In the first step, described in

Section 4.1, the experiments were analyzed as a function of IMEP. This was to gain a basic insight about the different influences of early intake valve closing angle and valve lift on overall efficiency, pumping losses, and combustion deterioration. Afterwards, in

Section 4.2, a brief comparison between unthrottled and throttled operation is presented. In the third step, in

Section 4.3, a Willans analysis was used, as explained in [

17], to distinguish between influences on thermodynamic efficiencies and gas exchange losses. Finally, in

Section 4.4, the first law energy balance [

18] is described for a constant fuel mass flow, different valve timings, and manifold pressures. This analysis provides insights about the disposition of the initial fuel energy [

19].

4.1. Intake Valve Closing Angle and Lift Combinations (IMEP Analysis)

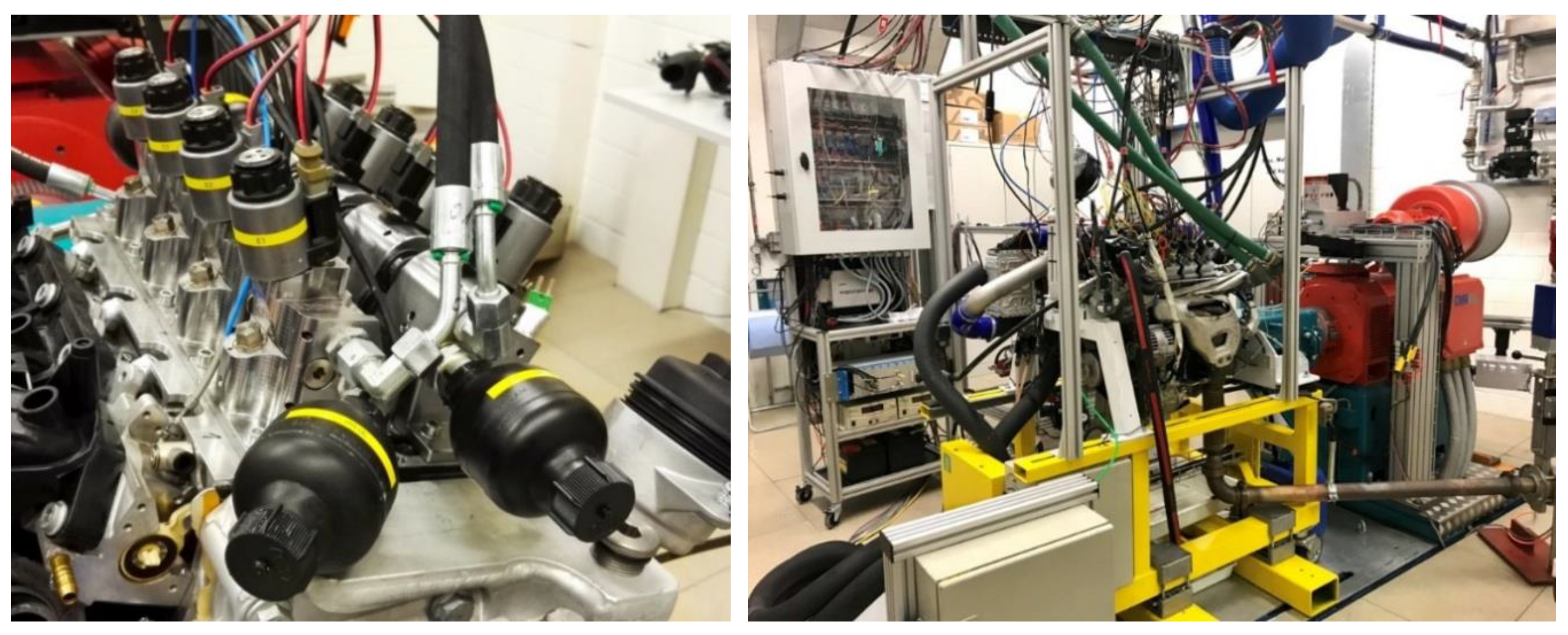

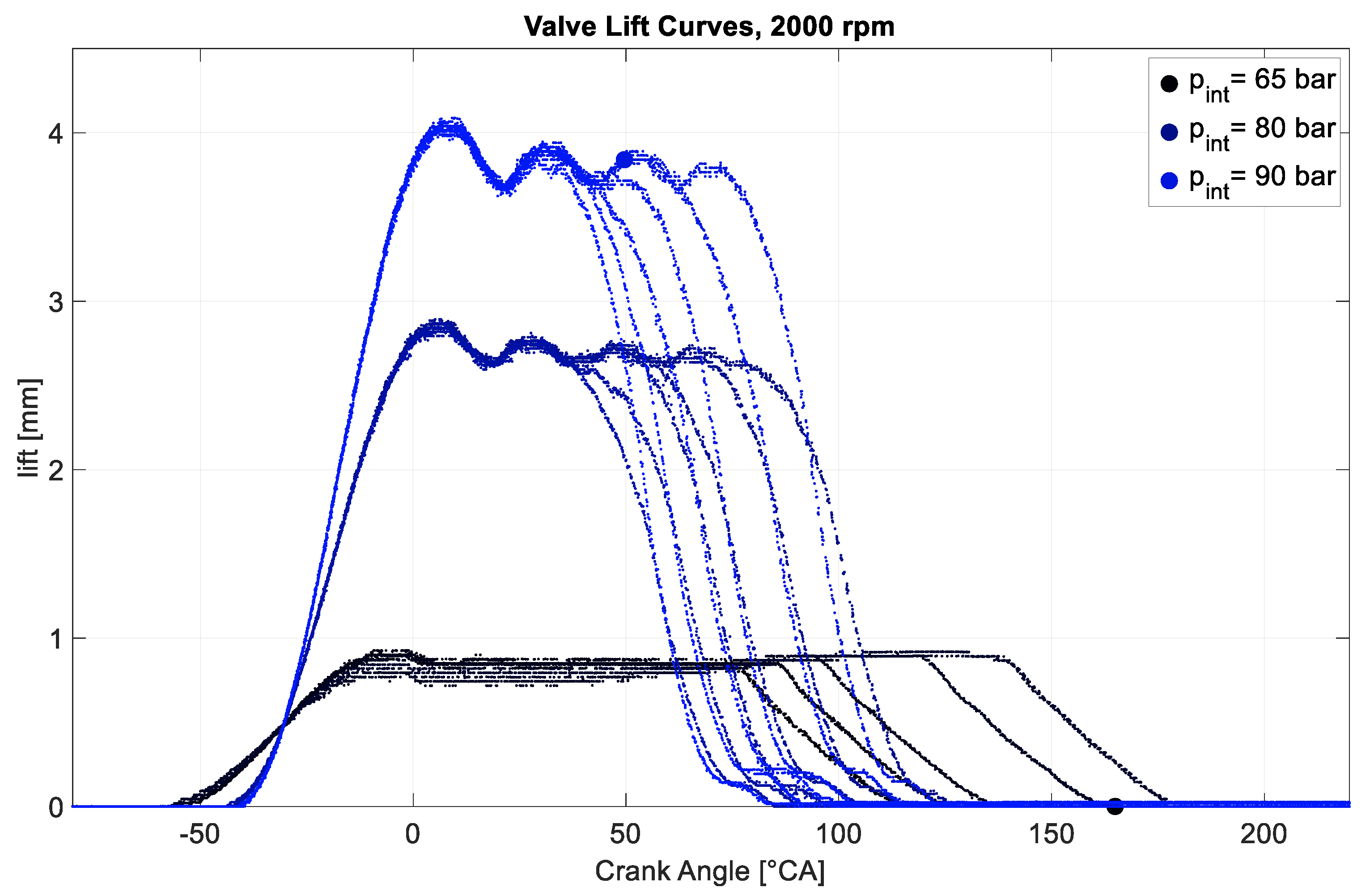

The same loads were achieved at different valve lifts using different IVC angles. The goal was to reconstruct the influences driving the efficiency variation for different IVC and lift combinations. Thanks to the fast opening of the valves, lifts as low as 0.9 mm were relevant for analysis. Lifts higher than 4.1 mm were not analyzed because, for the chosen engine speed and loads, no effects were seen using higher lifts.

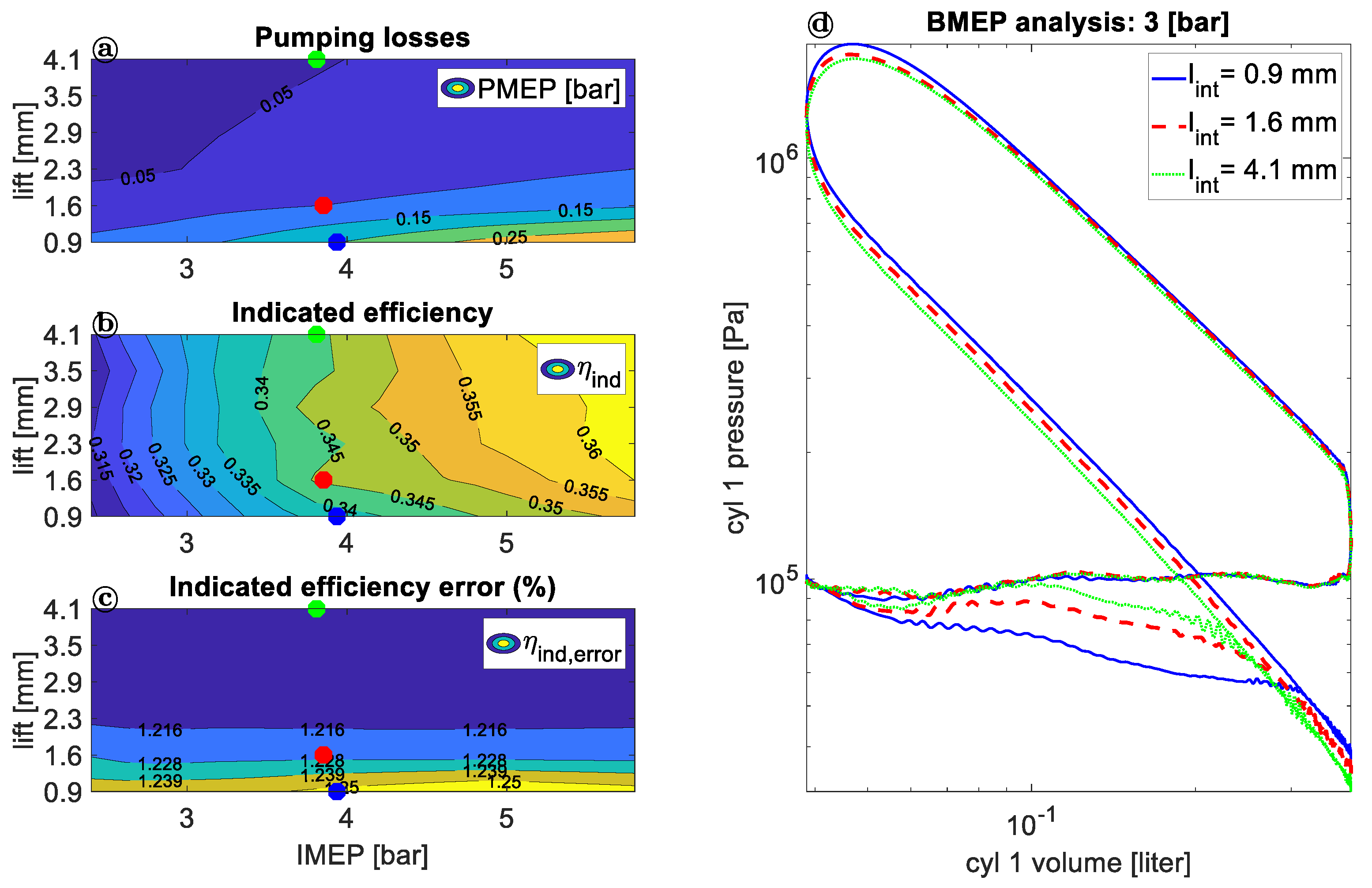

Figure 4 illustrates: (a) the pumping losses; (b) the indicated efficiencies; and (c) the experimental uncertainty of the indicated efficiency as a function of IMEP and intake valve lift. Plot (d) shows the pressure volume diagram of three experiments in double logarithmic scale. The engine output of all three experiments was the same, 3 bar brake mean effective pressure (BMEP), but it was achieved with different IVC and lift combinations. These three experiments are highlighted in the (a), (b) and (c) plots in

Figure 4 with blue red and green points. It has to be pointed out that the energy demand for valve actuation depends, among other parameters, on the valve lift. Smaller valve lifts mean less losses for valve actuation, especially because a large part of the actuation energy for exhaust valves is dissipative and cannot be recovered with any valve actuation system. Therefore, choosing the minimum valve lift for best indicated efficiency is generally beneficial.

