Operational Management Implemented in Biofuel Upstream Supply Chain and Downstream International Trading: Current Issues in Southeast Asia

Abstract

1. Introduction and Problem Statement

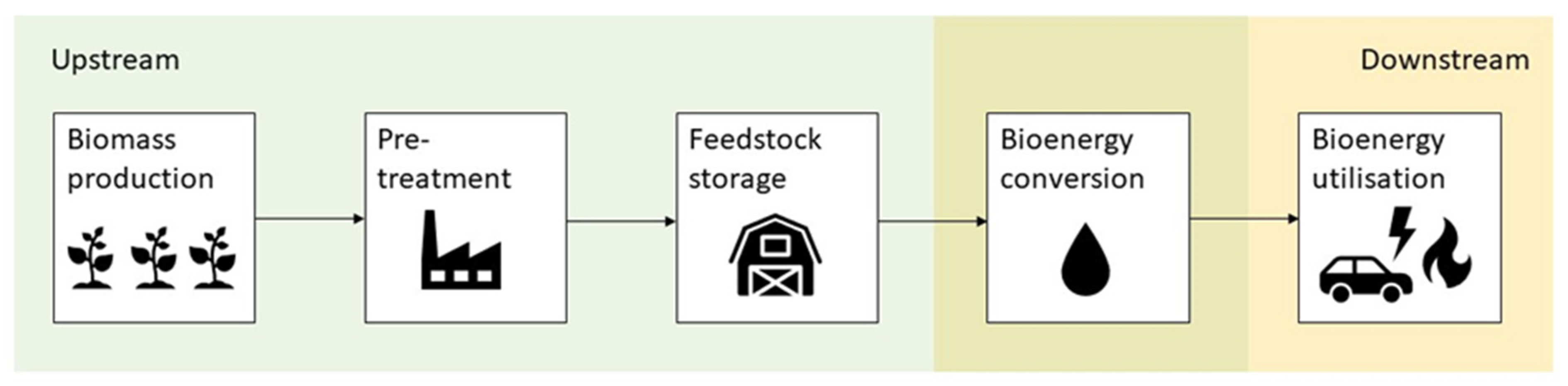

2. Biofuel Supply Chain Planning and Management

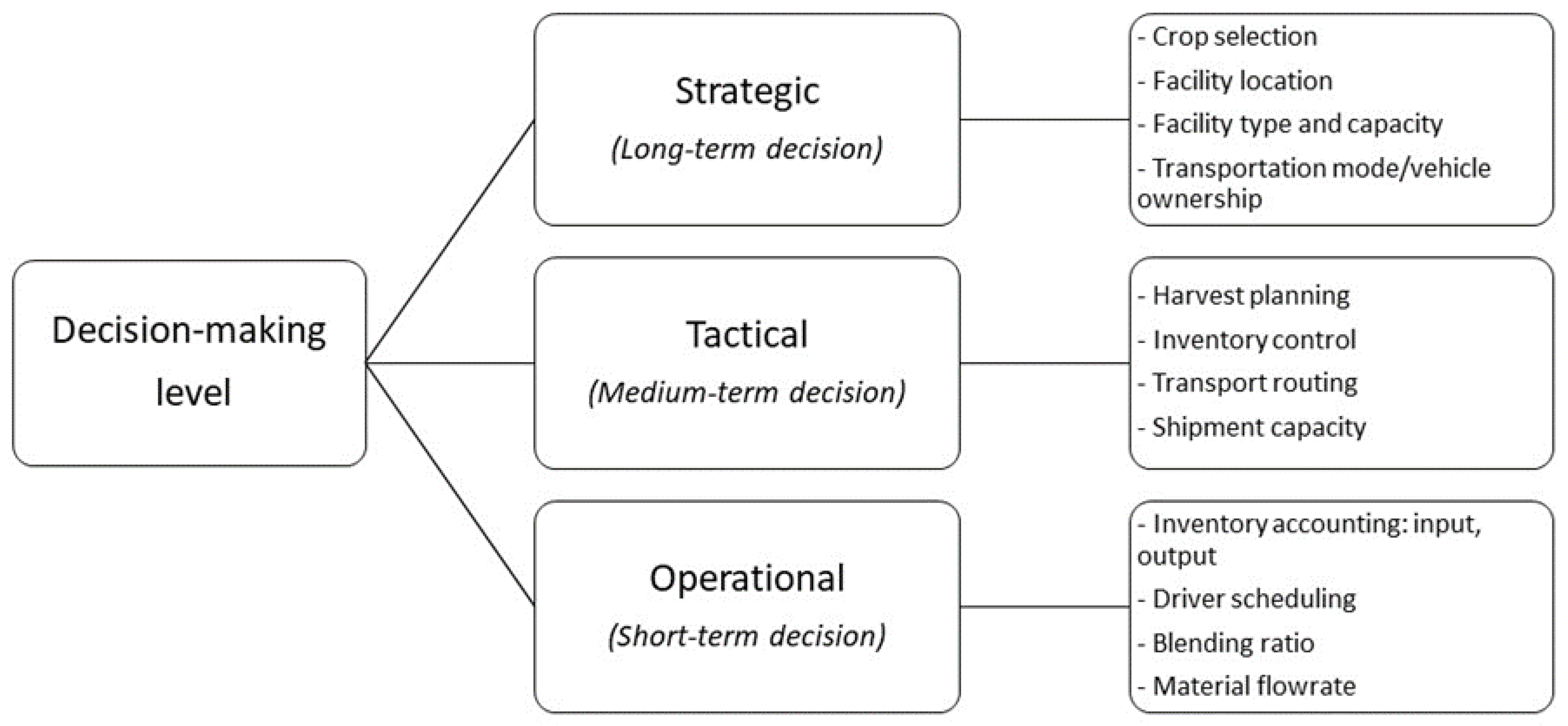

2.1. Methods Used in Biofuels Upstream Supply Chain Planning

- To maximise profit or to minimise the overall cost for an economic purpose.

- To minimise greenhouse gas (GHG) emission for environmental purpose.

- To maximise job creation for social purpose, while satisfying the limit of the constraints formulated in the model.

