Establishment and Validation of a Two-Component Surrogate Fuel Chemical Kinetic Skeletal Model for Fischer–Tropsch Fuel Synthesized from Coal

Abstract

1. Introduction

2. Model Development Theory

2.1. F–T Fuel Surrogate Model

2.2. Direct Relationship Graph (DRG) Method

2.3. Computational Singular Perturbation (CSP) Importance Index Method Method

2.4. Decoupling Method

3. Model Formulation

3.1. Simplified Mechanism of n-Dodecane

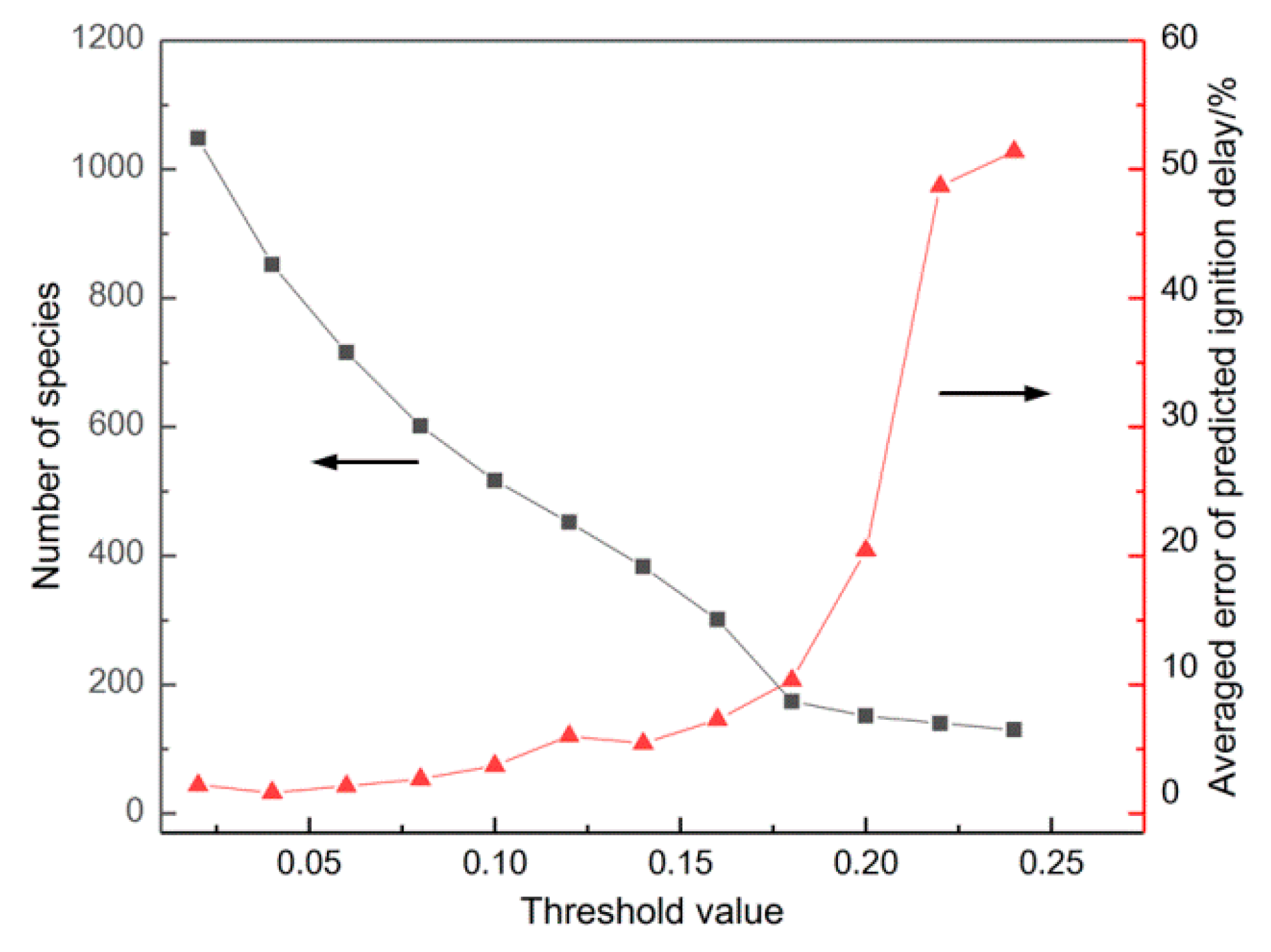

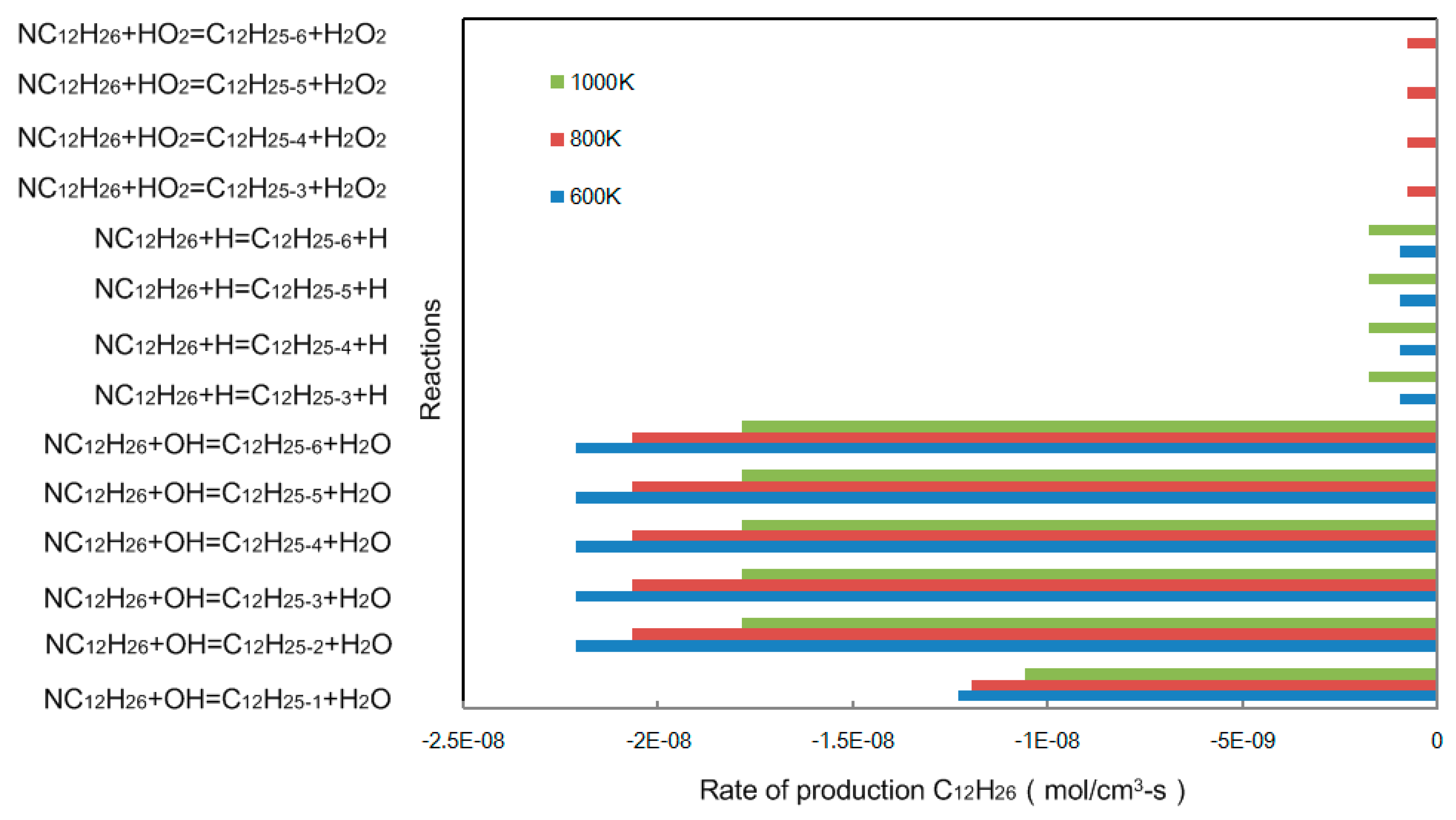

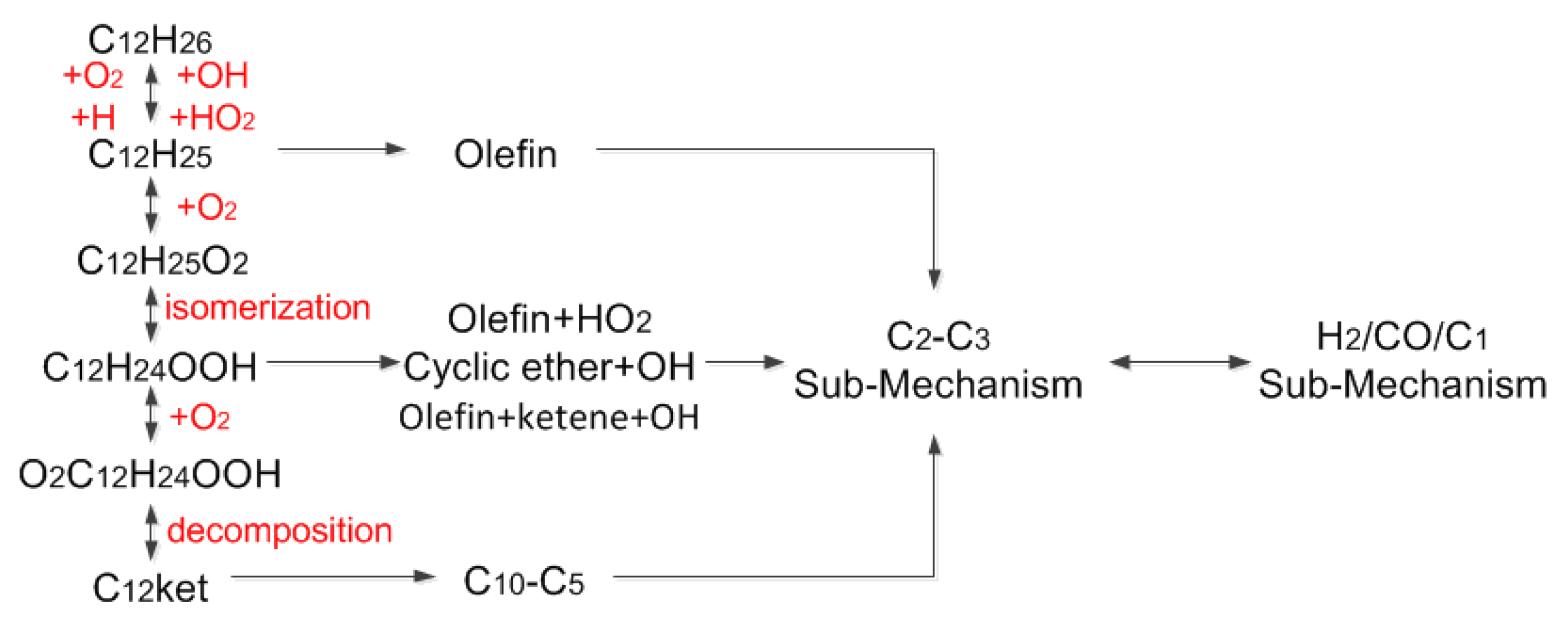

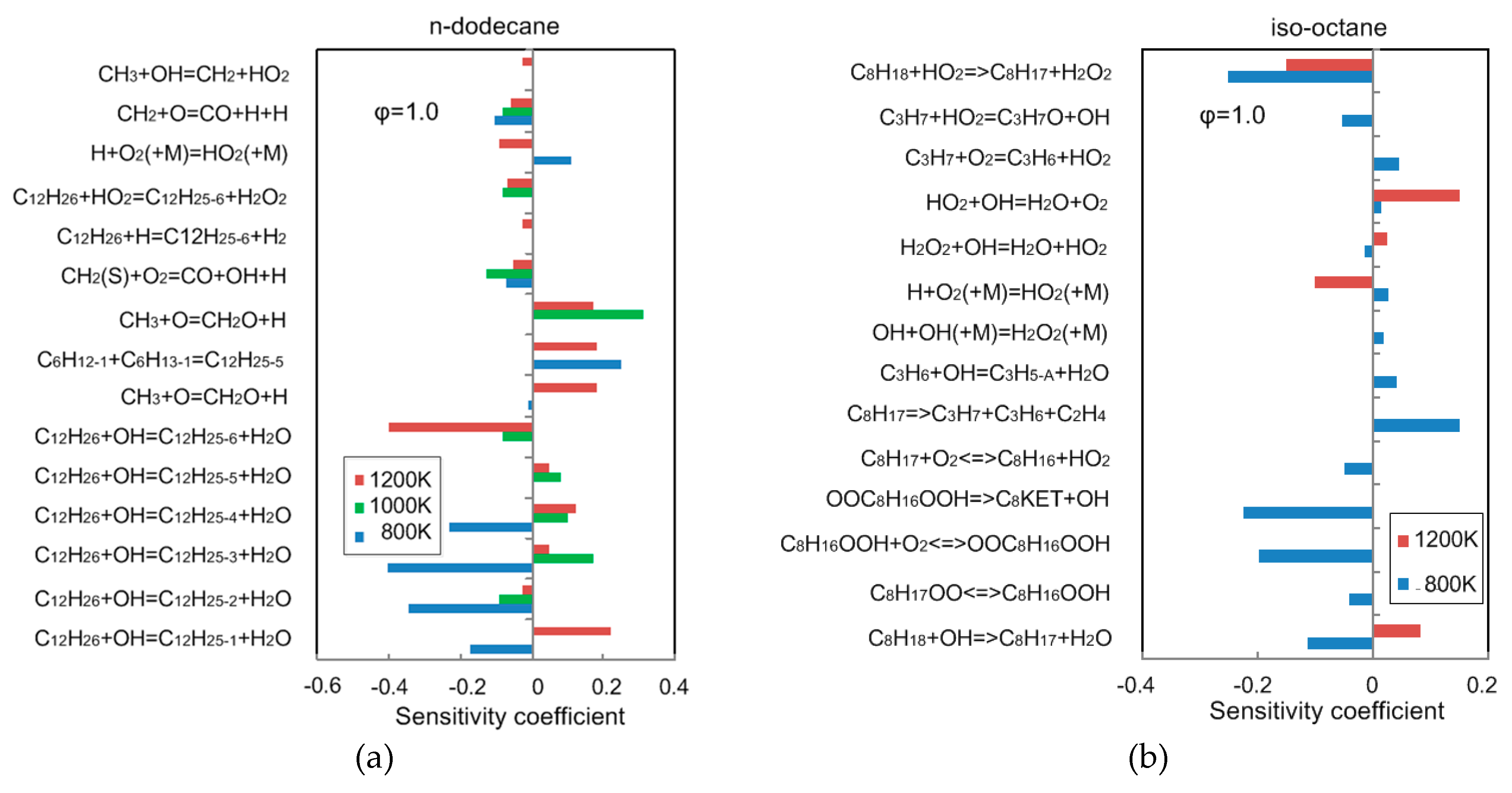

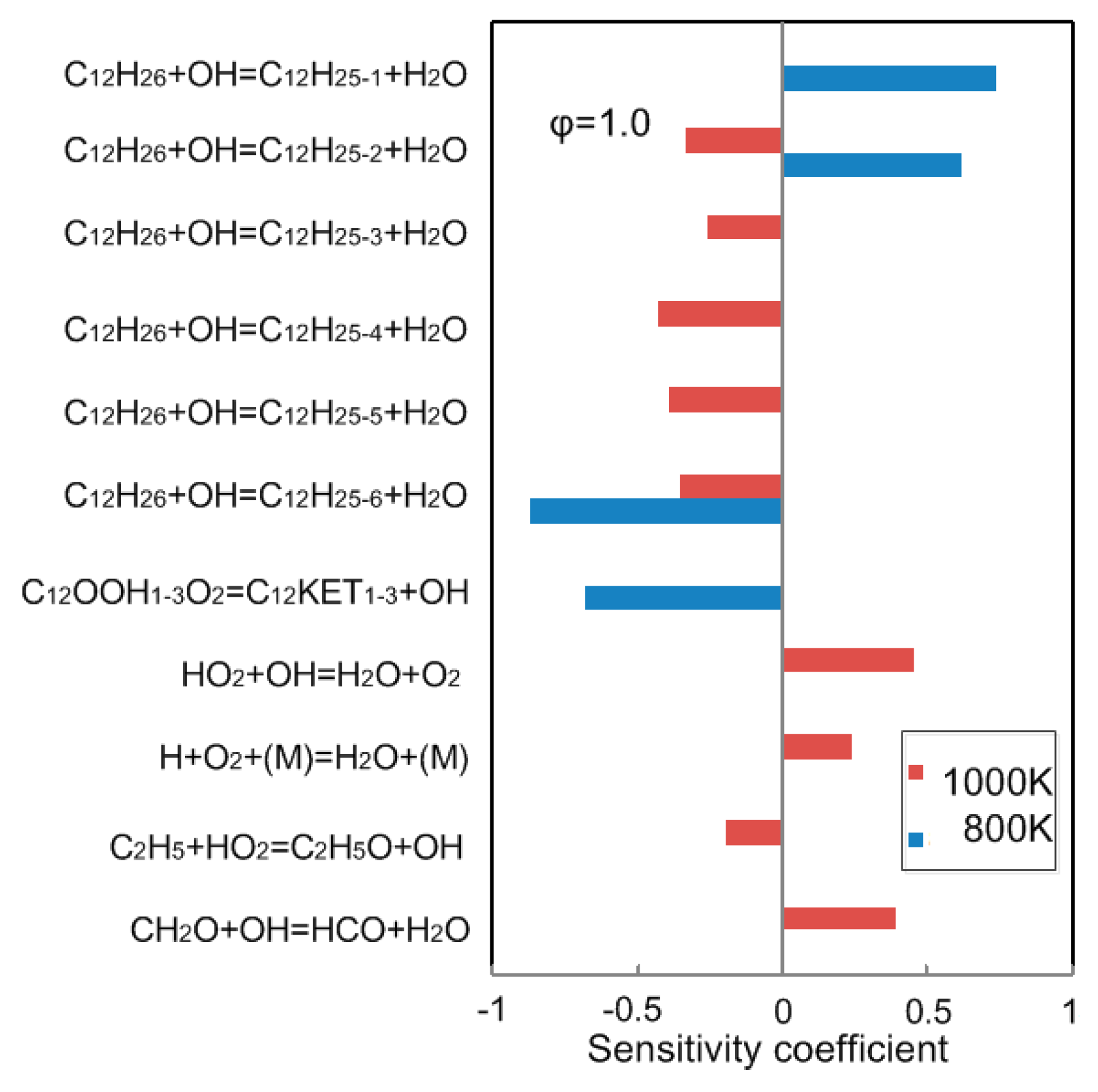

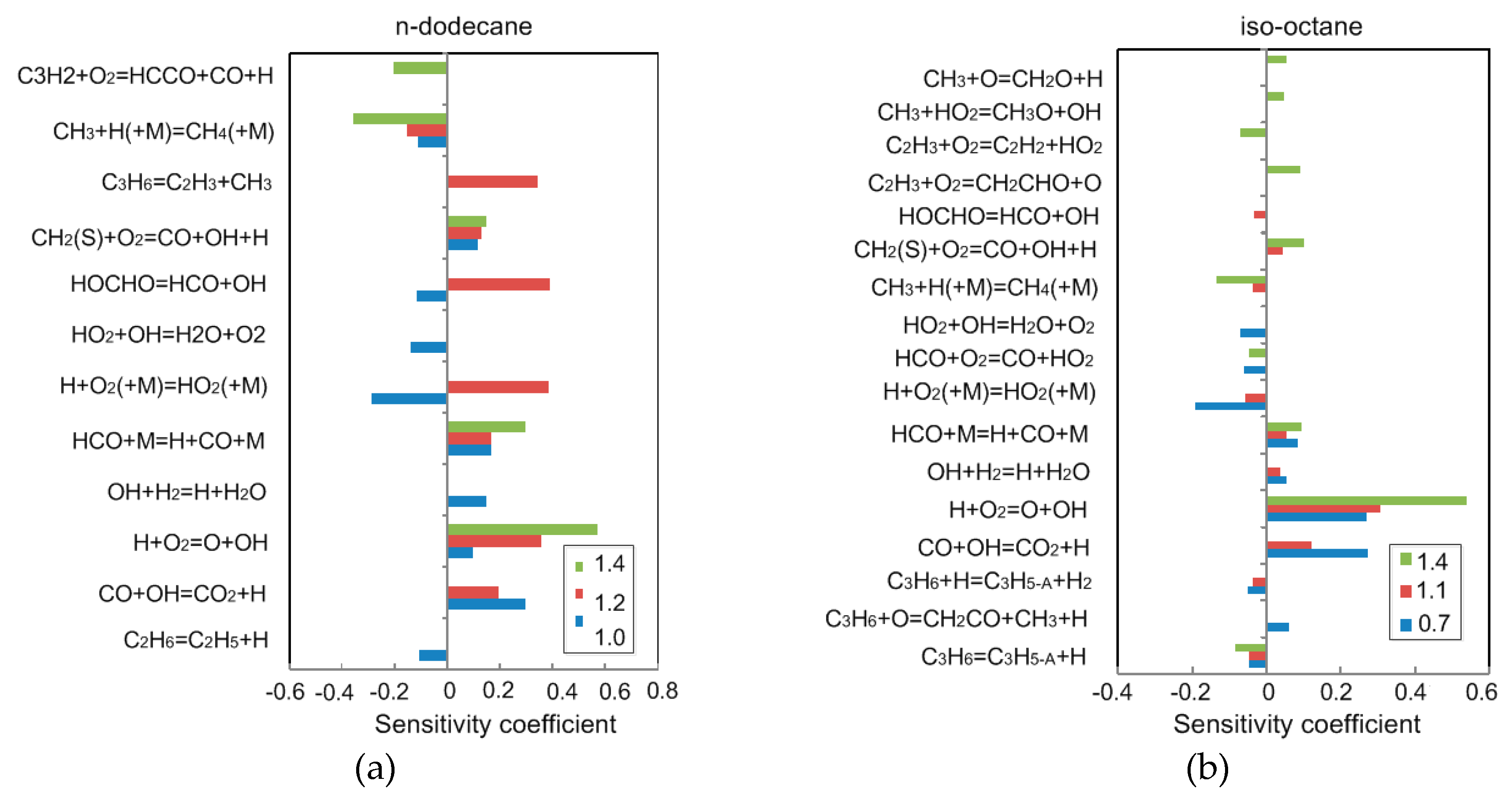

