The residential building, its environmental conditions, Heating, Ventilating and Air-Conditioning (HVAC) and energy systems including their operation and inner loads were modelled in transient systems simulation Program; TRNSYS (17, The University of Wisconsin, Madison, Wisconsin, USA). The total floor area of the building is 96 m

2 and the volume is 408 m

3, consisting of three zones in two stories. The structures, indoor climate, heating and ventilation were designed according to The National Building Code of Finland part D2 [

16]. In the simulation, the air change rate for each zone was set to 0.5 L/h throughout the year, without heat recovery. The internal heat loads were scheduled according to the assumed usage of a detached house.

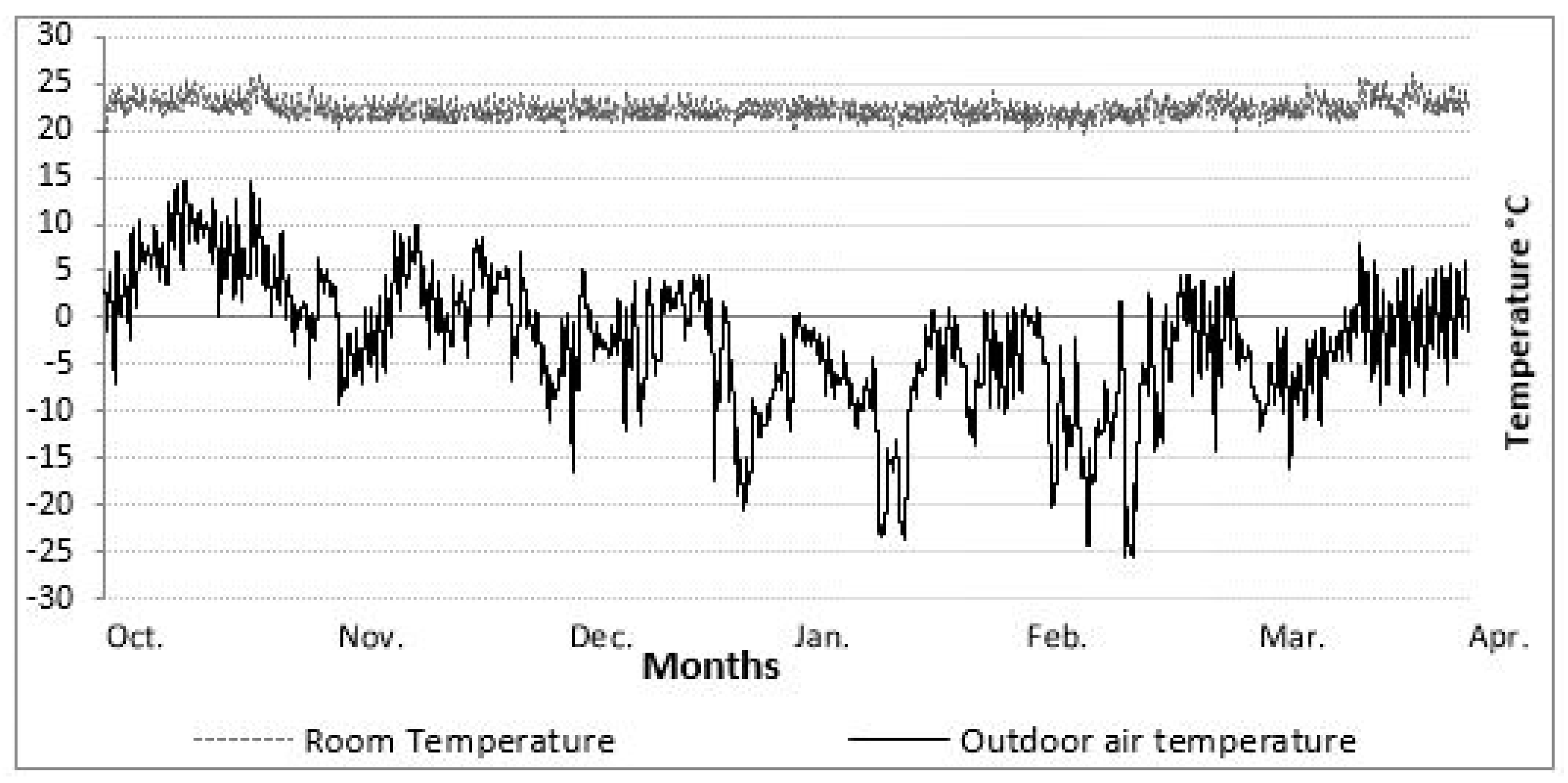

The building was assumed to be in Southern Finland. Therefore, weather data of the Typical Meteorological Year (TMY) from the city of Helsinki were used. Finland is one of the Nordic countries with a cold climate. Finland is divided into four climatic zones. The city of Helsinki is located in zone I, with a design temperature of −26 °C for winters.