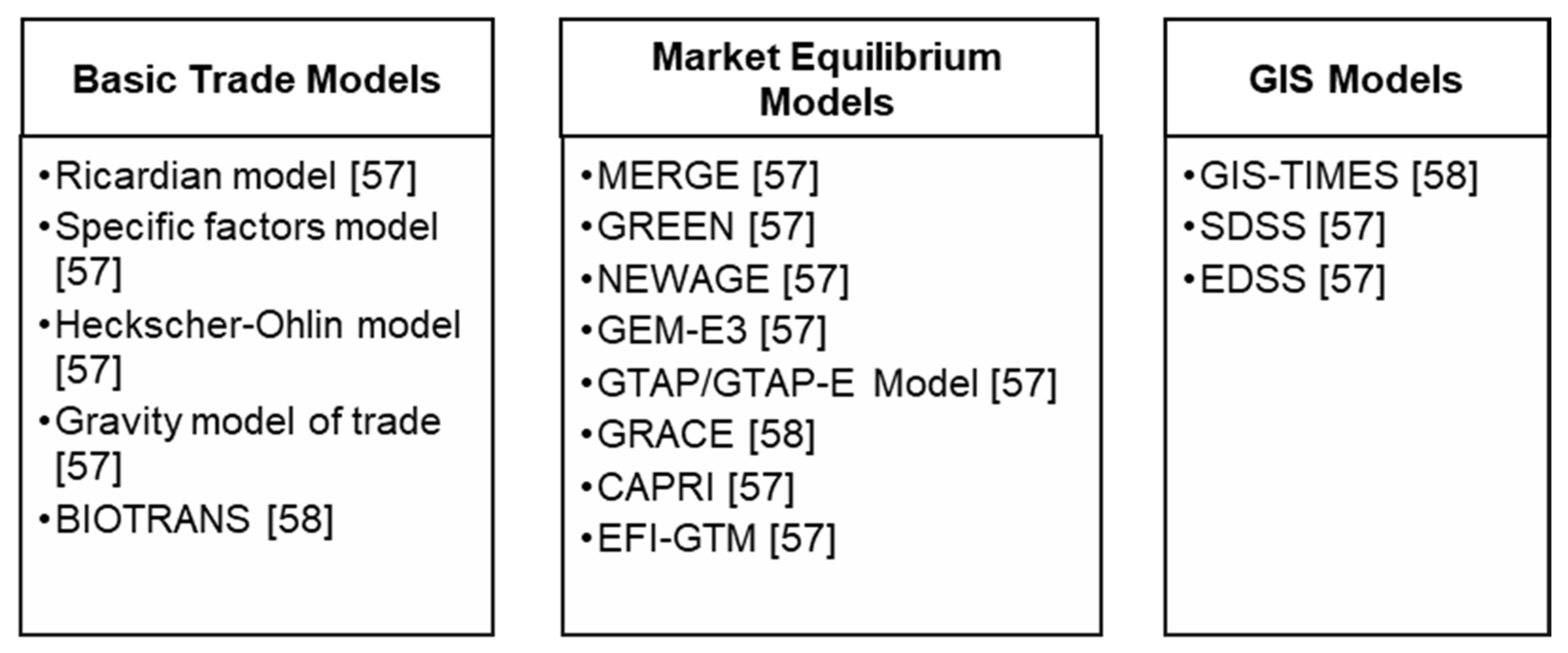

2.2. Methods Used in Biofuel Downstream Supply Chain Planning

3. Case Study: Malaysia, Indonesia, Thailand

3.1. Existing Policy and Current Status

3.1.1. Malaysia

3.1.2. Indonesia

3.1.3. Thailand

3.2. Discussion

- The time needed for maturation and the decreasing yield of oil palm following maturation.

- Economic performances involving local and export demand.

- Involvement of the installation of biofuel plants and blending facilities.

- The utilisation of readily available biomass residual to produce 2nd generation biofuel or other bioproducts, e.g., utilisation of biogas produced from agroindustry wastewater.

- The increasing mandate blend and the optimal mandate blend

- Expanded consumption of biofuel to other sectors

- Diversification of the product spectrum of the biomass

- The different conversion rate of biomass to the biofuel.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IEA (International Energy Agency). Renewables 2019; IEA: Paris, France, 2019. [Google Scholar]

- REUTERS. China Sets 2020 Target for Nationwide Ethanol to Cut Corn Stocks. Available online: www.reuters.com/article/us-china-biofuels/china-sets-2020-target-for-nationwide-ethanol-use-to-cut-corn-stocks-idUSKCN1BO03R (accessed on 29 November 2019).

- National Energy Council. National Blueprint of Energy in Indonesia; The Ministry of Energy and Mineral Resources of Indonesia: Jakarta, Indonesia, 2017.

- REUTERS. Indonesia President Wants B30 in Use by Jan 2020: Cabinet Secretary. Available online: www.reuters.com/article/us-indonesia-biodiesel/indonesia-president-wants-b30-in-use-by-january-2020-cabinet-secretary-idUSKCN1V20VR (accessed on 29 November 2019).

- Ministry of Plantation Industries and Commodities Malaysia. The National Biofuel Policy; Ministry of Plantation Industries and Commodities Malaysia: Putrajaya, Malaysia, 2006.

- REUTERS. Malaysia to Implement B10 Biodiesel Programme from Dec. 1. Available online: www.reuters.com/article/malaysia-palmoil-biodiesel/malaysia-to-implement-b10-biodiesel-programme-from-dec-1-idUSL4N1XY24I (accessed on 29 November 2019).

- Department of Energy Philippines. Biofuels Act of 2006; 13th Congress of the Philippines: Taguig, Philippines, 2007. [Google Scholar]

- Ison, L. Biofuels Industry Bats for B5 in Diesel by 2021. Available online: www.pna.gov.ph/articles/1074753 (accessed on 29 November 2019).

- Department of Alternative Energy Development and Efficiency Thailand. Alternative Energy Development Plan: AEDP 2015; Department of Alternative Energy Development and Efficiency Thailand: Bangkok, Thailand, 2015; p. 22.

- Trinh, T.A.; Linh Le, T.P. Biofuels Potential for Transportation Fuels in Vietnam: A Status Quo and SWOT Analysis. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Ho Chi Minh City, Vietnam, 17–19 April 2018; Volume 143, pp. 1–18. [Google Scholar]

- F+L Daily. Vietnam to Mandate 5% Ethanol Blends by January 2018. Available online: www.fuelsandlubes.com/vietnam-to-mandate-5-ethanol-blends-by-january-2018/ (accessed on 29 November 2019).

