Evaluation of the Properties and Usefulness of Ashes from the Corn Grain Drying Process Biomass

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

- 1.

- Corn cobs (CC)—residues of corn cobs without grains;

- 2.

- Corn grains (CG)—residues of grains from corn grain drying and cleaning process;

- 3.

- Corn husk (CH)—waste in the form of corn husks.

- -

- Corn cobs:

- 4.

- Corn cobs and corn husk (CC-CH);

- 5.

- Corn cobs and corn grains (CC-CG);

- -

- Corn grains:

- 6.

- Corn grains and corn cobs (CG-CC

- 7.

- Corn grains and corn husk (CG–CH);

- -

- Corn husk:

- 8.

- Corn husk and corn grains (CH-CG);

- 9.

- Corn husk and corn cobs (CH-CC).

2.2. Proximate and Ultimate Analysis

2.3. Preparation and Analysis of Ashes

2.4. Statistical Analysis

3. Results

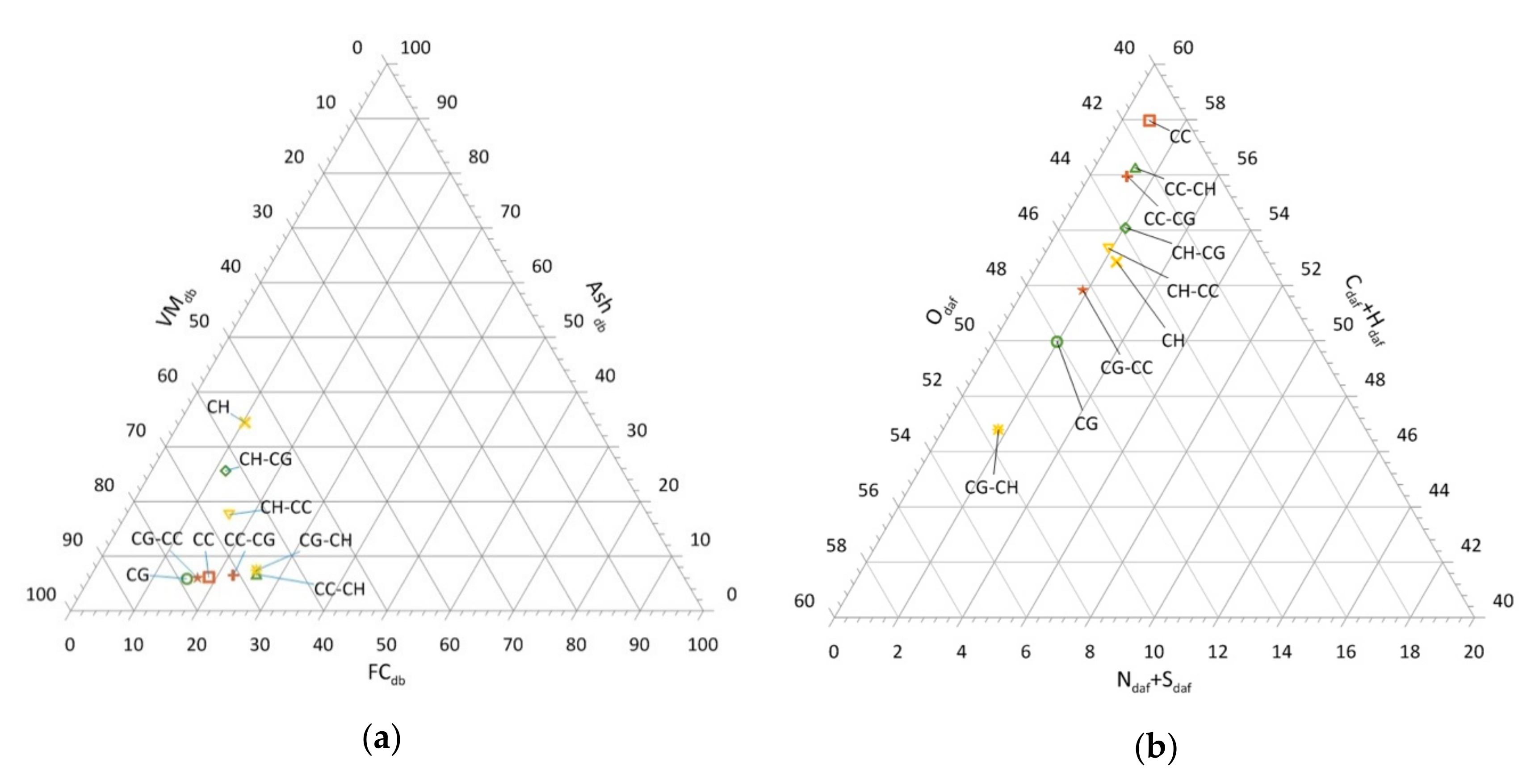

3.1. Characteristics of the Materials Used

3.2. Results of Ashes’ Chemical Composition Examination

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hawrot-Paw, M.; Zmuda, A.; Koniuszy, A. Thermochemical biomass conversion processes and their impact on the environment. Przem. Chem. 2019, 98, 1126–1129. [Google Scholar] [CrossRef]

