Abstract

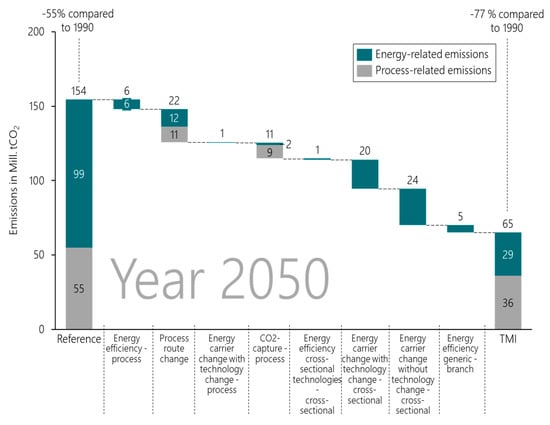

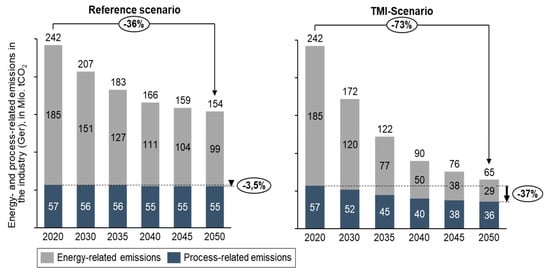

The dynamic bottom-up modelling of greenhouse gas (GHG) abatement measures in industry makes it possible to derive consistent transformation paths on the basis of heterogeneous, process-specific developments. The main focus is on the development of a transparent methodology for small-scale modelling and combination of individual GHG abatement measures. In this way, interactions between GHG abatement measures are taken into account when deriving industrial transformation paths. The presented three-part methodological approach comprises the preparation (1) and implementation (2) of GHG abatement measures as well as the resulting effects on the output parameters (3) in a technology mix module. In order to consider interactions in the measures implementation, year-specific overall measure matrices are created and prioritised based on the GHG abatement costs. Finally, the three-part methodology is tested in a consistent technology mix scenario. The results show that the methodology enables integrated industrial technology mix scenarios with a high level of climate ambition based on a plausible development of energy consumption and emissions. Compared to the reference scenario, the process-and energy-related emissions decrease by 90 million tCO2 (77% of the 1990 level in 2050). The developed methodology and the related technology mix scenario within the framework of the bottom-up industry model SmInd can support strategic decision-making in politics and an efficient transition to a greenhouse gas neutral industry.

1. Introduction

While considerable attention is paid to defossilising the supply, transport and household sectors, knowledge of how greenhouse gases can be abated in industry sector is lagging behind [1,2,3]. An analysis of recent German energy and climate scenarios shows that a combination of different GHG abatement measures in the industrial energy transition is usually more effective in achieving the climate goals [4,5,6,7], than focusing on stringent transformation paths without an openness to different technologies [8]. However, industrial heterogeneity leads to a wide range of GHG abatement technologies [9,10,11,12], some of which often show interdependencies [1]. Therefore, the combination of GHG abatement measures by modelling a consistent industrial technology mix scenario often leads to difficulties. For example, the order of GHG abatement measures in the implementation process is crucial for the development of efficient transformation paths. The implementation order in currently existing scenarios is often estimated exogenously by experts [4,13]. A few industrial models make it possible to compute technology-independent, consistent transformation paths that take interdependencies between individual small-scale GHG abatement measures into account [14]. With the many and complex ways in which GHG abatement measures affect industrial production volumes, energy consumption and emissions [15], as well as the related interdependencies between the individual measures, further problems arise in modelling industrial scenarios. Existing German industrial models have so far addressed these problems only to a limited extent. Therefore, the following section provides an overview of the current research state of numerous German industrial models and outlines further research needs. The analysis serves as a basis for this research contribution and further objectives.

The FORECAST Industry simulation model of the Fraunhofer Institute for Systems and Innovation Research (ISI) maps German and European industry from the bottom-up using five submodules. The submodules comprise energy-intensive processes, furnaces, electric motors and lighting, steam and hot water as well as space heating and cooling [14,16]. Energy-and emission-intensive processes are modelled using activity parameters such as production volume and specific consumption [17]. To reflect the development of less energy-intensive processes, generic parameters such as gross value added are used [14,17]. Similarly the development of activity parameters, as well as the framework parameters based on forecast data are specified exogenously in the model. GHG abatement options for energy efficiency, fuel switch, CO2-capture and storage as well as recycling management and material efficiency are implemented in the model [14] from a microeconomic perspective [16]. The methodology for implementing GHG abatement measures depends on the respective submodule [14]. The use of technology in the submodule “Steam and Hot Water”, for example, is determined by a utility function which, in addition to the classic CAPEX and OPEX, also includes technology revenues and state subsidies [18]. In addition, the technology stock is recorded in order to make the investment decision based on economic developments and natural reinvestment cycles. Also, the fuel switch is carried out by application of a utility function [19]. Investments in efficiency technologies are made taking the related amortisation-time into account [14]. The measures are prioritised with regard to the resulting present value of the technology investment. The transformation speed is therefore model-endogenous and partly non-linear [14]. Diffusion curves are implemented for several submodules to specify the transformation speed [14]. The diffusion of energy efficiency measures in the assets is based, for example, on logistic growth curves depending on the amortisation period. Simulation results are energy carrier, application and technology-specific energy consumption, load profiles, emissions and technology costs [14,17]. Analogously to process heat, process cooling is also subdivided by temperature level [17,20]. At industry level, a distinction is made between seven economic branches and applications as well as 15 energy carriers. FORECAST Industry is used in energy and climate studies [21,22].

In order to calculate the future economic branch-specific final energy consumption by energy carrier and application, the Prognos model maps industry in a bottom-up manner using activity parameters [5,23,24,25]. Based on the German energy balance and industry statistics, the model distinguishes between up to 14 economic branches, 26 applications and 35 energy carriers [5,24]. In order to determine future energy consumption, the branch-specific value density (Wh/€) and the specific energy consumption (Wh/kg) for particularly energy and emission-intensive branches are decisive variables [5]. In addition to energy-and emission-intensive industries, cross-sectional technologies are treated separately at industry level [24]. Economic branch-specific developments in gross value added (€) and production volume provide the basis for calculating the future final energy consumption of the respective branch [5,23]. Prognos uses the VIEW economic model to extrapolate the economic branch-specific gross value added and the number of employed persons [26]. Efficiency improvements, energy carrier substitutions and value density developments observed in the past are transferred to the future on a trend basis [24]. Measure clusters address technical changes in industrial production processes and are translated into economic cash flows [23]. The branch-specific GHG abatement measures are prioritised according to macroeconomic abatement costs. In addition to GHG abatement costs, practical restrictions as well as social acceptance are taken into account [5]. Furthermore, the saving potentials and costs of the GHG abatement measures are dynamically forecasted [23,25]. The diffusion of efficiency measures is based on replacement rates which are oriented on the lifetime and profitability of the facility replacement [24]. In addition, a certain technology modification is included in the more efficient facilities [24]. The simulations result in industry-specific energy consumption, energy costs and emissions [25]. The Prognos industrial model is used, inter alia, to calculate energy and climate-policy scenarios in [5,25].

The industrial module of the “Price-Induced Market Equilibrium System” (Primes) model of the University of Athens calculates the energy and emission development of the 28 EU member states [23,27,28]. Industry is divided into nine main and 24 sub-branches. In turn, the branches include individual processes and cross-sectional technologies [27]. The energy demand of the processes, cross-sectional technologies and branches is derived from the General Equilibrium Economic Model [27]. The Primes Industrial Model contains, inter alia, GHG abatement measures for process route, energy carrier, raw material switch and CO2-capture [14]. The implementation of the GHG abatement measures is determined from a microeconomic perspective in a cost-minimising, non-linear optimisation. The implementation of the GHG abatement measures is performed according to the economic optimality, the technology lifetime, the available capacity, the market penetration depending on the relative costs and risk, and the technology readiness level. Branch-and country-specific energy consumption and emissions form the model output [28].

The industrial module of the WISEE model is a bottom-up model of the Wuppertal Institute that maps production technologies of selected value chains using resources, product and energy flows [13]. Industrial simulations are based on at least twelve industrial processes. Parameters gathered in stakeholder processes provide the basis for deriving exogenous industrial transformation paths with the model. The focus lies on manufacturing processes, by means of which energy efficiency and GHG abatement potentials are highlighted. To deduce system-optimal, endogenous transformation paths for future industrial development is not part of the model [13]. Energy consumption is determined bottom-up via specific energy consumption and production volumes. Future emissions are calculated by multiplying energy consumption and emission factors. The model is based on three GHG abatement options: more energy-efficient production, increased material and resource efficiency and intensified recycling [13]. There is no model-endogenous rather a model-exogenous implementation of the three GHG abatement options [13]. The model results include emissions and final energy consumption subdivided by production and manufacturing processes [29].

