GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System

Abstract

1. Introduction

2. Preliminaries

2.1. Current Dynamic Model of IPMSM

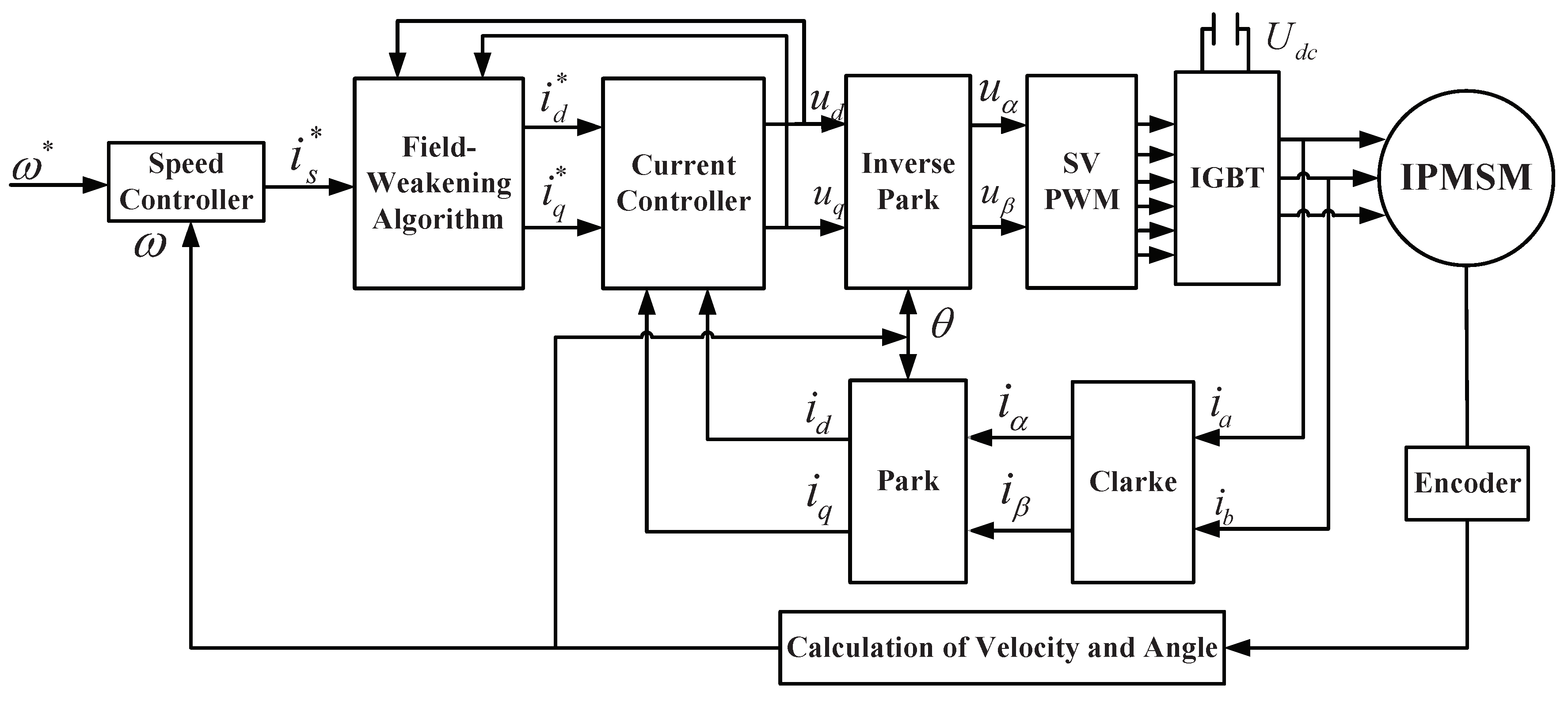

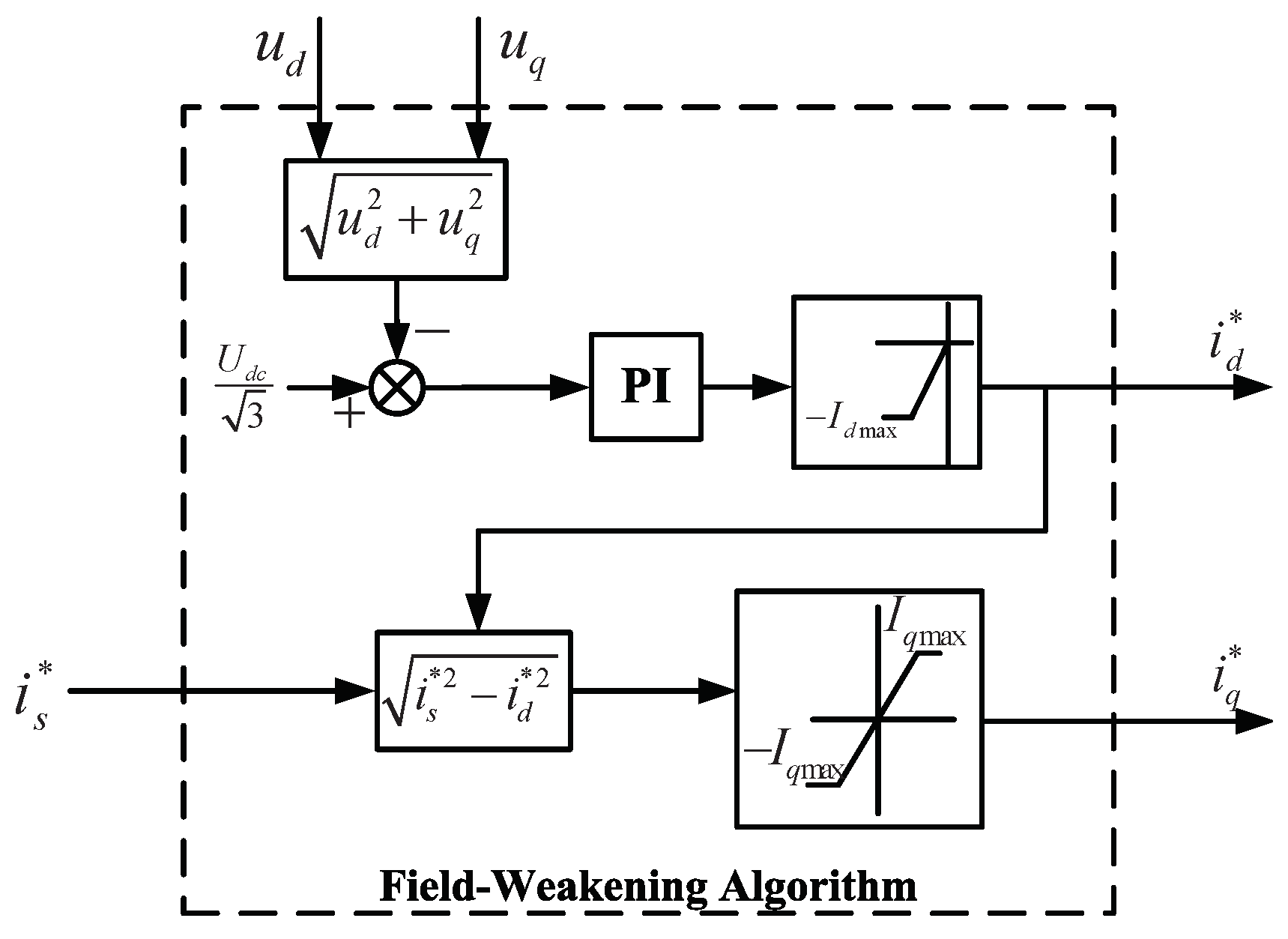

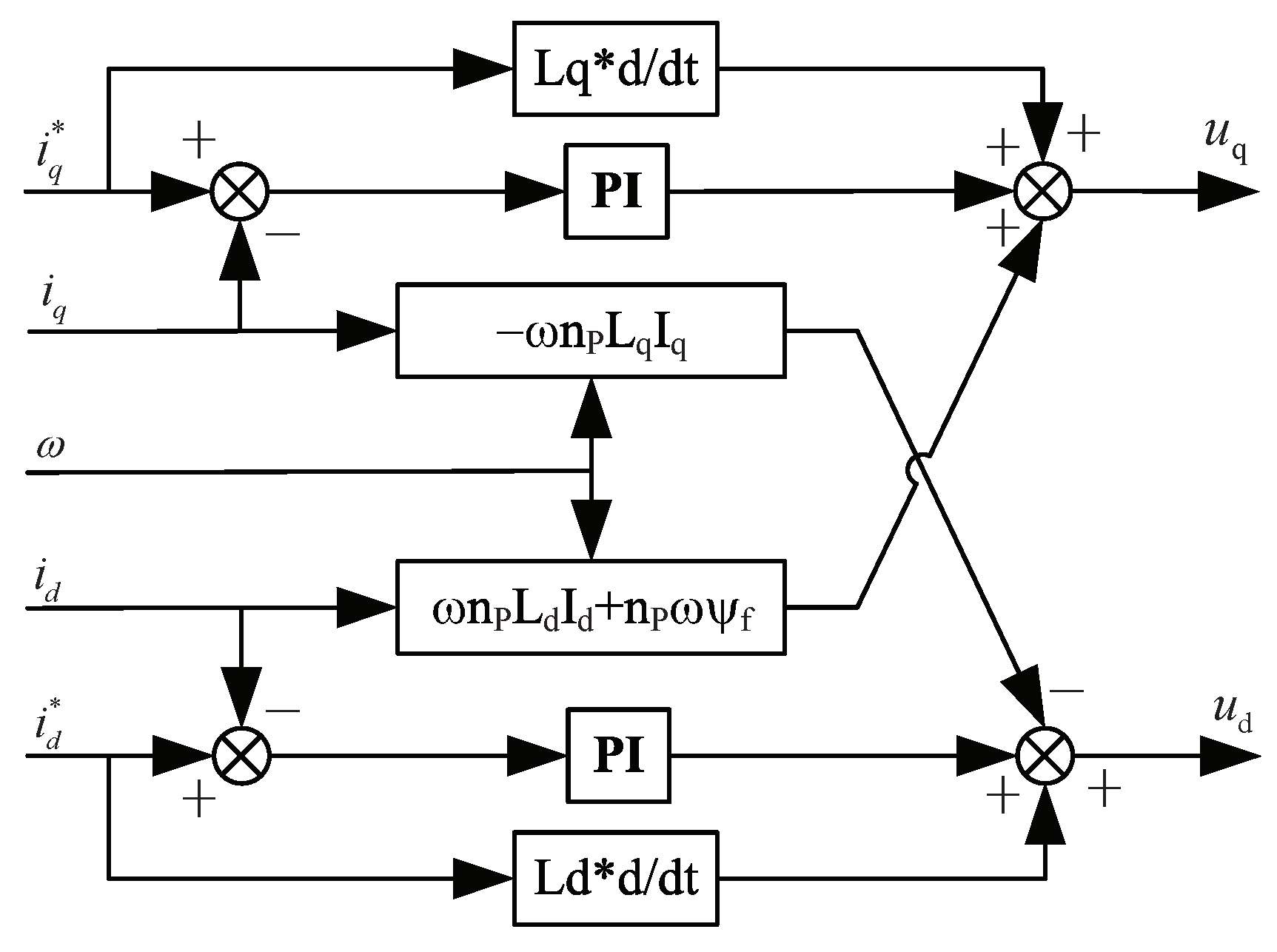

2.2. Cascade Flux-Weakening Control Framework

3. Controller Design

3.1. GPIO Design

3.2. Output Prediction with Disturbance Compensation

3.3. Receding Optimization and Control Law Design

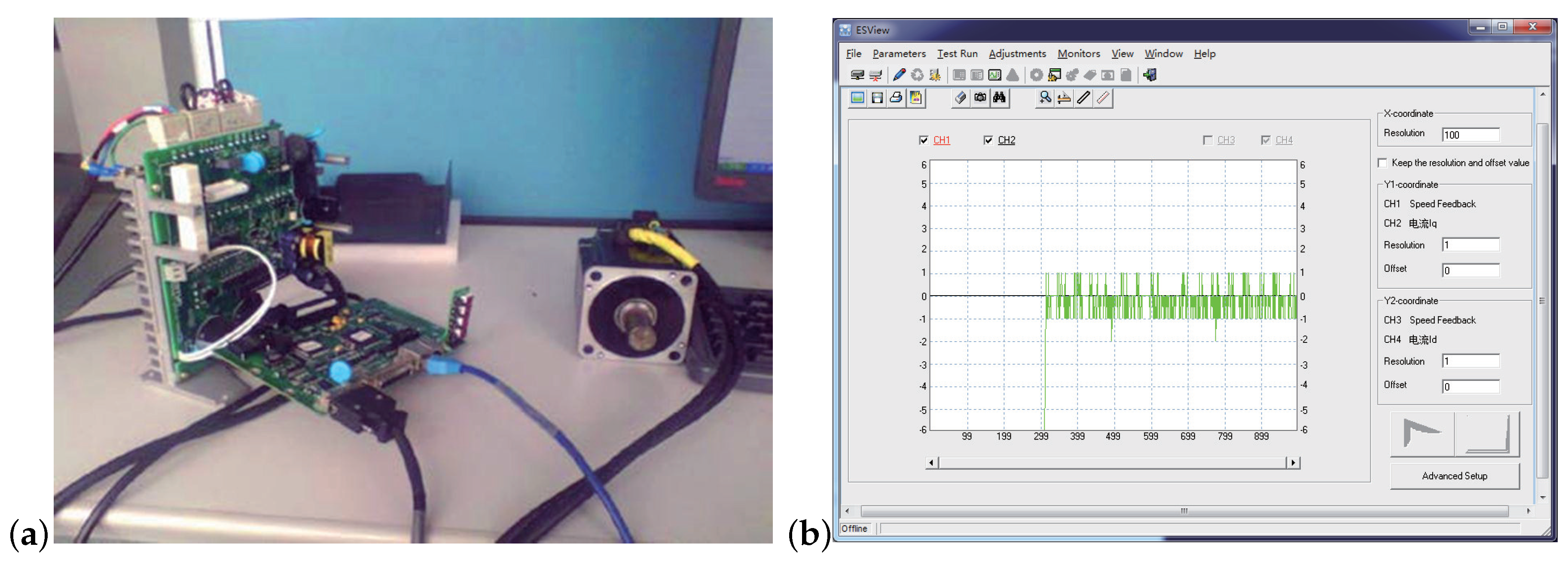

4. Experimental Validation

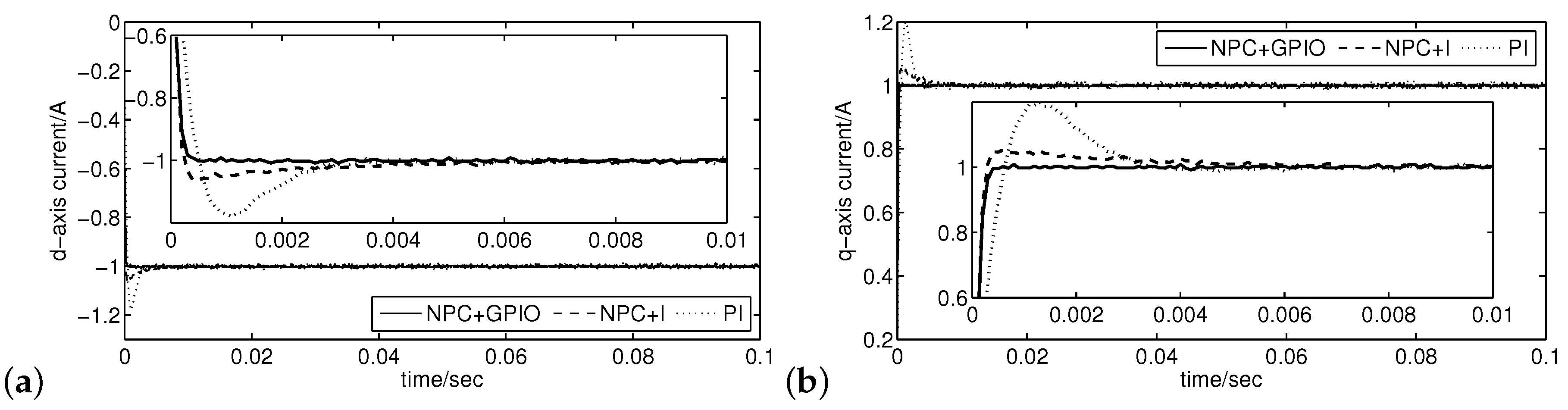

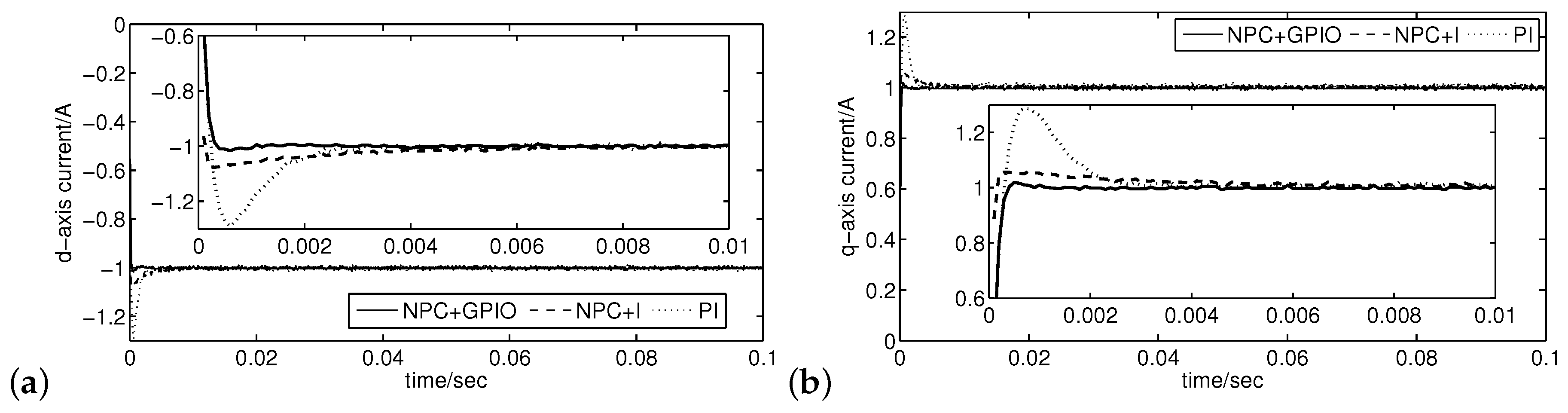

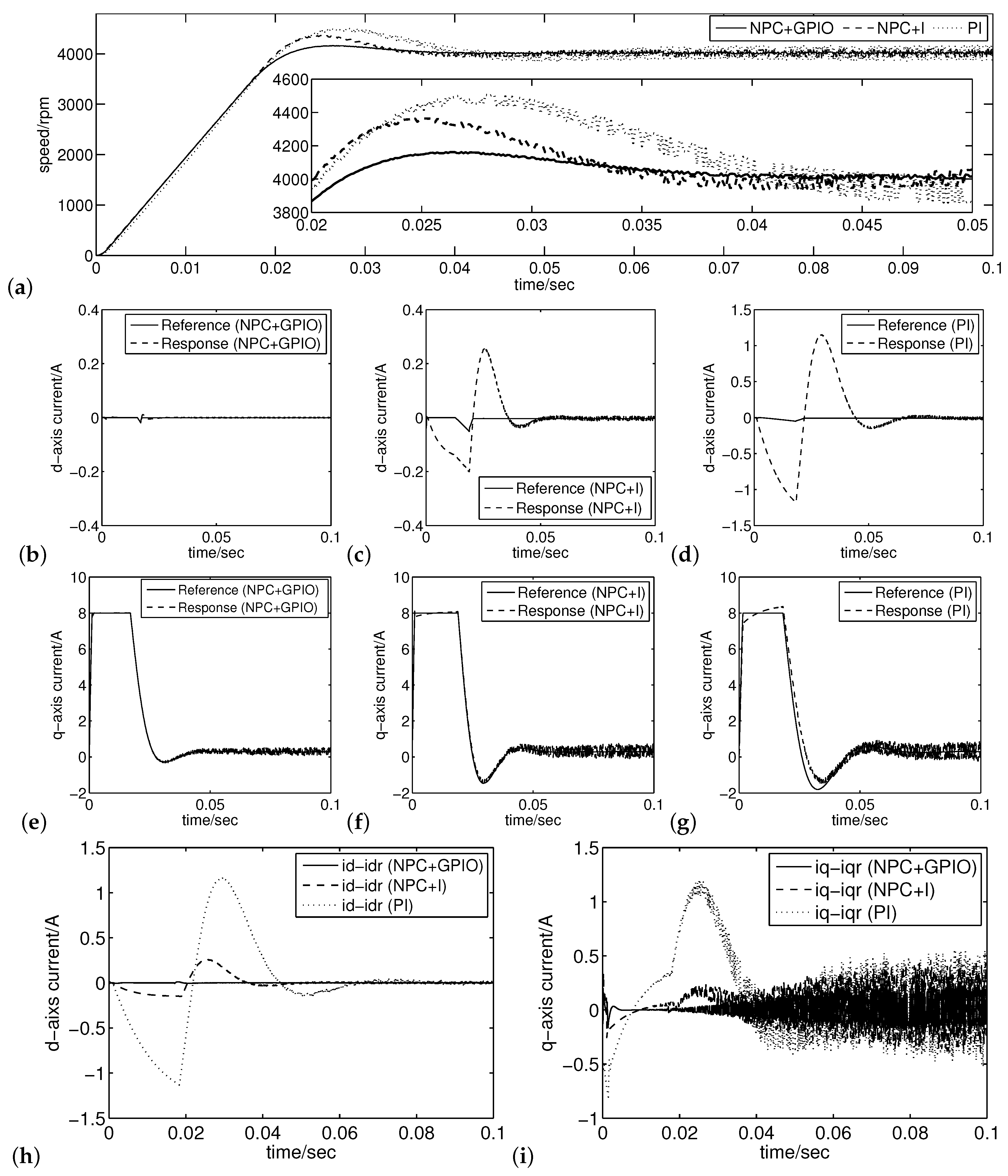

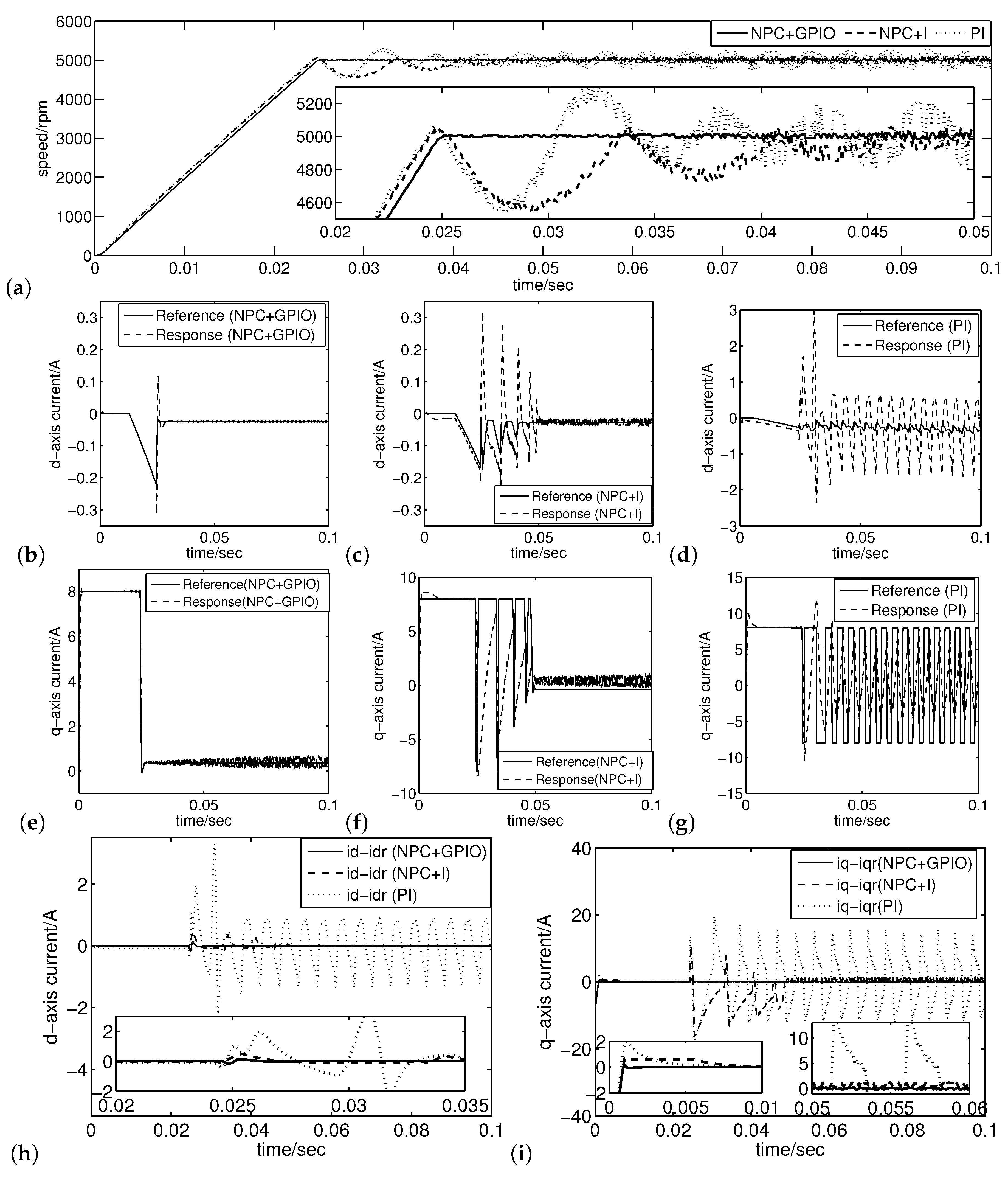

4.1. Control Performance under Current Control Model

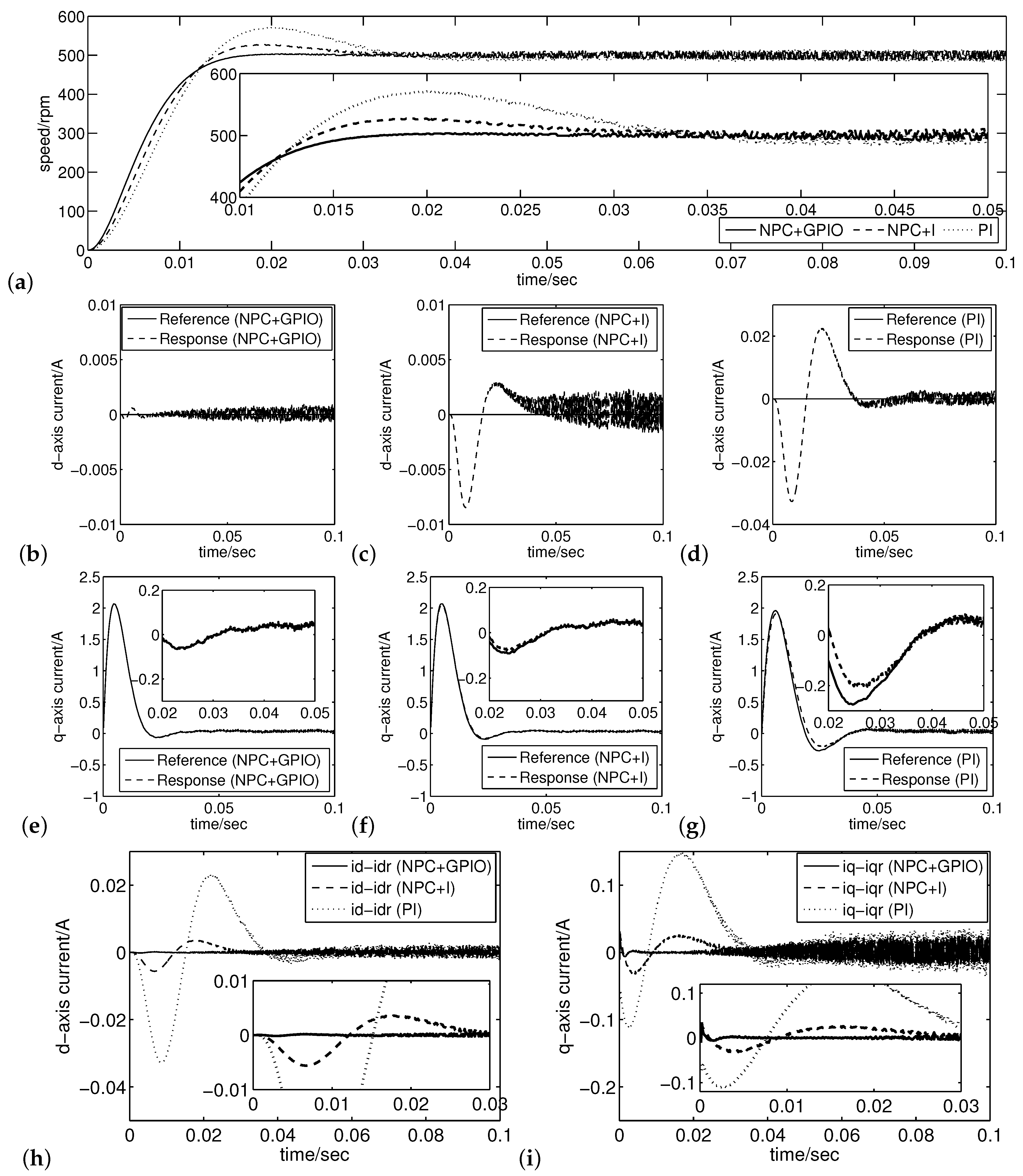

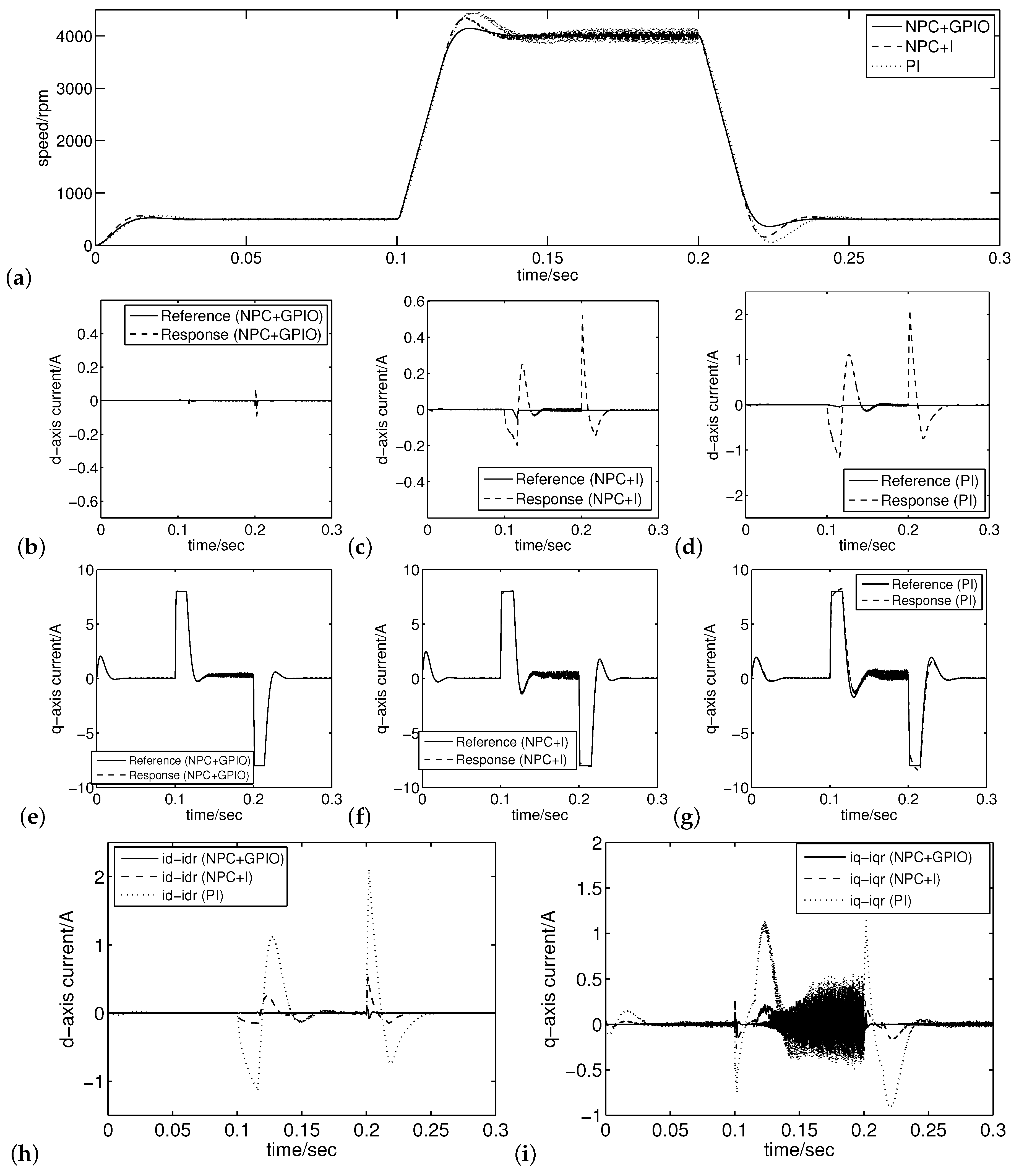