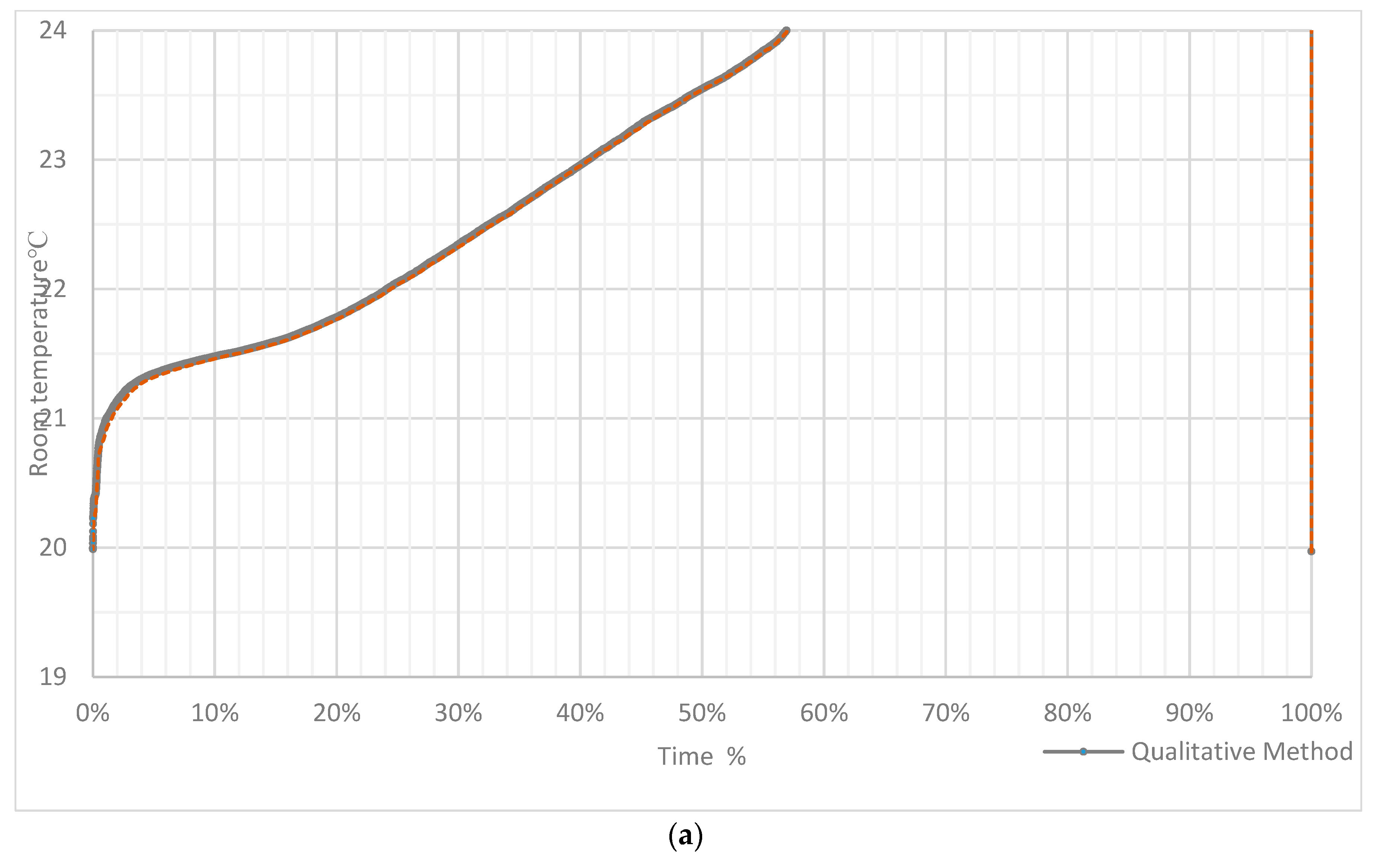

As a result, the total heating energy demand for the space heating and for the domestic hot water was a maximum power of 7.2 kW. The simulation was performed for the entire building, but the space heating system was built only for one zone on the ground floor. Thus, the presented energy demand and the maximum power concerned only the zone. The simulation started at the beginning of the year with the time step set to one minute.

