Abstract

Factors leading to coal and gas outbursts are complicated, and the accuracy of predicting outbursts remains difficult to achieve. Therefore, coal and gas outburst risk are still a scientific challenge in the fields of mining, geology, safe engineering, and rock mechanics. Theories explaining and predicting coal and gas outbursts associated with restored strain and gas energy are hot topics. Based on numerical modelling, the evolution of a plastic zone ahead of an excavation face with change of direction and magnitude of regional pre-mining stress field were analyzed. A mechanical analysis model for the expansionary evolution process of the plastic zone ahead of the excavation face was constructed, and the expansionary evolution characteristics of plastic zone ahead of the excavation face were analyzed. The physical and mechanical process and basic conditions for the initiation and development of coal and gas outbursts induced by evolution of plastic zone were discussed. The research provides some new insights into the mechanism, prediction, and prevention of goal and gas outbursts.

1. Introduction

Coal and gas outbursts are the sudden and violent releases of gas and coal, and are one of the most serious disasters in underground coal mining. Reasonable preventive measures and efficient management technology must be guided by a complete and mature basic theory. Outbursts are complicated dynamic events. Geology, stress regime, and gas pressure and content may all be contributing factors [1].

A great number of theories have been proposed, most of which summarized outburst behaviors, explained the phenomenon, and discussed precursors, energy sources, and its development. To date, three main hypotheses have been proposed explaining outburst behaviors: The geo stress leading role hypothesis, the chemical effect hypothesis, and the combination hypothesis [1,2,3,4,5,6]. Past theories have basically shown that coal and gas outbursts are the interactive result of regional quasi-static stress field, dynamic force source, and coal and rock mass, that is, gas which leads to the sudden failure of coal and rock mass around the working are and causes comminuted coal and rock, as well as gas, to burst out abruptly and violently. Elastic energy and gas energy stored within the intact coal and rock mass are the main sources of energy, and a sudden pressure change induced by the dynamic force source is the main precursor for occurring of the outburst. Guo et al. [7] studied the evolution of plastic zone around a roadway using FLAC software and proposed the criteria for underground rock structure failure. Zou et al. [8] established a production deployment evaluation system using a Bayesian network with 11 indices for outburst-prone coal mines based on summaries of experts and production experience of coal mines in Chongqing, China. Based on the Unipore Crank Diffusion Model for spherical grains and plane sheets, Norbert et al. [9] analyzed the phenomenon of gas emission during a coal and gas outburst. Using a statistical method, Nilufer et al. [10] employed Structural Equation Modeling (SEM) to identify the relationship between the parameters (mining depth, coal seam gas content, and moisture content) and contributing factors (seam thickness, seam inclination, and distance from fault) affecting the coal and gas outbursts for an underground coal mine in Turkey and to analyze multiple interactions among them. They found that mining depth is the most significant factor among all factors, and distance from fault is the most significant contributing factor to outburst. Li et al. [11] investigated the acoustic emissions (AE) characteristics of coal and rock samples under loading and monitored and predicted the coal and gas outburst dynamic disasters at the working face using self-developed AE continuous monitoring and early warning equipment. It was found that coal and gas outbursts occurred in stress post-peak zone. Lin et al. [12] carried out experiments connected with nitrogen adsorption on coal samples in order to find out the power source for coal and gas outburst. They reported that the gas desorption first occurs in a unit, which then triggers a desorption of the neighboring units of coal body. When it reaches a certain level that can push the coal body forward, the coal and gas outburst will happen. Gao et al. [13] used RFPA-GAS software to study the dynamic failure mechanism of coal and gas outburst under the conditions of different support intensity and unsupported conditions and concluded that the outstanding effect of the roadway without support is similar to that in the field, and the coal and gas outbursts are obviously weakened in supported roadways.

With respect to soil structure interaction, Ahmadi et al. [14,15] studied normal, rocking, and torsional forced time-harmonic vibrations of a rigid circular disk in a transversely isotropic full-space as well as half-space. The relations for the contact stress, the resultant force acting on the disk, and the dimensionless compliance factor were given for four vibration modes. Eskandari et al. [16] investigated lateral translation of an inextensible circular membrane embedded in a transversely isotropic half-space. Chen et al. [17] presented a new high-performance, fine-scale damage analysis method using efficient and detailed mesh discretization via octree and coupled scaled boundary finite element (SBFEs) into FEM and parameter matrices (e.g., stiffness, mass, damping) of geometrically similar elements generated by octree. Ai et al. [18] proposed a coupling method to study the effect of overlying single-phase soils and the time-dependent response of an axially-loaded pile in saturated multi-layered soils. These studies provide some insights into outbursts for excavations in soil.

Considering the conditions of methane hydrate existing in coal seam, Shepeleva and Dyrdin et al. [19] estimated volumes of gas emission in a fractured coal layer upon a drop in the gas pressure and also provided an assessment of outburst hazard of coal seam edge zone. In Reference [20], Dyrdin indicated that instantaneous dissociation of crystallohydrates results in coal methane pressure rise, which intensifies outburst hazard and affects the outburst gas balance. Dyrdin et al. [21] found that the low-frequency (2.0–4.5 Hz) attenuating vibrations generated in the main roof can induce both secondary rock mass disintegration, as well as methane desorption and decomposition of gas hydrates (if present) accompanied by an increases in gas pressure and in number of gas-dynamic events in outer zones of coal beds.

On the basis of experimental data, Smirnov et al. [22] proposed an equation expressing the amount of gas hydrate through the sorption capacity and actual humidity of coal and concluded that the high gradient of gas pressure and high gas content of coal beds along with local disruption of coal and re-distribution of rock pressure are the major factors causing instantaneous outbursts of coal and gas. Then, Smirnov et al. [23] experimentally studied the formation possibility of methane hydrate in the inner space of natural coal of several types and demonstrated that the peak methane emits into the gas phase when intersecting the curve of the equilibrium of gas hydrates. With the decrease of degree of metamorphism of coal, the amount of water that is absorbed by natural coal is increased, and a proportion of water involved in the formation of methane hydrate is decreased. Through experiments, Smirnov et al. [24] studied the physical processes occurring in the system of coal-natural gas with a change in external parameters and showed that decomposition of methane hydrate in coal occurs near the equilibrium curve, and the process of hydrate formation begins when supercooling by 3/7 °C and lasts several tens of hours.

Meshkov and Sidorenko [25] showed the significant influence of geological and mining conditions of conducting mining operations on distribution of air streams on longwall panels and effective management of gas emission. Kazanin and Sidorenko [26] demonstrated that interaction of gas emission into a goaf and mined-out extraction area with roof caving increments and indicated that accounting for roof caving increments upon forecast of gas emission and selection of reasonable management parameters of methane emission into mined-out extraction areas is necessary.

The above studies provide a significant basis for the prediction and prevention of outburst, which are also a strong basis for the research of this paper. However, due to limitation of the existing theories and the lack of effective prediction methods, outburst is still not well controlled or managed.

This paper presents a conjecture of explaining the outburst induced by the abrupt change of stress and failure state in butterfly wing part in the surrounding rock mass based on the butterfly-shaped plastic zone development around an excavation. Criteria for determining the onset of outburst are introduced. The key external factors leading to the outburst are proposed and verified. Using the proposed theory, a number of outbursts were able to be explained that could not be explained in the past. Then, the indexes for predicting the risk of outbursts are presented. The research is hoped to provide some insights in outburst prediction and prevention for mining engineers and researchers.

2. Expansionary Evolution of Surrounding Rock Mass Plastic Zone ahead of an Excavation Face

FLAC3D software was used for numerical modelling. Built-in Mohr-Coulomb constitutive model was used for rock failure, which is a linear failure surface corresponding to shear failure:

where σ1, σ3 is the maximum and minimum principle stress, and C and φ is cohesion and angle of internal friction. Shear yield is detected if fs > 0.

2.1. Numerical Model Development

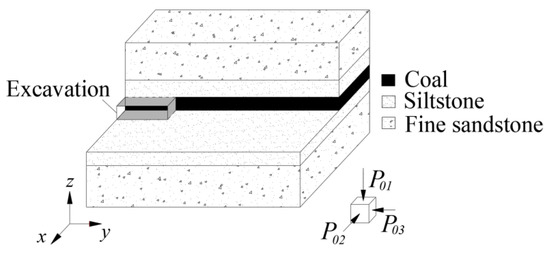

Numerical modelling was carried out against an excavation in #2-1 coal seam of a coal mine in China, which is an outburst-prone coal seam. The cover depth of the coal seam was about 800 m. The average thickness of the coal seam was 4 m. The compressive strength of the coal seam was 3.1–8.2 MPa. The roof mainly consisted of siltstone and fine sandstone. The compressive strength of roof was 23.5–79.9 MPa, which was classified as medium hard-quite hard rock according to roof classification of China. The floor mainly consisted of siltstone and fine sandstone. The compressive strength of floor was 22.8–85.89 MPa which was also classified as medium hard-quite hard rock.

