Abstract

The energy trilemma and UN SDG 7 form the key drivers for the future of all kinds of energy research. In nuclear technology, molten salt reactors are an interesting option, since they can offer a game-changing approach to deliver an attractive, highly sustainable option for a zero-carbon society by providing sufficient breeding for a self-sustained long-term operation based on spent nuclear fuel from existing reactors while being able to be controlled ideally by inherent processes. To achieve these goals, several basic challenges have already been identified and worked on; demonstration of sufficient breeding and development of a demand driven salt clean up system. This study follows up on the opportunity for reactor control based on inherent feedback mechanisms. It is demonstrated that the investigated sodium chloride-uranium chloride-based systems can feasibly deliver a thermal feedback effect, which is strong enough, to compensate for the critically change due to breeding and fission product accumulation for two different compositions. The achieved results provide a very positive outlook on the system inherent ability for reactor self-control and even for the feasibility of a load following operation based on inherent feedback effects instead of massive and costly manual/automated control system operation.

1. Introduction

Recently, the International Atomic Energy Agency (IAEA) has highlighted this rapidly growing interest in molten salt reactor technologies: “Initially developed in the 1950s, molten salt reactors have benefits in higher efficiencies and lower waste generation. Some designs do not require solid fuel, which eliminates the need for manufacturing and disposing of it. In recent years, growing interest in this technology has led to renewed development activities.” [1]. This mentioned growing interest is reflected by a variety of new start-up companies formed around the industrial development of molten salt reactors developing in different countries like Terrestrial Energy, Elysium Industries, TerraPower, MOLTEX and many more [2] as well as through the formation of national and international research projects, such as MOSART [3], EVOL [4] linked with the Rosatom project MARS [5] and the follow ups SAMOFAR [6] and SAMOSAFER [7]. In the UK, the increased governmental interest in the technology has led to the formation of the Academic Advisory group on molten salt technologies.

In our view, molten salt reactors can only leverage their full sustainability potential when operated in the closed fuel cycle mode. The feasibility of closing the fuel cycle has already been demonstrated on a laboratory scale, see the description of the whole set of processes needed given in [8], applying mixed oxide fuel production, sodium cooled fast reactors and aqueous reprocessing technology in France. For the future development of nuclear, operation in the closed fuel cycle mode would be one of the key objectives for improving the sustainability of innovative nuclear technology. However, up to now, establishing a closed fuel cycle operation on an industrial level has not been successful, even if most of the individual technologies have been already demonstrated. Thus, in general, we could call closed fuel cycle operation the ‘holy grail’ of industrial nuclear energy production based on nuclear fission. Key issues for not being successfully implemented are the technical complexity, proliferation concerns and the prohibitively high cost. Recently, a completely new, disruptive approach has been devised and rapidly taken up by many of the above-mentioned start-up companies, the reuse of existing spent nuclear fuel from thermal reactors used currently for energy production. This existing unused resource could be used for the operation of molten salt reactors [9,10] turning a legacy burden of nuclear waste into a profitable asset while eliminating the major cost drivers of the classical approach for closing the fuel cycle. A promising side effect would be reducing the currently existing challenges in the long-term nuclear waste management, which affect the acceptance of nuclear technologies in many countries. The result would be in a way comparable to the promises of the partitioning and transmutation approach [10,11], but leading to a combined solution delivering waste management and energy production in one facility applying new, innovative nuclear system development. Thus, the new development aim would be overcoming the traditional separation of waste management and power production [11,12], which has been established in the 1990s due to the available technological solutions. To achieve these very attractive goals several basic challenges have to be demonstrated or have already been demonstrated to be feasible:

- Achieving sufficient breeding in a molten salt system, see [13];

- Developing of a demand driven salt clean up system, see [14];

- Creating a deeper understanding of the operational behaviour of the system and potential control strategies.

The aim of this publication is to create an initial approach to the third point given above by:

- Investigating a possible control strategy for a molten salt system based on breeding and non-continuous feeding based on thermal feedback;

- Drawing conclusions from the results on the operational behaviour of a continuous fed molten salt system.

where both points are analysed on an initial composition based on uranium fuel and a growing plutonium content.

2. The Salt System

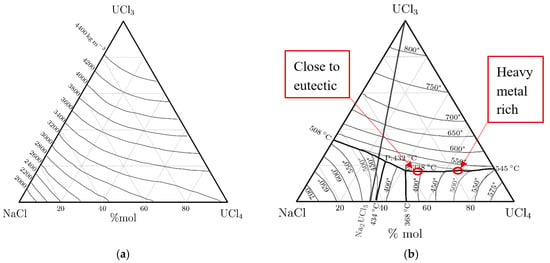

The choice of the salt system has been documented in [13] leading to a first choice of the tertiary system based on NaCl-UCl3-UCl4.

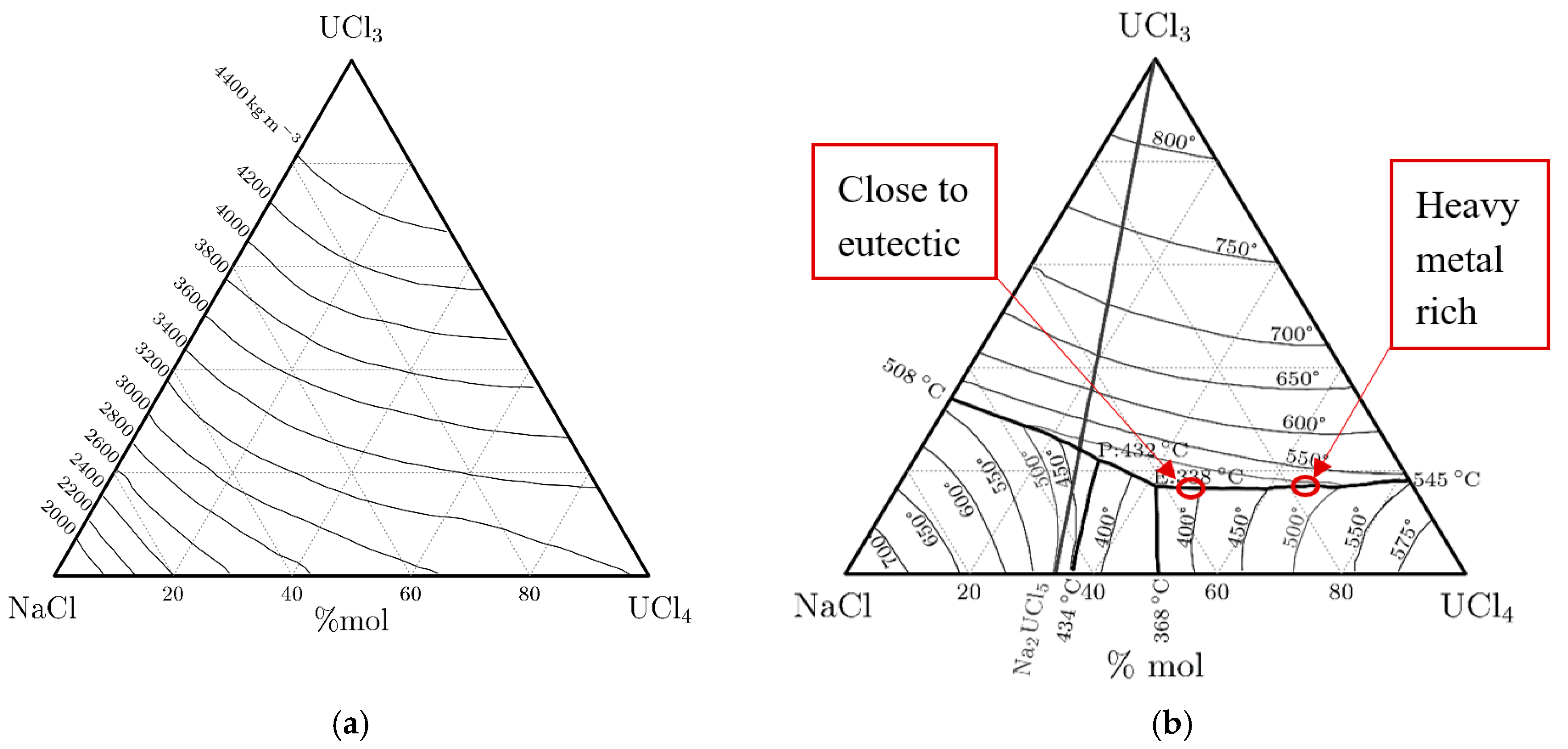

A first search for detailed information for the NaCl-UCl system led to the publications [15,16] providing preliminary information like the phase diagram and density field for 1050 K and the 3 component system NaCl-UCl3-UCl4, see Figure 1.

Figure 1.

Iso-density curves (kg/m3) at 1050 K (a) and melting point/melting temperatures diagram (b) for the NaCl-UCl3-UCl4 salt system with the eutectic at 42.5%-17.0%-40.5% (E—eutectic, P—peritectic) [13,16] showing the two compositions for the later analysis.

This reference identifies NaCl-UCl3-UCl4 having a eutectic composition at 42.5%-17.0%-40.5%, to be attractive for a further detailed investigation on different levels. The mentioned eutectic point of the NaCl-UCl3-UCl4 salt has a melting point of 338 °C [16] and acceptable melting temperatures even for non-eutectic compositions, which will almost be unavoidably formed during reactor operation. From the point of view of operating on spent nuclear fuel and the devolved requirement to achieve sufficient breeding the main attraction of this system would be the high loading of fertile material already at the eutectic point. This forms a very promising boundary condition to achieve sufficient breeding and thus the salt composition could be a promising candidate for a future reactor. However, this composition will require an upgrade of the thermo-physical dataset in a wide area around the eutectic.

The first starting point was the more detailed data on the density versus temperature curve, which allows an improved analysis of the system regarding feedback effects caused by the temperature and the resulting density change to the system criticality. Nevertheless, while being a good starting point, the data was limited to a very narrow temperature window and would have to be extended significantly during a future reactor development process to provide a dataset for the whole window of reactor operation temperature as well as possible transient conditions.

Based on the coefficients given in Table 1, the temperature dependent density was calculated based on the following formula:

Table 1.

