Active Shock Absorber Control Based on Time-Delay Neural Network

Abstract

1. Introduction

2. Methodology

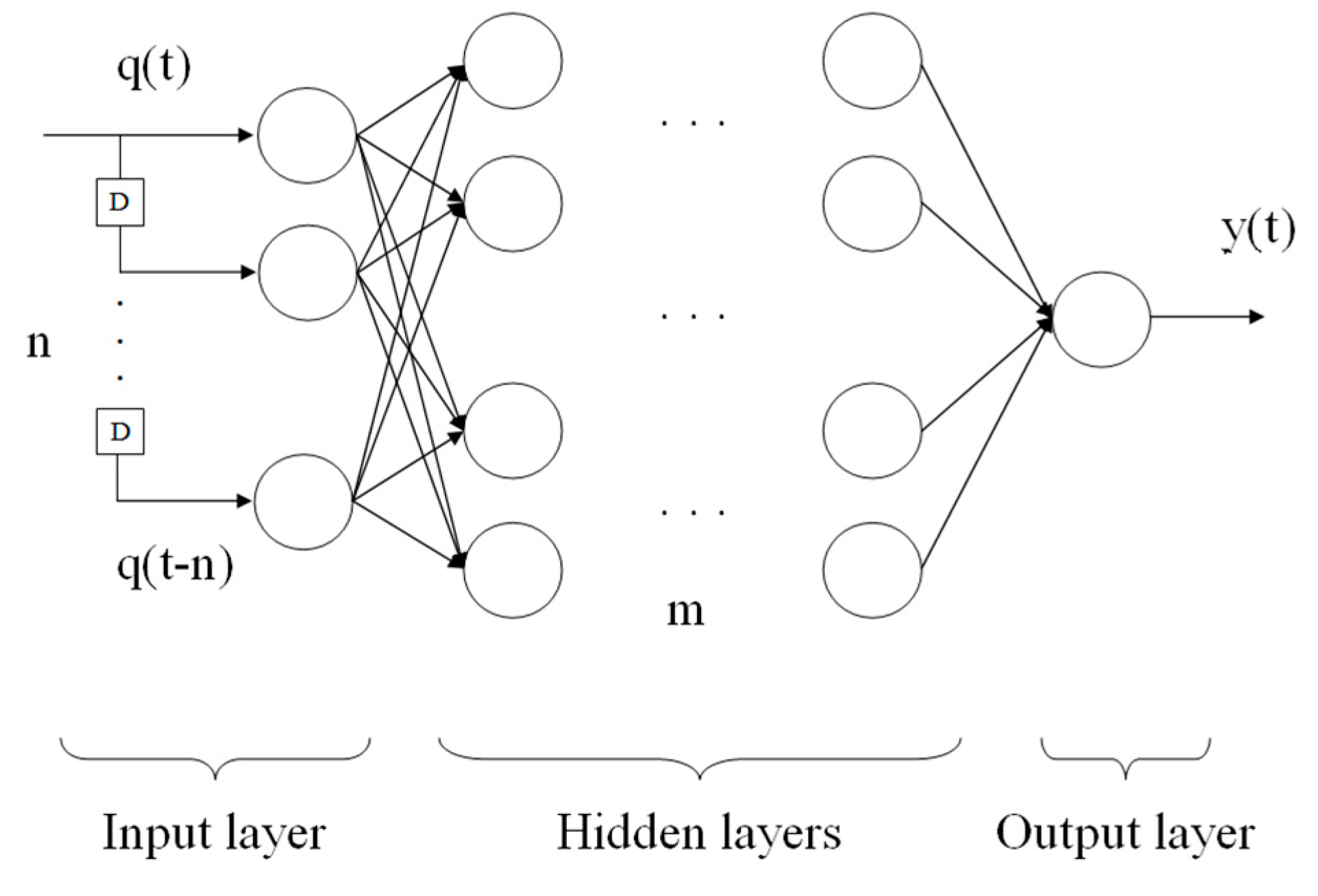

3. Time Delay Neural Network Controller Design

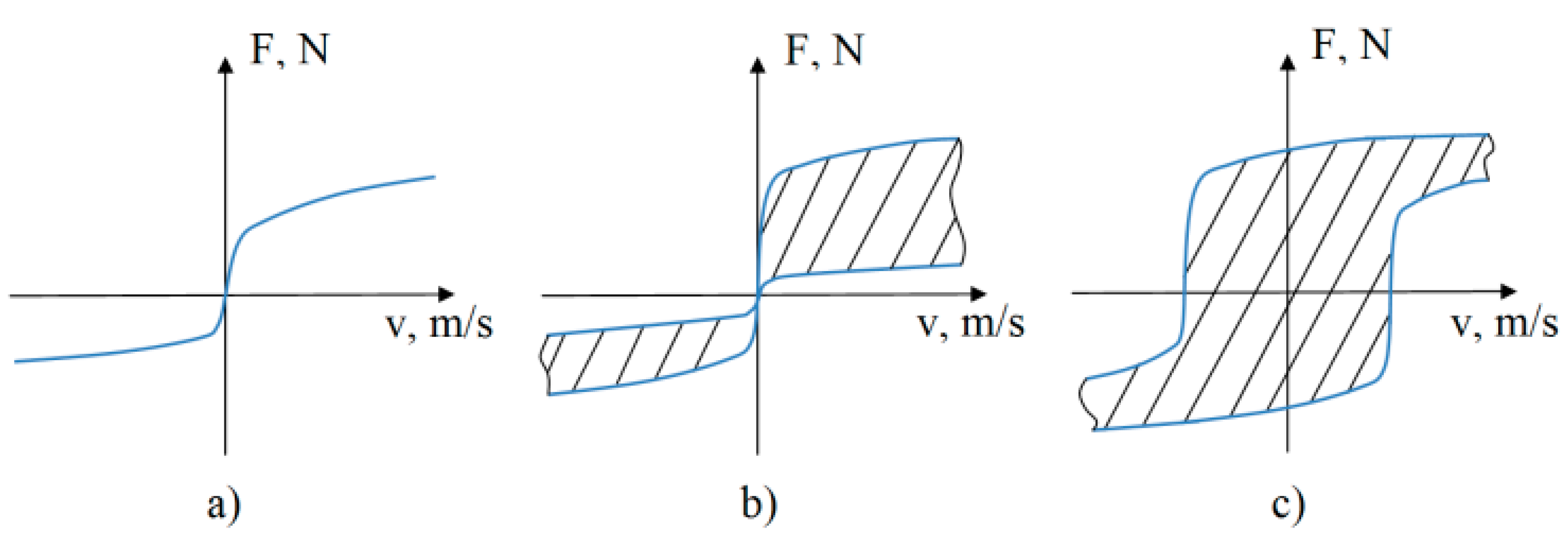

3.1. Active Shock Absorber Description

- The currents on the solenoid valves of the compression and rebound strokes , whose values lie in the range 0…1.8 A. Applying the current value to the valve changes its capacity. The values of the force on the shock absorber rod and the values of the speed of the rod always have the same sign. Thus, a shock absorber controlled only by the currents on the valves works as semi-active. The set of a dynamic dissipative characteristics of the shock absorber for different values of currents is shown in Figure 2. In Figure 2 and Figure 3, the following notation in used: force on the rod, —velocity of the rod, —control current, —hydraulic pump flow rate.