Pumping losses, plot (a) in

Figure 4, considerably decreased at constant IMEP for higher lifts and they slightly increased at constant lift for higher IMEP. For higher lifts, the pressure difference between in cylinder and intake manifold (which is close to ambient pressure with throttle fully open) decreased (by same mass flow), reducing the pumping losses. To achieve the same in cylinder mass, the IVC was therefore advanced. The increase of PMEP at higher loads and constant lift can be explained by the cylinder motion. In fact, the cylinder accelerated from top dead center to maximal speed at half stroke and decelerated in the second half stroke. For this reason, the in-cylinder pressure during intake in the middle of the stroke decreased. For constant valve lift, higher pumping losses occurred at higher loads. Two factors influenced the variation of indicated efficiency, plot (b) in

Figure 5. Firstly, the efficiency increased at higher loads. This is a normal trend in internal combustion engines, as some losses (e.g., wall heat losses) do not proportionally scale with load. Additionally, at higher loads, the thermodynamic efficiency increases due to the more efficient combustion. Secondly, the efficiency increased at higher lifts, thanks to the reduction in PMEP. No clear decrease in indicated efficiency was visible at high lifts. In fact, early IVC time could not only be responsible for reduced PMEP, but also for combustion deterioration, and hence lower efficiency due to lack of turbulence. Nevertheless gas exchange improvement at the engine speed of 2000 min

−1 investigated here was found to always overcome the possible degradation of the combustion process. The valve train was able to achieve valve lifts up to 9 mm, but for the engine speed of 2000 min

−1 discussed here lifts above 4 mm did not show an additional gain. As higher valve lifts need more energy for the valve train itself, which would negatively affect the engine’s effective work, an adaption of the valve lift to the engine speed is beneficial.

