Active Disturbance Rejection Control of a Longitudinal Tunnel Ventilation System

Abstract

1. Introduction

2. Dynamical Model of a General Tunnel System with Nonlinear Method

2.1. Ventilation model based on generalized Bernoulli equation

2.2. Exhaust distribution

2.3. Traffic

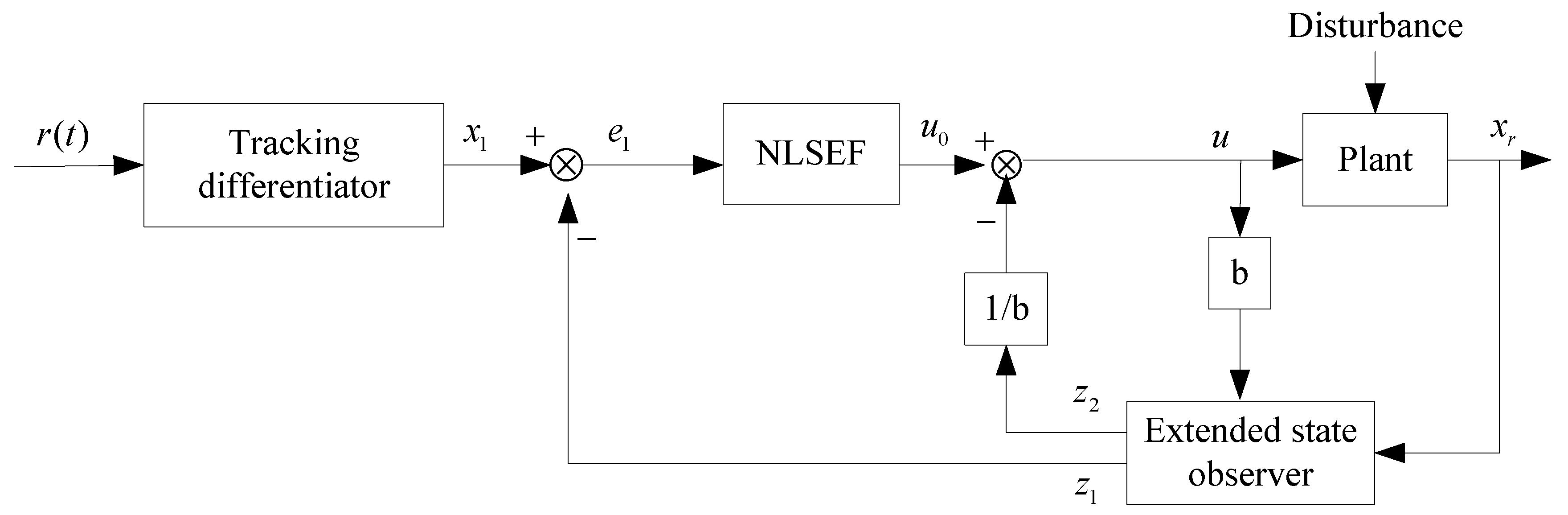

3. Principle of the ADRC

3.1. Tracking differentiator (TD)

3.2. Extended State Observer (ESO)

3.3. Nonlinear State Error Feedback Control Laws (NLSEF)