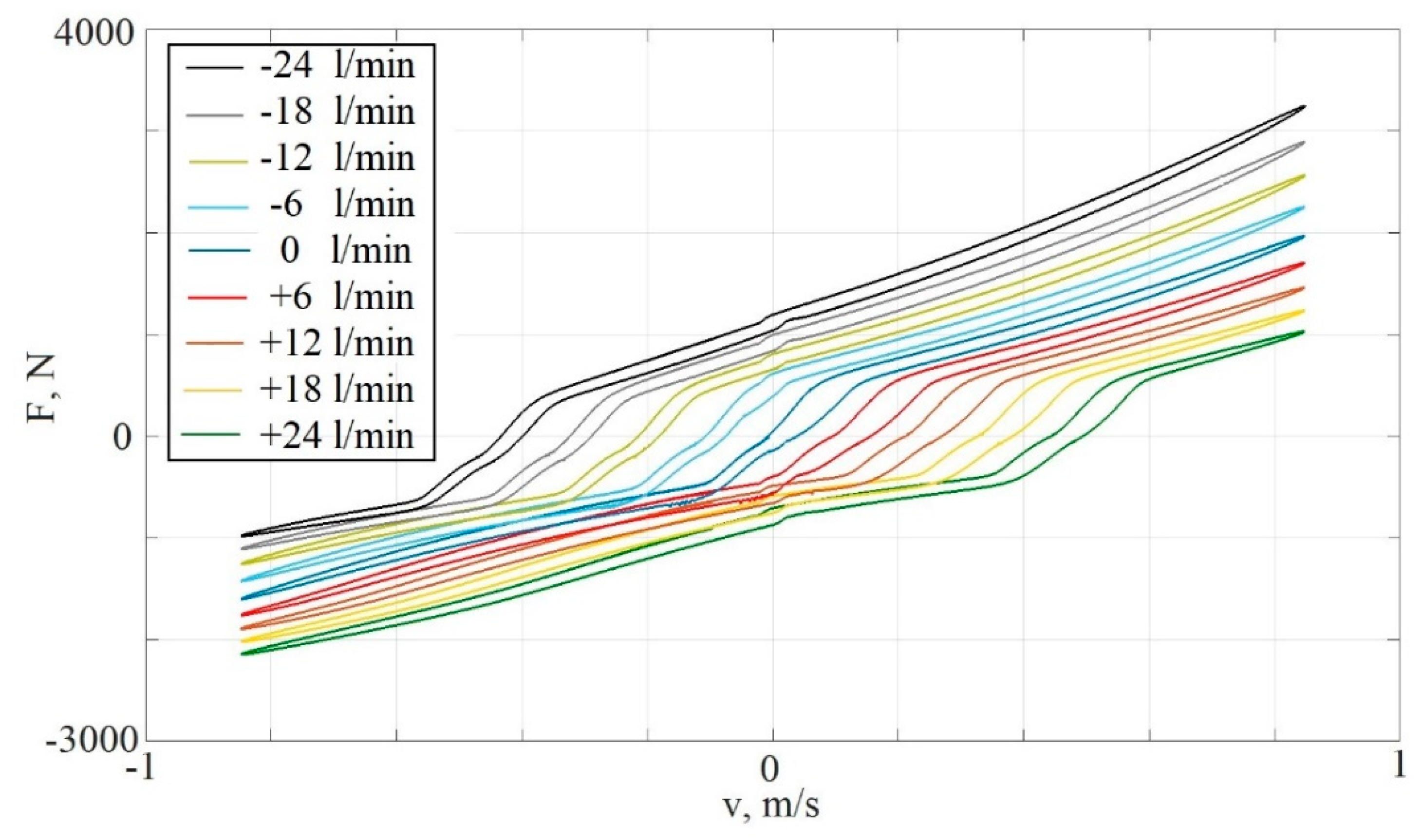

- The hydraulic pump flow rate Q lies in the range of −24…24 l/min, where the sign determines the direction of the fluid flow. The set of dissipative characteristics obtained for different values of Q are presented in Figure 3. A pump is essentially an external source of energy in the system, and thus it becomes possible to generate forces on the rod opposite to the direction of the movement of the rod. This is how the “active” property of the shock absorber is realized.

