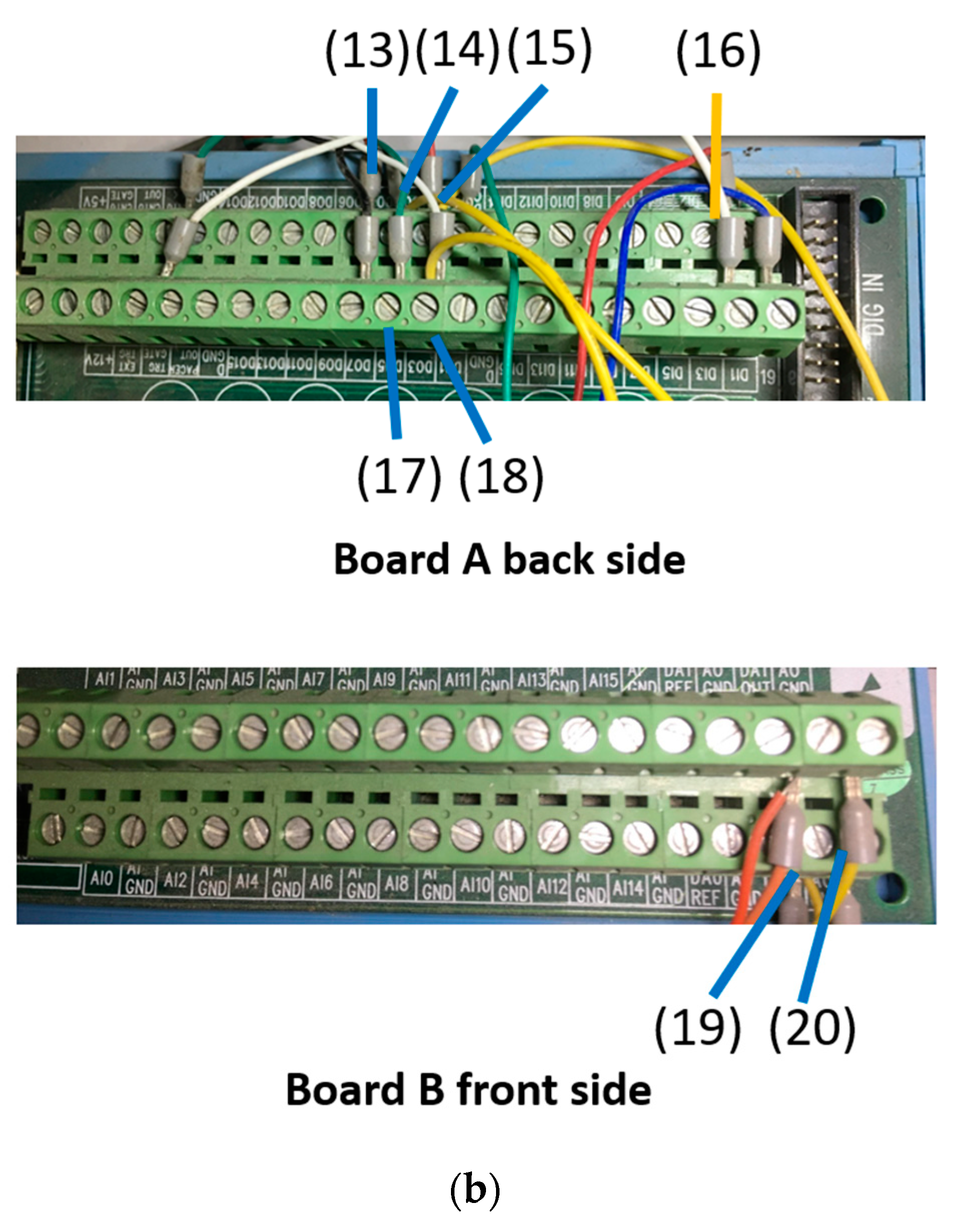

3. Experimental Platform and Mechatronics System

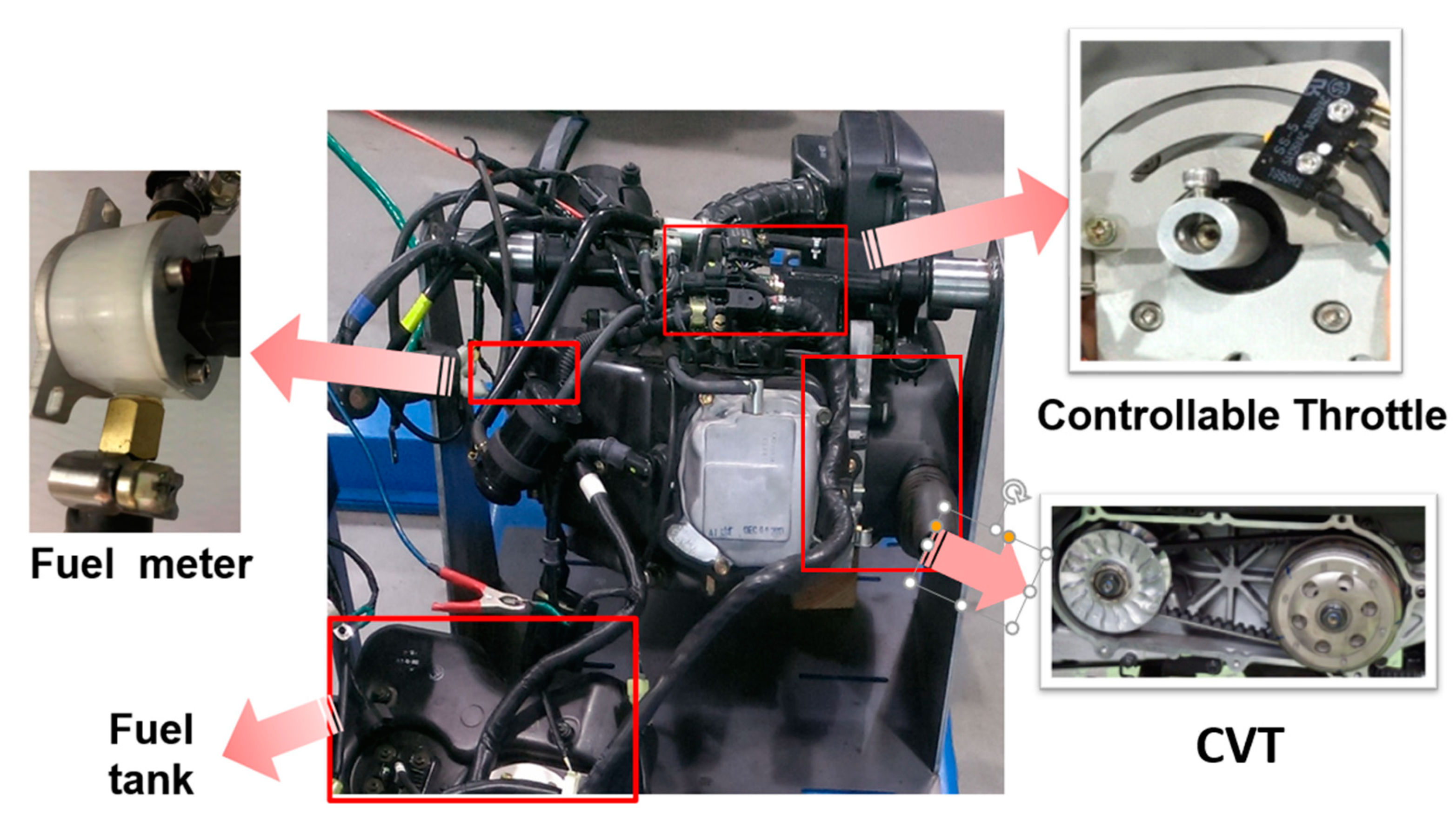

3.1. SI Engine System

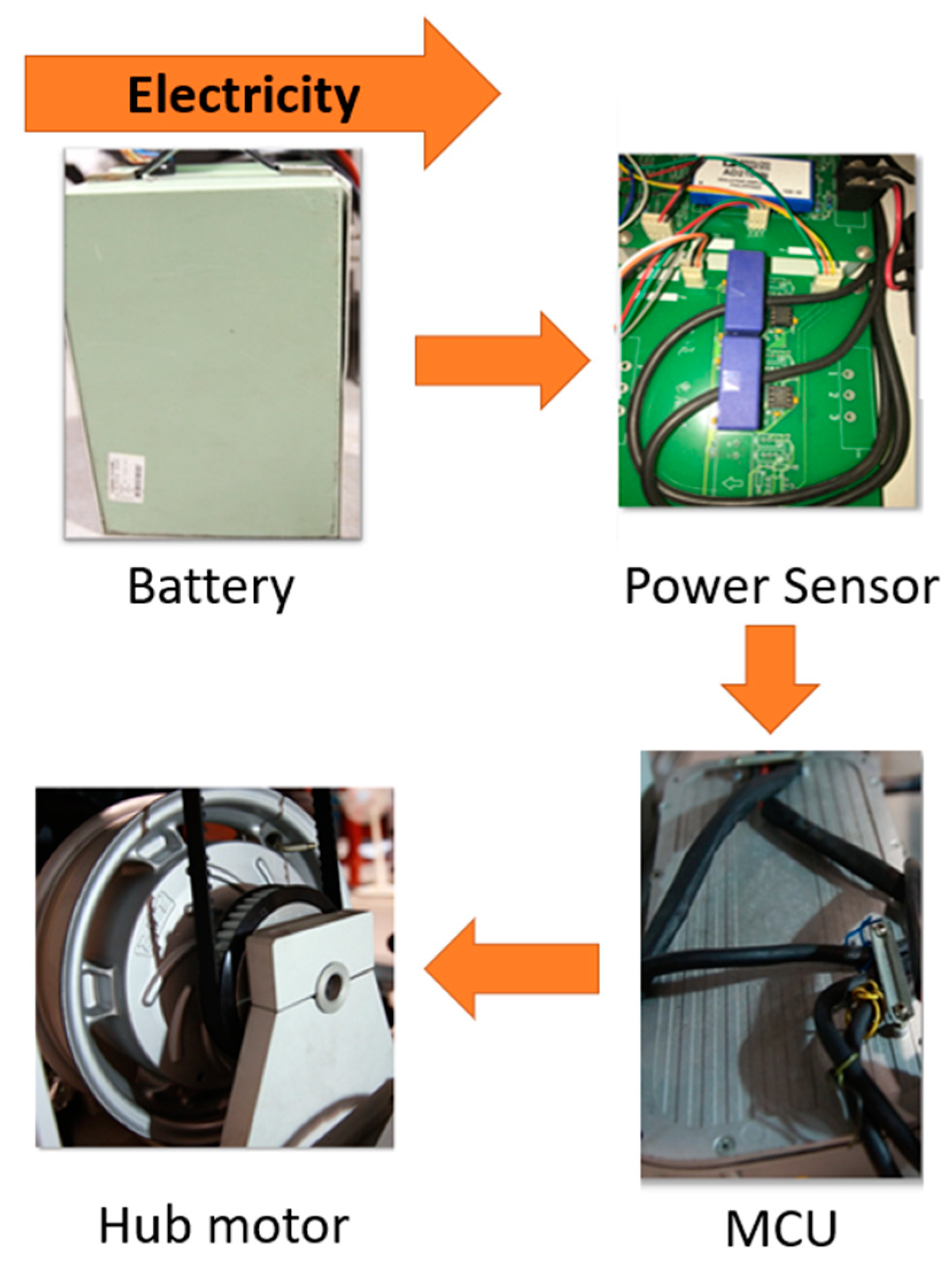

3.2. Traction Motor System