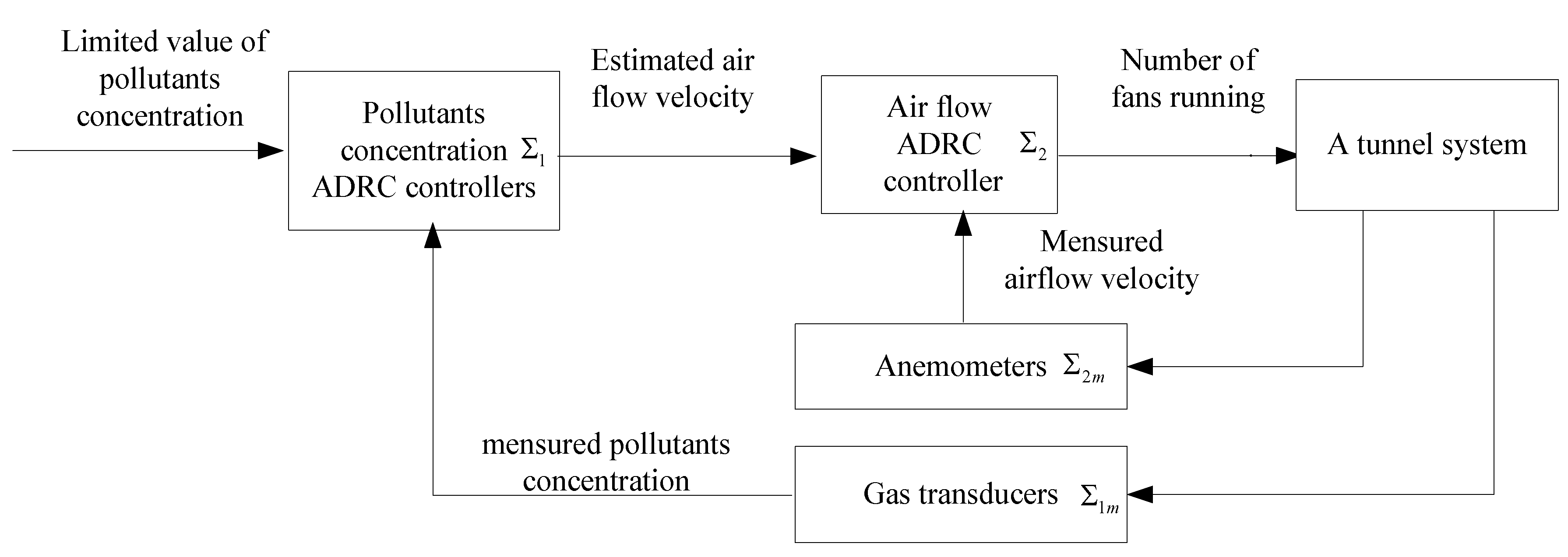

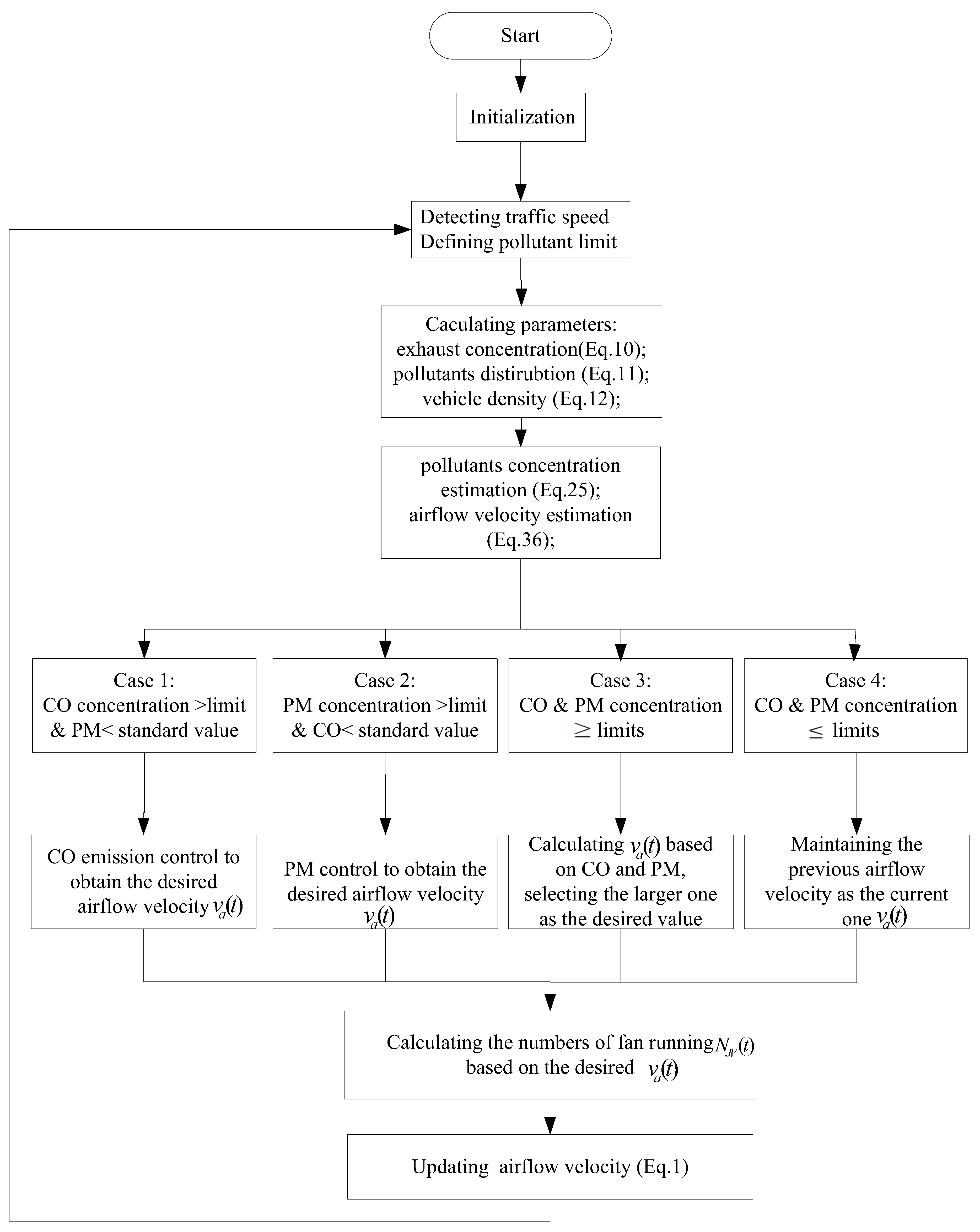

4. Tunnel Ventilation Control System Based on the Active Disturbance Rejection Technique

4.1. Pollutant Concentration Control Subsystem Based on ADRC

4.2. Airflow Velocity Control Subsystem Based on ADRC

5. Test Results

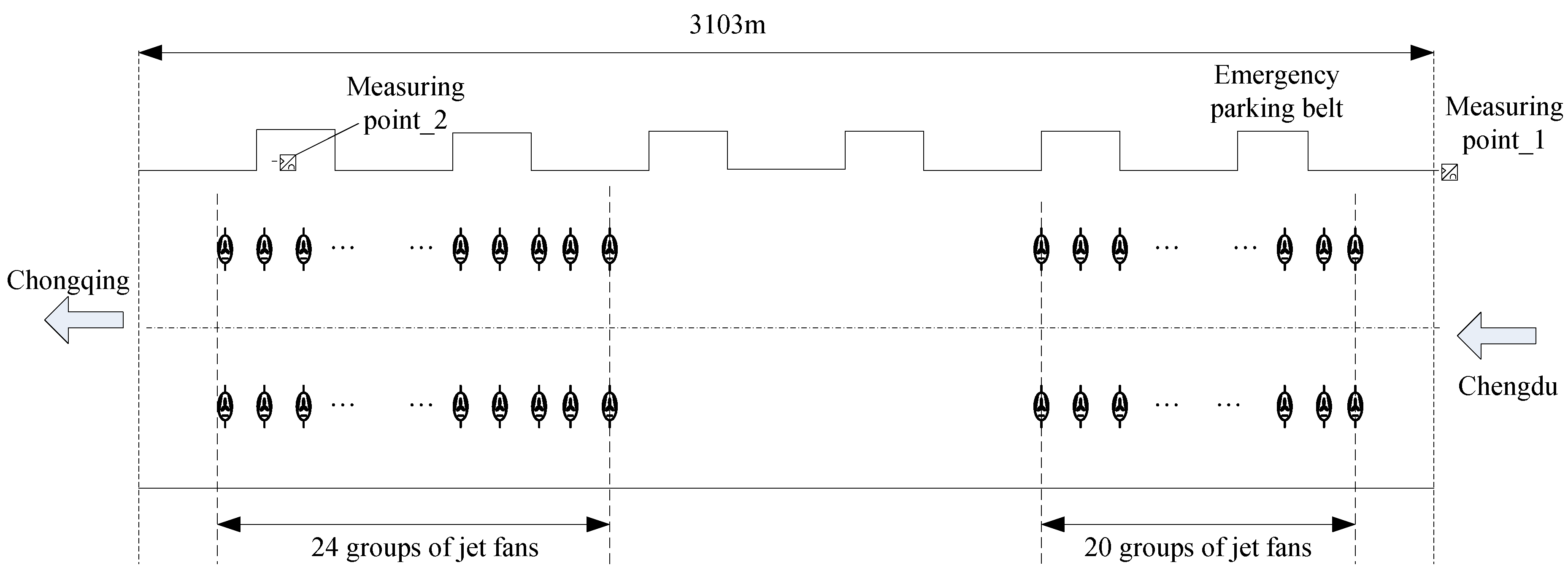

5.1. The Status of the Experimental Tunnel

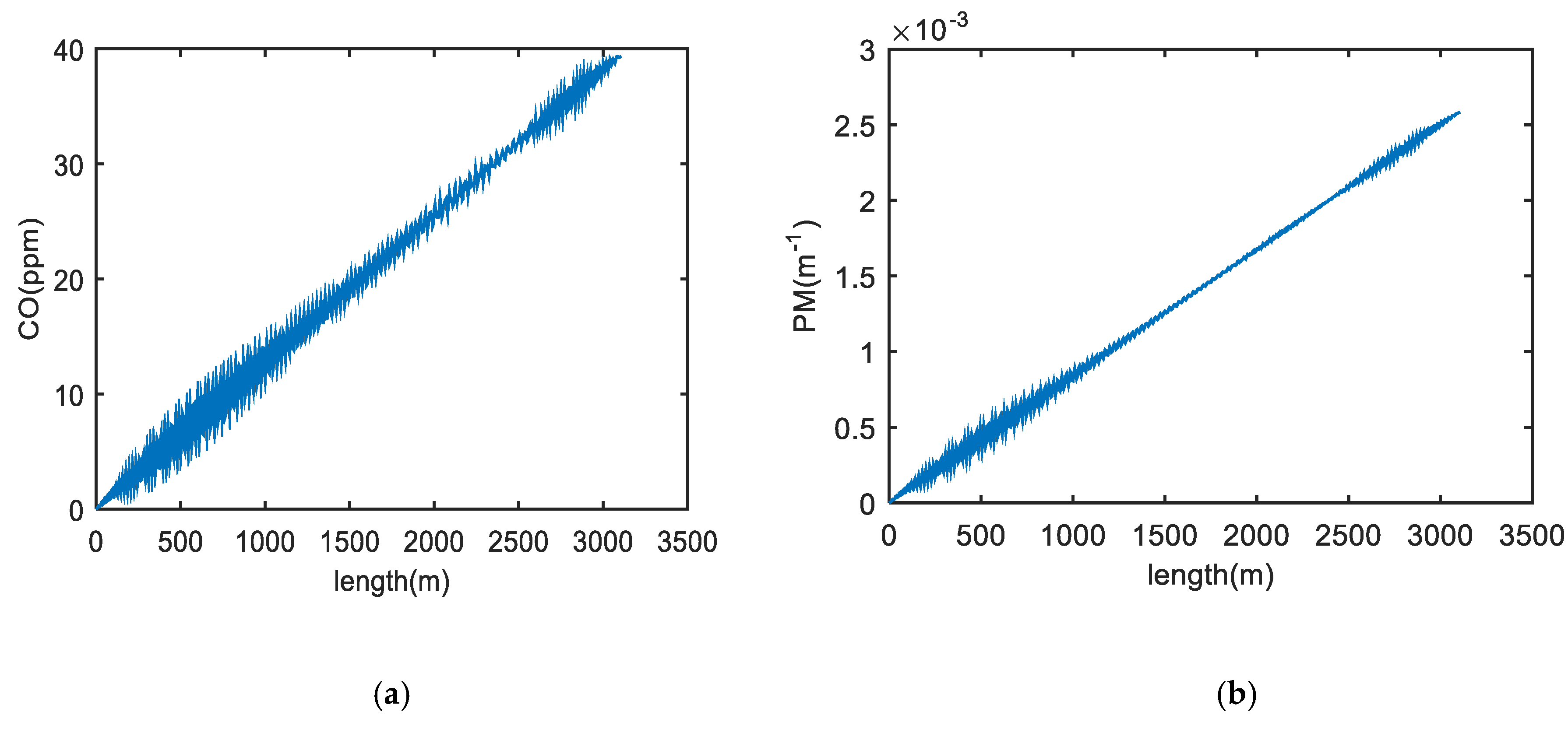

5.2. Effectiveness of the Tunnel Model