3.2. Skeletal Mechanism of n-Dodecane

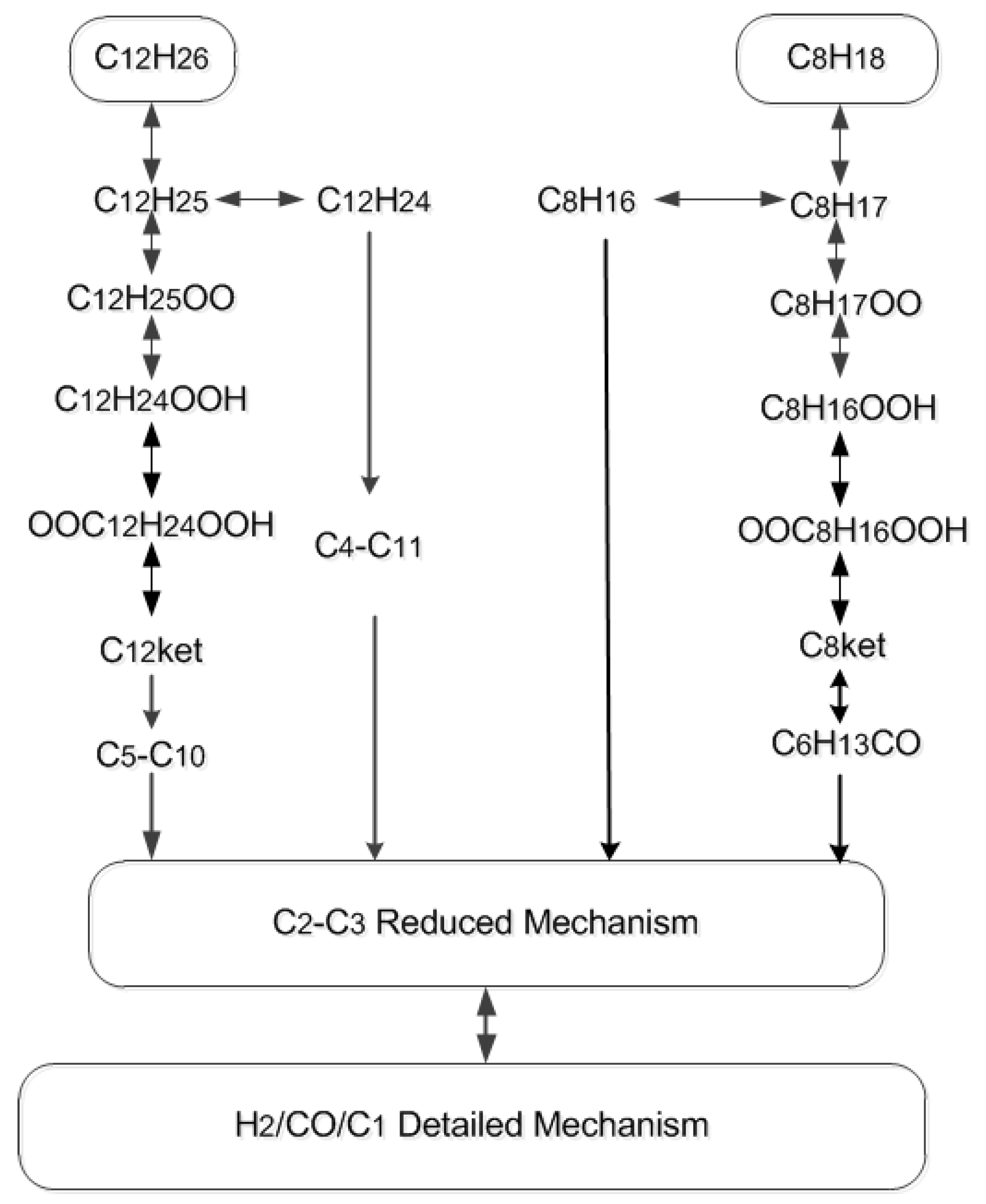

3.3. Skeletal Mechanism of Surrogate Fuel

4. Model Validation

4.1. Validation of Ignition Delay of Shock Tube

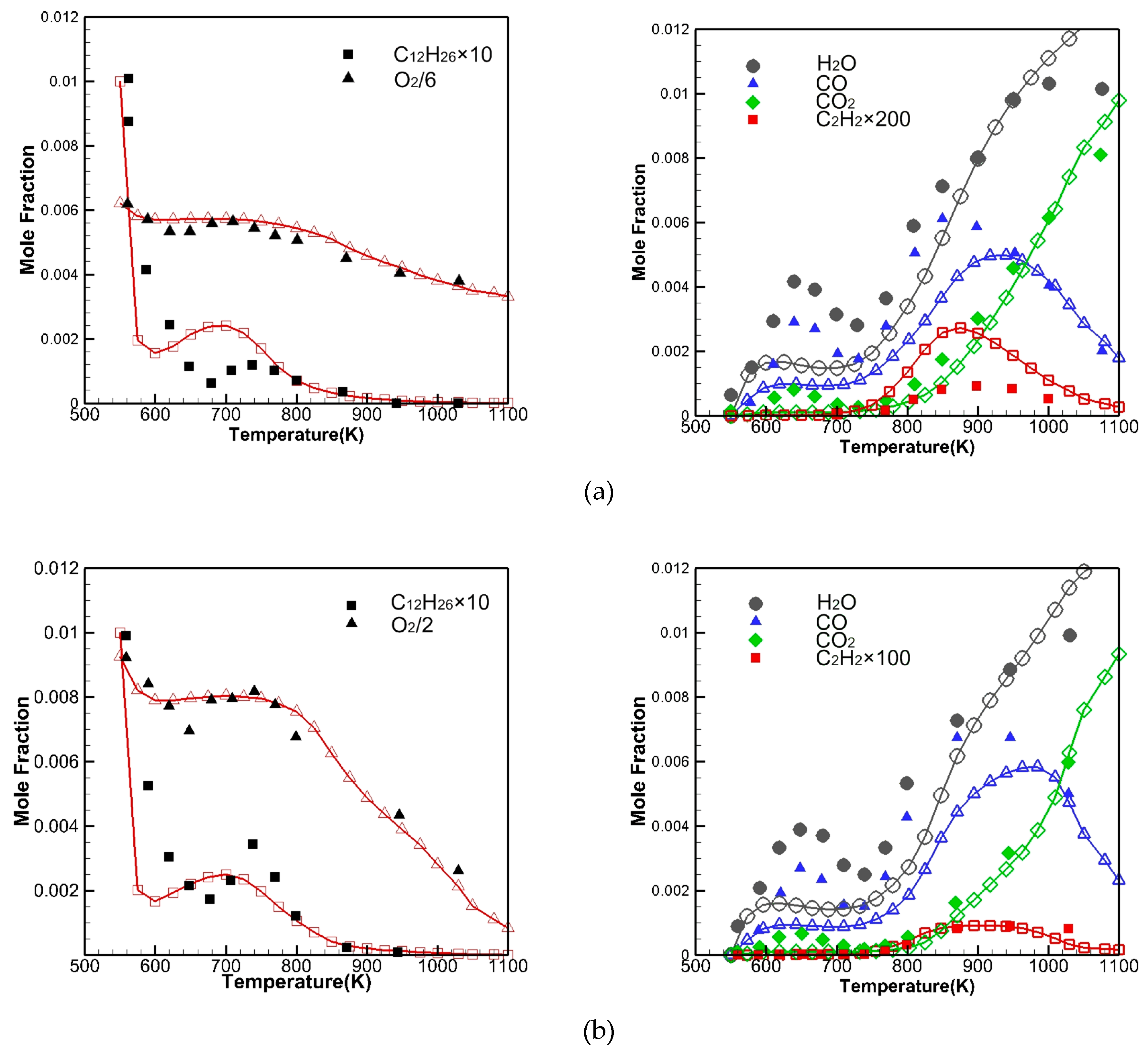

4.2. Validation of Primary Species Concentration of JSR

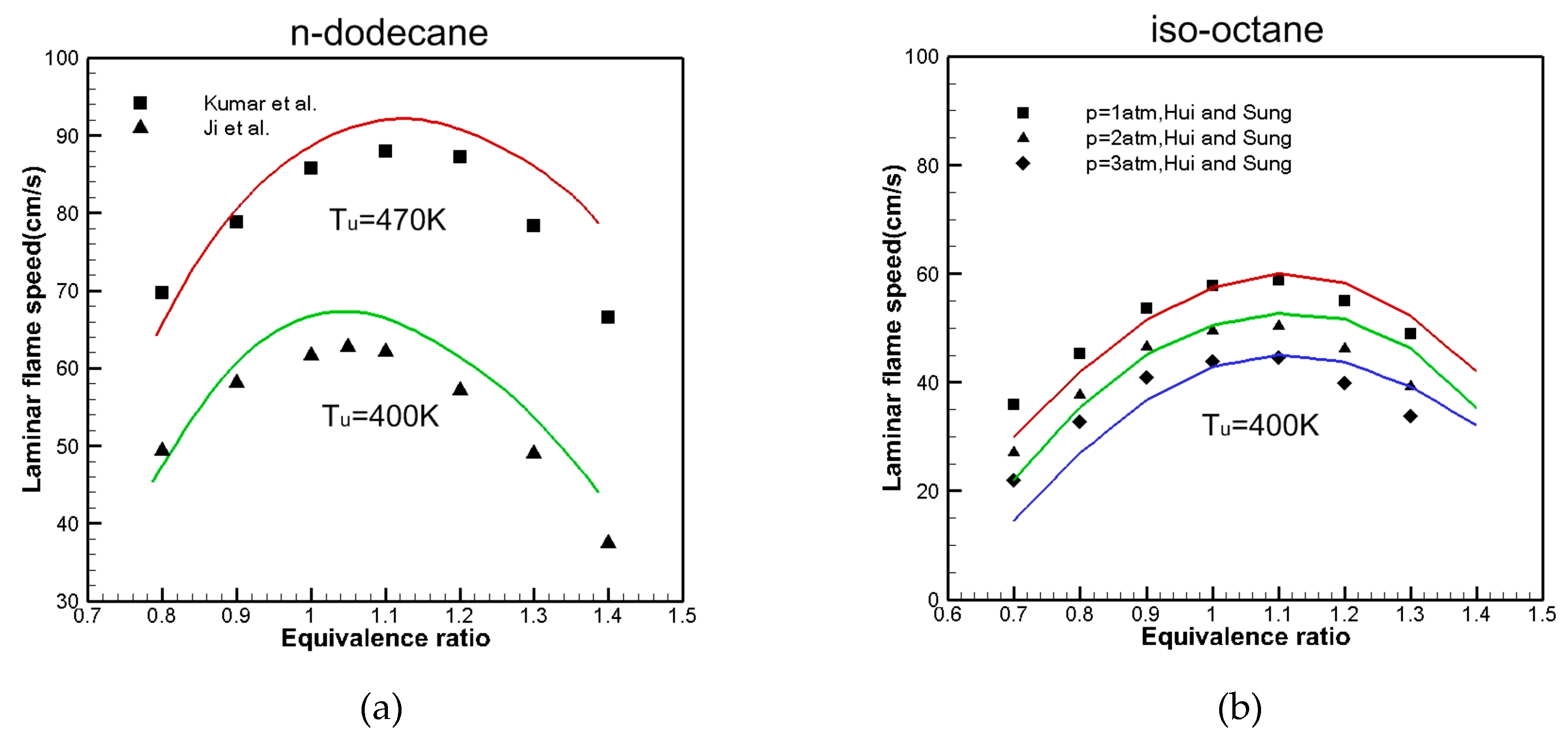

4.3. Validation of Laminar Flame Speeds

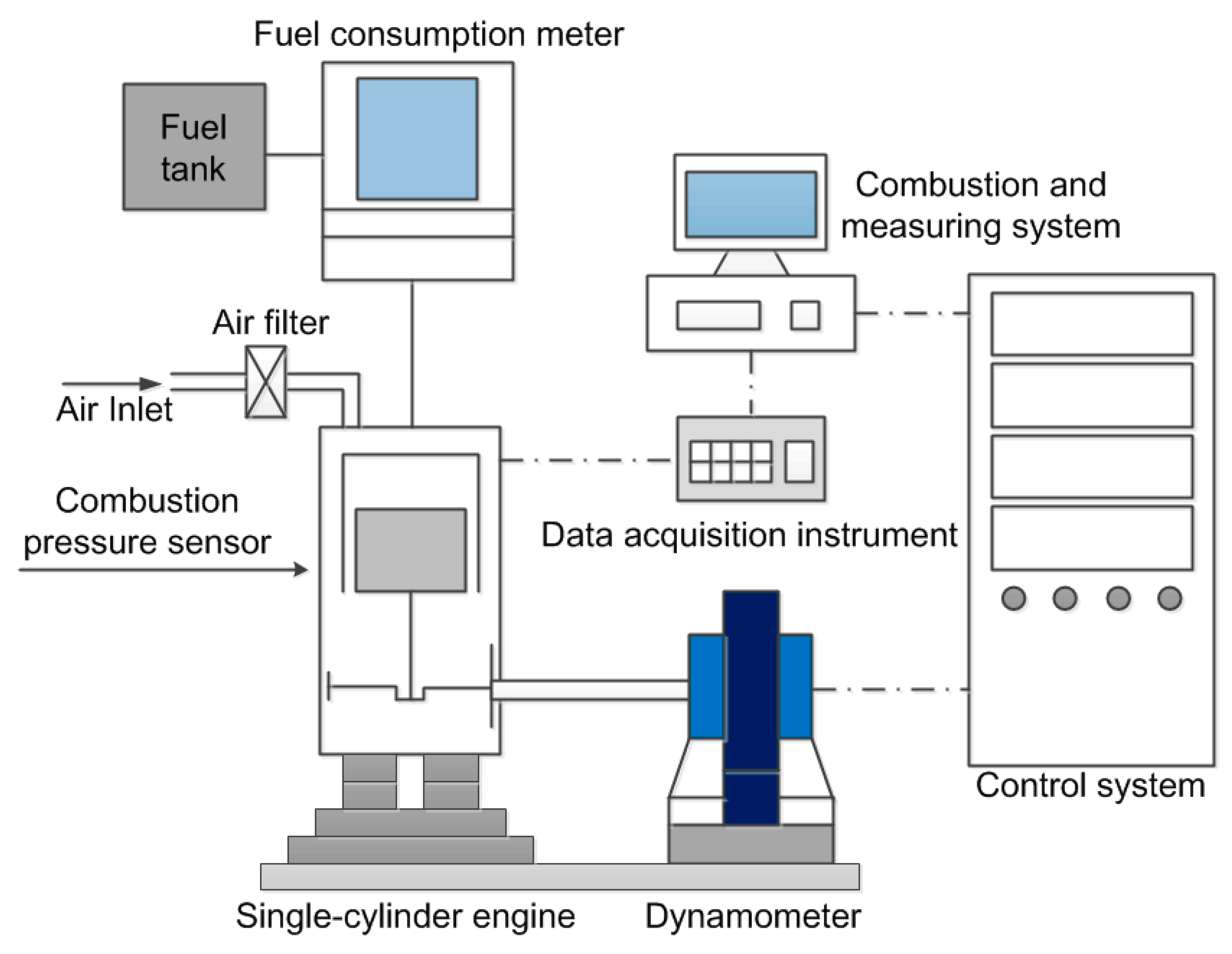

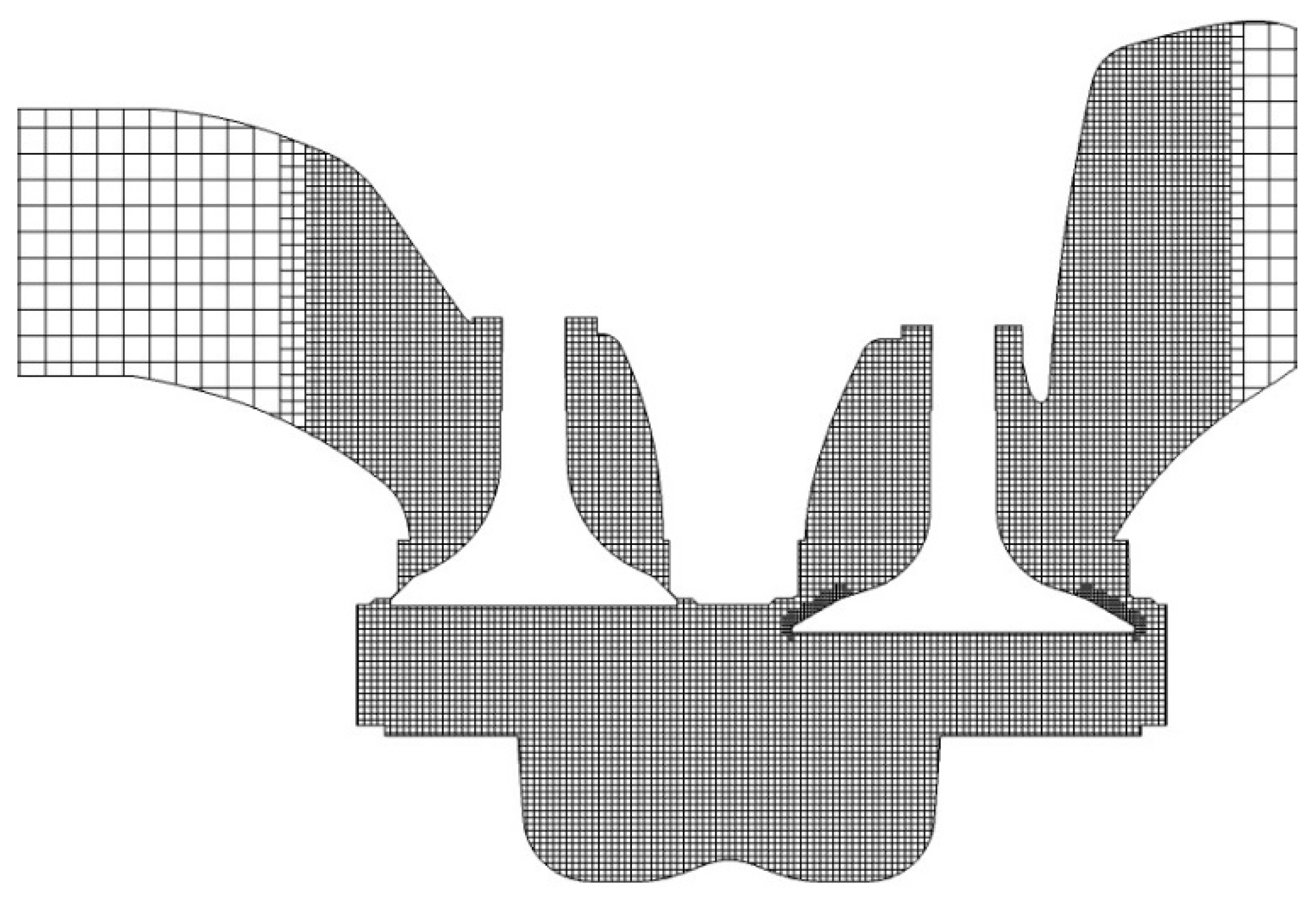

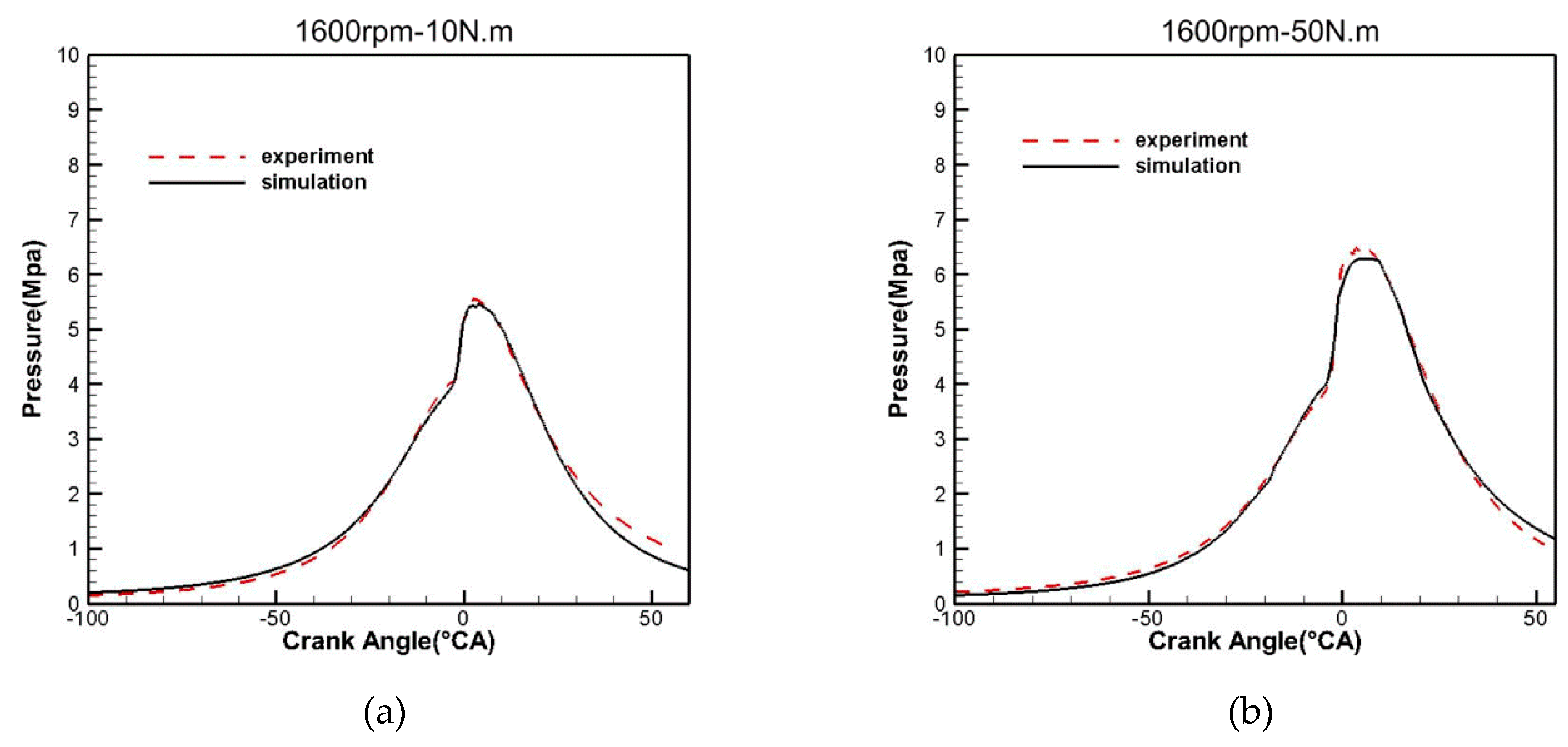

4.4. Validation Mechanism in an Engine

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Shahib-Eldin, A. New Energy Technologies: Trends in the Development of Clean and Efficient Energy Technologies. Opec Rev. 2010, 26, 261–307. [Google Scholar] [CrossRef]