- Kruszelnicka, W. A New Model for Environmental Assessment of the Comminution Process in the Chain of Biomass Energy Processing. Energies 2020, 330. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 3042. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 2885. [Google Scholar] [CrossRef]

- Mieldažys, R.; Jotautienė, E.; Jasinskas, A. The Opportunities of Sustainable Biomass Ashes and Poultry Manure Recycling for Granulated Fertilizers. Sustainability 2019, 4466. [Google Scholar] [CrossRef]

- Thy, P.; Lesher, C.E.; Jenkins, B.M.; Gras, M.A.; Shiraki, R.; Tegner, C. Trace Metal Mobilization During Combustion of Biomass Fuels. In PIER Energy- Related Environmental Research Program CEC-500-2008-014; California Energy Commission: Sacramento, CA, USA; University of California Davis: Davis, CA, USA, 2008. [Google Scholar]

- Payá, J.; Roselló, J.; Monzó, M.J.; Escalera, A.; Santamarina, P.M.; Borrachero, V.M.; Soriano, L. An Approach to a New Supplementary Cementing Material: Arundo donax Straw Ash. Sustainability 2018, 4273. [Google Scholar] [CrossRef]

- Barišić, I.; Netinger Grubeša, I.; Dokšanović, T.; Marković, B. Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials 2019, 1375. [Google Scholar] [CrossRef]

- Uliasz-Bocheńczyk, A.; Pawluk, A.; Pyzalski, M. Characteristics of ash from the combustion of biomass in fluidized bed boilers. Miner. Resour. Manag. 2016, 32, 149–162. [Google Scholar] [CrossRef]

- Zhang, Y.; He, F.; Li, X.; Behrendt, F.; Gao, Z.; Yu, R. Fertilizer properties of ash from corn-stover pellets using the sequential extraction and matrix expression. Waste Manag. 2018, 82, 111–117. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental impacts of food waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef]

- Maj, G.; Najda, A.; Klimek, K.; Balant, S. Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry. Energies 2019, 55. [Google Scholar] [CrossRef]

- Nayak, A.; Bhushan, B. An overview of the recent trends on the waste valorization techniques for food wastes. J. Environ. Manage. 2019, 233, 352–370. [Google Scholar] [CrossRef]

- Maj, G.; Krzaczek, P.; Stamirowska-Krzaczek, E.; Lipińska, H.; Kornas, R. Assessment of energy and physicochemical biomass properties of selected forecrop plant species. Renew. Energy 2019, 143, 520–529. [Google Scholar] [CrossRef]

- Bonassa, G.; Schneider, L.T.; Canever, V.B.; Cremonez, P.A.; Frigo, E.P.; Dieter, J.; Teleken, J.G. Scenarios and prospects of solid biofuel use in Brazil. Renew. Sustain. Energy Rev. 2018, 82, 2365–2378. [Google Scholar] [CrossRef]

- Czekała, W. Agricultural Biogas Plants as a Chance for the Development of the Agri-Food Sector. J. Ecol. Eng. 2018, 19. [Google Scholar] [CrossRef]

- Nagel, K.; Hoilett, N.O.; Mottaleb, M.A.; Meziani, M.J.; Wistrom, J.; Bellamy, M. Physicochemical Characteristics of Biochars Derived From Corn, Hardwood, Miscanthus, and Horse Manure Biomasses. Commun. Soil Sci. Plant Anal. 2019, 50, 987–1002. [Google Scholar] [CrossRef]

- Schulz, S.V.; Munz, S.; Stolzenburg, K.; Hartung, J.; Weisenburger, S.; Mastel, K.; Möller, K.; Claupein, W.; Graeff-Hönninger, S. Biomass and Biogas Yield of Maize (Zea mays L.) Grown under Artificial Shading. Agriculture 2018, 8, 178. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Sobczak, P.; Żukiewicz-Sobczak, W.; Niedziółka, I.; Zawiślak, K.; Dula, M. Movement of Chemical Elements in Ash on the Example of a Process of Combustion Corn Straw Briquettes in a Low Power Boiler. Annu. Set Environ. Prot. 2019, 21, 1294–1306. [Google Scholar]

- Tys, J.; Piekarski, W.; Jackowska, I.; Kaczor, A.; Zając, G.; Starobrat, P. Technological and Economic Conditions of Biofuel Production from Rapeseed; Acta Agrophysica: Lublin, Poland; Institute of Agrophysics: Lublin, Poland; Polish Academy of Sciences: Lublin, Poland, 2003; Volume 99. [Google Scholar]

- Bajus, P.; Mraz, M.; Rigo, I.; Findura, P.; Fürstenzeller, A.; Kielbasa, P.; Malaga-Tobola, U. The Influence of Drying Temperature and Moisture of Corn Seeds Planted on Their Damage. Agric. Eng. 2019, 23, 5–12. [Google Scholar] [CrossRef]