2.1. The Energy Systems

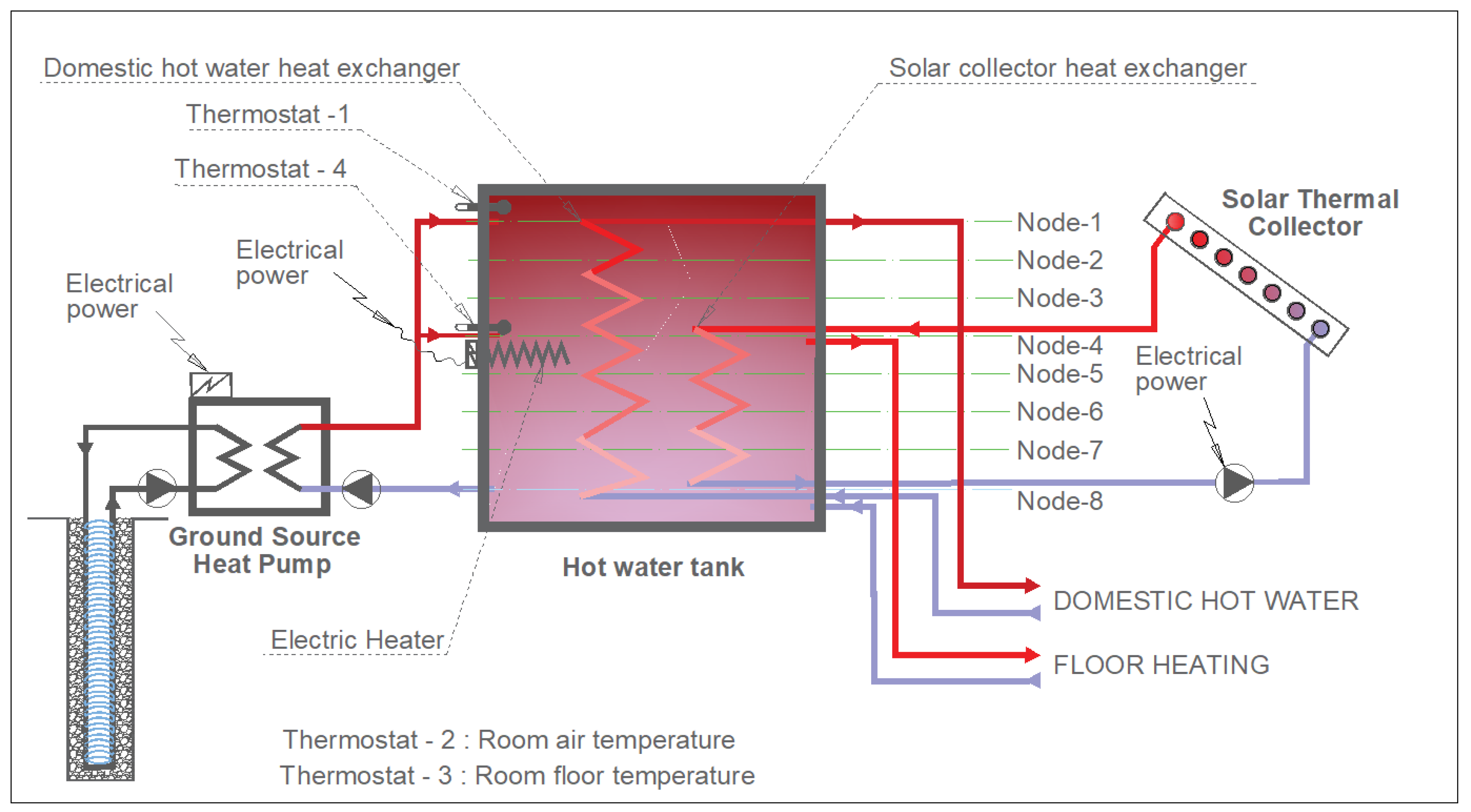

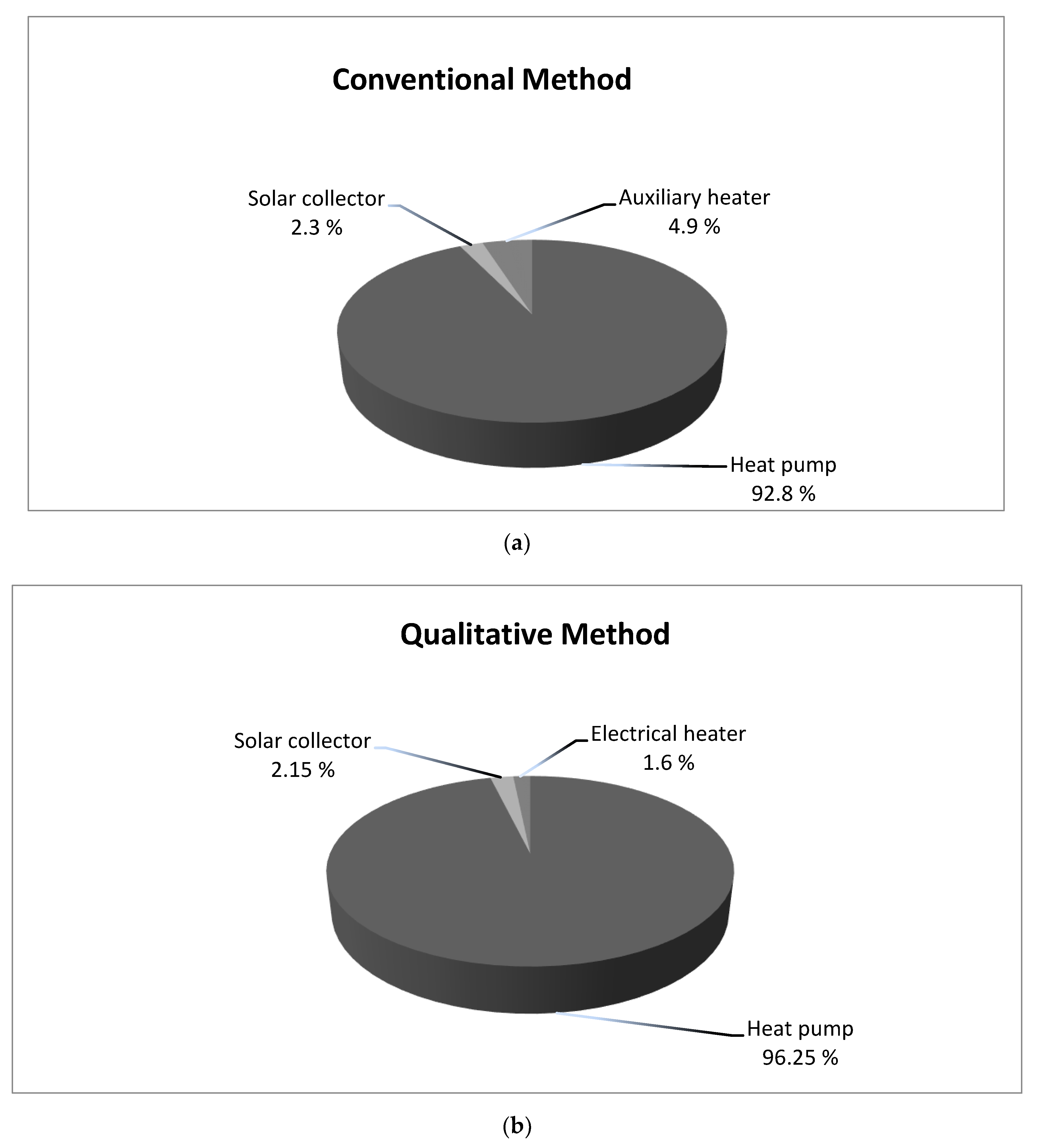

The hybrid energy system consisted of one hot water tank as energy storage and three energy sources, solar collector, geo-thermal heat pump and electrical heater. The hybrid energy systems and the transferring connections are illustrated in

Figure 1. The solar collector’s circuit consisted of three 2.5 m

2 solar collectors, 27 W circulating pump and 30 m piping. The circulating liquid was a water–glycol mixture which was separated from the tank water with a heat exchanger. The maximum heating power of the solar collector was 5 kW.

The geo-thermal heat pump (5.9 kW) consisted of a water-to-water heat pump, load and source side circulating pumps, and a vertical U-tube heat exchanger in the ground operating as a heat source. The borehole was 175 meters deep, where a 35% ethanol–water liquid mixture was circulated in a PolyEthylene Medium (PEM) pipe. The borehole and the building were connected to horizontal pipes (20 m). The properties of the pipes were the same as those in the borehole.

A cylindrical, insulated steel tank of 300 L, installed in a vertical position, served as energy storage. The tank contained input and output connections and inner heat exchangers for domestic hot water and the solar collector. In addition, the tank was equipped with an electrical heater element (5 kW). Due to the stratified water temperature, connections were designed vertically in different elevations (

Figure 1). The horizontal lines of the figure illustrate how the tank was divided into eight equal-sized nodes, starting from the uppermost node in