The pV diagram, plot (c) in

Figure 4, depicts the same loads, achieved with different combinations of IVC angle and lift. The three analyzed experiments are also shown as points in plots (a), (b) and (c) in

Figure 5. The important parameters for these experiments are listed in

Table 3.

At higher lifts, the IVC timing was advanced to keep the load constant. Earlier IVC corresponds to lower effective compression ratio, lowering the overall pressure during the high pressure loop (shown in

Figure 4 plot d). As expected, the pumping losses increased at lower lifts (up to four times). During the gas exchange process (where pumping losses occur), the lines diverged most between 0.1 and 0.3 L (visible in

Figure 4 plot d). The pumping losses were mainly present in the middle of the stroke, where the piston moves fastest. Comparing these unthrottled operating points, the fuel consumption was reduced up to 3% (relativ) at 3 bar BMEP with higher lifts and earlier valve closing.

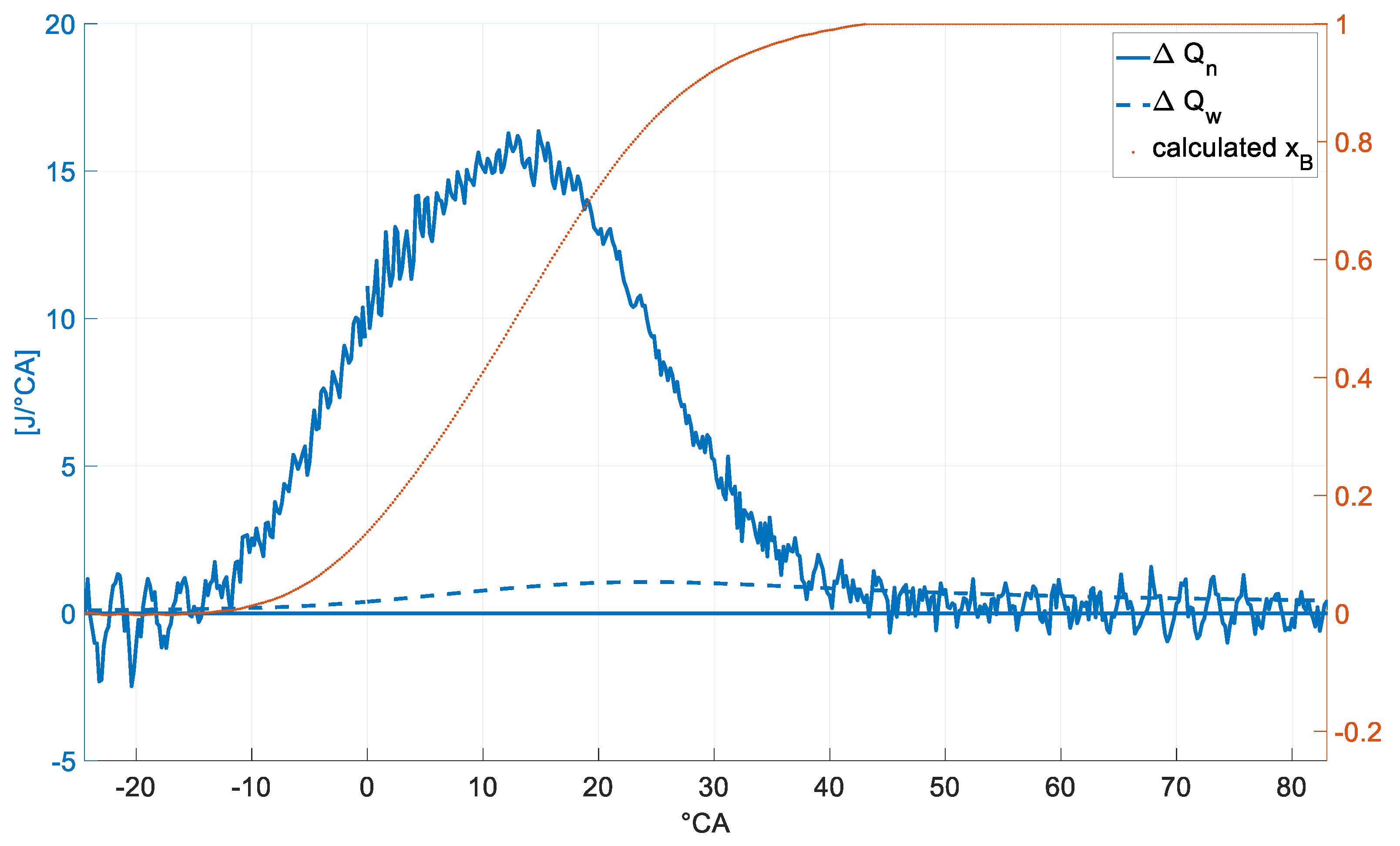

To understand the magnitude of the combustion deterioration, the burned rate variation was analyzed.