- Rechnio, C.; Ruciński, A. Analysis of the effectiveness of the corn drying process in a periodic device. Sci. Didact. Equip. 2018, 23, 138–145. [Google Scholar]

- Bartkowiak, A.; Gracz, W.; Marcinkowski, D.; Skrzypek, D.; Wojtaszyk, S. Research on Quality of Maize Grain as a Result of the Application of an Innnovative System for Storing Grain Under Operating Conditions. Agric. Eng. 2019, 23, 15–28. [Google Scholar] [CrossRef]

- Maj, G.; Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T.; Krzaczek, P.; Piekarski, W. Energy and Emission Characteristics of Biowaste from the Corn Grain Drying Process. Energies 2019, 4383. [Google Scholar] [CrossRef]

- EN ISO 3310-1:2016. In Test Sieves—Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth; Polish Committee for Standarization: Warsaw, Poland, 2016.

- EN ISO 14780:2017-07. In Solid Biofuels–Sample Preparation; Polish Committee for Standarization: Warsaw, Poland, 2017.

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Dragutinovic, N.; Höfer, I.; Kaltschmitt, M. Effect of additives on thermochemical conversion of solid biofuel blends from wheat straw, corn stover, and corn cob. Biomass Convers. Biorefinery 2019, 9, 35–54. [Google Scholar] [CrossRef]

- Song, D.; Tang, J.; Xi, X.; Zhang, S.; Liang, G.; Zhou, W.; Wang, X. Responses of soil nutrients and microbial activities to additions of maize straw biochar and chemical fertilization in a calcareous soil. Eur. J. Soil Biol. 2018, 84, 1–10. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Baxter, D. Trace element concentrations and associations in some biomass ashes. Fuel 2014, 129, 292–313. [Google Scholar] [CrossRef]

- Sapek, B. Soil phosphorus accumulation and release–sources, processes, causes. Woda Śr. Obsz. Wiej. 2014, 14, 77–100. [Google Scholar]

- Krzywy, E. Plant Nutrition; Wyd. Naukowe Akademii Rolniczej w Szczecinie: Szczecin, Poland, 2007; ISBN 83-7317-038-3. [Google Scholar]

- Kabata-Pendias, A.; Pendias, H. Biochemistry of Trace Elements; PWN–Polish Scientific Publishers: Warszawa, Poland, 1999. [Google Scholar]

- Kabata-Pendias, A. Trace Elements in Soils and Plants; CRC press: Boca Raton, FL, USA, 2000; ISBN 1-4200-3990-3. [Google Scholar]

- Meller, E.; Bilenda, E. Effects of biomass ash on the physicochemical properties of light soil. Energy Policy J. 2012, 15, 287–292. [Google Scholar]

- Piekarczyk, M. Effect of winter wheat straw ash on the some macro- and microelements available forms content in light soil. Fragm. Agron. 2013, 30, 92–98. [Google Scholar]