Concentration dependent densities for the system NaCl-UCl3-UCl4 with the uranium salt composition 30%UCl3 + 70%UCl4 and varying NaCl concentrations part reprinted form [17]. The experimental error in the density measurements is given with max ±1.5%.

3. Salt Data, Code and Model

Based on the given salt system investigation above, the applied standard salt composition for the study was based on the nominal case, the eutectic 42.5%NaCl-40.5%UCl4-17%UCl3. This composition was sufficiently close to the third column of Table 1, which delivered 45%NaCl-38.5%UCl4-16.5%UCl3 (close to eutectic composition, see Figure 1) to provide a reasonable density estimation. In addition, a more fissile and fertile concentrated case was investigated, which was based on a composition of 20%NaCl-56.35%UCl4-23.65%UCl3 (heavy metal rich composition, see Figure 1) and varying U-235 enrichment based on the requirement to achieve initial criticality.

The simulations for this feasibility and sensitivity study have been performed using the POLARIS module of the SCALE code system [18]. POLARIS is a new module for SCALE 6.2 that provides a 2D lattice physics analysis capability that uses a multigroup self-shielding method called the Embedded Self Shielding Method (ESSM) and a transport solver based on the Method of Characteristics (MoC). In general, POLARIS and its cross-section library has been developed and validated for light water reactors, thus we have provided in a recent publication [13] a first verification/validation against the Monte-Carlo code SERPENT [19]. Polaris is integrated with ORIGEN for depletion calculations on a sub region basis [18]. The v7-252 cross section set of SCALE [18] a 252-group library based on ENDF/B-VII.1 [20] and a set of burnup calculations at 0, 1, 5, 10, 20, 30, 40, 50, 60, 80, 100, 120 and 140 GWd/tHM without consideration of online feeding and online salt clean-up are used in the calculations performed here. It must be mentioned here that in contrast to a real molten salt reactor, the model will produce an artificial spatial burnup distribution in the material, which will not arise in the real liquid fuelled reactor. This is a limit of the application of a lattice code, which has been developed to model solid fuelled reactors. However, in the last stage of the modelling considering the temperature changes in the system, this will be eliminated through a stepwise calculation model that allows as an assessment of the mixing of the fuel.

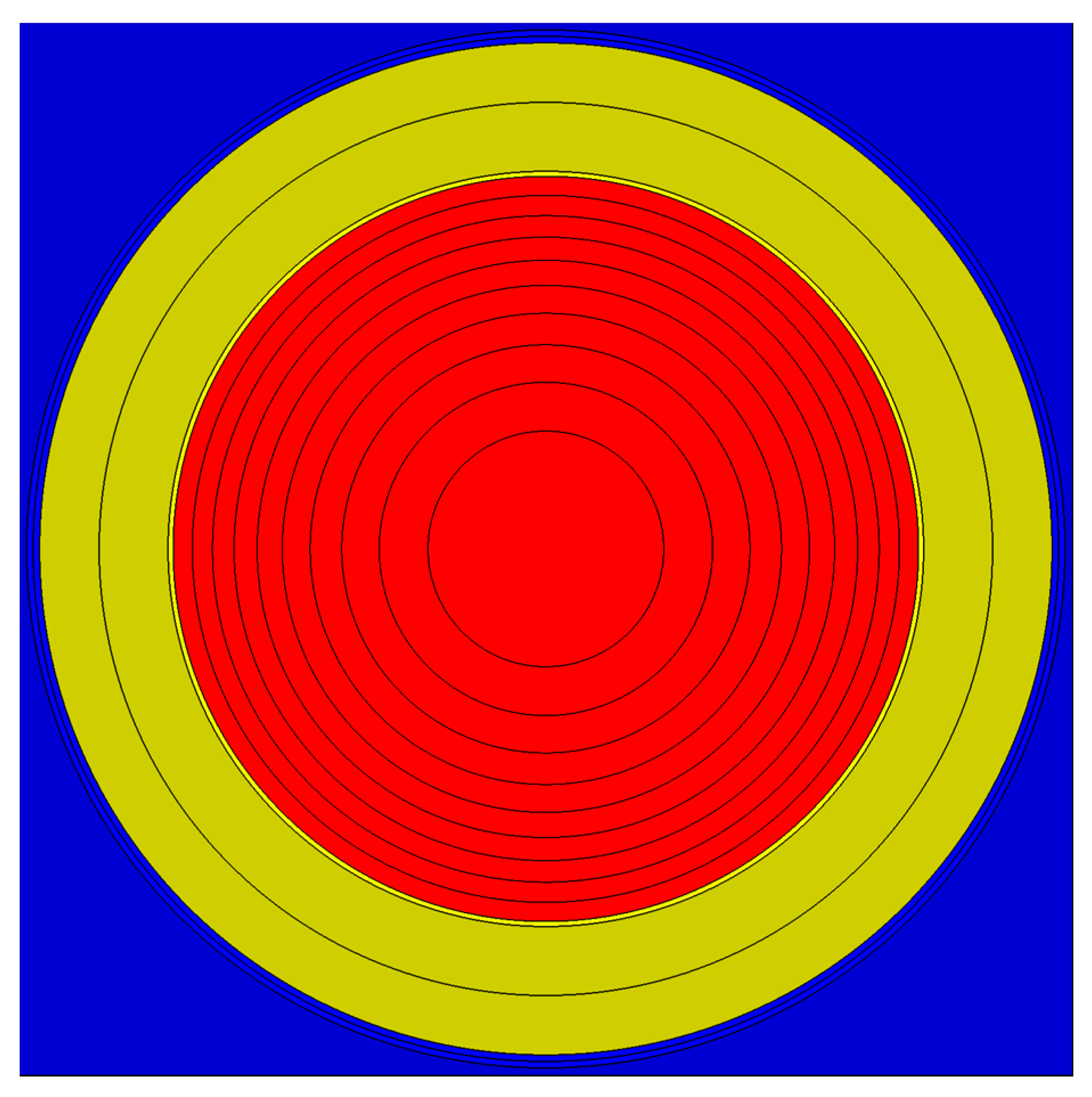

For the evaluation of the burnup and breeding, a very specific 2-D model has been built for the simulation (see Figure 2) to take care of the very important effect of the neutron leakage from the core, the most essential parameter to achieve a reasonable approximation for the breeding in the core of a molten salt reactor. The model consists of the reactor core with variable size (red), surrounded by a stainless-steel vessel of 20 mm thickness (bright yellow) and a sodium reflector of 50 cm thickness (dark yellow). The arrangement is surrounded by a vacuum gap (blue rings) and the rest of the unit cell is filled with a strong absorber (outer blue) to avoid the reflection of leaking neutrons from the core/reflector system.

Figure 2.

Model of the molten salt reactor core surrounded by an absorber.

The fuel temperature in the core varied between 930 and 1030 K with the nominal cases at 980 K, the vessel temperature was set to 873 K, and the reflector temperature was 800 K. The studies were based on enriched uranium with an enrichment varying between 11% and 12% for all investigated cases, depending on the system size and the salt composition. The parameters studied were the radius and the fissile material content.

A first verification/validation of the quality of the SCALE/POLARIS application for a molten salt fast reactor, based on a comparison to the SERPENT Monte-Carlo code for one specific case based on using identical modelling approaches as given above has been delivered in a recent publication [13].

4. Results and Discussion

4.1. Close to Eutectic Case

The first step is to define a reasonable base case close to eutectic composition 45%NaCl-38.5%UCl4-16.5%UCl3 with: on the one hand a critical system at the lowest considered average operational temperature (930 K) and on the other hand a maximal critical configuration at the point of highest criticality at the highest considered average operational temperature (1030 K). To develop this, three effects have to be brought into the right balance. The system has to be critical, this will be achieved by changing the U-235 enrichment. Based on this system the temperature will be varied by ±50 K to get a first estimate for the feedback effect. Using this first estimate the amount of criticality, which can be compensated by the temperature change will be determined. Finally, the system size will be adopted to create a system, which delivers the compensating reactivity swing while for each of the systems the enrichment has to be varied to achieve a critical initial value.

The process was based on the iterative approach given above and was started using a first guess of the thermal feedback of −6.5 pcm/K based on a first steady state calculation for a system with 210 cm radius, see Table 2.

Table 2.

Initial steady state calculations and determination of the feedback effect for a close to eutectic system with a radius of 210 cm.

This first guess led to the conservative approximation of a maximum compensation potential of 650 pcm at the envisaged average temperature change of 100 K without considering the effect of the operational temperature on the burnup/breeding behaviour.

