Research on the Roof Advanced Breaking Position and Influences of Large Mining Height Working Face in Shallow Coal Seam

Abstract

1. Introduction

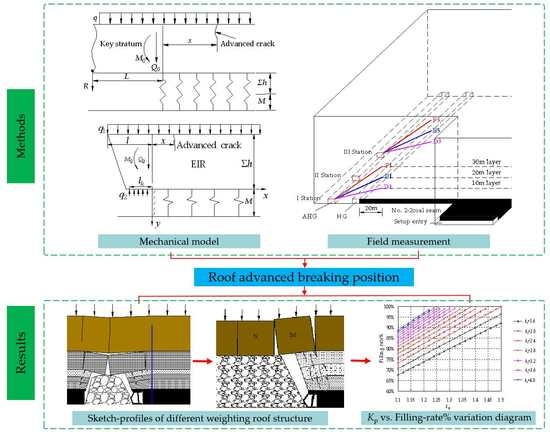

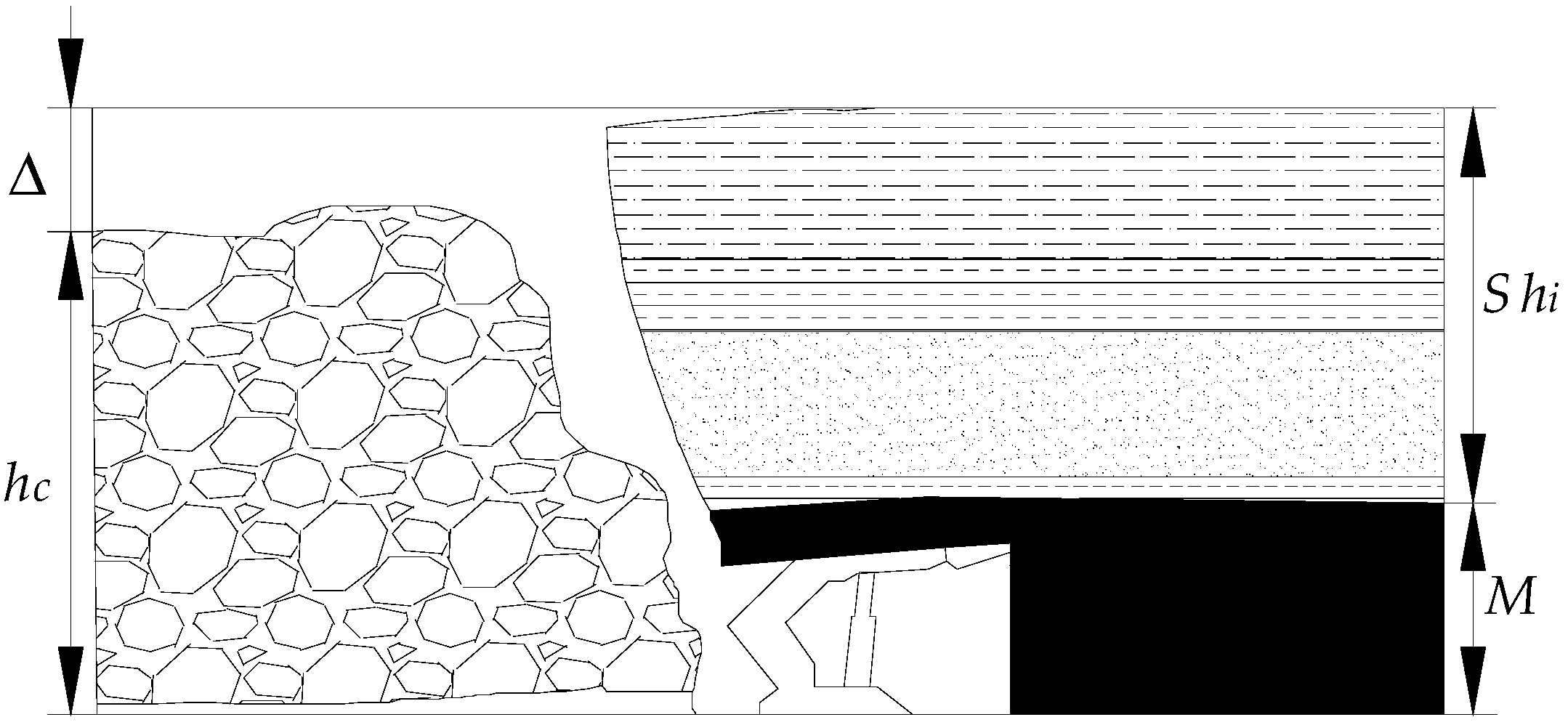

