Minimizing Power Consumption of an Experimental HVAC System Based on Parallel Grid Searching

Abstract

1. Introduction

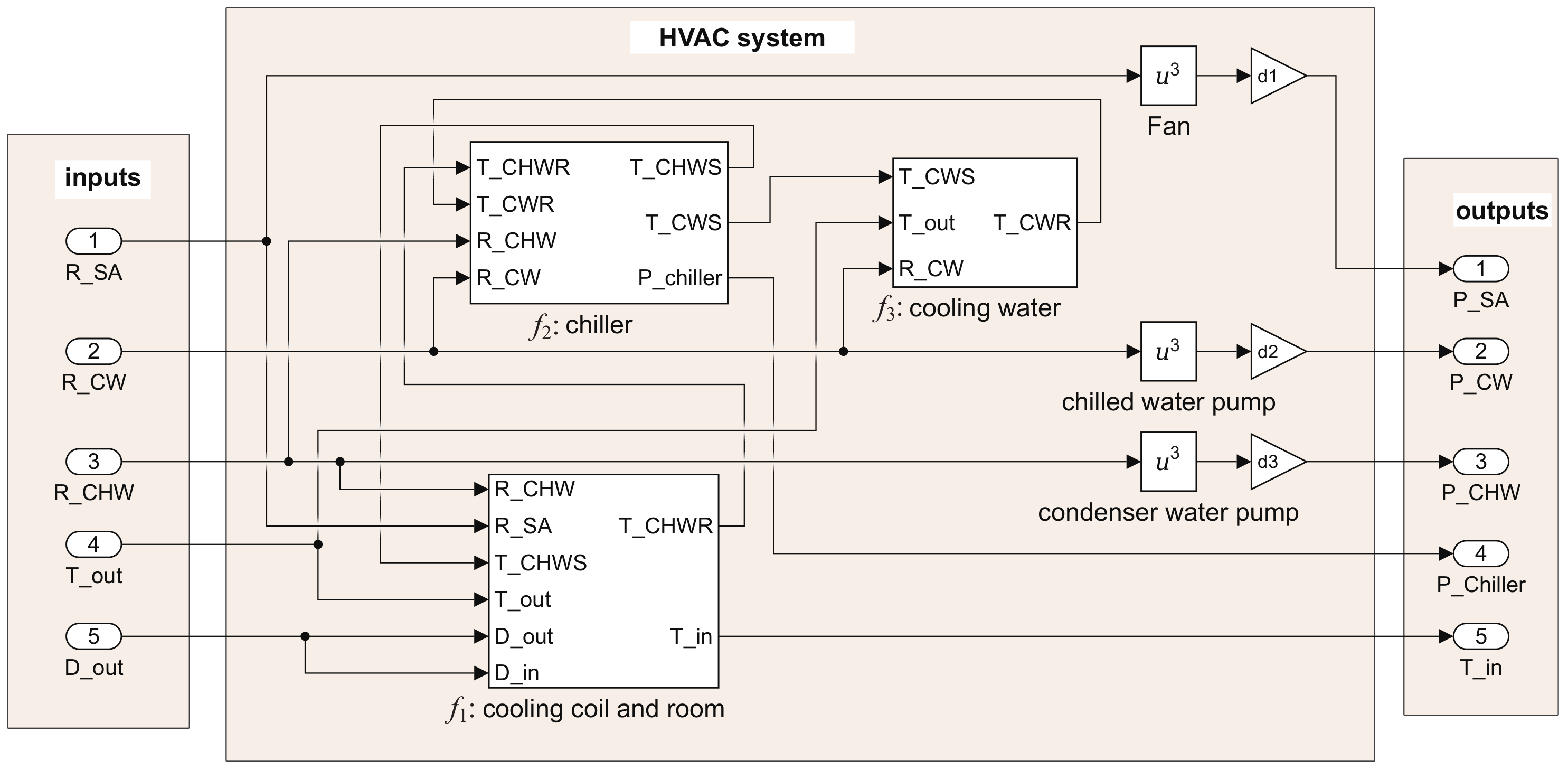

2. Problem Description

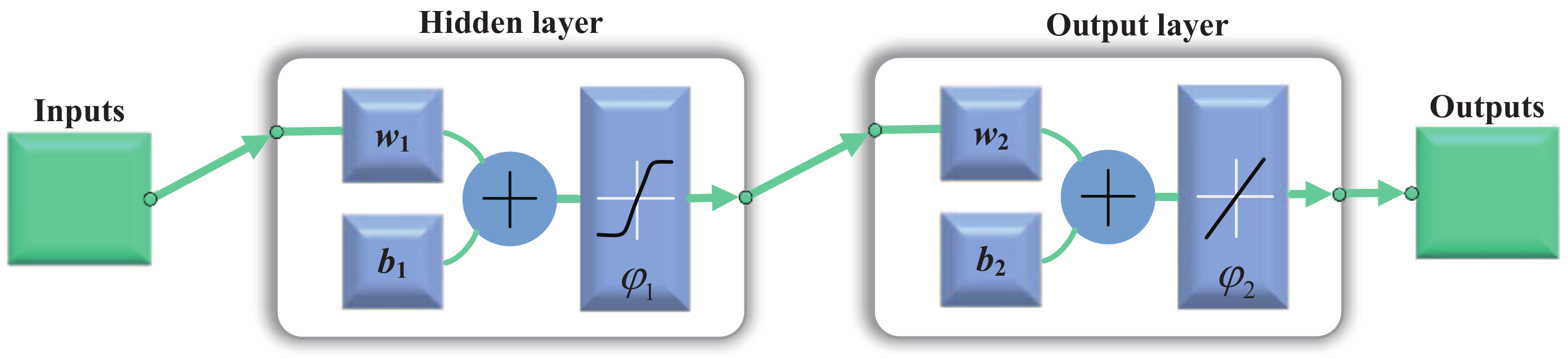

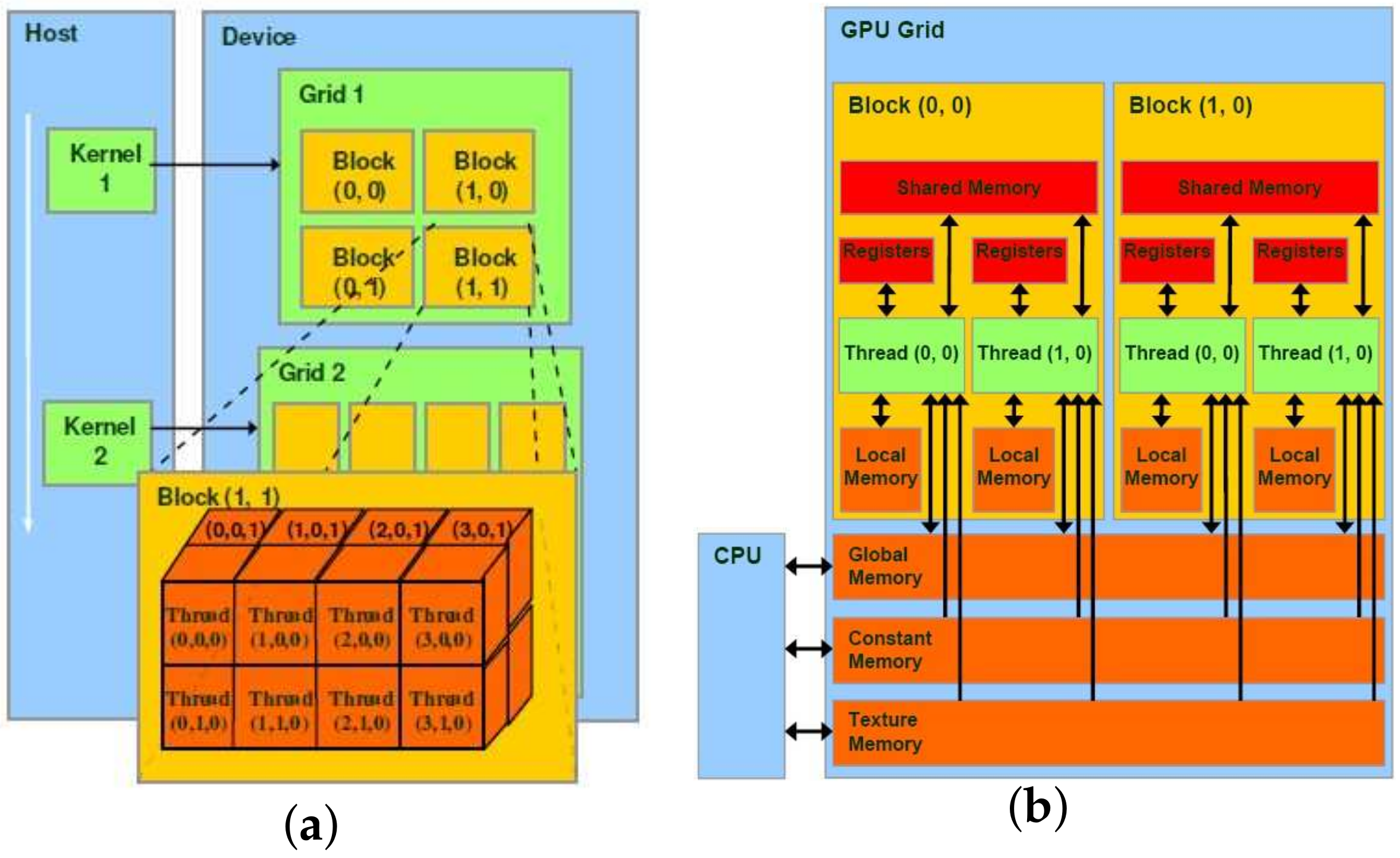

3. The Proposed Algorithm

| Algorithm 1. Detailed algorithm for power consumption optimization. |

| 1. Divide the entire searching grid by and allocate the global memory |

| 2. Formulate points of the searching grid for (, , ) using (9) |

| 3. Initialize the HVAC model coefficients and and |

| 4. Set the searching grid parameters and launch the kernels: |

| (inputs, ) |

| 5. Transfer all values of back to the host memory |

| 6. Compare the values of to obtain the optimal solution in (10) |

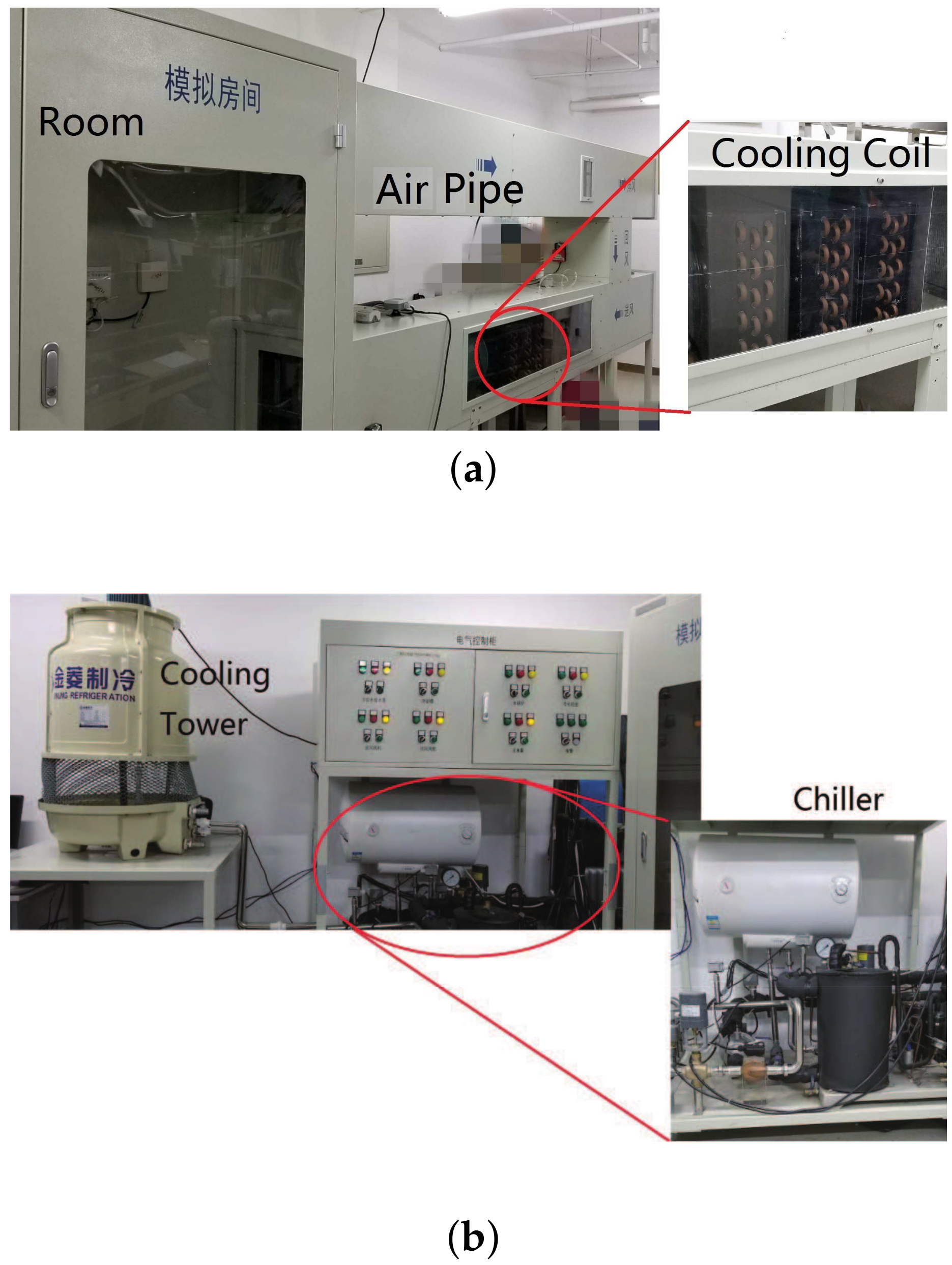

4. Experimental Studies

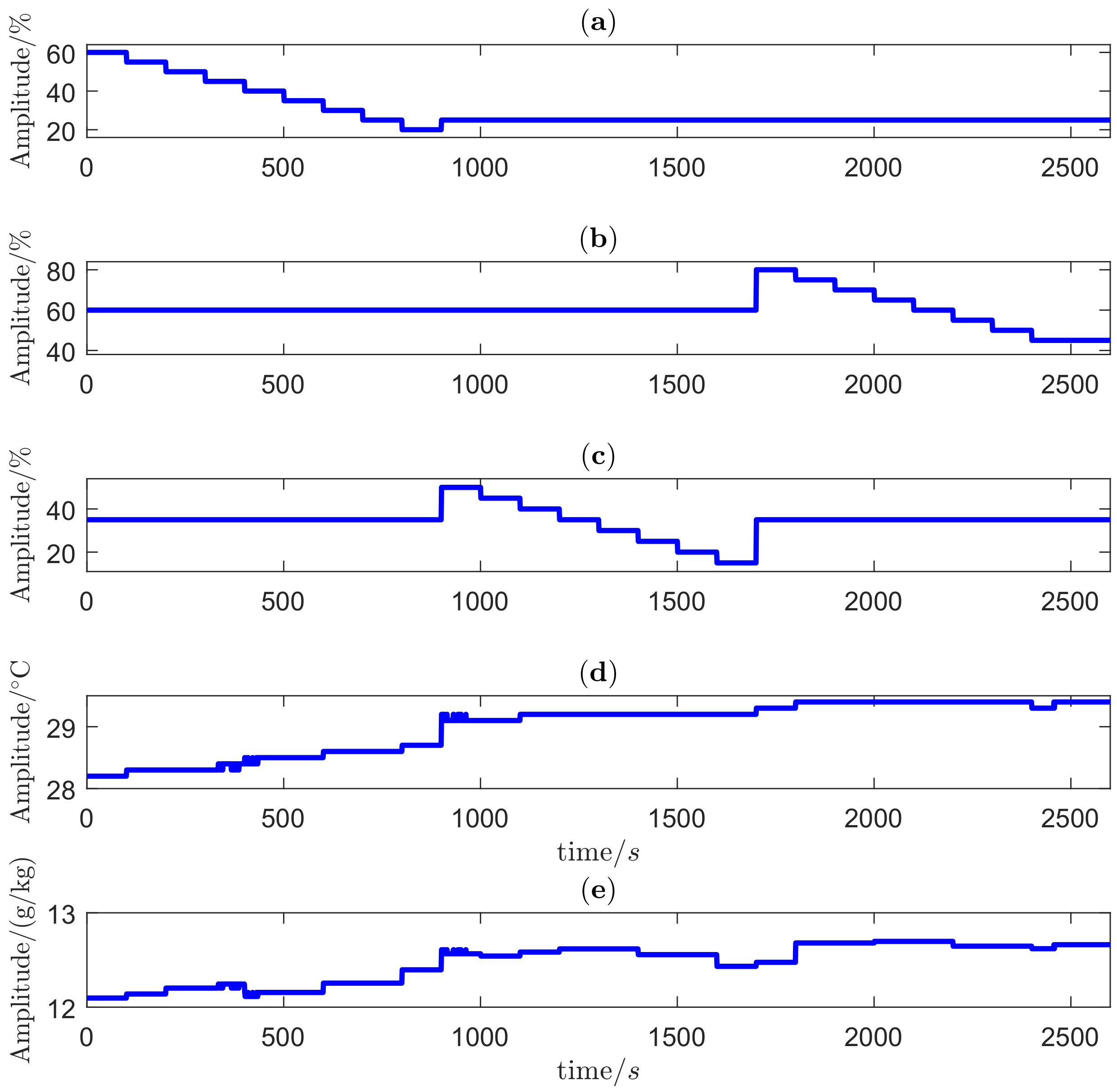