- De Meyer, A.; Cattrysse, D.; Rasinmäki, J.; Van Orshoven, J. Methods to Optimise the Design and Management of Biomass-for-Bioenergy Supply Chains: A Review. Renew. Sustain. Energy Rev. 2014, 31, 657–670. [Google Scholar] [CrossRef]

- Zandi Atashbar, N.; Labadie, N.; Prins, C. Modelling and Optimisation of Biomass Supply Chains: A Review. Int. J. Prod. Res. 2018, 56, 3482–3506. [Google Scholar] [CrossRef]

- Roy, B. Multicriteria Methodology for Decision Aiding; Springer US: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Aguayo, M.M.; Sarin, S.C.; Cundiff, J.S.; Comer, K.; Clark, T. A Corn-Stover Harvest Scheduling Problem Arising in Cellulosic Ethanol Production. Biomass Bioenergy 2017, 107, 102–112. [Google Scholar] [CrossRef]

- Ahn, Y.C.; Lee, I.B.; Lee, K.H.; Han, J.H. Strategic Planning Design of Microalgae Biomass-to-Biodiesel Supply Chain Network: Multi-Period Deterministic Model. Appl. Energy 2015, 154, 528–542. [Google Scholar] [CrossRef]

- Čuček, L.; Martín, M.; Grossmann, I.E.; Kravanja, Z. Multi-Period Synthesis of Optimally Integrated Biomass and Bioenergy Supply Network. Comput. Chem. Eng. 2014, 66, 57–70. [Google Scholar] [CrossRef]

- Foo, D.C.Y.; Tan, R.R.; Lam, H.L.; Abdul Aziz, M.K.; Klemeš, J.J. Robust Models for the Synthesis of Flexible Palm Oil-Based Regional Bioenergy Supply Chain. Energy 2013, 55, 68–73. [Google Scholar] [CrossRef]

- Miret, C.; Chazara, P.; Montastruc, L.; Negny, S.; Domenech, S. Design of Bioethanol Green Supply Chain: Comparison between First and Second Generation Biomass Concerning Economic, Environmental and Social Criteria. Comput. Chem. Eng. 2016, 85, 16–35. [Google Scholar] [CrossRef]

- Ng, R.T.L.; Maravelias, C.T. Design of Biofuel Supply Chains with Variable Regional Depot and Biorefinery Locations. Renew. Energy 2017, 100, 90–102. [Google Scholar] [CrossRef]

- Ng, W.P.Q.; Lam, H.L.; Yusup, S. Supply Network Synthesis on Rubber Seed Oil Utilisation as Potential Biofuel Feedstock. Energy 2013, 55, 82–88. [Google Scholar] [CrossRef]

- Rabbani, M.; Ramezankhani, F.; Giahi, R.; Farshbaf-Geranmayeh, A. Biofuel Supply Chain Considering Depreciation Cost of Installed Plants. J. Ind. Eng. Int. 2016, 12, 221–235. [Google Scholar] [CrossRef][Green Version]

- Santibañez-Aguilar, J.E.; González-Campos, J.B.; Ponce-Ortega, J.M.; Serna-González, M.; El-Halwagi, M.M. Optimal Planning and Site Selection for Distributed Multiproduct Biorefineries Involving Economic, Environmental and Social Objectives. J. Clean. Prod. 2014, 65, 270–294. [Google Scholar] [CrossRef]

- López-Díaz, D.C.; Lira-Barragán, L.F.; Rubio-Castro, E.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Optimal Location of Biorefineries Considering Sustainable Integration with the Environment. Renew. Energy 2017, 100, 65–77. [Google Scholar] [CrossRef]

- How, B.S.; Tan, K.Y.; Lam, H.L. Transportation Decision Tool for Optimisation of Integrated Biomass Flow with Vehicle Capacity Constraints. J. Clean. Prod. 2016, 136, 197–223. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; Rivera-Toledo, M.; Flores-Tlacuahuac, A.; Ponce-Ortega, J.M. A Mixed-Integer Dynamic Optimization Approach for the Optimal Planning of Distributed Biorefineries. Comput. Chem. Eng. 2015, 80, 37–62. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, T.; Chen, B. A Study of the LCA Based Biofuel Supply Chain Multi-Objective Optimization Model with Multi-Conversion Paths in China. Appl. Energy 2014, 126, 221–234. [Google Scholar] [CrossRef]

- Orjuela-Castro, J.A.; Aranda-Pinilla, J.A.; Moreno-Mantilla, C.E. Identifying Trade-Offs between Sustainability Dimensions in the Supply Chain of Biodiesel in Colombia. Comput. Electron. Agric. 2019, 161, 162–169. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Multi-Period Stochastic Optimization of a Sustainable Multi-Feedstock Second Generation Bioethanol Supply Chain—A Logistic Case Study in Midwestern United States. Land Use Policy 2017, 61, 420–450. [Google Scholar] [CrossRef]

- Azadeh, A.; Vafa Arani, H.; Dashti, H. A Stochastic Programming Approach towards Optimization of Biofuel Supply Chain. Energy 2014, 76, 513–525. [Google Scholar] [CrossRef]

- Bairamzadeh, S.; Saidi-Mehrabad, M.; Pishvaee, M.S. Modelling Different Types of Uncertainty in Biofuel Supply Network Design and Planning: A Robust Optimization Approach. Renew. Energy 2018, 116, 500–517. [Google Scholar] [CrossRef]

- Ghelichi, Z.; Saidi-Mehrabad, M.; Pishvaee, M.S. A Stochastic Programming Approach toward Optimal Design and Planning of an Integrated Green Biodiesel Supply Chain Network under Uncertainty: A Case Study. Energy 2018, 156, 661–687. [Google Scholar] [CrossRef]

- Maheshwari, P.; Singla, S.; Shastri, Y. Resiliency Optimization of Biomass to Biofuel Supply Chain Incorporating Regional Biomass Pre-Processing Depots. Biomass Bioenergy 2017, 97, 116–131. [Google Scholar] [CrossRef]