2. Establishment of the Mechanical Model of the Roof Advanced Breaking Position

2.1. Proposition of EIR

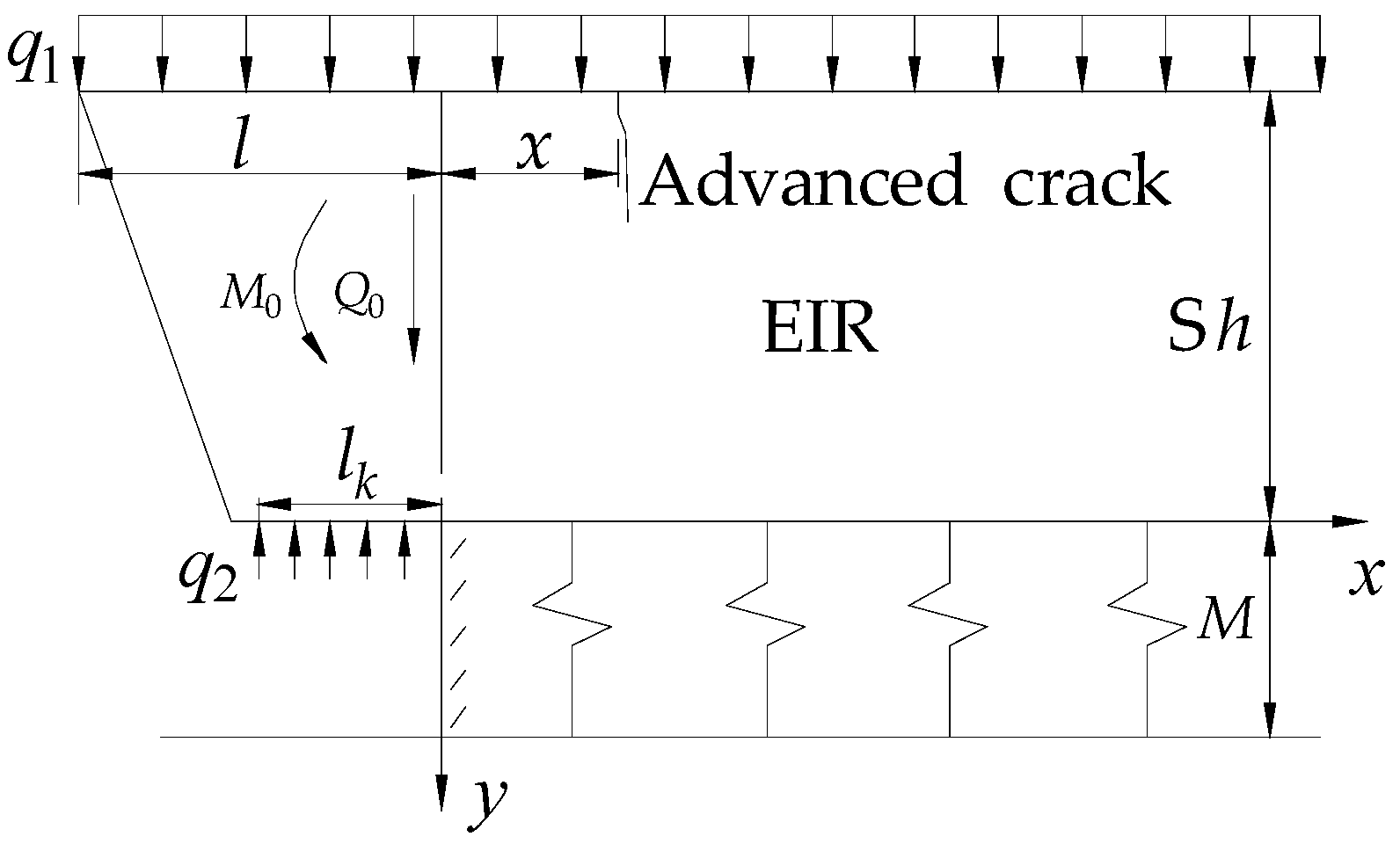

2.2. Mechanical Model of Key Stratum Advanced Breaking Position