5.3. The Performance ADRC on Longitudinal Ventilation System

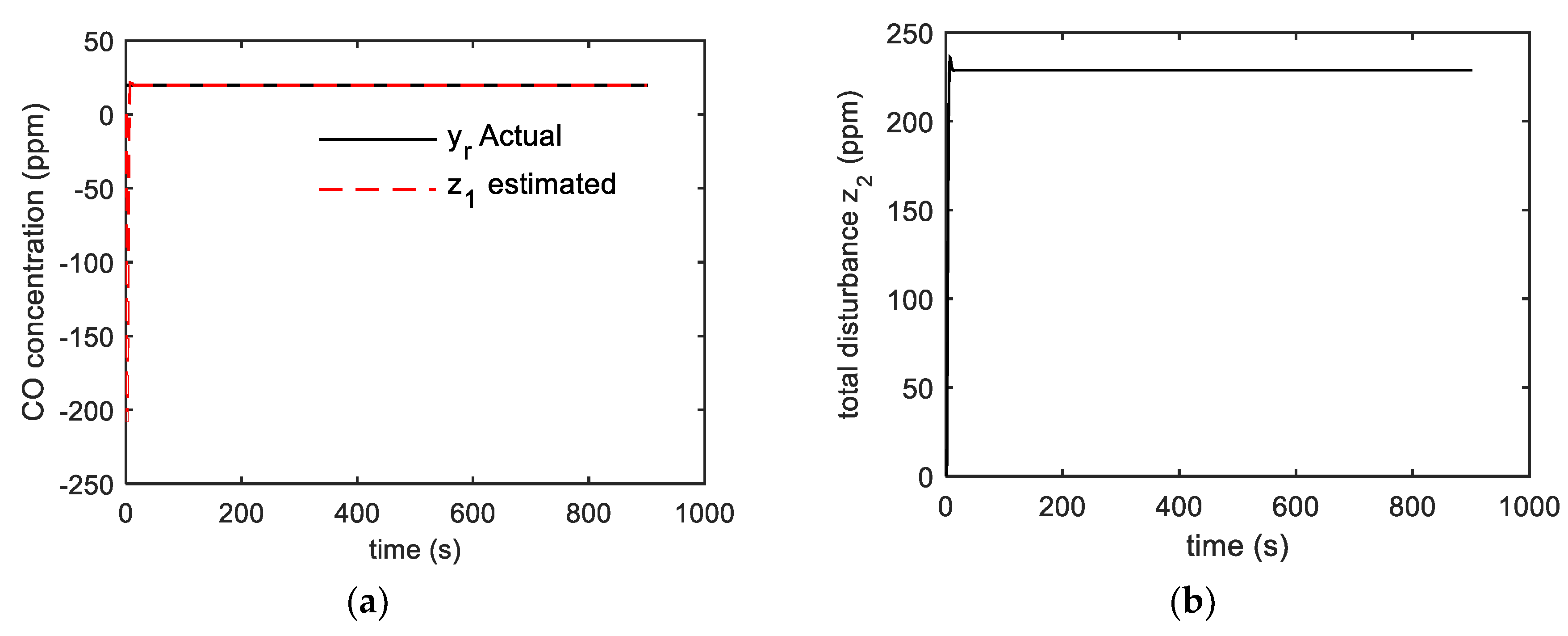

5.3.1. Performance Analysis of the ESO

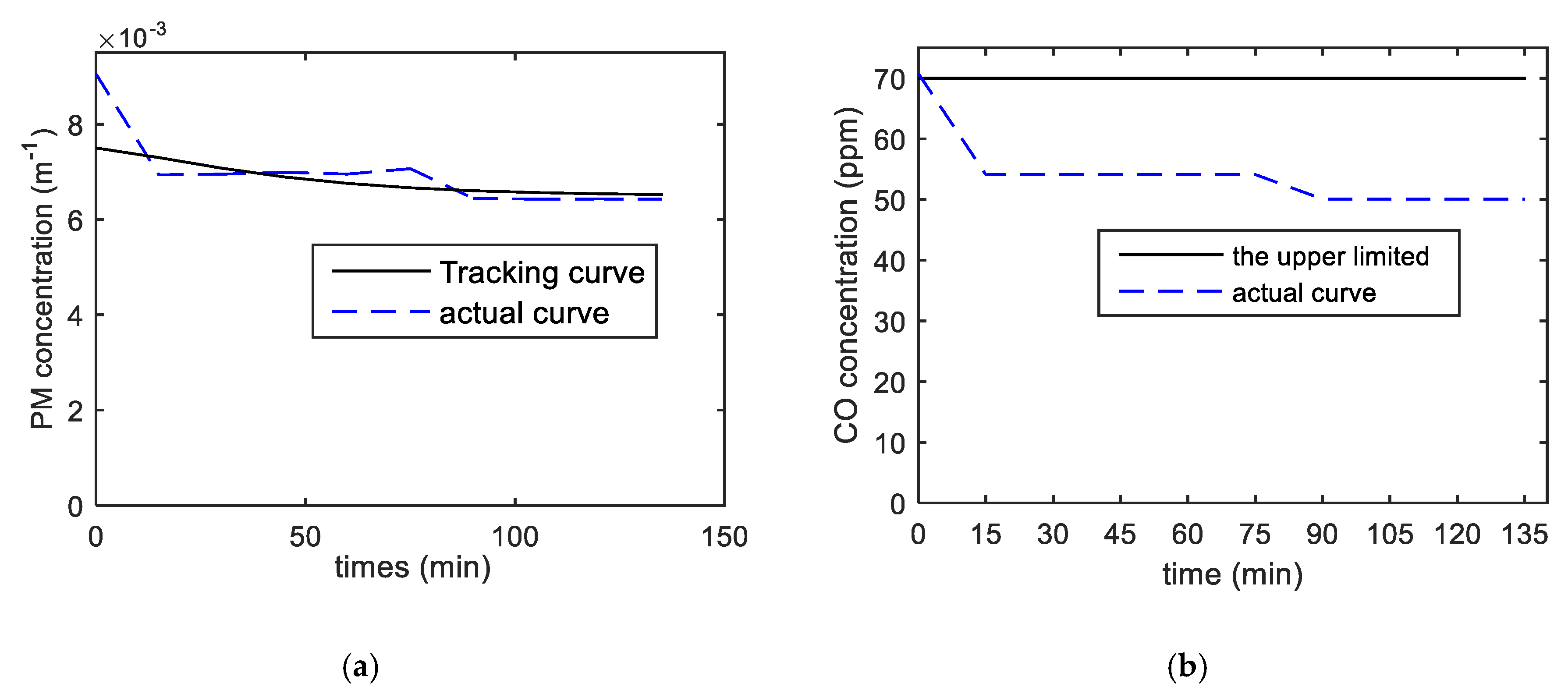

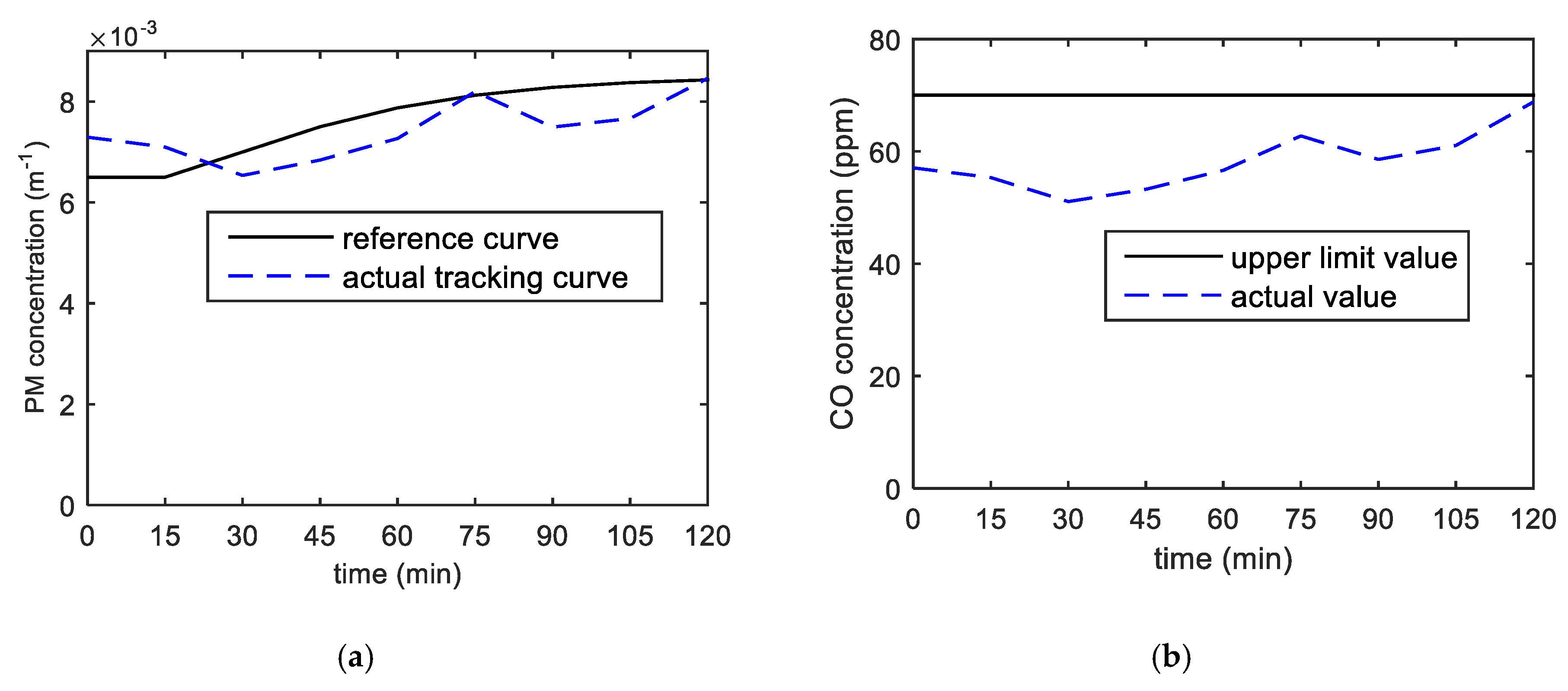

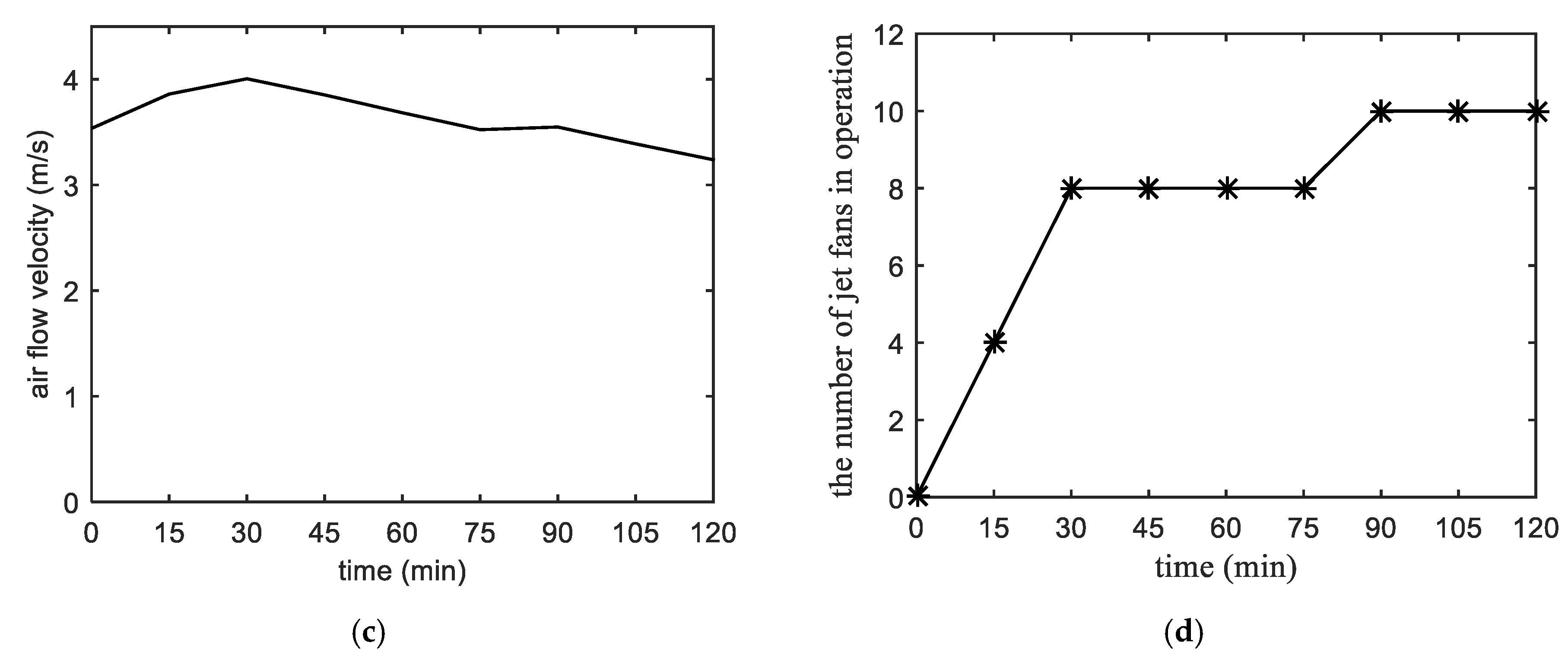

5.3.2. Steady tracking performance

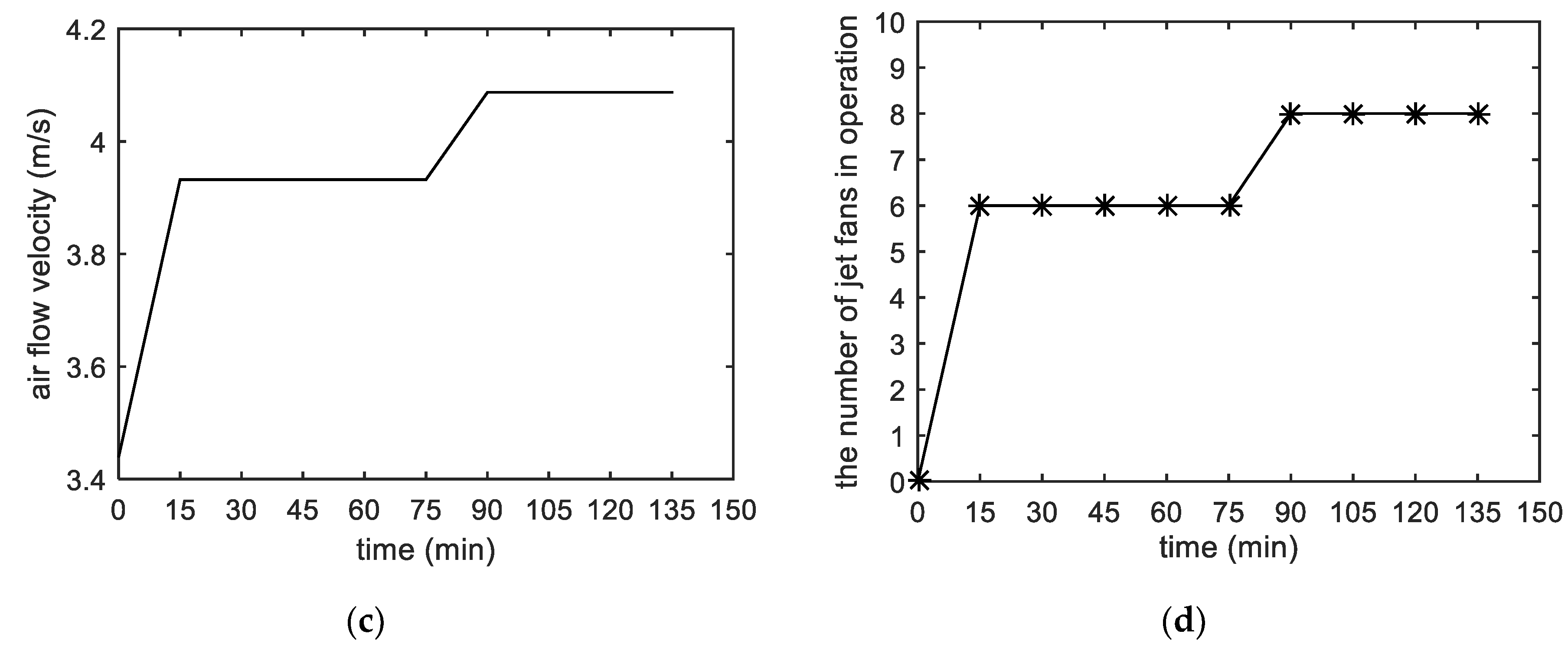

5.3.3. Dynamic Tracking Performance

5.3.4. Energy-Saving Performance Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Funabashi, M.; Aoki, I.; Yahiro, M.; Inoue, H. A