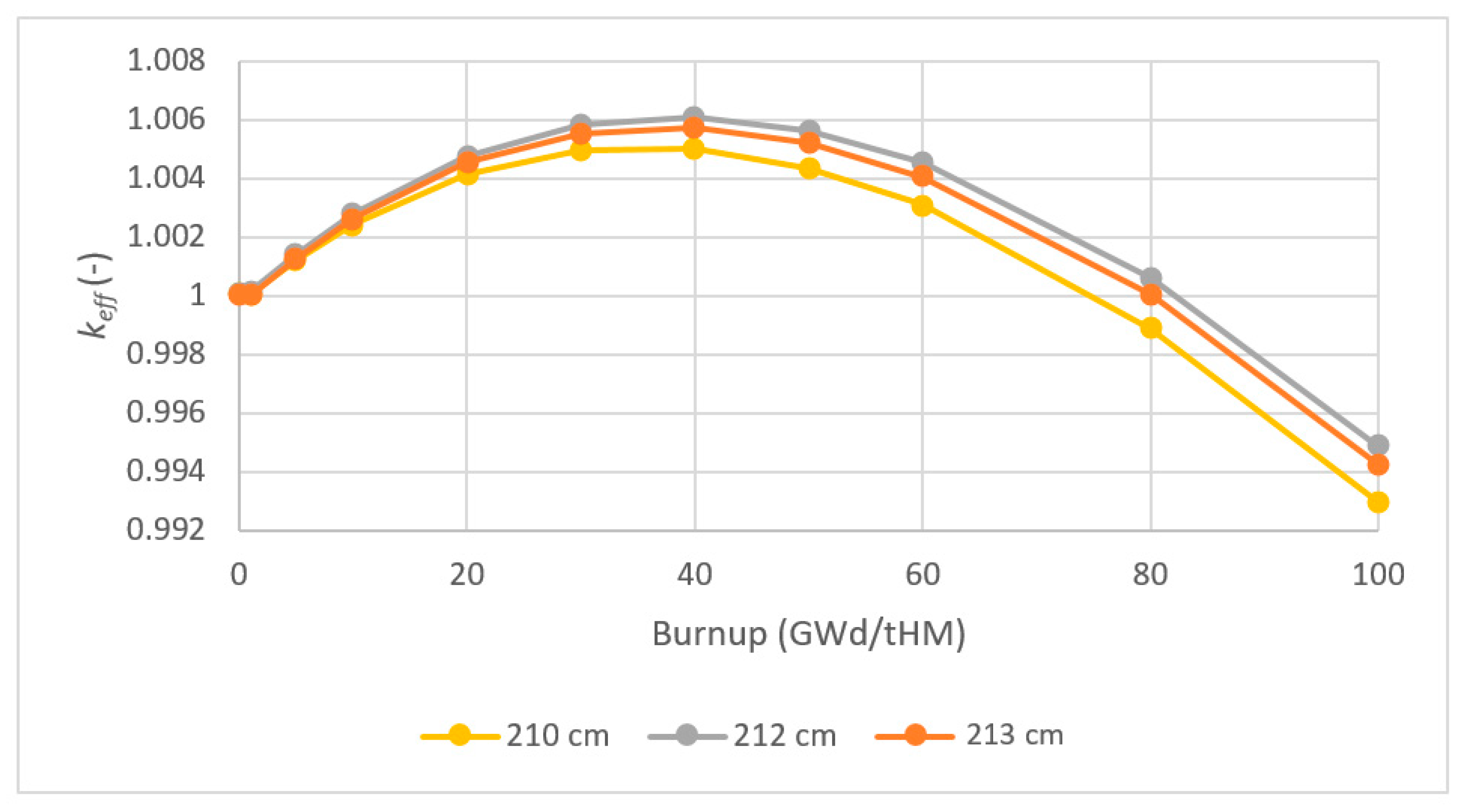

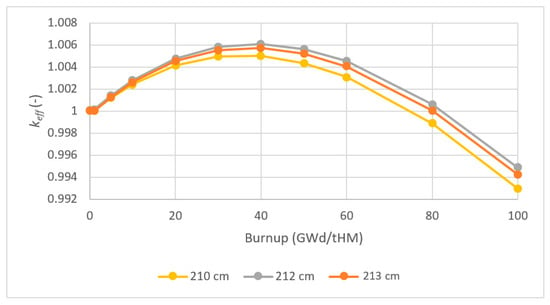

The typical burnup behaviour of a breeder system (see Figure 3, or [13]) was characterized by a profile modulated with a single peak with the curve starting at critical with the criticality rising due to the build-up of new fissile material in the breeding process. This process is characterized by a competition between the formation of new fissile material and the consumption of the fissile material. This breeding process was competing with the build-up of fission products, which had the stronger effect but happened on a longer time scale due to the accumulation of fission products caused by the fission process. While the first part of the burnup curve with increasing criticality was dominated by breeding, the second part was dominated by the decrease of the criticality due to the fission product accumulation while the increase of the amount of fissile material slowed down.

Figure 3.

Criticality of the 2D system over burnup for different system radii for the close to eutectic composition 45%NaCl-38.5%UCl4-16.5%UCl3.

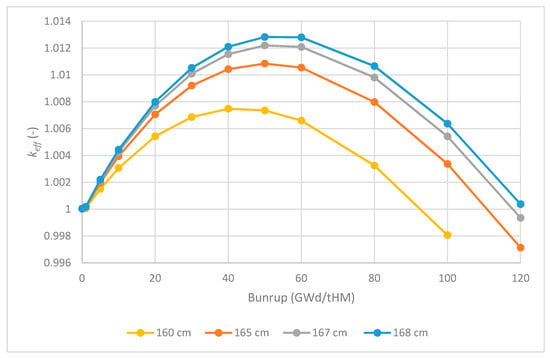

Based on these boundary conditions, a system size was iterated with an enrichment, which delivered on the one hand an initially critical system at the lowest allowed average fuel temperature. On the other hand, this arrangement had to deliver a maximum keff of 1.006 at the point of highest criticality, see Figure 3. The given amount of criticality increase could be compensated by the given allowed average fuel temperature increase combined with the calculated feedback effect given in Table 2. The initial criticality of the different iteration steps and the initial enrichments are given in Table 3 assuming that the system is critical within an uncertainty of max. ±20 pcm, which seemed to be sufficient for this kind of study.

Table 3.

Data (initial criticality and required uranium 235 enrichment) for the dimensional iteration for the averaged fuel temperature of 930 K for the close to eutectic system.

The single peak shaped burnup curve for the different iteration steps demonstrated that with increasing dimension of the system, the final target value of a keff max of 1.006 was achieved for the system with a radius of 213 cm in the applied two-dimensional model. This did not mean a real dimension of the system, since the leakage in the third dimension was not accounted for and therefore, a real system would be slightly larger. However, the approach demonstrated the feasibility of achieving the given boundary conditions.