In the industrial model of the Institute of Energy Economics at the University of Cologne (ewi) (DIMENSION+), in contrast to the Prognos and ISI models, no industry-related endogenous bottom-up modelling is carried out. Economic branch-specific transformation paths are determined top-down from a macroeconomic perspective [4,23,30]. The economic branch-specific development of the final energy consumption is determined on the basis of existing GHG abatement clusters, not on the endogenous implementation of individual GHG abatement measures [23]. Annual developments in gross value added, efficiency increases and recycling rates in industry serve as a database [30,31]. Historical developments and expert interviews provide the background. Capital costs are not taken into account in the industrial model when determining exogenous transformation paths [4,30,31]. Energy consumption and emissions at industry level as well as from individual energy-and emission-intensive processes are provided with model calculations.

The literature review supports the assumption that very few industrial models provide technology-independent, consistent transformation paths for German industry. For example, in the DIMENSION+ and WISEE models there is no endogenous implementation of individual measures, rather industrial transformation paths are predominantly exogenously defined [13,30]. With FORECAST Industry [14], the Prognos Industry Model [24] and the Industry Module of the Primes Model [27], it is possible to map transformation paths for German industry in consistent technology mix scenarios. However, “Primes Industry” is strongly focused on European industry [28]. The exact calculation and implementation methodology of Prognos AG’s industrial model for the combination of various GHG abatement measures and the consideration of interactions between individual measures remains unclear [24], as these are not fully accessible to the public. In addition, [24,27] do not describe the level of detail with which GHG abatement options are implemented in the model. However, [24] proposes the conclusion that GHG abatement measures in the Prognos industrial model are only implemented at branch-and not process-level. FORECAST Industry takes a microeconomic perspective, systemic connotations are not the main emphasis of the simulations. Heterogeneous industry also requires differentiated approaches in order to be able to use different perspectives in the derivation of industrial transformation paths.

Based on the research needs outlined above, the main objective of this publication is to develop a transparent methodology for small-scale modelling of individual GHG abatement measures in German industry and to test them on the basis of selected model calculations in a consistent technology mix scenario. This includes the development of an integrated open-independent modelling method that allows the combination of GHG abatement measures in a technology mix module at individual measure level and takes interactions of measure implementation into account. Restrictions and measure implementation, as well as methodological characteristics of scenario development with a time horizon up to 2050 are described in detail. In addition to the developed methodological, exemplary paths for energy consumption, emissions and other relevant industrial parameters up to 2050 are presented. The technology mix scenario assumes a high level of industrial climate ambition. Another objective is illustrating the effects of learning curves on technology development in the industry sector by means of sensitive model calculations.

2. Materials and Methods

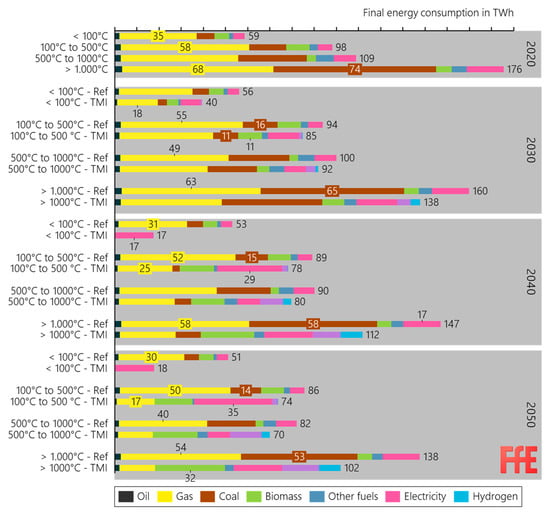

The sector model industry (SmInd) conducts energy and emission dynamic calculations with a time horizon up to 2050 [1,32]. SmInd has several substructures that divide the whole of German industry, in a top-down manner, into 14 branches [33]. In the energy carrier application matrix (EAM), the consumption of economic branches is combined by energy carrier and application. A distinction is made between ten electricity (space heating, hot water, process heat, process cooling, air-conditioning, compressed air, pumps, information and communication technology, other mechanical energy, lighting) and three fuel (process heat, mechanical energy, space heating and hot water) applications. For “process heat” at branch level, a subdivision by temperature is provided as well [33,34], which is based on [35]. A distinction is made between four temperature levels (Process heat less than 100 °C, between 100 °C and 500 °C, between 500 °C and 1000 °C and above 1000 °C). In order to perform bottom-up analyses, 22 selected energy-and emission-intensive processes are assigned to the economic branches [1,32].

2.1. Description of the Basic Functionality of the Model

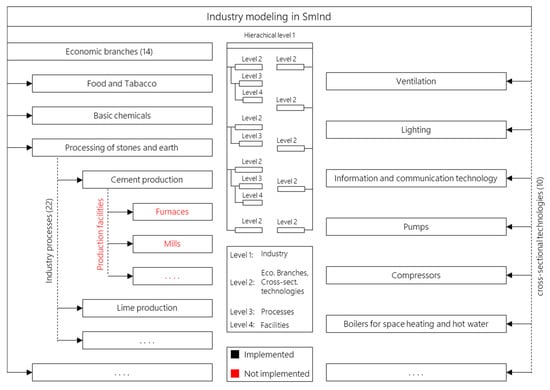

Figure 1 summarises the bottom-up technology modelling in SmInd. Individual production facilities are assigned to processes that are mapped using activity parameters. For these processes, annual production volumes [22,25], specific electricity and fuel consumption are available [1]. In turn, the processes are subordinated to economic branches on the left side of the figure. As part of the modelling of the technology mix scenario in SmInd, the processes are extended by a fuel distribution [36,37,38,39,40,41]. Cross-sectional technologies are modelled at a non-process-specific industrial level based on [42]. The model distinguishes ten cross-sectional technologies. Some examples are shown in Figure 1 on the right side. In the middle of Figure 1 the different hierarchical levels in the model are shown. A total of four hierarchy levels are distinguished in the model.

Figure 1.

Industrial technology modelling in SmInd. Terms written in black are already implemented in the model. The red terms are not yet available in the model, but should be implemented in the future.

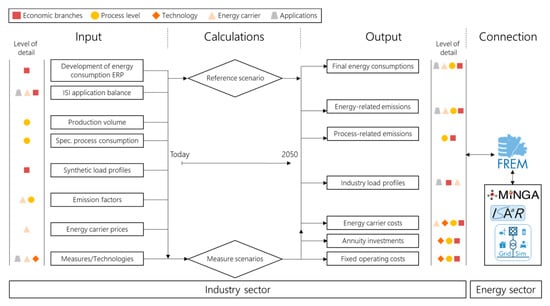

The functional principle of SmInd and its integration into the FfE model landscape (right-hand side) is shown in Figure 2. The figure also contains the level of detail of individual input and output variables on the left side. The operation base is the reference scenario, which contains the energy and emission-oriented reference development of German industry from 2015 to2050. In the reference scenario, the branch-specific energy consumption by energy carrier is determined based on existing scenarios up to the target year. In turn, this data serves as a basis for specifying energy consumption by application and temperature level according to [33,35]. Based on the energy carrier precise consumption, emission factors are used to compute the energy-related emissions of the reference scenario. Specific process emission factors are also used to determine the process-related emissions based on the production volume of the process. In addition to the bottom-up calculation, process-related emissions are also distributed top-down to the economic branches on the basis of the national inventory report [1]. The energy costs are based on the given energy prices and energy consumption data and are stored depending on the specific energy carrier. The reference scenario and the activity parameters are the baseline of all other implemented and calculated scenarios [1,32].

Figure 2.

Inputs and outputs of SmInd and integration into the FfE model landscape.

In the following section, the methodical and implementation-oriented enhancement of SmInd based on a technology mix module is developed by combining all available GHG abatement measures of the model and considering interdependencies between them. The SmInd modelling process is conducted using Matlab.

2.2. Overview of the Methodological Procedure

The procedure consists of four main steps, as shown in Figure 3.

Figure 3.

Overview of the methodological procedure.

In step (1), the individual, small-scale GHG abatement measures and the associated parameters are prepared and converted into a matrix containing all relevant data. In addition, measures for generic efficiency progress are derived from existing ones for the portion of energy consumption that is not covered by individual GHG abatement measures. In step (2), a methodology for implementing and combining small-scale GHG abatement measures in the industry sector is developed. In this context, a new methodology of measure prioritisation as well as implementation-related restrictions are presented. In addition, learning curves are taken into account. In the third step (3), a modelling approach is developed, analysing the effects of GHG abatement measures on energy consumption, emissions and production volumes. Interdependencies between the individual GHG abatement measures are taken into consideration as well. In addition, changed CAPEX and OPEX are calculated, which have accrued for the individual abatement measures and for the whole industrial transformation path. In the fourth step (4), the methodology is tested in a consistent technology mix scenario.