- Shi, J.; Wang, T.; Zhao, Z.; Yang, T.; Zhang, Z. Experimental Study of Injection Parameters on the Performance of a Diesel Engine with Fischer–Tropsch Fuel Synthesized from Coal. Energies 2018, 11, 3280. [Google Scholar] [CrossRef]

- Balagurunathan, J.; Flora, G.; Saxena, S.; Kahandawala, M.; Dewitt, M.; Sidhu, S.; Corporan, E. Ignition Delay Times of a Range of Alternate Jet-Fuels and Surrogate Fuel Candidate Hydrocarbons under Fuel-Lean Conditions: A Shock Tube Study. In Proceedings of the Aiaa Aerospace Sciences Meeting Including the New Horizons Forum & Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

- Dooley, S.; Sang, H.W.; Jahangirian, S.; Ju, Y.; Dryer, F.L.; Wang, H.; Oehlschlaeger, M.A. The combustion kinetics of a synthetic paraffinic jet aviation fuel and a fundamentally formulated, experimentally validated surrogate fuel. Combust. Flame 2012, 159, 3014–3020. [Google Scholar] [CrossRef]

- Dagaut, P.; Karsenty, F.; Dayma, G.; Diévart, P.; Hadj-Ali, K.; Mzé-Ahmed, A.; Braun-Unkhoff, M.; Herzler, J.; Kathrotia, T.; Kick, T. Experimental and detailed kinetic model for the oxidation of a Gas to Liquid (GtL) jet fuel. Combust. Flame 2014, 161, 835–847. [Google Scholar] [CrossRef]

- Naik, C.V.; Puduppakkam, K.V.; Modak, A.; Meeks, E.; Wang, Y.L.; Feng, Q.; Tsotsis, T.T. Detailed chemical kinetic