2.3. Mechanical Model of EIR Advanced Breaking Position

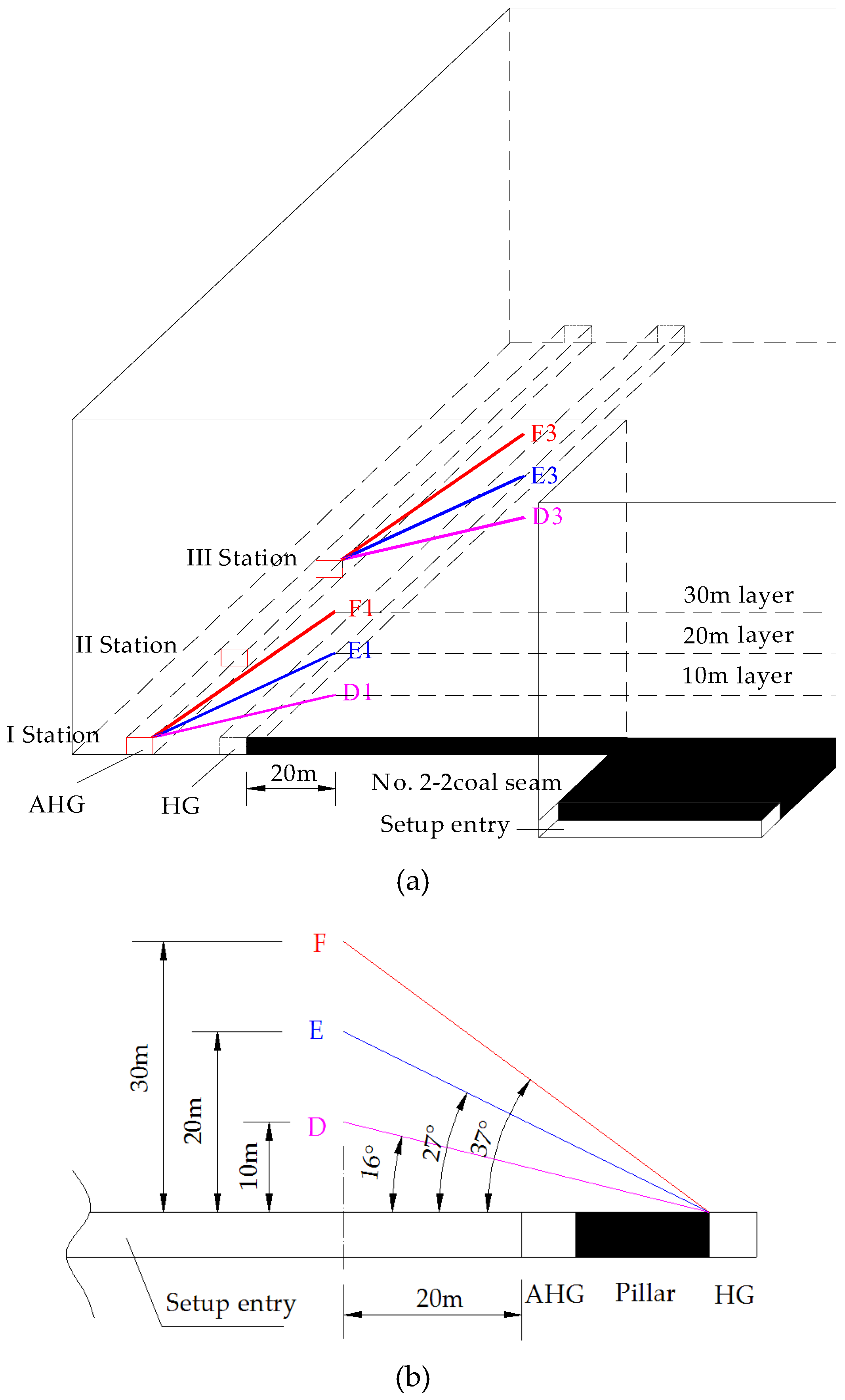

3. Field Measurement Method

4. Results

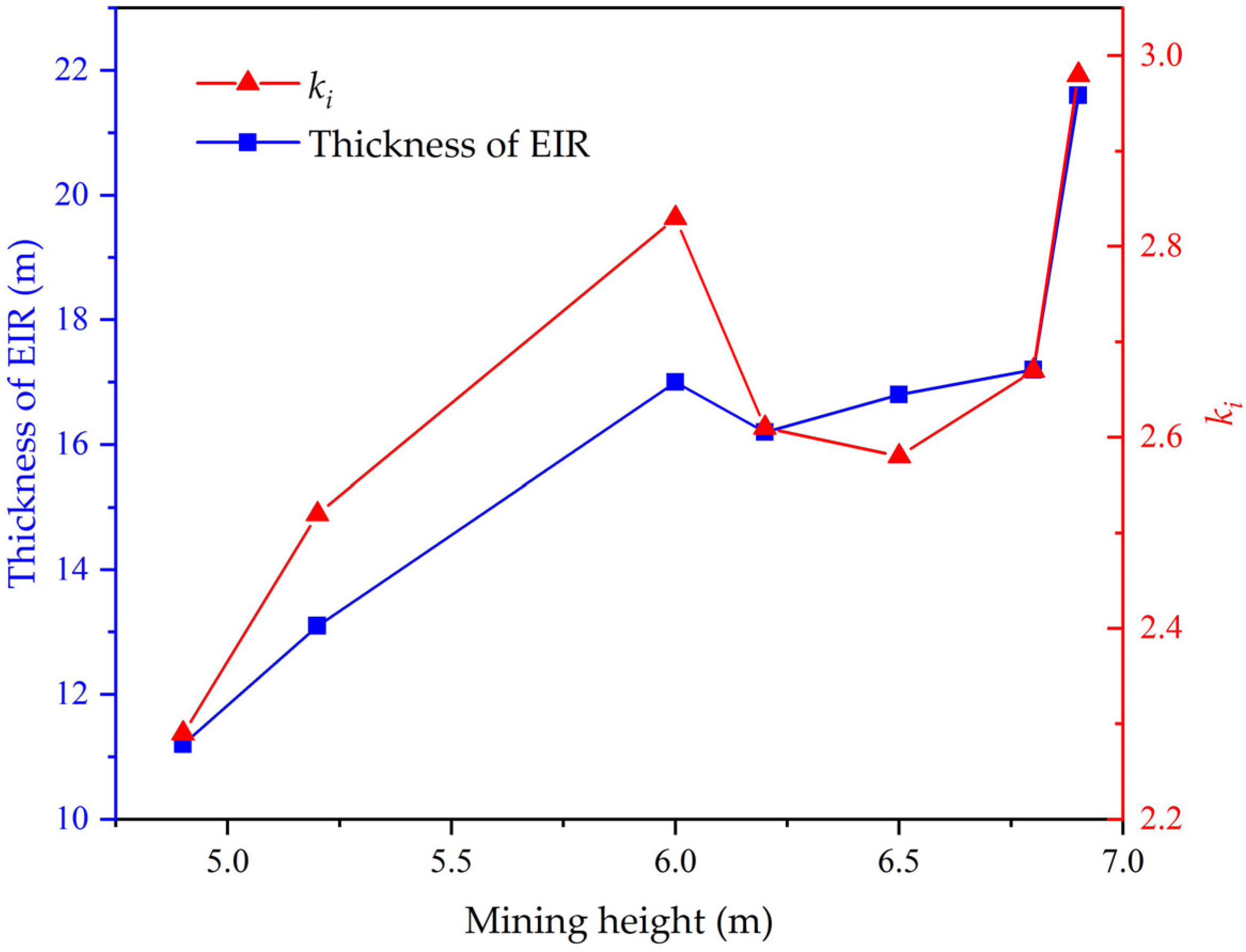

4.1. Calculation Results of the Theoretical Model