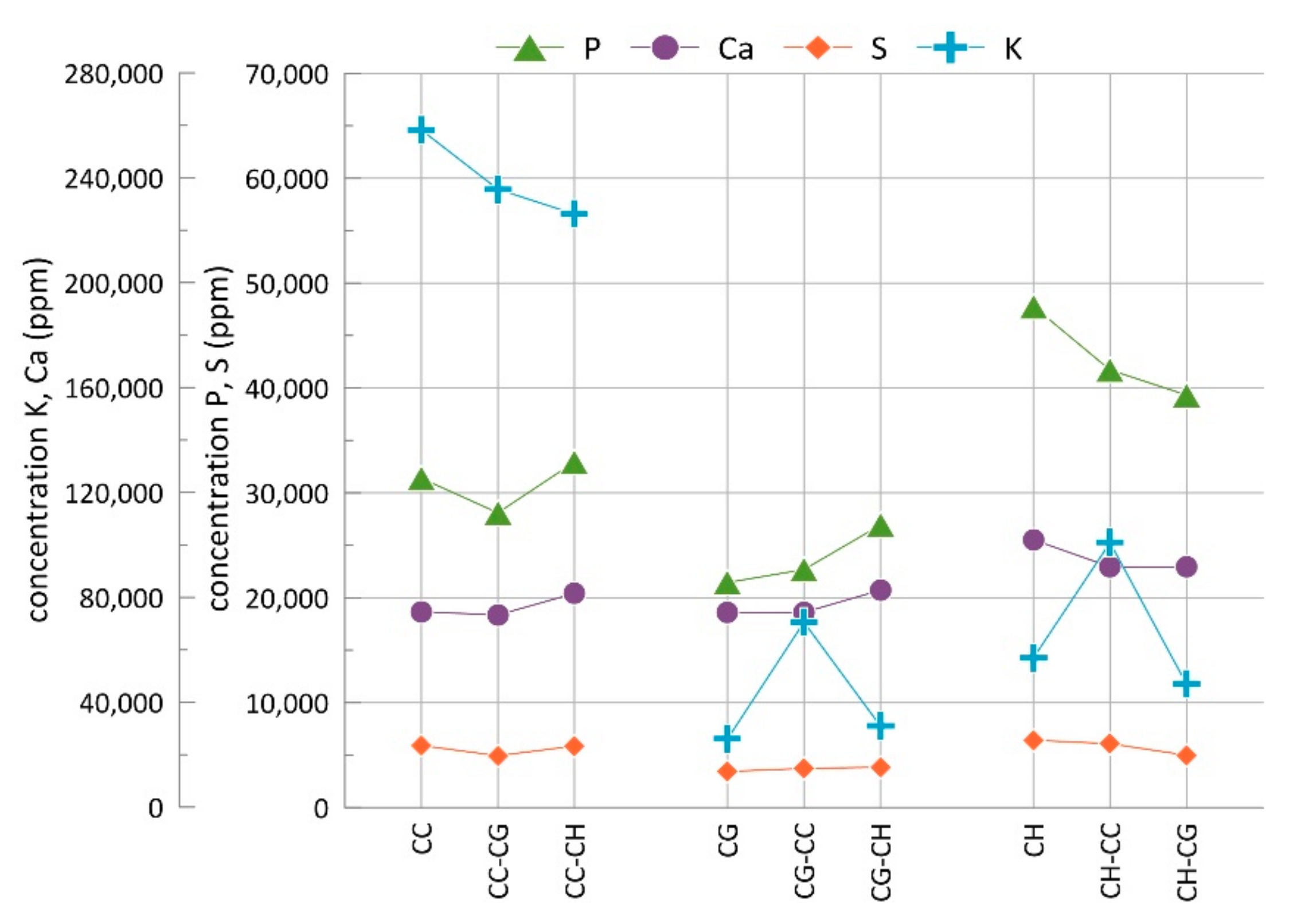

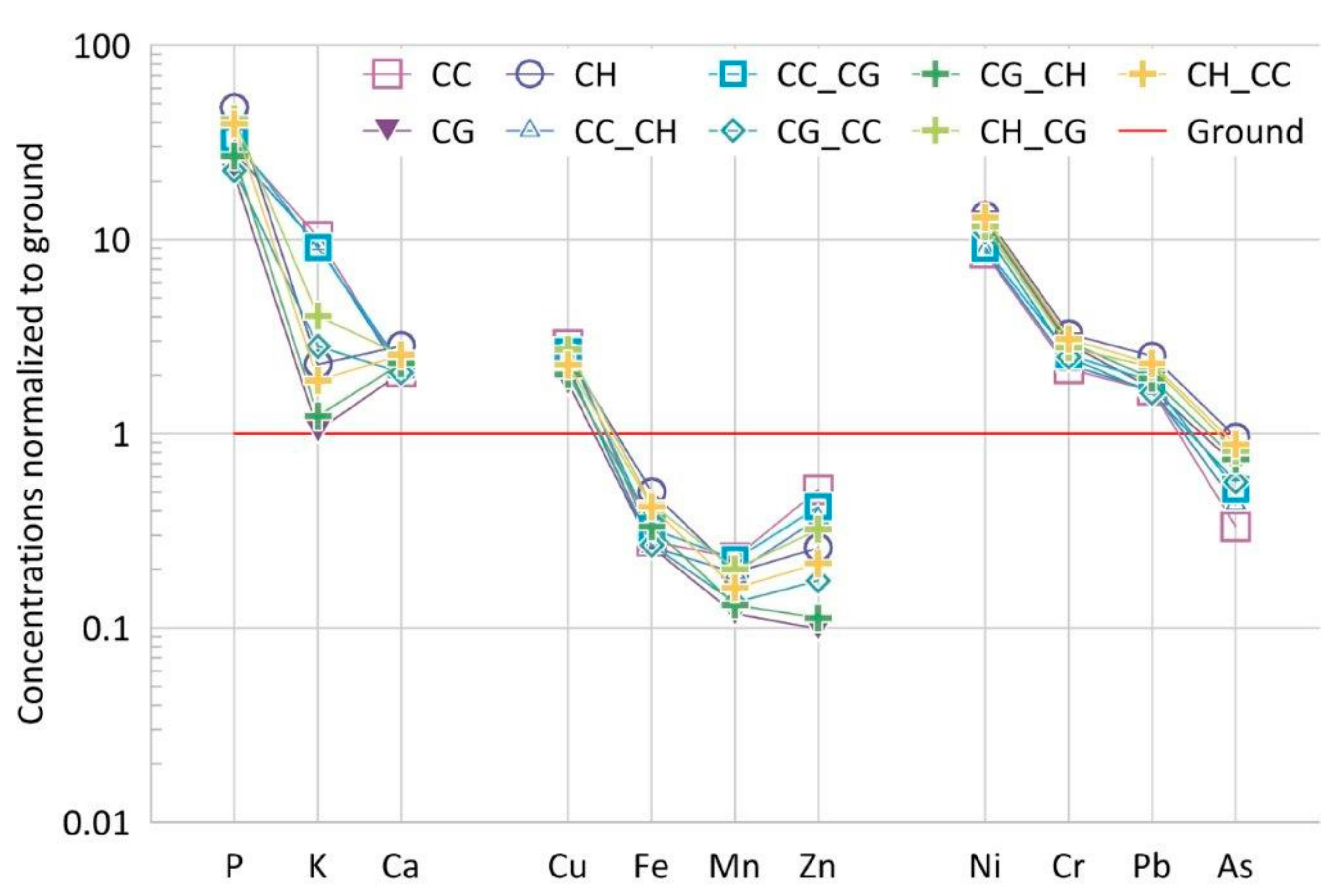

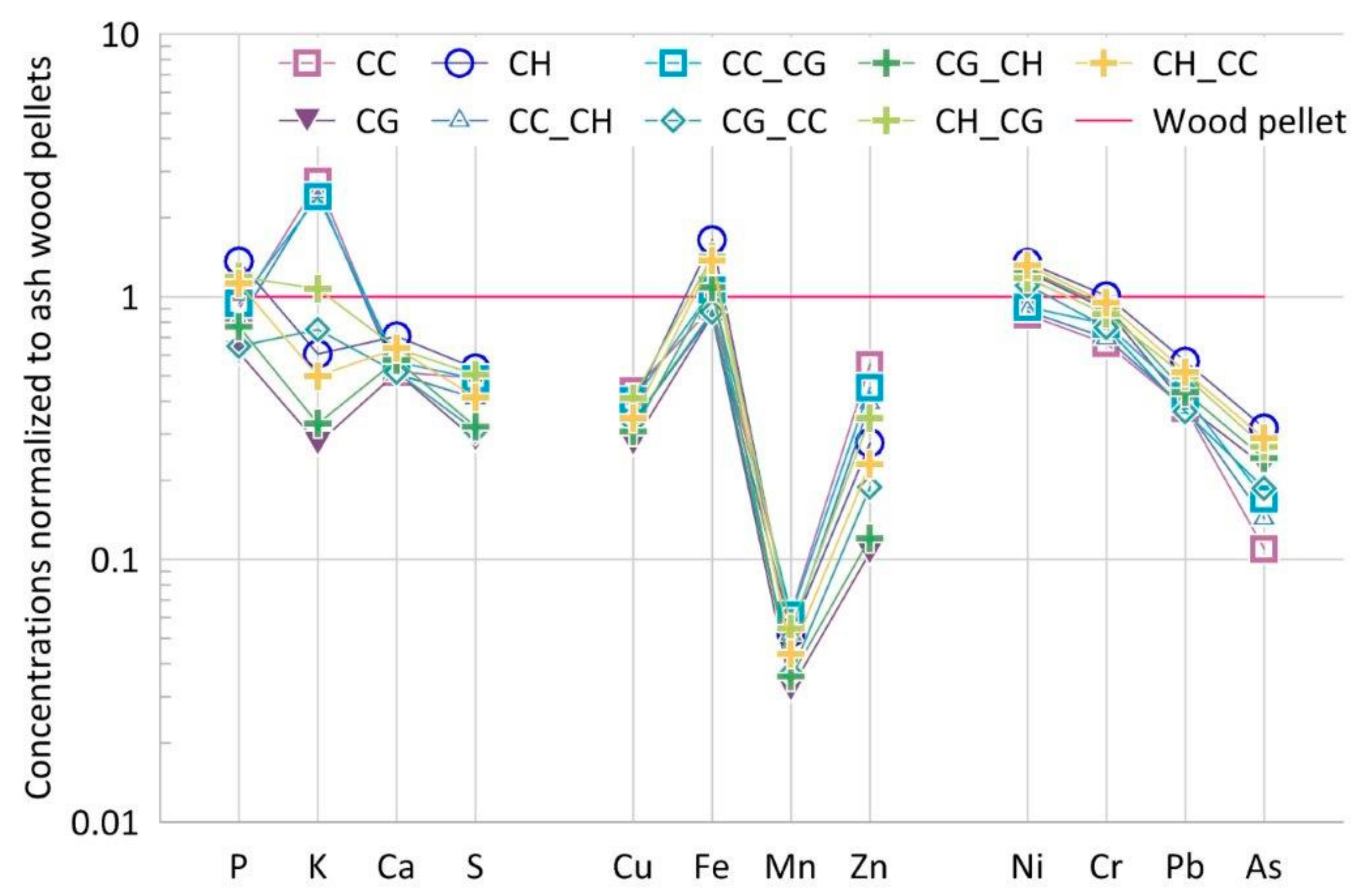

| Component | CC | CG | CH | CC-CG | CC-CH | CG-CC | CG-CH | CH-CC | CH-CG | p-Value |

|---|---|---|---|---|---|---|---|---|---|---|

| P ± Sx | 31,391 d ± 264 | 21,452 b ± 165 | 47,778 h ± 346 | 28,099 a ± 57 | 32,935 e ± 150 | 22,688 c ± 94 | 26,933 a ± 184 | 41,719 g ± 301 | 39,324 f ± 63 | <0.001 |