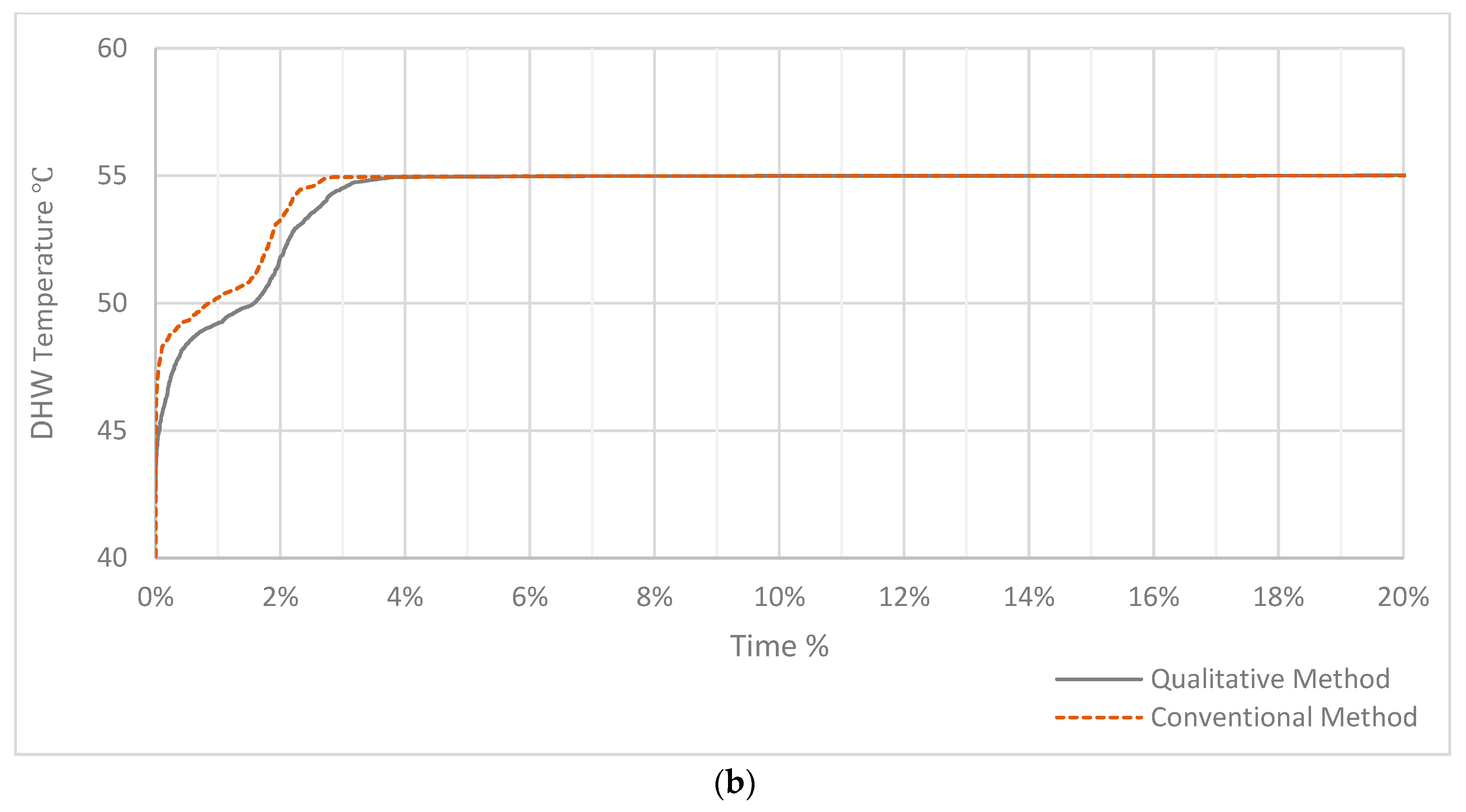

Figure 1. For instance, the domestic hot water output was connected to Node-1, where the output water temperature was kept at 55 °C.

The floor heating consists of a pump-driven circuit supplying water of 40 °C. The maximum power of the space heating is 4 kW. The structure and sizing of the energy systems are pragmatically selected in accordance with common design practices for a single-family house.

2.2. Thermostat Controls

The storage tank, shown in

Figure 1, provided heat both for the floor heating and for the domestic hot water. The set point temperature of the domestic hot water was 55 °C. This was controlled by the thermostat (1), locating in upper part of the tank (Node-1), where the outlet to the domestic hot water was located.

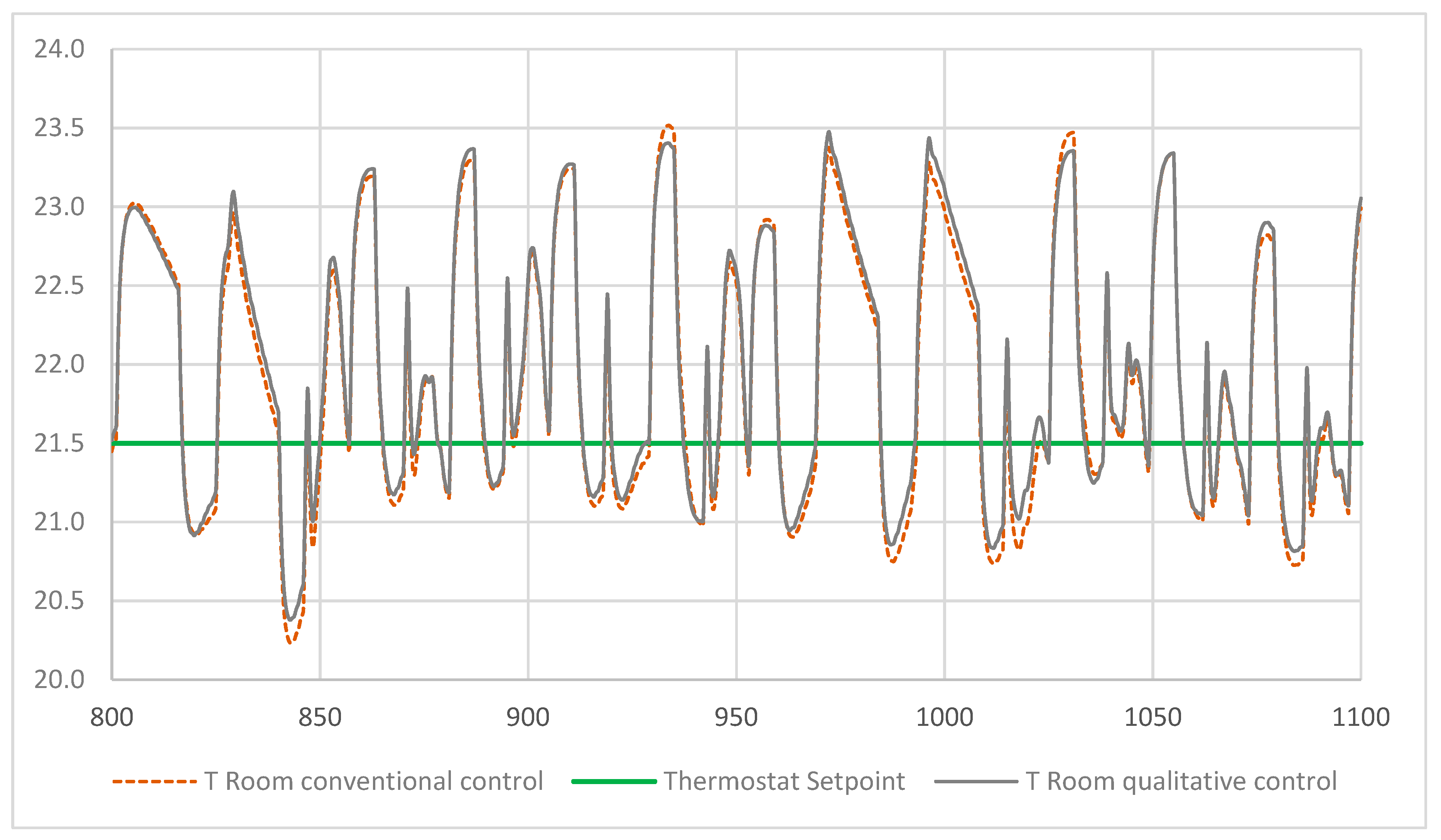

In the simulation, the room temperature was controlled by two thermostats (2) and (3), based on indoor air and floor surface temperatures which were set at 21.5 °C and 29 °C, respectively. If both temperatures dropped below the set points, floor heating circulating pump started. However, the space heating control was independent of the energy systems’ controls.

The heat pump and the electrical heater are connected to a two-stage thermostat (4) installed on Node-4 (

Figure 1). If the Node-4 temperature drops below the setpoint, the heat pump starts. In case, if the node temperature still drops, the electrical heater also turns on. The electrical heater acts mainly as back-up energy generator providing additional heating power during the high demand periods. If the temperature of Node-1 exceeds the upper limit temperature, the heat pump turns off.