2.3. Preparation of GHG Abatement Measures and Initial Calculations

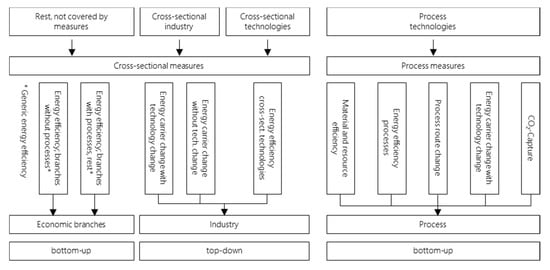

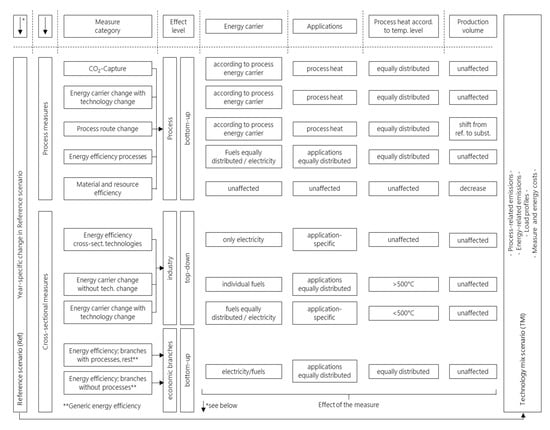

The technology mix module combines both process-specific and process-unspecific GHG abatement measures. Process-unspecific GHG abatement measures are termed as cross-sectional measures. Cross-sectional measures refer to applications such as industrial lighting or gas consumption in the entire industry sector, whereas process-specific GHG abatement measures are always assigned to a specific process such as steel production. Figure 4 summarises the allocation of the technology mapping to the measure categories in the technology mix module.

Figure 4.

Assignment of modelled technologies to the measure categories and effect level.

Process measures are divided into five measure categories in the technology mix module and affect the production processes as well as the associated industrial production facilities (Furnaces, electrolysers, mills and other industrial production facilities). Efficiency measures reduce the energy consumption of the processes. The process route change describes the conversion of conventional to new production processes for manufacturing the same product. In the technology mix module, it is possible to switch from one reference to several substitution processes. The energy carrier change with technology change at process level describes the conversion of existing facilities enabling the switch to climate-neutral energy sources. CO2-capture reduces both energy and process-related emissions in selected industrial production processes. No CO2-storage takes place because the captured CO2 is used in the supply sector to produce synthetic methane. The material and resource efficiency is indirectly considered in the model via the development of the production volumes and the specific process consumption and is therefore not described in more detail in the following sections. Process measures are always linked to the activity parameters of the production process. A detailed description of the measure categories can be found in [1,32]. The description of the technology mix scenario provides examples in the Section 1.

The technology mix module also distinguishes between five cross-sectional measure categories. Increasingly efficient cross-sectional technologies (lighting, electric drives, boilers for space heating and hot water generation and other cross-sectional technologies) reduce energy consumption compared to the reference scenario. The use of industrial heat pumps and electrode heating boilers as a result of the energy carrier change with technology change at cross-sectional level also enables the electrification of fuel applications in low-temperature heat. In addition, energy carrier changes are implemented without technology change, substituting natural with synthetic gas or coal with biomass. If coal is still used in industrial processes at the end of the scenario path, it can be ex-post replaced with a climate-neutral solid fuel over a period of five years.

The efficiency measures at process and cross-sectional level cover a large part of industrial energy consumption. To model a consistent technology mix scenario, both the remaining consumption of the economic branches with processes and economic branches without process efficiency must be assigned with generic efficiency progress. For economic branches that contain energy-and emission-intensive processes with relevant efficiency measures, the necessary parameters for the formation of a generic economic branch-specific measure are computed on the basis of the existing process measures. For this purpose, the mean of the relevant parameters is calculated. Average electricity and fuel savings as well as the associated CAPEX and OPEX form the basis of the generic efficiency measure. Since no relation to the production volume of energy-intensive processes or the number of factories (cross-sectional technologies) is possible, the diffusion of efficiency improvements also depends on the average of implemented efficiency measures. Therefore, generic efficiency measures differ from the specific parameters of the process and other cross-sectional measures. Therefore, the absolute change in electricity and fuel consumption is inserted in the measure matrix (kWh) [1]. CAPEX and OPEX (€/kWh) are incurred for each kilowatt hour by implementation of generic efficiency at industry level. The described methodology of generic energy efficiency applies analogously to economic branches without processes. However, in this case, average values of all relevant process efficiency measure parameters are formed in order to generate generic, economic branch-specific energy efficiency measures. The calculated generic efficiency per economic branch is divided by the average lifetime of the relevant process efficiency measures. Thus, annual parameters of the generic energy efficiency measures are generated. The generic efficiency measures at economic branch level are considered as ordinary efficiency measures in the measure matrix.

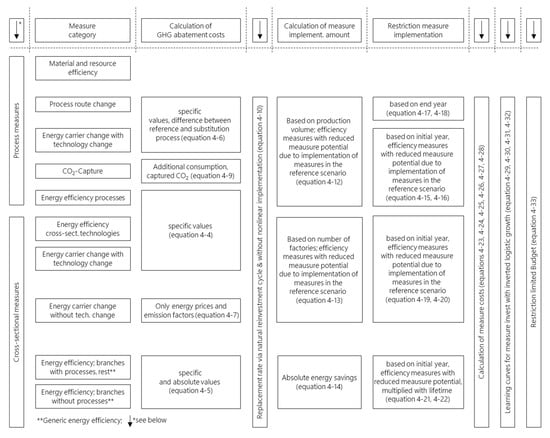

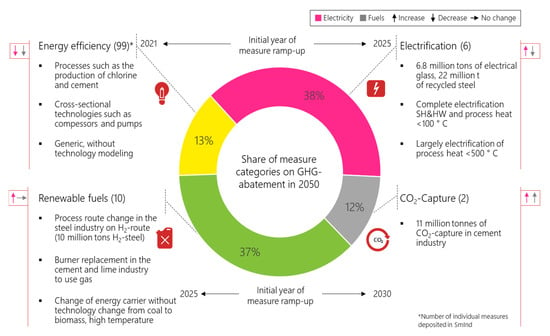

To model individual GHG abatement measures in industry and to combine them in a technology mix module, the existing model structure has to be changed from the implementation of measure clusters to individual GHG abatement measures [1]. The resulting overall matrix contains 27 parameters per GHG abatement measure that are required for the measure implementation and combination (see Appendix A, Table A1). The technology mix module combines 117 individual measures for GHG abatement, which can be assigned to ten measure categories (see Figure 5). Accordingly, up to nine different implementation and evaluation logics are required in the technology mix module depending on the measure category.

Figure 5.

Assignment of equations according to measure categories to implement GHG abatement measures in TMI.

To determine the effect of individual GHG abatement measures or measure categories, filter mechanisms are available in the technology mix module allowing selection of individual measures or categories. Thus, it is possible to compute and analyse the effects of individual GHG abatement measures or categories on energy consumption, emissions and process costs, economic branches or industry as a whole. As a result of the initial calculations, year-specific matrices with small-scale GHG abatement measures filtered according to predefined criteria are available. These are used as a basis for the temporally bound implementation of measures in the technology mix module.

2.4. Methodology for Implementing GHG Abatement Measures

At the beginning of the measure implementation, an individual measure matrix is available in the technology mix module for each year, which contains all year-specific relevant GHG abatement measures. In the technology mix module, it is possible to implement the measures with fundamentally different implementation logic. Two implementation logics are already implemented in the model:

- Implementation of the GHG abatement measures as a result of a ranking specified by expert assessment

- Implementation of measures according to annual, static GHG abatement costs

A target commitment is possible for the implementation logic, whereby the level of climate ambition in industry can be specified (e.g., specified GHG abatement by 2030). In the following technology mix module, the measures are implemented according to annual, static GHG abatement costs.

Figure 5 shows the basic methodology for the GHG abatement measure implementation depending on the measure category. The allocation of the equation to the respective implementation step and the measure category can also be taken from Figure 5.

As a result of the annual change in hourly emission factors and energy prices, each individual measure causes year-specific GHG abatement costs. If, in addition, learning curves, which influence the investment costs of GHG abatement measures depending on the implementation degree, are used, the basis for calculating year-specific GHG abatement costs changes. To compute the year-specific, static GHG abatement costs for each measure, the mean of the fluctuating electricity and fuel prices over the year is determined according to [43]. To compute GHG abatement costs, the annuity factor has to be calculated, which is defined according to [44].