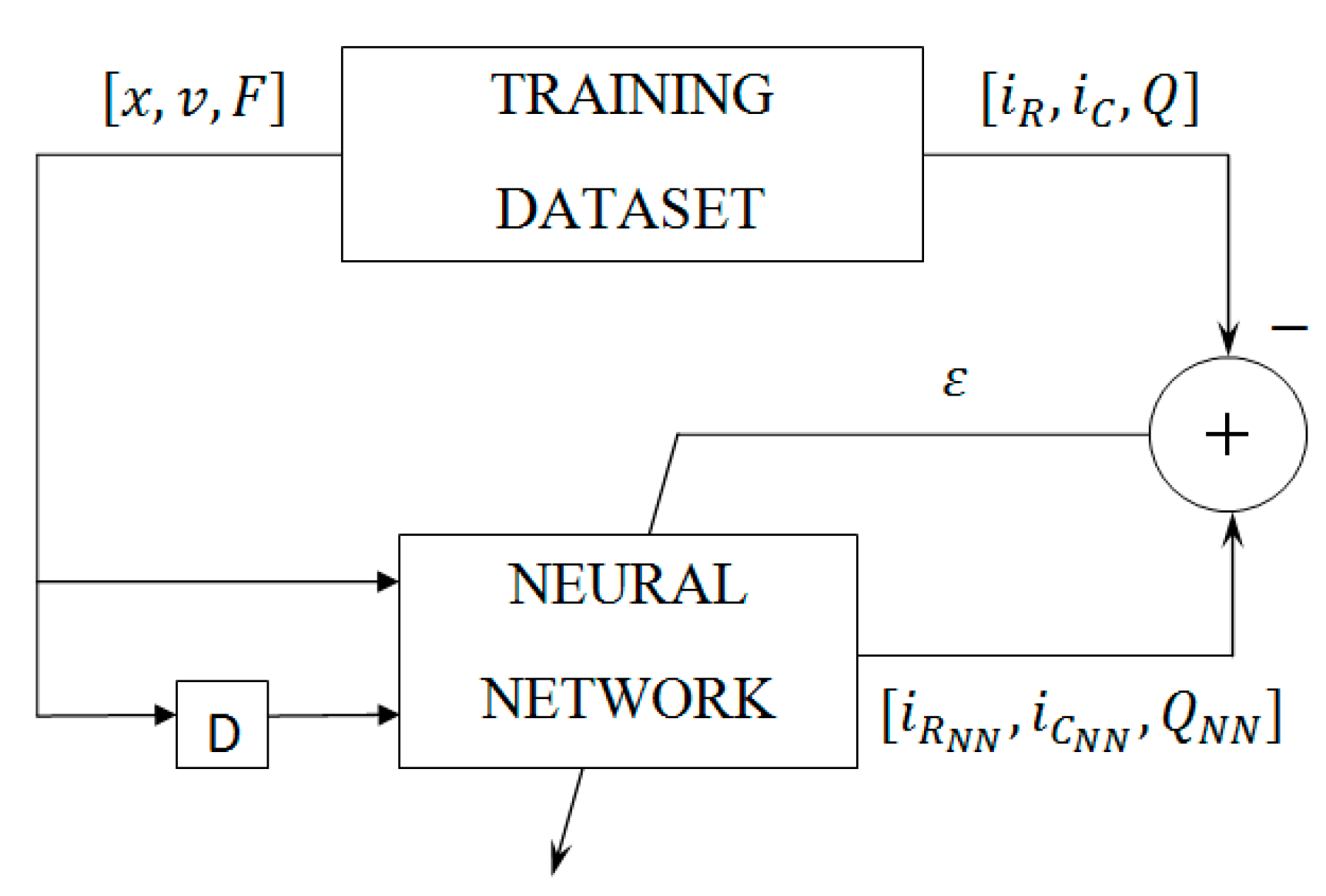

3.2. Neural Network Training

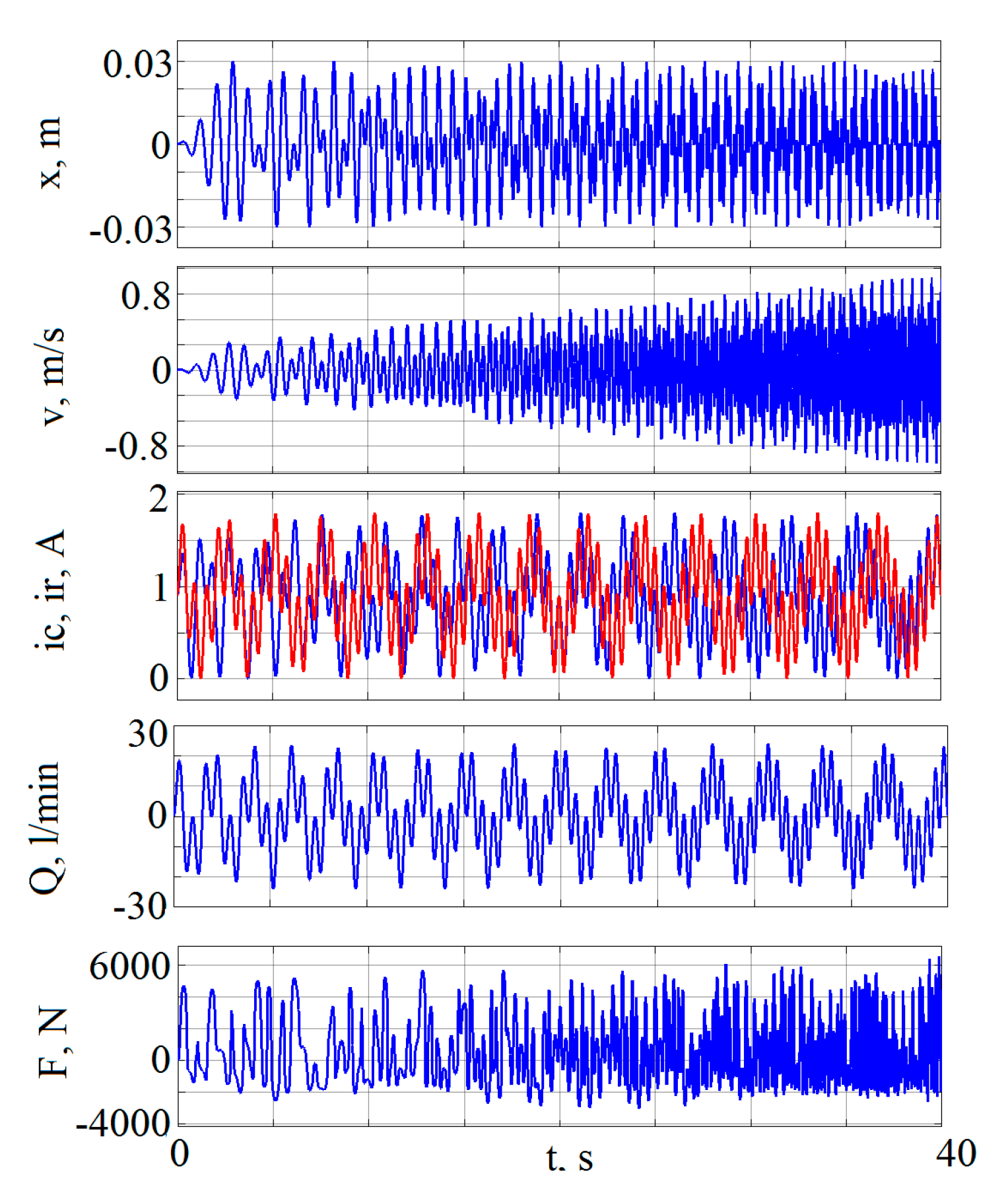

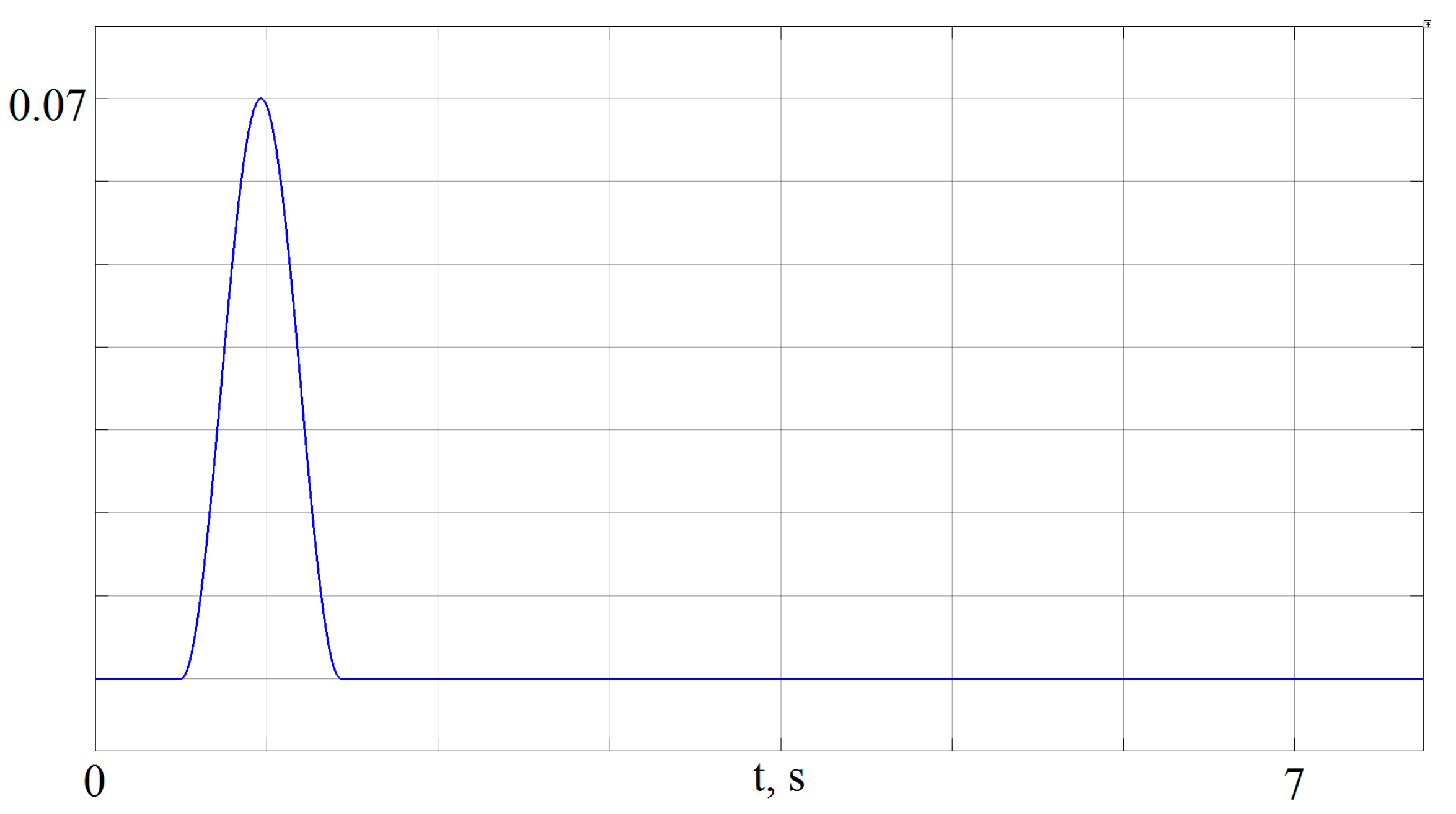

- Displacement of the shock absorber rod was defined as the product of two chirp signals, with a frequency varying from 0.01 to 2 Hz, and from 1 to 4 Hz. The gain of the multiplication is 0.03 m.

- The velocity of movement of the rod was defined as the time derivative of the displacement.

- Electrical currents and volumetric flow rate of a hydraulic pump were also defined as the product of two chirp signals, with frequencies variable for from 1 to 1.2 Hz, for from 1 to 1.3 Hz, and for from 1 to 1.3 Hz, with amplitudes in the range of their possible values.