The solar collector control (not shown in

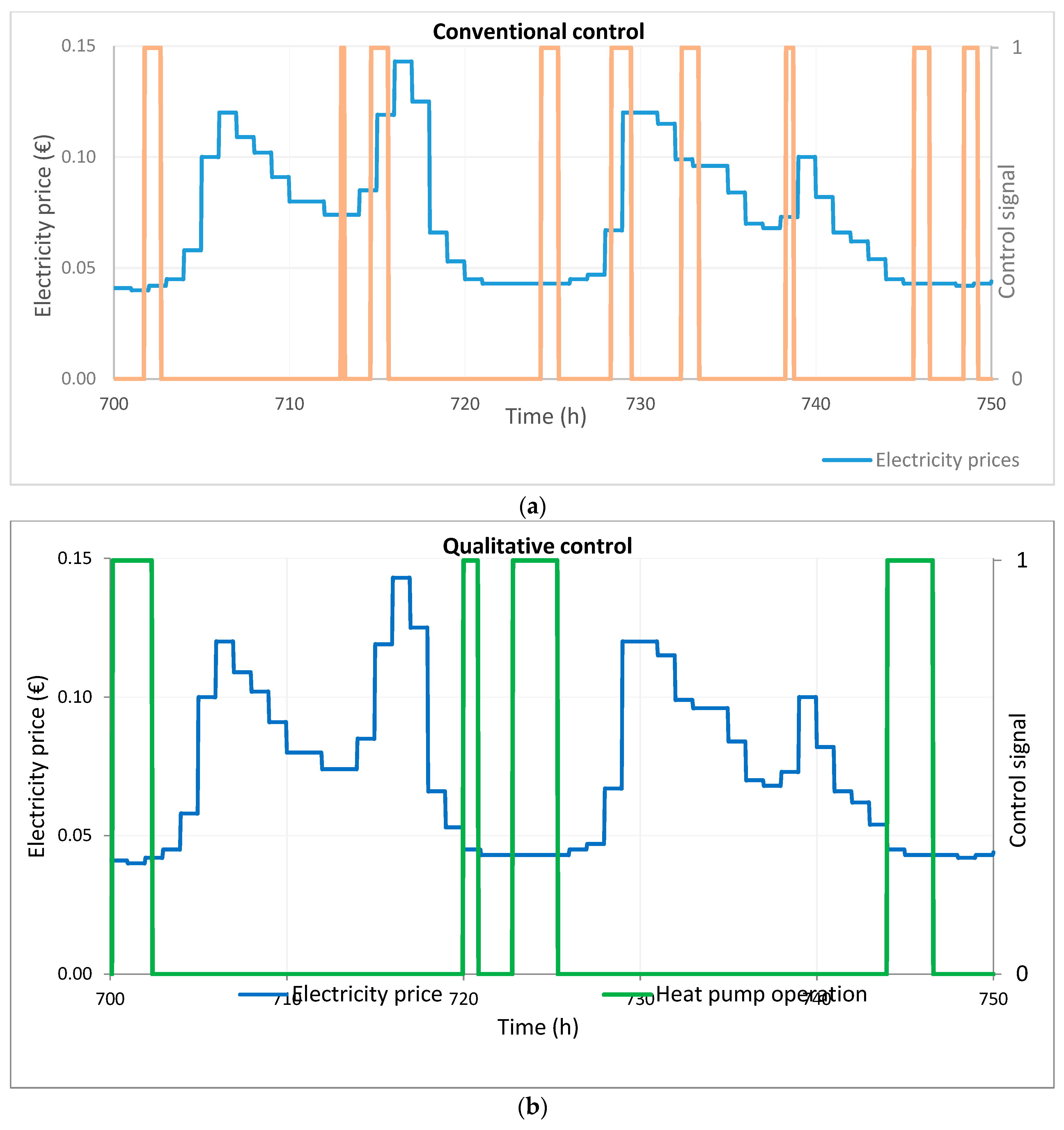

Figure 1) acts like a thermostat. The circulating pump turns on if the outlet temperature of the solar collector exceeds the inlet temperature and simultaneously higher than the Node-4 temperature. The above strategy, where each energy system operates independently based only on local thermostats is later referred as a conventional approach, conventional control or conventional method. Due to the independent operation of energy systems and the lack of connection to the energy cost information, the conventional approach does not reduce the costs of the external energy supplied from the grid. Therefore, the conventional method is used in comparison with the proposed qualitative method. The comparison gives an estimate of the resulting cost reductions of the qualitative method.