mechanism for surrogates of alternative jet fuels. Combus. Flame 2011, 158, 434–445. [Google Scholar] [CrossRef]

- May-Carle, J.B.; Pidol, L.; Nicolle, A.; Anderlohr, J.M.; Togbé, C.; Dagaut, P. Experimental and Numerical Study of F-T/Biodiesel/Bioethanol Surrogate Fuel Oxidation in Jet-Stirred Reactor. Combust. Sci. Technol. 2012, 184, 901–915. [Google Scholar] [CrossRef]

- Huang, Y.C.; Zhou, L.B.; Jiang, D.M. Study and Development of Fischer-Tropsch(F-T) Diesel Fuel as a Clean Alternative Fuel for Diesel Engines. Chin. Int. Combust. Engine Eng. 2005, 26, 18–23. [Google Scholar]

- Sang, H.W.; Haas, F.M.; Dooley, S.; Edwards, T.; Dryer, F.L. Reconstruction of chemical structure of real fuel by surrogate formulation based upon combustion property targets. Combust. Flame 2017, 183, 39–49. [Google Scholar]

- Dooley, S.; Sang, H.W.; Heyne, J.; Farouk, T.I.; Ju, Y.; Dryer, F.L.; Kumar, K.; Xin, H.; Sung, C.J.; Wang, H. The experimental evaluation of a methodology for surrogate fuel formulation to emulate gas phase combustion kinetic phenomena. Combust. Flame 2012, 159, 1444–1466. [Google Scholar] [CrossRef]

- Dooley, S.; Won, S.H.; Chaos, M.; Heyne, J.; Ju, Y.; Dryer, F.L.; Kumar, K.; Sung, C.-J.; Wang, H.; Oehlschlaeger, M.A.; et al. A jet fuel surrogate formulated by real fuel properties. Combust. Flame 2010, 157, 2333–2339. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Pitz, W.J.; Herbinet, O.; Curran, H.J.; Silke, E.J. A comprehensive detailed chemical kinetic reaction mechanism for combustion of n-alkane hydrocarbons from n-octane to n-hexadecane. Combust. Flame 2009, 156, 181–199. [Google Scholar] [CrossRef]

- Liu, Y.; Ming, J.; Xie, M.; Pang, B. Improvement on a skeletal chemical kinetic model of iso-octane for internal combustion engine by using a practical methodology. Fuel 2013, 103, 884–891. [Google Scholar] [CrossRef]

- Liu, Y.D.; Jia, M.; Xie, M.Z.; Pang, B. Enhancement on a Skeletal Kinetic Model for Primary Reference Fuel Oxidation by Using a Semidecoupling Methodology. Energy Fuels 2012, 26, 7069–7083. [Google Scholar] [CrossRef]