| K ± Sx | 258,259 i ± 1036 | 25,970 a ± 357 | 56,958d ± 219 | 235,629 h ± 519 | 226,174 g ± 90 | 70,538 e ± 148 | 30,913 b ± 144 | 100,864 f ± 300 | 46,953 c ± 63 | <0.001 |

| Ca ± Sx | 74,537 a ± 439 | 74,201 a ± 288 | 101,954 f ± 225 | 73,280 c ± 116 | 81,521 d ± 103 | 74,268 a ± 184 | 82,742 e ± 202 | 91,647 b ± 259 | 91,583 b ± 98 | <0.001 |

| S ± Sx | 5911 c,d ± 31 | 3438 e ± 20 | 6425 f ± 37 | 4942 b ± 69 | 5863 c ± 51 | 3726 a ± 57 | 3852 a ± 34 | 6085 d ± 86 | 4988 b ± 53 | <0.001 |

| Component | Material | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | CH | > | CH-CC | > | CH-CG | > | CC-CH | > | CC | > | CC-CG | > | CG-CH | > | CG-CC | > | CG |

| K | CC | > | CC-CG | > | CC-CH | > | CH-CC | > | CG-CC | > | CH | > | CH-CG | > | CG-CH | > | CG |

| Ca | CH | > | CH-CC | > | CH-CG | > | CG-CH | > | CC-CH | > | CC | > | CG-CC | > | CG | > | CC-CG |

| S | CH | > | CH-CC | > | CC | > | CC-CH | > | CH-CG | > | CC-CG | > | CG-CH | > | CG-CC | > | CG |

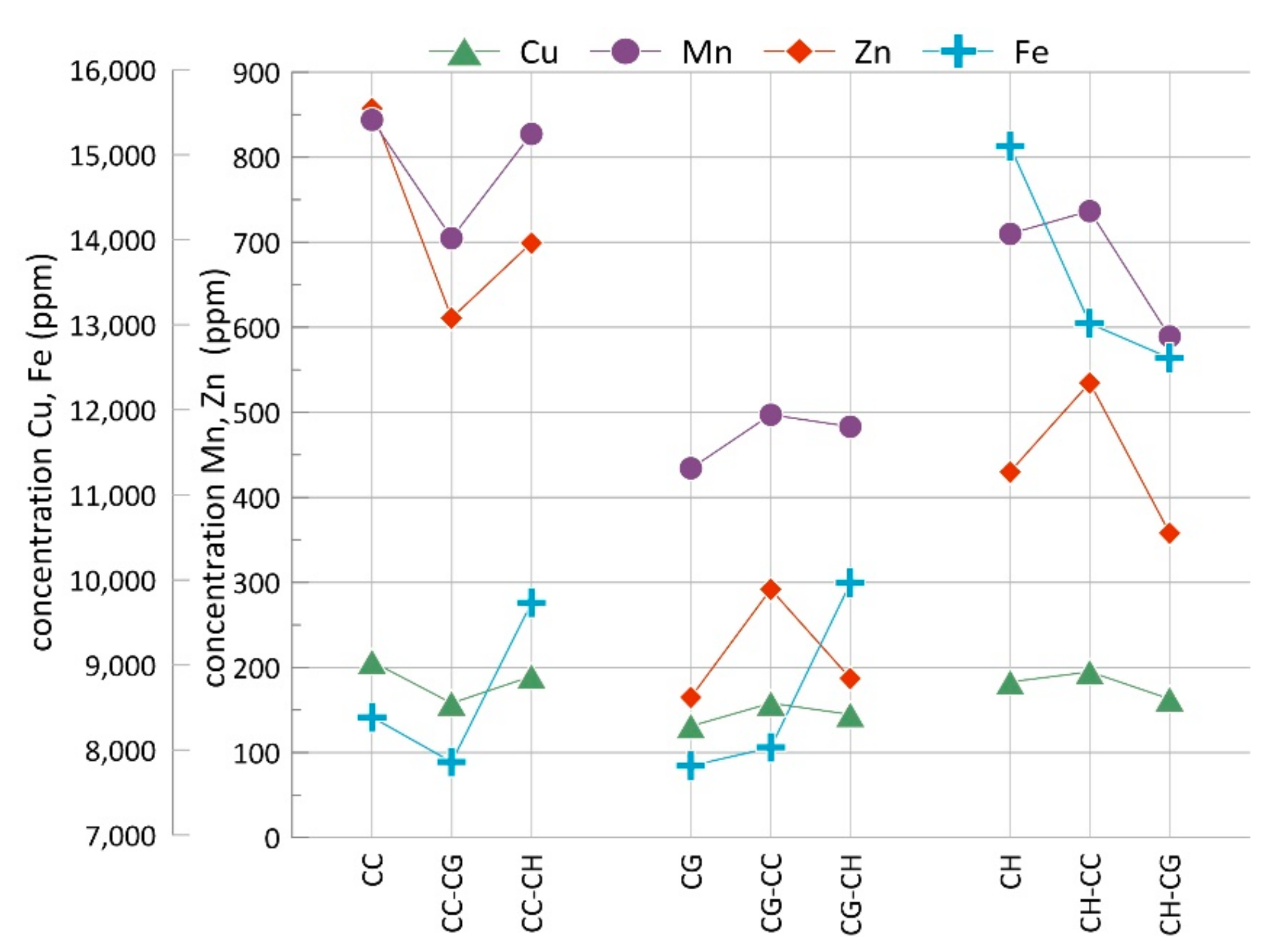

| Component | CC | CG | CH | CC-CG | CC-CH | CG-CC | CG-CH | CH-CC | CH-CG | p-Value |