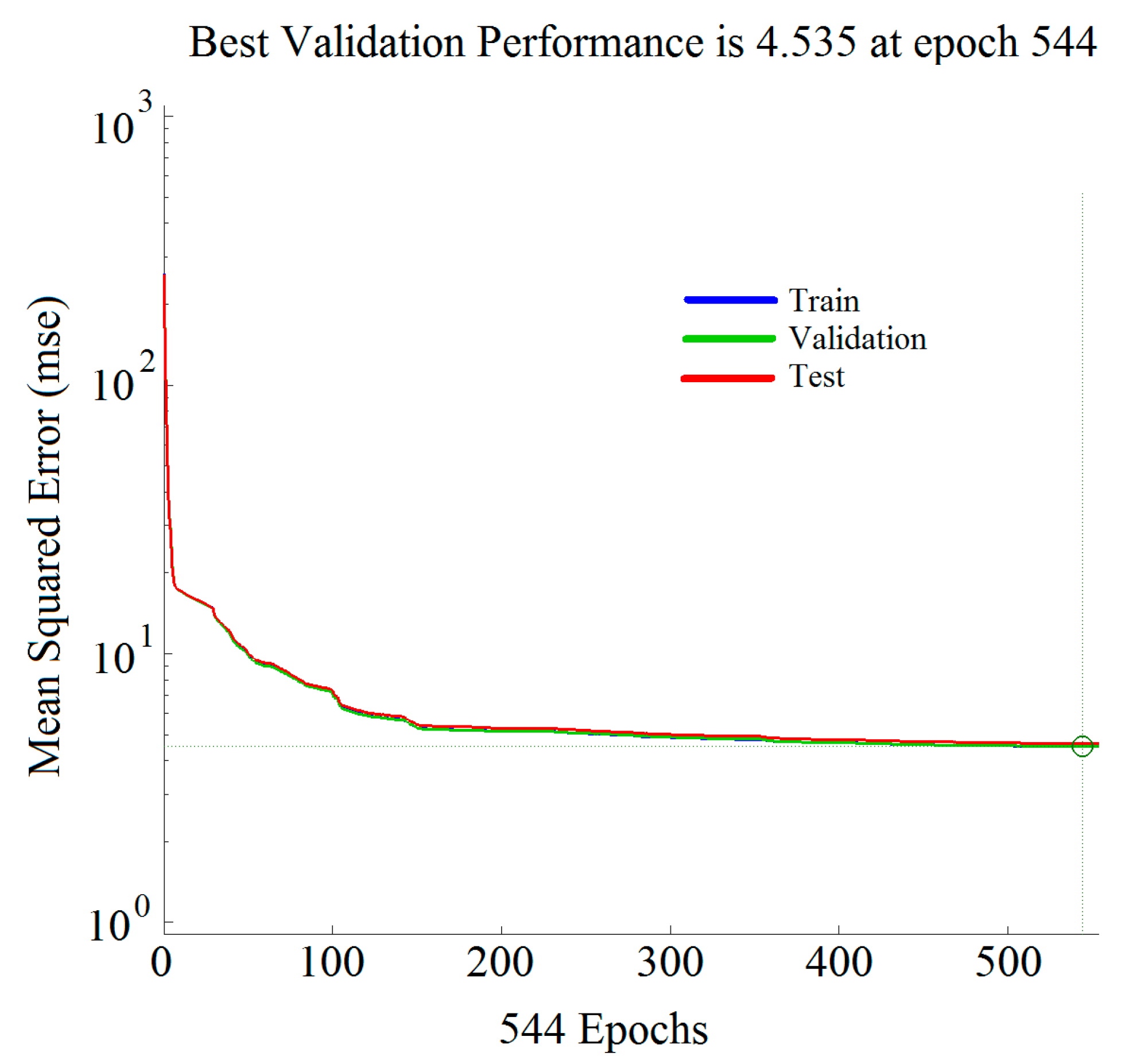

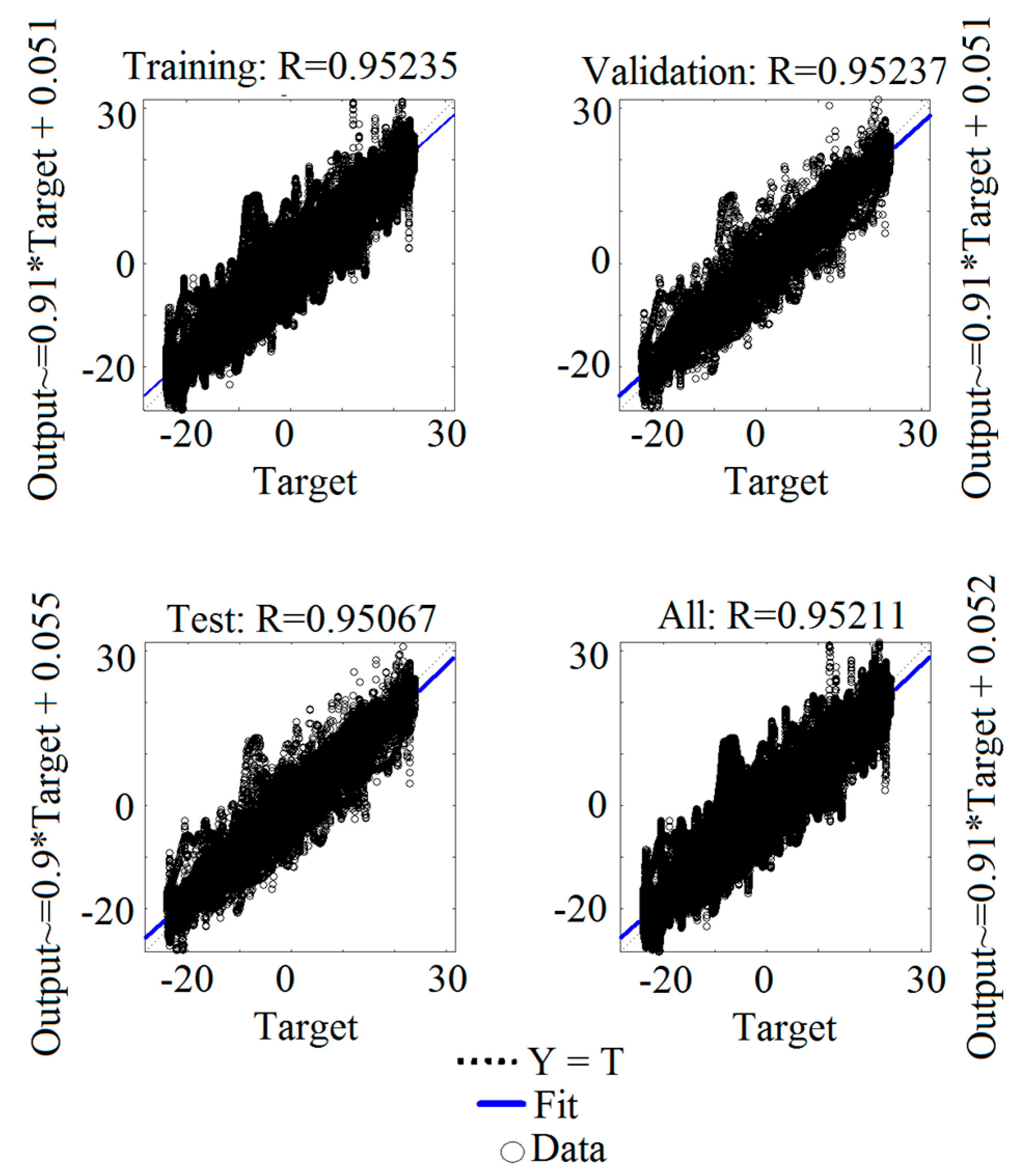

- Algorithm: Levenberg-Marquardt backpropagation

- NN performance criteria: mean squared error (MSE)

- Training epoch: 2000

- Maximum number of validation degradation checks: 10

- Data division: random, 60% for training, 20% for validation and 20% for testing