- Mohseni, S.; Pishvaee, M.S. A Robust Programming Approach towards Design and Optimization of Microalgae-Based Biofuel Supply Chain. Comput. Ind. Eng. 2016, 100, 58–71. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; Morales-Rodriguez, R.; González-Campos, J.B.; Ponce-Ortega, J.M. Stochastic Design of Biorefinery Supply Chains Considering Economic and Environmental Objectives. J. Clean. Prod. 2016, 136, 224–245. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Garcia, M.C.; Shah, N. Supply Chain Network Design and Operation: Systematic Decision-Making for Centralized, Distributed, and Mobile Biofuel Production Using Mixed Integer Linear Programming (MILP) under Uncertainty. Biomass Bioenergy 2015, 81, 401–414. [Google Scholar] [CrossRef]

- Van Fan, Y.; Klemeš, J.J.; Walmsley, T.G.; Perry, S. Minimising Energy Consumption and Environmental Burden of Freight Transport Using a Novel Graphical Decision-Making Tool. Renew. Sustain. Energy Rev. 2019, 114, 1. [Google Scholar] [CrossRef]

- Lam, H.L.; Varbanov, P.S.; Klemeš, J.J. Optimisation of Regional Energy Supply Chains Utilising Renewables: P-Graph Approach. Comput. Chem. Eng. 2010, 34, 782–792. [Google Scholar] [CrossRef]

- Harahap, F.; Leduc, S.; Mesfun, S.; Khatiwada, D.; Kraxner, F.; Silveira, S. Opportunities to Optimize the Palm Oil Supply Chain in Sumatra, Indonesia. Energies 2019, 12, 420. [Google Scholar] [CrossRef]

- Hoo, P.Y.; Hashim, H.; Ho, W.S.; Yunus, N.A. Spatial-Economic Optimisation of Biomethane Injection into Natural Gas Grid: The Case at Southern Malaysia. J. Environ. Manag. 2019, 241, 603–611. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, J.; Liu, S.; Zhang, S.; Sutherland, J.W. Integrating GIS with Optimization Method for a Biofuel Feedstock Supply Chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

- Asadi, E.; Habibi, F.; Nickel, S.; Sahebi, H. A Bi-Objective Stochastic Location-Inventory-Routing Model for Microalgae-Based Biofuel Supply Chain. Appl. Energy 2018, 228, 2235–2261. [Google Scholar] [CrossRef]

- Marufuzzaman, M.; Eksioglu, S.D.; Huang, Y. Two-Stage Stochastic Programming Supply Chain Model for Biodiesel Production via Wastewater Treatment. Comput. Oper. Res. 2014, 49, 1–17. [Google Scholar] [CrossRef]

- Poudel, S.; Marufuzzaman, M.; Quddus, M.A.; Chowdhury, S.; Bian, L.; Smith, B. Designing a Reliable and Congested Multi-Modal Facility Location Problem for Biofuel Supply Chain Network. Energies 2018, 11, 1682. [Google Scholar] [CrossRef]

- How, B.S.; Lam, H.L. Integrated Palm Biomass Supply Chain toward Sustainable Management. Chem. Prod. Process Model. 2017, 12, 1–19. [Google Scholar] [CrossRef]

- Ng, R.T.L.; Maravelias, C.T. Economic and Energetic Analysis of Biofuel Supply Chains. Appl. Energy 2017, 205, 1571–1582. [Google Scholar] [CrossRef]

- Geng, N.; Zhang, Y.; Sun, Y.; Geng, S. Optimization of Biodiesel Supply Chain Produced from Waste Cooking Oil: A Case Study in China. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 264. [Google Scholar]

- Schlamadinger, B.; Faaij, A.P.C.; Daugherty, E. Should We Trade Biomass, Electricity, Renewable Certificates, or CO2 Credits? In IEA Bioenergy Task 38 40; IEA: Paris, France, 2004. [Google Scholar]

- Welfle, A. Balancing Growing Global Bioenergy Resource Demands—Brazil’s Biomass Potential and the Availability of Resource for Trade. Biomass Bioenergy 2017, 105, 83–95. [Google Scholar] [CrossRef]

- Junginger, M.; Goh, C.S.; Faaij, A. International Bioenergy Trade; Lect. Notes Energy; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Lamers, P.; Hamelinck, C.; Junginger, M.; Faaij, A. International Bioenergy Trade—A Review of Past Developments in the Liquid Biofuel Market. Renew. Sustain. Energy Rev. 2011, 15, 2655–2676. [Google Scholar] [CrossRef]

- WBA (World Bioenegy Association). Biomass Supply Chains—Harvesting & Collection, Pre-Treatment & Upgrading, Storage, Transportation & Handling; World Bioenergy Association: Stockholm, Sweden, 2018. [Google Scholar]

- Laurijssen, J.; Faaij, A.P.C. Trading Biomass or GHG Emission Credits? Clim. Chang. 2009, 94, 287. [Google Scholar] [CrossRef]

- NREL (National Renewable Energy Laboratory). International Trade of Biofuels; NREL: Golden, CO, USA, 2013. [Google Scholar]

- Deng, Y.Y.; Koper, M.; Haigh, M.; Dornburg, V. Country-Level Assessment of Long-Term Global Bioenergy Potential. Biomass Bioenergy 2015, 74, 253–267. [Google Scholar] [CrossRef]

- Lamers, P.; Hoefnagels, R.; Junginger, M.; Hamelinck, C.; Faaij, A. Global Solid Biomass Trade for Energy by 2020: An Assessment of Potential Import Streams and Supply Costs to North-West Europe under Different Sustainability Constraints. GCB Bioenergy 2015, 7, 618–634. [Google Scholar] [CrossRef]

- Diesenreiter, F.; Kranzl, L. Approaches for Modelling the International Trade of Biomass for Bioenergy (to Evaluate Its Impacts on Bioenergy Markets). Available online: www.researchgate.net/publication/228558774_Approaches_for_modelling_the_international_trade_of_Biomass_for_Bioenergy_to_evaluate_its_impacts_on_bioenergy_markets (accessed on 11 February 2020).