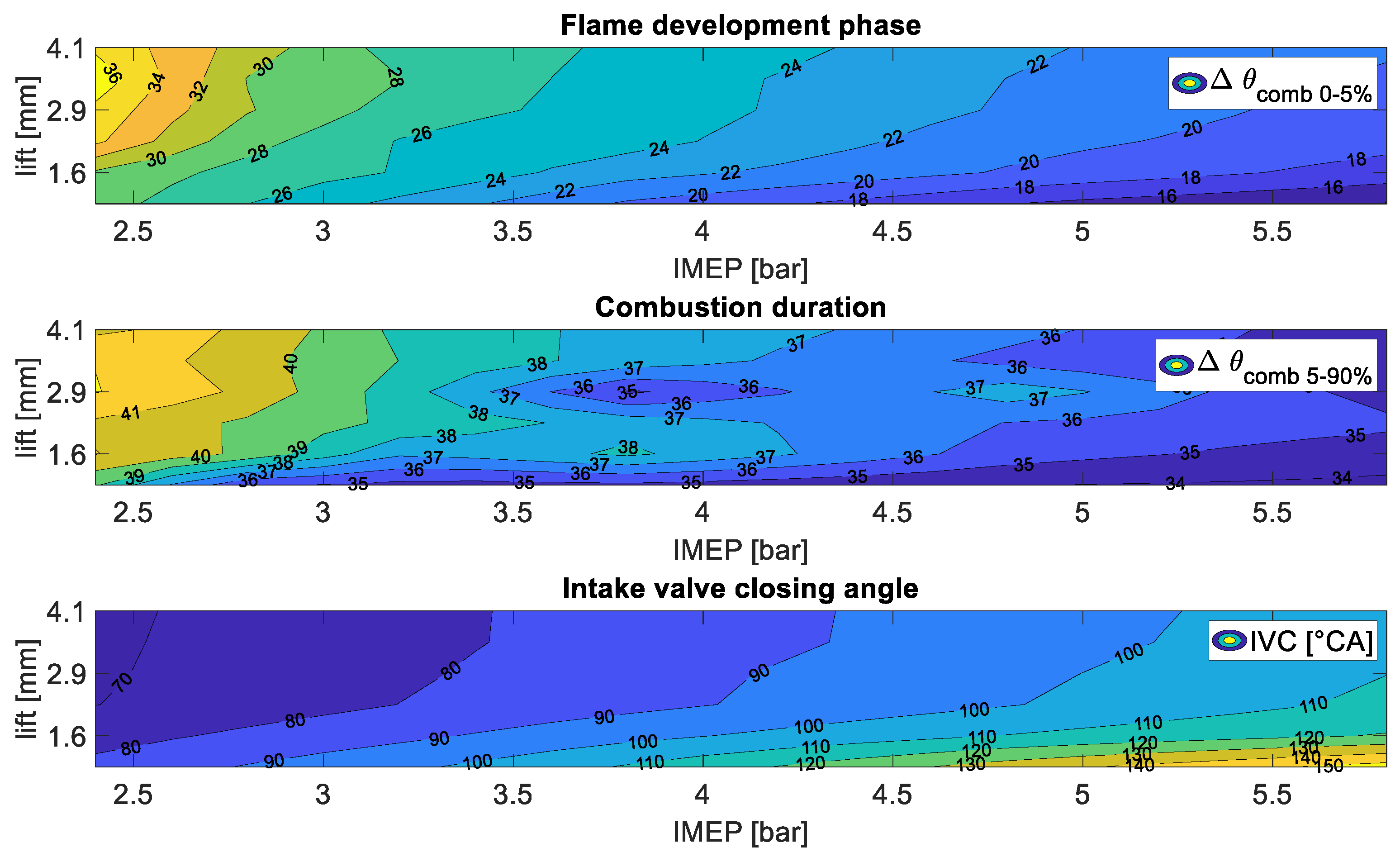

Figure 5 depicts the flame development phase (0–5% of mass fraction burned), the main combustion duration (5–95% of mass fraction burned), and the IVC angle as a function of IMEP and lift.

The flame development phase and combustion duration show inverse correlation with IVC time. This can be explained taking into account the turbulence dissipation inside the cylinder. Once the intake valves were closed, the turbulent kinetic energy dissipated, and the lack of turbulence slowed down the flame propagation. At constant load, a higher lift corresponded to earlier IVC and lead, therefore, to a longer combustion and flame development phase. In spite of the fact that the combustion duration increased for higher lift and earlier IVC, the efficiency increased as a combined effect of combustion deterioration, changes in heat losses (see also

Section 4.4) and a decrease in pumping loss.

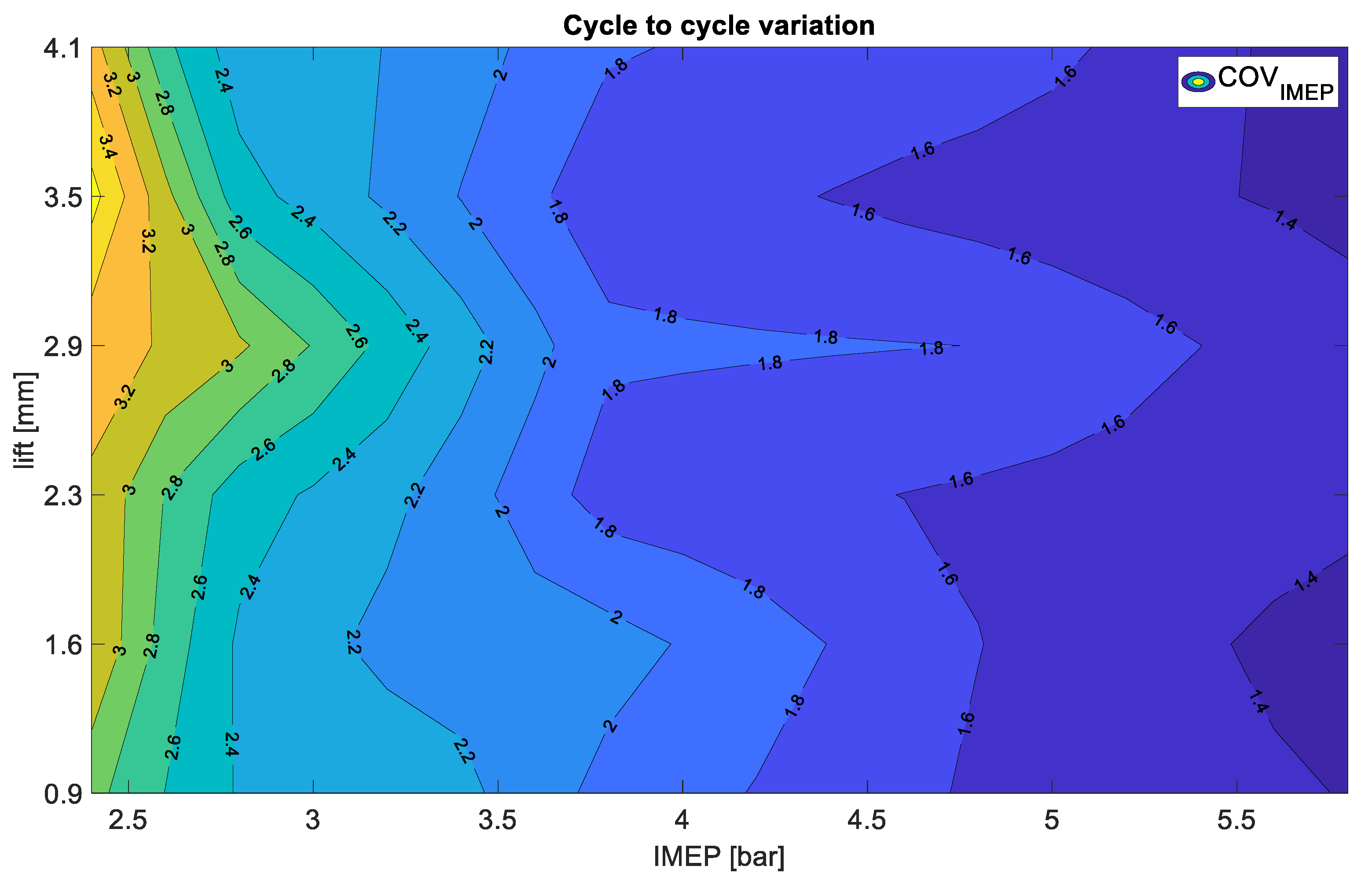

Cycle-to-cycle-variation is shown in

Figure 6. It depicts the coefficient of variation (COV) of IMEP as a function of lift and IMEP. The COV

IMEP was calculated according to Equation (3) and was evaluated for 167 consequently recorded cycles.