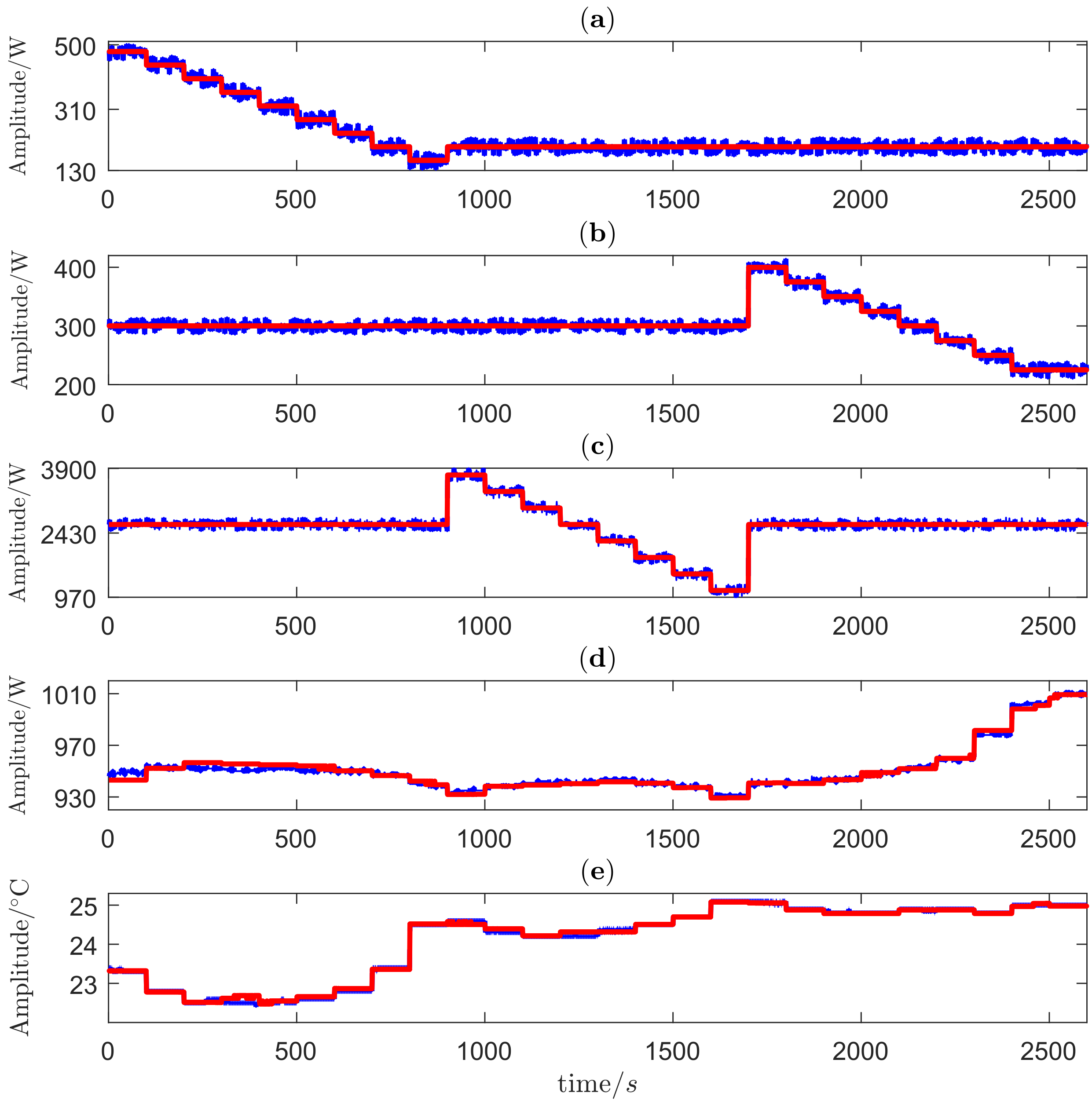

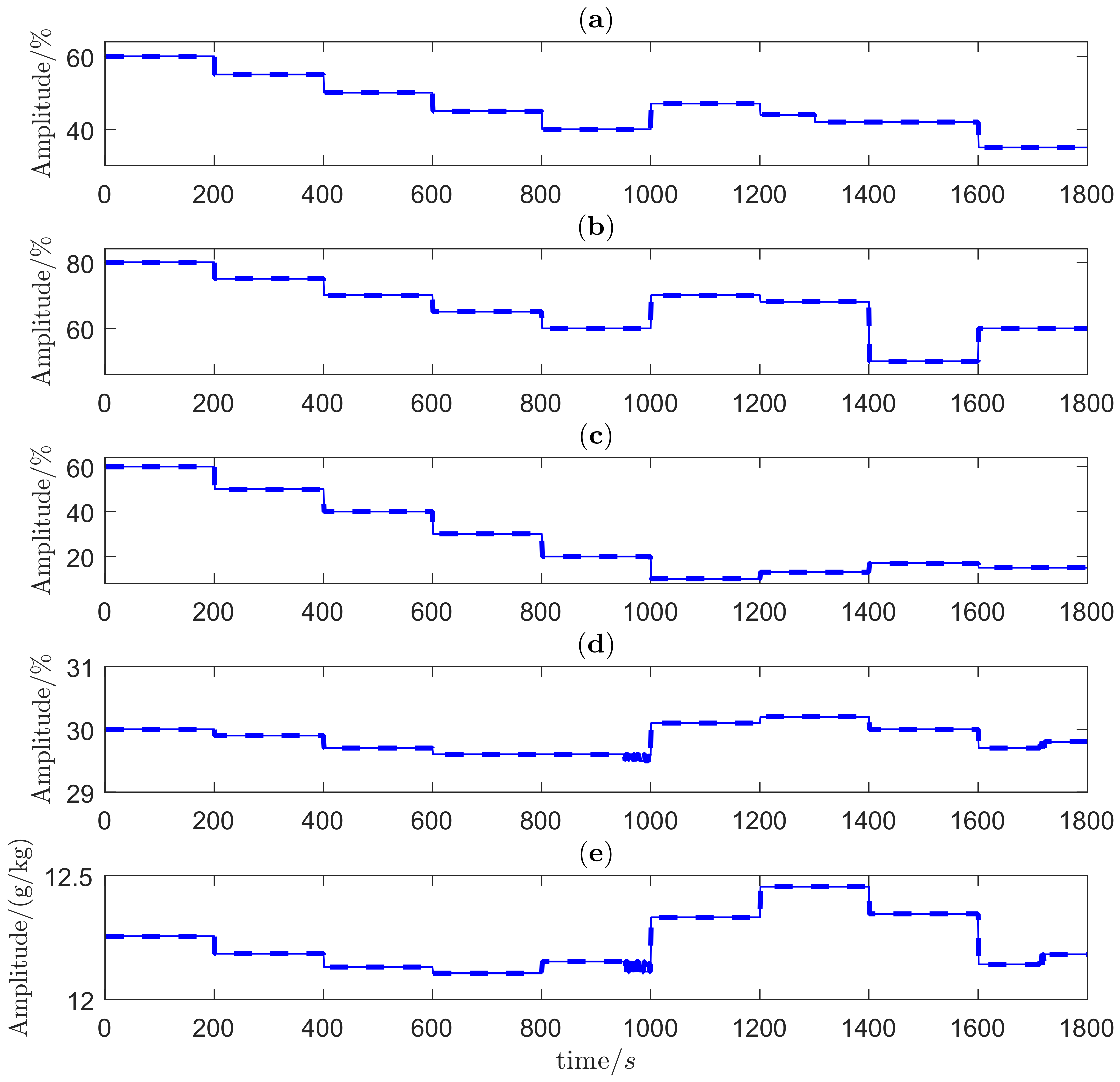

4.1. Model Coefficient Estimation

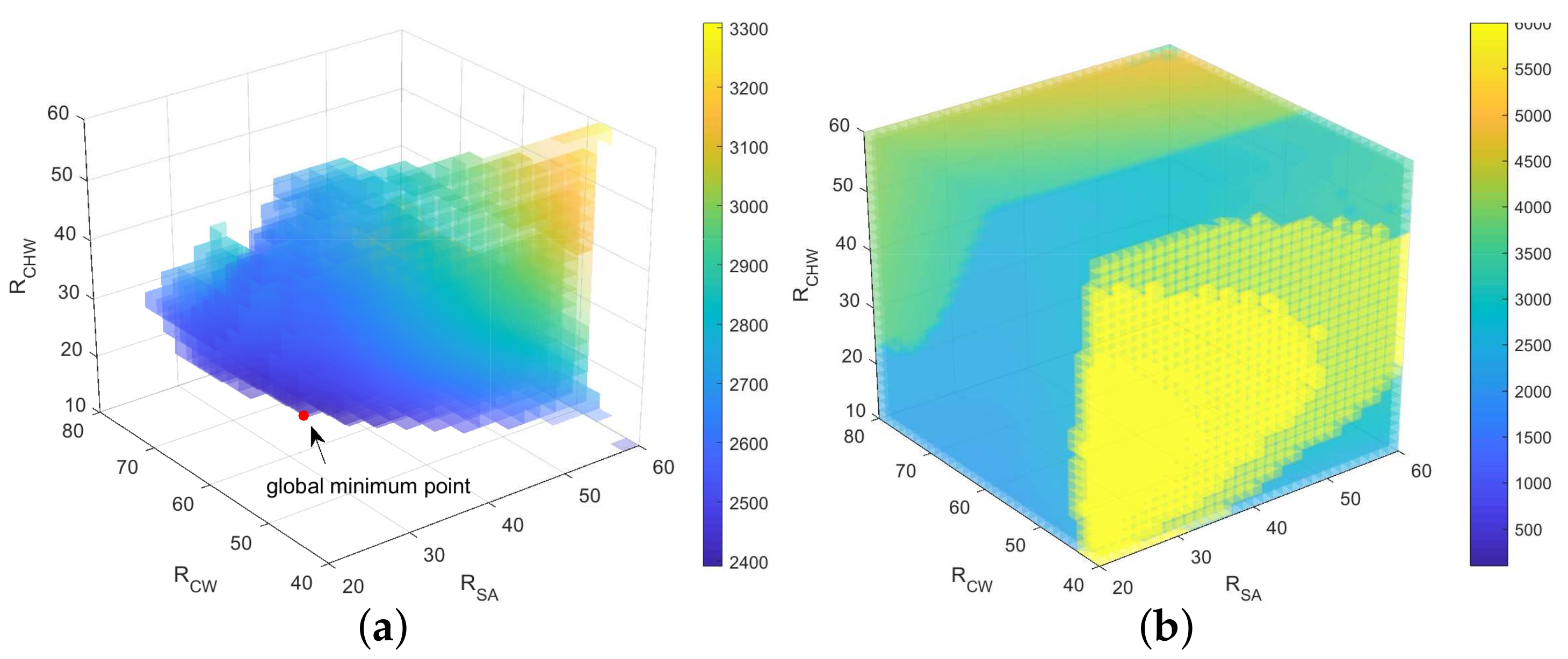

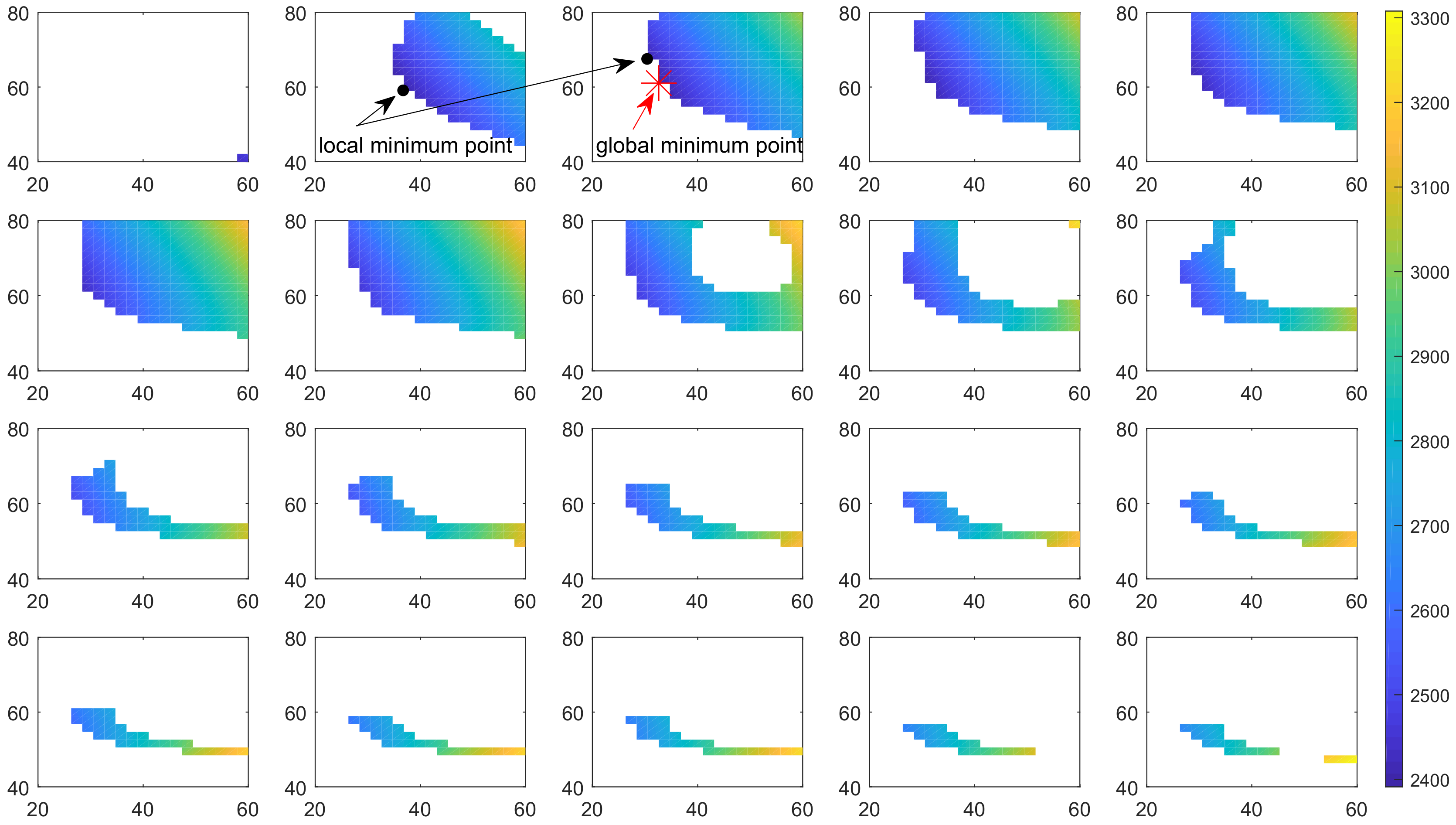

4.2. Performance Comparison of Optimization Algorithms

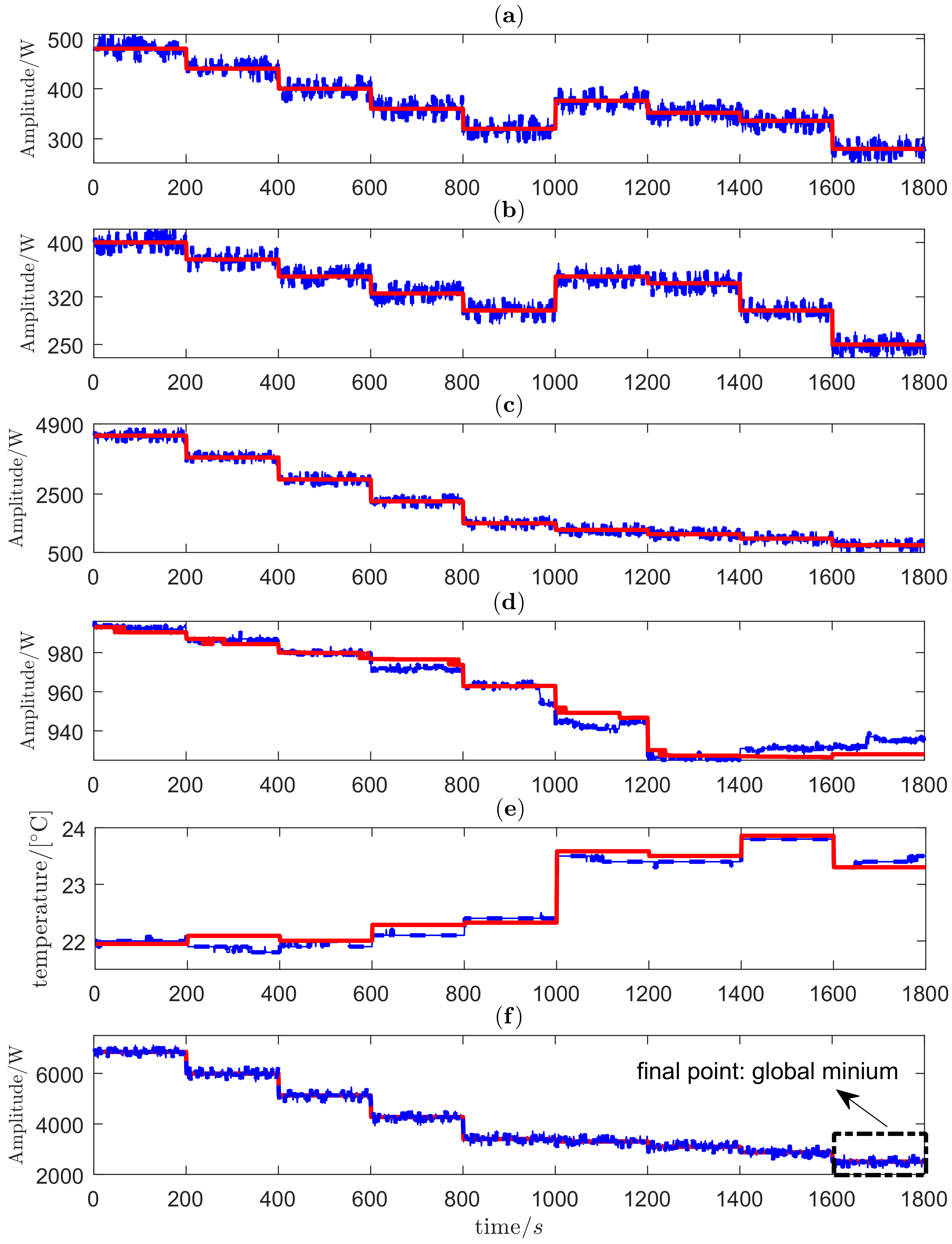

4.3. Optimization Result Validation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| chilled water pump speed | |

| cooling water pump speed | |

| cooling coil fan speed | |

| chilled water supply temperature | |

| chilled water return temperature | |

| cooling water supply temperature | |

| cooling water return temperature | |

| supplied air temperature through the cooling coil | |

| indoor temperature | |

| outdoor temperature | |

| indoor humidity | |

| outdoor humidity | |

| power consumption of the chiller | |

| power consumption of the chilled water pump | |