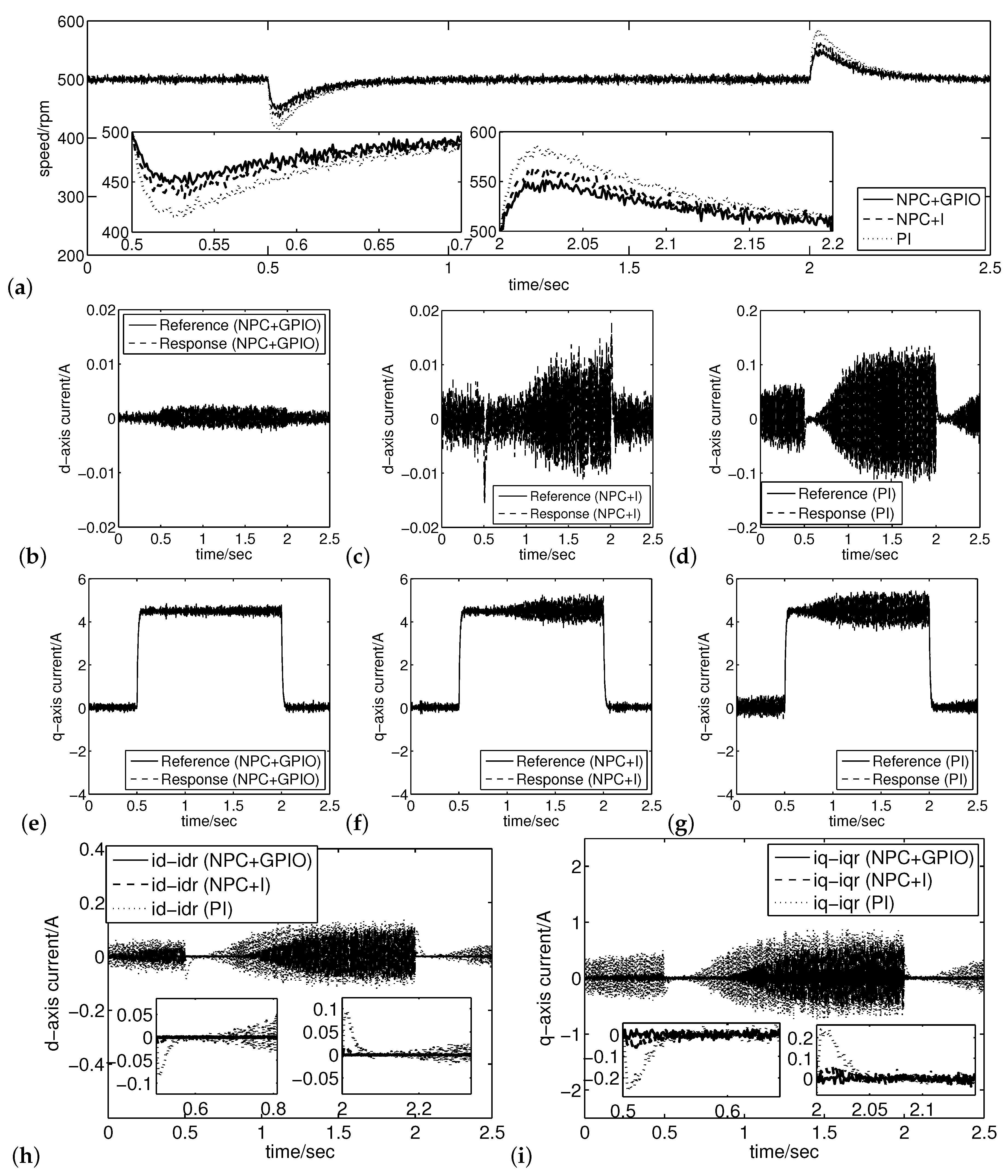

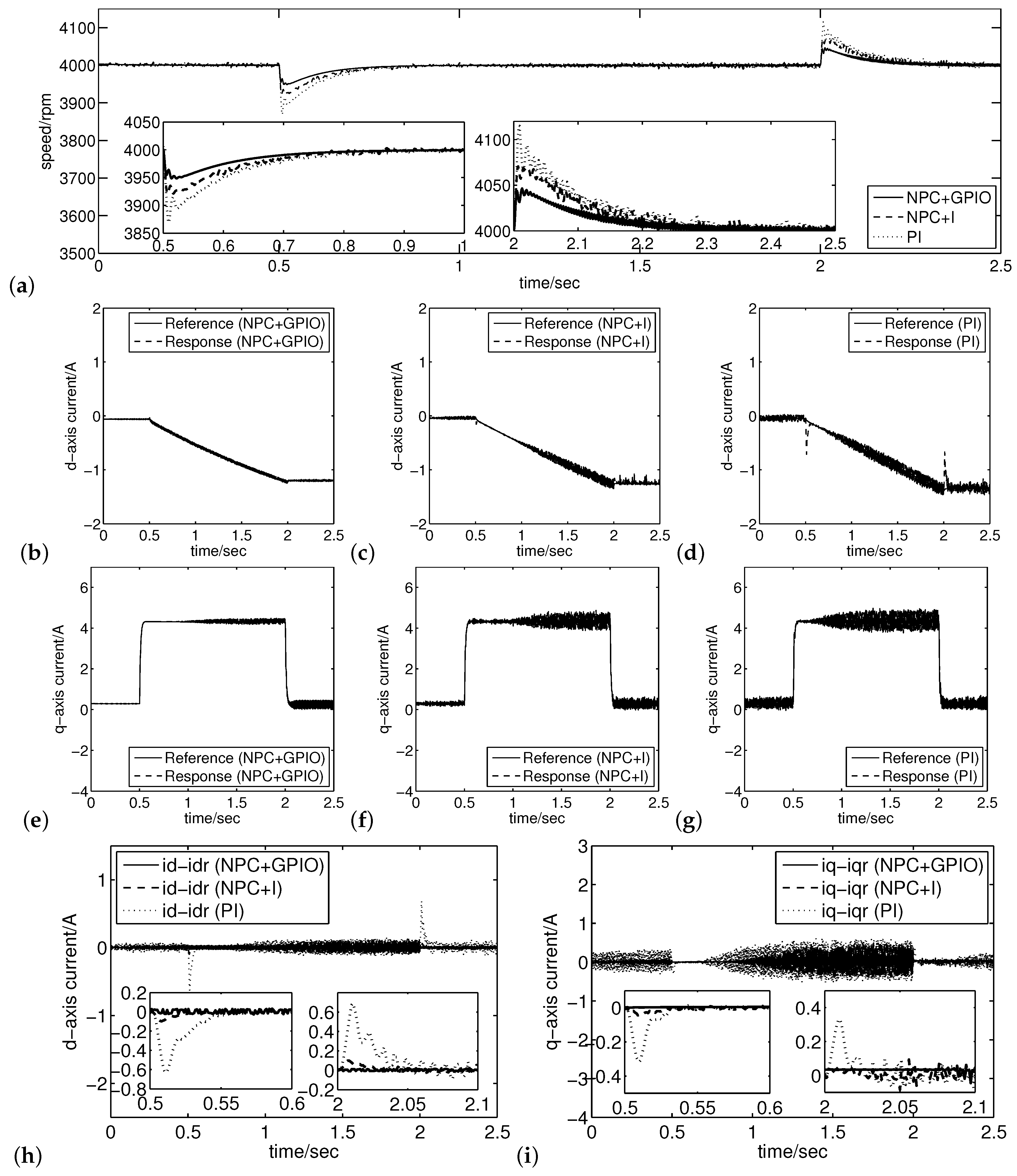

4.2. Control Performance under Speed Control Mode

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Lee, S.; Kim, K.; Cho, S.; Jang, J.; Lee, T.; Hong, J. Optimal design of interior permanent magnet synchronous motor considering the manufacturing tolerances using Taguchi robust design. IET Electr. Power Appl. 2014, 8, 23–28. [Google Scholar] [CrossRef]

- Kwon, T.S.; Sul, S.K. Novel antiwindup of a current regulator of a surface-mounted permanent-magnet motor for flux-weakening control. IEEE Trans. Ind. Appl. 2006, 42, 1293–1300. [Google Scholar] [CrossRef]

- Sue, S.; Pan, C. Voltage-constraint-tracking-based field-weakening control of IPM synchronous motor drives. IEEE Trans. Ind. Electron. 2008, 55, 340–347. [Google Scholar] [CrossRef]