The calculation of the GHG abatement costs is based on Equation (1) [45]. According to [45] this equation is only permissible if a measure leads to a CO2 abatement compared to the reference technology. A positive denominator of the equation is therefore a basic prerequisite for its validity:

| €/tCO2) abatement costs of measure j | (tCO2) emissions with measure |

| (€) costs of reference | (tCO2) emissions reference |

| (€) costs of measure | (tCO2) change in emissions |

| (€) change in costs | |

The calculation of the year-specific, static GHG abatement costs per measure in the model depends on the respective measure category. Dependent on the measure category, various parameters must be included. The full costs as given in Equation (1) are not used to calculate the GHG abatement costs, but only the changed costs resulting from the implementation of the GHG abatement measure.

The GHG abatement costs of the measure category “Energy efficiency processes” are calculated in the technology mix module according to Equation (2). The formula contains specific parameters related to the production volume:

| (€) abatement costs efficiency process of measure j | (€/MWh) price for electricity |

| () investment costs | (€/MWh) price for fuel f |

| (1/a) annuity factor | (%) quota of fuel f in the process |

| () fixed operation costs | (tCO2/MWh) emission factor electricity |

| () change in electricity | (tCO2/MWh) emission factor of fuel f |

| () change of fuel f | (dL) measure j |

| (dL) number of fuels | ∅ (dL) symbol for average of a variable |

The differential costs consist of the additional annuity investment and fixed operating costs as well as the changed energy costs due to the measure in the numerator. The denominator includes the changed emissions compared to the reference case. The changed energy consumption is multiplied by the average energy carrier-specific emission factors in the denominator. As fuel-specific consumption changes are not available in the measure matrix, the annual fuel distribution of the process is used to calculate the GHG abatement costs. Equation (3) is used by analogy for the cross-sectional measure of the measure category “Energy efficiency—cross-sectional technologies” at industry level. Instead of the fuel distribution at process level, the distributions at industry level are used. In addition, the specific values do not refer to tonnage, but to the number of factories where the measure can be applied. This also applies to the cross-sectional measure of the measure category “Change of energy carrier with technology change” (see Equation (3)).

Equation (3) is used to calculate GHG abatement costs for generic efficiency. For this measure category, the energy change is stored in the overall measure matrix without a specific reference value. Accordingly, the calculation is performed on the basis of absolute values. To calculate the energy consumption for each energy carrier, the change in fuel consumption is used on the basis of the annual fuel distribution at industry level:

| (€) abatement costs efficiency branch of measure j | (MWh) change of electricity |

| (€/MWh) investment costs | (MWh) change of fuel f |

| fixed operation costs | (%) quota of fuel f in branch |

A different methodology for calculating GHG abatement costs is used for the process route change, because the production volume of the process routes changes as a result of the measure. As different routes also have different fuel distributions, the energy carrier distribution changes as a result of the measure. This results in different absolute fuel costs and emissions. By switching from blast furnace to H2-steel, for example, hydrogen is mainly used as a reductant instead of coke, which entails different energy carrier costs.

To calculate the GHG abatement costs of the process route change, the change in the fuel-specific energy costs between the reference and substitution process of the individual process routes is equal to the product of specific consumption, the share of the fuel in the total fuel consumption and the average fuel price in the numerator. In the denominator, the change in emissions resulting from the changed fuel allocation is equal to the difference between the emissions from the reference and substitution processes. In turn, the emissions are equal to the product of the specific consumption, the share of the respective fuel in the total fuel consumption and the average emission factor. In addition, the changed process-related emissions are taken into account (see Equation (4)):

| (€) abatement costs, production route change | (dL) reference process |

| (MWh/) specific consumption | (dL) substitution process |

| () process emission factor | |

In addition to the process route change, the equation can be used to compute GHG abatement costs for the measure category “Change of energy carrier with technology change” at process level (see Equation (5)). A target distribution of the fuels must be defined for the energy carrier change with technology change, because the fuel distribution is not fixed in case of a process route change.

The GHG abatement costs for the cross-sectional measure category “energy carrier change without technology change” are calculated according to Equation (5). Changes in energy consumption, investments and fixed operating costs are not expected as there is no change in technology. Therefore, the abatement costs result from the difference in energy prices or emission factors between substitution and reference energy carriers in the numerator or denominator:

| (€) abatement costs energy carrier change without technology change | (dL) substitution |

| (dL) reference | |

| (dL) energy carrier | (dL) number of energy carriers |

The GHG abatement costs of CO2-capture take into account both the changed energy-related and process-related emissions. Initially, the existing direct energy-related emissions per tonne of production volume of the process without CO2-capture are determined (see Equation (6)). The GHG abatement is calculated from the difference between saved and additional emissions as a result of CO2-capture. In turn, the captured emissions consist of process-related, existing energy-related and direct energy-related emissions resulting from the increase in energy consumption. When calculating the abated emissions, the capture rate, which varies per process, must be taken into account (see Equation (7)). The additional emissions are subtracted from the abated emissions resulting from the use of CO2-capture. These consist of the additional indirect emissions and the additional direct emissions that cannot be captured:

| (€) abatement costs | (%) rate of CO2-capture |

| () production volume | () direct emissions of the process |

Next, the complete matrix of measures is prioritised according to the calculated GHG abatement costs. Accordingly, measures with lower GHG abatement costs are preferably implemented. The prioritised measure matrix is determined and processed on an annual basis. The year-specific implementation of each individual GHG abatement measure in SmInd depends on the following two fundamental restrictions:

- Full implementation of the measure

- Budget restriction

To comply with the first restriction, criteria must be observed that describe the complete implementation of a GHG abatement measure. An individual, annual measure implementation amount is calculated for each individual measure. Irrespective of the measure category, the calculation of the implementation amount is based on the annual replacement rate [32]. Each GHG abatement measure is assigned to a lifetime, which is used to determine the replacement rate of the technologies according to Equation (8):

| (%/a) replacement rate per year of measure j | (a) lifetime of measure j, const |

As a first step, it is assumed that the technologies are renewed at the end of their lifetime. The natural replacement rate per year describes the natural reinvestment cycles over the lifetime of an technology. The measure category “energy carrier change without technology change” does not consider a technology lifetime. On the basis of internal expert estimates based on developments in the supply sector, it is determined at what transformation rate the energy carrier change can be conducted without technology change.

As a second step, it is also possible to apply a non-linear measure ramp-up in the technology mix module. The following function could be used for a nonlinear measure ramp-up (see Equation (9)):

| (%/a) replacement rate per year of measure j | (a) lifetime of measure j, const |

| (a) time | |

In the following calculations and evaluations, a linear measure ramp-up with natural replacement rates is assumed for each individual measure.

The application factor is also required for calculating the implementation amount [32]. Application factors reflect limitations with regard to market penetration and the associated existing technologies of industrial production processes [46]. The application factors of the GHG abatement measures are taken from the literature or are estimated by industry experts [46].

The calculation methodology of an implementation amount varies dependent on the measure category. To calculate the implementation amount for process measures according to Equation (10), the production volume of the process is used [32]:

| () measure implementation amount according to production volume per year | () production volume, initial year |

| (%) application factor | () production volume, year t |

| (%/a) replacement rate per year | (%) reduced measure potential |

The equation is divided into two parts: In the first part, the implementation amount is calculated using the start production volume (part 1). Due to the already partially existing implementation amount in the reference scenario, the potential for measures in the technology mix module must be reduced. This only applies to energy efficiency measures. The first part of the equation only changes depending on the natural replacement rate per year. In the second part (part 2), the annually fluctuating production volumes are taken into account. For this purpose, the difference between the production volume of the current year and the previous year is calculated and multiplied by the replacement rate per year. The production volumes of the processes in the simulation model are exogenously defined for the period between 2015 and 2050 [22,25]. A distinction is made between three production volume fluctuation cases:

Case 1—The production volume increases compared to the previous year: If the production volume increases in time step t compared to the previous year (t − 1), the implementation amount for the time step t increases as well. The additional production volume of the industrial process is however, not fully added to the converted production volume, but multiplied by the replacement rate. In this context, it should be noted that the additional production volume is also produced with older facilities that were not previously fully utilised. An industrial production volume increase, would first and foremost contribute to the use of existing facility production capacities. The construction of a new facility to accommodate an additional production volume can only be assumed above a certain threshold value. Consequently, the additional production volume is subject to a replacement process in a realistic manner.

Case 2—The production volume decreases compared to the previous year: If the production volume in time step t decreases compared to the previous year (t − 1), the implementation amount also decreases in year t. However, the decreasing production volume of the industrial process is also not fully subtracted from the implemented production volume. It is taken into account that not only does the production volume of the production processes equipped with the enhanced technology decrease, but also that of all existing facilities.