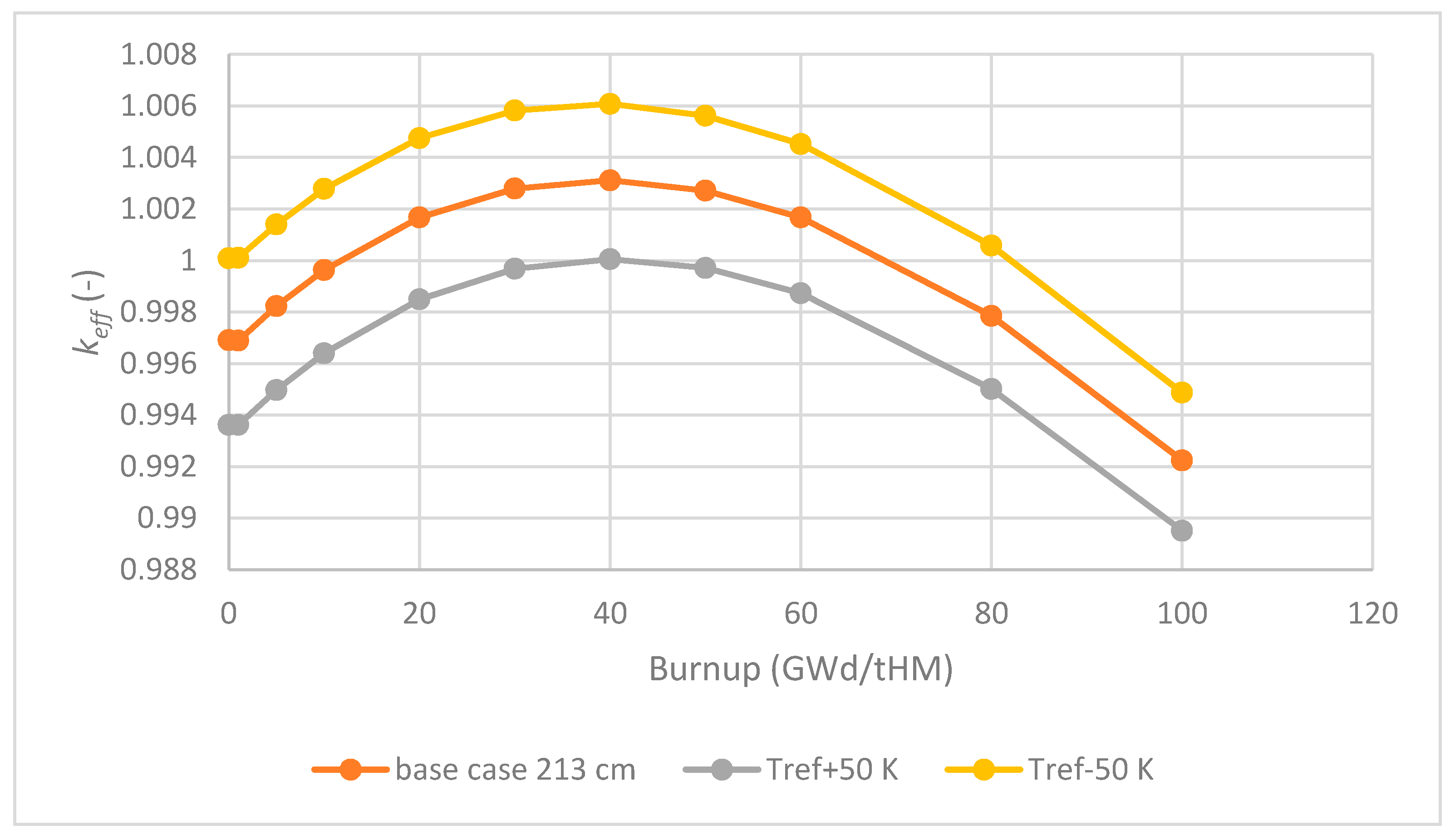

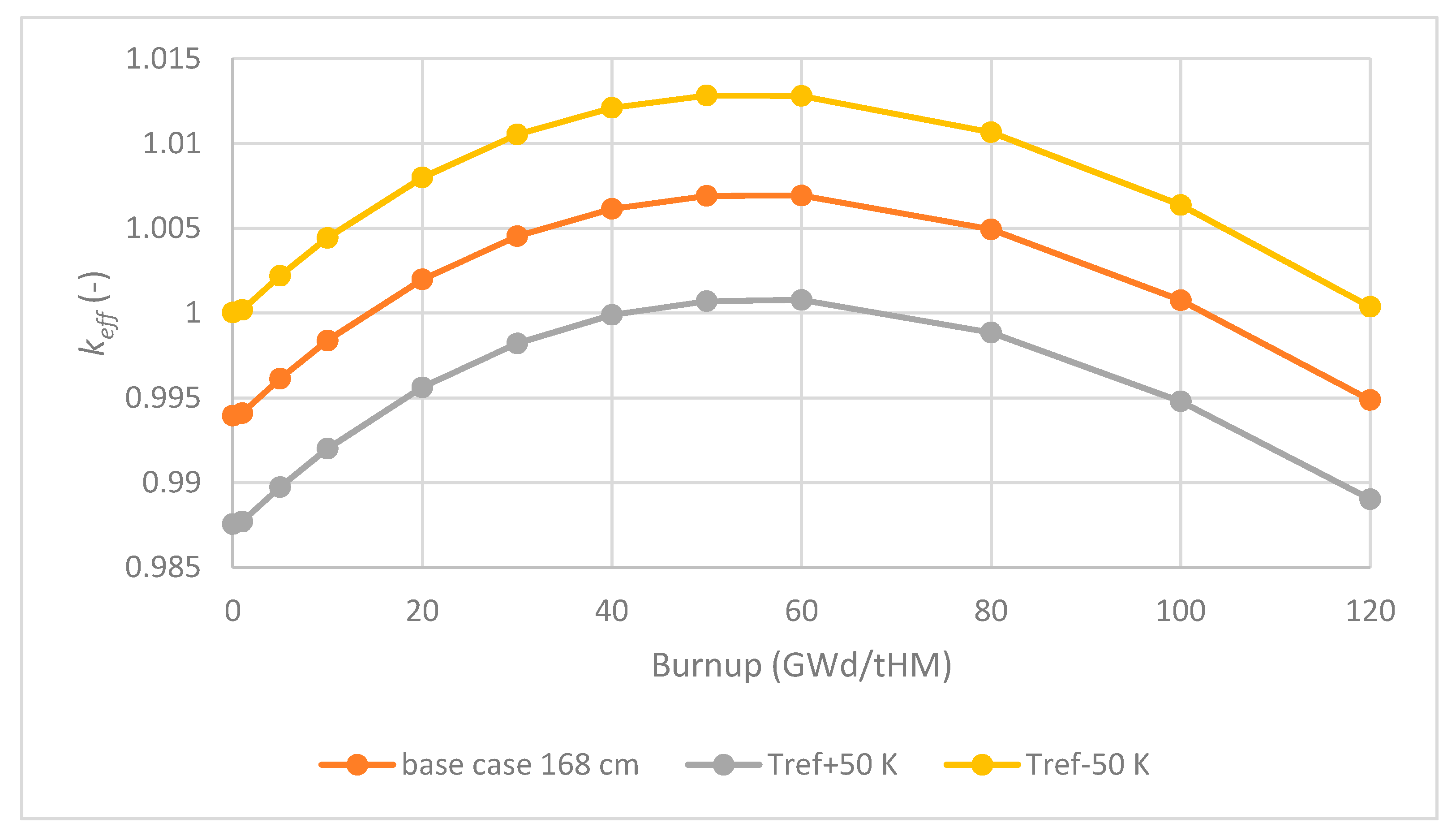

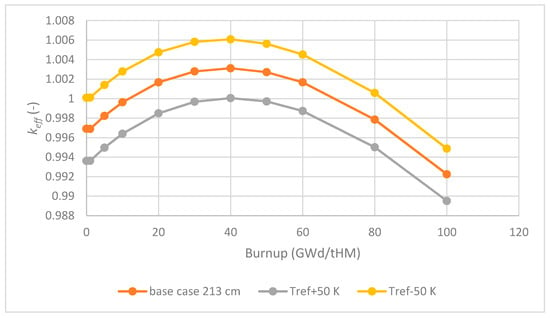

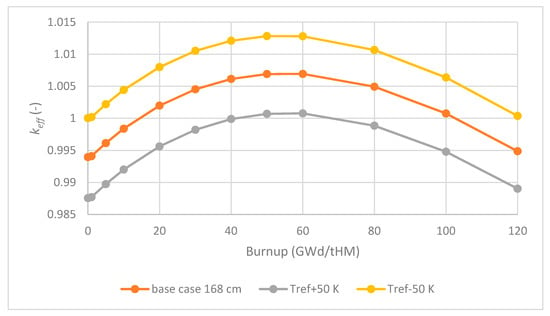

The following step demonstrated that the first guess of the allowable reactivity maxima was acceptable. Thus, a new set of calculations with different temperatures (reference temperature 980 ± 50 K) was performed to assure that the maximum criticality could be compensated by the temperature change. Figure 4 indicates that the maximum keff stayed below 1 at the point of maximum criticality and at an operational averaged fuel temperature of 1030 K. There was still a conservative margin in the approximation since in general the breeding process was slightly more efficient at higher temperatures and the whole burnup curve was calculated based on the highest average fuel temperature. By estimating that the normalization of the fission source on keff (creating a small number of artificial neutrons when k was lower than one) did not cause a major influence on the breeding performance since the system was very close to criticality over the whole operational period.

Figure 4.

Criticality of the 2D system over burnup for the nominal case with 980 K and cases with reduced and increased system temperature for the close to eutectic composition 45%NaCl-38.5%UCl4-16.5%UCl3.

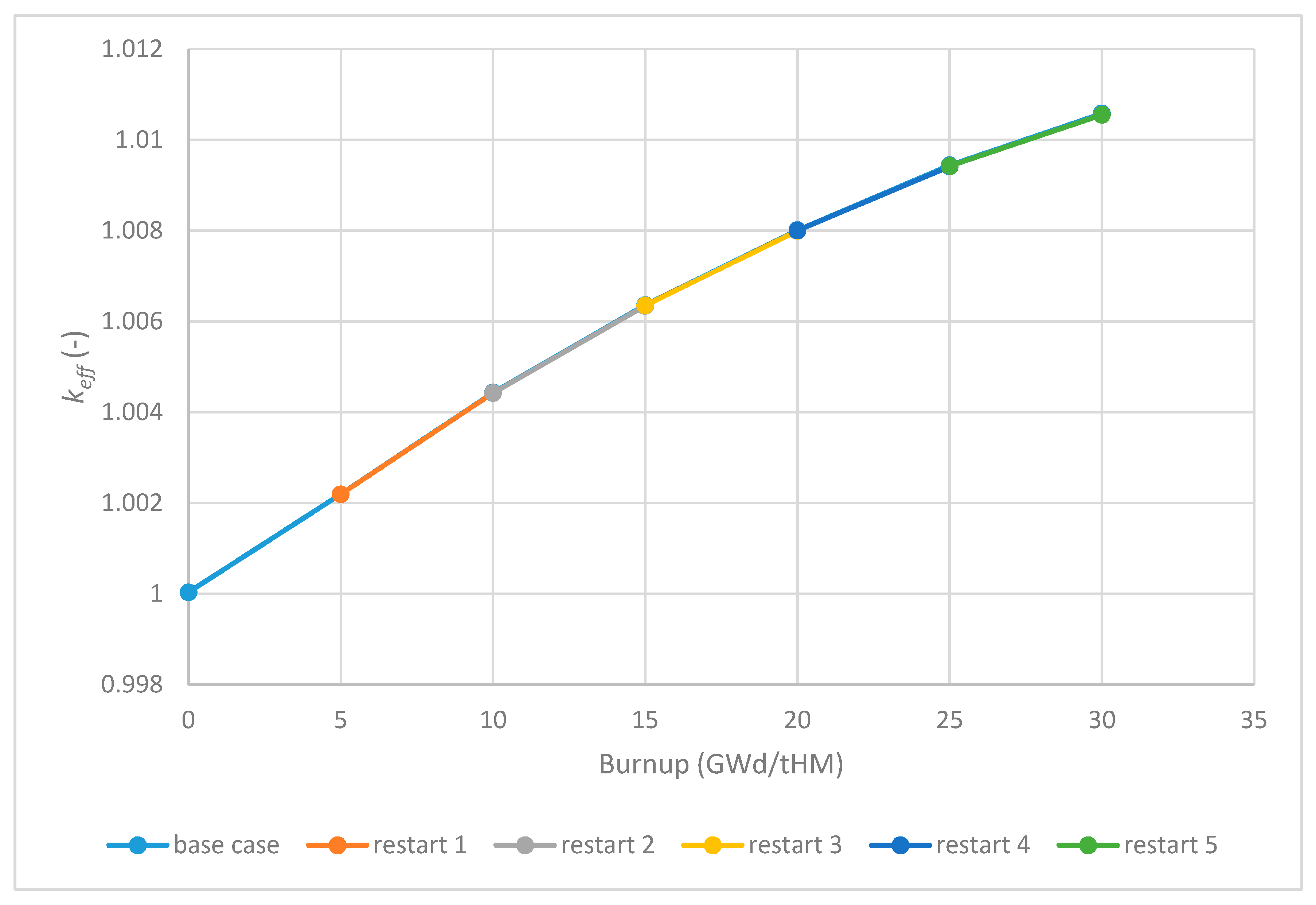

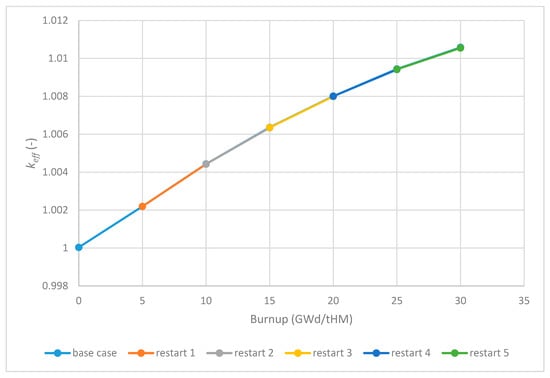

The next, much more demanding step was to deliver a dynamic calculation using temperature changes and to observe the system criticality, which should stay in a very narrow iterative band, in our case ±100 pcm from unity. A first, preparatory step was to analyse the number of isotopes, which had to be conserved when changing from one calculation based on one average fuel temperature to the next. Figure 5 shows the chosen test case of 142 isotopes (max deviation in the first step −1 pcm), after achieving unsatisfactory results for cases with 40 and 80 isotopes (max deviation in the first step +80 pcm and +6 pcm, respectively) observed. In the 142 isotope case the maximum deviation between the continuous run and the step procedure copying and restarting the code with the recovered isotope set was in the maximum 3 pcm at the beginning and end of the calculation step after a burnup of 30 GWd/tHM, see Figure 5. Based on this result the decision was made that 142 isotopes would deliver a sufficiently good result for the next step heavily relying on restarting the calculation scheme with different temperature and density settings. An evaluation over a longer period of burnup would be desirable, but it has to be kept in mind that there is a burnup distribution arising from the calculation, which will have an impact on the results, while in the stepwise approach all materials are redistributed with every restart. Thus, the comparison up to 30 GWd/tHM seems to be a good compromise. The system was modelled in the steady state mode, thus the precursors of the delayed neutrons were not explicitly considered.