- Solberg, B.; Dornburg, V.; Bolkesjø, T.F.; Faaij, A.; Junginger, M.; Trømborg, E. Bioenergy and Biomass Trade: Evaluation of Models’ Suitability for Analysing International Trade of Biomass and Bioenergy Products; Norwegian University of Life Sciences: Aas, Norway; Copernicus Institute, Utretch University: Utretch, The Netherlands, 2007. [Google Scholar]

- Hoefnagels, R.; Kluts, I.; Junginger, M.; Visser, L.; Resch, G.; Mantau, U.; Pelkmans, L.; Devriendt, N. Sustainable and Optimal Use of Biomass for Energy in the EU beyond 2020; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Van Bergeijk, P.A.G.; Brakman, S. The Gravity Model in International Trade: Advances and Applications; Van Bergeijk, P.A.G., Brakman, S., Eds.; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Baldwin, R.; Taglioni, D. Gravity Chains Estimating Bilateral Trade Flows When Parts and Components Trade Is Important; ECB (European Central Bank): Frankfurt, Germany, 2011. [Google Scholar]

- Röttgers, D.; Faße, A.; Ulrike, G. The Canola Oil Industry and EU Trade Integration: A Gravity Model Approach. In Proceedings of the German Development Economics Conference 2010, Hannover, Germany, 18–19 June 2010; p. 32. [Google Scholar]

- Rentizelas, A.; Melo, I.C.; Alves Junior, P.N.; Campoli, J.S.; Aparecida do Nascimento Rebelatto, D. Multi-Criteria Efficiency Assessment of International Biomass Supply Chain Pathways Using Data Envelopment Analysis. J. Clean. Prod. 2019, 237, 117690. [Google Scholar] [CrossRef]

- Matzenberger, J.; Kranzl, L.; Tromborg, E.; Junginger, M.; Daioglou, V.; Sheng Goh, C.; Keramidas, K. Future Perspectives of International Bioenergy Trade. Renew. Sustain. Energy Rev. 2015, 43, 926–941. [Google Scholar] [CrossRef]

- Čuček, L.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Total Footprints-Based Multi-Criteria Optimisation of Regional Biomass Energy Supply Chains. Energy 2012, 44, 135–145. [Google Scholar] [CrossRef]

- Jonkman, J.; Kanellopoulos, A.; Bloemhof, J.M. Designing an Eco-Efficient Biomass-Based Supply Chain Using a Multi-Actor Optimisation Model. J. Clean. Prod. 2019, 210, 1065–1075. [Google Scholar] [CrossRef]

- Lee, C.Y.; Sun, W.C.; Li, Y.H. Biodiesel Economic Evaluation and Biomass Planting Allocation Oprimisation in Global Supply Chain. IEEE Trans. Eng. Manag. 2019, 1–14. [Google Scholar] [CrossRef]

- De Matta, R.; Miller, T. Formation of a Strategic Manufacturing and Distribution Network with Transfer Prices. Eur. J. Oper. Res. 2015, 241, 435–448. [Google Scholar] [CrossRef]

- Gonela, V.; Zhang, J.; Osmani, A.; Onyeaghala, R. Stochastic Optimization of Sustainable Hybrid Generation Bioethanol Supply Chains. Transp. Res. Part E Logist. Transp. Rev. 2015, 77, 1–28. [Google Scholar] [CrossRef]

- Razm, S.; Nickel, S.; Sahebi, H. A Multi-Objective Mathematical Model to Redesign of Global Sustainable Bioenergy Supply Network. Comput. Chem. Eng. 2019, 128, 1–20. [Google Scholar] [CrossRef]

- Proskurina, S.; Junginger, M.; Heinimö, J.; Vakkilainen, E. Global Biomass Trade for Energy—Part 1: Statistical and Methodological Considerations. Biofuels Bioprod. Biorefin. 2019, 13, 358–370. [Google Scholar] [CrossRef]

- Fingerman, K.R.; Nabuurs, G.J.; Iriarte, L.; Fritsche, U.R.; Staritsky, I.; Visser, L.; Mai-Moulin, T.; Junginger, M. Opportunities and Risks for Sustainable Biomass Export from the South-Eastern United States to Europe. Biofuels Bioprod. Biorefin. 2019, 13, 281–292. [Google Scholar] [CrossRef]

- Pelkmans, L.; Van Dael, M.; Junginger, M.; Fritsche, U.R.; Diaz-Chavez, R.; Nabuurs, G.J.; Del Campo Colmenar, I.; Gonzalez, D.S.; Rutz, D.; Janssen, R. Long-Term Strategies for Sustainable Biomass Imports in European Bioenergy Markets. Biofuels Bioprod. Biorefin. 2019, 13, 388–404. [Google Scholar] [CrossRef]

- IRENA (International Renewable Energy Agency); ACE (ASEAN Centre for Energy). Renewable Energy Outlook for ASEAN; IRENA: Abu Dhabi, UAE; ACE: Jakarta, Indonesia, 2016. [Google Scholar]

- Masjuki, H.H.; Kalam, M.A.; Mofijur, M.; Shahabuddin, M. Biofuel: Policy, Standardization and Recommendation for Sustainable Future Energy Supply. Energy Procedia 2013, 42, 577–586. [Google Scholar] [CrossRef]

- MIDA (Malaysian Investment Development Authority). Time to Implement Malaysia’s Biodiesel Mandate. Available online: www.mida.gov.my/home/6751/news/time-to-implement-malaysia-s-biodiesel-mandate/ (accessed on 27 December 2019).

- Abdul-Manan, A.F.N.; Baharuddin, A.; Chang, L.W. A Detailed Survey of the Palm and Biodiesel Industry Landscape in Malaysia. Energy 2014, 76, 931–941. [Google Scholar] [CrossRef]

- MPI (Ministry of Primary Industry). Malaysia Biofuel Programme. Available online: mpi.gov.my/index.php/en/media-2/mpic-in-the-news/255-mpic-di-dalam-akhbar-2019/berita-biobahan-api/575-program-biobahan-api-malaysia-bi (accessed on 27 December 2019).

- Zainal, H. B7 Biodiesel to Be Launched to Replace B5 at Petrol Stations from Nov 1. Available online: www.thestar.com.my/news/nation/2014/10/29/b7-biodiesel-to-be-launched-lower-emission-fuel-to-replace-b5-at-petrol-stations-from-nov-1 (accessed on 27 December 2019).

- Wahab, A.G. Malaysia Biofuels Annual; United States Department of Agriculture (USDA) Global Agricultural Information Network (GAIN): Washington, DC, USA, 2018.

