Experimental and CFD Analysis of Impact of Surface Roughness on Hydrodynamic Performance of a Darrieus Hydro (DH) Turbine

Abstract

1. Introduction

2. Numerical Modeling

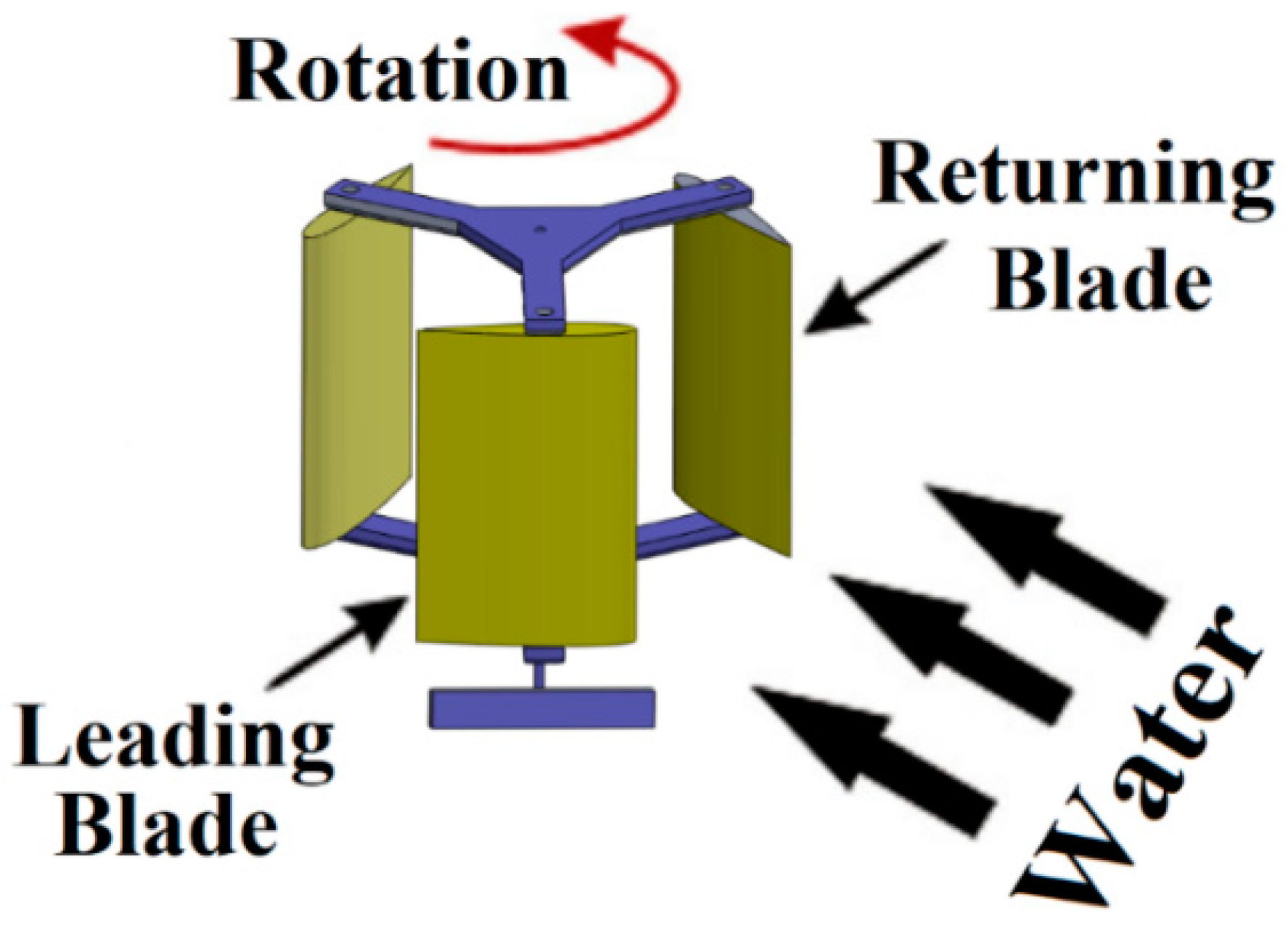

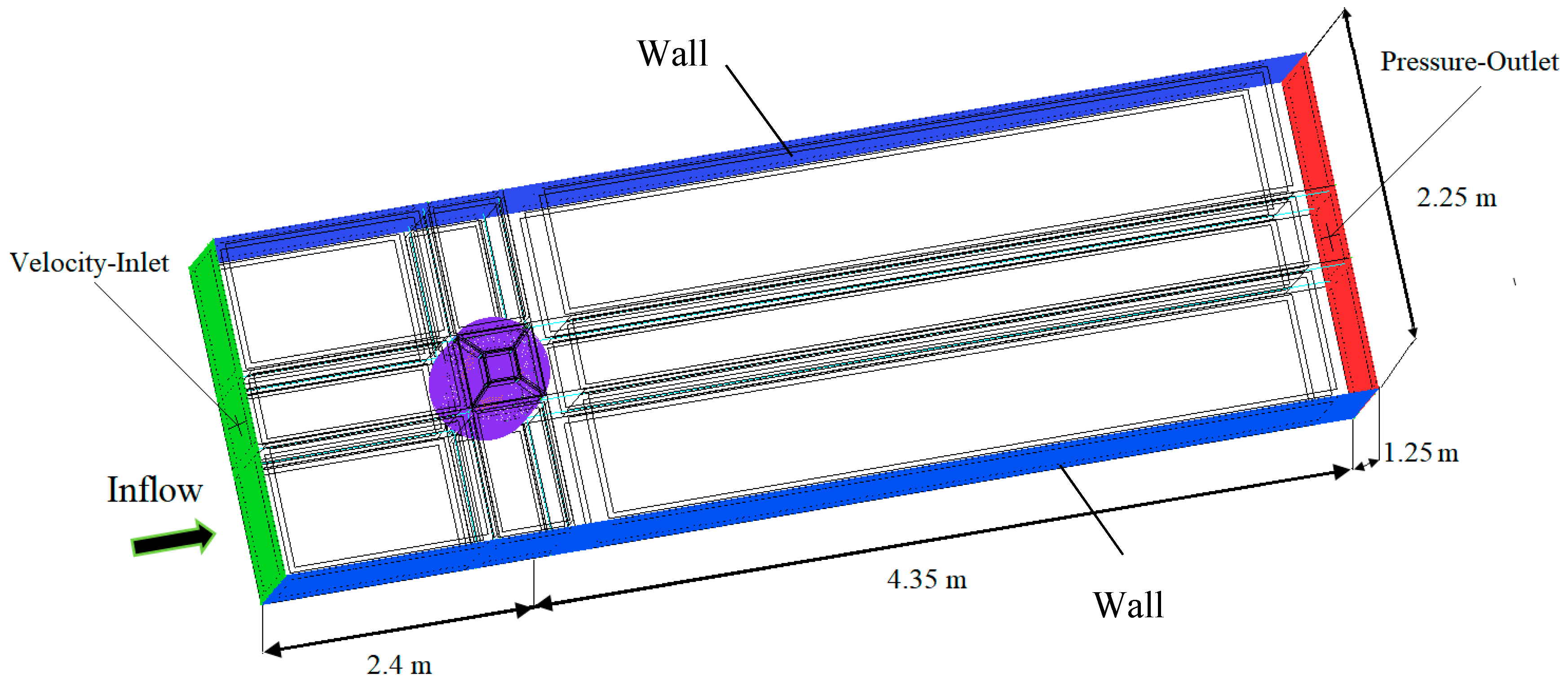

2.1. Model Geometry

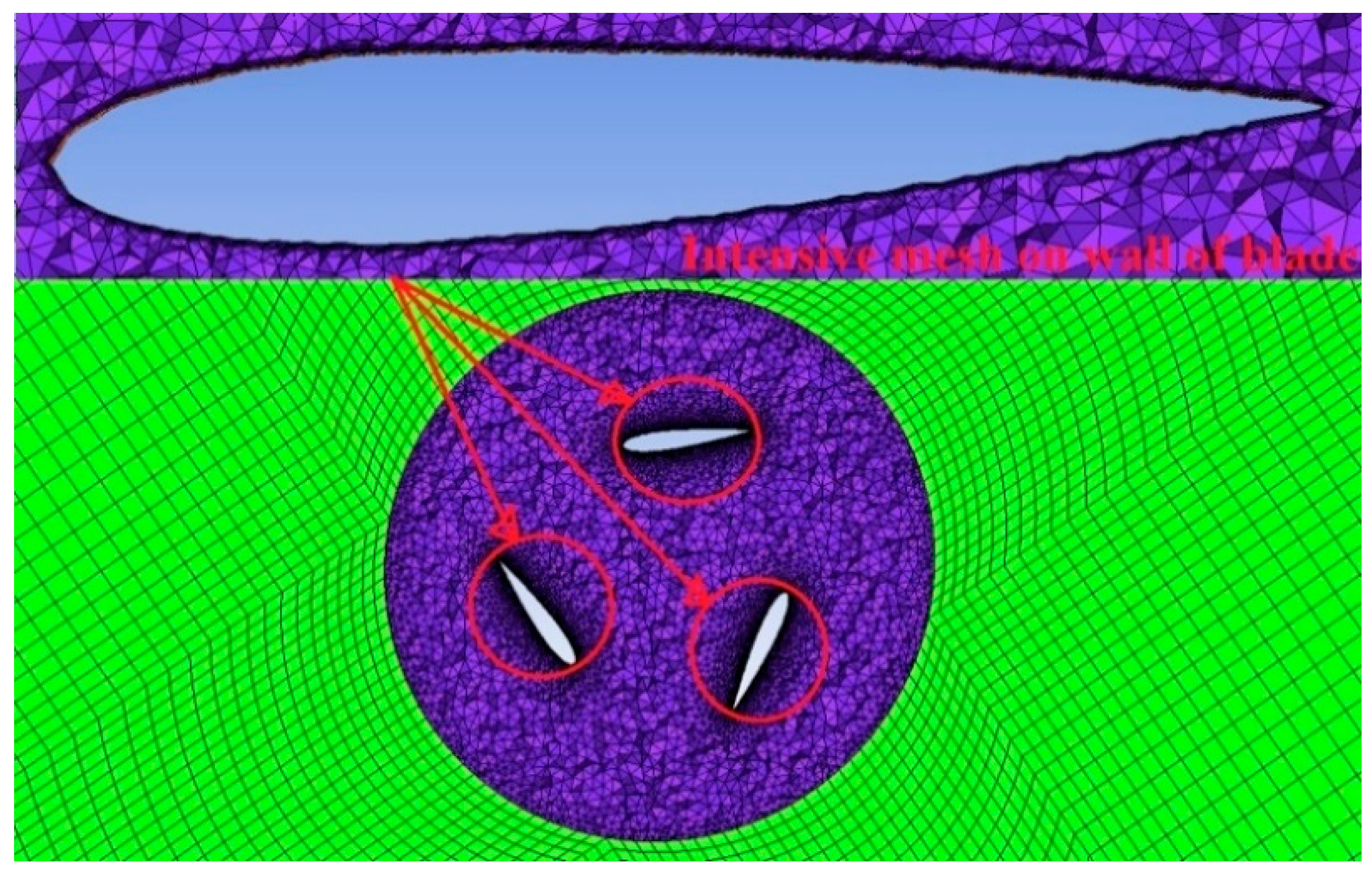

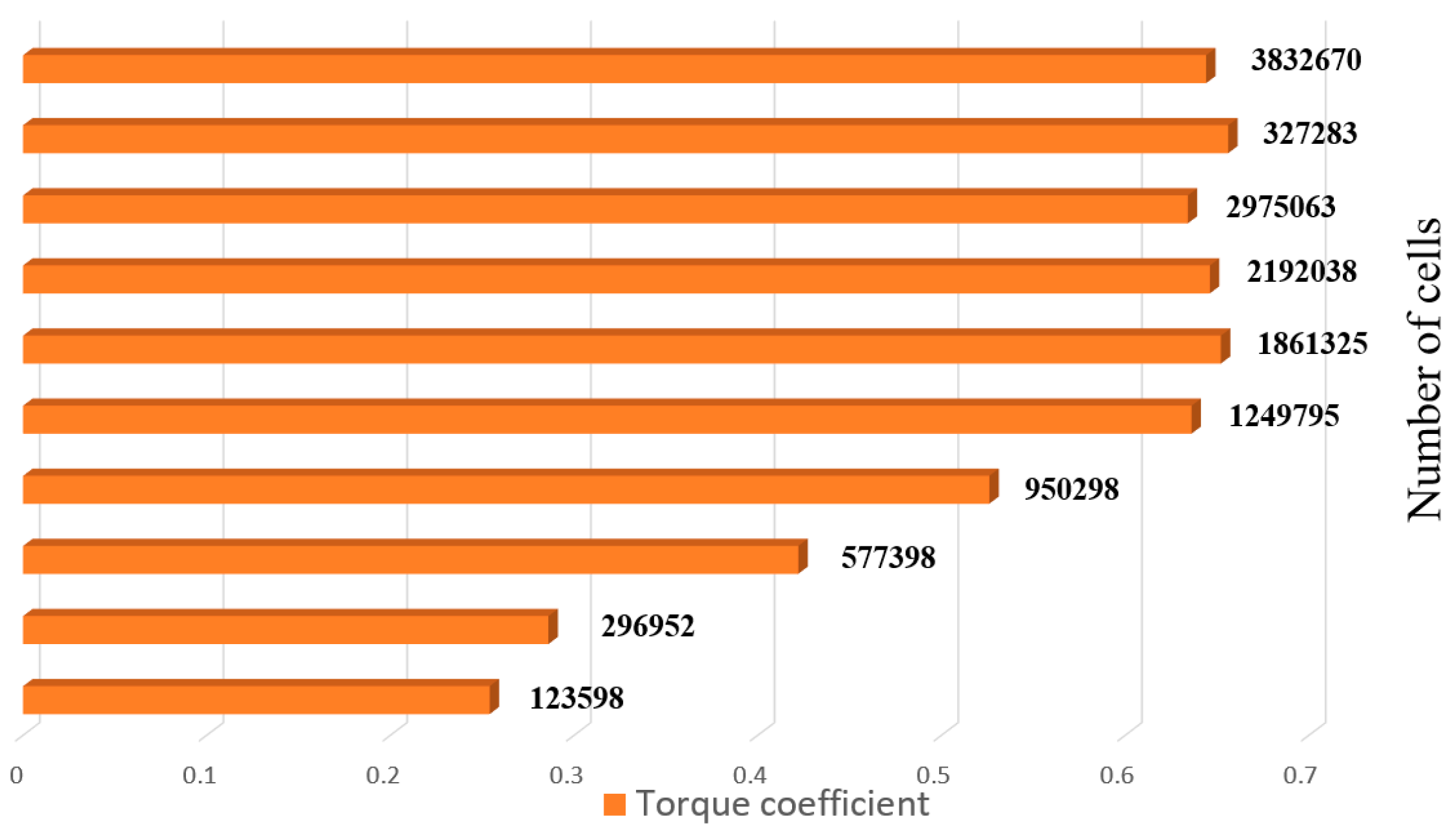

2.2. Grid Sensitivity (GS) Test

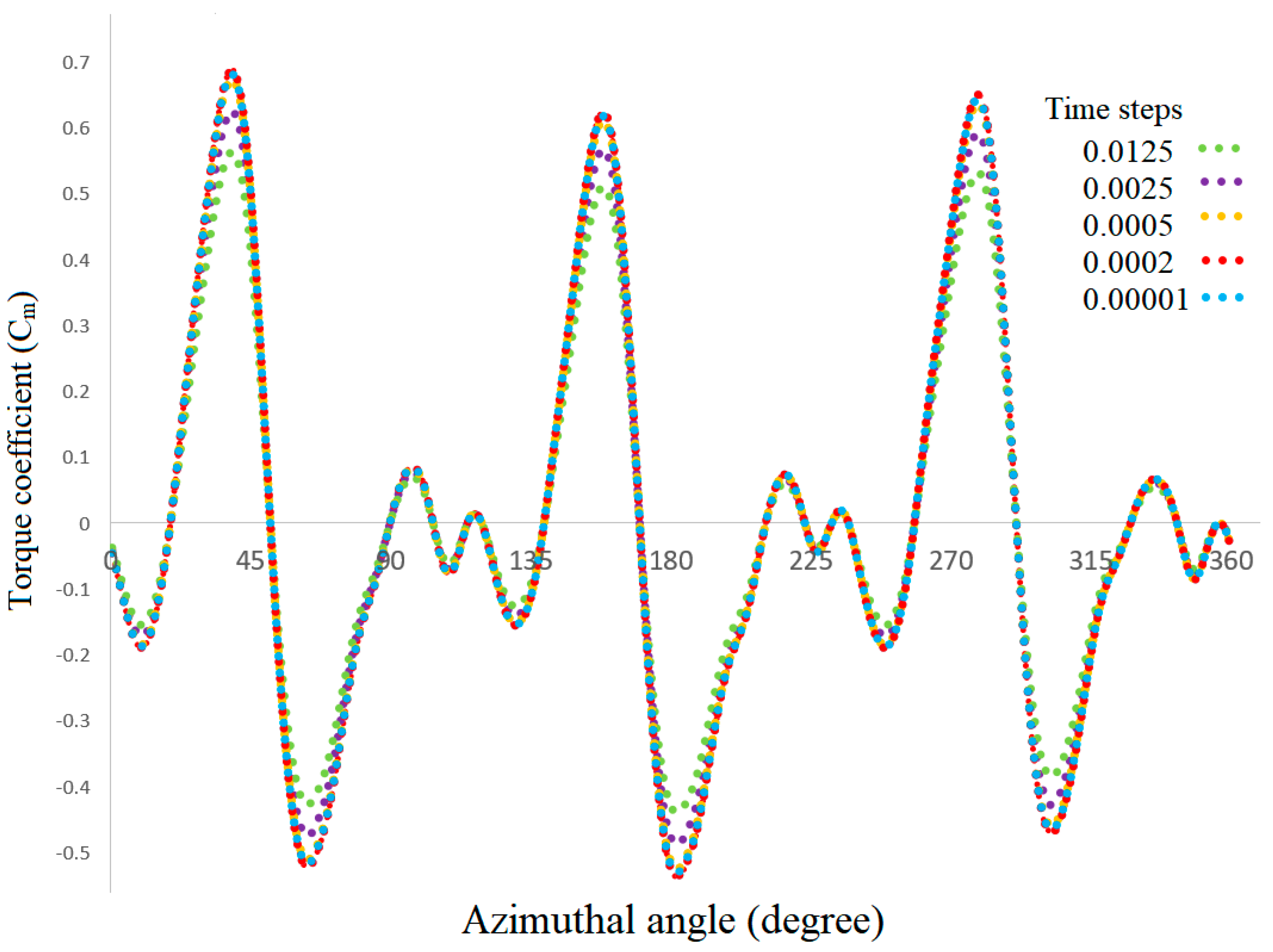

2.3. Time Sensitivity (TS) Test

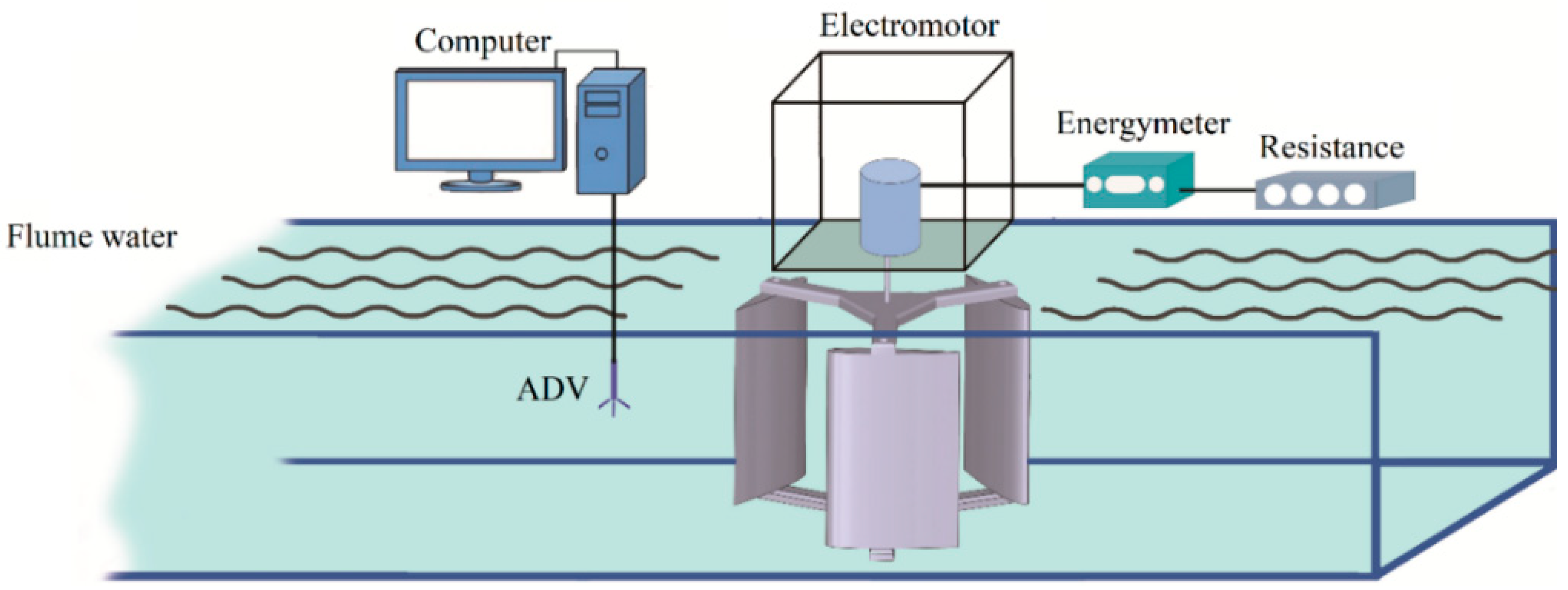

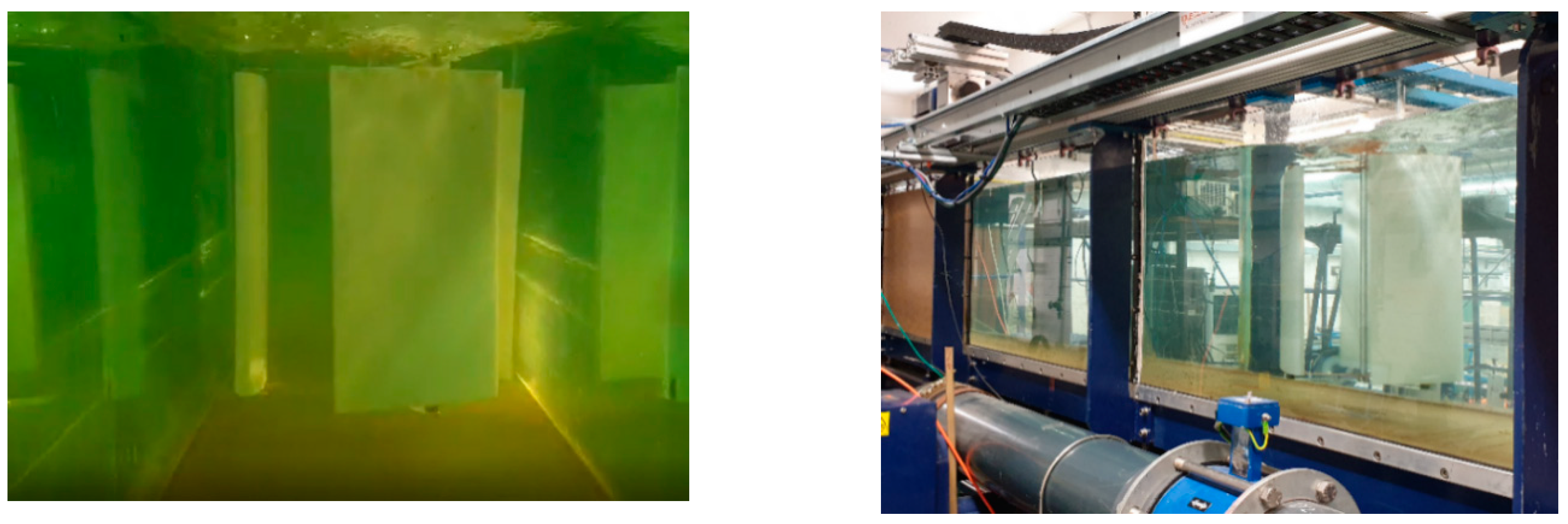

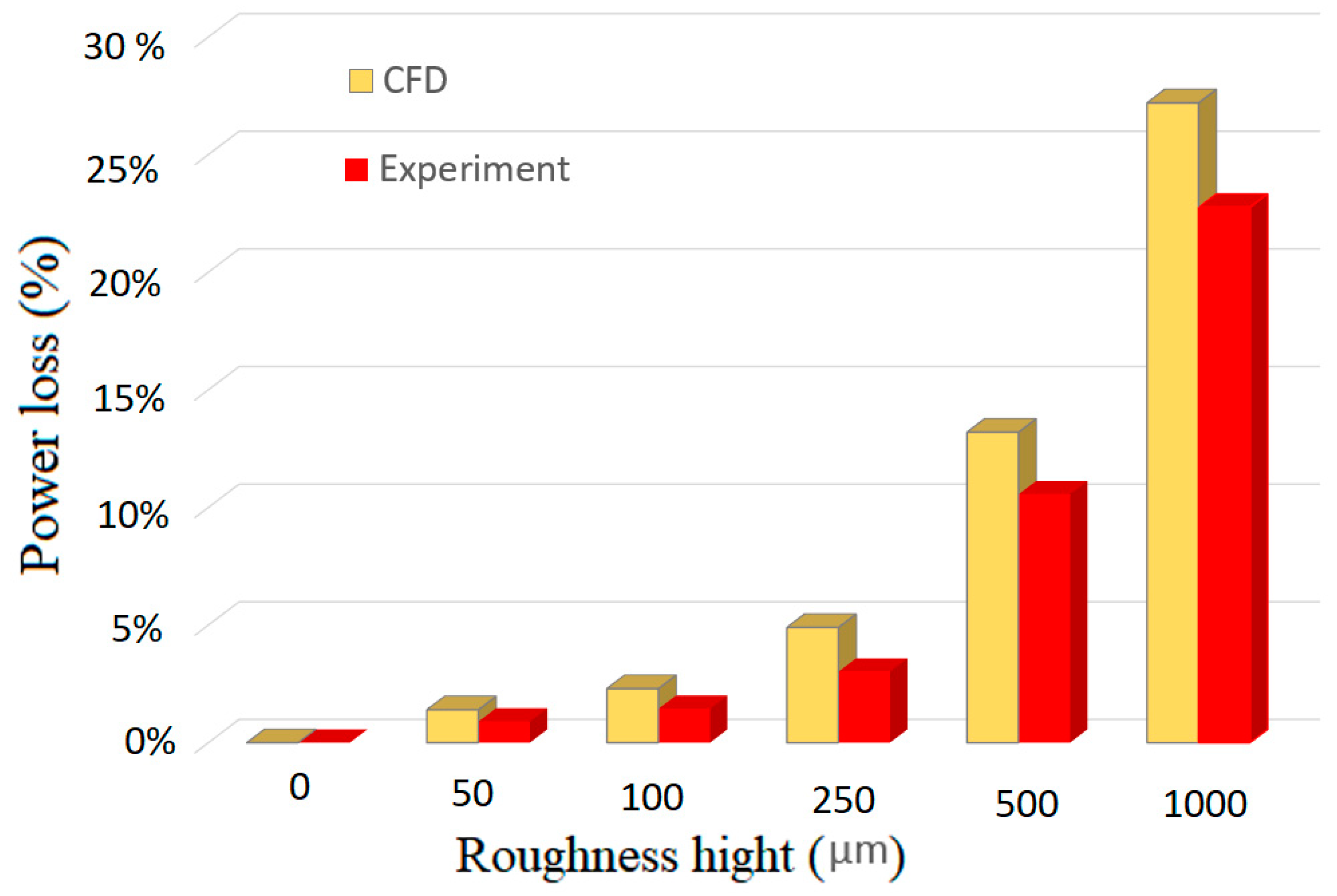

3. Experimental Setup

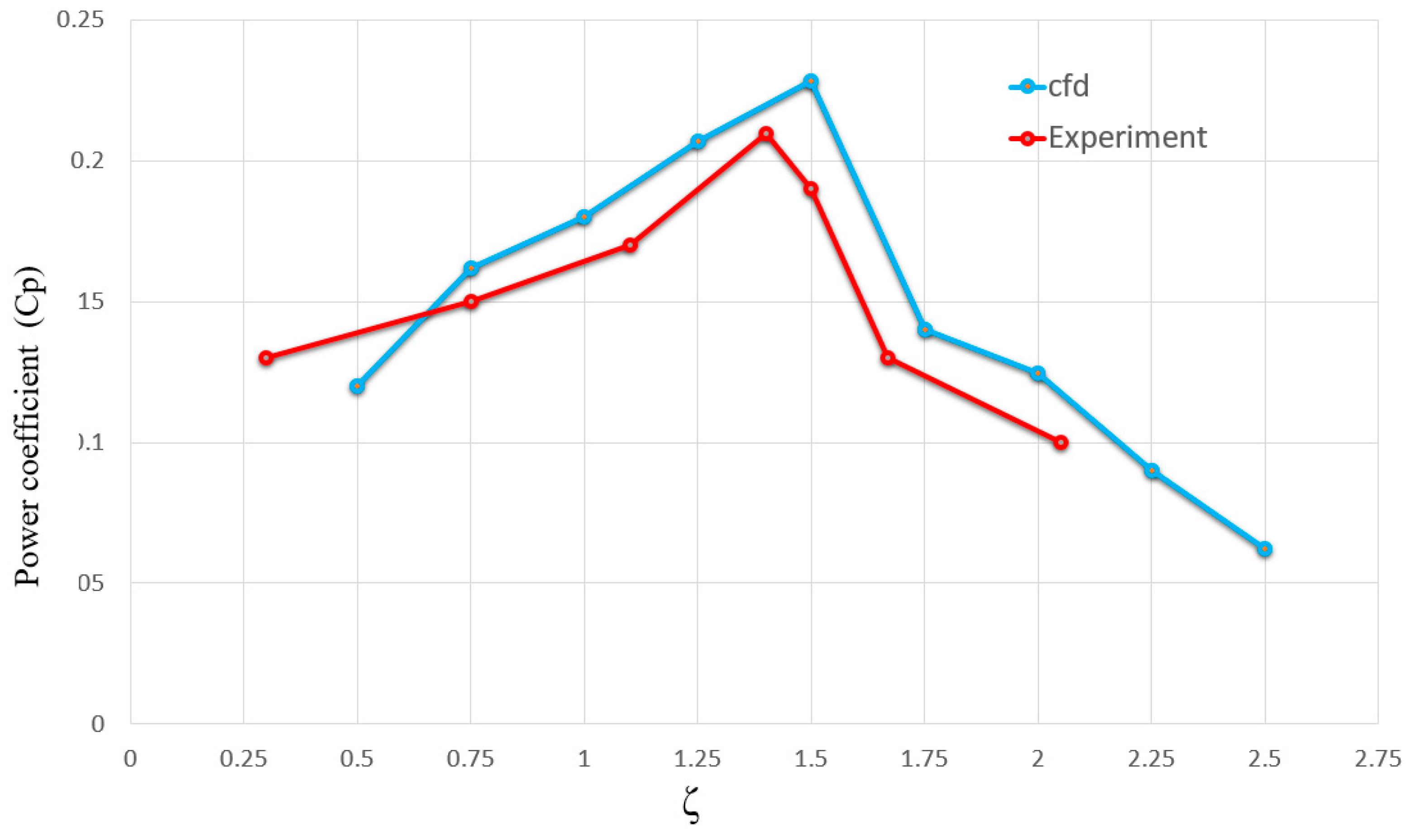

4. Validation of the CFD Model

5. Modeling of Roughness Based on Modified Law of the Wall