Figure 5.

Criticality versus burnup evaluation of the base case and the case with 142 isotopes tracked during the restart to assure a reliable restart of the calculation.

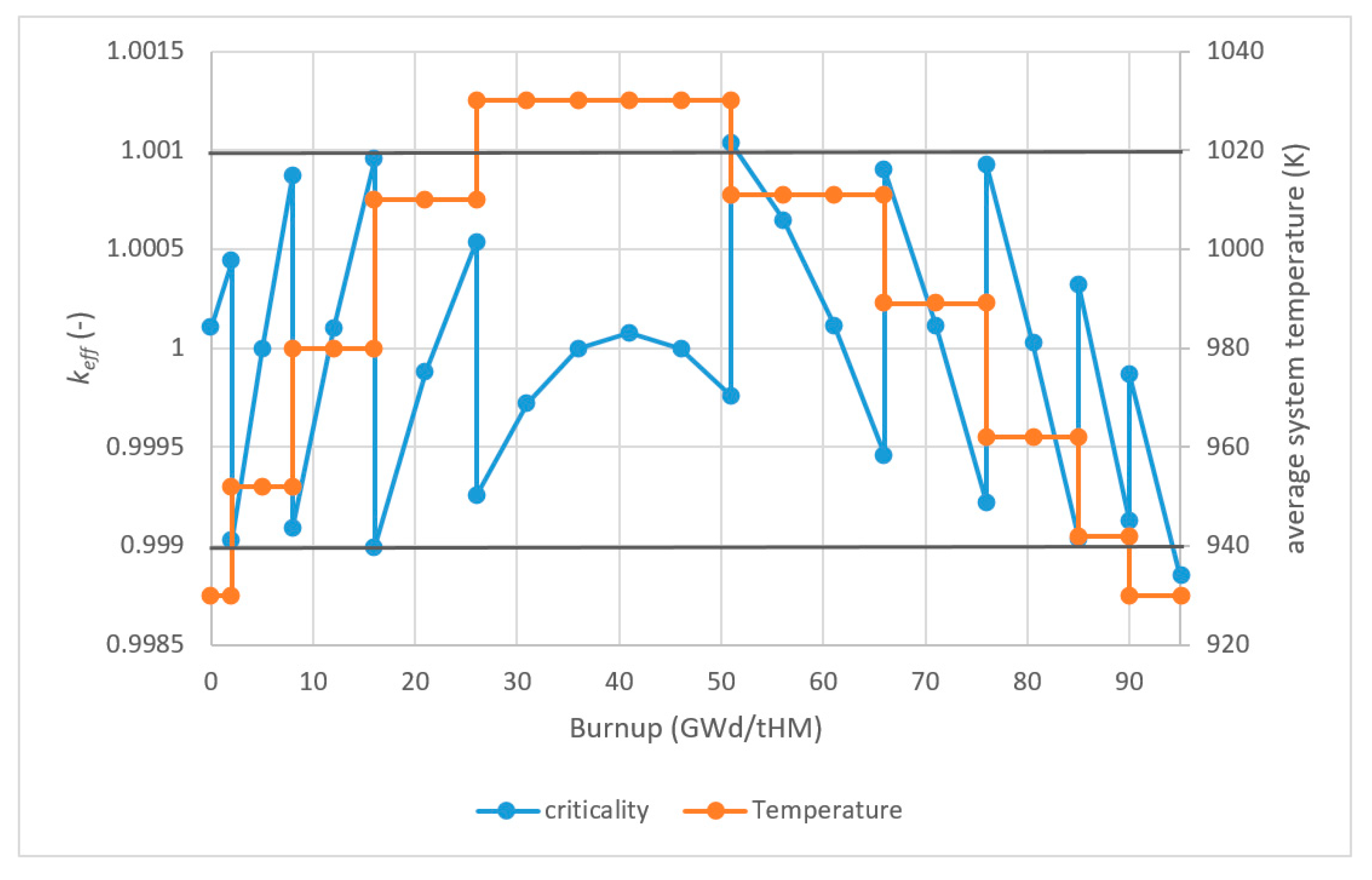

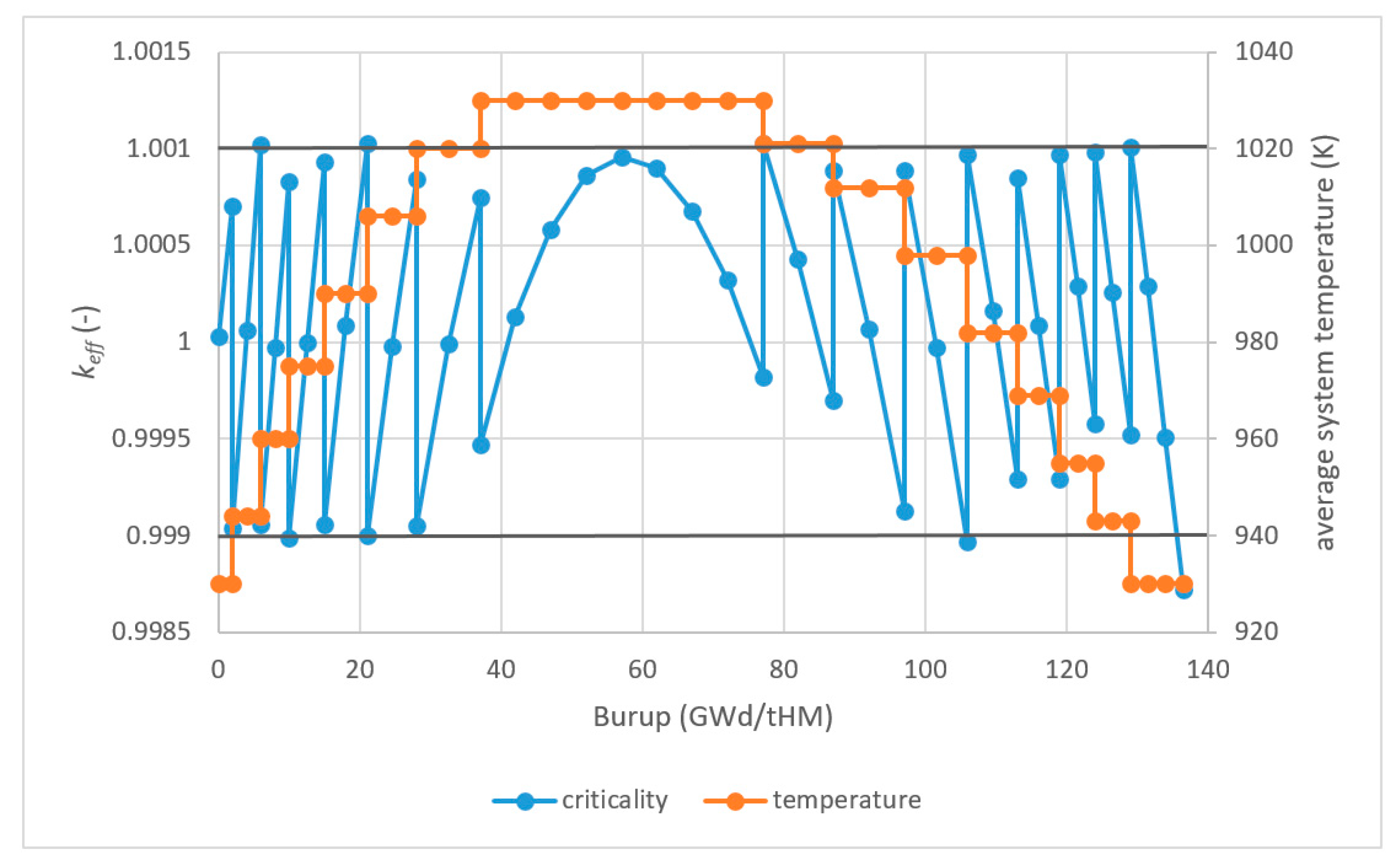

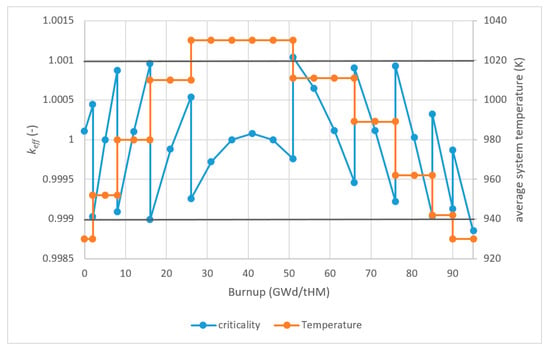

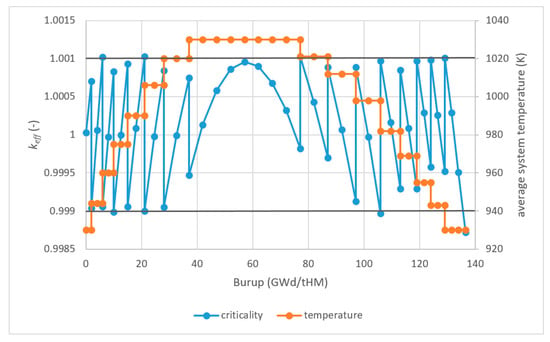

After clarifying the reliability of the procedure to reset every calculation with the printed-out number of isotopes and using the density over temperature curve based on the data in Table 1, a first temperature dependent calculation is given in Figure 6. The objective of the set of calculations was to keep the system criticality through the whole burnup period in the very narrow band of ±100 pcm. This was achieved through a set of temperature changes in the band of ±50 K. The initial calculation started with an average system temperature of 930 K and delivered an initial criticality value of keff = 1.00011. The next calculations were delivered with burnup steps between 2 and 5 GWd/tHM and every time the system criticality left the band of ±100 pcm, the system temperature was changed. The system temperature was increased in the first half when the criticality was increased over the upper limit while the temperature decreased in the second half every time the system criticality decreased below the lower limit. While the system criticality during the whole process was kept within the limits, the system temperature and the correlated material density (based on Table 1 and Equation (1)) changed from the lower limit of 930 K to the upper limit of 1030 K and decreased back to the lower limit of 930 K, see the orange temperature curve in Figure 6. Even if this result was a very rough approximation, the given result demonstrated that it would be possible to compensate the criticality curve by a system temperature change. In the given case this would work for a burnup up to 90 GWd/tHM. In these calculations the real temperature change was used, thus the correct composition dependent feedback effect due to the density change of the fuel and the coolant would be considered instead of the initial guess used for the determination of the system dimension.