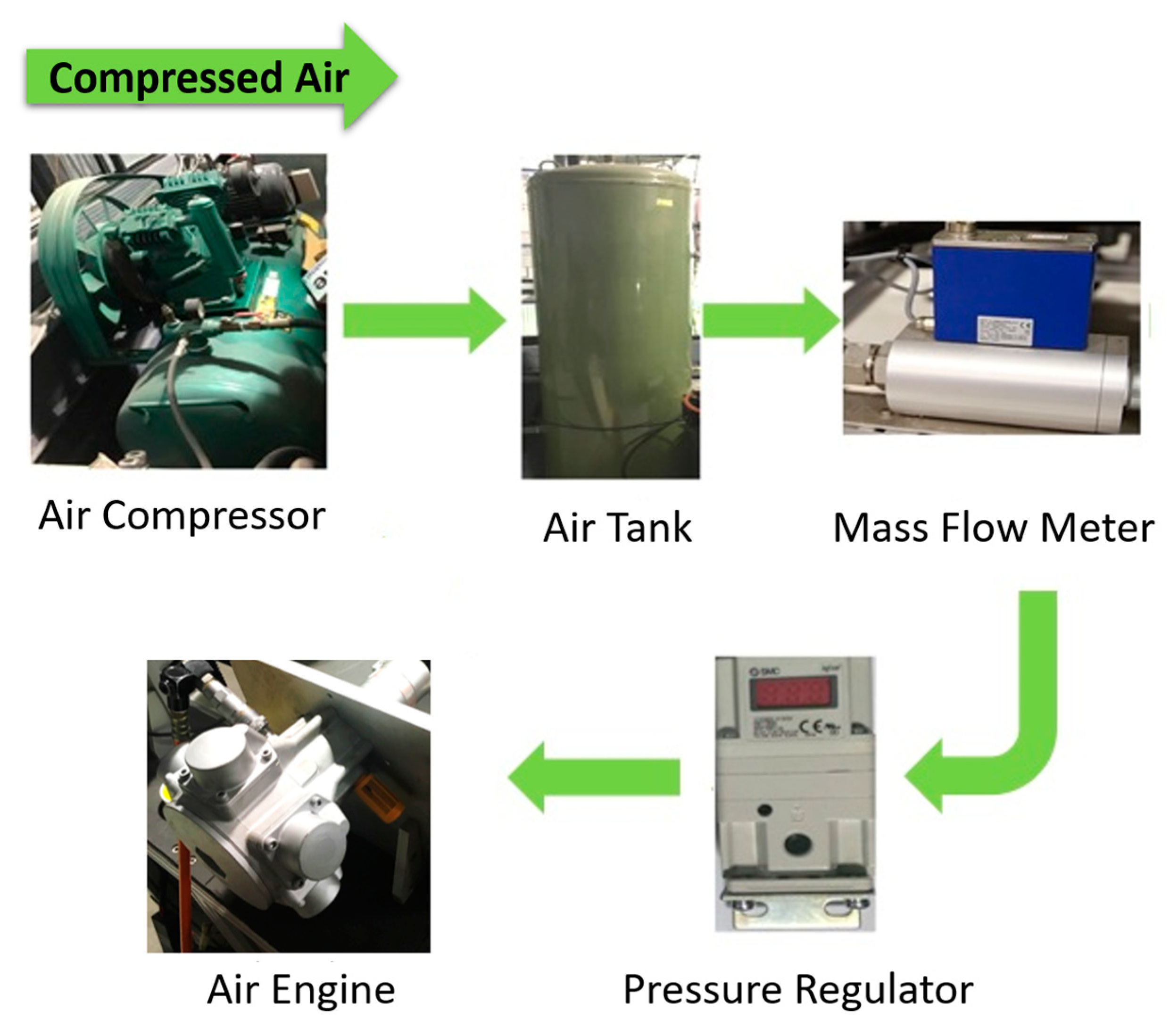

3.3. Air Engine System

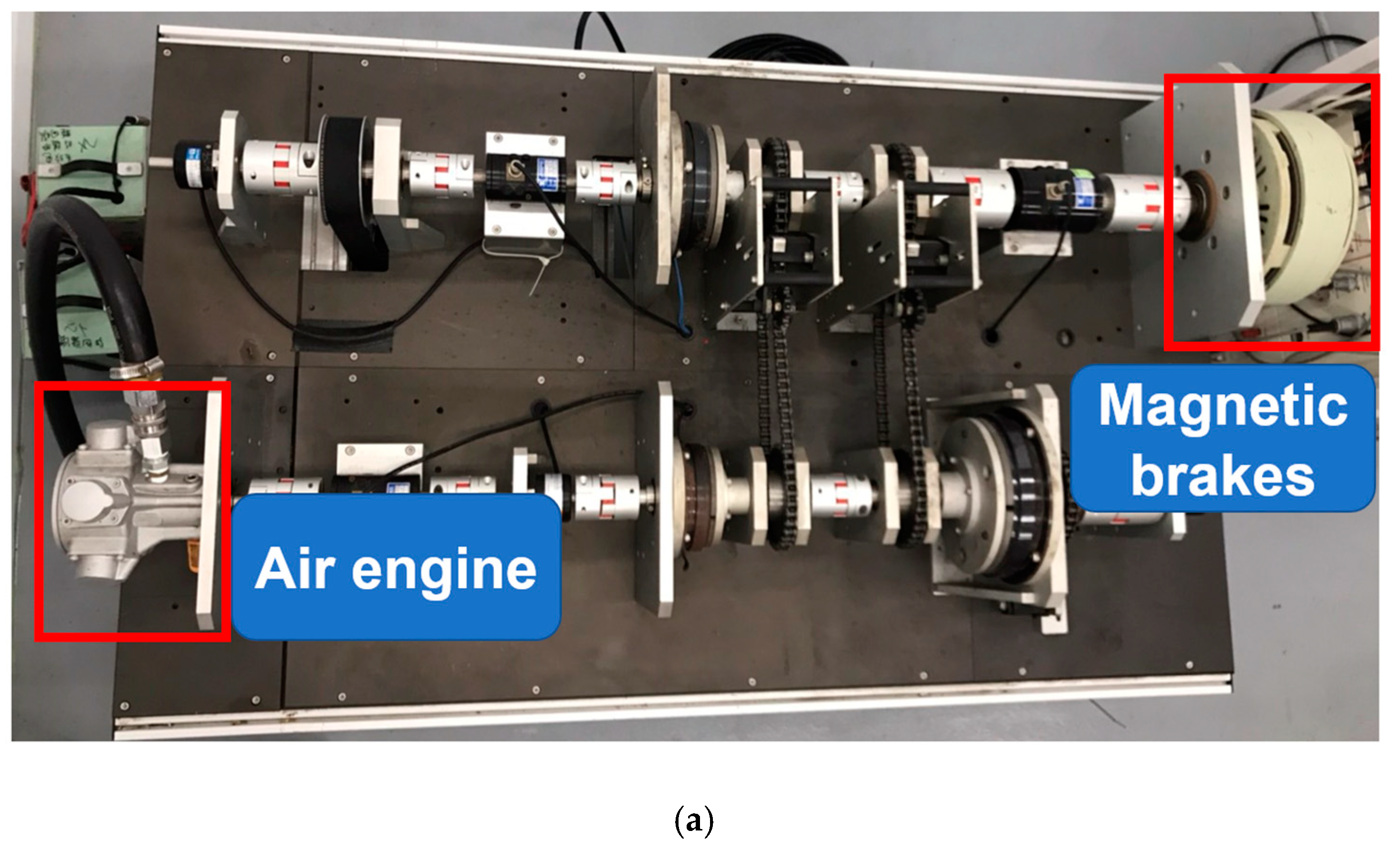

3.4. Three-Power-Source Platform Establishment

4. Experimental Results and Discussion