- MPOC (Malaysian Palm Oil Council). Palm Oil: B7 and B10 Biodiesel Will Use 450,000 Tonnes Additional CPO. Available online: mpi.gov.my/index.php/en/media-2/mpic-in-the-news/254-news-b10/2112-palm-oil-b7-and-b10-biodiesel-will-use-450-000-tonnes-additional-cpo (accessed on 27 December 2019).

- Wahab, A.G. Malaysia Biofuels Annual; United States Department of Agriculture (USDA) Global Agricultural Information Network (GAIN): Washington, DC, USA, 2019.

- Tye, Y.Y.; Lee, K.T.; Wan Abdullah, W.N.; Leh, C.P. Second-Generation Bioethanol as a Sustainable Energy Source in Malaysia Transportation Sector: Status, Potential and Future Prospects. Renew. Sustain. Energy Rev. 2011, 15, 4521–4536. [Google Scholar] [CrossRef]

- Derman, E.; Abdulla, R.; Marbawi, H.; Sabullah, M.K. Oil Palm Empty Fruit Bunches as a Promising Feedstock for Bioethanol Production in Malaysia. Renew. Energy 2018, 129, 285–298. [Google Scholar] [CrossRef]

- Abdulrazik, A.; Elsholkami, M.; Elkamel, A.; Simon, L. Multi-Products Productions from Malaysian Oil Palm Empty Fruit Bunch (EFB): Analyzing Economic Potentials from the Optimal Biomass Supply Chain. J. Clean. Prod. 2017, 168, 131–148. [Google Scholar] [CrossRef]

- Rahmadi, A.; Aye, L.; Moore, G. The Feasibility and Implications for Conventional Liquid Fossil Fuel of the Indonesian Biofuel Target in 2025. Energy Policy 2013, 61, 12–21. [Google Scholar] [CrossRef]

- Putrasari, Y.; Praptijanto, A.; Santoso, W.B.; Lim, O. Resources, Policy, and Research Activities of Biofuel in Indonesia: A Review. Energy Rep. 2016, 2, 237–245. [Google Scholar] [CrossRef]

- Ministry of Energy and Mineral Resources Indonesia. Bioenergy in Indonesia: Rules and Implementations. Available online: www.ieabioenergy.com/wp-content/uploads/2018/09/1.5-Elis-Heviati.pdf (accessed on 27 December 2019).

- REUTERS. Indonesia Launches B30 Biodiesel to Cut Costs, Boost Palm Oil. Available online: www.theedgemarkets.com/article/indonesia-launches-b30-biodiesel-cut-costs-boost-palm-oil (accessed on 27 December 2019).

- Lecksiwilai, N.; Gheewala, S.H.; Silalertruksa, T.; Mungkalasiri, J. LCA of Biofuels in Thailand Using Thai Ecological Scarcity Method. J. Clean. Prod. 2017, 142, 1183–1191. [Google Scholar] [CrossRef]

- Thailand Ministry of Energy. Thailand Power Development Plan. Available online: www.eppo.go.th/index.php/en/policy-and-plan/en-tieb/tieb-pdp (accessed on 27 December 2019).

- Bloyd, C. Thailand Alternative Fuels Update 2017; United State Department of Energy: Washington, WA, USA, 2017.

- Hong, C.S. Thailand’s Renewable Energy Transitions: A Pathway to Realize Thailand 4.0. Available online: thediplomat.com/2019/03/thailands-renewable-energy-transitions-a-pathway-to-realize-thailand-4-0/ (accessed on 27 December 2019).

- Oils & Fats International. B10 Biodiesel Introduced in Thailand. Available online: www.ofimagazine.com/news/b10-biodiesel-introduced-in-thailand (accessed on 27 December 2019).

- Sapp, M. Thai B20 Mandate Set for End-April. Available online: www.biofuelsdigest.com/bdigest/2019/04/08/thai-b20-mandate-set-for-end-april/ (accessed on 27 December 2019).

- Asia Biomass Office. Introduction Status for Biofuel in Thailand. Available online: www.asiabiomass.jp/english/topics/1505_01.html (accessed on 27 December 2019).

- Permpool, N.; Bonnet, S.; Gheewala, S.H. Greenhouse Gas Emissions from Land Use Change Due to Oil Palm Expansion in Thailand for Biodiesel Production. J. Clean. Prod. 2016, 134(Pt. B), 532–538. [Google Scholar] [CrossRef]

- Mukherjee, I.; Sovacool, B.K. Palm Oil-Based Biofuels and Sustainability in Southeast Asia: A Review of Indonesia, Malaysia, and Thailand. Renew. Sustain. Energy Rev. 2014, 37, 1–12. [Google Scholar] [CrossRef]

- Abdul-Manan, A.F.N.; Baharuddin, A.; Chang, L.W. Application of Theory-Based Evaluation for the Critical Analysis of National Biofuel Policy: A Case Study in Malaysia. Eval. Program Plan. 2015, 52, 39–49. [Google Scholar] [CrossRef] [PubMed]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A Review of Footprint Analysis Tools for Monitoring Impacts on Sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Tan, K.T.; Lee, K.T.; Mohamed, A.R.; Bhatia, S. Palm Oil: Addressing Issues and towards Sustainable Development. Renew. Sustain. Energy Rev. 2009, 13, 420–427. [Google Scholar] [CrossRef]

- Chien Bong, C.P.; Ho, W.S.; Hashim, H.; Lim, J.S.; Ho, C.S.; Peng Tan, W.S.; Lee, C.T. Review on the Renewable Energy and Solid Waste Management Policies towards Biogas Development in Malaysia. Renew. Sustain. Energy Rev. 2017, 70, 988–998. [Google Scholar] [CrossRef]

- Maulia, E.; Kumar, P.P. Palm Oil: Indonesia and Malaysia Push Back as EU Clamps Down. Available online: asia.nikkei.com/Spotlight/Asia-Insight/Palm-oil-Indonesia-and-Malaysia-push-back-as-EU-clamps-down (accessed on 27 December 2019).