| power consumption of the cooling water pump | |

| power consumption of the cooling coil fan |

References

- ASHRAE. HVAC Systems and Equipment; American Society of Heating, Refrigerating, and Air Conditioning Engineers: Atlanta, GA, USA, 2008. [Google Scholar]

- Real-Fernandez, A.; Navarro-Esbri, J.; Mota-Babiloni, A.; Barragan-Cervera, A.; Domenech, L.; Sanchez, F.; Aprea, C. Modeling of a PCM TES tank used as an alternative heat sink for a water chiller: Analysis of performance and energy savings. Energies 2019, 12, 3652. [Google Scholar] [CrossRef]

- Radzi, A.; Droege, P. Latest perspectives on global renewable energy policies. Curr. Sustain. Renew. Energy Rep. 2014, 1, 85–93. [Google Scholar] [CrossRef][Green Version]

- Vakiloroaya, V.; Samali, B.; Fakhar, A.; Pishghadam, K. A review of different strategies for HVAC energy saving. Energy Convers. Manag. 2014, 77, 738–754. [Google Scholar] [CrossRef]

- Lu, L.; Cai, W.; Soh, Y.C.; Xie, L.; Li, S. HVAC system optimization–condenser water loop. Energy Convers. Manag. 2004, 45, 613–630. [Google Scholar] [CrossRef]

- Lu, L.; Cai, W.; Xie, L.; Li, S.; Soh, Y.C. HVAC system optimization—In-building section. Energy Build. 2005, 37, 11–12. [Google Scholar] [CrossRef]

- Asiedu, Y.; Besant, R.W.; Gu, P. HVAC duct system design using genetic algorithms. HVAC R Res. 2000, 6, 149–173. [Google Scholar] [CrossRef]

- Chow, T.T.; Zhang, G.Q.; Lin, Z.; Song, C.L. Global optimization of absorption chiller system by genetic algorithm and neural network. Energy Build. 2002, 34, 103–109. [Google Scholar] [CrossRef]

- Ullah, I.; Kim, D. An improved optimization function for maximizing user comfort with minimum energy consumption in smart homes. Energies 2017, 10, 1818. [Google Scholar] [CrossRef]