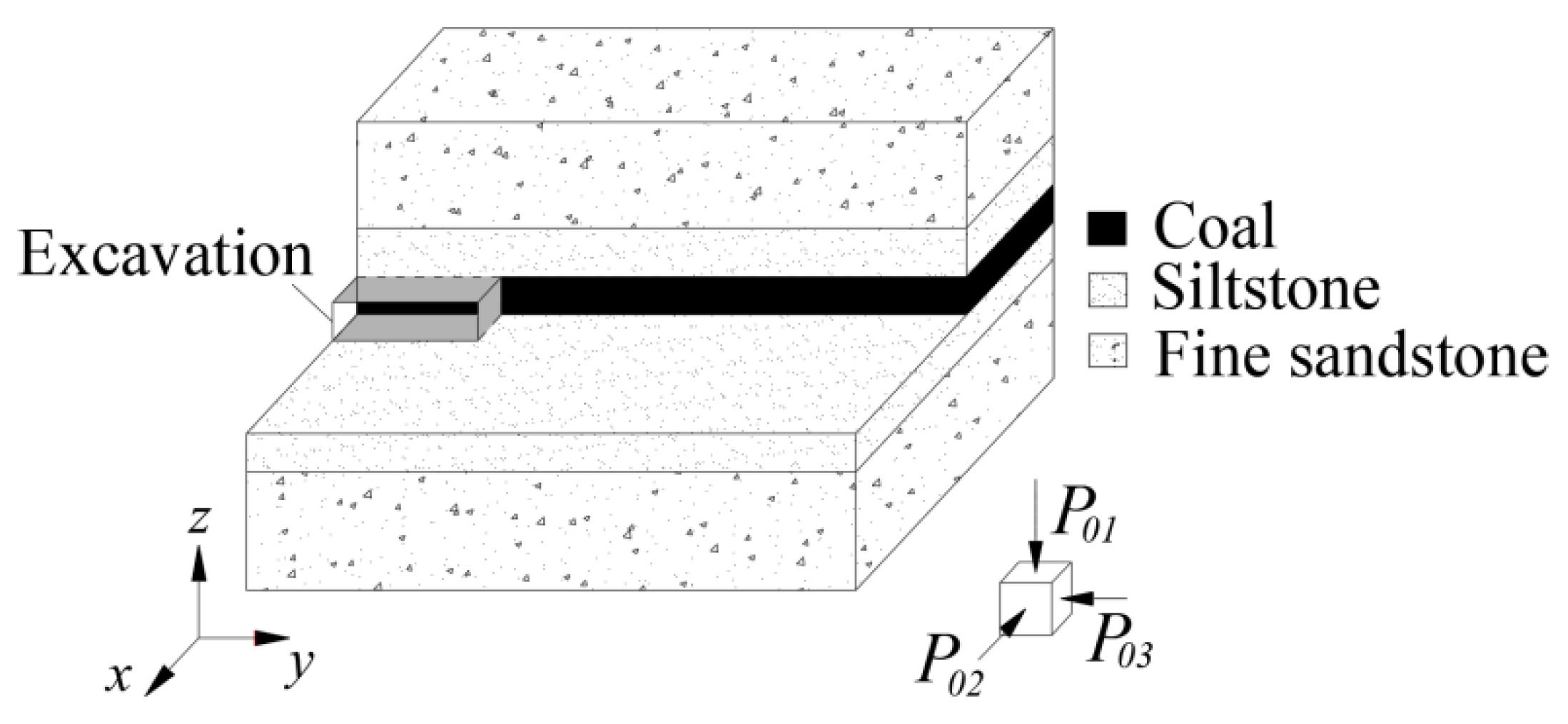

According to the geological conditions of the mine, the numerical model was built as shown in Figure 1. The geometrical measurements of this model was 50 m × 80 m × 50 m (X × Y × Z). The geometrical measurement of the roadway was 5 m × 4 m. The roadway excavated 20 m along the Y axis during the simulation. represents the initial pre-mining stress field. , , and represent the maximum, intermediate, and minimum principal stresses in the initial geostress field, respectively. The mechanical parameters for coal and rock are given in Table 1.

Figure 1.

The three-dimensional numerical model.

Table 1.

The parameters used for coal and rock.