Figure 6.

Criticality over burnup for the temperature varied system with the criticality given on the left axis and the system averaged temperature on the right axis for the close to eutectic system.

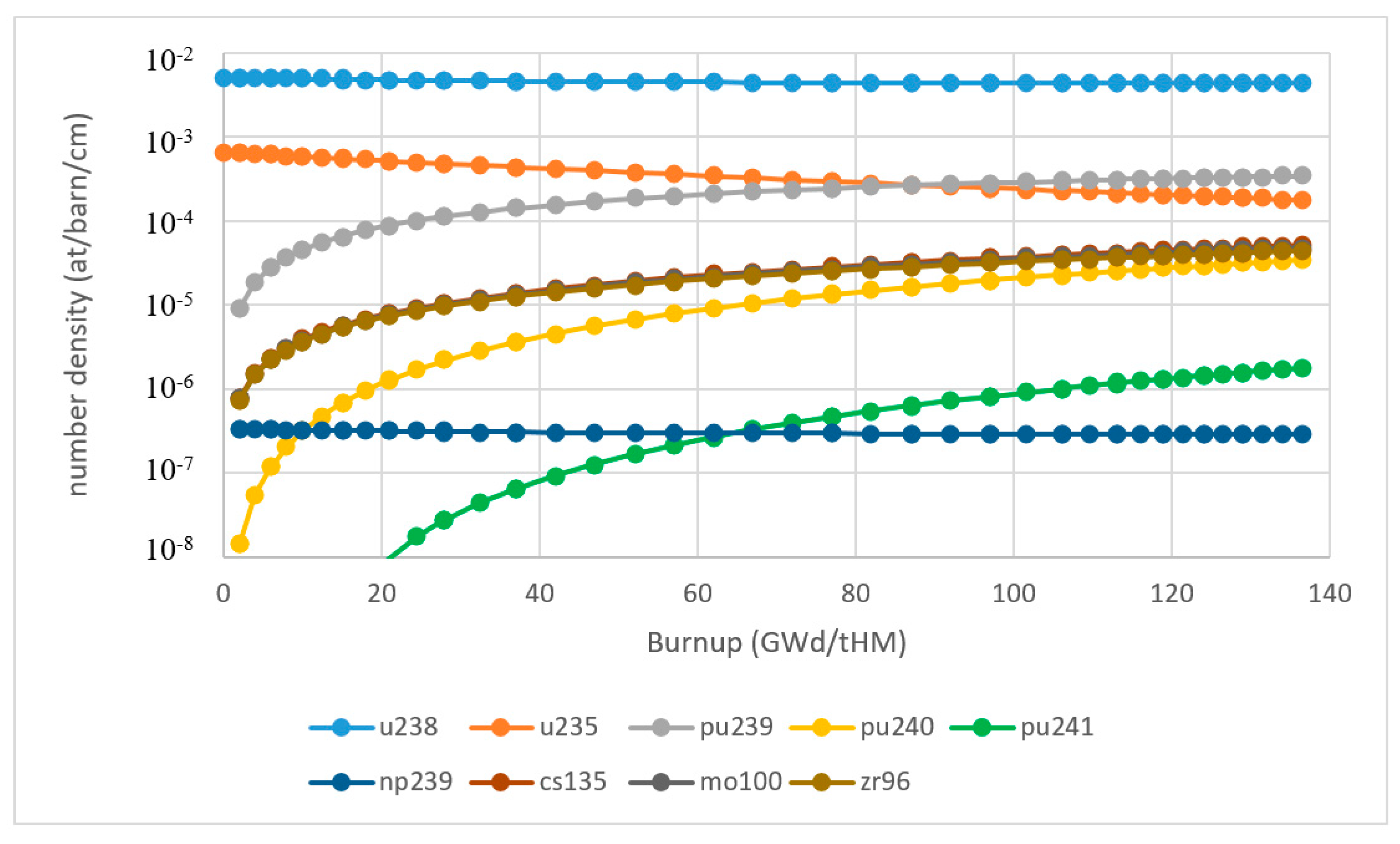

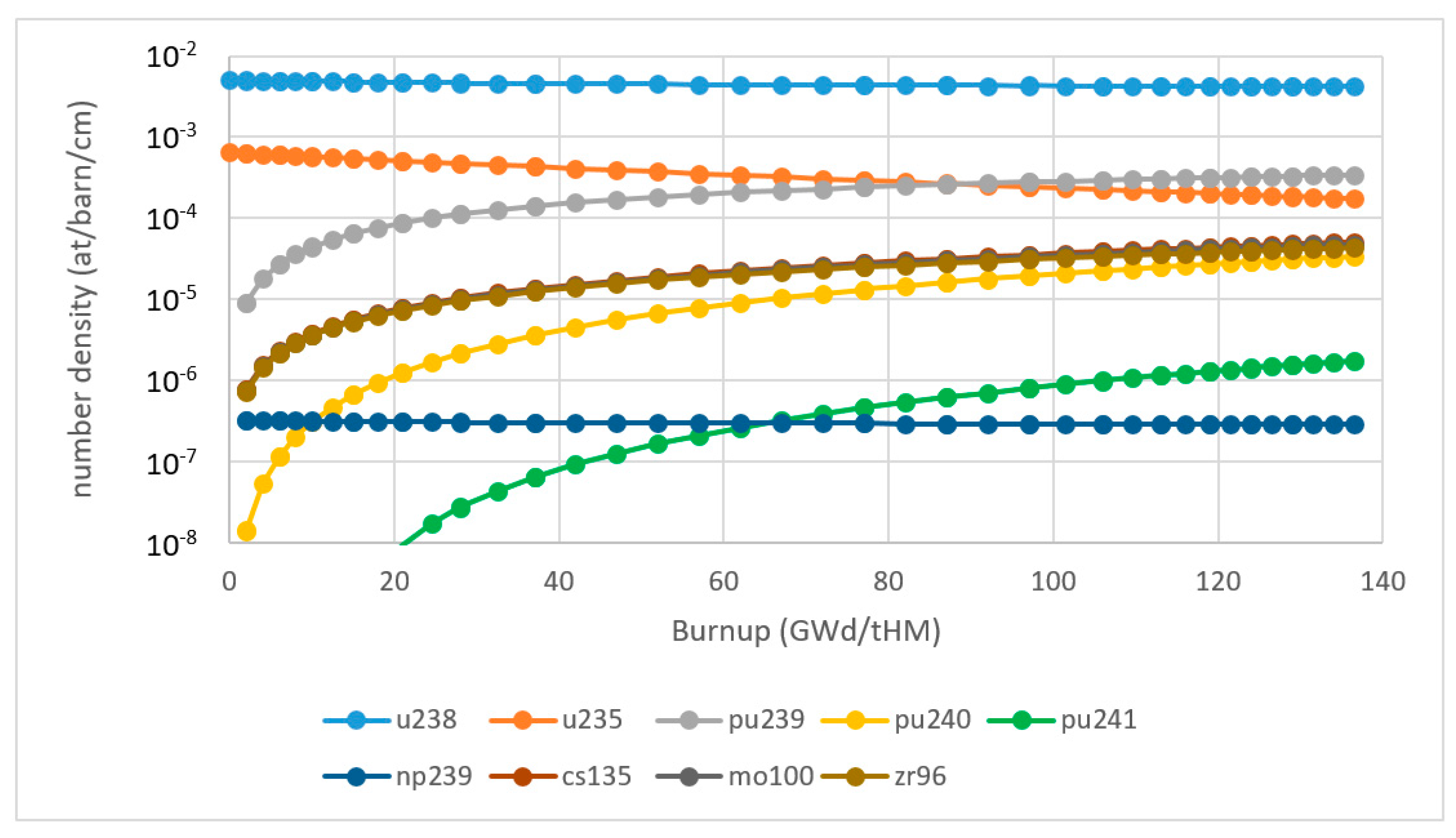

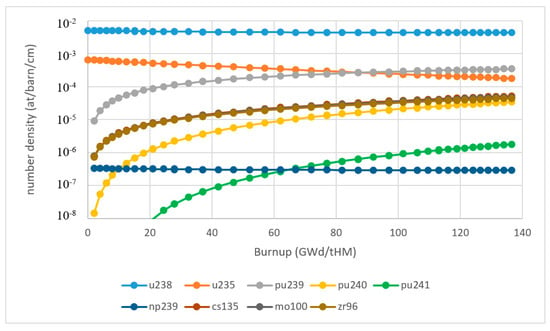

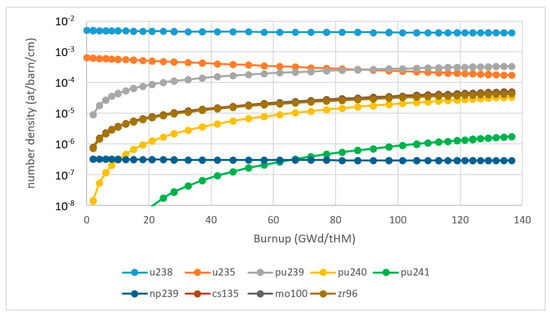

The evolution for selected fissile materials (U-235, Pu-239 and Pu-241), fertile materials (U-238 and Pu-240), the precursor for Pu-239 (Np-239) and selected fission products is given in Figure 7. The decrease of the leading initial fissile material U-235 was compensated by the build up of Pu-239 and later Pu-241 in addition. The Pu-239 content was reaching an almost asymptotic value between 80 and 100 GWd/tHM, which caused the mentioned change in the burnup behaviour, which was characterized in the first half by the dominating effect of the plutonium breeding and in the second half by the accumulation of the highly absorbing fission products. At about 90 GWd/tHM the leading fissile material was changing from U-235 to Pu-239, see the crossing of the curves. The Np-239 precursor for the Pu-239 breeding was almost constant through the whole burnup period, while the selected fission products accumulated almost at an identical rate with increasing burnup. In a real, operating molten salt reactor as proposed in iMAGINE, some of these fission products, with priority to the ones causing the highest reduction in criticality, would be those given in [14]. For any kind of long-term operation, all solubility issues have to be taken into account, which will in the long term require an additional process to reduce the absolute amount of fission products in the reactor.