3.3. Controller Design

4. Simulation Results

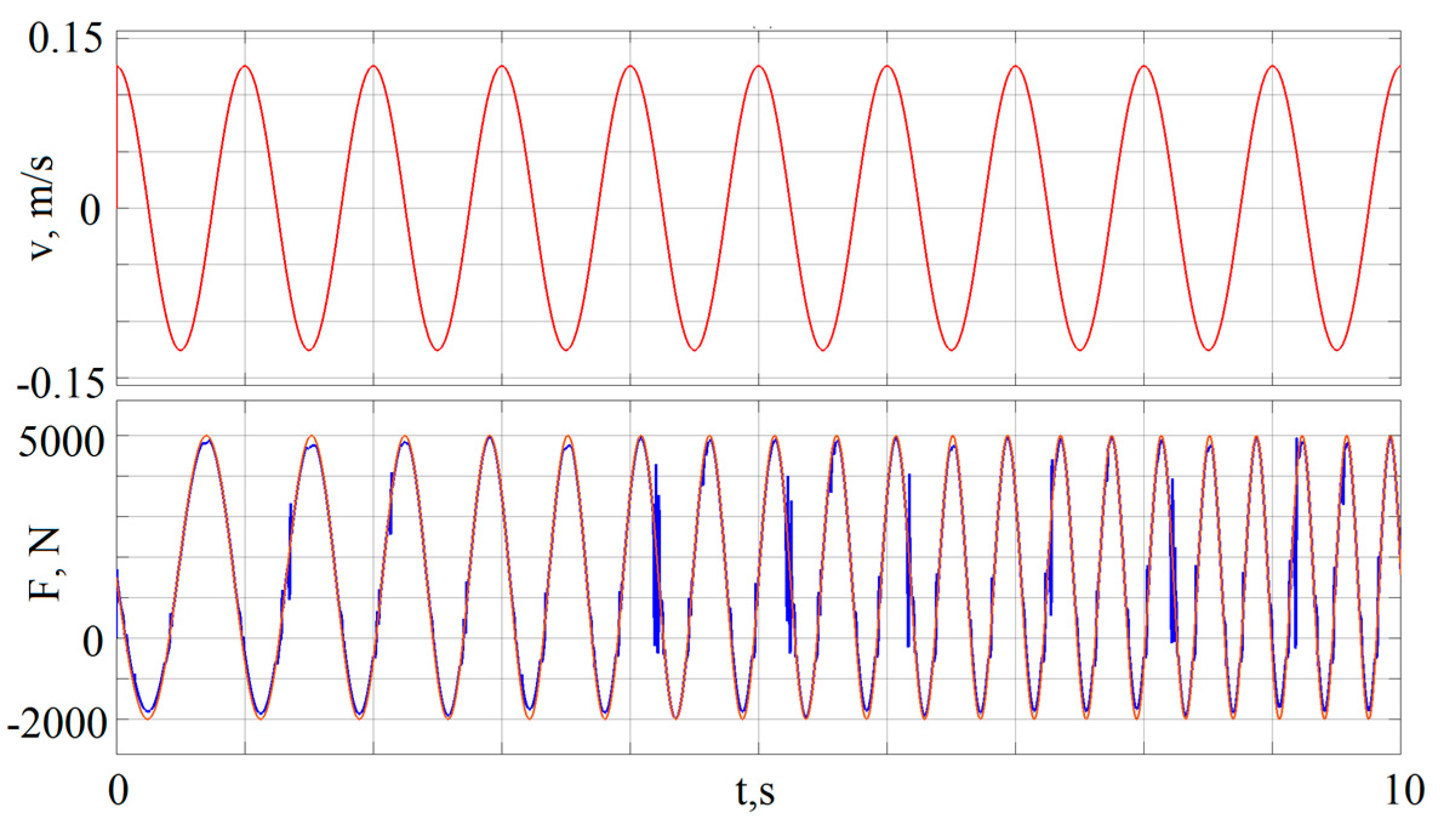

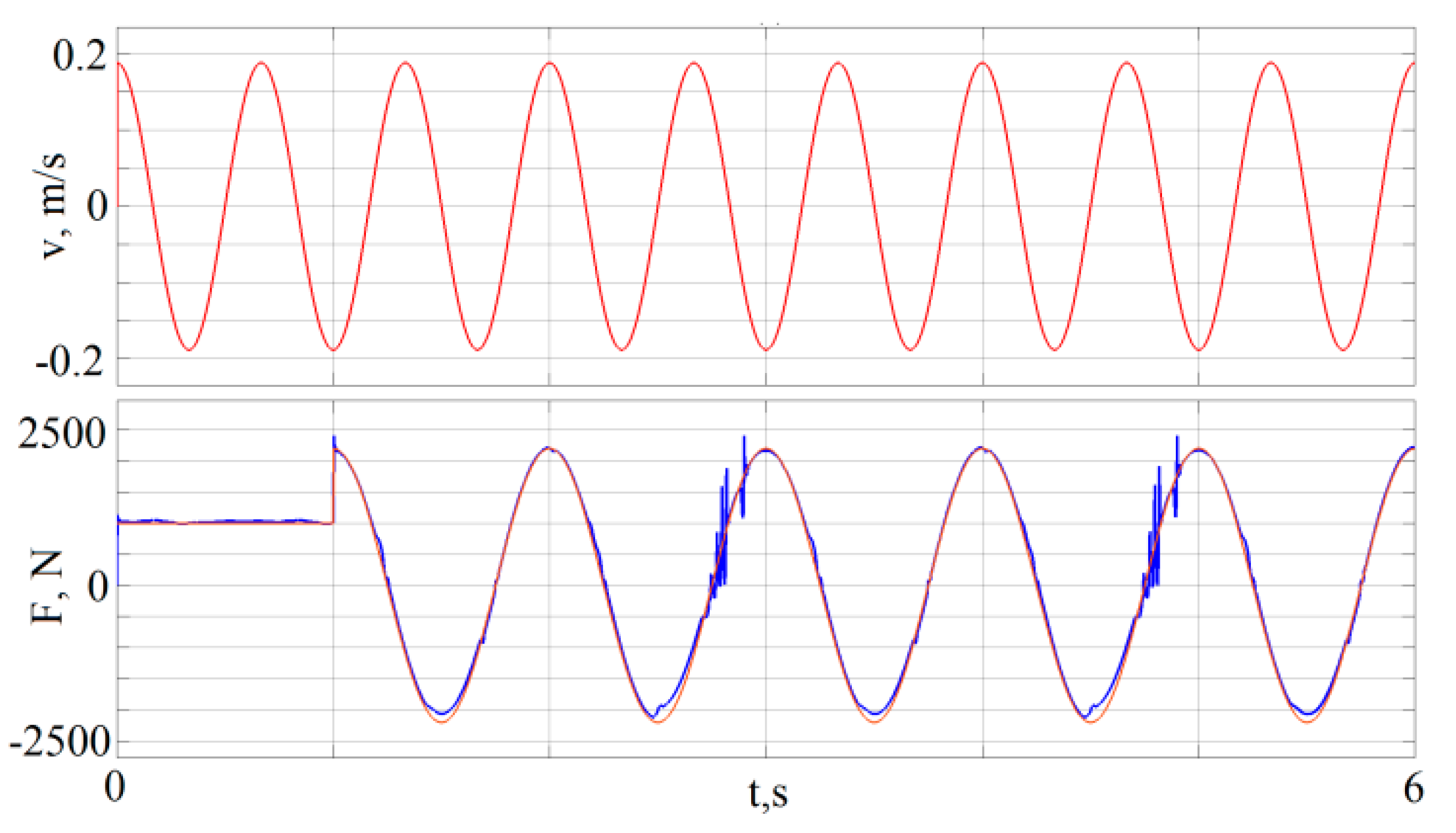

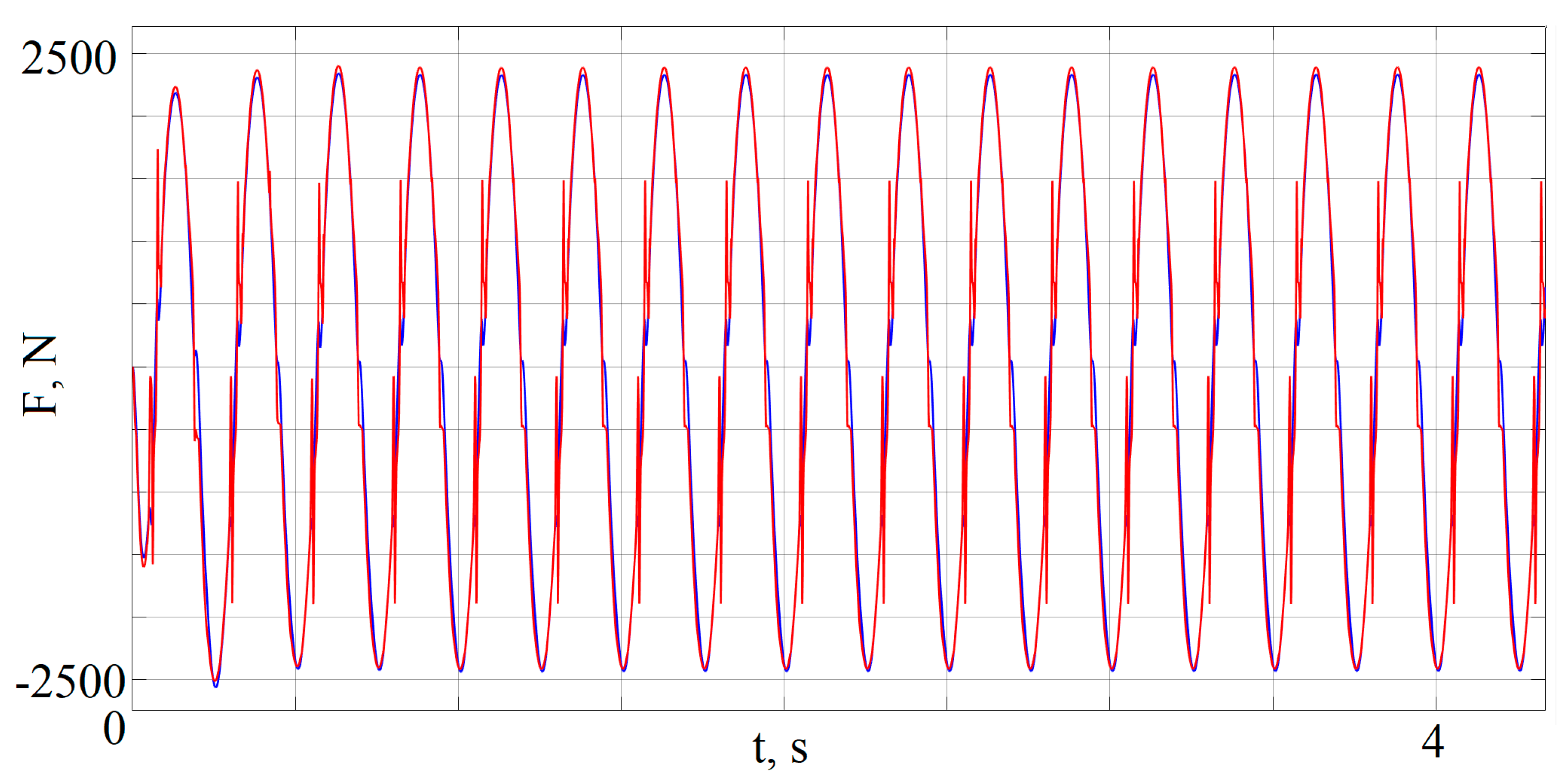

4.1. Providing the Desired Force in the Form of a Wave Signal with Increasing Frequency

4.2. Providing the Desired Force in the Form of a Wave Signal with Initial Time Delay

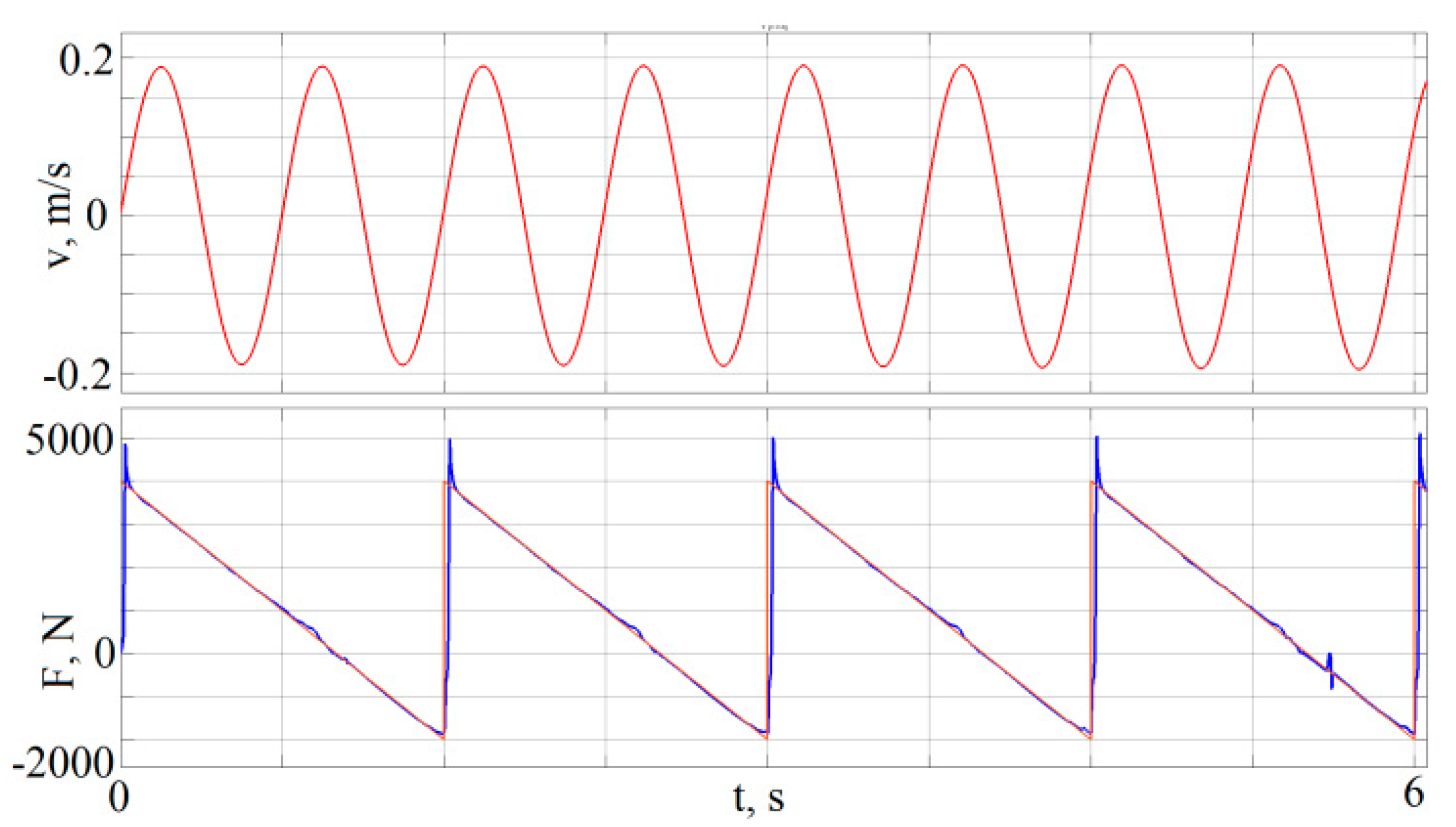

4.3. Providing the Desired Force in the Form of a Sawtooth Signal

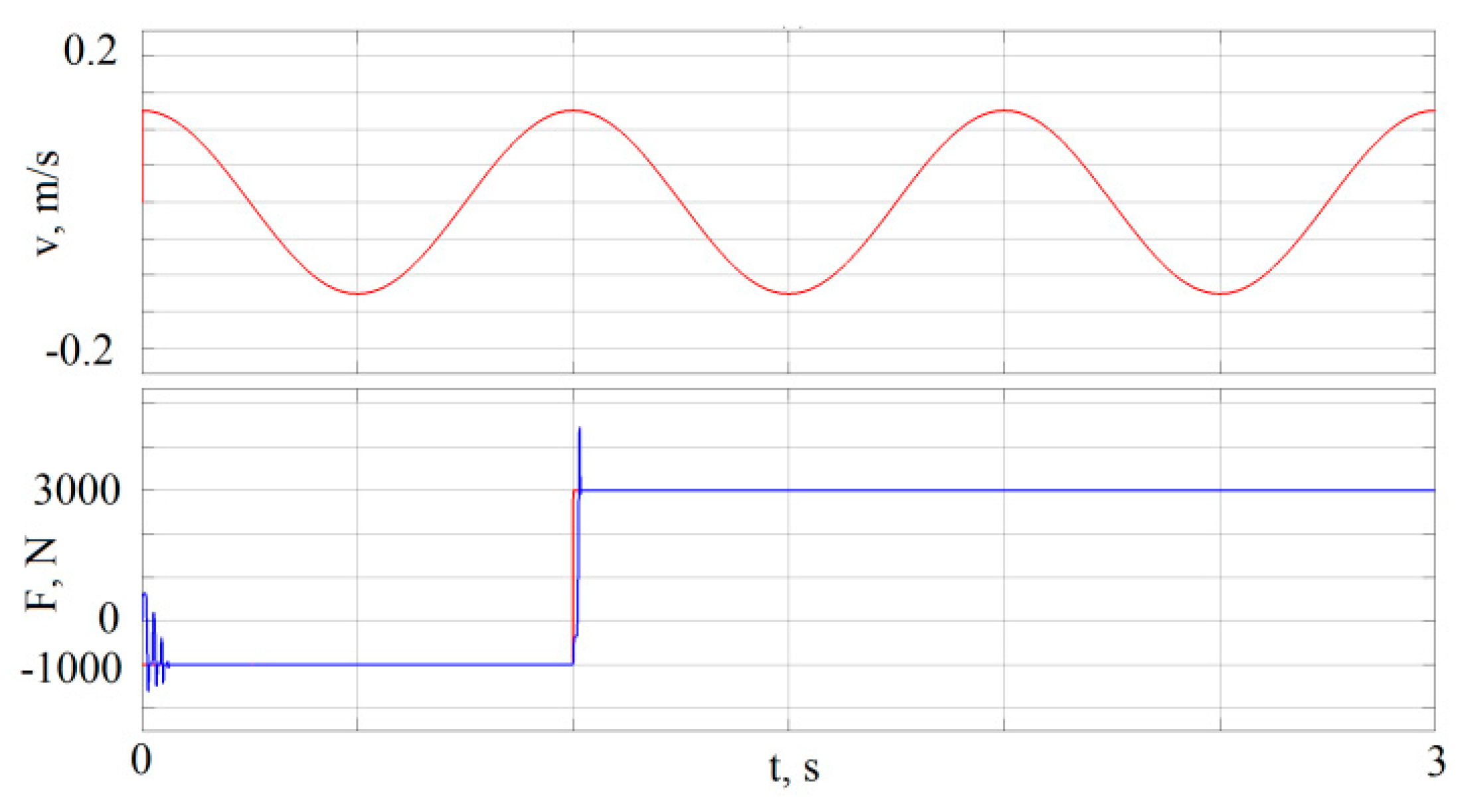

4.4. Providing the Desired Force in the Form of a Step Signal

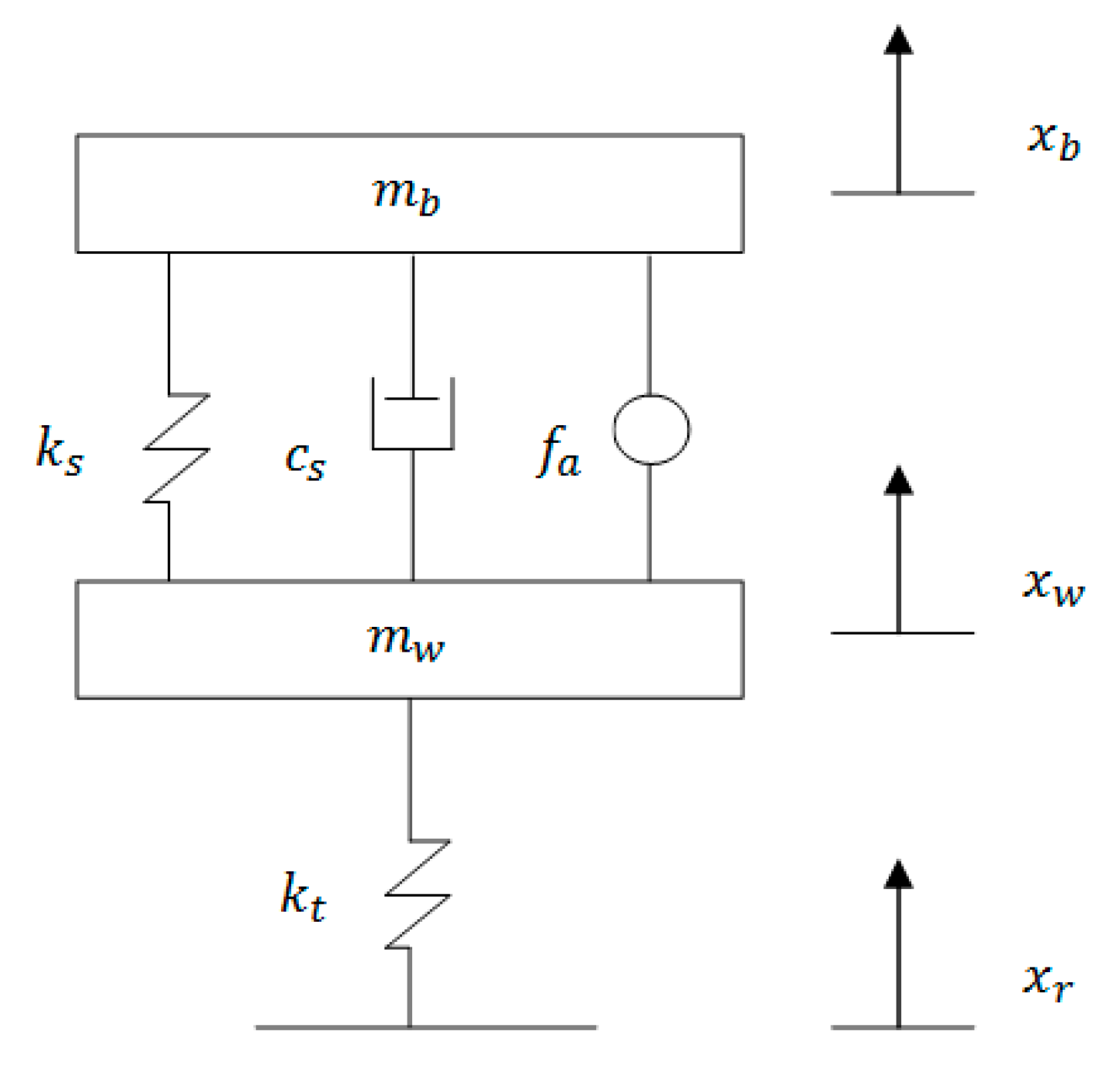

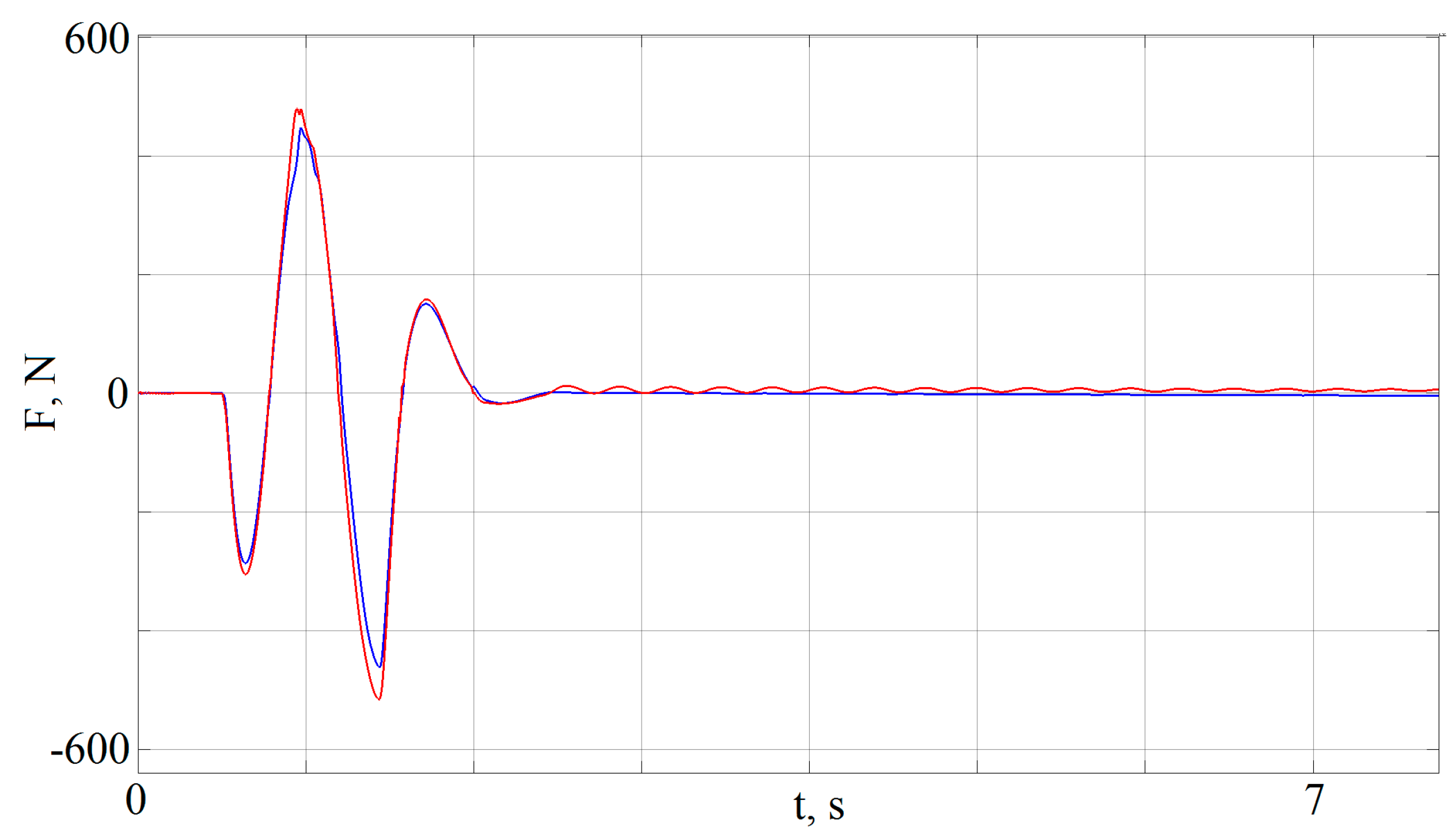

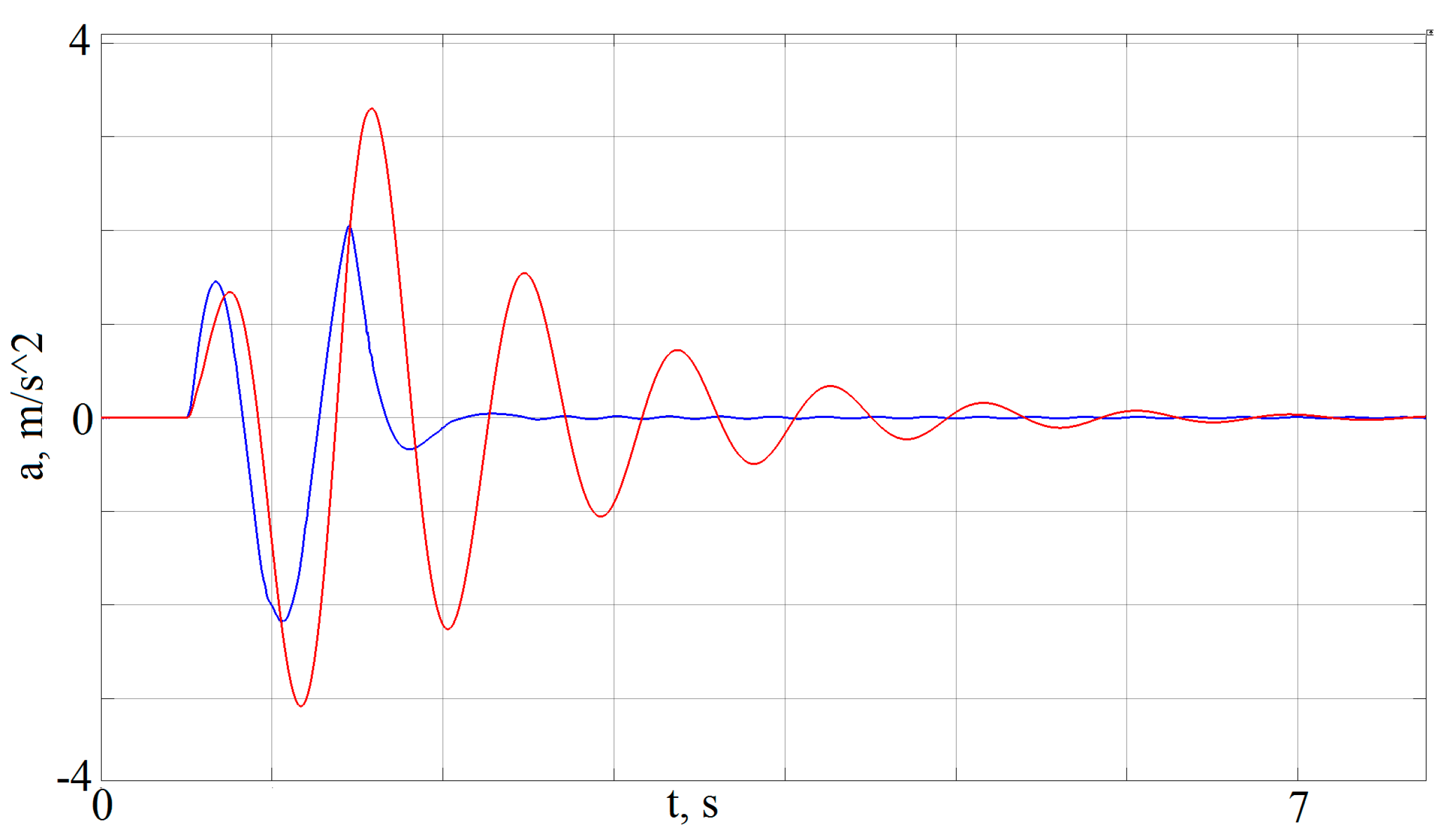

5. Implementation of the Developed Controller in the Quarter Vehicle Model

6. Conclusions and Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Heißing, B.; Ersoy, M. Chassis Handbook: Fundamentals, Driving Dynamics, Components, Mechatronics, Perspectives; Vieweg+Teubner Verlag: Berlin, Germany, 2011. [Google Scholar]