Case 3—The production volume remains constant compared to the previous year: As the production volume does not change compared to the previous year, the implementation amount for the current year is only influenced by the change in the replacement rate. The replacement rate in the technology mix module is constant as long as natural replacement rates based on lifetimes are used.

Cross-sectional measures are implemented according to Equation (11). Cross-sectional measures refer to overall industrial parameters. Therefore, their implementation is not linked to the production volume of a process, but based on the number of factories for which the GHG abatement measure can be applied:

| () measure implementation amount according to number of factories per year | (dL) number of factories, year t |

| (dL) number of factories, initial year | |

For the reason that only efficiency measures are implemented in the reference scenario, there is no limitation of the measure potential for all other measure categories. In this case, the reduced measure potential is equal to 1. For generic energy efficiency, the measure implementation is linked to the average lifetime of other efficiency measures. Accordingly, the replacement rate is already allowed for by the annual embedding of the measure in the measure matrix itself. Moreover, no effect-reducing application factor is considered. Correspondingly, the annual measure implementation amount results from the energy savings, implemented as shown in Equation (12):

| () measure implementation amount according to energy savings per year |

The criteria for the full implementation of a measure also differ with regard to the measure category. Process measures are considered fully implemented as soon as the entire production volume is produced with or supported by the technology (see Equations (13) and (14)):

| (| f | MWh) measured potential of j |

When a process route is changed, the following equation is used for complete implementation due to the natural production fluctuations (see Equations (15) and (16)). The fluctuating production volume after the complete implementation of the process route change measure is distributed evenly over the remaining process routes via a production volume module:

| () measure implementation amount process route change |

The complete implementation of the cross-sectional measures is based on the annual number of factories for which the measure is implemented. The initial measure potential is calculated on the basis of Equation (17). The complete implementation of cross-sectional measures is therefore completed if Equation (18) applies:

The full implementation of generic energy efficiency measures is determined by Equations (19) and (20). The measure potential is included in the reference scenario on the basis of the already implemented measures, the lifetime and the limited measure potential due to the already increased efficiency:

If a GHG abatement measure is fully implemented, it is removed from the subsequent measure matrices on an annual basis. In addition to the implementation, the equations also serve for the “explementation”, i.e., the removing of measures. A fictitious, negative production volume or number of factories is used to remove measures, which is subtracted from the implementation amount. Especially in scenarios with a time horizon up to 2050, the explementation is a relevant instrument for addressing technologies that bridge the gap to climate-friendly energy technologies.

In addition to the complete implementation of a measure, the budget restriction must also be adhered. In SmInd, the budget restriction describes the year-specific budget for the industry sector, which limits the annual measures implementation. Initially, the costs arising from the GHG abatement measures have to be computed. The measure costs are divided into investments and fixed operating costs. The variable operating costs, which are mainly caused by changes in energy consumption and energy prices, are not taken into account in the budget approach.

To calculate the total annuity investment, the annuity must first be determined according to Equation (21). Afterwards, a matrix is constructed in which the annuity investments over the lifetime are entered line by line (see Equation (22)). To determine the annual annuity investments, the matrix is summed column by column (see Equation (23)):

| (€) annuity of technology j | (€/ | €/f | €/MWh) specific investment for j |

| (€) Capital Expenditure of technology j in year t | (a) initial year |

| (a) end year | (a) lifetime |

| (€) matrix with annuity | (€) matrix entry of row i and column l |

| (a) time steps | |

The fixed operating costs of the technologies are also taken into account. Fixed operating costs are non-annuity expenditures. Fixed operating costs mainly subsume operational costs for maintenance and repair. The fixed operating costs are stored in a vector (see Equation (24)), which is then totalled on an annual basis (see Equation (25)):

| (€) Operation Expenditure of technology j in year t | (€/| €/f | €/MWh) specific operation costs for technology j in year t |

| (€) vector with fixed factory costs of measure j | |

The total measure costs per individual measure are the sum of CAPEX and OPEX according to Equation (26):

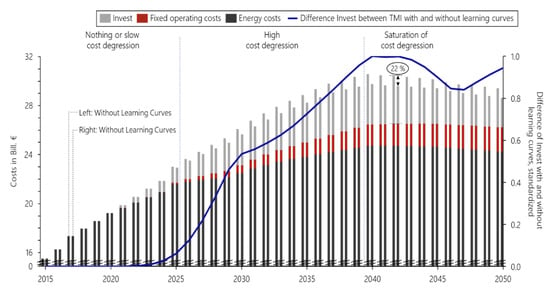

In the technology mix module of the sector model, it is also possible to assume that learning curves underlie the implemented technologies which, depending on the implementation amount, reduce the investments. Different learning curves can be used in the technology mix module. The Bernoulli nonlinear, ordinary first-order differential equation characterises logistic growth with saturation and is used below (see Equation (27)). Equation (28) represents the solution of Equation (27):

| change of the parameter | upper barrier for growth |

| proportionality constant | current value of the parameter |

| time | |

The solution function is inverted according to Equation (30) in order to reflect decreasing costs with increasing technology diffusion. To determine the technology diffusion, the implementation degree of the measure at time step t is first computed according to Equation (29). Second it is inserted into the solution of the differential equation. As described in Equation (30) the technology costs decrease with increasing output:

| (%) Measure Implementation Grade as a function of time for measure j |

The graph of the solution function describes an S-shaped curve in which the cost degression is initially low. However, the cost degression increases with increasing technology experience and reaches its maximum at the turning point of the function. If the turning point is exceeded, the cost degression decreases with increasing output. The lower limit of the cost degression is expressed by variable G. The lower limit of the cost degression is expressed by variable G. In the technology mix module, the lower limit is determined with a 50% cost reduction relative to the initial cost value of the GHG abatement measure. In order to reach the turning point of the inverted saturation curve at exactly half the cost saving, a value of 0.25 is defined for the proportionality constant.

The calculation methodology of CAPEX, OPEX and TOTEX in the technology mix module does not change due to learning effects. Accordingly, the cost parameters in the technology mix module with learning curves are also calculated according to the Equations (21)–(26).

The year-specific measure conversion ends when the annual budget has been used up. This can be expressed by the following Equation (31). The budget is given exogenously at the beginning of the simulation:

| (€) given budget as a function of time |

Taking into account the restrictions, a year-specific measure matrix is created at the end, which contains the implemented measures with the parameters required for evaluation. For this purpose, the measure matrix is extended by the static abatement costs. Additionally it is extendet by the annuity measure costs, the non-annuity fixed operating costs, the annuity total measure costs as well as the annual and cumulative measure implementation amount.

2.5. Evaluation Logic of the Applied GHG Abatement Measures

The effects of measure implementation on the output parameters of the model are determined in a separate evaluation module, whose basic functionality is shown in Figure 6. In the technology mix module the measure implementation is therefore not influenced by the amended energy consumption and emissions.

Figure 6.

Functionality of the evaluation module in the technology mix module.

Figure 1 shows the evaluations of the model calculations based on the reference scenario towards the technology mix scenario from left to right. The individual measure categories are shown in the figure according to the different evaluation methods. In order to explain the figure in more detail, an exemplary evaluation is first carried out using energy efficiency technologies. The technology mix scenario is based on the change in the reference scenario. The measure category “Energy efficiency processes” has an effect at process level. Consequently, a bottom-up approach is used. At the economic branch level, the efficiency measure only affects electricity and fuel consumption. No further distinction is made between energy carriers. Since the effect on different applications such as mechanical energy or process heat is not included in efficiency measures in the model, the measure is equally distributed across all applications. This also applies to the temperature distribution defined in the process heat. Production quantities are not affected by efficiency measures.

In order to use generic and homogeneous functions in the evaluation module, the heterogeneous GHG abatement measures must always act at the parameter level with the highest degree of detail. Therefore, a process-specific GHG abatement measure does not affect the total energy consumption of the industry, but the energy consumption of the respective process. Subsequently, the changed energy consumption is aggregated bottom-up to a higher parameter level. The effect of the measure categories on the respective parameter level is also shown in Figure 6.

In order to build on the reference scenario, it is necessary to clarify how to deal with the year-specific changes already made in the reference case. On the one hand, the reference change must be computed for all parameters that are affected by the measure implementation at the lowest parameter level. On the other hand, the reference change must be entered for those parameters that cannot be calculated bottom-up from the activity parameters:

- Process energy consumption and production volume (lowest parameter level of the processes)

- Energy carrier application matrix (EAM) (lowest parameter level of the economic branches)

Although GHG abatement measures also affect parameters at the industry level, their reference development need not be incorporated into the technology mix module. In the technology mix module, amended parameters at industry level are always distributed top-down to the processes, cross-sectional technologies and economic branches. Energy consumption is subsequently aggregated to higher parameter levels.