|---|---|---|---|---|---|---|---|---|---|---|

| Cu ± Sx | 207 c,d ± 1 | 131 a ± 2 | 183 d ± 1 | 158 a,b ± 11 | 190 c,d ± 10 | 158 a,b ± 12 | 145 a ± 17 | 195 c ± 12 | 163 b ± 14 | <0.001 |

| Fe ± Sx | 8387 b ± 58 | 7814 a ± 18 | 15,100 g ± 86 | 7859 a ± 51 | 9730 c ± 115 | 8028 a ± 79 | 9967 d ± 56 | 13,014 f ± 41 | 12,609 e ± 65 | <0.001 |

| Mn ± Sx | 844 e ± 16 | 434 a ± 5 | 710 c ± 10 | 705 c ± 46 | 827 e ± 42 | 497 a ± 8 | 483 a ± 32 | 737 c,d ± 3 | 589 b ± 18 | <0.001 |

| Zn ± Sx | 857 h ± 6 | 165 a ± 2 | 430 d ± 4 | 611 f ± 36 | 699 g ± 30 | 292 b ± 6 | 187 a ± 13 | 535 e ± 10 | 358 c ± 15 | <0.001 |

| Component | Material | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | CC | > | CH-CC | > | CC-CH | > | CH | > | CH-CG | > | CC-CG | > | CG-CC | > | CG-CH | > | CG |