- Ranzi, E.; Frassoldati, A.; Grana, R.; Cuoci, A.; Faravelli, T.; Kelley, A.P.; Law, C.K. Hierarchical and comparative kinetic modeling of laminar flame speeds of hydrocarbon and oxygenated fuels. Prog. Energy Combust. Sci. 2012, 38, 468–501. [Google Scholar] [CrossRef]

- Ji, C.; Dames, E.; Wang, Y.L.; Hai, W.; Egolfopoulos, F.N. Propagation and extinction of premixed C 5 –C 12 n -alkane flames. Combust. Flame 2010, 157, 277–287. [Google Scholar] [CrossRef]

- Hu, H.; Keck, J. Autoignition of Adiabatically Compressed Combustible Gas Mixtures. SAE Trans. 1987, 96, 592–604. [Google Scholar]

- Cox, R.A.; Cole, J.A. Chemical aspects of the autoignition of hydrocarbon air mixtures. Combust. Flame 1985, 60, 109–123. [Google Scholar] [CrossRef]

- Chang, Y.; Ming, J.; Li, Y.; Liu, Y.; Xie, M.; Hu, W.; Reitz, R.D. Development of a skeletal mechanism for diesel surrogate fuel by using a decoupling methodology. Combust. Flame 2015, 162, 3785–3802. [Google Scholar] [CrossRef]

- Chang, Y.; Jia, M.; Niu, B.; Xu, Z.; Liu, Z.; Li, Y.; Xie, M. Construction of a skeletal oxidation mechanism of n-pentanol by integrating decoupling methodology, genetic algorithm, and uncertainty quantification. Combust. Flame 2018, 194, 15–27. [Google Scholar] [CrossRef]

- Lu, T.; Law, C.K. Linear time reduction of large kinetic mechanisms with directed relation graph: N-Heptane and iso-octane. Combust. Flame 2006, 144, 24–36. [Google Scholar] [CrossRef]

- Klippenstein, S.J.; Harding, L.B.; Davis, M.J.; Tomlin, A.S.; Skodje, R.T. Uncertainty driven theoretical kinetics studies for CH3OH ignition: HO2 + CH3OH and O2 + CH3OH. Proc. Combust. Inst. 2011, 33, 351–357. [Google Scholar] [CrossRef]

- Vasu, S.S.; Davidson, D.F.; Hong, Z.; Vasudevan, V.; Hanson, R.K. n-Dodecane oxidation at high-pressures: Measurements of ignition delay times and OH concentration time-histories. Proc. Combust. Inst. 2009, 32, 173–180. [Google Scholar] [CrossRef]

- Shen, H.-P.S.; Vanderover, J.; Oehlschlaeger, M.A. A shock tube study of iso-octane ignition at elevated pressures: The influence of diluent gases. Combust. Flame 2008, 155, 739–755. [Google Scholar] [CrossRef]

- Davidson, D.F.; Gauthier, B.M.; Hanson, R.K. Shock tube ignition measurements of iso-octane/air and toluene/air at high pressures. Proc. Combust. Inst. 2005, 30, 1175–1182. [Google Scholar] [CrossRef]

- Pitz, W.J.; Mueller, C.J. Recent progress in the development of diesel surrogate fuels. Prog. Energy Combust. Sci. 2011, 37, 330–350. [Google Scholar] [CrossRef]

- Mzé-Ahmed, A.; Hadj-Ali, K.; Dagaut, P.; Dayma, G. Experimental and Modeling Study of the Oxidation Kinetics of n-Undecane and n-Dodecane in a Jet-Stirred Reactor. Energy Fuels 2012, 26, 4253–4268. [Google Scholar] [CrossRef]

- Mehl, M.; Pitz, W.J.; Sarathy, S.M.; Westbrook, C.K. Modeling the combustion of high molecular weight fuels by a functional group approach. Int. J. Chem. Kinet. 2012, 44, 257–276. [Google Scholar] [CrossRef]

- Kumar, K.; Sung, C.J. Laminar flame speeds and extinction limits of preheated n -decane/O2/N2 and n -dodecane/O2/N2 mixtures. Combust. Flame 2007, 151, 209–224. [Google Scholar] [CrossRef]

- Hui, X.; Sung, C.-J. Laminar flame speeds of transportation-relevant hydrocarbons and jet fuels at elevated temperatures and pressures. Fuel 2013, 109, 191–200. [Google Scholar] [CrossRef]

- Ji, C.; Sarathy, S.M.; Veloo, P.S.; Westbrook, C.K.; Egolfopoulos, F.N. Effects of fuel branching on the propagation of octane isomers flames. Combust. Flame 2012, 159, 1426–1436. [Google Scholar] [CrossRef]

| F–T Fuel | Surrogate Fuel | |

|---|---|---|

| n-paraffin(mol.%) | 76.234 | - |

| iso-paraffin(mol.%) | 23.766 | - |

| n-dodecane(mol.%) | - | 76 |

| iso-octane(mol.%) | - | 24 |

| C/H ratio by weight | 5.466 | 5.45 |

| Cetane number | 65 | 65 |

| Item/Parameter | Details |

|---|---|

| Engine type | Single cylinder, Vertical, four-stroke |

| Cooling way | Water-cooled |

| Bore×stroke | 125 × 120 |

| Compression ratio | 17.5 |

| The piston displacement | 1.473L |

| Intake valve opening | 12°CA before TDC |

| Intake valve closing | 38°CA after BDC |

| Exhaust valve opening | 55°CAbefore BDC |

| Exhaust valve closing | 12°CA after TDC |

| Rated power | 20.1kW@2200rpm |

| Instrument | Parameters | Range | Accuracy | Uncertainty (%) |

|---|---|---|---|---|

| Electric eddy current | Torque | 0–160 Nm | ±0.4% | - |

| Dynamometer | Speed | 0–10000 r/min | ±1 r/min | - |

| Fuel consumption meter | F–T Fuel | 0–20 kg | ±0.4% | - |

| Pressure sensor | In-cylinder pressure | 0–5 MPa | ±0.05 MPa | ±0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Zhang, R.; Feng, Y.; Yang, T. Establishment and Validation of a Two-Component Surrogate Fuel Chemical Kinetic Skeletal Model for Fischer–Tropsch Fuel Synthesized from Coal. Energies 2020, 13, 1168. https://doi.org/10.3390/en13051168

Liu R, Zhang R, Feng Y, Yang T. Establishment and Validation of a Two-Component Surrogate Fuel Chemical Kinetic Skeletal Model for Fischer–Tropsch Fuel Synthesized from Coal. Energies. 2020; 13(5):1168. https://doi.org/10.3390/en13051168

Chicago/Turabian StyleLiu, Ruiqing, Ruiliang Zhang, Yizhuo Feng, and Tiantian Yang. 2020. "Establishment and Validation of a Two-Component Surrogate Fuel Chemical Kinetic Skeletal Model for Fischer–Tropsch Fuel Synthesized from Coal" Energies 13, no. 5: 1168. https://doi.org/10.3390/en13051168

APA StyleLiu, R., Zhang, R., Feng, Y., & Yang, T. (2020). Establishment and Validation of a Two-Component Surrogate Fuel Chemical Kinetic Skeletal Model for Fischer–Tropsch Fuel Synthesized from Coal. Energies, 13(5), 1168. https://doi.org/10.3390/en13051168