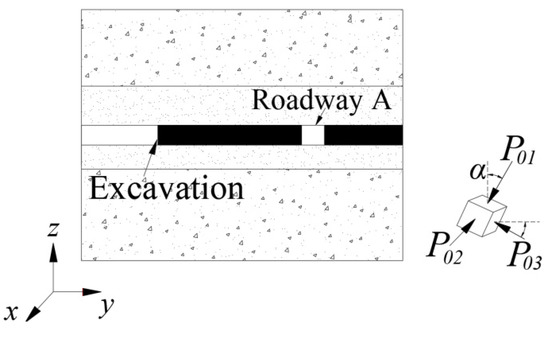

2.2. Modelling Plans

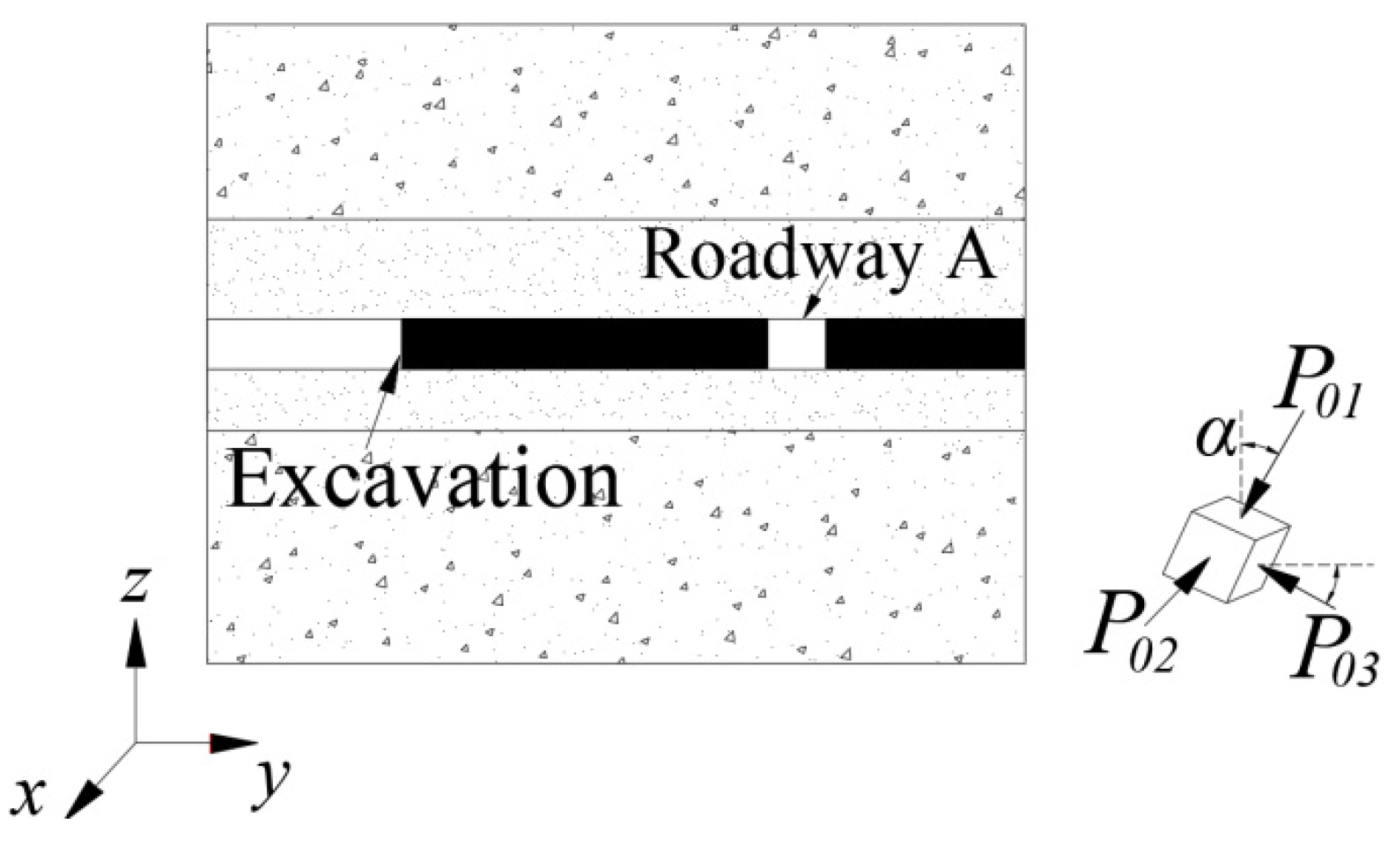

Guo et al. [27] studied the characteristics of plastic zone in the surrounding rock mass of roadways in different stress fields. They concluded that the boundary configurations of the surrounding rock mass plastic zone of the round roadway are generally circular, oval, and butterfly-shaped. Ma et al [28,29] investigated the evolution of plastic zone around a roadway with the change of principal stress values and directions. A cutaway view of a roadway is shown in Figure 2. Assume that a roadway A is arranged in front of an excavation face perpendicular to the direction of the excavation. The initial pre-mining stress field for the numerical model were set as follows: , , and . Please note that a new combination may generate different result but with a similar implication. According to Guo et al. [7], the plastic zone around roadway A is butterfly shaped. According to the directional characteristics of the butterfly-shaped plastic zone, when the direction of the pre-mining stress field rotates around the X axis, the plastic zone around the roadway A would also change correspondingly [28].

Figure 2.

The cross-sectional view of the roadway.

In this section, we propose two modelling plans to investigate the expansionary evolution of plastic zone ahead of the excavation face by altering the magnitude and direction of the pre-mining stress field.

(1) Plan 1

The parameters of the initial pre-mining field for the numerical model were set as follows: , , and . α is the angle formed by and Z axis. In plan 1, the expansionary evolution of plastic zone ahead of the excavation face under different was investigated.

(2) Plan 2

According to the directional characteristics of the butterfly-shaped plastic zone, the butterfly wing around roadway A was in the coal seam when . Therefore, the parameters of the initial pre-mining field were set as: , and . In Plan 2, the expansionary evolution law of the surrounding rock mass plastic zone in the excavation face with different values of was investigated.

2.3. Results and Discussion

(1) Development of the plastic zone ahead of excavation face under different α.

The modelling result of Plan 1 is shown in Figure 3. It shows that with the increase of , the range of the plastic zone V ahead of the excavation face increased at first and then decreased. The data approximately complied with Gaussian distribution. When , and , the range V increased slightly, but not obviously. In this case, the value of V did not exceed . The range V increased greatly when . The range V peaked when and . The range of the plastic zone when , and was not significantly different from the range of the plastic zone when , and .

Figure 3.

The relationship between and the range of the plastic zone (Plan 1).