Figure 7.

Composition changes over burnup for major fissile, fertile isotopes and fission products over burnup for the temperature varied system with the criticality given on the left axis and the system averaged temperature on the right axis for the close to eutectic system.

The given artificial approximation (stepwise modelling of a transient process) based on a lattice calculation without feedback effects was provided for demonstration. In a real molten salt reactor system this process will happen inherently since the system will stay critical over the whole time period due to the inherent feedback effect, thus the jumps given here will not appear. The real reactor behaviour will follow a smooth temperature change, which will affect the criticality in the same smooth way not allowing the reactor to deviate from the critical state. The results demonstrate the very strong feedback effect, which will allow for burnup compensation and very favourable load following behaviour. The changes in the energy demand to be delivered into the net as asked for by the network demand planning will be reflected in a change in the energy removal through the heat exchanger. Reduced energy demand will lead to an increased inlet temperature in the reactor, which will increase the average system temperature, which will imply a negative feedback and will thus lead to a reduced power production adopting the reactor power to the reduced demand. However, to show this process in detail another model will be required, which has to be able to take the heat exchanger and the system temperature changes directly into account. These are processes that typically cannot be directly accounted for in a lattice type calculation like those applied here.

4.2. Enhanced Breeding Case

To achieve improved breeding, it would be of interest to increase the amount of fertile material in the reactor core. To create a deeper understanding a second case was investigated with a higher content of fissile and fertile material based on a composition of 20%NaCl-56.35%UCl4-23.65%UCl3. The increased amount of heavy metal led to an about 100 to 150 K higher melting point of the salt. In a real reactor operation, this would have to be considered when deciding the lower temperature level of the system to assure a sufficient margin to solidification.

The initial determination of the feedback effect for the lower temperature limit 930 K and the upper temperature limit 1030 K is given in Table 4. Based on the given results the initial guess for the feedback effect was −13 pcm/K. The reduction of the carrier salt component from 45% to 20% in the heavy metal rich composition had obviously not only led to a significant reduction of the system size from 210 to 160 cm due to the higher density of the salt and the higher load of heavy metal, but also to a strong increase of the feedback effect for −6.5 to −13 pcm/K, mainly based on the much higher amount of heavy metal in the system, which increased the sensitivity of the system to density changes. Both effects, a stronger feedback and reduced core size would be very favourable from reactor design point of view, however, the drawback will be the already mentioned required increase of the lower temperature limit.

Table 4.

Initial steady state calculations and determination of the feedback effect for the heavy metal rich system with a radius of 160 cm.

This first guess is leading to the conservative approximation of a compensation potential of maximum 1300 pcm at the envisaged average temperature change of 100 K without considering the effect of the operational temperature on the burnup/breeding behaviour.

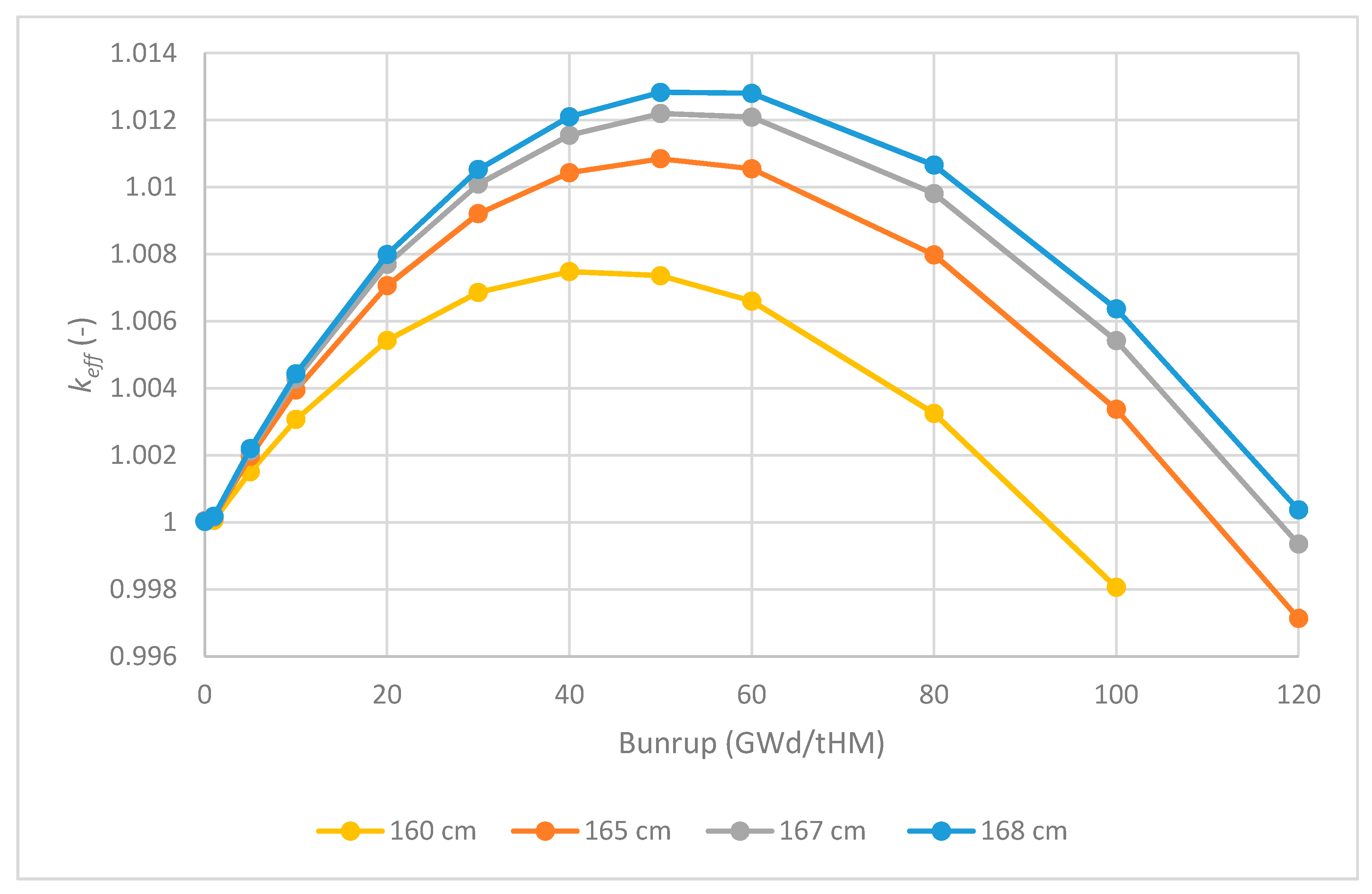

Based on these boundary conditions the system size for this changed system was iterated with an enrichment, which delivered on the one hand an initially critical system at the lowest allowed average fuel temperature, in our case 930 K. On the other hand, this arrangement has to deliver a maximum keff of 1.013 at the point of highest criticality in the same case as in the approach given above, see maximum criticality in Figure 8. The given amount of criticality increase was expected to be possible to be compensated by the allowed average fuel temperature increase by 100 K combined with the calculated feedback effect given in Table 4. The initial criticality of the different iteration steps in system size and the therefore required initial enrichments are given in Table 5, assuming that the system was critical within an acceptable uncertainty of ±20 pcm. From the criticality over burnup curve given in Figure 8, it became obvious that a significantly higher target burnup would be achievable (compare the crossing of the curves with the unity line between Figure 8, 120 GWd/tHM with Figure 3, 80 GWd/tHM) in the system with the reduced carrier material content in the heavy metal rich system.

Figure 8.

Criticality of the 2D system over burnup for different system radii for the heavy metal rich composition 20%NaCl-56.35%UCl4-23.65%UCl3.

Table 5.

Data (initial criticality and required uranium 235 enrichment) for the dimensional iteration for the averaged fuel temperature of 930 K for the heavy metal rich system.

The following step had to demonstrate that the first guess of the allowable reactivity maxima was acceptable. Thus, a new set of calculations on different temperatures (reference temperature 980 ± 50 K) was performed for the heavy metal rich system with only 20% NaCl to assure that the maximum criticality could be compensated for by the temperature change. Figure 9 indicates that the maximum keff stayed very close to 1 (keff = 1.00077) at the point of maximum criticality and at an operational averaged fuel temperature of 1030 K, which should be acceptable due to the conservative margin in the approximation relying on the breeding process being slightly more efficient at higher temperatures.

Figure 9.

Criticality of the 2D system over burnup for the nominal case with 980 K and cases with reduced and increased system temperature for the heavy metal rich composition 20%NaCl-56.35%UCl4-23.65%UCl3.

The first temperature dependent calculation for the heavy metal rich system is given in Figure 10. The set of calculations aimed to keep the system criticality through the whole burnup period in the very narrow band of approximately ±100 pcm. This was achieved through a set of temperature changes in the band of ±50 K.

Figure 10.

Criticality over burnup for the temperature varied system with the criticality given on the left axis and the system averaged temperature on the right axis for the heavy metal rich system.

The initial calculation started with an average system temperature of 930 K and delivered an initial criticality value of keff = 1.00003. The calculations were delivered with burnup steps between 2 and 5 GWd/tHM and every time the system criticality left the band of ±100 pcm, the system temperature was adapted accordingly.

The system temperature again increased in the first half when the criticality was increased over the upper limit. While the temperature decreased in the second half every time the system criticality decreased below the lower limit.

