Enhancement of Turbulent Convective Heat Transfer using a Microparticle Multiphase Flow

Abstract

1. Introduction

2. Experiments

2.1. Microfluid Preparation

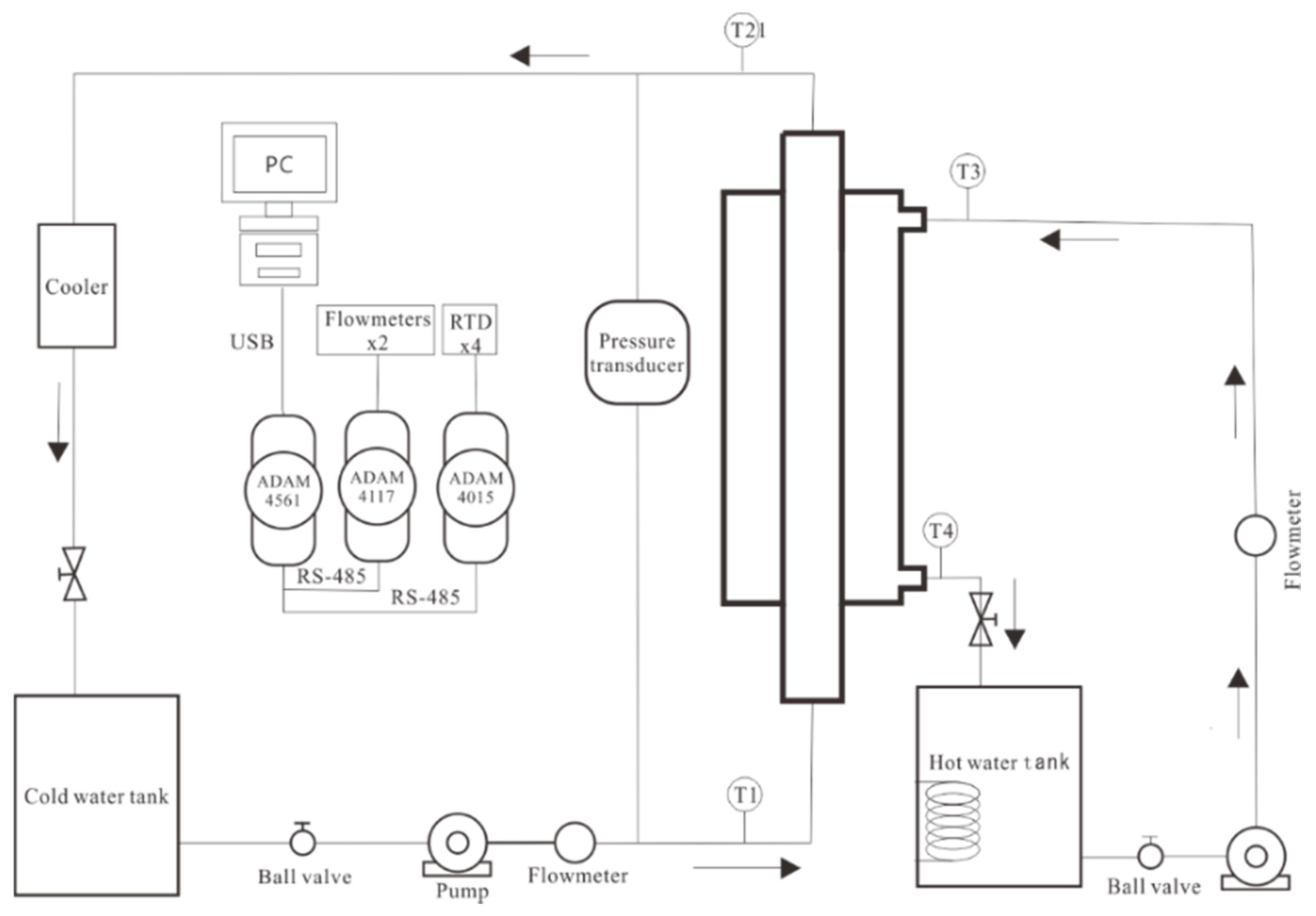

2.2. Experimental Device

2.3. Data Processing

2.3.1. The Thermophysical Properties of Microfluids

2.3.2. Heat Transfer and Friction Factor

2.4. Experimental Results and Discussion

2.4.1. Heat Transfer and Flow Characteristics

2.4.2. Thermal Performance

2.4.3. Regression Equation

2.4.4. Graphite Particle Size and Regression Equation

3. Numerical Study

3.1. Simulation Model

3.2. Simulation Results and Discussion

4. Conclusions

- (1)