6. Results and Discussion

6.1. Numerical Results

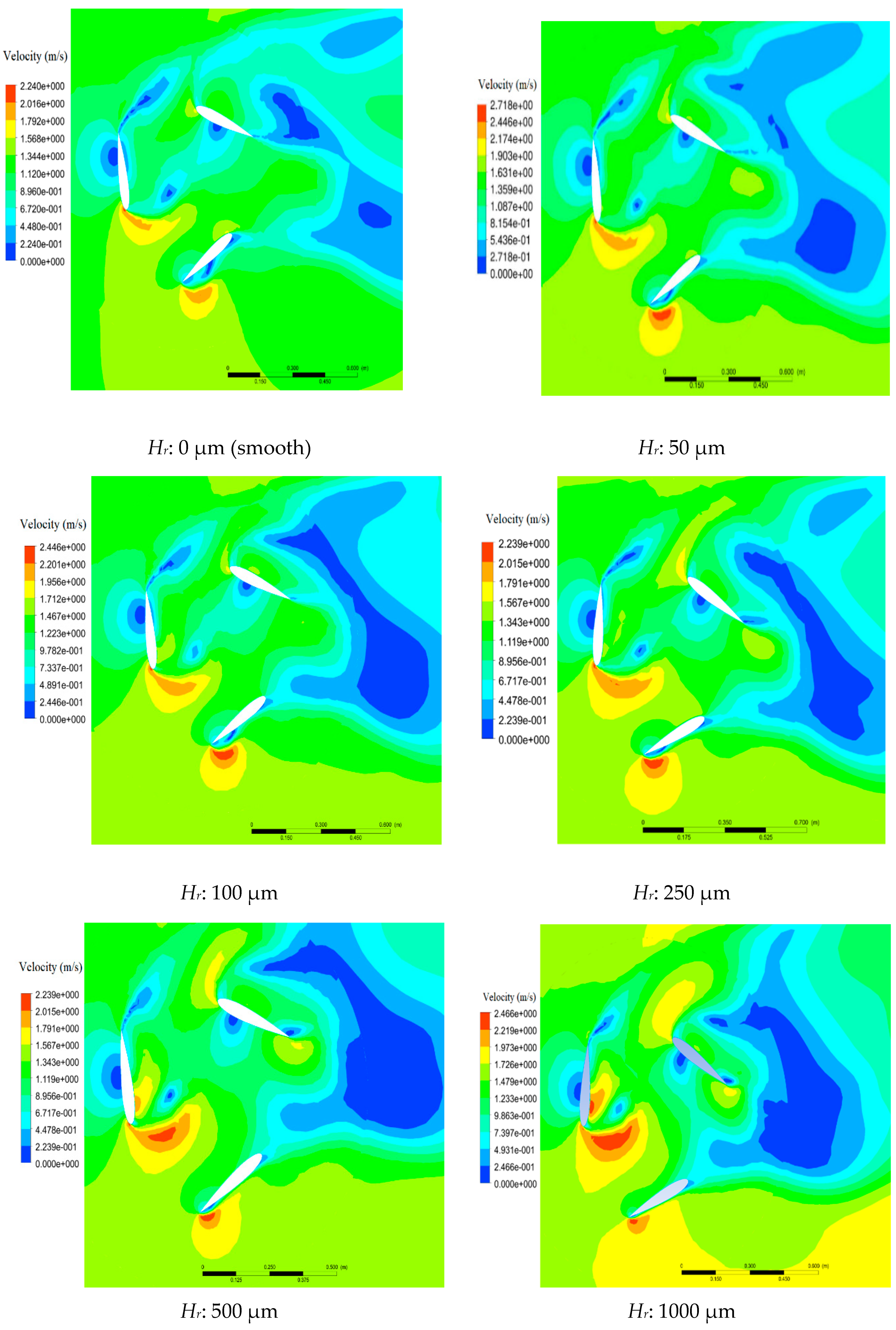

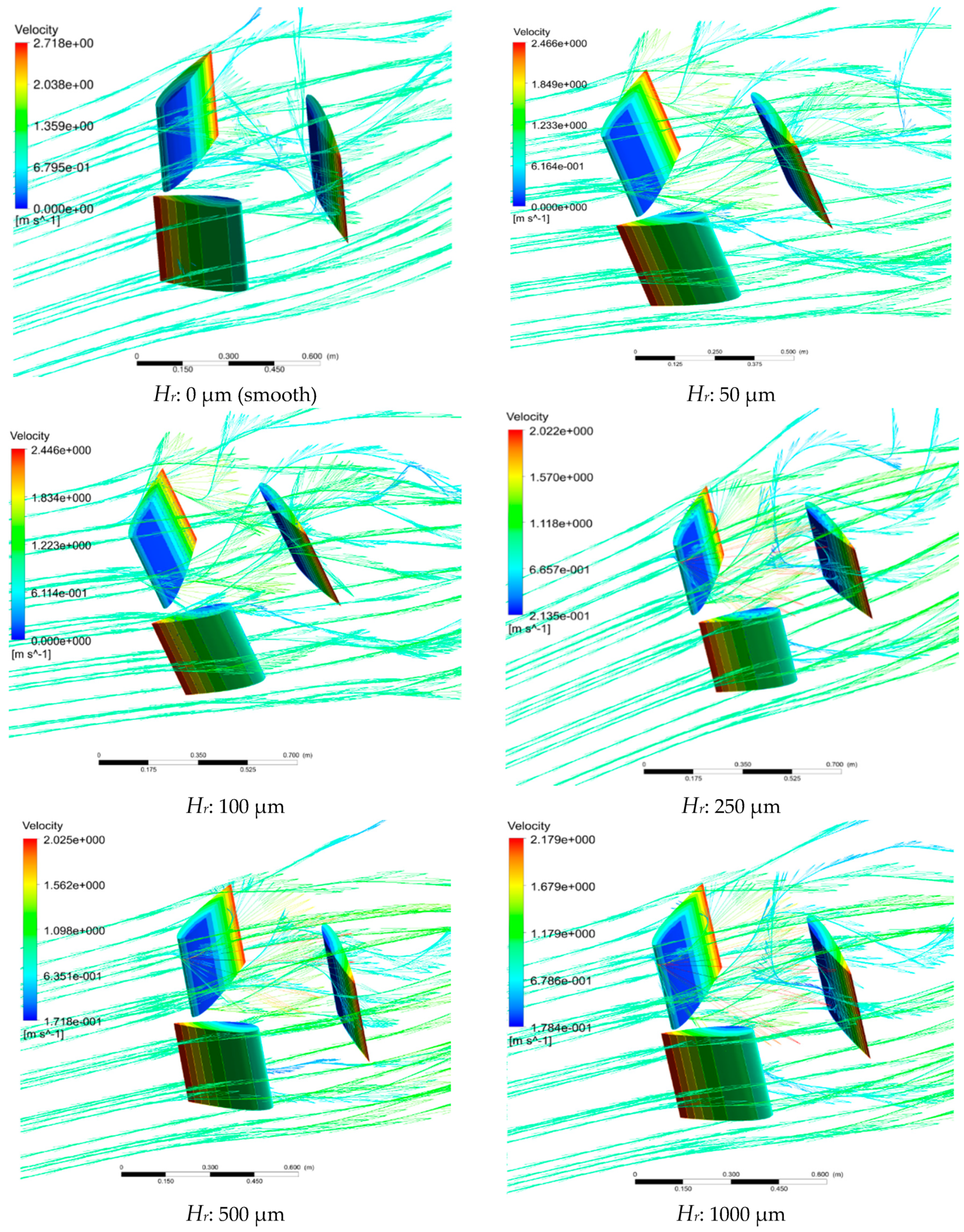

6.1.1. Effects of Surface Roughness on Flow Pattern

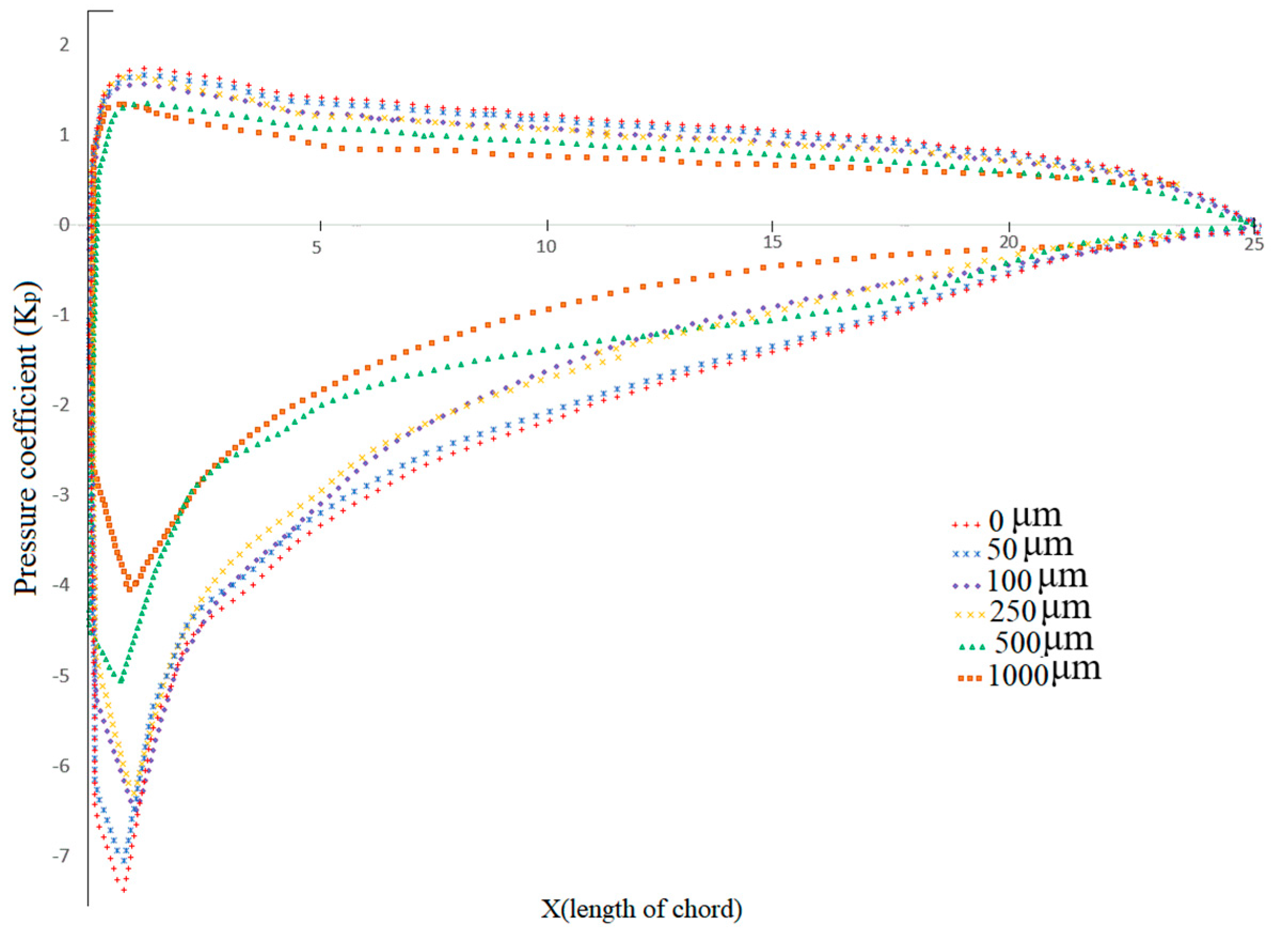

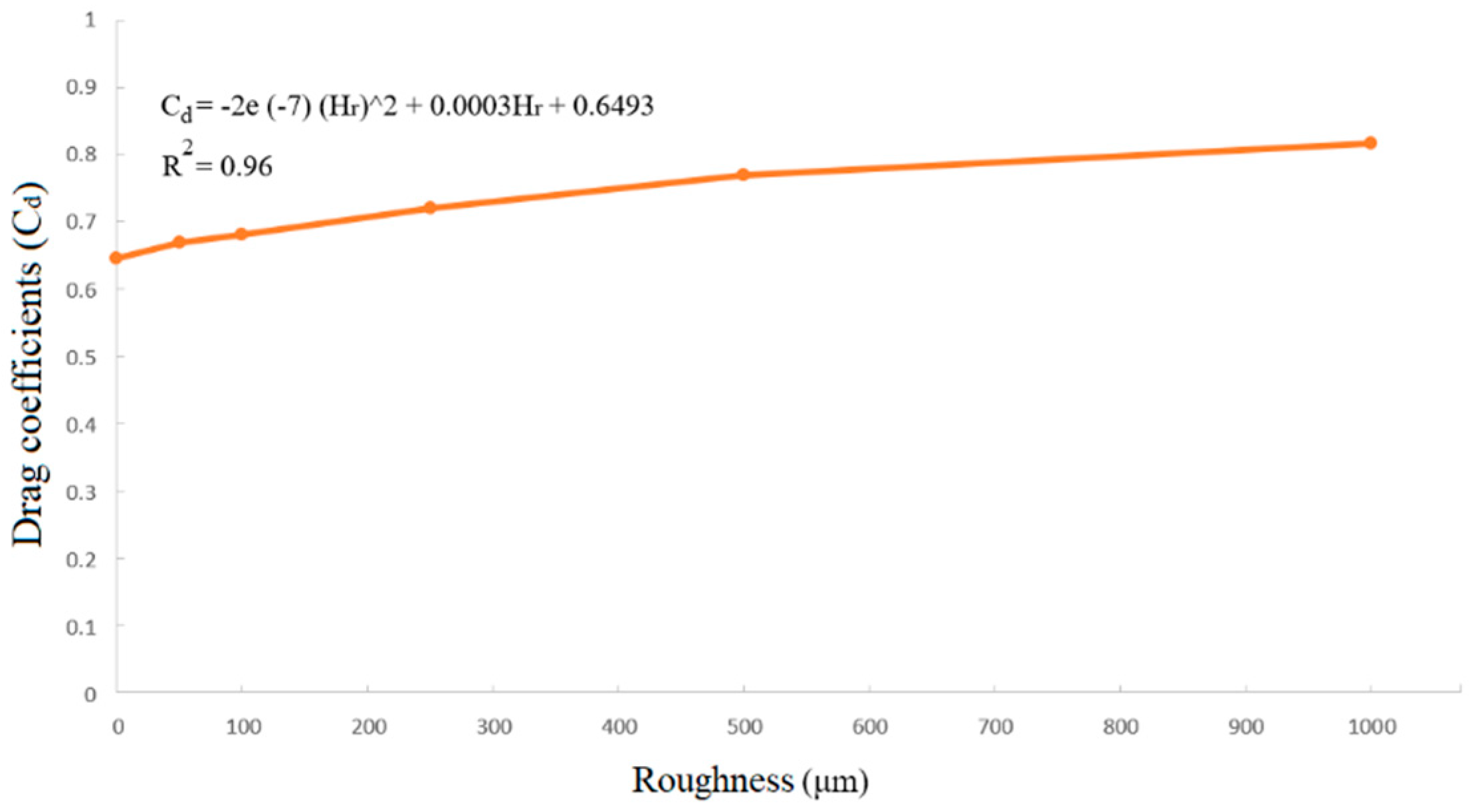

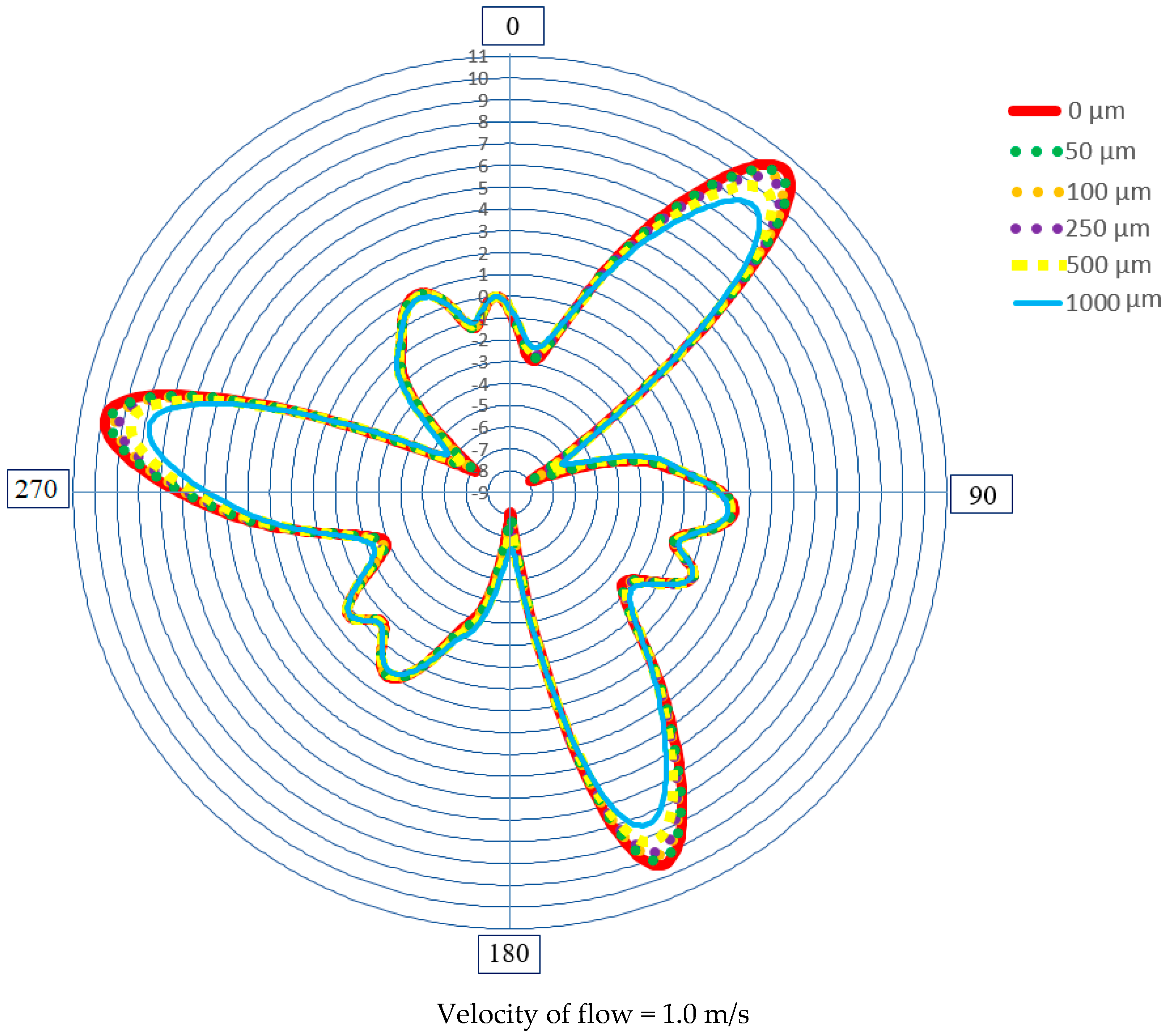

6.1.2. Effects of Surface Roughness on Pressure Coefficient (Kp) and Drag Coefficient (Cd)

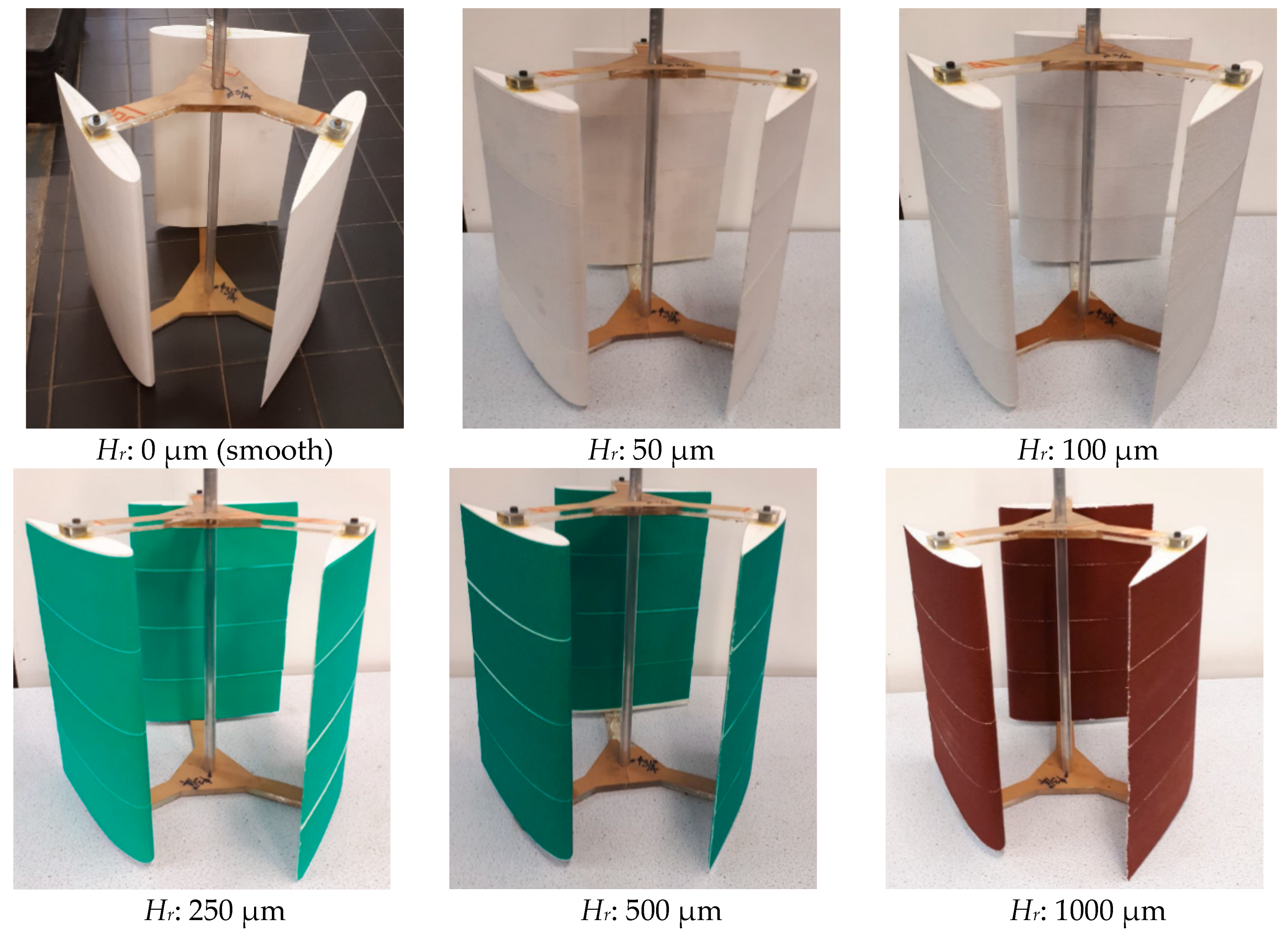

6.1.3. Effects of Surface Roughness on Torque, T

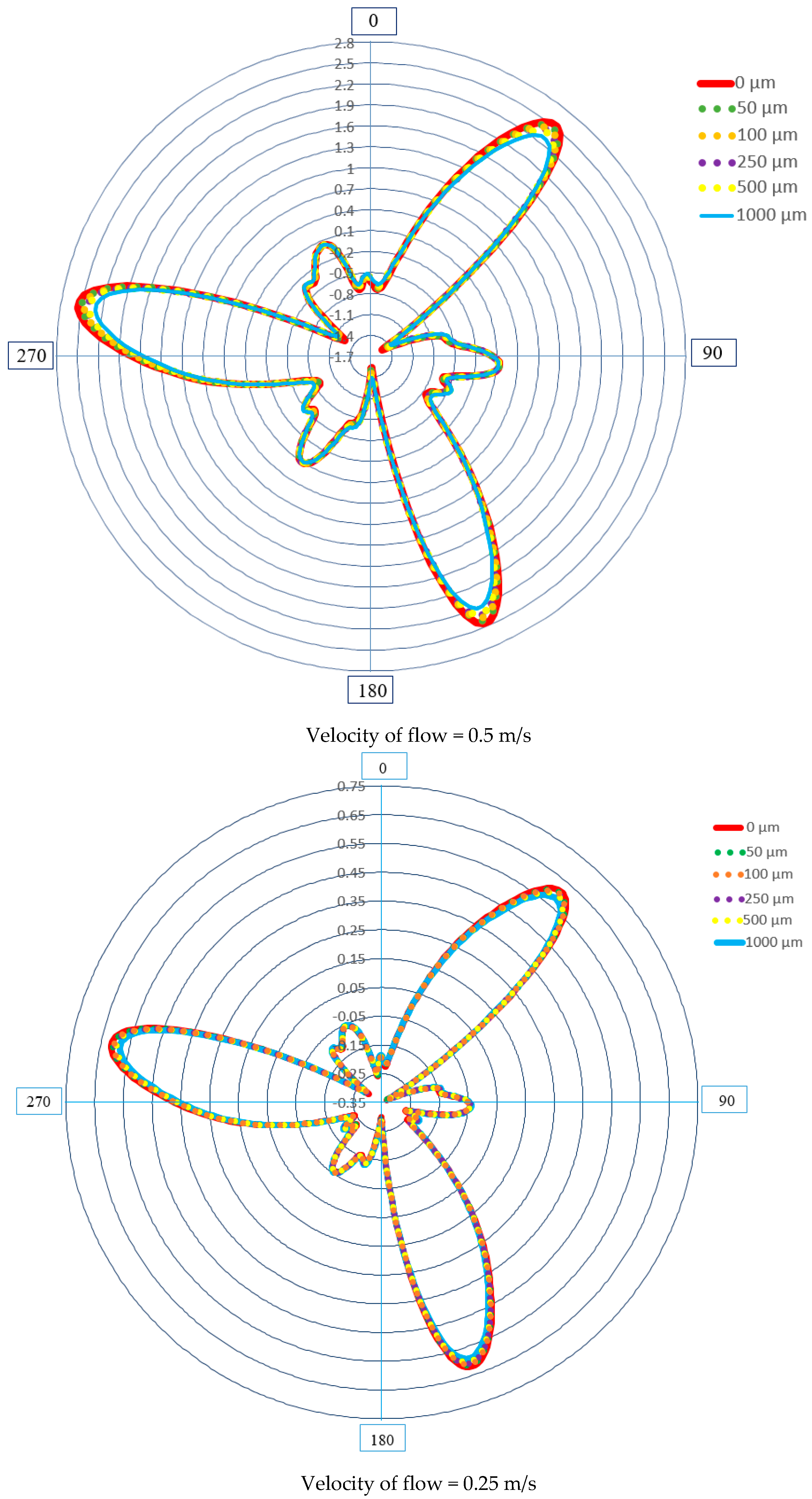

6.1.4. Effects of Surface Roughness on Power Loss, Pl

6.2. Experimental Results

7. Conclusions

- (1)

- Velocity distributions show that turbulence will increase with increasing the surface roughness of DH turbine. Turbulence reduces the kinetic energy which in turn, reduces the total turbine efficiency.