- Kampelis, N.; Sifakis, N.; Kolokotsa, D.; Gobakis, K.; Kalaitzakis, K.; Isidori, D.; Cristalli, C. HVAC optimization genetic algorithm for industrial near-zero-energy building demand response. Energies 2019, 12, 2177. [Google Scholar] [CrossRef]

- Fong, K.F.; Hanby, V.I.; Chow, T.T. System optimization for HVAC energy management using the robust evolutionary algorithm. Appl. Therm. Eng. 2009, 29, 2327–2334. [Google Scholar] [CrossRef]

- Klein, S.A.; Beckman, W.A.; Cooper, P.I. TRNSYS—A Transient System Simulation Program; Mathematical Reference; Solar Energy Laboratory, University of Wisconsin-Madison: Wisconsin, USA, 2004; Chapter 4; Volume 4, pp. 120–161. [Google Scholar]

- TESS Library Documentation. TESS Component Libraries v2.0 for TRNSYS v16.0 and TRNSYS Simulation Studio; Thermal Energy System Specialists: Wisconsin, MD, USA, 2004. [Google Scholar]

- Wemhoff, A.P.; Frank, M.V. Predictions of energy savings in HVAC systems by lumped models. Energy Build. 2010, 42, 1807–1814. [Google Scholar] [CrossRef]

- Wemhoff, A.P. Application of optimization techniques on lumped HVAC models for energy conservation. Energy Build. 2010, 42, 2445–2451. [Google Scholar] [CrossRef]

- Zakula, T.; Armstrong, P.; Norford, L. Optimal coordination of heat pump compressor and fan speeds and subcooling over a wide range of loads and conditions. HVAC R Res. 2012, 18, 1153–1167. [Google Scholar]

- Kim, J.H.; Seong, N.C.; Choi, W. Modeling and optimizing a chiller system using a machine learning algorithm. Energies 2019, 12, 2860. [Google Scholar] [CrossRef]

- Kusiak, A.; Zeng, Y.; Xu, G. Minimizing energy consumption of an air handling unit with a computational intelligence approach. Energy Build. 2013, 60, 355–363. [Google Scholar] [CrossRef]

- Wei, X.; Kusiak, A.; Li, M.; Tang, F.; Zeng, Y. Multi-objective optimization of the HVAC (heating, ventilation, and air conditioning) system performance. Energy 2015, 83, 294–306. [Google Scholar] [CrossRef]

- Kim, W.; Jeon, Y.; Kim, Y. Simulation-based optimization of an integrated daylighting and HVAC system using the design of experiments method. Appl. Energy 2016, 162, 666–674. [Google Scholar] [CrossRef]

- Afram, A.; Janabi-Sharifi, F.; Fung, A.S.; Raahemifar, K. Artificial neural network (ANN) based model predictive control (MPC) and optimization of HVAC systems: A state of the art review and case study of a residential HVAC system. Energy Build. 2017, 141, 96–113. [Google Scholar] [CrossRef]

- Alibabaei, N.; Fung, A.S.; Raahemifar, K.; Moghimi, A. Effects of intelligent strategy planning models on residential HVAC system energy demand and cost during the heating and cooling seasons. Appl. Energy 2017, 185, 29–43. [Google Scholar] [CrossRef]