Furthermore, it must be determined how the year-specific reference change is taken into account in the technology mix module. In principle, two methods are conceivable: in the first option, the reference change has a percentage effect on the parameters of the technology mix module. Inconsistencies such as those that could arise from any negative parameters as a result of the absolute reference change are thus avoided. However, the reference change would be increasingly attenuated, because most parameters would decrease as a result of the GHG abatement measures. The percentage reference changes would be calculated increasingly on the basis of lower values in the technology mix module. For this reason, the second option, where the absolute reference change is related to the parameters of the technology mix module, is considered below. Thus, the change of the parameters in the technology mix module due to the reference change has an equi-constant distance to the change of the parameters in the reference scenario.

Regardless of the parameters, the reference change results from Equation (32). The reference change is applied to the parameters of the technology mix module according to Equation (33). In addition to the reference change, the GHG abatement measures implemented must also be taken into account:

| parameter in technology mix including reference change in t | change of parameters in reference |

| measure effect on parameter P in t |

The measure implementation is not linked to the changed parameters of the evaluation module. Therefore, it is a risk with the second option that both the reference change and the GHG abatement measures continue to be implemented even though parameters such as energy consumption or production volumes have already reached a zero value. If this problem occurs, a compensation function returns the parameters to their initial state. In the long term, however, it makes sense to include the evaluation module in the measure implementation function.

Each GHG abatement measure has an individual effect and is therefore implemented separately. Interactions of the individual measures are thus taken into account. The measure sequence previously determined based on the GHG abatement costs and measure implementation plays a decisive role in the measure effect. If, for instance, the process route changes from primary to secondary steel production before CO2-capture is used in the primary steel route, lower energy consumption and emissions from the original production process remain. The CO2-capture potential in primary steel production is reduced accordingly.

The methodology of the measure effect in the evaluation part of the technology mix module is described in detail below. Initially, the change in electricity and fuel consumption is calculated according to Equations (34) and (35):

| (MWh) absolute change of electricity in t by measure j | (MWh): absolute change of fuel in t by measure j |

| (MWh/tp | MWh/f) specific change of electricity | (MWh/ | MWh/f) specific change of fuel |

The calculation of the change in electricity and fuel consumption is different for the measure categories of process route change, energy carrier change with technology change and energy efficiency at economic branch level. For the process route change, the annual energy difference between the reference route and the substitution route is calculated. Instead of calculating the energy difference between two process routes, for the energy carrier change with technology change at process level the initial fuel distribution is compared with the target one. Equations (36) and (37) apply for both measure categories:

| (MWh): absolute change of electricity in t by measure j | (MWh): absolute change of fuel in t by measure j |

| (MWh/t): specific electricity consumption of reference or substitution | (MWh/t): specific fuel consumption of reference or substitution |

| (%): vector with percentage of fuels of reference or substitution process | |

For generic energy efficiency at the economic branch level, the annual, absolute energy savings are already available in the measure matrix. Therefore, Equations (38) and (39) apply:

| (MWh): change of electricity | (MWh): change of fuel |

Equations (34)–(39) calculate the annual change in electricity and fuel consumption. However, the measures implementation is not always connoted with decreasing electricity and fuel consumption. For example, the electrification of low-temperature heat reduces fuel consumption, but electricity consumption increases. The total energy consumption is still reduced due to the higher efficiency through electrification. The effect of the individual GHG abatement measures at parameter and parameter level depends on the respective measures category. Since production processes do not fully cover the economic branches and therefore aggregation from process to industry level is not possible, process measures affect both the electricity and fuel consumption of the process itself and the EAM of the economic branch. Furthermore, there are endogenous changes in the process production volume as a result of process route change. Accordingly, Equations (40) and (41) require a recalculation of the production volumes for the reference process (e.g., primary steel production) and the substitution process (e.g., H2-steel production). The production volume of the final product produced in Germany does not change as a result of the measure implementation:

| (t): production volume of reference route in t | (t): measure implementation amount of production route change |

| (t): production volume of substitution route in t | |

The effect on the electricity and fuel consumption of the processes is described by Equations (42)–(44). On this basis, the specific electricity and fuel consumption is also recalculated in Equations (45) and (46):

| (MWh) absolute electricity consumption of the process | (MWh/) specific electricity consumption of the process |

| (MWh) absolute fuel consumption of the process | (MWh/) specific fuel consumption of the process |

In order to implement the effect of a process measure on the EAM at economic branch level, different methods are required depending on the measure category. As long as the effect on specific energy carriers and applications is not known for some measure categories, the percentage distribution of the EAM available at time t is first calculated according to Equation (47):

| (%) percentage of element a in row I and column l | (dL) Matrix A with m times n elements |

| (div) element a of matrix in row i and column l | |

On the basis of the percentage EAM, the amended electricity and fuel consumption changes the existing applications and energy carriers according to Equations (48) and (49):

| (MWh) matrix with percentage distribution of energy carrier and applications electricity | (MWh) matrix with distribution of energy carrier and applications, fuels |

| (%) matrix with percentage distribution of EAM electricity | (%) matrix with percentage distribution of EAM fuels |

In contrast, the effect of process route changes and CO2-capture on the EAM can be determined based on the existing energy carrier distribution of the process. The process route change only affects the process heat of the EAM (see Equations (50) and (51)):

| (MWh) process heat, electricity | (MWh) vector with distribution of fuels for process heat |

| (%) vector with percentage distribution of fuels for process heat | |

Similarly, the measure category “energy carrier change with technology change” at process level only affects the process heat of the EAM. In contrast to the process route change, a target distribution for the production process with modified technology is used instead of the process difference.

The increased energy consumption due to CO2-capture only changes the process heat of the EAM. For this purpose, the changed fuel consumption is multiplied by the fuel distribution of the process in which CO2-capture is implemented (see Equation (52)). The change in electricity consumption is computed analogously to Equation (50):

| (MWh): vector with constant percentage distribution of fuels |

The process heat of the EAM is still divided by the temperature level. Where no temperature levels are available for each measure, the previously calculated process heat for process measures is distributed to the temperature levels on the basis of the existing temperature distribution for each economic branch. For this purpose, the existing percentage temperature distribution of the process heat is calculated according to Equation (47). The process heat subdivision between electricity and fuel consumption is computed as shown in Equations (53) and (54):

| (MWh) vector with distribution of power heat by temperature level, electricity | (%) vector with percentage of power heat by temperature level, electricity |

| (MWh) matrix with distribution of power heat by temperature level, fuels | (%) matrix with percentage of power heat by temperature level, fuels |

For the process route change from the primary steel route to the H2-steel route, it is also taken into account that the required hydrogen is only used in a temperature band above 500 °C.

With the exception of generic energy efficiency, the changed energy consumption is calculated top-down for the cross-sectional measures in the technology mix module. For generic energy efficiency, therefore, Equations (48) and (49) are used to compute the EAM, and Equations (53) and (54) to calculate the temperature-distributed process heat. The remaining cross-sectional measures affect the EAM at industry level. The application affected by the cross-sectional measures, is already available in the measure matrix. Accordingly, the EAM is calculated as shown in Equations (55) and (56):

| (MWh) vector with distribution of energy carriers of application x, fuels | (%) vector with percentage of EAM of applications x, fuels |

| (MWh) value of EAM of application x, electricity | |

Despite the available related applications for cross-sectional measures, the fuel change in the measure matrix is so far not distributed by energy carriers. However, it is taken into account that fossil fuels are substituted first’. Secondly the GHG abatement measures also have an effect on renewable fuels such as biomass. The measures category “efficiency of cross-sectional technologies” only affects electricity-based applications.

The distribution of process heat by temperature level at industry level is available for the measure categories “energy carrier change with technology change” and “energy carrier change without technology change” for each individual measure. The measure effects on the temperature band of the process heat is described in Equations (57) and (58):

| (MWh) power heat for temperature level x, electricity | (MWh) vector with power heat for temperature level x by energy carrier, fuels |

| (%) vector with percentage of power heat for temperature level x by energy carrier, fuels | |

Subsequently, the changed energy consumption is subdivided from industry level to economic branch level. The distribution is based on the premise that the energy carrier and application distribution of the economic branches do not change as a result of the measure implementation at industry level. In addition, the measures does not change the share of economic branches in the total industrial energy consumption.