- Andreescu, G.; Pitic, C.; Blaabjerg, F.; Boldea, I. Combined flux observer with signal injection enhancement for wide speed range sensorless direct torque control of IPMSM drives. IEEE Trans. Energy Convers. 2008, 23, 393–402. [Google Scholar] [CrossRef]

- Huynh, T.; Hsieh, M. Performance analysis of permanent magnet motors for electric vehicles (EV) traction considering driving cycles. Energies. 2018, 11, 1385. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.; Wang, N.; Liu, S. Sensorless control of ship propulsion interior permanent magnet synchronous motor based on a new sliding mode observer. ISA Trans. 2015, 54, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Kwon, T.; Choi, G.; Kwak, M.; Sul, S. Novel flux-weakening control of an IPMSM for quasi-six-step operation. IEEE Trans. Ind. Appl. 2008, 44, 1722–1731. [Google Scholar] [CrossRef]

- Wang, G.; Yang, R.; Xu, D. DSP-based control of sensorless IPMSM drives for wide-speed-range operation. IEEE Trans. Ind. Electron. 2013, 60, 720–727. [Google Scholar] [CrossRef]

- Ishikawa, T.; Yamada, M.; Kurita, N. Design of magnet arrangement in interior permanent magnet synchronous motor by response surface methodology in consideration of torque and vibration. IEEE Trans. Magn. 2011, 47, 1290–1293. [Google Scholar] [CrossRef]

- Park, C.; Lee, J. A torque error compensation algorithm for surface mounted permanent magnet synchronous machines with respect to magnet temperature variations. Energies 2017, 10, 1365. [Google Scholar] [CrossRef]

- Jung, S.; Hong, J.; Nam, K. Current minimizing torque control of the IPMSM using Ferrari’s method. IEEE Trans. Power Electron. 2013, 28, 5603–5617. [Google Scholar] [CrossRef]