- Ghahramani, A.; Karvigh, S.A.; Becerik-Gerber, B. HVAC system energy optimization using an adaptive hybrid metaheuristic. Energy Build. 2017, 152, 149–161. [Google Scholar] [CrossRef]

- Xiong, W.; Wang, J. Semi-physical modeling static behaviors of an experimental HVAC system. Control Eng. Pract. 2020, 96, 104312. [Google Scholar] [CrossRef]

- McQuiston, F.C.; Parker, J.D. Heating, Ventilating, and Air Conditioning: Analysis and Design; John Wiley and Sons: New York, NY, USA, 2005. [Google Scholar]

- Steven, M.; LaValle, M.; Branicky, S.; Lindemann, S.R. On the relationship between classical grid search and probabilistic roadmaps. Int. J. Robot. Res. 2004, 23, 673–692. [Google Scholar]

- Sanders, J.; Kandrot, E. Parallel Programming in CuDA C. In CUDA by Example: An Introduction to General-Purpose GPU Programming; Addison-Wesley Professional: Boston, MA, USA, 2010; pp. 37–57. [Google Scholar]

- Nvidia, C.U.D.A. Programming Model. In Programming Guide Version 8.0; Nvidia Corporation: Santa Clara, CA, USA, 2016; pp. 8–15. [Google Scholar]

| References | System to Be Optimized | Optimization Variables | Cost Function | Optimization Algorithm |

|---|---|---|---|---|

| [5,6] | Static overall HVAC system | Number of operating chillers chilled water pumps, cooling coils, condenser water pumps and cooling tower fans, temperatures of chilled water supply and condenser water supply, air flow rate of supply air and cooling tower fun, chilled and condenser water flow rate of pumps | Total energy consumption | Modified GA |

| [10] | Dynamic overall HVAC system | hourly HVAC temperature set points | cost of energy | GA |

| [11] | Static overall HVAC system | Set point of chilled water supply temperature of chiller and supply air temperature of AHU | Monthly energy consumption | REA |

| [14,15] | Static two-room system | Fan rotation speed, actuating damper, pump rotation speed, chiller work input | Energy consumption | MC |

| [16] | Static heat pump | Evaporator and condenser airflow rate, condenser area fraction devoted to subcooling | Total power consumption | Adaptive grid search |

| [17] | Static chiller | chilled water flow rate cooling water temperature outside dry-bulb temperature outside wet-bulb temperature dew-point temperature outside relative humidity hour, type of day | total Power consumption | ANN |

| [18] | Dynamic AHU | Chilled water flow rate, supply fan VFD speed, chilled water coil valve position, chilled water coil supply temperature | Total energy consumption | DPEM |

| [19] | Dynamic overall HVAC system | Supply air temperature and static pressure setpoint | Total energy consumption | Modified PSO |

| [20] | Dynamic overall HVAC system | Venetian blind slat angle, AHU supply air setpoint temperature, AHU operation status, Relative water flow rate of FCU, Outdoor-air mixing ratio | Total power consumption | GA |

| [21] | Dynamic overall HVAC system | Control signal of AHU, RFH, GSHP and RFH | Total cost of operating the HVAC system | MPC |

| [22] | House energy system | Not mention * | HVAC system energy cost | SDFSS, LSH, LSH-SDFSS |

| [23] | Overall HVAC system | Not mention * | Energy consumption | Adaptive hybrid metaheuristic |

| Output variables | /kW | /kW | /kW | /kW | /K |

| Coefficient of variations | 2.91% | 1.95% | 0.59% | 0.84% | 0.075% |

| Component Type | Component Performance |

|---|---|

| CPU | Intel Xeon E5-4640 v4, 2.1 GHz, 12 cores |

| GPU | Tesla K80, 562 MHz, 4992 CUDA cores |

| CPU memory | 64 GB |

| GPU memory | 24 GB |

| GPU peak floating-point performance with double precision | 2.91 Teraflops * |

| GPU compiler | NVCC 8.0 ** |

| Algorithm | Optimization Result | Computing Time/s | |

|---|---|---|---|

| Interior-reflective Newton initial point: [58.3 78.3 34.2] [52.0 45.7 31.1] [36.3 56.7 13.4] | [58.82, 78.28, 34.27] [56.33, 51.80, 33.91] [36.31, 56.62, 14.74] | 2629.76 2988.22 2413.10 | 23.53 26.87 13.56 |

| parallel GA initial point: random random random | [33.13 60.12 14.14] [30.91 62.58 16.35] [31.79 61.76 15.59] | 2374.21 2390.33 2387.21 | 1238.83 1159.34 1108.72 |

| Parallel grid search | 2374.10 | 685.71 | |

| Serial grid search | ≈891000 |

| Global Minimum | Local Minimum 1 | Local Minimum 2 | |

|---|---|---|---|

| center | 2374.10 | 2393.18 | 2406.30 |

| Up | 2430.08 | 2444.28 | 2442.10 |

| Down | NaN * | NaN | NaN |

| right | 2406.57 | 2409.71 | 2424.8 |

| Left | NaN | NaN | NaN |

| Forward | 2425.04 | 2425.33 | 2441.43 |

| backward | NaN | NaN | NaN |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, W.; Wang, J. Minimizing Power Consumption of an Experimental HVAC System Based on Parallel Grid Searching. Energies 2020, 13, 2083. https://doi.org/10.3390/en13082083

Xiong W, Wang J. Minimizing Power Consumption of an Experimental HVAC System Based on Parallel Grid Searching. Energies. 2020; 13(8):2083. https://doi.org/10.3390/en13082083

Chicago/Turabian StyleXiong, Wangqi, and Jiandong Wang. 2020. "Minimizing Power Consumption of an Experimental HVAC System Based on Parallel Grid Searching" Energies 13, no. 8: 2083. https://doi.org/10.3390/en13082083

APA StyleXiong, W., & Wang, J. (2020). Minimizing Power Consumption of an Experimental HVAC System Based on Parallel Grid Searching. Energies, 13(8), 2083. https://doi.org/10.3390/en13082083