No significant influence on lift/IVC on cycle-to-cycle-variation was observed; COVIMEP depends mainly on the in cylinder mass. All levels were unproblematic as it is usually accepted that COVIMEP values below 5% lead to very smooth engine operation. It must be mentioned that cyclic variation can be more prominently influenced by changing the valve overlap, which was not done in this analysis.

4.2. Throttled versus Unthrottled Operation

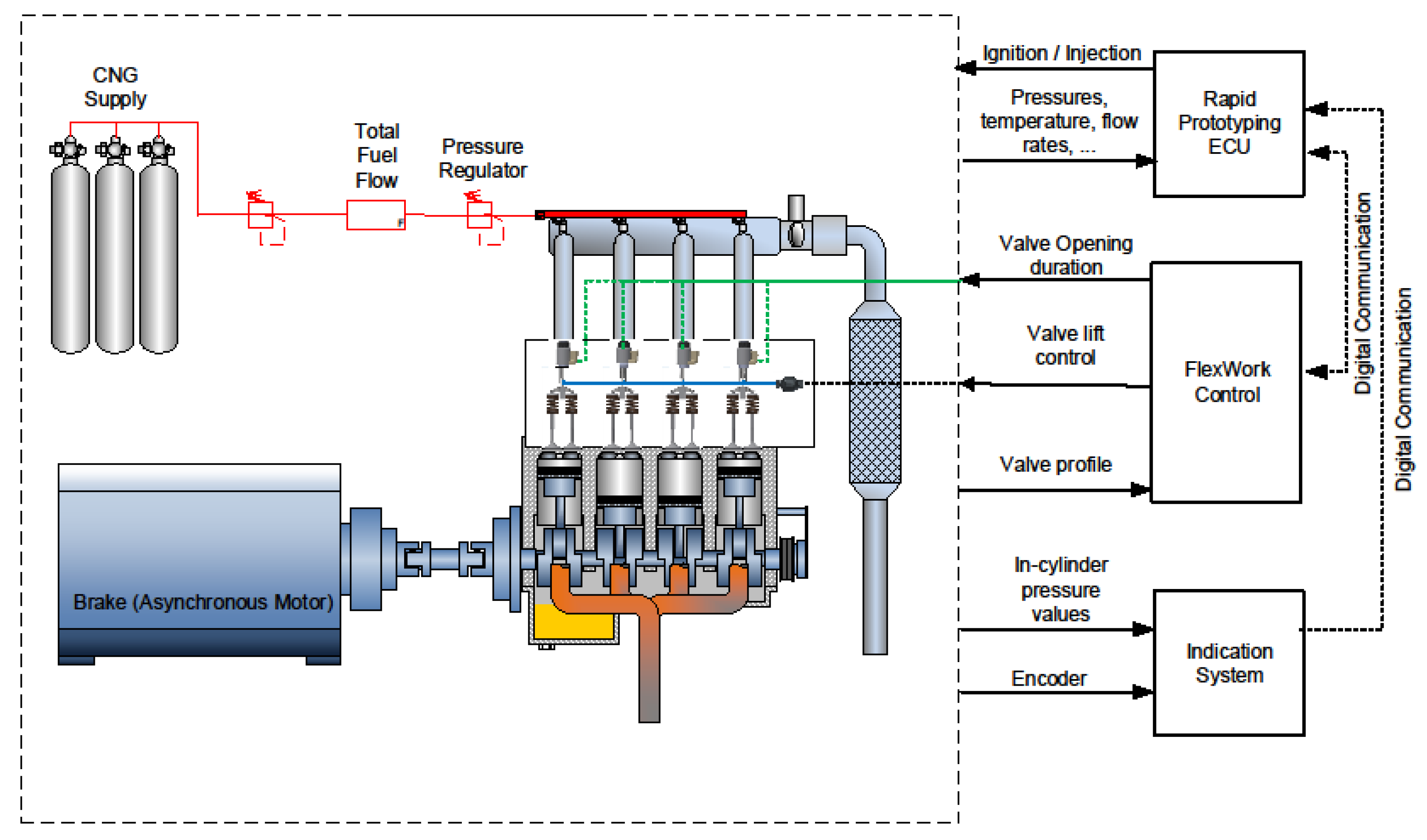

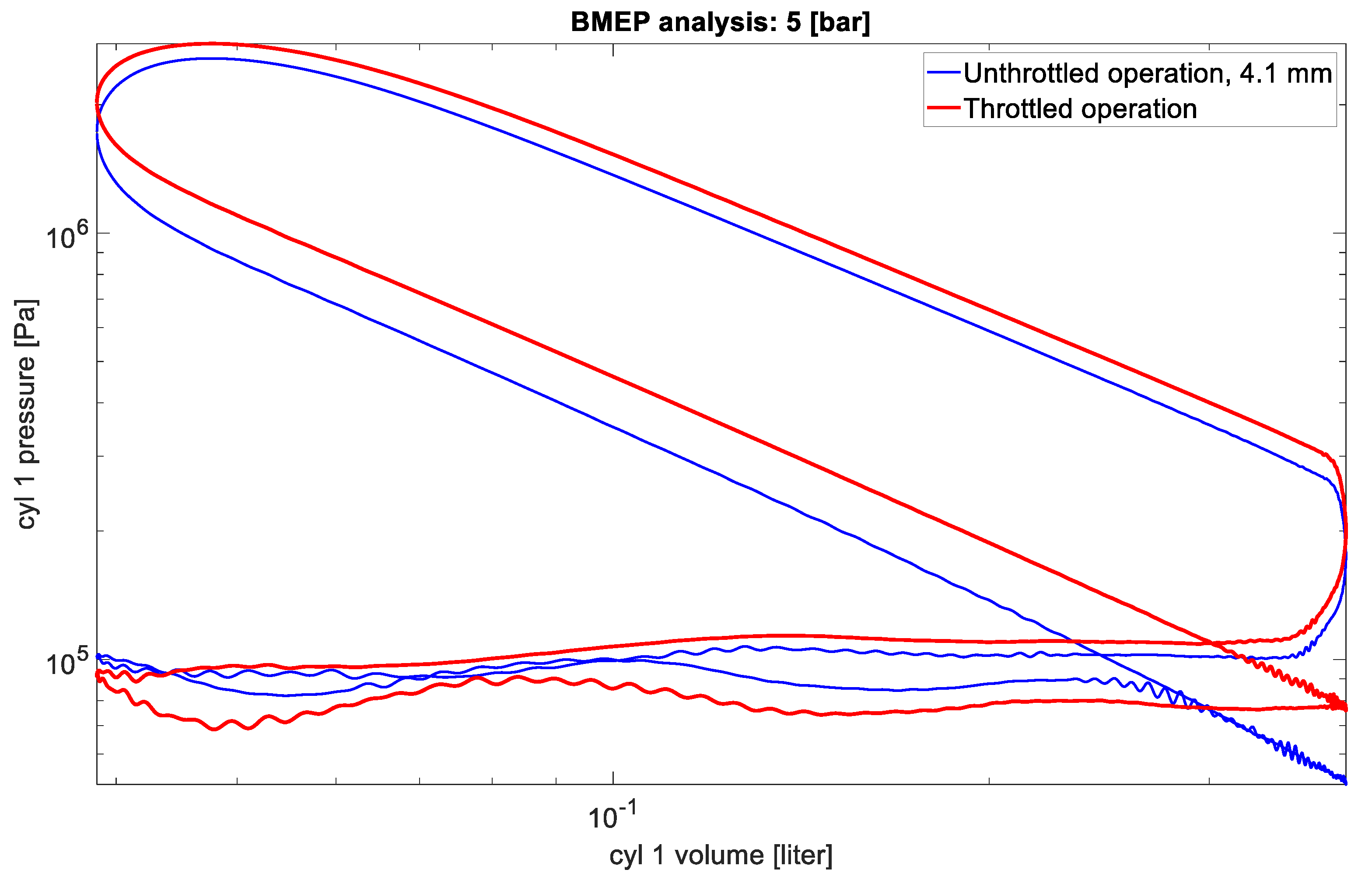

Measurements were made to compare the standard throttled Otto cycle, where IVC is set to 200 °CA and load is controlled by adjusting the pressure in the intake manifold, with the Miller cycle where the intake valve timing is adjusted while the throttle upstream the intake manifold remains open.

Table 4 lists, for three IMEP values, the indicated efficiencies and the pumping losses for the throttled Otto cycles, as well as for the Miller cycles using best efficiency IVC lift/timing combinations.

For all three IMEP values (2.5, 3.5 and 4.5 bar) significant fuel savings were achieved using Miller cycles instead of throttled operation.

Figure 7 depicts the pressure volume diagram of the throttled and unthrottled case for 4 bar BMEP.

Even at medium load, where the differences in pumping losses are low (0.3 and 0.06 bar), an improvement in efficiency of 3.9% was recorded. This suggests that the combustion deterioration losses due to lack of turbulence are often overestimated or mitigated by other factors.

4.3. Willans Approximation to Decouple Thermal Efficiency and Pumping Losses

Typically, the energetic behavior of an energy conversion or transmission device is described by its efficiency, which is the ratio of the useful to the invested energy. Energy conversion devices always have intrinsic dissipative losses, which means that they need a certain input to cover dissipation, even if no output is delivered. This leads to nonlinear efficiency versus load curves, especially towards low output. In order to systematically analyze the energetic input-to-output behavior of an energy conversion device, the direct representation of output versus input-energy turns out to be much more meaningful than the study of the efficiency, or the specific fuel consumption, versus load. This kind of representation is usually called a “Willans plot” [

21], referring to observations of Peter Willans [

22], who saw in the late 19th century that input versus output power on high-speed steam engines can be represented by an affine relationship.

Equation (3) outlines the affine Willans approximation for internal combustion engines, which returns the IMEP (output) as a function of fuel mean effective pressure (FuelMEP, input). PMEP represents the gas exchange losses (calculated as stated in previous chapter) and the Willans efficiency (e