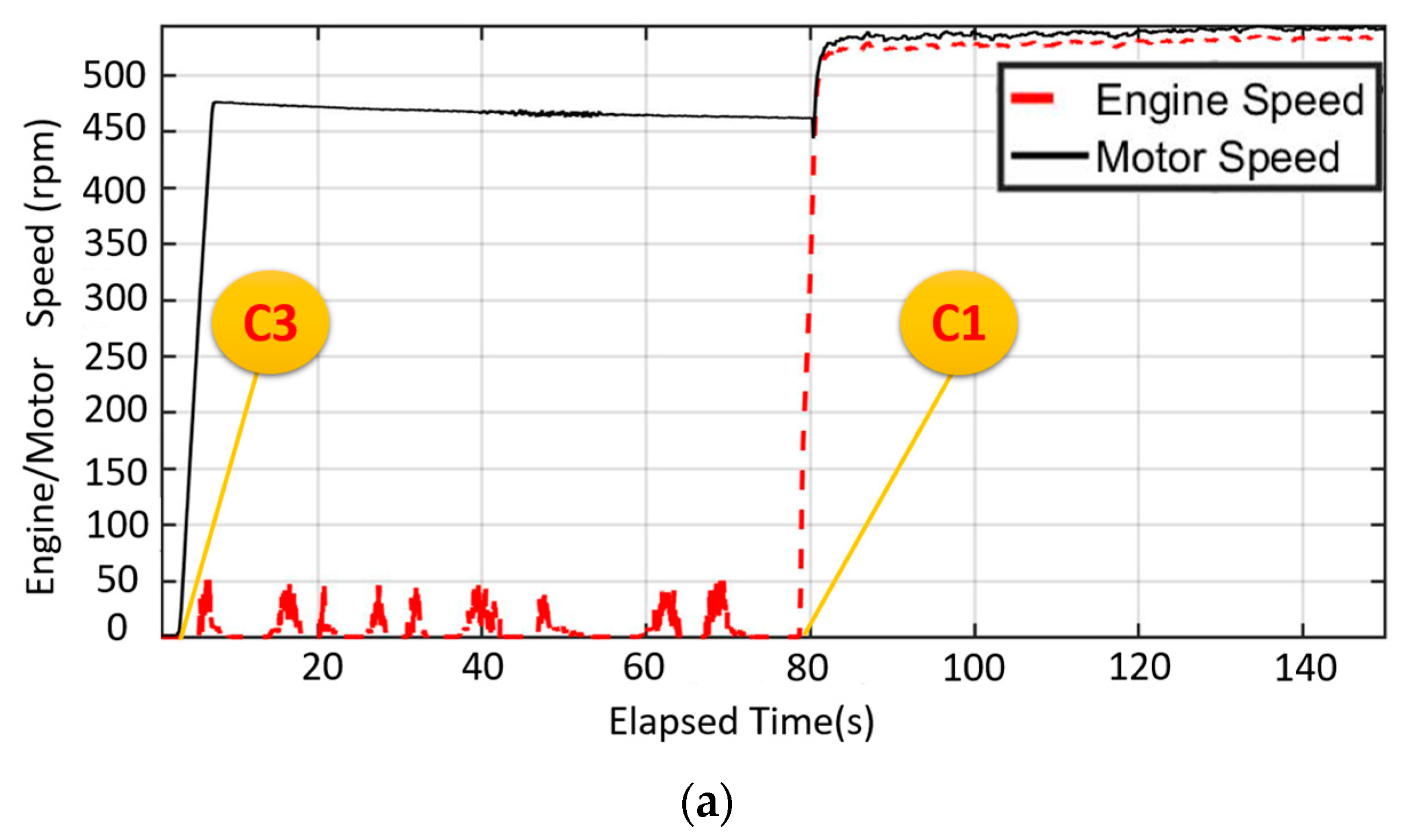

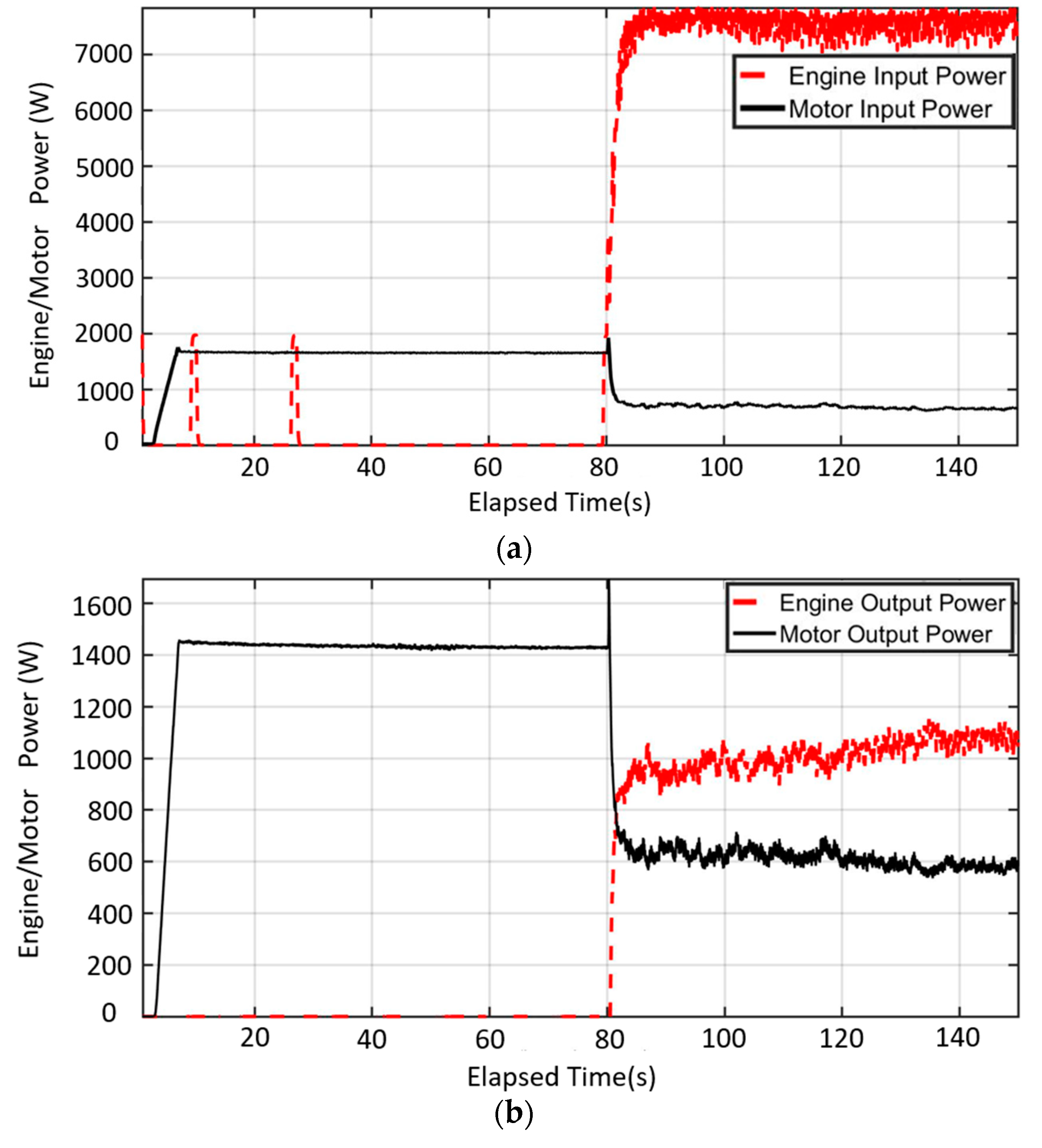

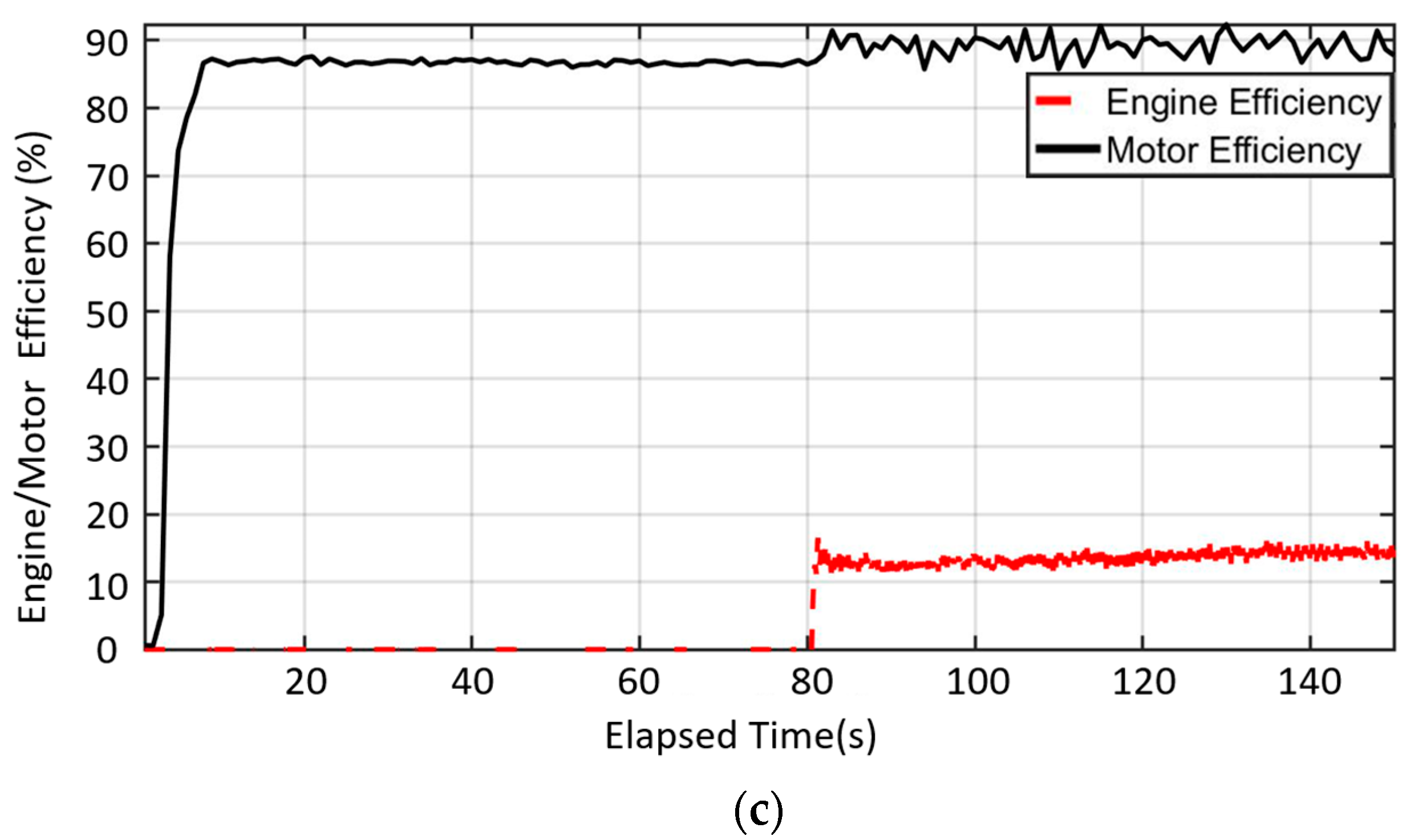

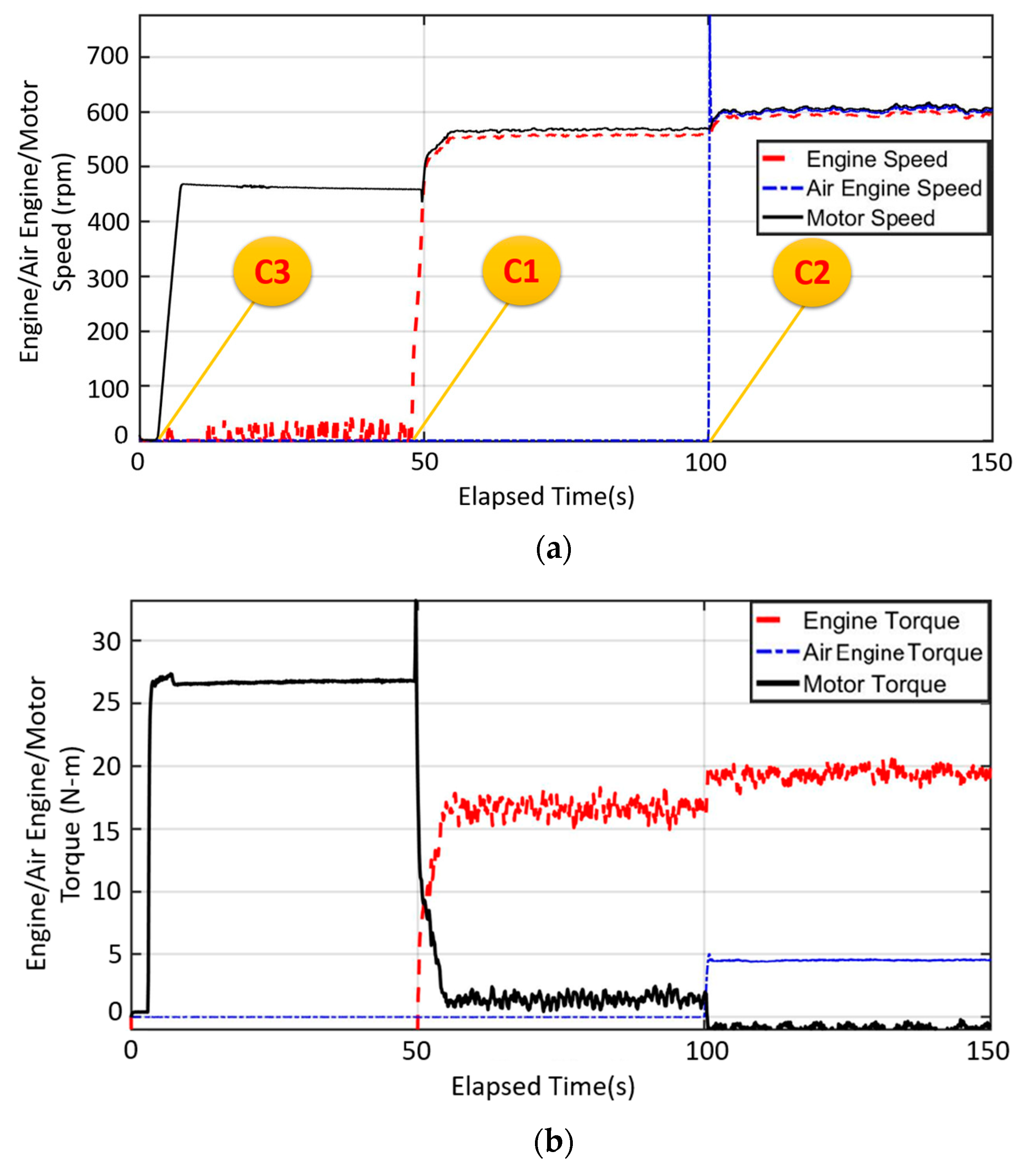

4.1. Engine/hub Motor Hybrid Mode

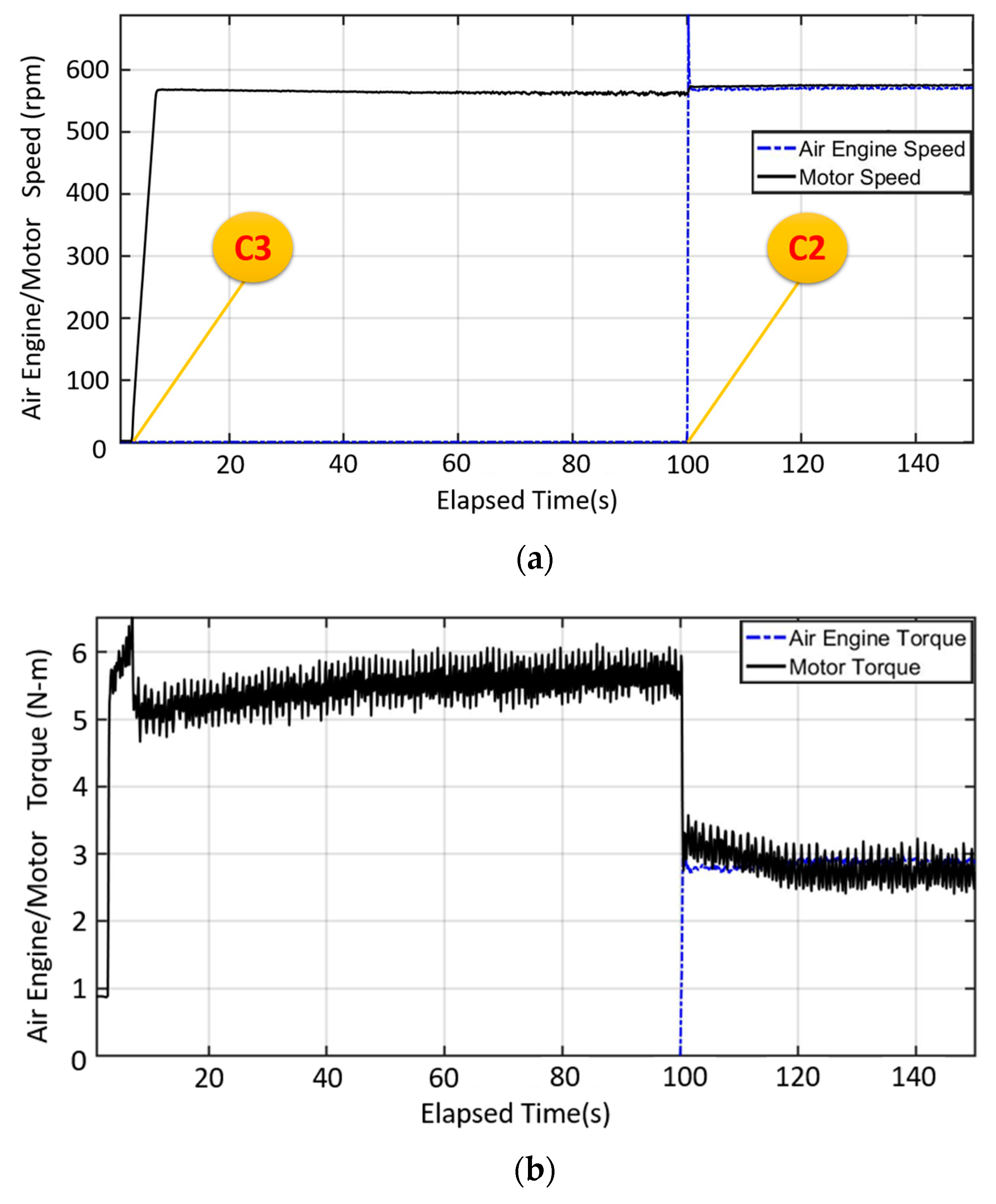