2.3. The Qualitative Control Strategy

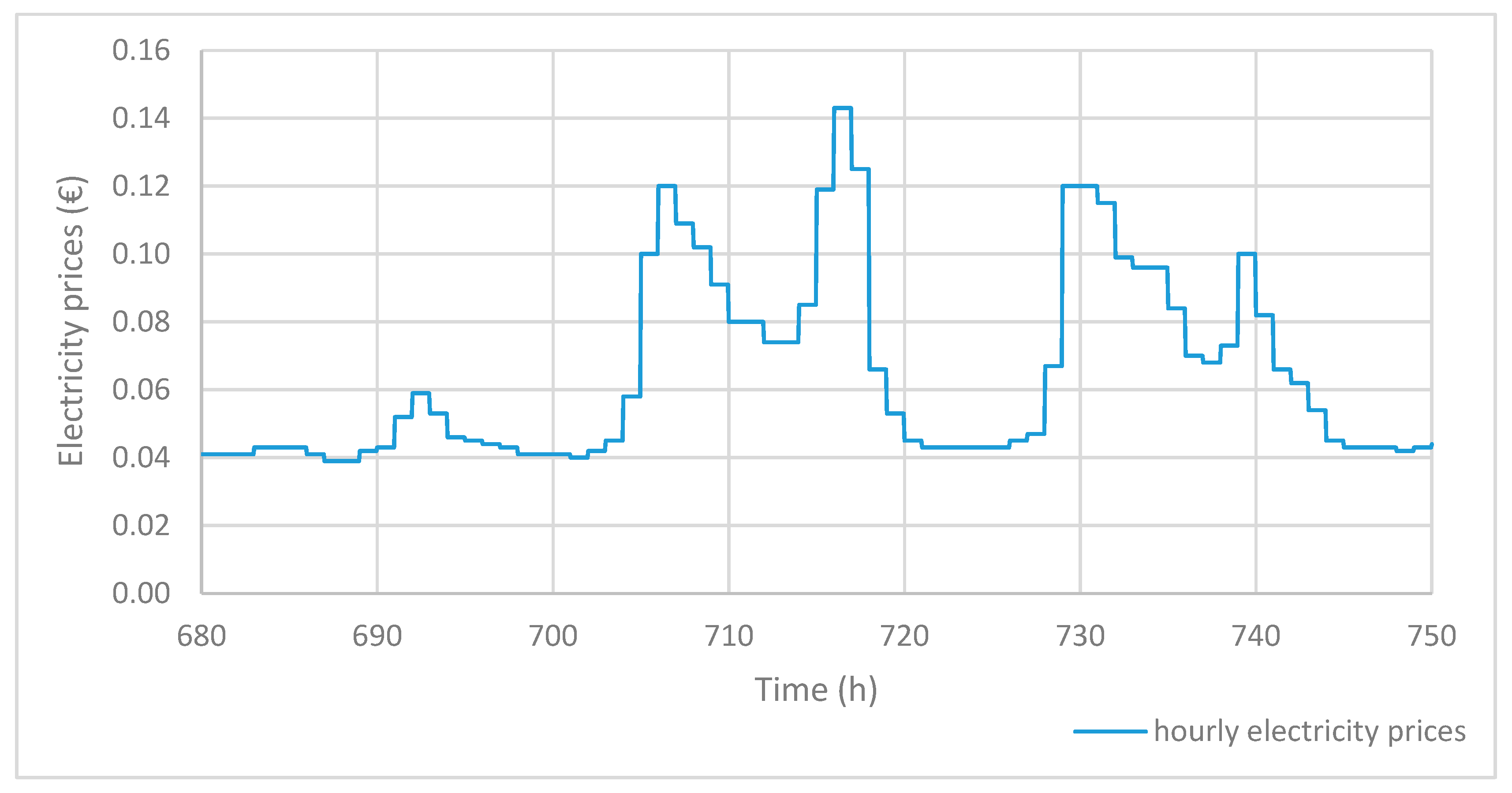

The qualitative approach, also later referred to as qualitative control or the qualitative method, aims to efficiently utilize the renewable energy sources and simultaneously, to produce domestic hot water and maintain indoor conditions comfortable. Principally, the idea is to reduce the costs caused by external electrical energy supplied from the grid. This is implemented by periodically estimating the future need of heating power and choosing the best cost-effective means to produce power. In practice, the proposed method shifts the load of electrical power when the tariff is high by using stored heating energy of the tank, and reversely, when the tariff is low, forwards heat generation to be stored in the tank. The following approach is based on time-varying electricity prices, changing dynamically once in an hour. Hourly price information is provided to the user 24 h in advance by the power supply company.

Figure 2 shows the electricity price variations against hours of the year.

The main difference between the qualitative and conventional approach is that the former is a comprehensive control which supervises all energy systems simultaneously. The conventional approach means a set of independent energy systems controlled by local thermostats. However, the qualitative control takes advantage of the conventional control, i.e., both approaches use the same set points, parameters and thermostats. Thus, the qualitative control supervises and utilizes the conventional control.

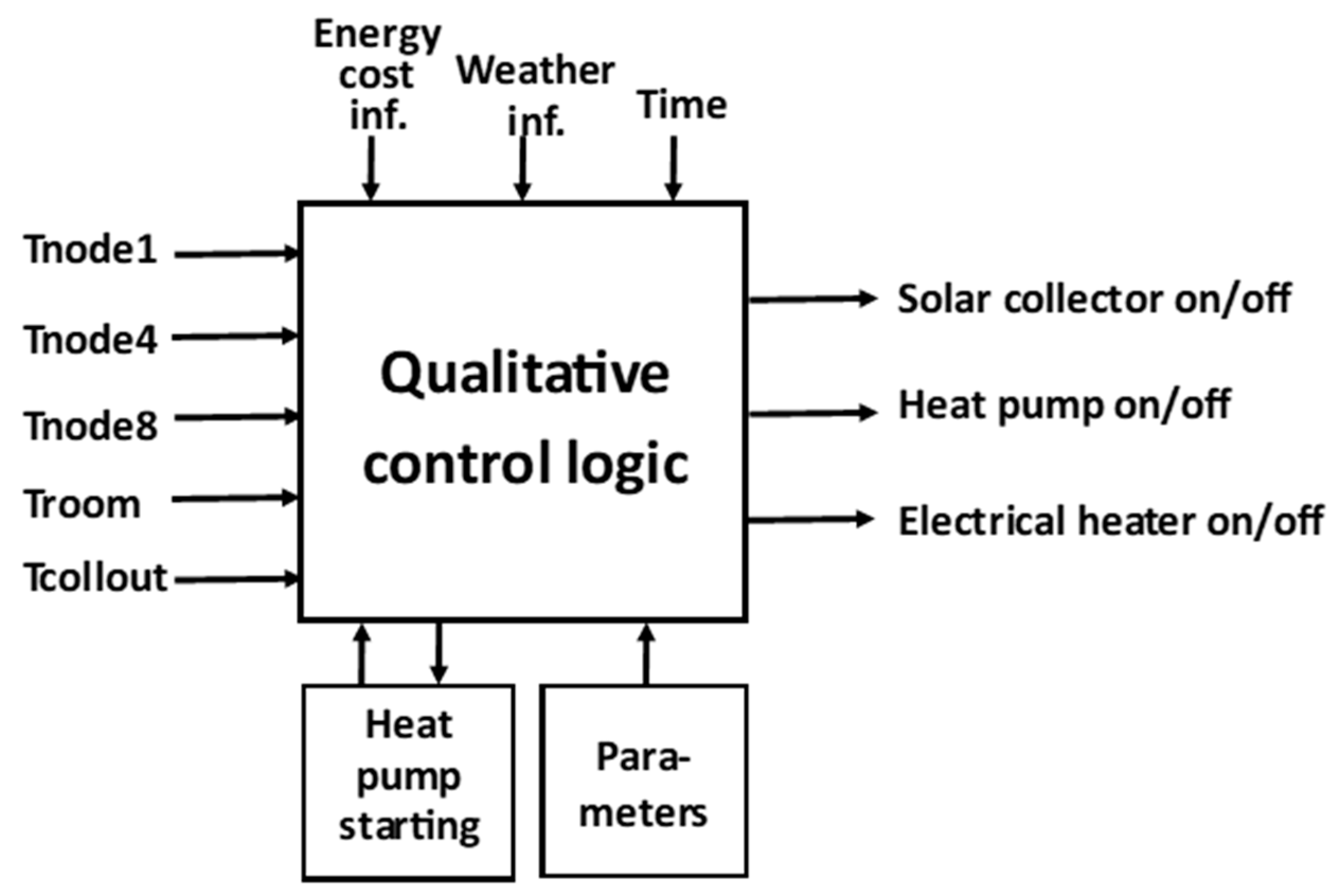

Figure 3 outlines the qualitative control system which performs the designed operations when combined with the energy systems shown in

Figure 1. The left side of the figure illustrates the input signals of the system, consisting of temperatures inside the tank, room and solar collector output; the upper side are time, weather and electricity hourly price inputs. The outputs are connected to the energy systems. Each output signal turns on or off the circulating pump of the solar collector or the heat pump including the compressor and its circulating pumps or the auxiliary heater.

The geothermal heat pump has a special role in the strategy. The heat pump consumes most of the electrical power supplied from the grid. Therefore, by delaying its operation, load shifting becomes effective. The starting time and length of the load shifting period depends on several variables. They are evaluated in a computer program which determines the time and length of the period and operates parallel to the control logic (

Figure 3).