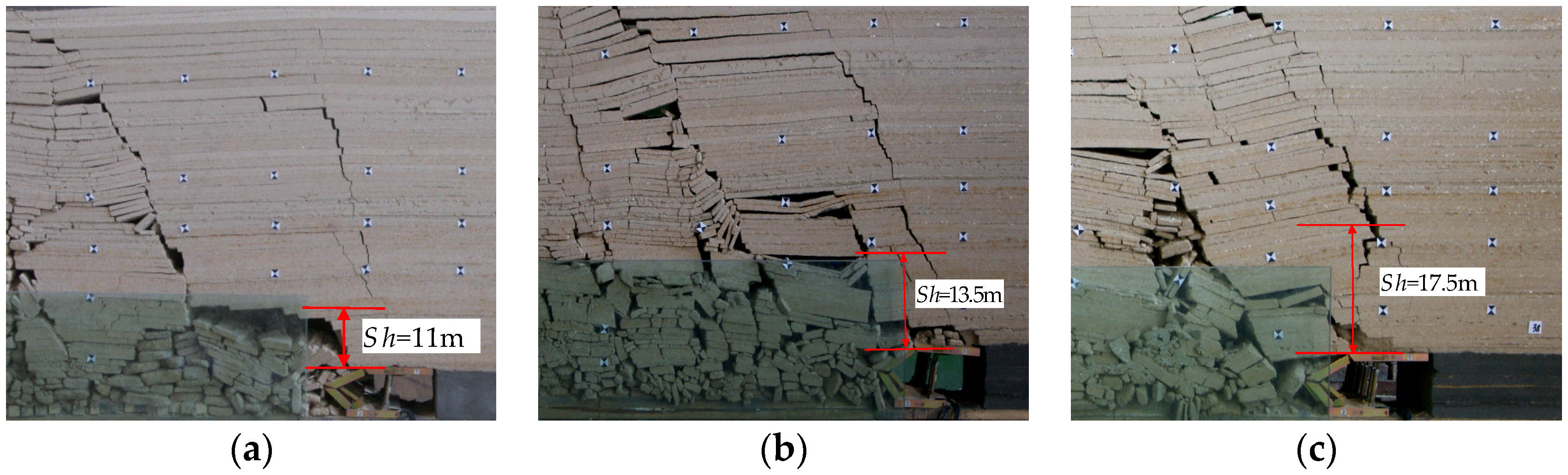

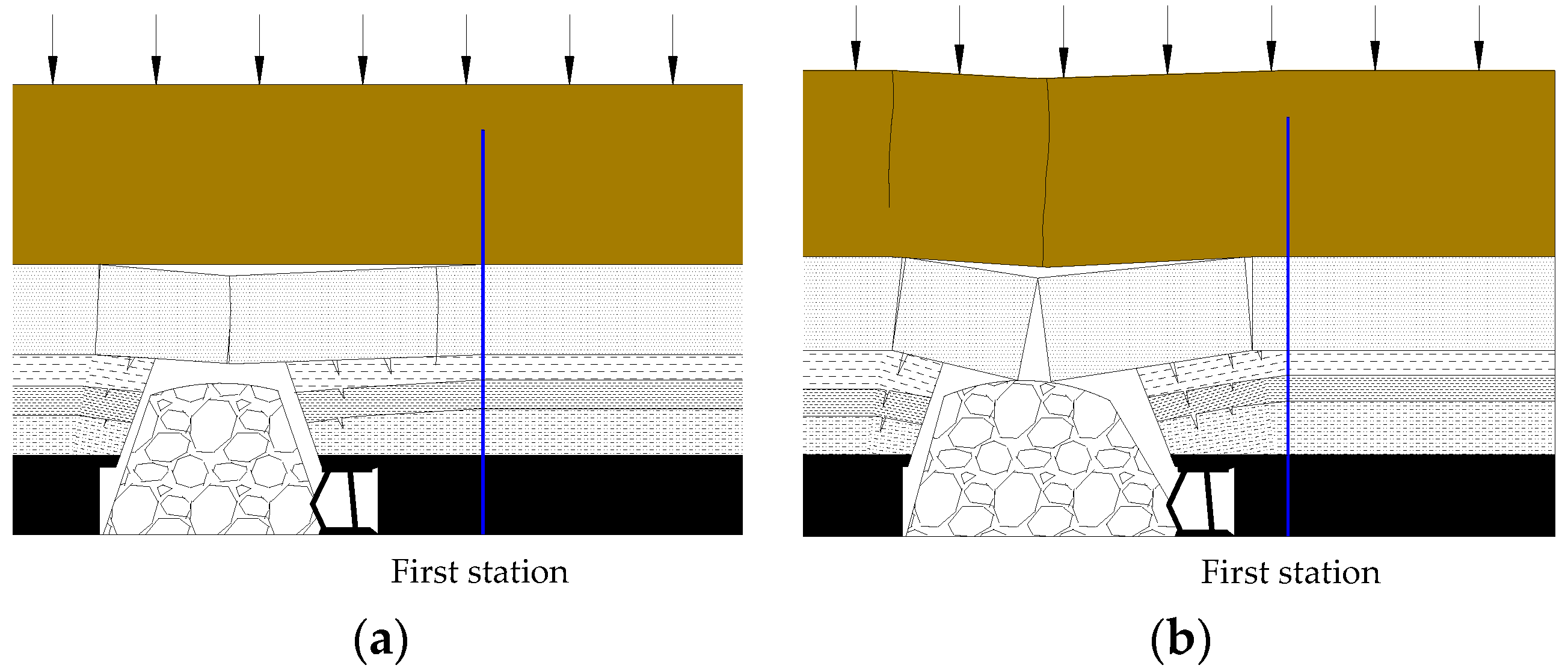

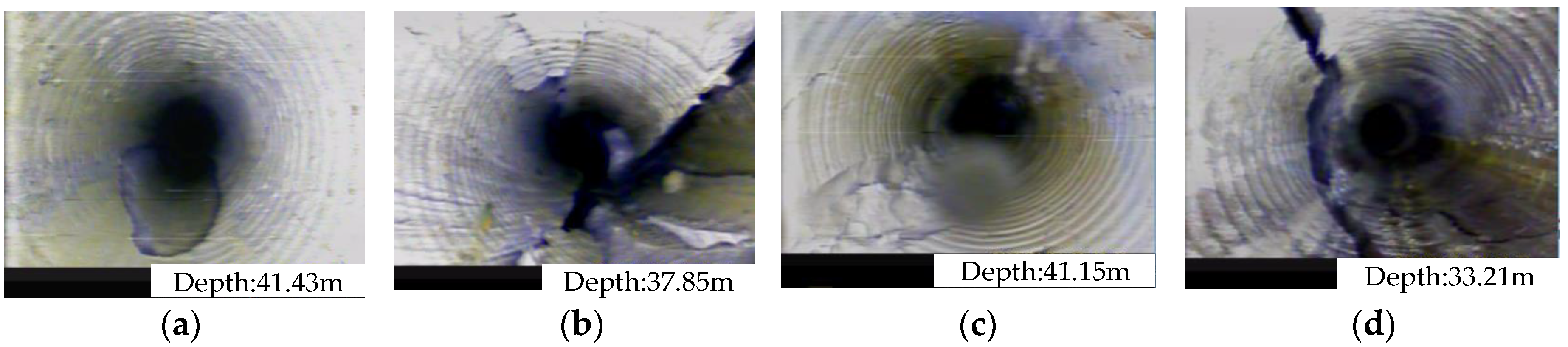

4.2. Field Measurement Results

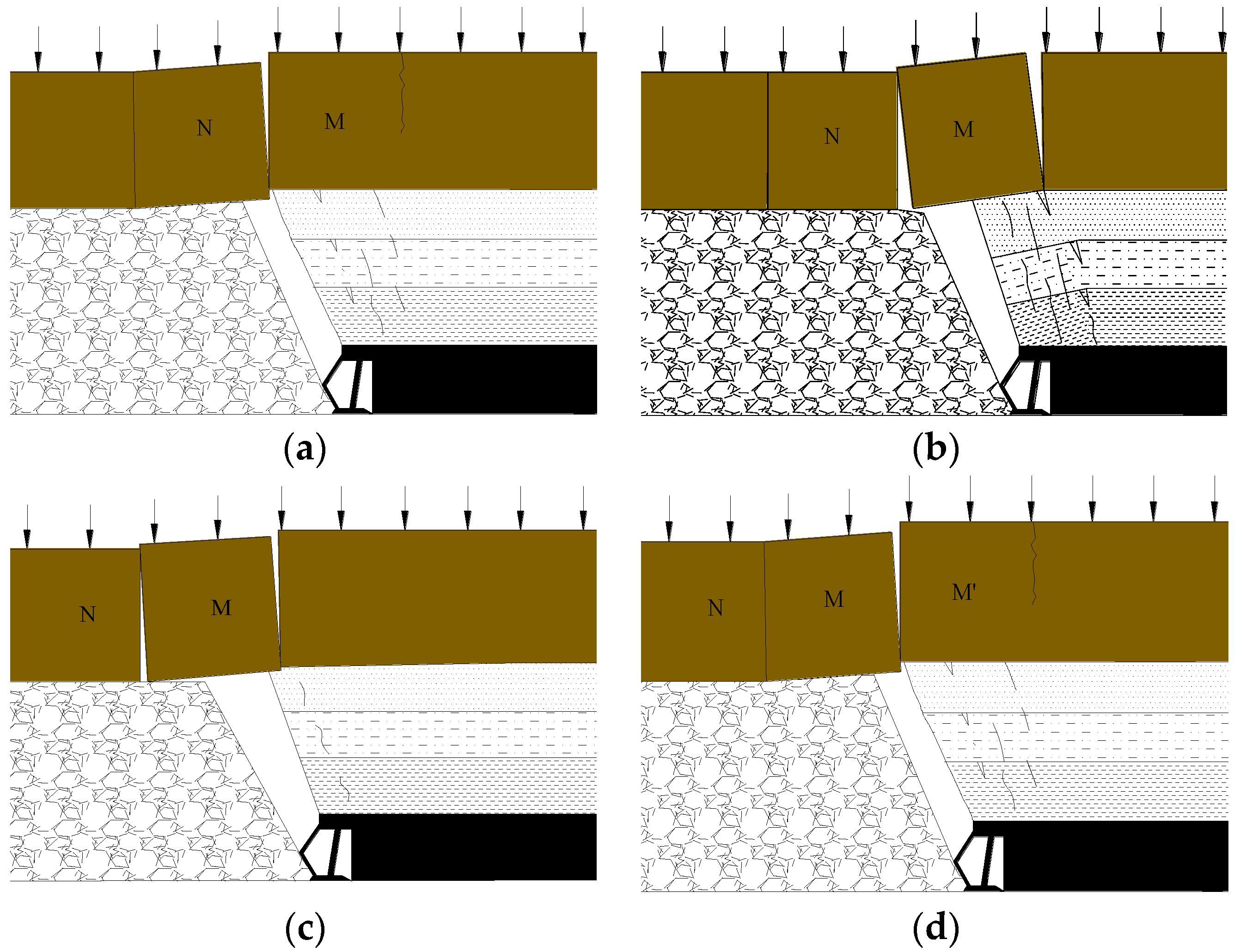