w) represents the thermodynamic properties of the engine [

17].

FuelMEP, which is proportional to the fuel quantity, can be interpreted as the IMEP level an engine would deliver without pumping losses (PMEP = 0) and with a hypothetical efficiency of 100% (e

w = 1, i.e., perfect conversion of the fuel’s thermal energy into work) [

17]. The Willans efficiency e

w can be interpreted as the engine’s “inner efficiency” driven by the quality of the thermodynamic cycle.

Equation (4) outlines the energy conservation equation for a control volume that surrounds the engine [

19].

The fuel energy power calculated with the fuel mass flow (

) and fuel lower heating value (

) is divided between power delivered to the pistons (P

p), wall heat losses (

), exhaust enthalpy (

), and exhaust enthalpy loss due to incomplete combustion (

). By integrating Equation (4) over one engine cycle and dividing it by the displacement volume (

), the specific per cycle mean effective pressures were derived. Equation (5) outlines the energy equation in mean effective pressure terms.

In Equation (5), the IMEP is further divided into positive IMEP (IMEP

+) and PMEP. The remaining terms are wall heat losses mean effective pressure (MEP), incomplete combustion enthalpy MEP, and exhaust enthalpy MEP. The latter was calculated according to Equation (6) [

17]. The temperature used in Equation (6) is the one measured at exhaust manifold entrance and the mass (m) is the total mass flowing through the engine in one engine cycle.

Since precise calculation of wall heat losses and incomplete combustion enthalpy need complex modeling, these two terms were combined and named rest heat losses mean effective pressure (

). They were calculated as the remaining part of the FuelMEP according to Equation (7).

This approximation is valid for two reasons. First, the remaining term is mostly dependent on the wall heat losses, which normally have a minimum share of 20% of fuel energy compared to a maximal share of incomplete combustion of 5% [

19]. Second, both wall heat losses and incomplete combustion (quenching and blowby) are expected to decrease for lower pressures and temperatures. For the same load, shorter IVC time with higher lift results in lower pressures and therefore lower temperatures, reducing the wall heat losses. For lower pressure, the amount of fuel in the crevice volume and the amount of leakage decreased, lowering the incomplete combustion enthalpy.

As the Willans approximation was used to split the influences into pumping losses and fuel conversion efficiency at constant IMEP, it allowed us to separate the effect that early IVC has on gas exchange and thermodynamic properties.