2.4. The Control Logic

The qualitative approach consists of the qualitative model of the energy systems combined with a control algorithm. The model was developed by analysing all different states of the energy systems. However, the idea was not to create a strict mathematical model typical in control engineering but to combine different kinds of knowledge together which enables reasoning and transitions from one state to another. Each state of the system is unique and subject to one or more conditions which are modified into inequalities and equalities. The conditions are created using time, former states, current and history data of inputs (

Figure 3). Finally, a software algorithm combines all details together and implements the control.

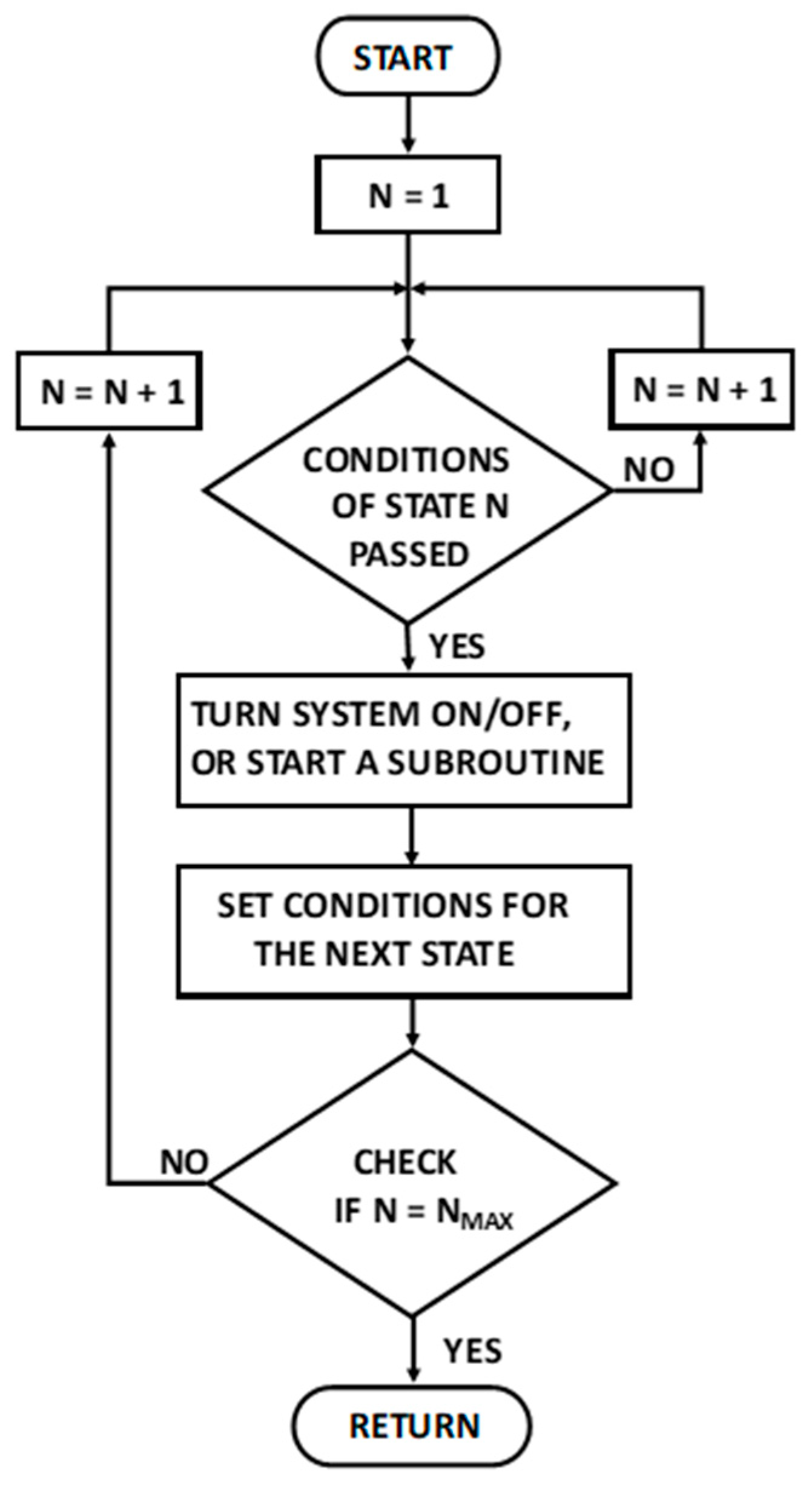

In practice, the control logic is a collection of IF–THEN–ELSE commands, where conditions are combined with Boolean functions. Once a minute in every time step, the computer program goes through all of them. If a condition is true, the program turns on or off an energy system and/or determines the transition to the next state (

Figure 4).

The above control logic can be combined with the TRNSYS simulation software either using a Fortran component compiled and integrated with the simulation software or calling an external EXCEL-program at each time step. The current version has been done using the latter method, which gives more flexibility in implementation of the logic.

2.5. Prioritizing Energy Systems

All three energy systems operate with the aid of electrical energy. A natural way to reduce external energy costs is to prioritize energy sources based on the ratio of useful heating power provided by the energy system compared to the electrical input power to that system. This is known as the coefficient of performance (COP). Among these three systems, solar collector has the highest COP. Therefore, the strategy makes the solar collector, which needs only a little quantity of electrical power to run the circulating pump, as a top priority. In principle, the solar collector feeds the tank all the time, whenever the collector output temperature is greater than the bottom and the middle node temperatures of the tank, i.e., . A necessity safety condition is that at the same the time water temperature on the top node of the tank is not too high: . If the collector output temperature is high enough, but the middle node temperature rises over the limit , then the tank is fully loaded. A similar decision is made if the water temperature on the top of the tank is too high .