- Kraxner, F.; Nordström, E.M.; Havlík, P.; Gusti, M.; Mosnier, A.; Frank, S.; Valin, H.; Fritz, S.; Fuss, S.; Kindermann, G.; et al. Global Bioenergy Scenarios—Future Forest Development, Land-Use Implications, and Trade-Offs. Biomass Bioenergy 2013, 57, 86–96. [Google Scholar] [CrossRef]

- Chanthawong, A.; Dhakal, S.; Jongwanich, J. Supply and Demand of Biofuels in the Fuel Market of Thailand: Two Stage Least Square and Three Least Square Approaches. Energy 2016, 114, 431–443. [Google Scholar] [CrossRef]

- Mekhilef, S.; Siga, S.; Saidur, R. A Review on Palm Oil Biodiesel as a Source of Renewable Fuel. Renew. Sustain. Energy Rev. 2011, 15, 1937–1949. [Google Scholar] [CrossRef]

- EPA (Environmental Protection Agency). Renewable Fuel Annual Standards. Available online: https://www.epa.gov/renewable-fuel-standard-program/renewable-fuel-annual-standards (accessed on 3 February 2020).

- Shafie, S.M.; Mahlia, T.M.I.; Masjuki, H.H.; Andriyana, A. Current Energy Usage and Sustainable Energy in Malaysia: A Review. Renew. Sustain. Energy Rev. 2011, 15, 4370–4377. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Necessity of Biodiesel Utilization as a Source of Renewable Energy in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5732–5740. [Google Scholar] [CrossRef]

| Country/Region | Forecast Annual Production Growth in 2019–24 (%) | Required Production Growth Needed to Meet SDS in 2019–30 (%) |

|---|---|---|

| USA | 1 | 6 |

| EU | 0.5 | 8 |

| Brazil | 3.5 | 6 |

| India | 11 | 22 |

| China | 16 | 17 |

| ASEAN | 9 | 8 |

| Country | Policy/Strategy | The Biofuel Production Target for the Transportation Sector | Government Ministries/Agencies |

|---|---|---|---|

| Indonesia | Indonesia National Energy Plan (Ministerial Regulation No. 22/2017) [3] | 30% biodiesel plan by 2025 (update: the government has announced B30 blending recently to start in January 2020 [4]) | Ministry of Energy and Mineral Resources (MEMR) |

| Malaysia | National Biofuels Policy 2006 [5] | B5 programme was launched in 2011 to encourage 5% biofuels blend (update: the government has announced the B10 biodiesel program starting December 2018 [6]) | Ministry of Plantation Industries and Commodities (MPIC) (renamed: Ministry of Primary Industries) |

| Philippines | National Biofuels Program (NBP) [7] | 1% ethanol blend by 2007, 2% by 2008, 5% by 2009, 10% blend by 2011 and increasing to 20 % by 2020. Meanwhile, 5% biodiesel blend by 2015 and 20% by 2025 (update: current biodiesel blend is at 2% [8]) | Department of Energy |

| Thailand | Alternative Energy Development Plan (AEDP) 2015–2036 [9] | 25% RE share in the transportation sector by 2036 | Department of Renewable Energy Development and Energy Efficiency (2015), Ministry of Energy |

| Vietnam | The scheme on Development of Biofuels up to 2015 with the Vision to 2025 (Decision No. 177/2007QD-TTg); National Strategy on Renewable Energy [10] | Aims to produce 1.8 × 106 tons of biofuels per year by 2025; to supply 5% of total transport fuel demand by 2020 and to raise to 13% by 2030. (update: the government announced 5% mix of ethanol starting December 2014, however, was postponed to January 2018 [11]) | Ministry of Industry and Trade |

| Source | Decision Level | Obj. | Decision Variables | Method | Case Study |

|---|---|---|---|---|---|

| Aguayo et al. [15] | T | EC | Tactical: - minimum number of balers required - harvest and routing decision | MP - MILP | USA |

| Ahn et al. [16] | S + T | EC | Strategic: - refineries facility location and capacity Tactical: - feedstock sourcing location and amount | MP - MILP | South Korea |

| Asadi et al. [42] | S + T | EC + EN | Strategic: - number and location of distribution facility - allocation of extraction sites to these facilities Tactical: - minimum inventory level - routing of extraction sites | H - algorithm | Iran |

| Azadeh et al. [30] | S | EC | Strategic: - facility locations and capacities- technology and material flows | MP - MILP | Iran |

| Bairamzadeh et al. [31] | S + T | EC | Strategic: - facilities location & capacity - technology type Tactical: - biomass allocation - inventory levels - production amounts - transportation among network | MP - MILP | Iran |

| Fan et al. [37] | T | EC + EN | Tactical: - transportation mode selection | MP - LP + P-graph | Rotterdam to Antwerp, Netherlands and Genova, Italy |

| Foo et al. [18] | T | EN | Tactical: - plant capacity - feedstock capacity | MP - LP + MILP | Malaysia |

| Čuček et al. [17] | S | EC | Strategic: - raw materials sourcing - conversion technologies - intermediate & final product flows | MP - MILP | EU |

| Ghelichi et al. [32] | S + T | EC | Strategic: - numbers, locations and capacities of cultivation and facility Tactical: - transportation mode allocation - number of purchased and rented trucks | MP - MILP | Iran |

| Harahap et al. [39] | S | EC | Strategic: - technology selection for biomass conversion | MP - MILP + GIS | Sumatra, Indonesia |

| Hoo et al. [40] | S + T | EC | Strategic: - facility location - biomethane plant size Tactical: - transportation mode | MP – MILP + GIS | Johor, Malaysia |

| How and Lam [45] | T | EC + EN | Tactical: - biomass allocation - biomass transportation mode | MP - MILP | Johor, Malaysia |

| How et al. [25] | S + T | EC | Strategic: - processing hub selection Tactical: - biomass allocation - transportation mode selection | MP - MINLP | Johor, Malaysia |

| Lam et la. [38] | S | EN | Strategic: - biomass supply chain network design | MP - LP + P-graph | Central European region |

| Liu et al. [27] | S | EC + EN + SO | Strategic: - optimal conversion pathway - biomass type, locations - facility locations - network topology structure | MP - MILP | China |

| López et al. [24] | S | EC + EN | Strategic: - feedstocks type - location of cultivation sites - location of biomass facilities - biomass conversion technologies | MP - MINLP | Central-west part of Mexico |