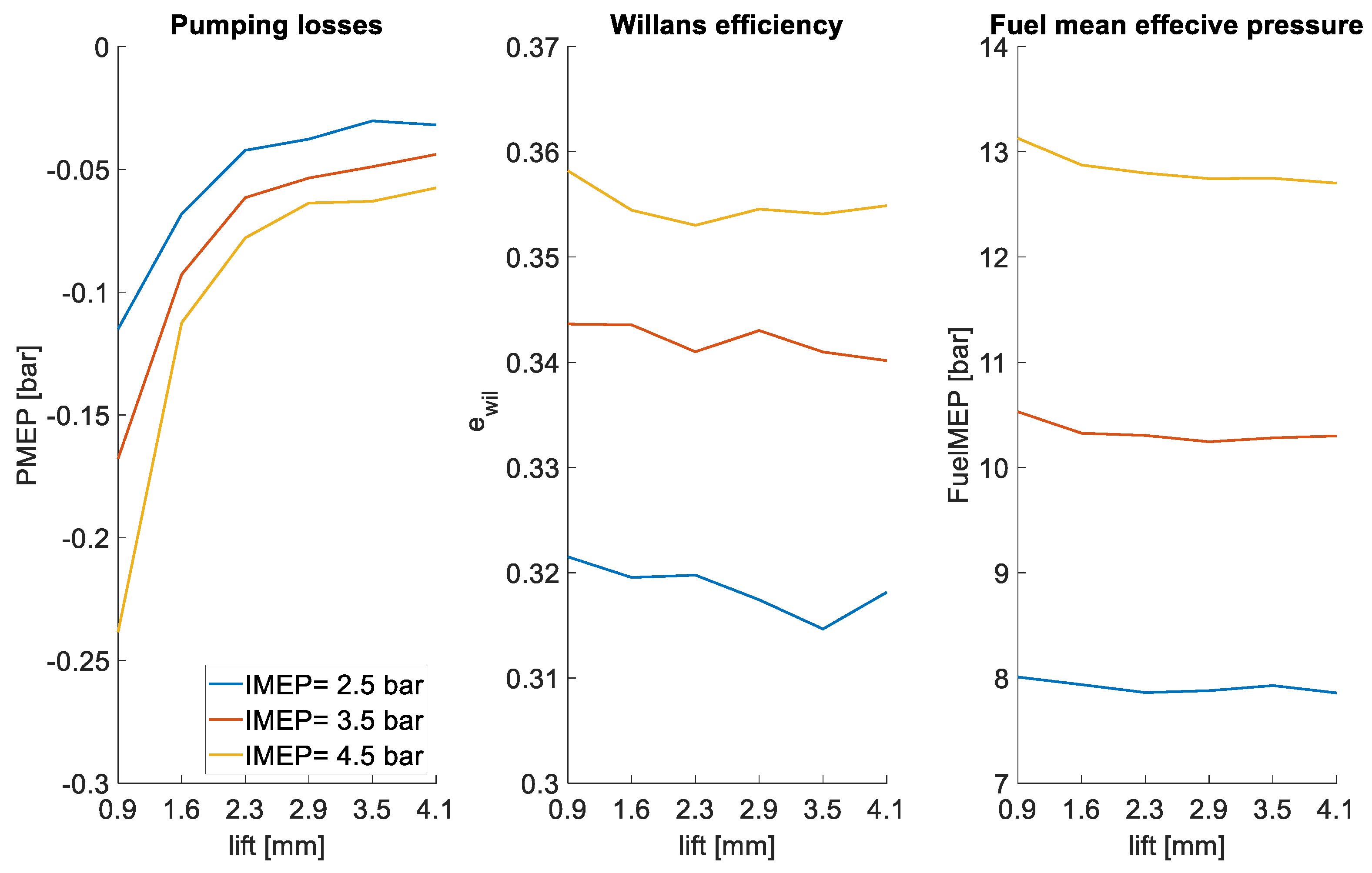

Figure 8 depicts, from left to right, the pumping losses PMEP, the Willans efficiency e

w, and the fuel mean effective pressure FuelMEP as a function of lift for three different IMEP.

Higher Willans efficiency was reached at higher IMEP because higher in cylinder mass generally results in better Willans conversion efficiency. The Willans efficiency at constant IMEP slightly decreased with higher valve lifts (earlier IVC), which was a combined effect of slower combustion, lower heat losses (detailed discussion see below), and lower in cylinder mass. As expected, when using early IVC to control the load a clear reduction in PMEP was visible at higher lifts, and therefore earlier IVC for all three IMEP. FuelMEP decreased with increasing valve lift (earlier IVC) and, since FuelMEP is proportional to the fuel use, this suggest that increasing valve lift (earlier IVC) has a net beneficial effect.

The variations in Willans efficiency are driven by various influences.

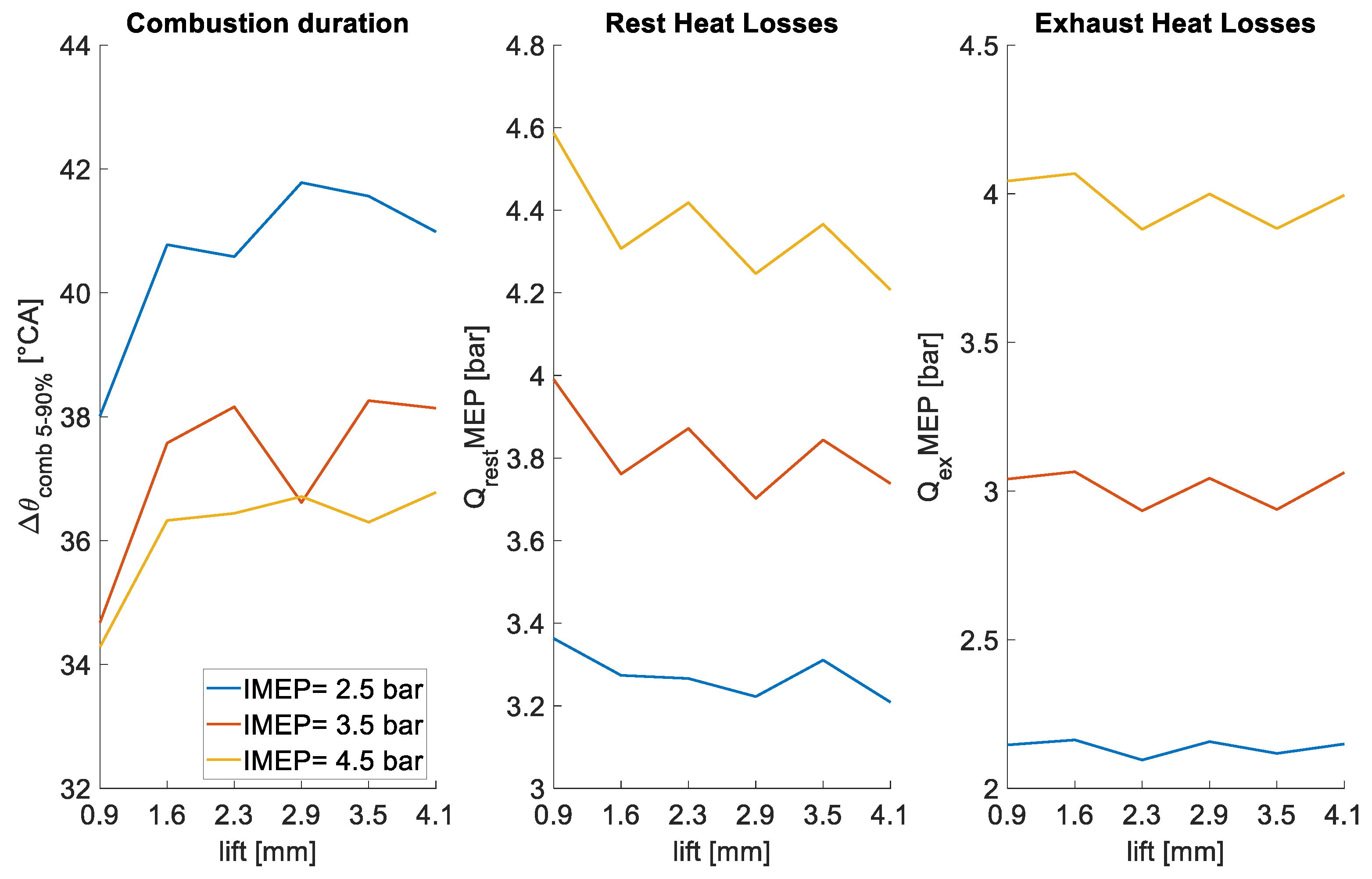

Figure 9 illustrates some factors affecting these variations. It depicts, from left to right, the combustion duration, the rest heat losses mean effective pressure (composed from wall heat losses and incomplete combustion), and the exhaust heat losses mean effective pressure as a function of intake valve lift for the three IMEP levels discussed.