- Tang, M.; Zhuang, S. On speed control of a permanent magnet synchronous motor with current predictive compensation. Energies 2019, 12, 65. [Google Scholar] [CrossRef]

- Park, Y.; Koo, M.; Jang, S.; Choi, J.; You, D. Dynamic characteristic analysis of interior permanent magnet synchronous motor considering varied parameters by outer disturbance based on electromagnetic field analysis. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Model predictive direct torque control with finite control set for PMSM drive systems, part 2: Field weakening operation. IEEE Trans. Ind. Inf. 2008, 23, 393–402. [Google Scholar] [CrossRef]

- Liu, H.; Li, S. Speed control for PMSM servo system using predictive functional control and extended state observer. IEEE Trans. Ind. Electron. 2012, 59, 1171–1183. [Google Scholar] [CrossRef]

- Li, X.; Li, S. Speed control for a PMSM servo system using model reference adaptive control and an extended state observer. J. Power Electron. 2014, 14, 549–563. [Google Scholar] [CrossRef]

- Shi, J.; Li, S. Analysis and compensation control of dead-time effect on space vector PWM. J. Power Electron. 2015, 15, 431–442. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Yang, J.; Zhou, X. Continuous sliding mode control for permanent magnet synchronous motor speed regulation systems under time-varying disturbances. J. Power Electron. 2016, 16, 1324–1335. [Google Scholar] [CrossRef]

- Mengoni, M.; Zarri, L.; Tani, A.; Serra, G.; Casadei, D. A comparison of four robust control schemes for field-weakening operation of induction motors. IEEE Trans. Power Electron. 2012, 27, 307–320. [Google Scholar] [CrossRef]

- Morimoto, S.; Sanada, M.; Takeda, Y. Wide-speed operation of interior permanent magnet synchronous motors with high-performance current regulator. IEEE Trans. Ind. Electron. 1994, 30, 920–926. [Google Scholar] [CrossRef]

- Zhou, K.; Ai, M.; Sun, D.; Jin, N.; Wu, X. Field weakening operation control strategies of PMSM based on feedback linearization. Energies 2019, 12, 4526. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Qu, R. Maximum-torque-per-ampere and magnetization-state control of a variable-flux permanent magnet machine. IEEE Trans. Ind. Electron. 2017, 65, 1158–1169. [Google Scholar] [CrossRef]

- Mynar, Z.; Vesely, L.; Vaclavek, P. PMSM model predictive control with field-weakening implementation. IEEE Trans. Ind. Electron. 2016, 63, 5156–5166. [Google Scholar] [CrossRef]