- Barton, D.C.; Fieldhouse, J.D. Automotive Chassis Engineering; Springer: New York, NY, USA, 2018. [Google Scholar]

- Pellegrini, E. Model-Based Damper Control for Semi-Active Suspension Systems. Ph.D. Thesis, TU Munchen, München, Germany, 2012. [Google Scholar]

- Causemann, P. Moderne Schwingungsdämpfung. Automob. Z. 2003, 11, 1070–1079. [Google Scholar] [CrossRef]

- Jautze, M.; Bogner, A.; Eggendinger, J.; Rekewitz, G.; Stumm, A. Der neue BMW 7er:Das Verstelldämpfersystem Dynamische Dämpfer Control; Automobiltechnische Zeitschrift, ATZ extra; Springer: New York, NY, USA, 2008; pp. 100–103. [Google Scholar]

- Schwarz, R.; Biesalki, A.; Schöpfel, A.; Stingls, H. Der Neue Audi Q5: Audi Drive Select; Automobiltechnische Zeitschrift, ATZ extra; Springer: New York, NY, USA, 2008; pp. 60–64. [Google Scholar]

- Savaresi, S.M.; Poussot-Vassal, C.; Spelta, C.; Sename, O.; Dugard, L. Semi-Active Suspension Control Design for Vehicles; Elsevier Ltd.: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Heyer, G. Trends in Stoßdämpferentwicklung. In Federungs- und Dämpfungssysteme; Krettet, O., Ed.; Fortschritte der Fahrzeugtechnik—Vieweg: Berlin, Germany, 1992; pp. 233–260. [Google Scholar]

- Reimpel, J.; Stoll, H. Fahrwerktechnik: Stoß- und Schwingungsdämpfer, 2nd ed.; Vogel Verlag: Würzburg, Germany, 1989. [Google Scholar]

- Causemann, P. Kraftfahrzeugstoßdämpfer; Bibliothek der Technik: Berlin, Germany, 1999; Volume 185. [Google Scholar]

- Spielmann, M. Elektronische Dämpfkraftregelung EDCC. In Elektronik im Kraftfahrzeugwesen—Steuerungs-, Regelungs-, und Kommunikationssysteme; Kontakt & Studium—expert Verlag: Berlin, Germany, 2002; pp. 8–14. [Google Scholar]

- Aliukov, S.; Alyukov, A. Analysis of Methods of Solution of Differential Equations of Motion of Inertial Continuously Variable Transmissions; SAE Technical Paper, SAE World Congress Experience; WCX: Warrendale, PA, USA, 2017; Volume 2017. [Google Scholar]