- (2)

- The surface roughness degrades the margin of pressure coefficient, especially at high values of roughness.

- (3)

- The drag coefficient increases as a second order polynomial function of Hr. When NACA 0015 airfoil is used in DH turbine, the drag coefficient is very sensitive to the variations of Hr. The drag coefficient of roughed turbine (with Hr = 1000 μm) studied in this paper was 20% higher than the smooth blade.

- (4)

- The average torque shows small changes at low flow velocities. The adverse impact of surface roughness is significantly greater at high inlet velocities (i.e., high Reynold numbers). In the CFD simulation, all parameters in the Re equation were constant except the velocity of water. It was shown that the negative impacts of roughness are much greater at high Reynolds numbers.

- (5)

- The decrease in torque due to surface roughness reduces the output power of the turbine. For the turbine studied in this research, the maximum reductions in output power numerically and experimentally were about 27% and 22% for Hr = 1000 μm, respectively.

- (6)

- The results of this research would be useful for manufacturers and operators of DH turbines in decisions about practical measures (e.g., coating or cleaning of blades) to reduce roughness of the turbine blades.

Author Contributions

Funding

Conflicts of Interest

References

- Akinyele, D.; Rayudu, R. Review of energy storage technologies for sustainable power networks. Sustain. Energy Technol. Assess. 2014, 8, 74–91. [Google Scholar] [CrossRef]

- Gunn, K.; Stock-Williams, C. Quantifying the global wave power resource. Renew. Energy 2012, 44, 296–304. [Google Scholar] [CrossRef]

- Dunnett, D.; Wallace, J.S. Electricity generation from wave power in Canada. Renew. Energy 2009, 34, 179–195. [Google Scholar] [CrossRef]

- Khanjanpour, M.; Javadi, A.; Akrami, M. CFD analyses of a tidal hydro-turbine (THT) for utilising in sea water desalination. In Proceedings of the ISER 209th International Conference, London, UK, 7 July 2019. [Google Scholar]

- Soleimani, K.; Ketabdari, M.J.; Khorasani, F. Feasibility study on tidal and wave energy conversion in Iranian seas. Sustain. Energy Technol. Assess. 2015, 11, 77–86. [Google Scholar] [CrossRef]