4.3. The “Space-Time” Relationship between the Roof Structure Movement and Ground Pressure

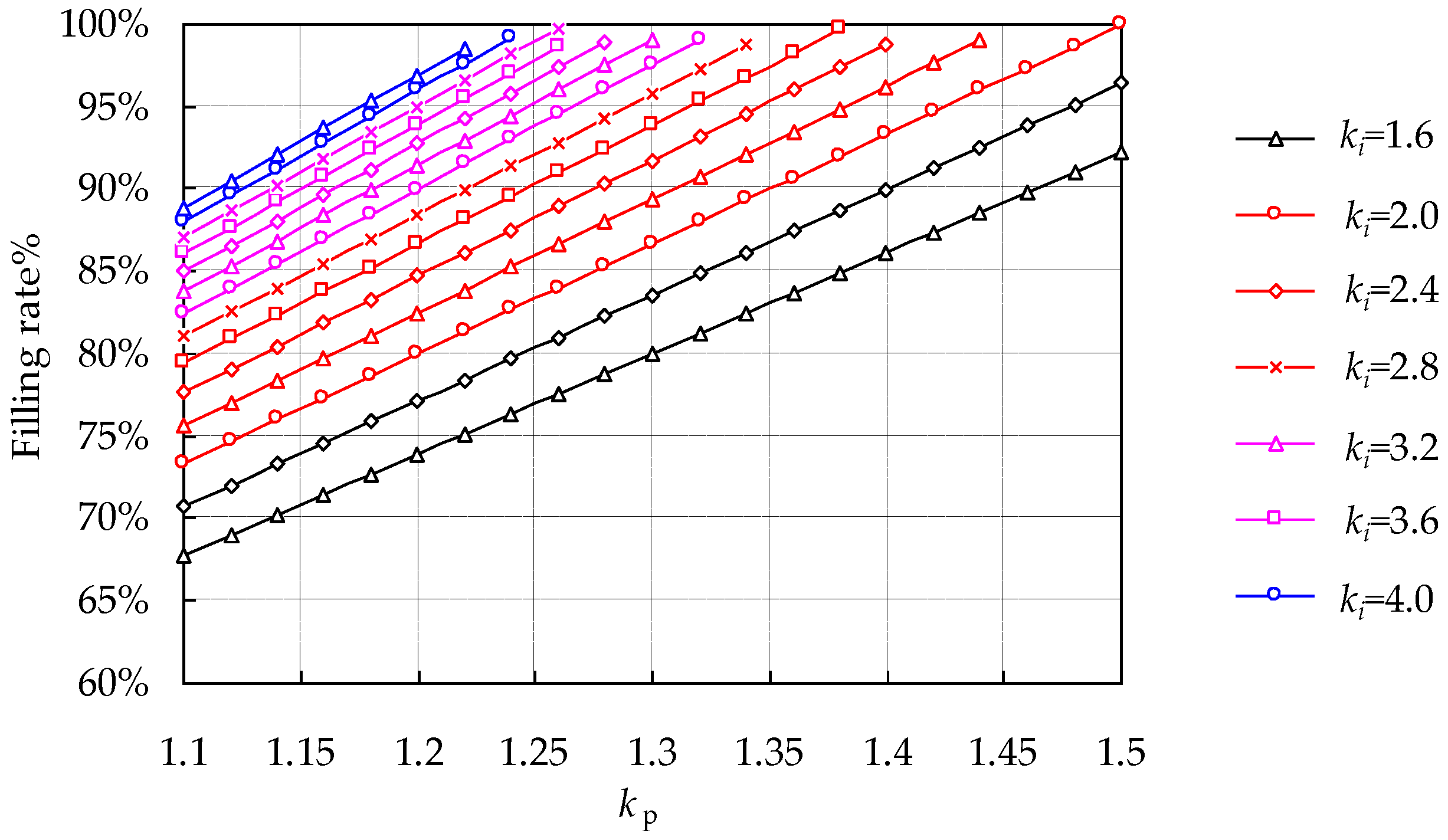

4.4. The Relationship between Filling Rate of EIR and Roof Structure

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, Q.X. Study on Roof Structure and Ground Control in Shallow Seam Longwall Mining; China University of Mining and Technology press: Xuzhou, China, 2000. [Google Scholar]