| Fe | CH | > | CH-CC | > | CH-CG | > | CG-CH | > | CC-CH | > | CC | > | CG-CC | > | CC-CG | > | CG |

| Mn | CC | > | CC-CH | > | CH-CC | > | CH | > | CC-CG | > | CH-CG | > | CG-CC | > | CG-CH | > | CG |

| Zn | CC | > | CC-CH | > | CC-CG | > | CH-CC | > | CH | > | CH-CG | > | CG-CC | > | CG-CH | > | CG |

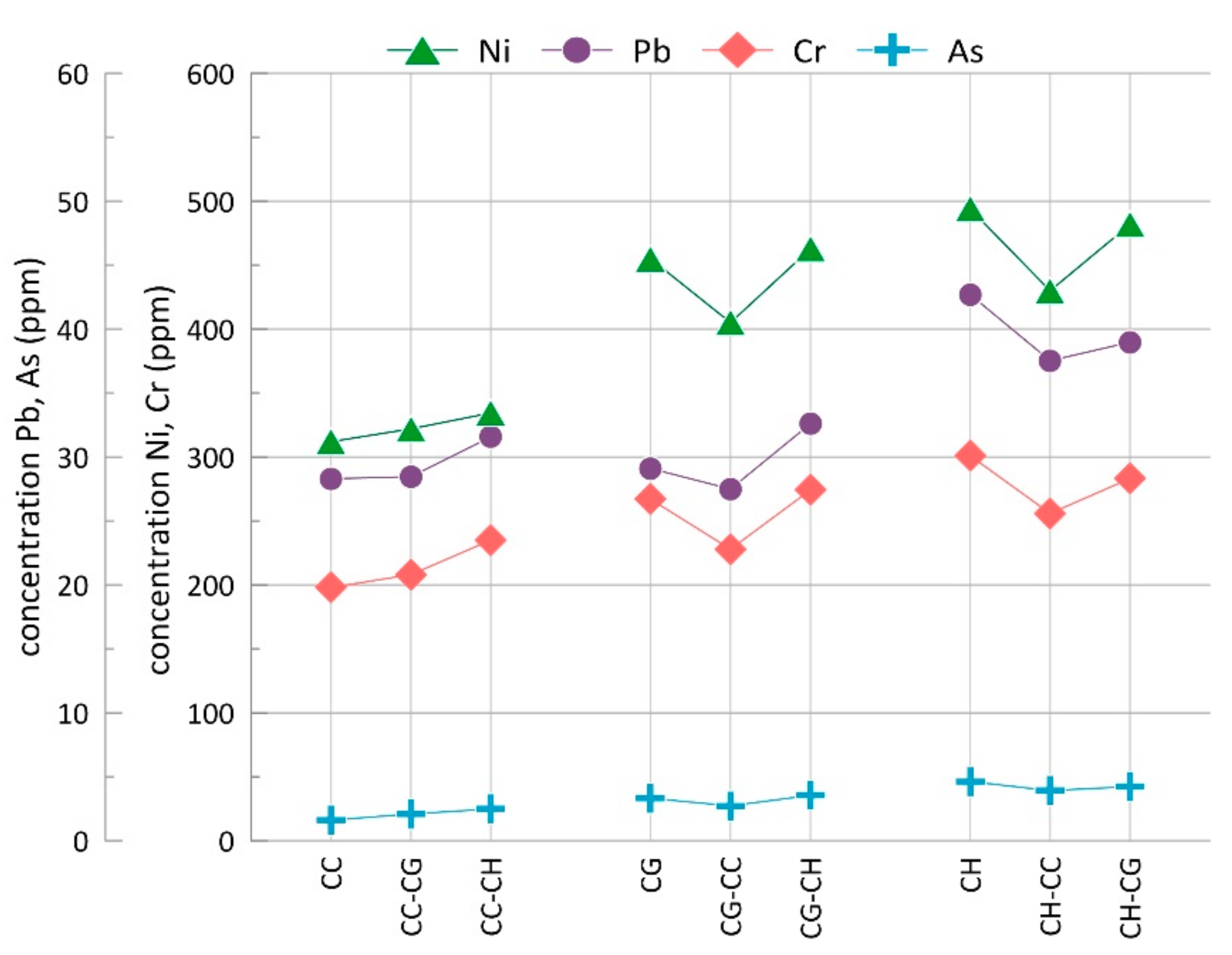

| Component | CC | CG | CH | CC-CH | CC-CG | CG-CC | CG-CH | CH-CG | CH-CC | p-Value |

|---|---|---|---|---|---|---|---|---|---|---|

| Ni ± Sx | 312 a ± 3 | 455 c,d ± 2 | 494 e ± 1 | 322 a ± 22 | 334 a ± 10 | 405 b ± 18 | 463 d ± 43 | 430 c ± 13 | 482 e ± 12 | <0.001 |

| Cr ± Sx | 198 a ± 1 | 267 c,d ± 9 | 301 e ± 4 | 208 a ± 6 | 235 b ± 13 | 228 b ± 14 | 274 d ± 13 | 256 c ± 20 | 283 d ± 10 | <0.001 |

| Pb ± Sx | 28.3 a,b ± 2.02 | 29.1 a,b ± 1.15 | 42.7 b ± 2.94 | 28.46 a,b ± 9.24 | 31.57 a,b ± 8.09 | 27.49 a ± 4.04 | 32.60 a,b ± 6.35 | 37.53 a,b ± 6.40 | 38.97 a,b ± 4.04 | <0.01 |

| As ± Sx | 1.6 a ± 0.58 | 3.31 a ± 1.22 | 4.62 a ± 1.10 | 2.09 a ± 0.28 | 2.48 a ± 0.43 | 2.72 a ± 0.57 | 3.54 a ± 0.74 | 3.92 a ± 0.35 | 4.22 a ± 0.85 | <0.03 |

| Component | Material | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | CH | > | CH-CG | > | CG-CH | > | CG | > | CH-CC | > | CG-CC | > | CC-CH | > | CC-CG | > | CC |

| Cr | CH | > | CH-CG | > | CG-CH | > | CG | > | CH-CC | > | CC-CH | > | CG-CC | > | CC-CG | > | CC |

| Pb | CH | > | CH-CG | > | CH-CC | > | CG-CH | > | CC-CH | > | CG | > | CC-CG | > | CC | > | CG-CC |

| As | CH | > | CH-CG | > | CH-CC | > | CG-CH | > | CG | > | CG-CC | > | CC-CH | > | CC-CG | > | CC |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zając, G.; Maj, G.; Szyszlak-Bargłowicz, J.; Słowik, T.; Krzaczek, P.; Gołębiowski, W.; Dębowski, M. Evaluation of the Properties and Usefulness of Ashes from the Corn Grain Drying Process Biomass. Energies 2020, 13, 1290. https://doi.org/10.3390/en13051290

Zając G, Maj G, Szyszlak-Bargłowicz J, Słowik T, Krzaczek P, Gołębiowski W, Dębowski M. Evaluation of the Properties and Usefulness of Ashes from the Corn Grain Drying Process Biomass. Energies. 2020; 13(5):1290. https://doi.org/10.3390/en13051290

Chicago/Turabian StyleZając, Grzegorz, Grzegorz Maj, Joanna Szyszlak-Bargłowicz, Tomasz Słowik, Paweł Krzaczek, Wojciech Gołębiowski, and Marcin Dębowski. 2020. "Evaluation of the Properties and Usefulness of Ashes from the Corn Grain Drying Process Biomass" Energies 13, no. 5: 1290. https://doi.org/10.3390/en13051290

APA StyleZając, G., Maj, G., Szyszlak-Bargłowicz, J., Słowik, T., Krzaczek, P., Gołębiowski, W., & Dębowski, M. (2020). Evaluation of the Properties and Usefulness of Ashes from the Corn Grain Drying Process Biomass. Energies, 13(5), 1290. https://doi.org/10.3390/en13051290