fuzzy model based control scheme and its application to a road tunnel ventilation system. In Proceedings of the IECON ‘91: 1991 International Conference on Industrial Electronics, Control and Instrumentation, Kobe, Japan, 28 October–1 November 1991; Volume 2, pp. 1596–1601. [Google Scholar]

- Koyama, T.; Watanabe, T.; Shinohara, M.; Miyoshi, M.; Ezure, H. Road tunnel ventilation control based on nonlinear programming and fuzzy control. Trans. Inst. Electr. Eng. Jpn. 1993, 113-D, 160–168. [Google Scholar]

- Chu, B.; Kim, D.; Hong, D.; Park, J.; Chung, J.T.; Chung, J.-H.; Kim, T.-H. GA-based fuzzy controller design for tunnel ventilation systems. Autom. Constr. 2008, 17, 130–136. [Google Scholar] [CrossRef]

- Bogdan, S.; Birgmajer, B.; Kovačić, Z. Model predictive and fuzzy control of a road tunnel ventilation system. Transp. Res. Part C Emerg. Technol. 2008, 16, 574–592. [Google Scholar] [CrossRef]

- Euler-Rolle, N.; Fuhrmann, M.; Reinwald, M.; Jakubek, S. Longitudinal tunnel ventilation control. Part 1: Modelling and dynamic feedforward control. Control Eng. Pract. 2017, 63, 91–103. [Google Scholar] [CrossRef]

- Fuhrmann, M.; Euler-Rolle, N.; Killian, M.; Reinwald, M.; Jakubek, S. Longitudinal tunnel ventilation control. Part 2: Non-linear observation and disturbance rejection. Control Eng. Pract. 2017, 63, 44–56. [Google Scholar] [CrossRef]

- Roman, R.; Precup, R.; Bojan-Dragos, C.; Szedlak-Stinean, A. Combined model-free adaptive control with fuzzy component by virtual reference feedback tuning for tower crane systems. Procedia Comput. Sci. 2019, 162, 267–274. [Google Scholar] [CrossRef]

- Kurokawa, R.; Sato, T.; Vilanova, R.; Konishi, Y. Design of optimal PID control with a sensitivity function for resonance phenomenon-involved second-order plus dead-time system. J. Frankl. Inst. 2020, in press. [Google Scholar] [CrossRef]