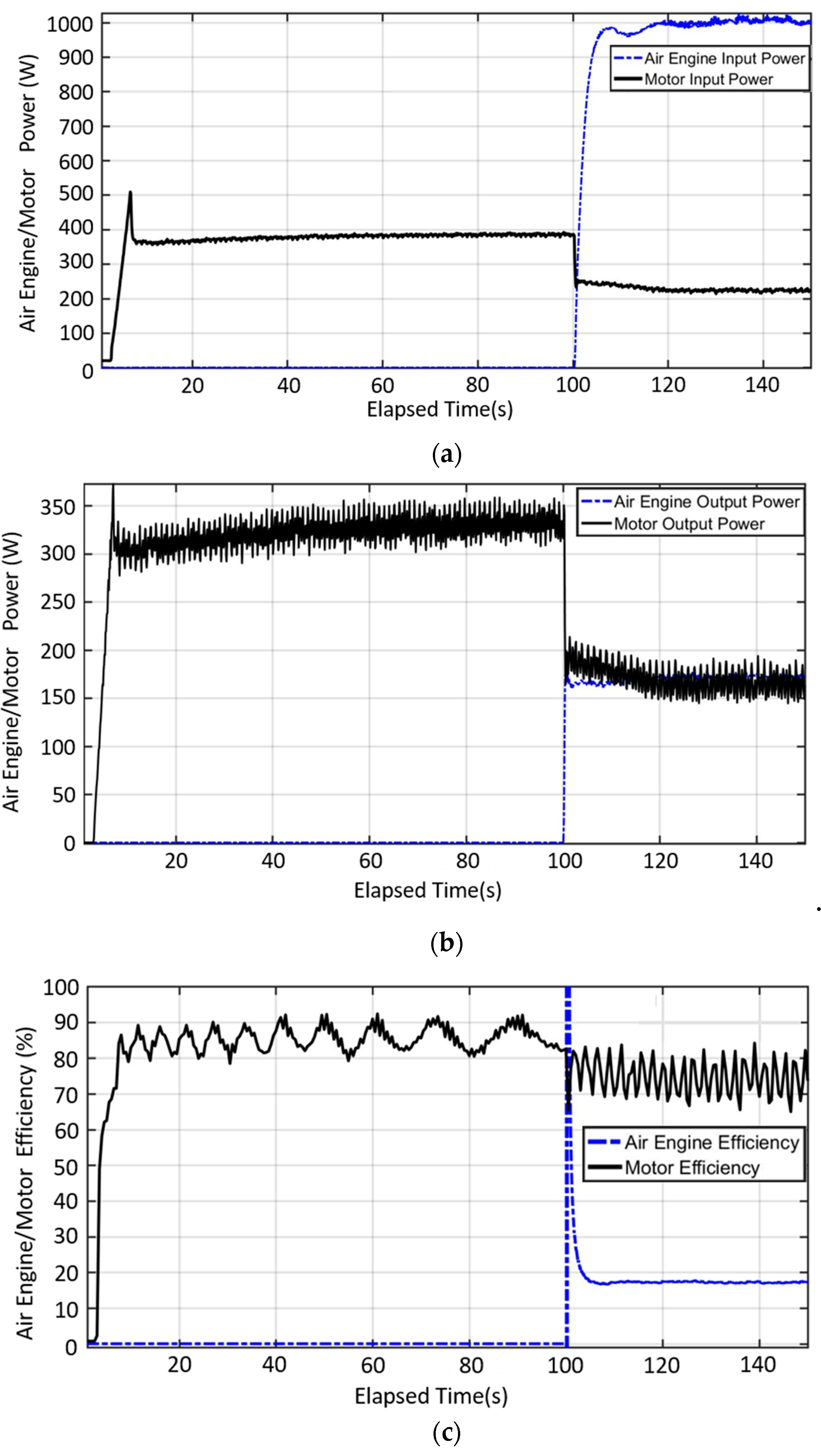

4.2. Hub Motor/Air Engine Hybrid Mode

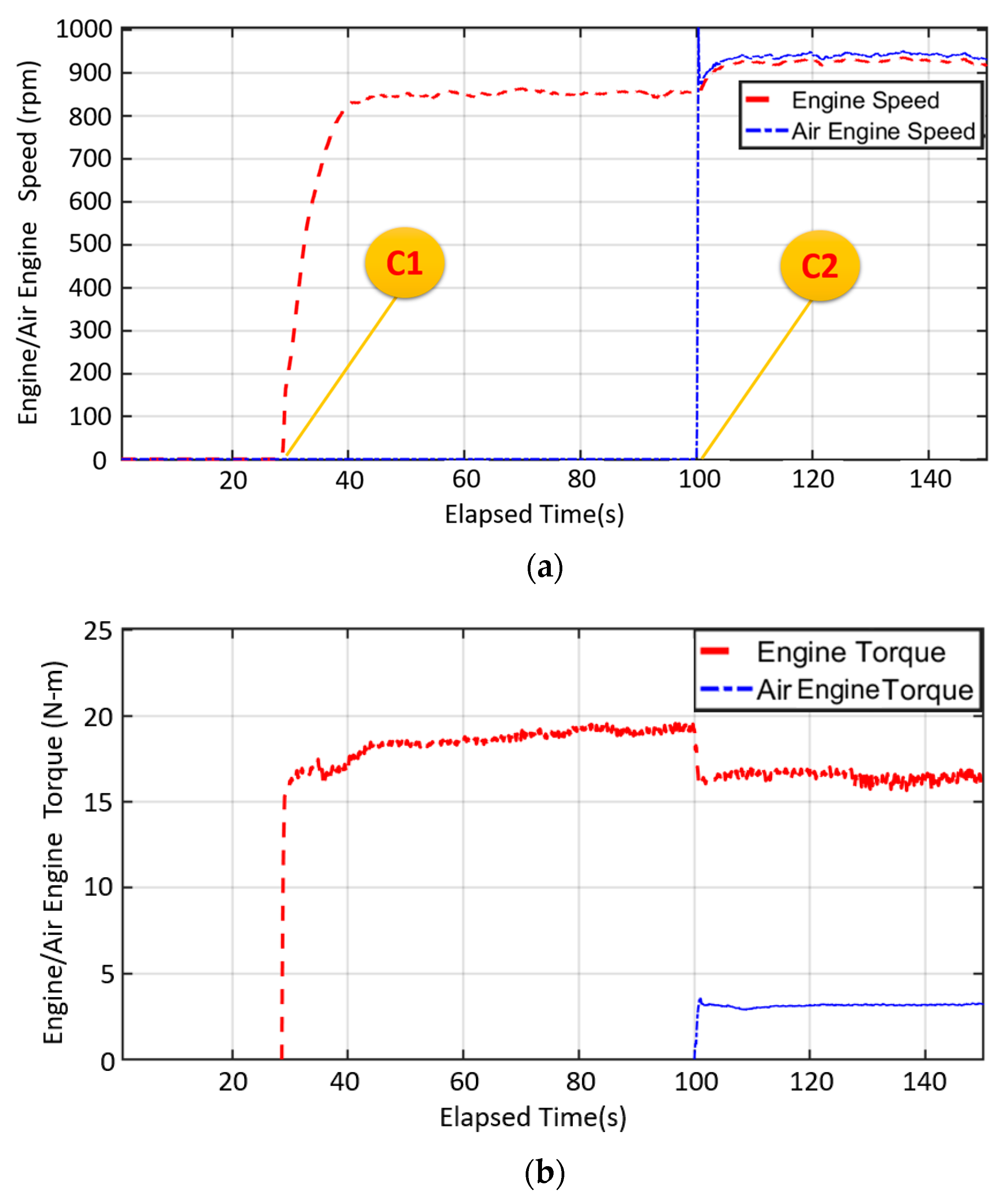

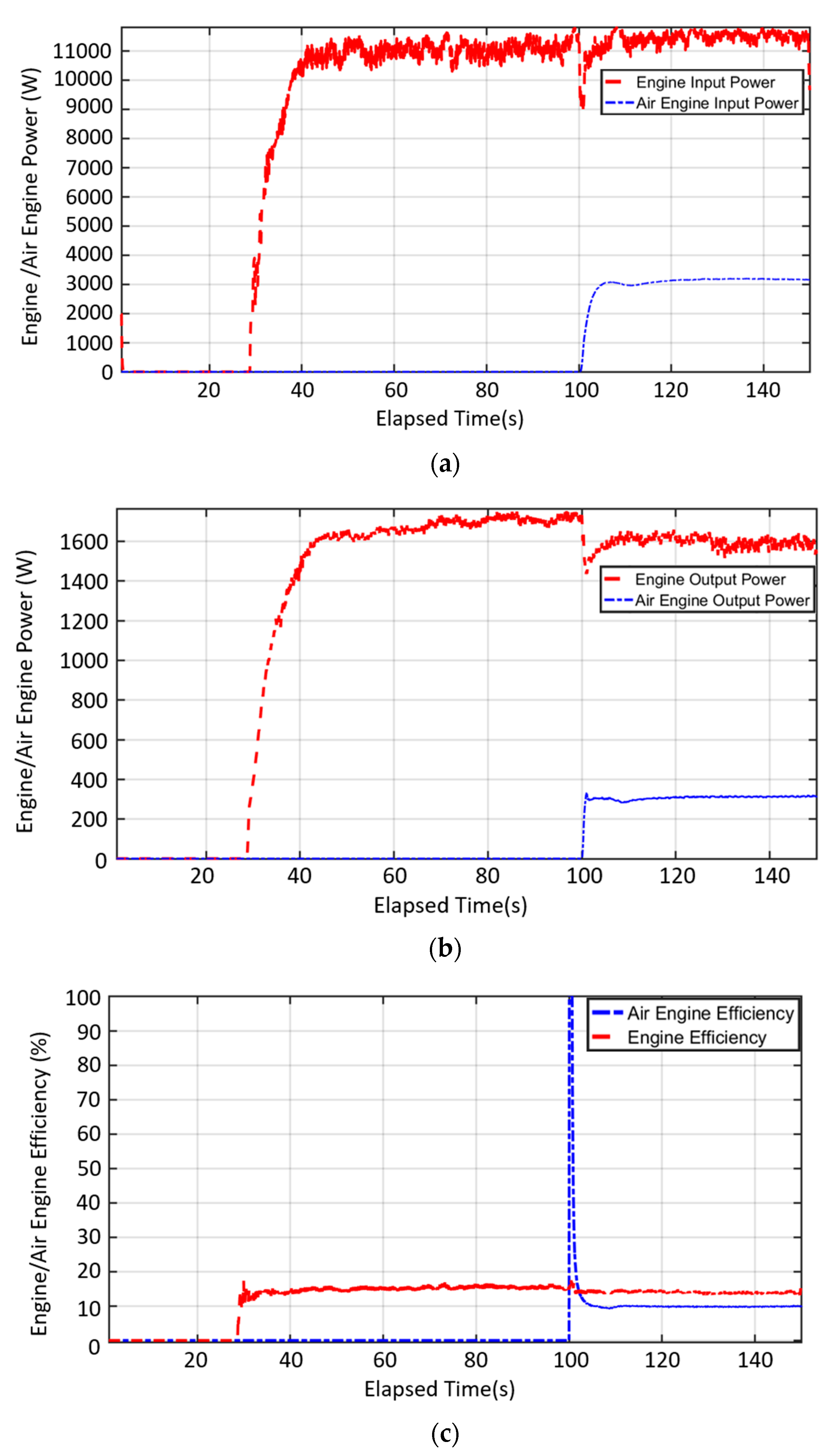

4.3. Engine/Air Engine Hybrid Mode

4.4. Engine/Hub Motor/Air Engine Hybrid Mode

5. Conclusions

- Innovative all-in-one mechatronics system: a 125 c.c. SI engine, a 1.5kW hub motor, a 1kW air engine, and a outload simulation system are combined on two transmission shafts where three e-clutches and two chain belts deliver the power flow.

- The integration of control, harness, and signals: on the Matlab/Simulink environment, it receives the measured signals and sends the control commands to actuators (throttles and the MCU). The rule-based control of three e-clutches, three single-source modes, three dual-source modes, and one three-source mode (3+3+1) can be conducted.