- Wang, S.M.; Huang, Q.X.; Fan, L.M.; Wang, W.K. The Key Technology of Water Conservation Mining in Fragile Ecologically Mining Coal Resources; Science Press: Beijing, China, 2010. [Google Scholar]

- Qian, M.G.; Shi, P.W.; Xu, J.L. Coal Mine Pressure and Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Peng, S.S.; Chiange, H.S. Longwall Mining; Wiley: New York, NY, USA, 1984. [Google Scholar]

- Mahdi, S.; Charlie, C.L. Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int. J. Rock Mech. Min. Sci. 2012, 51, 24–34. [Google Scholar]

- Ghosh, G.K.; Sivakumar, C. Application of underground microseismic monitoring for ground failure and secure longwall coal mining operation: A case study in an Indian mine. J. Appl. Geophys. 2018, 150, 21–39. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Li, X.H.; Ning, J.G.; Qiu, P.Q. In situ investigations into mining-induced hard main roof fracture in longwall mining: A case study. Eng. Fail. Anal. 2019, 106, 104188. [Google Scholar] [CrossRef]

- Liu, S.Y.; Qian, M.G. The numerical analysis of the cracked position and inclination of the main roof. J. China Univ. Min. Techno. 1989, 18, 31–36. [Google Scholar]

- Sofianos, A.I. Analysis and design of underground hard rock voussoir beam roof. Int. J. Rock Mech. Min. Sci. 1996, 33, 153–166. [Google Scholar] [CrossRef]

- Huang, Q.X.; Qian, M.G.; Shi, P.W. Structural analysis of main roof stability during periodic weighting in long wall face. J. China Coal Soc. 1999, 24, 581–585. [Google Scholar]

- Hou, Z.J. Concept of both short voussoir beam and step beam in shallow seam and voussoir beam theory. J. China Coal Soc. 2008, 33, 1201–1204. [Google Scholar]

- Huang, Q.X. Experimental research of overburden movement and subsurface water seeping in shallow seam mining. J. Univ. Sci. Tech. Beijing 2007, 14, 483–489. [Google Scholar] [CrossRef]

- Holla, L.; Buizen, M. Strata Movement Due to Shallow Longwall Mining and the Effect on Ground Permeability. Proc. Aust. IMM 1990, 295, 11–18. [Google Scholar]

- Singh, K.B.; Kumar, P.; Kiran, S.; Saxena, N.C.; Singh, B. Subsidence behavior of Motur clays. J. Mines Met Fuels. 1992, 2, 93–100. [Google Scholar]

- Maleki, H. Coal pillar mechanics of violent failure in U.S. Mines. Int. J. Min. Sci. Technol. 2017, 27, 387–392. [Google Scholar] [CrossRef]

- Huang, Q.X.; He, Y.P.; Cao, J. Experimental investigation on crack development characteristics in shallow coal seam mining in China. Energies 2019, 12, 1302. [Google Scholar] [CrossRef]

- Wang, S.R.; Wu, X.G.; Zhao, Y.H.; Hagan, P.; Cao, C. Evolution characteristics of composite pressure-arch in thin bedrock of overlying strata during shallow coal mining. Int. J. Appl. Mech. 2019, 11, 1–16. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Xu, J.L.; Liu, H.L.; Li, H.W. Influencing laws study of depth of gully on dynamic strata pressure of working face in shallow coal seams. J. Min. Saf. Eng. 2013, 30, 501–505. [Google Scholar]

- Huang, Q.X.; Zhou, J.L. Roof weighting behavior and roof structure of large mining height longwall face in shallow coal seam. J. China Coal Soc. 2016, 41, 279–286. [Google Scholar]

- Huang, Q.X.; Zhou, J.L.; Ma, L.T.; Tang, P.F. Double key stratum structure analysis of large mining height longwall face in nearly shallow coal seam. J. China Coal Soc. 2017, 42, 2504–2510. [Google Scholar]

- Huang, Q.X.; Tang, P.F. Roof structure analysis on large mining height longwall face in shallow coal seam. J. Min. Saf. Eng. 2017, 34, 282–286. [Google Scholar]

- Gong, P.L.; Jin, Z.M. Study on the structure characteristics and movement laws of overlying strata with large mining height. J. China Coal Soc. 2004, 29, 7–12. [Google Scholar]

- Gong, P.L.; Jin, Z.M. Mechanical model study on roof control for fully-mechanized coal face with large mining height. Chin. J. Rock Mech. Eng. 2008, 27, 193–198. [Google Scholar]

- Xu, J.L.; Ju, J.F. Structural morphology of key stratum and its influence on strata behaviors in fully- mechanized face with super-large mining height. Chin. J. Rock Mech. Eng. 2011, 30, 1547–1556. [Google Scholar]

- Xu, J.L.; Zhu, W.B.; W, X.Z.; Yi, M.S. Classification of key stratum structure of overlying strata in shallow coal seam. J. China Coal Soc. 2009, 34, 865–870. [Google Scholar]