- Fliess, M.; Lévine, J.; Martin, P.; Rouchon, P. Flatness and defect of nonlinear systems: Introductory theory and examples. Int. J. Control 1995, 61, 1327–1361. [Google Scholar] [CrossRef]

- Chen, W.-H.; Yang, J.; Guo, L.; Li, S. Disturbance-observer-based control and related methods—An overview. IEEE Trans. Ind. Electron. 2015, 63, 1083–1095. [Google Scholar] [CrossRef]

- Yang, J.; Chen, W.-H.; Li, S.; Guo, L.; Yan, Y. Disturbance/uncertainty estimation and attenuation techniques in pmsm drives—A survey. IEEE Trans. Ind. Electron. 2016, 64, 3273–3285. [Google Scholar] [CrossRef]

- Chen, W.; Ballance, D.; Gawthrop, P. Optimal control of nonlinear systems: A predictive control approach. Automatica 2013, 39, 633–641. [Google Scholar] [CrossRef]

- Errouissi, R.; Ouhrouche, M.; Chen, W.; Trzynadlowski, A. Robust cascaded nonlinear predictive control of a permanent magnet synchronous motor with antiwindup compensator. IEEE Trans. Ind. Electron. 2012, 59, 3078–3088. [Google Scholar] [CrossRef]

- Yang, J.; Zheng, W. Offset-free nonlinear MPC for mismatched disturbance attenuation with application to a static var compensator. IEEE Trans. Circuits Syst. II Express Briefs 2014, 61, 49–53. [Google Scholar] [CrossRef]

- Yang, J.; Zheng, W.; Li, S.; Wu, B.; Cheng, M. Design of a prediction-accuracy-enhanced continuous-time MPC for disturbed systems via a disturbance observer. IEEE Trans. Ind. Electron. 2015, 62, 5807–5816. [Google Scholar] [CrossRef]

- Wu, C.; Yang, J.; Li, S.; Li, Q.; Guo, L. Disturbance observer based model predictive control for accurate atmospheric entry of spacecraft. Adv. Space Res. 2018, 61, 2457–2471. [Google Scholar] [CrossRef]

- Quintal-Palomo, R.E.; Gwozdziewicz, M.; Dybkowski, M. Modelling and co-simulation of a permanent magnet synchronous generator. COMPEL Int. J. Comp. Math. Electr. Electron. 2019, 38, 1904–1917. [Google Scholar] [CrossRef]

- Quintal-Palomo, R.E. Analysis of Current Signals in a Partially Demagnetized Vector Controlled Interior Permanent Magnet Generator. Power Electron. Drives 2019, 4, 179–190. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Rated power P | 750 (W) | Stator inductance on d axis | 3.5 (mH) |

| Rated voltage | 200 (V) | Stator inductance on q axis | 4 (mH) |

| Rated current | 4.5 (A) | Rotor inertia | 1.76 (kg· m2) |

| Rated torque | 2.4 (Nm) | Stator resistance | 1.74 () |

| Rated speed | 3000 (rpm) | Flux linkage | 0.1267 (Wb) |

| Maximum speed | 5000 (rpm) | Torque constant | 0.5422 (Nm/A) |

| Pole pairs | 4 | Viscous coefficient B | 7.388 (Nm · s/rad) |

| Current Controller | Control Parameters |

|---|---|

| NPC + GPIO | GPIO order = 4, , , , |

| , , and are tuned to be nominal or inaccurate respectively in the two cases | |

| NPC + I | , |

| , , and are also tuned to be nominal or inaccurate respectively in the two cases | |

| PI | , , , (subscripts d and q mean d- or q- axis, respectively) |

| , , and are also tuned to be nominal or inaccurate respectively in the two cases |

| Speed Controller | d- or q-Axis | Current Controller | Dynamic-State | Steady-State | ||

|---|---|---|---|---|---|---|

| OS (%) | (ms) | Offset Error (mA) | Fluctuation Rate (%) | |||

| – | d-axis | NPC + GPIO | 0.25 | 0.6 | 0 | 0.83 |

| NPC + I | 6.36 | 3.4 | 0 | 0.94 | ||

| PI | 17.99 | 3.1 | 0 | 1.25 | ||

| – | q-axis | NPC + GPIO | 0.83 | 0.6 | 0 | 2.78 |

| NPC + I | 5.27 | 4.1 | 0 | 3.13 | ||

| PI | 19.93 | 3.0 | 0 | 4.17 | ||

| Speed Controller | d- or q-Axis | Current Controller | Dynamic-State | Steady-State | ||

|---|---|---|---|---|---|---|

| OS (%) | (ms) | Offset Error (mA) | Fluctuation Rate (%) | |||

| – | d-axis | NPC + GPIO | 1.76 | 0.6 | 0 | 0.86 |

| NPC + I | 6.36 | 5.05 | 1.3 | 0.97 | ||

| PI | 29.11 | 3.54 | 2.2 | 1.32 | ||

| – | q-axis | NPC + GPIO | 1.76 | 0.6 | 0 | 2.85 |

| NPC + I | 7.76 | 5.05 | 4.4 | 3.27 | ||

| PI | 19.93 | 3.0 | 7.4 | 4.96 | ||

| Speed Controller | Reference Speed | Current Controller | Dynamic-State | Steady State | ||

|---|---|---|---|---|---|---|

| OS (%) | (ms) | Offset Error (rpm) | Fluctuation Rate (%) | |||

| PI | 500 rpm | NPC + GPIO | 0.9 | 14.8 | 0.63 | 1.23 |

| NPC + I | 5.49 | 29.1 | 0.76 | 2.18 | ||

| PI | 14.23 | 32.7 | 1.45 | 3.14 | ||

| PI | 4000 rpm | NPC + GPIO | 0.25 | 23.6 | 0.86 | 1.29 |

| NPC + I | 1.16 | 31.6 | 4.62 | 2.08 | ||

| PI | 5.85 | 38.8 | 11.65 | 3.26 | ||

| PI | 5000 rpm | NPC + GPIO | 0.26 | 25.2 | 1.16 | 1.27 |

| NPC + I | 1.26 | 44.5 | 2.93 | 2.23 | ||

| PI | 6.16 | – | 3.18 | 5.44 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Yang, J.; Li, Q. GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System. Energies 2020, 13, 1716. https://doi.org/10.3390/en13071716

Wu C, Yang J, Li Q. GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System. Energies. 2020; 13(7):1716. https://doi.org/10.3390/en13071716

Chicago/Turabian StyleWu, Chao, Jun Yang, and Qi Li. 2020. "GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System" Energies 13, no. 7: 1716. https://doi.org/10.3390/en13071716

APA StyleWu, C., Yang, J., & Li, Q. (2020). GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System. Energies, 13(7), 1716. https://doi.org/10.3390/en13071716