- Pilla, R.; Azar, A.T.; Gorripotu, T.S. Impact of flexible AC transmission system devices on automatic generation control with a metaheuristic based fuzzy PID controller. Energies 2019, 12, 4193. [Google Scholar] [CrossRef]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Sun, B.; Gao, Z. A DSP-based active disturbance rejection control design for a 1-kW H-bridge DC–DC power converter. IEEE Trans. Ind. Electron. 2005, 52, 1271–1277. [Google Scholar] [CrossRef]

- Lotfi, N.; Zomorodi, H.; Landers, R.G. Active disturbance rejection control for voltage stabilization in open-cathode fuel cells through temperature regulation. Control Eng. Pract. 2016, 56, 92–100. [Google Scholar] [CrossRef]

- Madonski, R.; Shao, S.; Zhang, H.; Gao, Z.; Yang, J.; Li, S. General error-based active disturbance rejection control for swift industrial implementations. Control Eng. Pract. 2019, 84, 218–229. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, C.; Duan, B. Automatic disturbances rejection controller for precise motion control of permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2005, 52, 814–823. [Google Scholar] [CrossRef]

- Chu, Z.; Sun, Y.; Wu, C.; Sepehri, N. Active disturbance rejection control applied to automated steering for lane keeping in autonomous vehicles. Control Eng. Pract. 2018, 74, 13–21. [Google Scholar] [CrossRef]

- Michalek, M.M. Robust trajectory following without availability of the reference time-derivatives in the control scheme with active disturbance rejection. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 1536–1541. [Google Scholar] [CrossRef]

- Xia, Y.; Shi, P.; Liu, G.P.; Rees, D.; Han, J. Active disturbance rejection control for uncertain multivariable systems with time-delay. IET Control Theory Appl. 2007, 1, 75–81. [Google Scholar] [CrossRef]

- Madonski, R.; Nowicki, M.; Herman, P. Practical solution to positivity problem in water management systems—An ADRC approach. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 1542–1547. [Google Scholar] [CrossRef]

- Kurka, L.; Ferkl, L.; Sládek, O.; Porízek, J. Simulation of traffic, ventilation and exhaust in a complex road tunnel. In Proceedings of the 16th IFAC World Congress, Prague, Czechia, 3–8 July 2005; pp. 60–65. [Google Scholar]

- Ferkl, L.; Meinsma, G. Finding optimal ventilation control for highway tunnels. Tunn. Undergr. Space Technol. 2007, 22, 222–229. [Google Scholar] [CrossRef]

- Šulc, J.; Ferkl, L.; Cigler, J.; Zápařka, J. Model-based airflow controller design for fire ventilation in road tunnels. Tunn. Undergr. Space Technol. 2016, 60, 121–134. [Google Scholar] [CrossRef]

- Šulc, J.; Skogestad, S. A systematic approach for airflow velocity control design in road tunnels. Control Eng. Pract. 2017, 69 (Suppl. C), 61–72. [Google Scholar] [CrossRef]

- JTG/T D70/2-02-2014. Guidelines for Design of Ventilation of Highway Tunnels; Communications Publishing &Media Management Co., Ltd.: Beijing, China, 2014. (In Chinese)

- Liu, H.; Wang, X.; Chen, J. Test and analysis of Zhongliangshan road tunnel. J. Chongqing Jiaotong Univ. Nat. Sci. 2010, 29, 529–532. (In Chinese) [Google Scholar]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| /(m) | 3103 | /(m2) | 51.7 | /(m) | 6.44 |

| /(kg/m3) | 1.156 | 0.5 | 1 | ||

| 0.02 | /(m/s) | 27.5 | /(m2) | 0.63 | |

| 0.7 | 88 |

| Vehicle Category | Passenger Cars | Truck | Total Amount | |||

|---|---|---|---|---|---|---|

| Large | Small | Heavy | Medium | Light | ||

| Peak traffic flow (veh/h) | 161 | 1562 | 257 | 273 | 48 | 2301 |

| Proportion (%) | 7 | 68 | 11 | 12 | 2 | 100 |

| Traffic Condition | Normal Traffic (50–100 km/h) | Congestion | Traffic Block | |

|---|---|---|---|---|

| Number of jet fans | step control | zero | 24 or 48 | 88 |

| Cascade ADRC | zero | 8 | 10 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, L.; Cao, W.; Chen, X. Active Disturbance Rejection Control of a Longitudinal Tunnel Ventilation System. Energies 2020, 13, 1871. https://doi.org/10.3390/en13081871

Si L, Cao W, Chen X. Active Disturbance Rejection Control of a Longitudinal Tunnel Ventilation System. Energies. 2020; 13(8):1871. https://doi.org/10.3390/en13081871

Chicago/Turabian StyleSi, Liyun, Wenping Cao, and Xiangping Chen. 2020. "Active Disturbance Rejection Control of a Longitudinal Tunnel Ventilation System" Energies 13, no. 8: 1871. https://doi.org/10.3390/en13081871

APA StyleSi, L., Cao, W., & Chen, X. (2020). Active Disturbance Rejection Control of a Longitudinal Tunnel Ventilation System. Energies, 13(8), 1871. https://doi.org/10.3390/en13081871