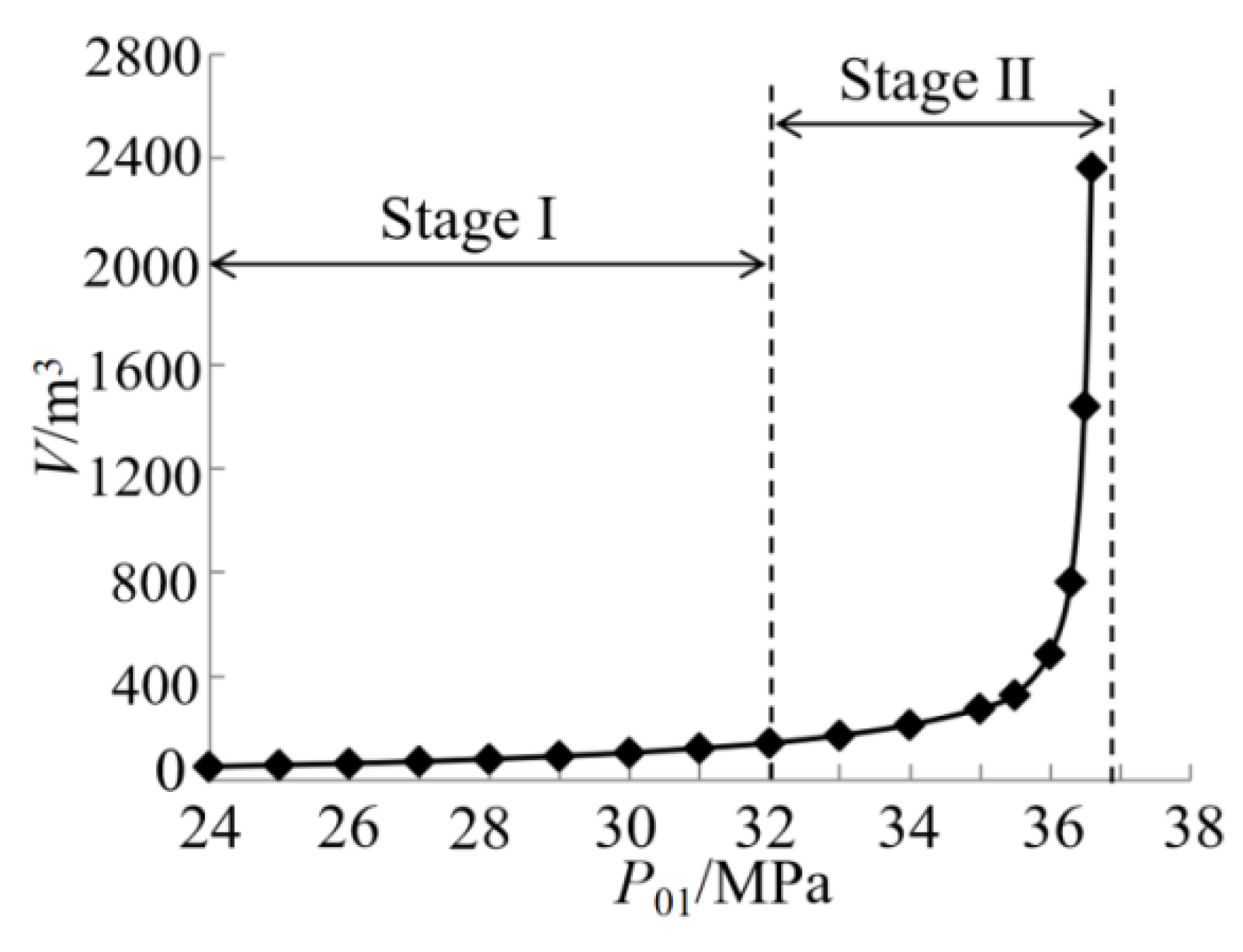

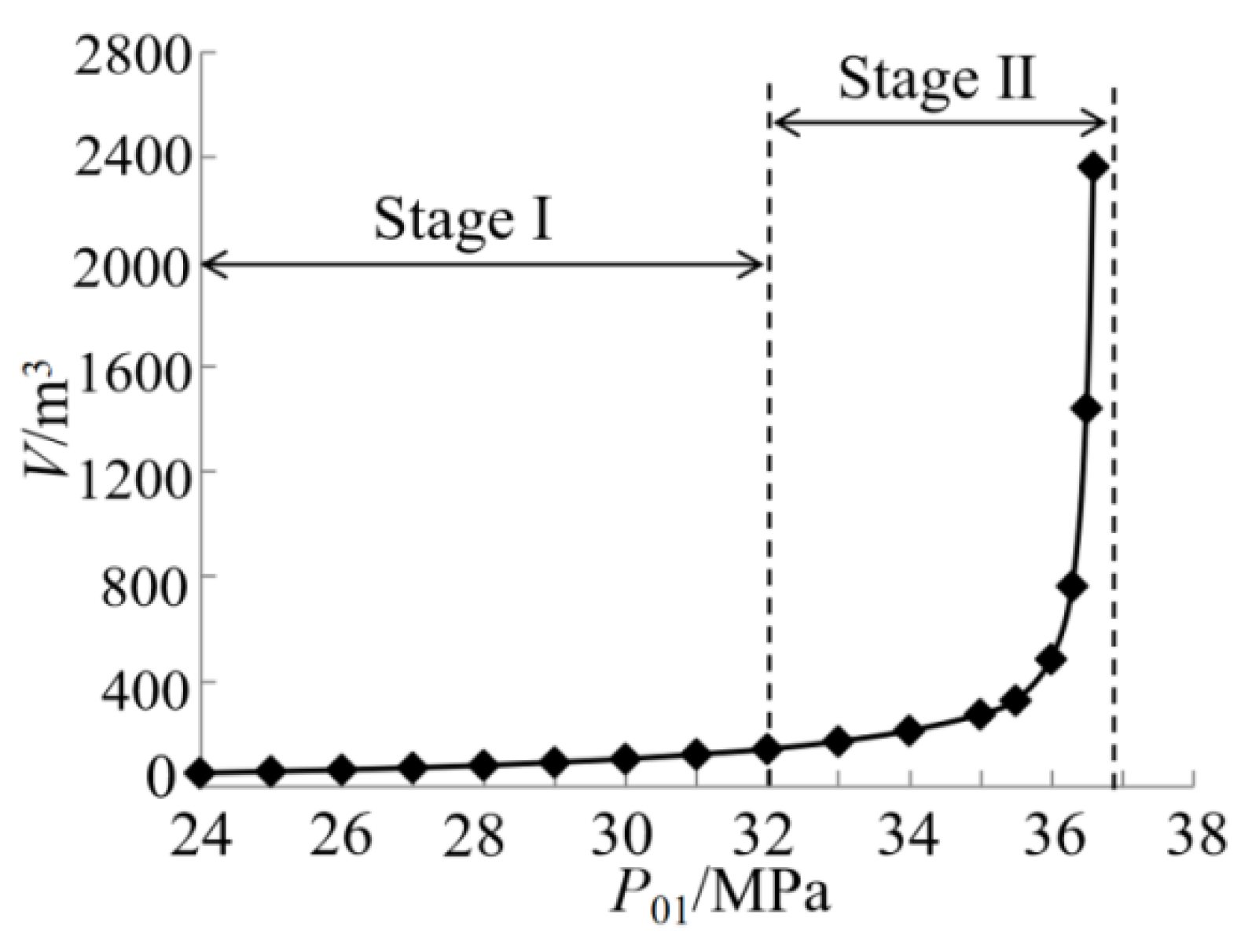

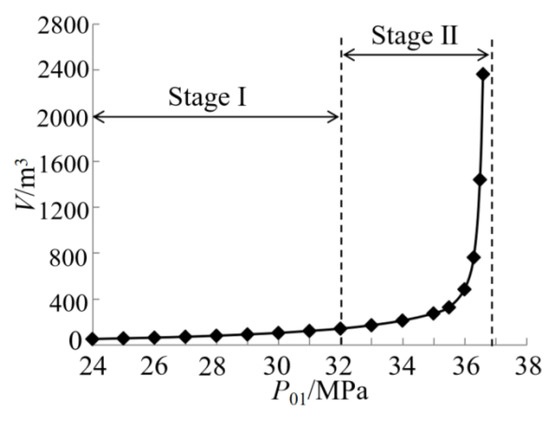

(2) The results of the plastic zone ahead of the excavation face with different .

According to Plan 2, as shown in Figure 4, with the increase of the value of , the range V of the plastic zone ahead of excavation face had roughly gone through two stages: (I) The linear growth stage and (II) the exponential growth stage. In stage I, with the increase of , the range V increased slowly and steadily. increased from 24 Mpa to 32 Mpa, the range V increased from to . In stage II, the range V increased rapidly and sharply. The range V increased to when . It is also noted that there was a critical value satisfying the relationship when was around 37 MPa.

Figure 4.

The relationship between and the range of the plastic zone (Plan 2).

3. Expansionary Evolution Characteristics of the Plastic Zone ahead of an Excavation Face

3.1. Mechanical Analysis Model for the Expansionary Evolution of Plastic Zone ahead of an Excavation Face

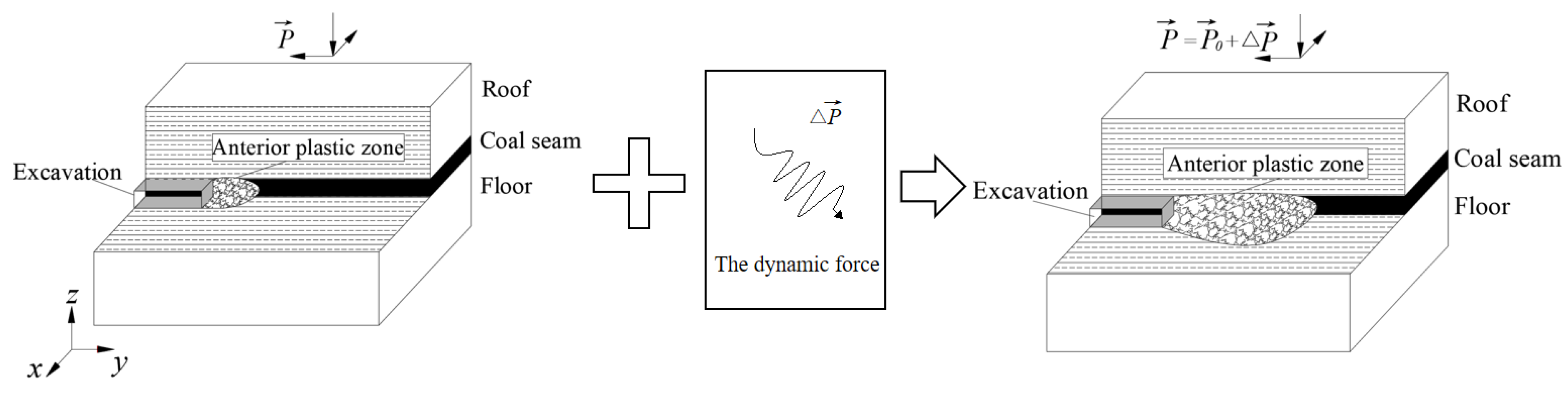

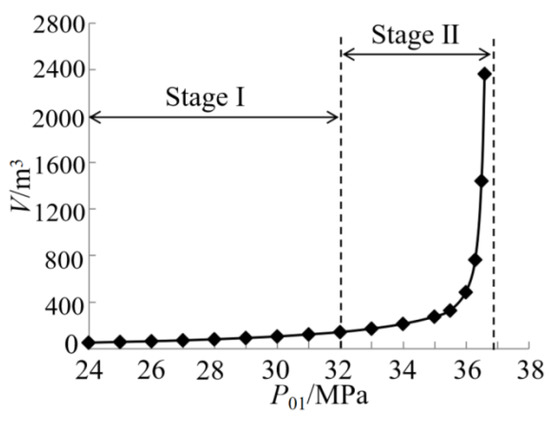

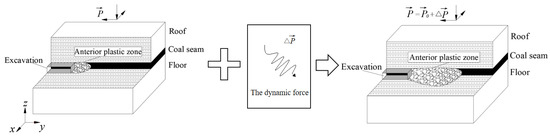

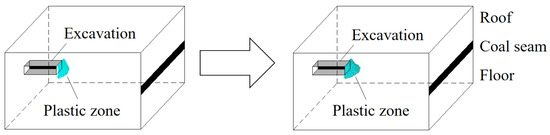

As shown in Figure 5, the mechanical analysis model for the expansionary evolution of plastic zone ahead of an excavation face was established according to the characteristics of surrounding rock and the stress environment based on actual production. The model mainly included the basic elements, including the dynamic force source , the regional static stress field , the regional transient stress field , the roadway, and the coal and rock mass containing gas. The whole model can be divided into two submechanical models: The anterior plastic zone model and the transient plastic zone model.

Figure 5.

Schematic of the expansionary evolution of plastic zone ahead of excavation face.

(1) The dynamic force source

For a specific coal seam roadway in production practice, the dynamic force source is generated by trigger events such as earthquake, fault activation, roof periodic weighting, moving abutment pressure, mining activities, etc. Although the size, time, and location of the generation have many uncertainties, the dynamic force source is the direct influencing factor for the extension of plastic zone around and excavation.

(2) The regional static stress field

The disturbance to the pre-mining stress field due to excavation of the roadway is negligible at a distance of more than five times the radius of a roadway from the center of the hole. Therefore, it can be considered that before the dynamic force influences, the stress field outside five times the radius of a roadway is regional static stress field applied to the surrounding rock around the roadway. This regional static stress and the surrounding rock mass in the tunneling process are objectively existed, which constitute the anterior mechanical model of plastic zone. This model is mainly used to explain the plastic failure of coal and rock mass ahead of the excavation face under the action of the regional static stress field , which is also called anterior plastic zone.