In order to divide the changed energy consumption, resulting from the implementation of individual cross-sectional measures, in a top-down manner from industry to economic branch level the percentage share of economic branches in the total energy consumption of the EAM at industry level must first be computed (see Equation (59)). The resulting distribution of energy consumption from industry level to economic branch level is based on Equations (60) and (61):

| (MWh) EAM at branch level, old | (%) matrix with percentage of EAM at branch level based on EAM at industry level |

| (MWh) EAM at branch level, new | (MWh) EAM at industry level |

Once the cross-sectional effect of the measures is distributed across the economic branches, the changed parameters resulting from the measure implementation are available both for process measures and for cross-sectional measures at the economic branch level. Once the effect of the individual GHG abatement measure is applied, three function-based aggregation steps are carried out, for both cross-sectional and process measure categories:

- The energy carrier application matrices are aggregated from economic branch to industry level

- At economic branch as well as at industry level, the energy carrier application matrices are reduced by the dimension of the applications. Therefore, the energy consumption is aggregated by energy carrier.

- Afterwards, the energy carrier-specific vectors are aggregated to electricity, fuel and total energy consumption per economic branch and industry.

After the effect of an individual measure is applied, the new percentage distribution of the EAM and the temperature distribution of the process heat are computed at both economic branch and industry level, based on Equation (47). Additionally, based on Equation (59), the new percentage share of the economic branch-specific EAM’s in the total industrial energy consumption is also determined.

On the basis of the energy consumption in the technology mix module, the standardised, real data synthesised load profiles contained in the model are multiplied by the energy-carrier-specific consumption at economic branch level (see Equation (62)). The load profiles are differentiated once by energy carrier and once by application “space heating and hot water” and the remaining applications [32]. Finally, the load profiles are aggregated from economic branch level to industry level:

| (MWh) load profile according to energy carrier branch, and application | (MWh) consumption according to energy carrier branch and application |

| (%/100) standardised load profile of branch b | |

In addition, the model distinguishes between energy-and process-related emissions. In industry, energy-related emissions are caused mainly by the conversion of energy sources to generate electricity and heat. GHG abatement measures that reduce electricity and fuel consumption, consequently also reduce energy-related emissions. By contrast, process-related emissions do not result from the conversion of energy sources into other forms of energy, but are emitted by the operation of a facility or by process-related conversion steps of goods or materials used in production.

In SmInd, there are currently two options available for reducing process-related emissions: process route change and CO2-capture. When switching from primary to H2-steel, for example, the process-related emissions are significantly reduced, because the direct reduction of iron oxide with hydrogen results in significantly lower process-related emissions. Process emission factors are used to compute the process-related emissions. The use of CO2-capture in the production process usually increases both electricity and fuel consumption [22]. Initially, the utilisation of CO2-capture results in additional energy-related emissions. However, some of the additional direct energy-related emissions can in turn be reduced by CO2-capture, depending on the capture rate. In addition, CO2-capture also reduces process-related emissions, depending on the capture rate. The captured emissions are calculated in SmInd according to Equations (63)–(65):

| (tCO2) additional capture through increased energy consumption | (tCO2) capture of process-related emissions |

| (tCO2) capture of energy-related emissions according to fuel | (%) percentage fuels of process p |

| (MWh/) specific energy consumption of process p | MICC,k,p () implementation amount of carbon capture of process p |

| (a) actual time step | (a) initial year |

| (%) carbon capture rate | |

The total energy-related emissions in the technology mix module in SmInd are equal to the product of the final energy consumption and the energy carrier-specific emission factor. The resulting emissions are abated by the captured energy-related CO2 emissions. The calculation methodology applies in an analogous way for process, economic branch and industry level, based on Equation (66). The process-related emissions at process level are calculated in the technology mix module according to Equation (67):

| (tCO2) energy-related emissions | (dL) number of fuels |

| (MWh) final energy consumption of energy carrier ec | () production volume process p |

| (tCO2) process-related emissions | |

The change in process-related emissions due to the process route change is already included in the changed production volume and the process-specific emission factor. If the production volume decreases as a result of the process route change, the mathematical product of the production volume and the process-specific emission factor also decreases.

The process-related emissions at economic branch level are not implied by the process-related emissions at process level and therefore cannot be determined bottom-up via activity parameters. Hence, according to (68), the measure effect at process level is taken into account for the calculation of process-related emissions at economic branch level:

| () production volume of process p after measure implementation | () production volume of process p before measure implementation |

| (tCO2) process-related emissions, branch level | |

The changed energy costs resulting from measures implementation are computed according to Equation (68). The energy carrier precise energy consumption at economic branch level is multiplied by the specific energy carrier prices. The economic branch-specific energy costs are subsequently aggregated to industry level. Finally, several modules aggregate energy consumption, load profiles, energy-and process-related emissions as well as energy carrier and measure costs to a higher parameter level in the model.

2.6. Modelling Parameter and Description of the Scenario

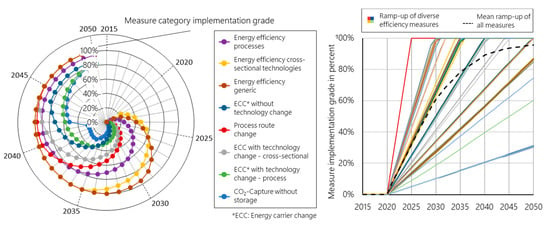

Technology Mix Industry (TMI) combines GHG abatement measures in a consistent industrial energy and climate scenario. In the scenario, interactions between the small-scale GHG abatement measures are taken into account. A CO2-abatement target in the industry sector is not included in the TMI scenario. Table 1 summarises the general data of the TMI.

Table 1.

Overview scenario Technology Mix Industry (TMI).

In the TMI scenario, model calculations are conducted annually between 2015 and 2050, with energy consumption and emissions being calculated annually on an hourly basis using synthetic load profiles. The implementation of GHG abatement measures is not conducted on the basis of a cost-minimising target function. However, the GHG abatement measures are prioritised by abatement costs and replaced over natural reinvestment cycles dependent on the facility lifetime. The additional implementation of measures in the TMI scenario begins in 2021. The model has an macroeconomic perspective. Accordingly, neither an additional CO2 price nor other taxes or levies are taken into account in the industry sector. The assumed interest rate for investments is 3.5% without distinction between equity and debt capital. In the scenario, an unrestricted budget is predefined. Accordingly, the measures are implemented independently of their costs. CO2 capture as well as slightly increased industrial use of biomass are part of the TMI scenario. The scenario-sensitive analyses include learning curves that reduce the investments in the technology mix module. It is explicitly indicated, if learning curves are included in the evaluation.

The development of final energy consumption in the TMI scenario is determined by the implementation of additional GHG abatement measures compared to the start scenario. The categories of measures contained in Figure 4 are implemented in the TMI. These measure categories contain a total of 117 individual measures for industrial GHG abatement, which are combined in the TMI scenario.

The data of the measures used in the TMI scenario are available in [46,47]. Table 2 shows the mean of the input data for each measure category. Furthermore, the initial and end year are included for each measure category. However, individual GHG abatement measures of the respective measure category can also be fully implemented before 2050 (latest end year). In the following section, the individual measure categories and the most important associated individual measures for GHG abatement in the scenario are briefly described.

Table 2.

Characteristic parameters and values by measure category in TMI.

2.6.1. Energy Efficiency Processes

For the process-specific increase in energy efficiency, a distinction is made between the internal use of waste heat, the conversion of waste heat back into electricity (e.g., Organic Rankine Cycle) and the increase of general process efficiency, e.g., through improved process control and monitoring. The additional diffusion of efficiency technologies to increase process efficiency in the TMI scenario begins in 2021. The included process-specific efficiency measures are almost completely implemented by 2050 with a natural replacement rate. The scenario contains 71 process efficiency measures with an average natural replacement rate of 6% per year. In addition, the average application factor is 56%.

2.6.2. Energy Efficiency Cross-Sectional Technologies

In addition to process-specific efficiency, efficient cross-sectional technologies and their efficient use and operation are key drivers for reducing final energy consumption in the TMI scenario. These include the increasingly efficient supply of air conditioning, space heating and hot water, compressed air, pumps, information and communication technology, other mechanical energy, and lighting. Increasing efficiency of power-based cross-sectional technologies is implemented in the TMI scenario between 2021 and 2050.

2.6.3. Generic Energy efficiency

Due to a strongly heterogeneous German industry [10], the complete modelling of more efficient energy utilisation via individual GHG abatement measures is not practicable. Accordingly, the change in the efficiency of the remaining energy consumption, which is not reflected by the 22 energy-and emission-intensive processes in SmInd, is represented by generic energy efficiency measures. The average replacement rate for generic efficiency measures is, based on energy efficiency at process level, also 6% per year.