- Ju, J.F.; Xu, J.L.; Zhu, W.B. Longwall chock sudden closure incident below coal pillar of adjacent upper mined coal seam under shallow cover in the Shendong coalfield. Int. J. Rock Mech. Min. Sci. 2015, 77, 192–201. [Google Scholar] [CrossRef]

- Yan, S.H.; Yin, X.W.; Xu, H.J.; Xu, G.; Liu, Q.M. Roof structure of short cantilever-articulated rock beam and calculation of support resistance in full-mechanized face with large ming height. J. China Coal Soc. 2011, 36, 1816–1820. [Google Scholar]

- Wang, F.T.; Duan, C.H.; Tu, S.H.; Liang, N.N.; Bai, Q.S. Hydraulic support crushed mechanism for the shallow seam mining face under the roadway pillars of room mining goaf. Int. J. Min. Sci. Eng. 2017, 27, 853–860. [Google Scholar] [CrossRef]

- Yuan, Y.; Tu, S.H.; Zhang, X.; Li, B. System dynamics model of the support- surrounding rock system in fully mechanized mining with large mining height face and its application. Int. J. Min. Sci. Tec. 2013, 23, 879–884. [Google Scholar] [CrossRef]

- Liu, C.Y.; Li, H.M.; Mitri, H.; Jiang, D.J.; Li, H.G.; Feng, J.F. Voussoir beam model for lower strong roof strata movement in longwall mining-Case study. J. Rock. Mech. Geo. Eng. 2017, 9, 1171–1176. [Google Scholar] [CrossRef]

- Li, H.M.; Jiang, D.J.; Li, D.Y. Analysis of ground pressure and roof movement in fully- mechanized top coal caving with large mining height in ultra-thick seam. J. China Coal Soc. 2014, 39, 1956–1960. [Google Scholar]

- Huang, Q.X.; He, Y.P. Research on overburden movement characteristics of large mining height working face in shallow buried thin bedrock. Energies 2019, 12, 4208. [Google Scholar] [CrossRef]

- Huang, Q.X. Study on loading distribution law on key roof and its structure upon mining face under thick sandy horizon. J. China Univ. Min. Technol. 2005, 34, 289–293. [Google Scholar]

- Huang, Q.X. Ground pressure behavior and definition of shallow seams. Chin. J. Rock Mech. Eng. 2002, 21, 1174–1177. [Google Scholar]

- Huang, Q.X.; Zhang, P. Study on dynamic load distribution on key roof blocks. Chin. J. Rock Mech. Eng. 2004, 24, 4179–4182. [Google Scholar]

| Working Face of Coal Mine | Mining Height (m) | Period Weighting Intervals (m) | Thickness of Key Strata (m) | Thickness of EIR (m) | ki |

|---|---|---|---|---|---|

| 31301 working face of Wanli coal mine | 4.9 | 17.6 | 5.6 | 11.2 | 2.29 |

| 22406 working face of Halagou coal mine | 5.2 | 12.1 | 10.3 | 13.1 | 2.52 |

| 22201 working face of Zhangjiamao coal mine | 6.0 | 13.0 | 14 | 17 | 2.83 |

| 15201 working face of Zhangjiamao coal mine | 6.2 | 15.6 | 9.5 | 16.2 | 2.61 |

| 85201 working face of Sandaogou coal mine | 6.5 | 24.2 | 10.3 | 16.8 | 2.58 |

| 22303 working face of Bulianta coal mine | 6.8 | 11.0 | 9.4 | 18.2 | 2.67 |

| 52303 working face of Daliuta coal mine | 6.9 | 16.8 | 12.0 | 20.6 | 2.98 |

| Lithology | Compressive Strength (MPa) | Elastic Modulus ×104 (MPa) | Poisson’s Ratio | Cohesion (MPa) |

|---|---|---|---|---|

| Coal | 35.57 | 2827 | 0.19 | / |

| Coarse sandstone | 18.94 | 2217 | 0.22 | 1.40 |

| Muddy siltstone | 39.04 | 7588 | 0.14 | 4.95 |

| Mudstone | 31.57 | 2956 | 0.19 | 4.29 |

| Carbonaceous mudstone | 19.79 | 2618 | 0.21 | 2.60 |

| Siltstone | 22.16 | 2901 | 0.20 | 2.79 |

| Weathered siltstone | 12.27 | 3729 | 0.18 | 1.75 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Q.; He, Y.; Li, F. Research on the Roof Advanced Breaking Position and Influences of Large Mining Height Working Face in Shallow Coal Seam. Energies 2020, 13, 1685. https://doi.org/10.3390/en13071685

Huang Q, He Y, Li F. Research on the Roof Advanced Breaking Position and Influences of Large Mining Height Working Face in Shallow Coal Seam. Energies. 2020; 13(7):1685. https://doi.org/10.3390/en13071685

Chicago/Turabian StyleHuang, Qingxiang, Yanpeng He, and Feng Li. 2020. "Research on the Roof Advanced Breaking Position and Influences of Large Mining Height Working Face in Shallow Coal Seam" Energies 13, no. 7: 1685. https://doi.org/10.3390/en13071685

APA StyleHuang, Q., He, Y., & Li, F. (2020). Research on the Roof Advanced Breaking Position and Influences of Large Mining Height Working Face in Shallow Coal Seam. Energies, 13(7), 1685. https://doi.org/10.3390/en13071685