| Maheshwari et al. [33] | S | EC | Strategic: - locations and capacities of pre-processing facility & biorefinery plant - biomass and intermediate product flows | MP - MILP | Southern Illinois, USA |

| Marufuzzaman et al. [43] | S + T | EC + EN | Strategic: - transportation mode - facility location Tactical: - inventory control | H - algorithm | Mississippi, USA |

| Miret et al. [19] | S + T | EC + EN + SO | Strategic: - facilities location - process selection Tactical: - inventory | MP - MILP | France |

| Mohseni and Pishvaee [34] | S + T | EC | Strategic: - optimal production scale Tactical: - intermediate product and product flows - amount of fertiliser needed | MP - MILP | Iran |

| Nana et al. [47] | S | EC + EN | Strategic: - facility location & capacity | MCDA - AHP + GIS | Jiangsu, China |

| Ng and Maravelias [20] | S + T | EC | Strategic: - biomass selection and allocation - technology selection - regional depots and biorefineries locations and capacity Tactical: - production, inventory and shipment | MP - MILP | South Central, South of Wisconsin, USA |

| Ng and Maravelias [46] | - | EC + ENE | - | General method | NA |

| Ng et al. [21] | T + O | EC | Tactical + operational: - optimal blending ratio | MP - MILP | Malaysia |

| Orjuela et al. [28] | S | EC + EN + SO | Strategic: - strategy/solution selection | MP - LP | Columbia |

| Osmani and Zhang [29] | S | EC + EN + SO | Strategic: - land allocation for switchgrass cultivation - locations and capacities of facility - conversion technology | MP - MILP | Midwestern USA |

| Poudel et al. [44] | S + T | EC | Strategic: - facility location Tactical:- production & storage - routing plan | MP - MINLP; H - algorithm | Mississippi and Alabama, USA |

| Rabbani et al. [22] | S | EC | Tactical: - whether to purchase or rent the warehouses and plants - selection of pre-processing centre - selection of biofuel plants - selection of warehouses to store biofuels | MP - MILP | NA |

| Santibañez et al. [23] | T | EC + EN + SO | Tactical: - feedstock produced - feedstock transported - feedstock arrived/accumulated - product arrived/accumulated | MP - MILP | Mexico |

| Santibañez et al. [26] | T | EC | Strategic: - processing facility and technology Tactical: - material flow - inventory level | MP - MINLP | Mexico |

| Santibañez et al. [35] | S + T | EC + EN | Strategic: - facility location technology type Tactical: - raw materials and products - market | MP - MILP | Mexico |

| Sharifzadeh et al. [36] | S + T + O | EC | Strategic: - number, type, location and size of processing plants and mobile pyrolyser Tactical + operational: - materials flowrates | MP - MILP | London, Liverpool, UK |

| Zhang et al. [41] | S + T | EC | Strategic: - facility location Tactical: - inventory level | MP - MILP + GIS | Northern part of Michigan’s Lower Peninsula, USA |

| Agricultural Residues | Industrial Wastewater | Energy Crops | Microalgae | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CS | MR | WS | RS | CR | BS | WR | PR | SR | MSW | WS | WCO | C | W | S | PO | RO | RSO | SF | J | SG | WB | SGS | M | SFR | GS | MA | |

| [15] | x | ||||||||||||||||||||||||||

| [16] | x | ||||||||||||||||||||||||||

| [42] | x | ||||||||||||||||||||||||||

| [30] | x | x | x | x | x | x | |||||||||||||||||||||

| [31] | x | x | x | x | |||||||||||||||||||||||

| [17] | x | x | x | x | x | ||||||||||||||||||||||

| [37] | NS | ||||||||||||||||||||||||||

| [18] | x | ||||||||||||||||||||||||||

| [32] | x | ||||||||||||||||||||||||||

| [39] | x | x | |||||||||||||||||||||||||

| [40] | x | x | x | ||||||||||||||||||||||||

| [45] | x | ||||||||||||||||||||||||||

| [25] | x | x | x | ||||||||||||||||||||||||

| [38] | x | x | x | x | |||||||||||||||||||||||

| [27] | x | x | x | x | |||||||||||||||||||||||

| [24] | x | x | x | x | x | ||||||||||||||||||||||

| [33] | x | x | x | ||||||||||||||||||||||||

| [43] | x | ||||||||||||||||||||||||||

| [19] | x | x | x | ||||||||||||||||||||||||

| [34] | x | ||||||||||||||||||||||||||

| [47] | x | ||||||||||||||||||||||||||

| [20] | x | x | |||||||||||||||||||||||||

| [46] | x | ||||||||||||||||||||||||||

| [21] | x | x | |||||||||||||||||||||||||

| [28] | x | ||||||||||||||||||||||||||

| [29] | x | x | |||||||||||||||||||||||||

| [44] | x | x | |||||||||||||||||||||||||

| [22] | x | ||||||||||||||||||||||||||

| [23] | x | x | x | x | x | x | x | x | |||||||||||||||||||

| [26] | x | x | x | x | x | x | x | x | |||||||||||||||||||

| [35] | x | x | x | x | x | x | x | x | |||||||||||||||||||

| [36] | x | x | |||||||||||||||||||||||||

| [41] | x | ||||||||||||||||||||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, H.P.; Phun Chien, C.B.; Yee Van, F. Operational Management Implemented in Biofuel Upstream Supply Chain and Downstream International Trading: Current Issues in Southeast Asia. Energies 2020, 13, 1799. https://doi.org/10.3390/en13071799

Ying HP, Phun Chien CB, Yee Van F. Operational Management Implemented in Biofuel Upstream Supply Chain and Downstream International Trading: Current Issues in Southeast Asia. Energies. 2020; 13(7):1799. https://doi.org/10.3390/en13071799

Chicago/Turabian StyleYing, Hoo Poh, Cassendra Bong Phun Chien, and Fan Yee Van. 2020. "Operational Management Implemented in Biofuel Upstream Supply Chain and Downstream International Trading: Current Issues in Southeast Asia" Energies 13, no. 7: 1799. https://doi.org/10.3390/en13071799

APA StyleYing, H. P., Phun Chien, C. B., & Yee Van, F. (2020). Operational Management Implemented in Biofuel Upstream Supply Chain and Downstream International Trading: Current Issues in Southeast Asia. Energies, 13(7), 1799. https://doi.org/10.3390/en13071799