(3) The regional transient stress field

The regional transient stress field is formed by disturbance of dynamic force field on the regional static stress field , which is mainly the vector superposition of the above stress fields, that is, . The transient mechanical model of plastic zone is the mechanical response of the mechanical model of the anterior plastic zone under the action of regional transient stress field . It is formed by the transient expansion of the plastic zone ahead of the excavation face in the mechanical model of the anterior plastic zone under the action of the regional transient stress field .

3.2. Expansionary Evolution Characteristics of the Plastic Zone

During the coal mining, there are large differences in the regional principle stress field and the source of the disturbed load at different locations and during the different mining periods [30]. According to the above numerical modelling results and the mechanical analysis model, four typical events are listed to analyze the expansionary evolution characteristics of the plastic zone, as follows:

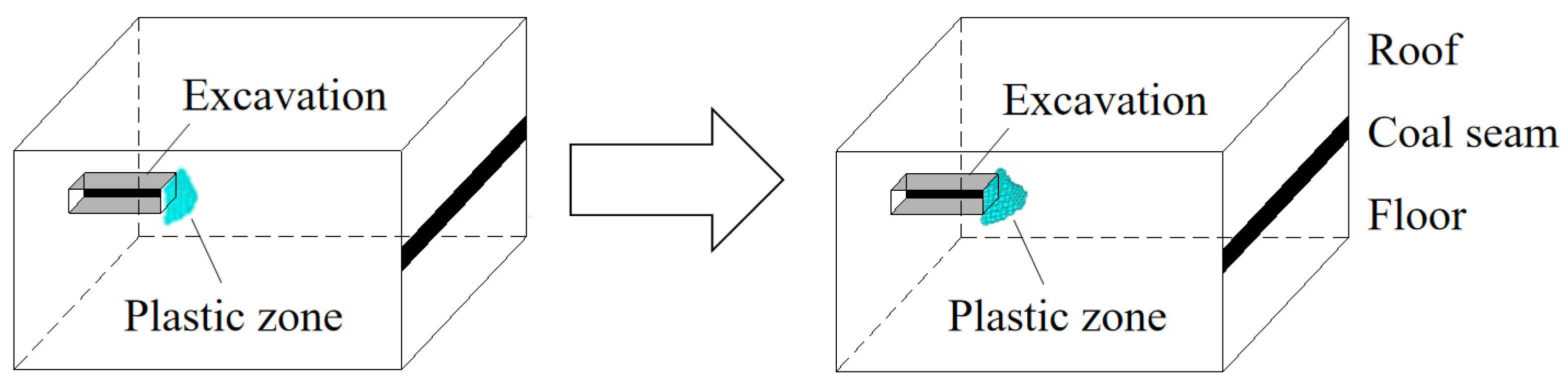

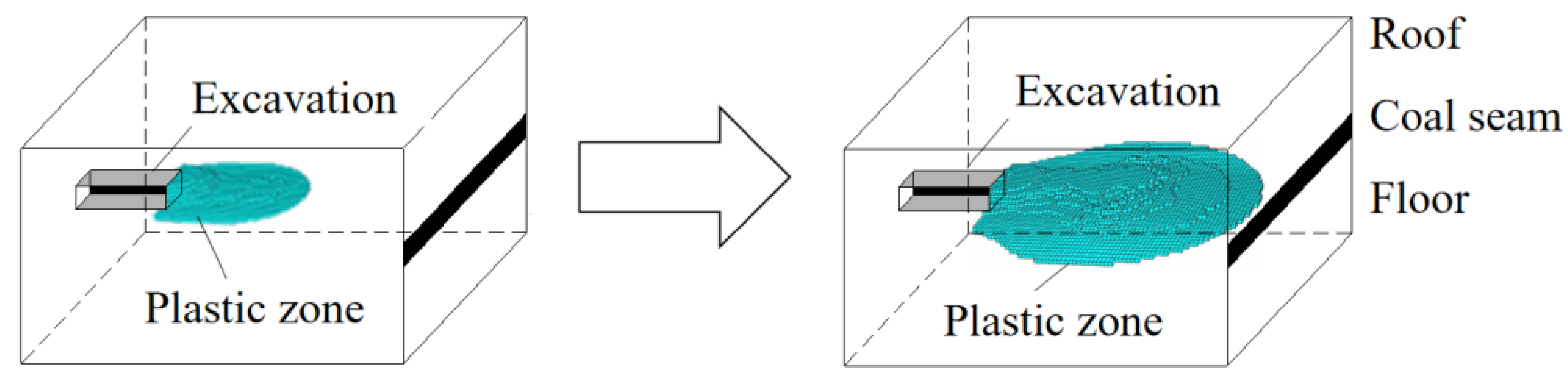

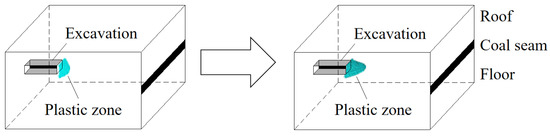

(1) Event I

Before event I, the parameters of the regional static stress field at the location where the excavation is located were , , and . The range of the plastic zone ahead of the excavation face was . The regional transient stress field would be formed if the maximum principal stress of was instantaneously increased by 5 MPa, which is caused by the dynamic disturbance under the external force . Then, the range of the plastic zone extended to under the action of . During this process, the range of the plastic zone was expanded from to . The numerical result of the expansion process of the plastic zone is shown in Figure 6.

Figure 6.

The expansionary evolution of the plastic zone in event I.

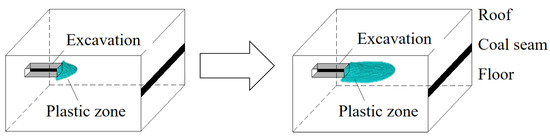

(2) Event II

Before the occurrence of event II, the parameters of the regional static stress field at the location where the excavation was located were the same as event I. The regional transient stress field would be formed if the maximum principal stress of was instantaneously increased by 10 MPa, which is caused by the dynamic disturbance under the external force . Then, the range of the plastic zone extended to under the action of . During this process, the range of the plastic zone was expanded from to . The numerical result of the expansion process of the event II is shown in Figure 7.

Figure 7.

The expansionary evolution of the plastic zone in event II.

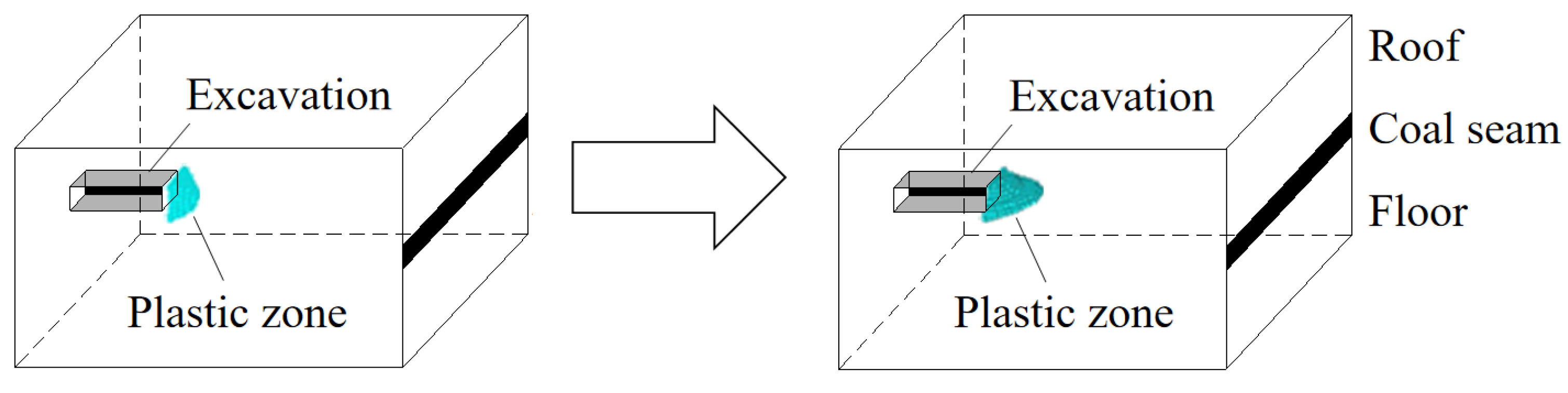

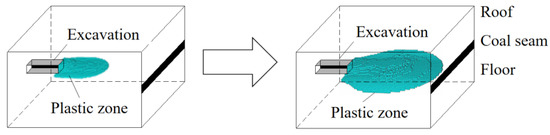

(3) Event III

Before event III occurs, the parameters of the regional static stress field at the location where the excavation was located were , , and . The range of the plastic zone of coal and rock mass ahead of the excavation face was . The regional transient stress field would be formed if the maximum principal stress of was instantaneously increased by 5 MPa, which is caused by the dynamic disturbance under the external force . Then the range of the plastic zone extended to under the action of . During this process, the range of the plastic zone was expanded from to . The numerical result of the expansion process of the event III is shown in Figure 8.