- A variety of microfluids (Graphite, A12O3 and CuO) were studied in a vertical tube. The results show that the heat transfer performance of the various microfluids is better than that of water. The graphite microfluid provides the best thermal performance compared to the other two microparticle suspensions. All the microfluids enhanced heat transfer but increased flow resistance.

- (2)

- Both graphite microfluids (those with 5 μm and 1 μm graphite particles) further show that the microfluid with 1 μm particles experiences higher heat transfer enhancement than that with 5 μm particles. It is concluded that the smaller the size of particles, the stronger the heat transfer effect and the more significant the friction loss.

- (3)

- The regression equations obtained in the present paper provide the correlative coefficient of the Nusselt number and the friction factor. The predicted results are in good agreement with the experimental results within a deviation of ± 10% and ± 5% for the Nusselt number and friction factor, respectively.

- (4)

- The simulation results using the Eulerian–Eulerian granular flow model and considering the microparticle suspension as a continuum show that an increase in the equivalent thermal conductivity of the microfluid and an increase in the turbulent kinetic energy near the wall are two key factors that enhance turbulent convective heat transfer.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | heat transfer surface area (m2) |

| cp | specific heat capacity of fluid (J/kg·K) |

| d | diameter of the tube (m) |

| f | friction factor |

| h | heat transfer coefficient (W/m2·K) |

| k | thermal conductivity (W/m·K) |

| L | length of the test section (m) |

| m | mass flow rate (kg/s) |

| Nu | Nusselt number |

| ΔP | pressure drop (Pa) |

| Q | heat transfer rate (W) |

| Re | Reynolds number |

| T | temperature (K) |

| V | mean axial flow velocity (m/s) |

| K | overall heat transfer coefficient (W/m2·K) |

| ϕ | volume fraction of microparticle (%) |

| ρ | density (kg/m3) |

| μ | fluid dynamic viscosity (Pa·s) |

| η | thermal performance factor |

| Greek symbols | |

| c | cold fluid |

| h | hot fluid |

| i | inner |

| o | outer |

| w | water |

| mf | microfluid |

| mp | microparticle |

| in | inlet |

| out | outlet |

References

- Hajmohammadi, M.R.; Maleki, H.; Lorenzini, G.; Nourazar, S.S. Effects of Cu and Ag nano-particles on flow and heat transfer from permeable surfaces. Adv. Powder Technol. 2015, 26, 193–199. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, C.; Liu, S.; Tang, Y.; Yin, Y. Effects of nanoparticles clustering and alignment on thermal conductivities of Fe3O4 aqueous nanofluids. Appl. Phys. Lett. 2006, 89, 1–3. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K.; Namburu, P.K. Numerical study of fluid dynamic and heat transfer performance of Al2O3 and CuO nanofluids in the flat tubes of a radiator. Int. J. Heat Fluid Flow 2010, 31, 613–621. [Google Scholar] [CrossRef]

- Demir, H.; Dalkilic, A.S.; Kürekci, N.A. Numerical investigation on the single phase forced convection heat transfer characteristics of TiO2 nanofluids in a double-tube counter flow heat exchanger. Int. Commun. Heat Mass Transf. 2011, 38, 218–228. [Google Scholar] [CrossRef]

- Utomo, A.T.; Haghighi, E.B. The effect of nanoparticles on laminar heat transfer in a horizontal tube. Int. J. Heat Mass Transf. 2014, 69, 77–91. [Google Scholar] [CrossRef]

- Takabi, B.; Shokouhmand, H. Effects of Al2O3-Cu/water hybrid nanofluid on heat transfer and flow characteristics in turbulent regime. Int. J. Mod. Phys. C. 2015, 26, 15–47. [Google Scholar] [CrossRef]