When the system criticality during the whole process was kept within the limits, the system temperature increased from the lower limit of 930 K to the upper limit of 1030 K and it then decreased back to the lower limit of 930 K, see the orange temperature curve in Figure 10. Even if this result was a very rough approximation, the given result demonstrated that it would be possible to compensate the criticality curve by a system temperature change. In the given heavy metal rich composition, the achievable target burnup was around 136 GWd/tHM and thus more than 50% higher than the systems, which were close to the eutectic composition. The significantly higher achievable burnup had some consequences on the material compositions, too (see Figure 11). The evolution of the curves was almost the same, but due to the extended operation to achieve the higher burnup and thus the higher amount of energy produced, the system achieved a composition closer to an equilibrium composition of a molten salt reactor that had run on a long term basis. The final amount for the fission products (Cs-135, Mo-100 and Zr-96) increased by 70%, U-235 was reduced by 22% and U-238 by 15% while the Pu-239 content increased by 37%, and the higher Pu isotopes were still accumulating at a rather rapid rate with increasing mass number (Pu-240 +79%, Pu-241 +118% and Pu-242 +298%).

Figure 11.

Composition changes over burnup for major fissile, fertile isotopes and fission products for the temperature varied system with the criticality given on the left axis and the system averaged temperature on the right axis for the heavy metal rich system.

5. Conclusions and Outlook

In nuclear technology, molten salt reactors have gained growing interest since they offer a game-changing approach for the future of nuclear energy production. However, the key for making nuclear energy an attractive, highly sustainable option for a net-zero society would be to operate these reactors in a closed fuel cycle mode providing sufficient breeding for a self-sustained long-term operation. The reactors should ideally run on spent nuclear fuel from existing reactors, while being able to be controlled ideally by inherent physical feedback processes.

To achieve these very attractive goals, two basic challenges were already identified and worked on; the demonstration of sufficient breeding in a molten salt system and the development of a demand driven salt clean up system. The aim of this publication was to investigate the opportunities for innovative reactor control based on inherent feedback mechanisms over a very wide range of operational parameters. Firstly, we must identify data sources for a molten salt system with a high solubility for the fertile component providing the required density over temperature data for the study. This was successful, identifying a new data source providing density over temperature data for the system NaCl-UCl3-UCl4 in a temperature range between 900 and 1050 K. Secondly, a simulation approach was developed and demonstrated to integrate this information into a process that was able to simulate the thermal feedback within a lattice code based simulation, which ran using the SCALE/POLARIS code system. Both points were essential to demonstrate the opportunity of controlling the reactor based on the often pointed out strong thermal feedback effects, which are typical for molten salt reactors with their unity of fuel and coolant.

It was demonstrated that the investigated sodium chloride-uranium chloride-based systems could feasibly deliver a thermal feedback effect, which was sufficiently strong, −6.5 pcm/K, to promise a reliable feedback during operation. In a long-term burnup study the feasibility of compensating the critically change due to breeding and fission product accumulation by the thermal feedback within a given range of 100 K temperature changed for up to 90 GWd/tHM for being close to the eutectic system. The additional investigation of a heavy metal rich system showed an even stronger feedback (−13 pcm/K) and thus it was able to compensate the reactivity changes up to 130 GWd/tHM with the given reactor temperature change of 100 K; however, this had a drawback of a 100–150 K higher melting point, which would then require an increase in the limit of the lower operating temperature by about this amount.

The achieved results gave a very positive outlook on the opportunity to use system inherent mechanisms for reactor control via negative feedback effects and even for the feasibility of a load following operation mainly based on inherent feedback effects instead of massive manual/automated control system operation as in current reactor systems. However, deeper investigation of reactor control and load following will require a new approach in modelling and simulation with more adequate tools that can tackle the multidisciplinary challenges of the interaction between reactor operation, breeding, fission product accumulation and reactivity changes due to temperature changes in the reactor. These effects tend to keep the reactor critical by developing a dynamic interplay between fissile material content/core criticality and fuel temperatures/power production, which could in addition be a promising approach for future autonomous operating systems. However, a sensitive balance has to be found due to the cost of the components, which will increase for systems designed for higher operational temperature, which in turn requires an interplay between the temperature control as a fast acting limitation system and the optimization of the online feeding stream in a real molten salt reactor.

Author Contributions

Conceptualization, B.M.; Data curation, A.D., S.A. and G.C.-G.; Investigation, B.M. and A.D.; Methodology, B.M., D.L. and G.C.-G.; Software, A.D. and S.A.; Supervision, B.M.; Validation, D.L. and G.C.-G.; Visualization, A.D. and D.L.; Writing—original draft, B.M.; Writing—review & editing, D.L., S.A. and G.C.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. The APC was funded by the library of The University of Liverpool.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Molten Salt Reactors, IAEA. Available online: https://www.iaea.org/topics/molten-salt-reactors (accessed on 9 January 2019).

- Advances in Small Modular Reactor Technology Developments A Supplement to: IAEA Advanced Reactors Information System (ARIS) 2016 Edition. Available online: https://aris.iaea.org/Publications/SMR-Book_2016.pdf (accessed on 9 January 2019).

- Ignatiev, V.; Feynberg, O.; Merzlyakov, A.; Surenkov, A.; Zagnitk, A. Progress in development of MOSART concept with Th support. In Proceedings of the ICAPP2012, Paper 12394, Chicago, IL, USA, 24–28 June 2012. [Google Scholar]

- Evaluation and Viability of Liquid Fuel Fast Reactor System. Available online: https://cordis.europa.eu/project/rcn/97054/reporting/en (accessed on 9 January 2019).

- Ignatiev, V.; Feynberg, O.; Gnidoi, I.; Konakov, S.; Kormilitsyn, M.; Merzliakov, A.; Surenkov, A.; Uglov, V.; Zagnitko, A. MARS: Story on Molten Salt Actinide Recycler and Transmuter Development by Rosatom in Co-Operation with Euratom (NEA-NSC-R--2015-2); Nuclear Energy Agency of the OECD (NEA): Paris, France, 2015. [Google Scholar]

- A Paradigm Shift in Reactor Safety with the Molten Salt Fast Reactor. Available online: https://cordis.europa.eu/project/rcn/196909/factsheet/en (accessed on 9 January 2019).

- Severe Accident Modeling and Safety Assessment for Fluid-fuel Energy Reactors. Available online: https://cordis.europa.eu/project/id/847527 (accessed on 1 April 2020).

- Merk, B.; Stanculescu, A.; Chellapandi, P.; Hill, R. Progress in reliability of fast reactor operation and new trends to increased inherent safety. Appl. Energy 2015, 147, 104–116. [Google Scholar] [CrossRef]

- Merk, B.; Litskevich, D.; Whittle, K.R.; Bankhead, M.; Taylor, R.; Mathers, D. On a Long Term Strategy for the Success of Nuclear Power. Energies 2017, 10, 867. [Google Scholar] [CrossRef]

- Merk, B.; Litskevich, D.; Bankhead, M.; Taylor, R. An innovative way of thinking Nuclear Waste Management—Neutron physics of a reactor directly operating on SNF. PLoS ONE 2017, 12, e0180703. [Google Scholar] [CrossRef] [PubMed]

- Merk, B.; Litskevich, D.; Peakman, A.; Bankhead, M. The Current Status of Partitioning & Transmutation and How to Develop a Vision for Nuclear Waste Management. ATW Int. J. Nucl. Power 2019, 64, 261–266. Available online: https://www.yumpu.com/en/document/view/62643225/atw-international-journal-for-nuclear-power-052019 (accessed on 1 April 2020).

- Merk, B.; Litskevich, D.; Peakman, A.; Bankhead, M. iMAGINE—A disruptive change to nuclear or how can we make more out of the existing spent nuclear fuel and what has to be done to make it possible in the UK? ATW Int. J. Nucl. Power 2019, 64, 353–359. Available online: https://www.yumpu.com/en/document/view/62740120/atw-international-journal-for-nuclear-power-06-072019 (accessed on 1 April 2020).

- Merk, B.; Detkina, A.; Atkinson, S.; Litskevich, D.; Cartland-Glover, G. Evaluation of the Breeding Performance of a NaCl-UCl-Based Reactor System. Energies 2019, 12, 3853. [Google Scholar] [CrossRef]

- Merk, B.; Litskevich, D.; Gregg, R.; Mount, A.R. Demand driven salt clean-up in a molten salt fast reactor—Defining a priority list. PLoS ONE 2018, 13, e0192020. [Google Scholar] [CrossRef] [PubMed]

- Thoma, R.E. (Ed.) Phase Diagrams of Nuclear Reactor Materials; USA, 1959; Web, doi:10.2172/4234144—Reproduced a phase diagram reported by Kraus, C.A., Phase Diagrams of Some complex salts of uranium with halides of the alkali and alkaline earth metals, US Atomic Energy Commission Report M-251, 1943. Available online: https://www.osti.gov/biblio/4234144 (accessed on 1 April 2020).

- Katyshev, S.; Teslyuk, L. Ionic Melts in Nuclear Power. In Challenges and Solutions in the Russian Energy Sector; Innovation and Discovery in Russian Science and Engineering; Syngellakis, S., Brebbia, C., Eds.; Springer International Publishing: Cham, Germany, 2018. [Google Scholar]

- Desyatnik, V.N.; Katyshev, S.F. Volumetric and surface properties of the NaCl-UCl3-UCl4 melts. Zhurnal Fiz. Khimii 1980, 54, 1606–1610. [Google Scholar]

- Jessee, M.A.; Jarrell, J.J.; Wieselquist, W.A.; Williams, M.L.; Kim, K.S.; Evans, T.M.; Hamilton, S.P.; Gentry, C.A. Polaris—2d Light Water Reactor Lattice Physics Module. In SCALE Code System; Rearden, B.T., Jessee, M.A., Eds.; ORNL/TM-2005/39 Oak Ridge National Laboratory: Oak Ridge, TN, USA, February 2017. [Google Scholar]

- Leppänen, J.; Pusa, M.; Viitanen, T.; Valtavirta, V.; Kaltiaisenaho, T. The Serpent Monte Carlo code: Status, development and applications in 2013. Ann. Nucl. Energy 2015, 82, 142–150. [Google Scholar] [CrossRef]

- Chadwick, M.B.; Herman, M.; Obložinský, P.; Dunn, M.E.; Danon, Y.; Kahler, A.C.; Smith, D.L.; Pritychenko, B.; Arbanas, G.; Arcilla, R.; et al. ENDF/B-VII. 1 Nuclear Data for Science and Technology: Cross Sections, Covariances, Fission Product Yields and Decay Data. Nucl. Data Sheets 2011, 112, 2887–2996. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).