Figure 8.

The expansionary evolution of the plastic zone in event III.

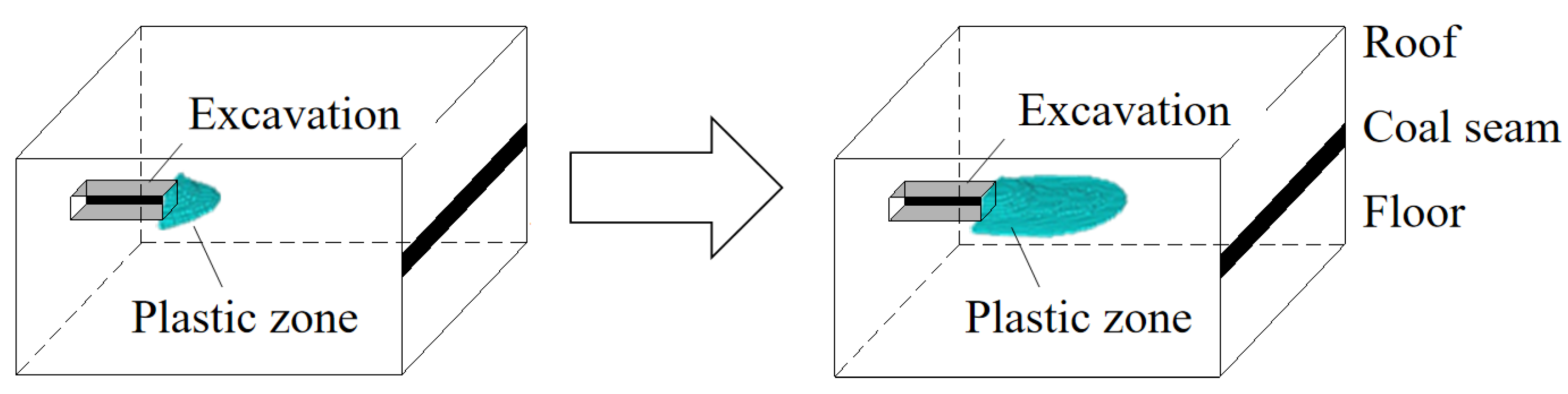

(4) Event IV

Before the occurrence of event IV, the parameters of the regional static stress field in the excavation roadway were , , , and . The range of the plastic zone of the coal and rock mass ahead of the excavation face was . The regional transient stress field would be formed if the maximum principal stress of was instantaneously increased by 0.5 MPa, which is caused by the dynamic disturbance under the external force . Then, the range of the plastic zone extended to under the action of . During this process, the range of the plastic zone was expanded from to . The numerical result of the expansion process of the event IV is shown in Figure 9.

Figure 9.

The expansionary evolution of the plastic zone in event IV.

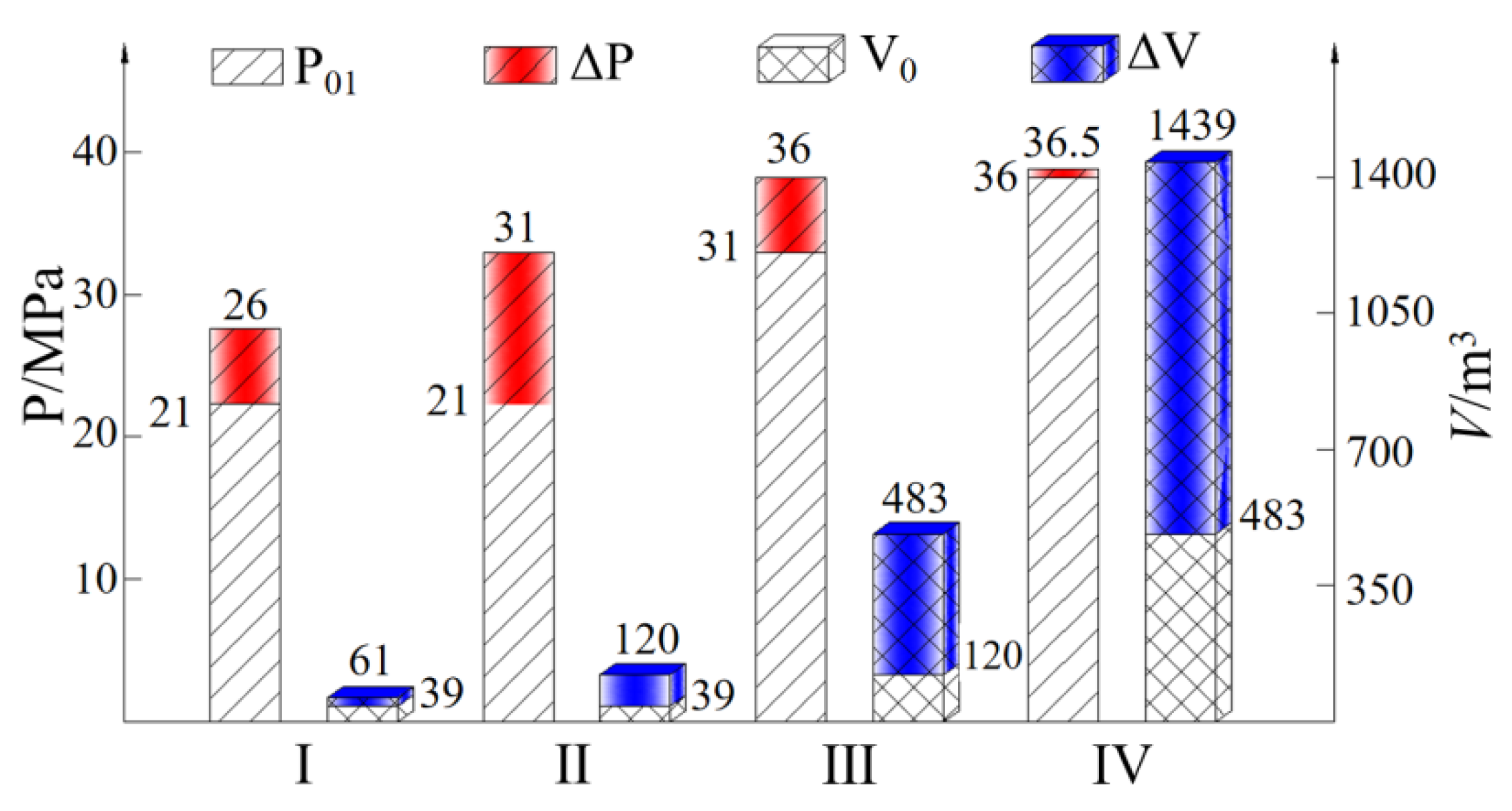

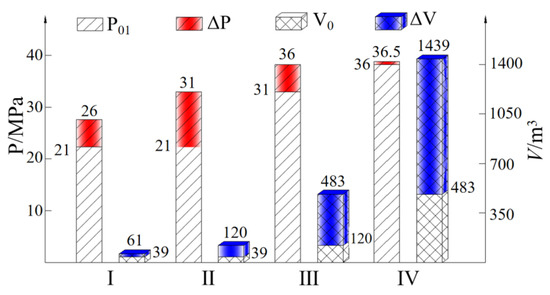

Figure 10 shows the modelling data of events I to IV. From the data, for a certain strength of the surrounding rock mass, the expansionary evolution of the plastic zone has the following characteristics:

Figure 10.

The statistical results of the numerical modelling data of events I to IV.

- (1)

- When the regional static stress field is the same, the external dynamic force field is the key factor affecting the development of the plastic zone. For instance, in events I and II, the external dynamic force of event I was smaller than the external dynamic force of event II with the same regional static stress field. The range of the plastic zone in the two events were and . That is, the larger the disturbance caused by the external dynamic force , the larger the expansioned range of the plastic zone .