- Takabi, B.; Gheitaghy, A.M.; Tazraei, P. Hybrid water-based suspension of Al2O3 and Cu nanoparticles on laminar convection effectiveness. J. Thermophys. Heat Transf. 2016, 30, 523–532. [Google Scholar] [CrossRef]

- Azmi, W.H.; Abdul, H.K.; Mamat, R.; Sharma, K.V.; Mohamad, M.S. Effects of working temperature on thermo-physical properties and forced convection heat transfer of TiO2 nanofluids in water-Ethylene glycol mixture. Appl. Therm. Eng. 2016, 106, 1190–1199. [Google Scholar] [CrossRef]

- Sun, D.; Yang, D. Experimental study on the heat transfer characteristics of nanorefrigerants in an internal thread copper tube. Int. J. Heat Mass Transf. 2013, 64, 559–566. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, L.; Xu, H. Experimental study on convective heat transfer and flow resistance characteristics of water flow in twisted elliptical tubes. Appl. Therm. Eng. 2011, 31, 2981–2991. [Google Scholar] [CrossRef]

- Tang, X.; Dai, X.; Zhu, D. Experimental and numerical investigation of convective heat transfer and fluid flow in twisted spiral tube. Int. J. Heat Mass Transf. 2015, 90, 523–541. [Google Scholar] [CrossRef]

- Bhadouriya, R.; Agrawal, A.; Prabhu, S.V. Experimental and numerical study of fluid flow and heat transfer in a twisted square duct. Int. J. Heat Mass Transf. 2015, 82, 143–158. [Google Scholar] [CrossRef]

- Pal, S.; Saha, S.K. Laminar fluid flow and heat transfer through a circular tube having spiral ribs and twisted tapes. Exp. Therm. Fluid Sci. 2015, 60, 173–181. [Google Scholar] [CrossRef]

- Wongcharee, K.; Eiamsa-ard, S. Heat transfer enhancement by using CuO/water nanofluid in corrugated tube equipped with twisted tape. Int. Commun. Heat Mass Transf. 2012, 39, 251–257. [Google Scholar] [CrossRef]

- Sun, B.; Yang, A.; Yang, D. Experimental study on the heat transfer and flow characteristics of nanofluids in the built-in twisted belt external thread tubes. Int. J. Heat Mass Transf. 2017, 95, 712–722. [Google Scholar] [CrossRef]

- Buzea, C.; Pacheco, I.I.; Robbie, K. Nanomaterials and nanoparticles: sources and toxicity. Biointerphases 2007, 2, MR17–MR71. [Google Scholar] [CrossRef]

- Tae-Hyun, C.; Kwon-Soo, L.; Chang-Hoan, L. An experimental study on velocity and temperature of Al/water microfluid in a circular tube with swirl. J. Vis. 2014, 17, 59–68. [Google Scholar]

- Zhu, J.Y.; Tang, S.; Pyshar, Y.; Thomas, B.; Khoshmanesh, K.; Ghorbani, K. Enhancement of laminar convective heat transfer using microparticle suspensions. Heat Mass Transf. 2017, 53, 169–176. [Google Scholar] [CrossRef]

- Wang, T.; Jin, W.; Gao, Z.; Xiao, J.; Tao, W.; Tang, J. Turbulent flow and enhanced heat transfer induced by Cu-water microfluid in tube. J. Vib. Shock 2018, 37, 108–114. [Google Scholar] [CrossRef]

- Stokes, G.G. On the Effect of the Internal Friction of Fluids on the Motion of Pendulums. Trans. Camb. Philo. Soc. 1851, 9, 89–106. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Fluid Therm. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Maxwell, J.C. Treatise on Electricity and Magnetism; Dover: New York, NY, USA, 1954. [Google Scholar]

- Einstein, A. Berichtigung, zu, meiner, Arbeit. eine neue Bestimmung der Molekul-dimensionen. Ann. Phys. 1911, 34, 591. [Google Scholar] [CrossRef]

- Wilson, E.E. A basis of rational design of heat transfer apparatus. ASME J. Heat Transf. 1915, 37, 47–70. [Google Scholar]