- Four mode demonstration: the results show that four modes, including three dual-source modes and one three-source mode, were successfully operated. The torque and speed, input/output power, and the efficiencies can be recorded and analyzed. For engine/hub motor mode, the hub motor activates and accelerates first (C3 on), and then the engine starts (C1 on). The hub motor efficiency ranged from 87–89%, while 13% for the engine. For the hub motor/air engine mode, the major power-hub motor starts first (C3 on), and then the air engine (C2 on). The hub motor efficiency varies from 70% to 90%, while 17.5% for the air engine. For the engine/air engine mode, the main power-engine lunches first (C1 on) and the air engine (C2 on), where the engine efficiency is nearly 15% while 10% for the air engine. For the three-power-source mode, the hub motor provides large torque in the beginning (C1 on), then the engine starts as the main power, while the air engine is for the power assistance. The motor efficiency is 86%, and 10% and 12.9% for the engine and the air engine, respectively. The above results prove the high flexibility of power combination, and this research provides a good platform for the research of hybrid powertrains and energy control.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, X.I.; He, H.W.; Sun, F.C.; Zhang, J.L. Architectures of Planetary Hybrid Powertrain System: Review, Classification and Comparison. Energies 2020, 13, 329. [Google Scholar] [CrossRef]

- Chen, X.; Hu, G.G.; Guo, F.; Ye, M.Q.; Huang, J.Y. Switched Energy Management Strategy for Fuel Cell Hybrid Vehicle Based on Switch Network. Energies 2020, 13, 247. [Google Scholar] [CrossRef]

- Hung, Y.H.; Tung, Y.M.; Li, H.W. A real-time model of an automotive air propulsion system. Appl. Energy 2014, 129, 287–298. [Google Scholar] [CrossRef]

- Bagwe, R.M.; Byerly, A.; Santos, E.C.D.; BenMiled, Z. Adaptive Rule-Based Energy Management Strategy for a Parallel HEV. Energies 2019, 12, 4472. [Google Scholar] [CrossRef]

- Wang, X.I.; He, H.W.; Sun, F.C.; Zhang, J.L. Application Study on the Dynamic Programming Algorithm for Energy Management of Plug-in Hybrid Electric Vehicles. Energies 2015, 8, 3225–3244. [Google Scholar] [CrossRef]

- Chung, C.T.; Hung, Y.H. Performance and energy management of a novel full hybrid electric powertrain system. Energy 2015, 89, 626–636. [Google Scholar] [CrossRef]

- Khaligh, A.; Li, Z. Battery, ultracapacitor, fuel cell, and hybrid energy storage systems for electric, hybrid electric, fuel cell, and plug-in hybrid electric vehicles: State of the art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Tate, E.; Harpster, M.; Savagian, P. The Electrification of the automobile: From conventional hybrid, to plug-in hybrids, to extended-range electric vehicles. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2009, 1, 156–166. [Google Scholar] [CrossRef]

- Wang, Y.; Song, X.; Sun, Z. Hybrid powertrain control with a rapid prototyping research platform. In Proceedings of the IEEE 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011; pp. 997–1002. [Google Scholar]

- Ye, X.; Jin, Z.; Liu, B.; Chen, M.; Lu, Q. Design and application of parallel hybrid vehicle simulation platform. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Hangzhou, China, 17–20 October 2010; pp. 1–5. [Google Scholar]

- Timmermans, J.; Van Mierlo, J.; Lataire, P.; Van Mulders, F.; McCaffree, Z. Test platform for hybrid electric power systems: Development of a HIL test platform. In Proceedings of the IEEE European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007; pp. 1–7. [Google Scholar]

- Padian, S.R.; Takemura, F.; Hayakawa, Y.; Kawamura, Y.S. Control performance of an air motor-can air motors replace electric motors? In Proceedings of the IEEE International Conference on Robotics & Automation, Detroit, MI, USA, 10–15 May 1999; pp. 518–524. [Google Scholar]

- Hwang, Y.R.; Shen, Y.D.; Jen, K.K. Fuzzy MRAC controller design for vane-type air motor systems. J. Mech. Sci. Technol 2008, 22, 497–505. [Google Scholar] [CrossRef]

- Wang, J.; Yan, L.; Luo, X.; Mangan, S.; Derby, J.W. Mathematical modeling study of scroll air motors and energy efficiency analysis—Part I. IEEE/ASME Trans. On Mech. 2011, 16, 112–121. [Google Scholar] [CrossRef]

- Wang, J.; Yan, L.; Luo, X.; Mangan, S.; Derby, J.W. Mathematical modeling study of scroll air motors and energy efficiency analysis—Part II. IEEE/ASME Trans. On Mech. 2011, 16, 122–132. [Google Scholar] [CrossRef]

- Huang, K.D.; Tzeng, S.C. Development of a hybrid pneumatic-power vehicle. Appl. Energy 2005, 80, 47–59. [Google Scholar] [CrossRef]

- Huang, K.D.; Tzeng, S.C.; Ma, W.P.; Chang, W.C. Hybrid pneumatic-power system which recycles exhaust gas of an internal-combustion engine. Appl. Energy 2005, 82, 117–132. [Google Scholar] [CrossRef]

- Huang, K.D.; Tzeng, S.C.; Chang, W.C. Energy-saving hybrid vehicle using a pneumatic-power system. Appl. Energy 2005, 81, 1–18. [Google Scholar] [CrossRef]

- Shen, Y.T.; Hwang, Y.R. Design and implementation of an air-powered motorcycle. Appl. Energy 2009, 86, 1105–1110. [Google Scholar]

- Hung, Y.H.; Chen, J.H.; Wu, C.H.; Chen, S.Y. System design and mechatronics of an air supply station for air-powered scooters. Comput. Electr. Eng. 2016, 54, 185–194. [Google Scholar] [CrossRef]

| Model | Clutch1 | Clutch2 | Clutch3 | Switch Condition |

|---|---|---|---|---|

| Hub Motor | OFF | OFF | ON | -- |

| Engine | ON | OFF | OFF | -- |

| Air Engine | OFF | ON | OFF | -- |

| Engine + Hub Motor | ON | OFF | ON | (1) Hub motor on (2) Clutch 1 on when engine speed reaches motor speed |

| Engine + Air Engine | ON | ON | OFF | (1) Engine on (2) Clutch 2 on when air engine speed reaches engine speed |

| Hub Motor + Air Engine | OFF | ON | ON | (1) Hub motor on (2) Clutch 2 on when air engine speed reaches hub motor speed |

| Engine + Hub Motor + Air Engine | ON | ON | ON | (1) Hub motor on (2) Clutch 1 and 2 on when engine and air engine speeds reach motor speed |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-H.; Chang, H.-Y.; Hung, Y.-H.; Wu, C.-H.; Xu, J.-J. System Designs and Experimental Assessment of a Seven-Mode Vehicle-Oriented Hybrid Powertrain Platform. Energies 2020, 13, 2104. https://doi.org/10.3390/en13082104

Chang C-H, Chang H-Y, Hung Y-H, Wu C-H, Xu J-J. System Designs and Experimental Assessment of a Seven-Mode Vehicle-Oriented Hybrid Powertrain Platform. Energies. 2020; 13(8):2104. https://doi.org/10.3390/en13082104

Chicago/Turabian StyleChang, Chun-Hsin, Hsuan-Yung Chang, Yi-Hsuan Hung, Chien-Hsun Wu, and Ji-Jia Xu. 2020. "System Designs and Experimental Assessment of a Seven-Mode Vehicle-Oriented Hybrid Powertrain Platform" Energies 13, no. 8: 2104. https://doi.org/10.3390/en13082104

APA StyleChang, C.-H., Chang, H.-Y., Hung, Y.-H., Wu, C.-H., & Xu, J.-J. (2020). System Designs and Experimental Assessment of a Seven-Mode Vehicle-Oriented Hybrid Powertrain Platform. Energies, 13(8), 2104. https://doi.org/10.3390/en13082104