- (2)

- When the regional static stress field is different, the plastic zone extends in different ranges even if the external dynamic force is the same. For instance, in events I and III, the static stress fields were different and the external dynamic forces were the same. In event III, the expanded range of the plastic zone was , which was much larger than .

- (3)

- Under the actions of the different static stress fields and dynamic forces, the expanded range of the plastic zone has a greater difference. For a certain regional static stress field, even small external dynamic forces can cause a wide extended range of the plastic zone. For instance, in events II and IV, the regional static stress fields were different. Although the external dynamic force of event II was 20 times the external dynamic force of event IV, the extended range of the plastic zone in event IV reached , which was more than 10 times the extended range of the plastic zone in event II.

4. Discussion

4.1. Mechanical Mechanism of Initiation of Coal and Gas Outbursts Induced by Extension of Plastic Zone

According to the expansionary evolution characteristics of plastic zone ahead of an excavation face, for the gassy coal and rock, when the plastic zone instantly extends in the coal and rock mass and forms a transient plastic zone, multiple cracks and even crushed rock mass are developed. In this very short period of time, the adsorbed gas is rapidly desorbed, and the free gas is rapidly accumulated. That is to say, with the formation of the transient plastic zone, a "gas bulb" is rapidly generated in the extended plastic zone due to rapid desorption and accumulation of gas in it. If the plastic zone extension range becomes larger, the elastic energy released from the surrounding rock mass and the gas energy accumulated in the “gas bag” would be more. When the total released energy is large enough, the coal and gas outburst will be triggered. Therefore, the expansionary evolution of the plastic zone is a precursor for the initiation of the coal and gas outburst.

Considering the triggering process of coal and gas outbursts, the physical and mechanical process of initiation of coal and gas outbursts induced by the expansionary evolution of the plastic zone is described as follows:

Loading and unloading due to such events as earthquakes, fault activation, roof pressure, abutment pressure, excavation activities, etc., lead to stress change in a very short time or instantaneously in the surrounding rock mass around an excavation. This causes the instantaneous expansionary evolution of plastic zone ahead of the excavation face. During this period, the failure of the surrounding rock mass would make the elastic energy and gas energy accumulated within it release rapidly. If the expanded range of the plastic zone and the total energy released are large enough, then the reverse constraining force of the comminuted coal and gas against intact surrounding rock is exceeded instantly and burst coal and gas into the working space of the roadway occurs.

In conclusion, the expansionary evolution of plastic zone ahead of the excavation is the direct inducement for initiation of coal and gas outburst under disturbance of the external dynamic forces. It is also the key external factor for coal and gas outburst. The elastic energy and gas energy in the surrounding rock mass are the energy source for the sustainable development of coal and gas outbursts after initiation, as well as the key internal inducement of coal and gas outbursts. In other words, if there are no elastic energy and gas energy, the coal and gas outbursts will not occur, and the rock mass ahead of an excavation would not have instantaneous expansionary evolution of the plastic zone, i.e., with no triggering effect of the expansionary evolution of plastic zone, the coal and gas outbursts will not occur.

4.2. The Basic Conditions for the Initiation and Development of the Coal and Gas Outburst Induced by the Expansionary Evolution of Plastic Zone

Based on the expansionary evolution of the plastic zone and the physical and mechanical process of the initiation and development of coal and gas outbursts, the basic conditions for their initiation and development induced by the expansionary evolution of the plastic zone are as follows:

(1) Trigger condition

The dynamic force source produced by the trigger event at time makes the stress state of the regional static stress field change abruptly. The regional transient stress field , which is formed during the dynamic adjustment of regional stress field at time , satisfies the following condition,

(2) The expansion condition of the failed zone

The expansionary evolution of the plastic zone of surrounding rock mass with a certain strength mainly depends on the regional static stress field , dynamic force and regional transient stress field . Under the trigger event, the regional transient stress field must satisfy that a plastic failure with a range of is regenerated in the surrounding rock, which can be expressed as follows:

where is the failed range of the surrounding rock mass ahead of the excavation under the action of , and is the failed range of the surrounding rock mass under the action of . has to be formed by rapidly expansionary evolution from in a short period of time, i.e., is formed instantly.

(3) The stress-strength condition

Before the trigger event occurs, if the stress value of is higher than the peak strength of the surrounding rock mass in this region, the surrounding rock mass around the roadway will all be in a state of plastic failure. Obviously, when tends to infinity, does not exist, and there will be no regional transient stress field that satisfies condition (3). Therefore, the value of regional static stress field is expected to be large so that the surrounding rock mass is in the plastic failure state. At the same time, should be less than the ultimate stress, which completely fails the surrounding rock mass. This can be expressed as:

(4) The angle condition

The direction of the regional stress field affects the plastic zone of the rock mass ahead of the excavation face. The generation, location, and size of are closely related to the direction of principal stress of the regional transient stress field . The direction of principle stress must satisfy that generates in the coal seam of the excavation. Therefore, the maximum and minimum principal stresses of should be within the vertical cross section of the roadway. The angle between the maximum principal stress field and the direction perpendicular to the coal seam is:

where .

(5) The energy condition

From the perspective of energy, coal and gas outburst energy mainly include the elastic potential energy and gas internal energy in coal and rock mass. During coal and gas outbursts, these energies are transformed into the following four parts: Work done on crushing coal: , work done to overcome the resistance , work done by the comminuted coal travelling in the roadway , and the energy , including friction heat, vibration, and sound energy generated by coal bumping into the sidewall of the roadway, steel sets, and other obstacles [6]. For a specific project, given certain parameters of coal and rock mass and gas, after four conditions described above are met, the larger the expansionary evolution range of the plastic zone , the more elastic energy and gas energy release and the higher the risk of outburst. Under the action of the regional transient stress field , the following energy condition has to be met:

The above five conditions are necessary to trigger coal and gas outbursts induced by expansionary evolution of the plastic zone. When the five conditions are simultaneously satisfied, it will be sufficient for coal and gas outburst. At the same time, Conditions (1)–(4) are necessary and sufficient for the key external factors of the instantaneous expansionary evolution of plastic zone. They are also the conditions for initiation of outburst. It is noted that the key internal factors, the elastic energy, and gas energy existing in the surrounding rock mass must satisfy condition (5) to trigger the outburst.

5. Conclusions

- (1)

- The numerical modelling was carried out to analyze the evolution of the plastic zone ahead of an excavation face with the change of the direction and magnitude of the regional pre-mining stress field. With the increase of the angle α formed by and Z axes, the range of the plastic zone V ahead of the excavation face increased at first and then decreased, approximately complying with Gaussian distribution with peak value when . With the increase of the value of , the range V had two stages: (Ι) The linear growth stage and (II) the exponential growth stage.

- (2)

- A mechanical analysis model for the expansionary evolution process of plastic zone ahead of excavation face was constructed, and the expansionary evolution characteristics of plastic zone were analyzed. The model consisted of dynamic force source , the regional static stress field , the regional transient stress field , the roadway, and the coal and rock mass containing gas. The whole model can be divided into two submechanical models: The anterior plastic zone model and the transient plastic zone model. When the regional static stress field was the same, the external dynamic force field was the key factor affecting the development of the plastic zone. When the regional static stress field was different, the plastic zone extended in different ranges even if the external dynamic force was the same. Under the action of the different static stress fields and dynamic forces, the expanded range of the plastic zone had a significant difference. For a certain regional static stress field, even small external dynamic forces can cause a wide extended range of the plastic zone.

- (3)

- The physical and mechanical process and the basic conditions for the initiation and development of coal and gas outburst induced by the extension of plastic zone are discussed. The expansionary evolution of the plastic zone ahead of the roadway was the direct cause for the initiation of the coal and gas outburst under the disturbance of the external dynamic forces. The elastic energy and gas energy in the surrounding rock mass were the energy sources for the sustainable development of coal and gas outbursts after initiation. To trigger coal and gas outbursts, five conditions have to be met: Trigger condition, expansion condition of the failed zone, stress-strength condition, angle condition, and energy condition.

Author Contributions

Conceptualization, H.L., L.G. and X.Z.; Methodology, L.G.; software, X.Z.; Validation, H.L.; Formal analysis, L.G.; Investigation, L.G.; Data curation, X.Z.; Writing—original draft preparation, L.G.; Writing—review and editing, X.Z.; Supervision, H.L.; Funding acquisition, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51804117, 51774288 and 51674243).