2.6.4. Process Route Change

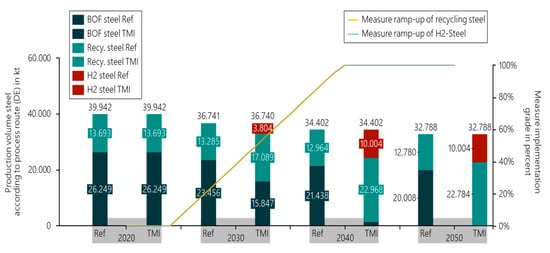

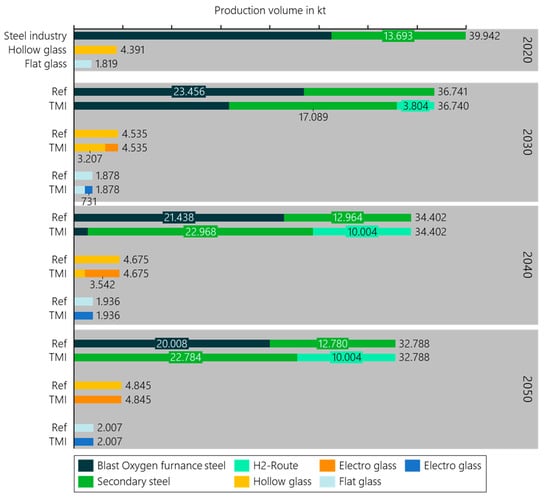

The process route change measure category summarises process-specific GHG abatement measures that involve a change away from the classic production process. The process route change is not necessarily accompanied by a reduction in the final energy consumption, but usually promises a change to climate-neutral energy sources. In the TMI scenario, the glass industry increasingly deviates from the classic production processes of hollow glass and flat glass production to switch to electricity based glass production. Firstly, the final energy consumption can be significantly reduced through increased electrical efficiency compared to the use of gas. Secondly, instead of the fossil fuel natural gas, electricity is used, which is almost climate-neutral if renewables are used for electricity generation. Additionally, in the TMI scenario, primary steel production using blast furnaces is substituted by alternative processes. For this purpose, H2-based direct reduction with a subsequent melting process is used and the proportion of recycled steel (secondary steel production) is increased.

2.6.5. Energy Carrier Change with Technology Change—Cross-Sectional Measure

In the case of emission-free electricity, GHG abatement is also achieved by electrifying industrial low-temperature heat. Proven technologies such as the industrial heat pump and the electrode heating boiler are available in an industrial temperature range of up to 250 °C. This involves a technology change from fuel-based to electricity-based heat generation plants and the related infrastructure. In contrast to the process route change, the production process itself does not change. The electrification of low-temperature heat in a temperature range below 100 °C Space heating and hot water as well as process heat below 100 °C by use of the industrial heat pump offers a high potential for reducing fuel consumption, while electricity consumption hardly increases.

2.6.6. Energy Carrier Change with Technology Change—Process Measure

In addition to low-temperature electrification, a partial energy carrier change with technology change in the cement and lime industry is carried out. By changing the solid fuel burner to a multi-fuel one, the use of gaseous fuels becomes possible. As many cement and lime kilns already have a multi-fuel burner installed, the remaining application potential is assumed to be only 20%.

2.6.7. Energy Carrier Change without Technology Change

A change of energy carrier without a technology change requires that industrial processes can be operated unchanged even if the energy carrier is changed. This is the case, for example, with similar properties of reference and substitute fuels. The substitution of natural gas by synthetic methane therefore does not require any technology change and therefore no additional investment. For this measures category, the energy consumption of the process does not change. However, emissions are reduced if synthetic methane is produced from renewable carbon sources and almost emission-free electricity. In addition to replacing natural gas with synthetic methane, coal is increasingly being substituted by solid biomass in the TMI scenario. It is assumed that the biomass is raised to a similar energy level to coal through additional conversion steps in advance. Biocoal with similar properties is already available on the market [48,49]. Thus, no technology change is necessary for the energy carrier change from coal to biomass. Therefore, the electricity and fuel consumption does not change with this GHG abatement measure either.

2.6.8. CO2-Capture

CO2-capture in industry is in particular an important instrument for reducing process-related emissions, such as those generated during the deacidification of limestone in the cement industry [39]. In addition to the cement industry, the steel industry is a not negligible emitter of process-related emissions, which are mainly caused by the reduction of ferric oxide to iron by coke in the blast furnace route [50]. In the TMI scenario, CO2-capture is conducted for the cement and steel industries. The use of carbon capture in the model is possible from 2030.

3. Results and Discussion

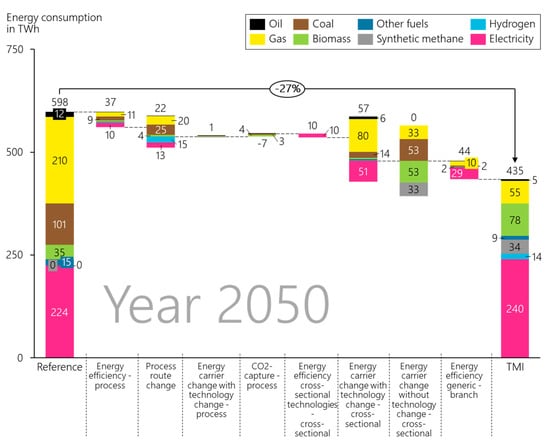

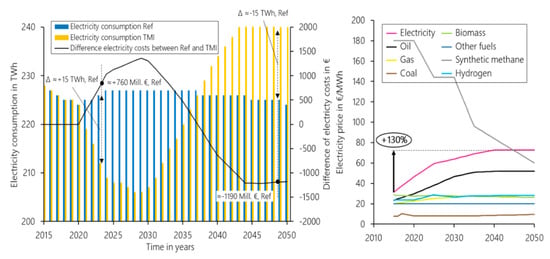

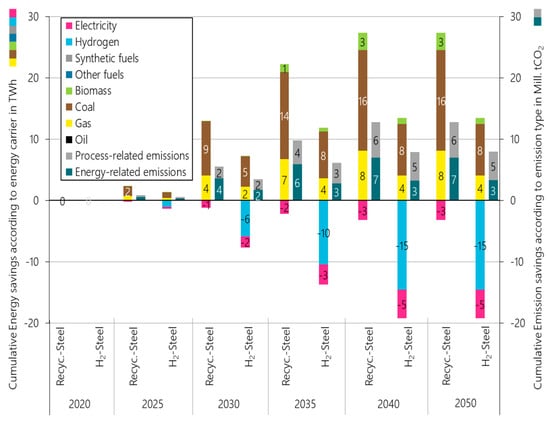

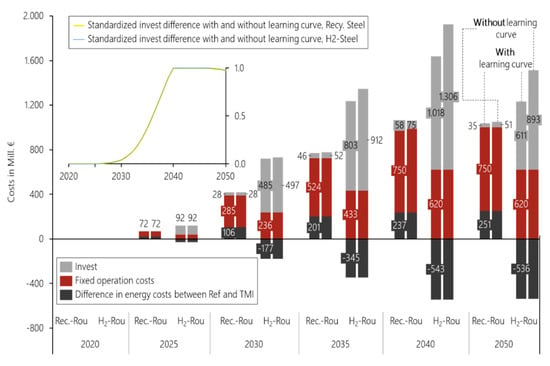

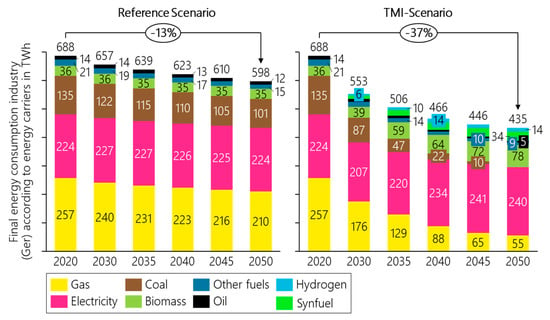

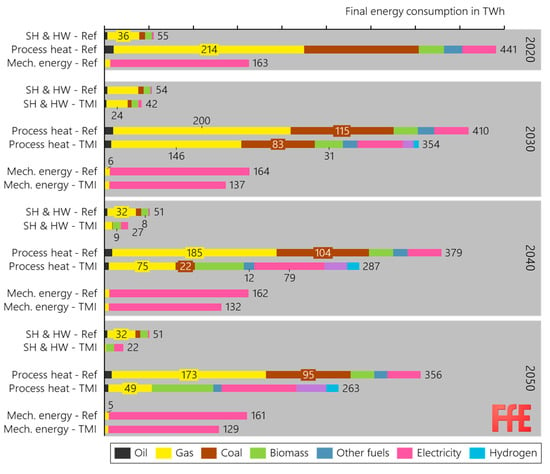

Figure 7 shows the difference in industrial final energy consumption between the reference and the TMI scenario in 2050, unbundled by energy carrier and measure category. The development of energy consumption between 2020 and 2050 of the reference as well as the TMI scenario is also available in Appendix C, Figure A1. In order to better classify the results in the technology mix module based on the developed methods, a comparison with the studies [4,5,22,25] is possible.

Figure 7.

Difference in industry’s final energy consumption between Reference and TMI-Scenario.