An increase in combustion duration was observed at constant IMEP for higher lifts because of the aforementioned turbulence decrease with earlier IVC, which reduce the Willans efficiency. At the same time, the wall heat losses for higher lifts decreased and the exhaust heat losses remained approximately constant. The combined effect was, as shown in

Figure 8, a slight reduction of the Willans efficiency.

Based on the Willans analysis for the engine considered, it can be concluded that the positive effect on engine efficiency of reducing pumping losses with early IVC is stronger than the losses attributed to early IVC. A tradeoff, or at least an attenuation of the disadvantage of the slightly less efficient combustion, can be recognized in the variation of the heat losses and in the incomplete combustion due to the lower pressures and temperatures achieved with early IVC. This experimental observation is in opposition to some results from the literature [

7,

23].

4.4. Engine Energy Balance

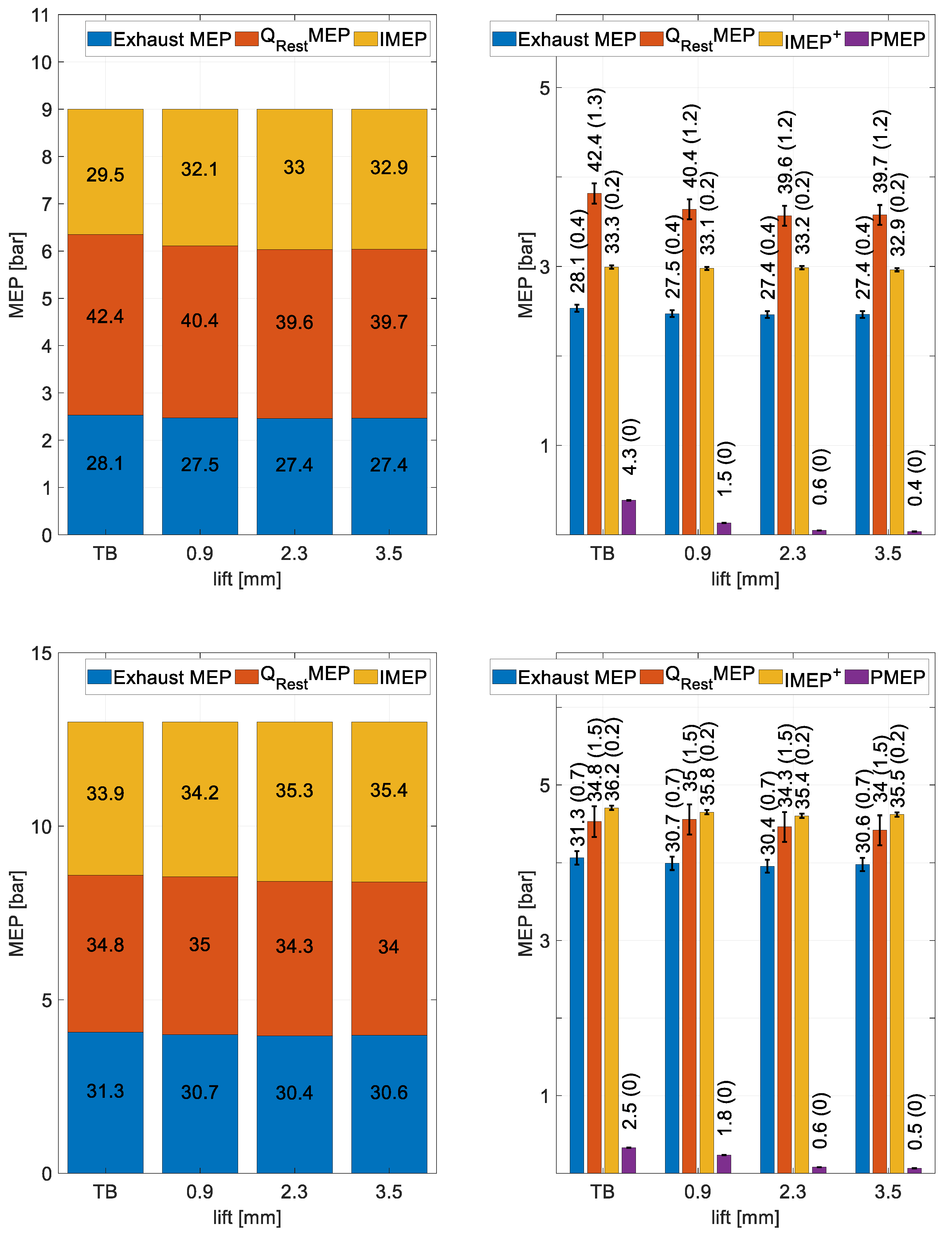

Variation in the Willans efficiency at constant IMEP and different IVC lift combination depend on the variation of in cylinder mass, combustion deterioration, exhaust heat losses, wall heat losses, and incomplete combustion heat losses. In order to interpret the influences driving the efficiency variation, an energy balance analysis was carried out for a constant FuelMEP level. Since FuelMEP is directly proportional to the fuel mass and the engine is strictly run at λ = 1, this resulted in a constant in cylinder air- and fuel mass. For this analysis, the losses arising from wall heat losses and incomplete combustion were grouped together into rest heat MEP. In this way, the FuelMEP (i.e., the hypothetical IMEP a 100% efficient engine would produce) was divided between IMEP, exhaust heat MEP, and rest heat MEP.

Figure 10 shows this analysis for 9 bar and 13 bar FuelMEP. On the left sides, the FuelMEP was divided into exhaust heat MEP, IMEP, and the rest heat MEP. On the right side, the IMEP was further split into positive IMEP and PMEP. Four points with the same FuelMEP were compared. The first point represents throttled operation (TB), the remaining ones represents three Miller cycles achieved with increasing valve lift (therefore earlier IVC). The right plot in

Figure 10 shows, beside the division between the different terms of the energy balance, their relative experimental uncertainties as a percentage of FuelMEP, which was calculated according to Equation (1). IMEP and PMEP uncertainty arises only from pressure measurement, whereas the exhaust MEP uncertainty is derived from the air to fuel ratio, fuel mass flow, and exhaust temperature measurements. The remaining MEP uncertainty is derived from the sum of the previous uncertainties and from the FuelMEP uncertainty, which depends on air to fuel ratio, fuel mass flow, and lower heating value measurements.

On the left side in

Figure 10, the increase in IMEP (from left to right columns) depicts the increase in indicated efficiency with higher valve lift (earlier IVC). To compensate for this effect, both wall heat losses MEP and exhaust heat MEP decreased. As the right side shows, the increase in efficiency was dominated by the reduction in PMEP. In spite of the fact that the wall heat losses and the exhaust heat losses decreased, the positive IMEP slightly decreased with higher valve lift (earlier IVC) because of the turbulence effect discussed.