- Aliukov, S.; Keller, A.; Alyukov, A. On the question of mathematical model of an overrunning clutch. In Lecture Notes in Engineering and Computer Science; 2015 World Congress on Engineering; WCE: London, UK, 2015; Volume 2218. [Google Scholar]

- Wallentowitz, H. Aktive Fahrwerkstechnik; Vieweg: Berlin, Germany, 1991. [Google Scholar]

- Schiehlen, W.; Hanss, M.; Iroz, I. Robust design of road vehicle suspension using fuzzy methods. In Proceedings of the 24th Symposium of the International Association for Vehicle System Dynamics (IAVSD 2015), Graz, Austria, 17–21 August 2015. [Google Scholar]

- Causemann, P.; Kutschem, T. CDC(Continuous Damping Control) Ausführungen mit integriertem oder extern ausgeführten Proportional—Dämpfer—Ventile—Eine Bewertung zweier unterschiedlicher Konzepte. In Reifen—Fahrwerk—Fahrbahn (VDI Berichte); VDI-Gesellschaft Fahrzeug- und Verkehrstechnik, VDI-Verlag: Berlin, Germay, 1997; pp. 135–153. [Google Scholar]

- Jungbluth, T. Federungs- und Dämpfungsinnovationen von ThyssenKrupp Bilstein; Fachpresse-Mitteilung IAA PKW: Berlin, Germany, 2005. [Google Scholar]

- Obinabo, E.C.; Ighodalo, O. The utilization of an electric field sensitive effect for vibration control of viscous isolating system. Res. J. Appl. Sci. Eng. Technol. 2011, 3, 153–158. [Google Scholar]

- Bose Suspension System. Available online: http://bose.de/DE/de/index.jsp (accessed on 29 February 2020).

- Brown, S.N. Active Vehicle Suspension System. Patent EP 1 440 826 B1, 23 December 2013. [Google Scholar]

- Münster, M.; Mair, U.; Gilsdorf, H.J.; Thom, A.; Müller, C.; Hippe, M.; Hoffmann, J. Electromechanical Active Body Control. Atz Autotechnology 2009, 3, 24–29. [Google Scholar]

- Hilgers, C.; Brandes, J.; Ilias, H.; Oldenettel, H.; Stiller, A.; Treder, C. Aktives Luftfederfahrwerk für eine großere Bandbreite zwischen Komfort- und Dynamik-Abstimmung. Automob. Z. 2009, 9, 600–609. [Google Scholar] [CrossRef]

- Hohenstein, J.; Schutz, A.; Gaisbacher, D. Das elektropneumatische Vorderachliftsystem des Porsche 997 GT3. Automob. Z. 2010, 9, 622–626. [Google Scholar]

- Puff, M.; Pelz, P.; Mess, M. Beeinflussung der Fahrdynamik durch geregelte Luftdämpfer. Automob. Z. Atz 2010, 4, 286–291. [Google Scholar] [CrossRef]

- Schindler, A. Neue Konzeption und Erstmalige Realisierung Eines Aktiven Fahrwerks Mit Preview-Strategie. Ph.D. Thesis, Karlsruher Institut für Technologie, Karlsruhe, Germany, 2009. [Google Scholar]

- Streiter, R. ABC Pre-Scan im F700. Automob. Z. 2008, 110, 388–397. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, D.; Gong, M.; Yang, B. Research on Robust Model Predictive Control for Electro-Hydraulic Servo Active Suspension System; IEEE Access: Piscataway, NJ, USA, 2018; Volume 8. [Google Scholar]

- Zhang, J.; Sun, W.; Jing, H. Nonlinear Robust Control of Antilock Braking System Assisted by Active Suspensions for Automobile. IEEE Trans. Control Syst. Technol. 2019, 27, 1352–1359. [Google Scholar] [CrossRef]

- Soh, M.; Jang, H.; Park, J.; Sohn, Y.; Park, K. Development of Preview Active Suspension Control System and Performance Limit Analysis by Trajectory Optimization. Int. J. Automot. Technol. 2018, 19, 1001–1012. [Google Scholar] [CrossRef]

- Alleyne, A.; Hendrick, J.K. Nonlinear Adaptive Control for Active Suspensions. IEEE Trans. Control Syst. Technol. 1995, 3, 94–101. [Google Scholar] [CrossRef]

- Zhang, Y.; Alleyne, A. A practical and effective approach to active suspension control. Veh. Syst. Dyn. 2005, 43, 305–330. [Google Scholar] [CrossRef]

- Spencer, B.F.; Dyke, S.J.; Sain, M.K.; Carlson, J.D. Phenomenological model of a magnetorheological damper. J. Eng. Mech. 1997, 123, 230–238. [Google Scholar] [CrossRef]

- Barethiye, V.; Pohit, G.; Mitra, A. A combined nonlinear and hysteresis model of shock absorber for quarter car simulation on the basis of experimental data. Eng. Sci. Technol. Int. J. 2017, 20, 1610–1622. [Google Scholar] [CrossRef]

- Hong, S.R.; Choi, S.B.; Choi, Y.T.; Wereley, N.M. A hydro-mechanical model for the hysteretic damper force prediction of ER damper: Experimental verification. J. Sound Vib. 2005, 285, 1180–1188. [Google Scholar] [CrossRef]

- He, H.; Tan, Y.; Yang, W.; Peng, F.; Zhang, W. Automatic Hysteresis Feature Recognition of Vehicle Dampers Using Duhem Model and Clustering. In Proceedings of the 2018 11th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 8–9 December 2018. [Google Scholar]

- Chen, P.; Bai, X.X.; Qian, L.J.; Choi, S.B. An Approach for Hysteresis Modeling Based on Shape Function and Memory Mechanism. IEEE/ASME Trans. Mechatron. 2018, 23, 1270–1278. [Google Scholar] [CrossRef]

- Pellegrini, E.; Koch, G.; Lohmann, B. A dynamic feedforward control approach for a semi-active damper based on a new hysteresis model. Ifac Proc. Vol. 2011, 44, 6248–6253. [Google Scholar] [CrossRef]

- Waibel, A.; Hanazawa, T.; Hinton, G.; Shikano, K.; Lang, K. Phoneme Recognition Using Time Delay Neural Networks. IEEE Trans. Acoust. Speech Signal Process. 1989, 37, 328–339. [Google Scholar] [CrossRef]

- Zong, L.H.; Gong, X.L.; Guo, C.Y.; Xuan, S.H. Inverse neuro-fuzzy MR damper model and its application in vibration control of vehicle suspension system. Veh. Syst. Dyn. 2012, 50, 1025–1041. [Google Scholar] [CrossRef]

- Duchanoy, C.A.; Moreno-Armendariz, M.; Moreno-Torres, J.; Cruz-Villar, C. A Deep Neural Network Based Model for a Kind of Magnetorheological Dampers. Sensors 2019, 19, 1333. [Google Scholar] [CrossRef]

- Bhowmik, S.; Weber, F. Experimental calibration of forward and inverse neural networks for rotary type magnetorheological damper. Struct. Eng. Mech. 2013, 46, 673–693. [Google Scholar] [CrossRef]

- Ding, Z.; Zhao, F.; Qin, Y.; Tan, C. Adaptive neural network control for semi-active vehicle suspension. J. Vibroengineering 2017, 19, 2654–2669. [Google Scholar] [CrossRef]

- Xia, P. An inverse model of MR damper using optimal neural network and system identification. J. Sound Vib. 2003, 266, 1009–1023. [Google Scholar] [CrossRef]

- Metered, H.; Abbas, W.; Emam, A.S. Optimized Proportional Integral Derivative Controller of Vehicle Active Suspension System using Genetic Algorithm; SAE Technical Paper; Warrendale, PA, USA, 2018; Available online: https://www.researchgate.net/publication/324199872_Optimized_Proportional_Integral_Derivative_Controller_of_Vehicle_Active_Suspension_System_Using_Genetic_Algorithm (accessed on 14 January 2020). [CrossRef]

| Parameter | Symbol | Value (Unit) |

|---|---|---|

| Mass of the body | 375 (kg) | |

| Mass of the wheel | 29.5 (kg) | |

| Suspension stiffness | 20.58 (kN/m) | |

| Damping coefficient | 772 (Ns/m) | |

| Tire stiffness | 200 (kN/m) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alyukov, A.; Rozhdestvenskiy, Y.; Aliukov, S. Active Shock Absorber Control Based on Time-Delay Neural Network. Energies 2020, 13, 1091. https://doi.org/10.3390/en13051091

Alyukov A, Rozhdestvenskiy Y, Aliukov S. Active Shock Absorber Control Based on Time-Delay Neural Network. Energies. 2020; 13(5):1091. https://doi.org/10.3390/en13051091

Chicago/Turabian StyleAlyukov, Alexander, Yuri Rozhdestvenskiy, and Sergei Aliukov. 2020. "Active Shock Absorber Control Based on Time-Delay Neural Network" Energies 13, no. 5: 1091. https://doi.org/10.3390/en13051091

APA StyleAlyukov, A., Rozhdestvenskiy, Y., & Aliukov, S. (2020). Active Shock Absorber Control Based on Time-Delay Neural Network. Energies, 13(5), 1091. https://doi.org/10.3390/en13051091