Acknowledgments

Special thanks to Pengfei Wang, Associate Professor at Taiyuan University of Technology and Visiting Scholar at McGill University, who performed significant review and editing of the manuscript. The authors are thankful to the anonymous reviewers for their kind suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hyman, D. A Review of the Mechanisms of Gas Outbursts in Coal. Information Circular IC 9155; US Bureau of Mines: Washington, DC, USA, 1987.

- Fan, C.J.; Li, S.; Luo, M.K.; Du, W.Z.; Yang, Z.H. Coal and gas outburst dynamic system. Int. J. Min. Sci. Technol. 2017, 27, 49–55. [Google Scholar] [CrossRef]

- Feng, G.R.; Wang, P.F.; Chugh, Y.P.; Zhao, J.L.; Wang, Z.Q.; Zhang, Z.P. A Coal Burst Mitigation Strategy for Tailgate during Deep Mining of Inclined Longwall Top Coal Caving Panels at Huafeng Coal Mine. Shock Vib. 2018, 2018. [Google Scholar] [CrossRef]

- Aziz, N.; Black, D.; Ren, T. Keynote paper mine gas drainage and outburst control in Australian underground coal mines. Procedia Eng. 2011, 26, 84–92. [Google Scholar] [CrossRef][Green Version]

- Xie, H.P.; Xie, J.; Gao, M.Z.; Zhang, R.; Zhou, H.W.; Gao, F.; Zhang, Z.T. Theoretical and experimental validation of mining-enhanced permeability for simultaneous exploitation of coal and gas. Environm. Earth Sci. 2015, 73, 5951–5962. [Google Scholar] [CrossRef]

- Fisne, A.; Esen, O. Coal and gas outburst hazard in Zonguldak Coal Basin of Turkey, and association with geological parameters. Nat. Hazards 2014, 74, 1363–1390. [Google Scholar] [CrossRef]

- Guo, X.F.; Zhao, Z.Q.; Gao, X.; Ma, Z.K.; Ma, N.J. The Criteria of Underground Rock Structure Failure and Its Implication on Rockburst in Roadway: A Numerical Method. Shock Vib. 2019, 2019. [Google Scholar] [CrossRef]

- Zou, Q.L.; Liu, H.; Zhang, Y.J.; Li, Q.M.; Fu, J.W.; Hu, Q.T. Rationality evaluation of production deployment of outburst-prone coal mines: A case study of nantong coal mine in Chongqing, China. Saf. Sci. 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Norbert, S.; Pajdak, A.; Koziel, K.; Braga, L.T.P. Methane Emission during Gas and Rock Outburst on the Basis of the Unipore Model. Energies 2019, 12, 1999. [Google Scholar] [CrossRef]

- Kursunoglu, N.; Onder, M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunn. Undergr. Space Technol. 2019, 88, 63–72. [Google Scholar] [CrossRef]

- Li, J.G.; Hu, Q.T.; Yu, M.G.; Li, X.L.; Hu, J.; Yang, H.M. Acoustic emission monitoring technology for coal and gas outburst. Energy Sci. Eng. 2019, 7, 443–456. [Google Scholar] [CrossRef]

- Hong, L.; Gao, D.M.; Wang, J.R.; Zheng, D. The Power Source for Coal and Gas Outburst. J. Min. Sci. 2019, 55, 239–246. [Google Scholar] [CrossRef]

- Gao, M.Z.; Zhang, S.; Li, J.; Wang, H.Y. The Dynamic Failure Mechanism of Coal and Gas Outbursts and Response Mechanism of Support Structure. Therm. Sci. 2019, 23, S867–S875. [Google Scholar] [CrossRef]

- Ahmadi, S.F.; Eskandari, M. Vibration Analysis of a Rigid Circular Disk Embedded in a Transversely Isotropic Solid. J. Eng. Mech. 2014, 140, 04014048. [Google Scholar] [CrossRef]

- Ahmadi, S.F.; Eskandari, M. Rocking rotation of a rigid disk embedded in a transversely isotropic half-space. Civil. Eng. Infrastruct. J. 2014, 47, 125–138. [Google Scholar]

- Eskandari, M.; Shodja, H.M.; Ahmadi, S.F. Lateral translation of an inextensible circular membrane embedded in a transversely isotropic half-space. Eur. J. Mech. A/Solids 2013, 39, 134–143. [Google Scholar] [CrossRef]

- Chen, K.; Zou, D.G.; Kong, X.J.; Liu, J.M. Elasto-plastic fine-scale damage failure analysis of metro structures based on coupled SBFEM-FEM. Comput. Geotech. 2019, 108, 280–294. [Google Scholar] [CrossRef]

- Ai, Z.Y.; Li, P.C.; Song, X.Y. Analysis of an axially loaded pile in saturated multi-layered soils with anisotropic permeability and elastic superstrata. Comput. Geotech. 2018, 98, 93–101. [Google Scholar] [CrossRef]

- Shepeleva, S.A.; Dyrdin, V.V. Gas Emission under Coal and Gas Outbursts. J. Min. Sci. 2011, 47, 660–663. [Google Scholar] [CrossRef]

- Dyrdin, V.V.; Smirnov, V.G.; Shepeleva, S.A. Parameters of Methane Condition during Phase Transition at the Outburst-Hazardous Coal Seam Edges. J. Min. Sci. 2013, 49, 908–912. [Google Scholar] [CrossRef]

- Dyrdin, V.V.; Oparin, V.N.; Fofanov, A.A.; Smirnov, V.G.; Kim, T.L. Possible Effect of Main Roof Settlement on Outburst Hazard in Case of Gas Hydrate Dissociation during Coal Mining. J. Min. Sci. 2017, 53, 801–810. [Google Scholar] [CrossRef]

- Smirnov, V.G.; Dyrdin, V.V.; Kim, T.L.; Manakov, A.Y. Effect of the hydrate saturation of the pores of coal bed on the gradient of gas pressure and the rise of outburst danger. In Proceedings of the 4th International Innovative Mining Symposium, T F Gorbachev Kuzbass State Tech Univ, Kemerovo, Russia, 2–4 August 1994; pp. 239–245. [Google Scholar]

- Smirnov, V.G.; Dyrdin, V.V.; Manakov, A.Y.; Ismagilov, Z.R.; Adamova, T.P. Problem of Pulverized Coal Formation at Mine Outburst Caused by Decomposition of Gas Hydrates in Coal Seams. Khimiya Interes. Ustoichivogo Razvit. 2016, 24, 499–507. [Google Scholar]

- Smirnov, V.G.; Manakov, A.Y.; Dyrdin, V.V.; Kim, T.L.; Shepeleva, S.A. The rate of formation and decomposition of gas hydrate formed in natural coal. Russ. Phys. J. 2019, 62, 112–121. [Google Scholar] [CrossRef]

- Meshkov, S.; Sidorenko, A. Numerical Simulation of Aerogasdynamics Processes in a Longwall Panel for Estimation of Spontaneous Combustion Hazards. In Proceedings of the 2nd International Innovative Mining Symposium (Devoted to Russian Federation Year of Environment), Kemerovo, Russia, 20–22 November 2017. [Google Scholar]

- Kazanin, O.I.; Sidorenko, A.A. Interaction between Gas Dynamic and Geomechanical Processes in Coal Mines. ARPN J. Eng. Appl. Sci. 2017, 12, 1458–1462. [Google Scholar]

- Guo, X.F.; Ma, N.J.; Zhao, X.D.; Zhao, Z.Q.; Li, Y.G. General shapes and criterion for surrounding rock mass plastic zone of round roadway. Int. J. Coal Sci. Technol. 2016, 41, 1871–1877. [Google Scholar]

- Ma, N.J.; Zhao, X.D.; Zhao, Z.Q.; Li, J.; Guo, X.F. Stability analysis and control technology of mine roadway roof in deep mining. Int. J. Coal Sci. Technol. 2015, 40, 2287–2295. [Google Scholar]

- Ma, N.J.; Guo, X.F.; Zhao, Z.Q.; Zhao, X.D.; Liu, H.T. Occurrence mechanisms and judging criterion on circular tunnel butterfly rock burst in homogeneous medium. Int. J. Coal Sci. Technol. 2016, 41, 2679–2688. [Google Scholar]

- Feng, G.R.; Wang, P.F.; Chugh, Y.P. Stability of gate roads next to an irregular yield pillar: A case study. Rock Mech. Rock Eng. 2019, 52, 2741–2760. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).