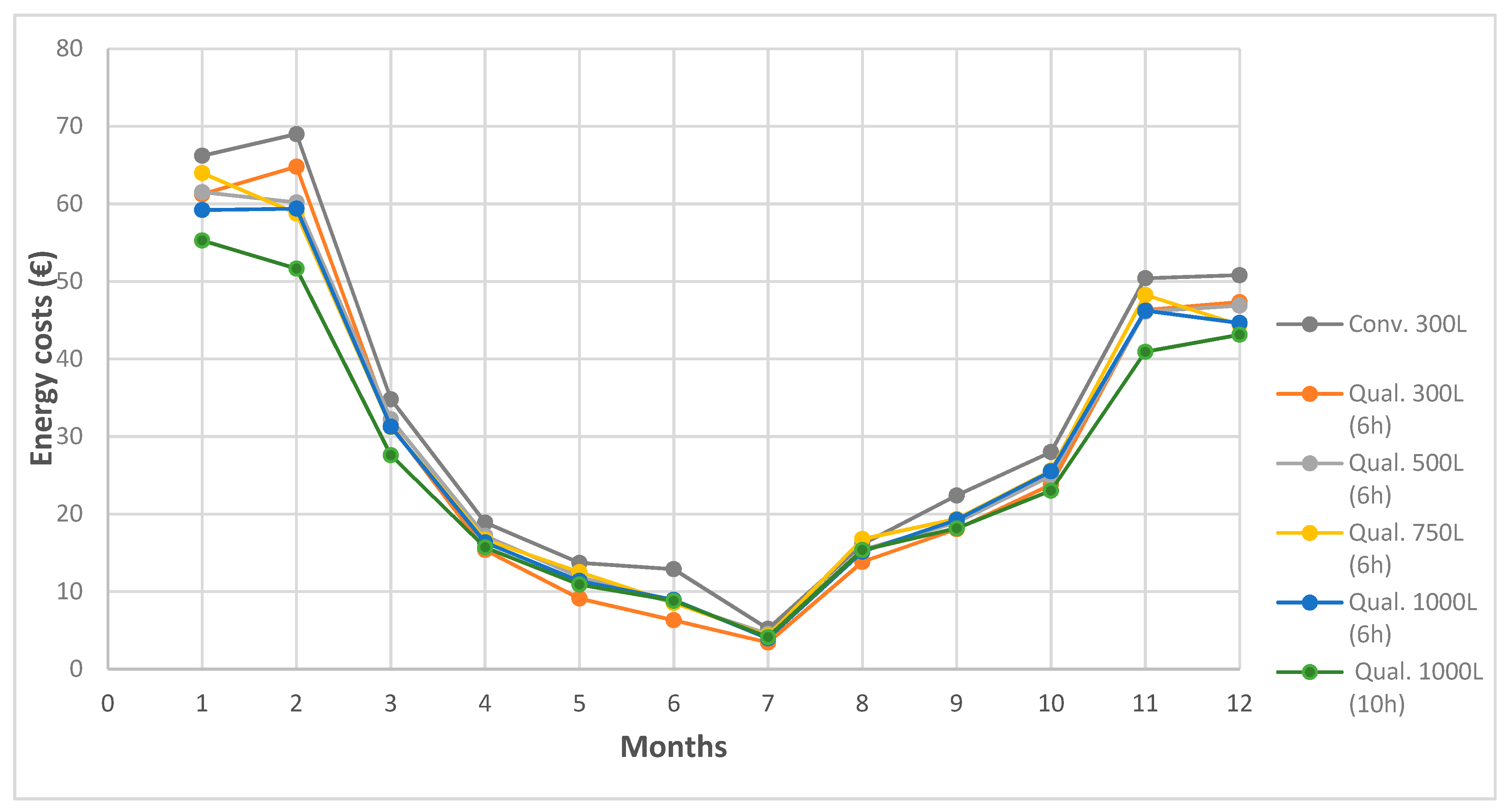

The geothermal heat pump can provide major amount of heat for the building, but it consumes a considerable portion of total electrical energy. Therefore, controlling the heat pump plays a central role in the control strategy to reduce energy costs. The operation of the geothermal heat pump depends on several conditions. First, in the beginning of the six h period, the control algorithm checks if the tank needs charging and determines the best cost-effective charging period. The same subroutine is also called if the room temperature decreases under the minimum allowable room temperature TL, i.e., and the same applies when the middle node temperature of the tank is decreasing, i.e., . The minimum allowable room temperature TL is an input parameter of the control algorithm, and usually set to 21.0 . The heat pump operates until after starting. If the solar collector output temperature exceeds the bottom temperature of the tank , both energy systems may operate at the same time.

The electrical heater has the lowest COP, approximately one. That is why it has the smallest priority and a minor role in heat production. Its main function is to operate as a back-up energy system to support other energy systems in producing domestic hot water and in keeping indoor conditions comfortable. The electrical heater is controlled by the thermostat (4), installed in Node-4, and its operation depends on the water temperature of . The electrical heater may operate for longer time period in circumstances where the energy price is low.

2.6. Predicting the Need of Energy with the Aid of Weather Forecast

Estimating the need of energy for the whole building is made periodically once every six h. Six h is roughly the period a 300 L tank can provide the whole building’s energy demand in most outdoor conditions during winter. The first step is to check the current amount of heat (

Q) available stored in the hot water tank.

where

refers to specific heat and

m to the mass of water.

represents the current water temperature of the tank, measured from Node 4, and

is the minimum allowable water temperature of the same node. The

is one of the parameters (

Figure 3) given as an initial value of the procedure. Then, the stored amount of heat (

Q) will be compared to the heating energy demand of the building with respect to the outdoor weather condition within present time up to next 6 h. The comparison gives a period of hours that the storage tank can provide heat to the floor heating and domestic water. In practice, the heating energy demand of the building will be estimated by means of a static thermal model of the building and a weather forecast.

The static thermal model is created by collecting data of a twelve-month simulation of the building. The data are further processed to a simple linear regression model which presents the heating energy demand

of the building per one hour as a function of outdoor temperature

T.

It is assumed that indoor temperature is kept stable. Thus, variable T could also represent the difference between indoor and outdoor temperatures.

The next step is to check how long the storage tank can deliver domestic hot water and, at the same time, supply heat to the building through floor heating to maintain the indoor conditions at comfortable levels. This is done by testing for the largest value of

M of index

, where the following equation holds:

where

means the predicted hourly outdoor temperature, and

i is 6 h forward from the current time instant. The predicted outdoor temperature is directly read from the TMY data file. In a real building, the weather forecast data would be periodically picked up from an Internet server of a weather service provider.

If

M = 6, there is energy enough for the whole period and the next checking will be done again after six h. If

M < 6, the heat amount of the storage tank must be increased within the next

M hours. This is done by starting the geothermal heat pump. A necessity is that, at the same time, the cost of the electrical energy is low enough. If the heat pump operates for two hours, it is enough to charge the tank for the next six hours. Therefore, the control procedure tries to find a 2 h period within the next

M hours, where the cost of electrical energy is lower than average. The idea is to avoid peak load times and find the maximum cost difference

between average energy costs during continuous pair of hours

i, and

i + 1, i.e.,

and the average energy costs

. Thus,

can be written as:

where:

The continuous pair of hours means, the sequential hours as: . If such a pair is found, the program starts the geothermal heat pump in the beginning of the hour i. If no such period is found, the heat pump will be started within the next hour despite the energy costs. The whole procedure is repeated after six hours.

Tabulated data are defined according to the thermal model of the building to evaluate the heating demand for the next 1 hour up to the next 6 h for the control algorithm. As shown in

Table 1, values are based on an outdoor temperature index. The index is defined as one if the outdoor temperature is less than −25 °C

, and it is two when the outdoor temperature is within −25 °C, up to −20 °C,

etc.

The above procedure assumes that the price reading period is fixed to six hours. The next step is to find out what is the effect of enlarging the period according to the size of the water tank. Therefore, the algorithm was modified, and the price reading period was extended to 10 h and the table is accordingly continued for evaluating the heating demands of up to 10 h.