- Gidaspow, D. Multiphase Flow and Fluidization; Academic Press: Boston, MA, USA, 1994. [Google Scholar]

- Wen, C.Y.; Yu, Y.H. Mechanics of Fluidization. Chem. Eng. Prog. Symp. Ser. 1966, 62, 100–111. [Google Scholar]

- Ergun, S. Fluid Flow through Packed Columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Schmidt, A.; Renz, U. Numerical Prediction of Heat Transfer in Fluidized Beds by a Kinetic Theory of Granular Flows. Int. J. Therm. 2000, 39, 871–885. [Google Scholar] [CrossRef]

- Martinek, J.; Ma, Z. Granular Flow and Heat-Transfer Study in a Near-Blackbody Enclosed Particle Receiver. J. Sol. Energy Eng. 2015, 137, 1–9. [Google Scholar] [CrossRef]

- White, F.M. Viscous Fluid Flow; McGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Bayat, J.; Nikseresht, A.H. Thermal performance and pressure drop analysis of nanofluids in turbulent forced convective flows. Int. J. Therm. Sci. 2012, 60, 236–243. [Google Scholar] [CrossRef]

- Gnielinski, V. New equations for heat and mass-transfer in turbulent pipe and channel flow. Int. Chem. Eng. 1976, 16, 359–368. [Google Scholar]

| Parameter | Graphite | Al2O3 | CuO |

|---|---|---|---|

| Average grain diameter/μm | 5 | 5 | 5 |

| Purity/% | 99.9 | 99.9 | 99.9 |

| Density/kg·m−3 | 2250 | 3970 | 6500 |

| Specific heat/J·kg−1 °C−1 | 708 | 765 | 540 |

| Thermal conductivity/W·m−1·K−1 | 127 | 25 | 18 |

| Material Property | Experimental Velocity /mm·s−1 | Calculated Velocity by the Stokes Formula [17] /mm·s−1 | Error/% |

|---|---|---|---|

| Graphite | 0.021 | 0.0198 | 6 |

| Al2O3 | 0.050 | 0.0469 | 7 |

| CuO | 0.091 | 0.0866 | 5 |

| Apparatus Name | Uncertainty /% |

|---|---|

| Pt100 | 0.5 |

| pressure transducer | 0.5 |

| turbine flowmeters | 0.5 |

| Experimental Parameters | Uncertainty /% |

|---|---|

| f | 1.42 |

| Nu | 12 |

| Re | 0.55 |

| Fluid | Microfluid | Water |

|---|---|---|

| Fluid flow | Eulerian multiphase | single-phase model |

| Turbulence modeling | Realizable k–ε model | Same as microfluid |

| Near-wall modeling method | Enhanced wall treatment | Same as microfluid |

| Microfluid concentrations | 0.25%, 0.5%, 0.75%, 1.0% | 0% |

| y+ | <1 | <1 |

| Boundary Conditions | Setting |

|---|---|

| tube wall | No-slip |

| shell wall | No-Slip |

| tube inlet | velocity |

| tube outlet | pressure |

| shell inlet | velocity |

| shell outlet | pressure |

| tube inlet temperature | 300 K |

| shell inlet temperature | 320 K |

| two sides of the tube wall | coupled thermal conditions |

| shell wall | adiabatic |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Gao, Z.; Jin, W. Enhancement of Turbulent Convective Heat Transfer using a Microparticle Multiphase Flow. Energies 2020, 13, 1282. https://doi.org/10.3390/en13051282

Wang T, Gao Z, Jin W. Enhancement of Turbulent Convective Heat Transfer using a Microparticle Multiphase Flow. Energies. 2020; 13(5):1282. https://doi.org/10.3390/en13051282

Chicago/Turabian StyleWang, Tao, Zengliang Gao, and Weiya Jin. 2020. "Enhancement of Turbulent Convective Heat Transfer using a Microparticle Multiphase Flow" Energies 13, no. 5: 1282. https://doi.org/10.3390/en13051282

APA StyleWang, T., Gao, Z., & Jin, W. (2020). Enhancement of Turbulent Convective Heat Transfer using a Microparticle Multiphase Flow. Energies, 13(5), 1282. https://doi.org/10.3390/en13051282