- Hammons, T.J. Tidal power. Proc. IEEE 1993, 81, 419–433. [Google Scholar] [CrossRef]

- Antonio, F.d.O. Wave energy utilization: A review of the technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar]

- Mohamed, M. Performance investigation of H-rotor Darrieus turbine with new airfoil shapes. Energy 2012, 47, 522–530. [Google Scholar] [CrossRef]

- Batten, W.M.J.; Bahaj, A.S.; Molland, A.F.; Chaplin, J.R. Experimentally validated numerical method for the hydrodynamic design of horizontal axis tidal turbines. Ocean Eng. 2007, 34, 101–1020. [Google Scholar] [CrossRef]

- Batten, W.M.J.; Bahaj, A.S.; Molland, A.F.; Chaplin, J.R. The prediction of the hydrodynamic performance of marine current turbines. Renew. Energy 2008, 33, 1085–1096. [Google Scholar] [CrossRef]

- Thiébot, J.; Du Bois, P.B.; Guillou, S. Numerical modeling of the effect of tidal stream turbines on the hydrodynamics and the sediment transport–Application to the Alderney Race (Raz Blanchard), France. Renew. Energy 2015, 75, 356–365. [Google Scholar] [CrossRef]

- Batten, W.M.J.; Bahaj, A.S.; Molland, A.F.; Chaplin, J.R. Hydrodynamics of marine current turbines. Renewable energy 2006, 31, 249–256. [Google Scholar] [CrossRef]

- Polagye, B. Hydrodynamic Effects of Kinetic Power Extraction by In-Stream Tidal Turbines; University of Washington: Seattle, WA, USA, 2009. [Google Scholar]

- Mahmud, S.; Sampebatu, L.; Kwang, S.C. Mechanical Power efficiency of Modified Turbine Blades. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017. [Google Scholar]

- Shaheen, M.; Abdallah, S. Efficient clusters and patterned farms for Darrieus wind turbines. Sustainable Energy Technol. Assess. 2017, 19, 125–135. [Google Scholar] [CrossRef]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer Science & Business Media, 2013. [Google Scholar]

- Kiho, S.; Shiono, M.; Suzuki, K. The power generation from tidal currents by Darrieus turbine. Renew. Energy 1996, 9, 1242–1245. [Google Scholar] [CrossRef]

- Joubert, J.R.; L.v.N., J.; Reinecke, J.; Meyer, I. Wave Energy Converters (WECs); CRSES: Matieland, South Africa, 2013. [Google Scholar]

- Rasool, G.; Johnstone, C.; Stack, M.M. Tribology of Tidal Turbine Blades: Impact angle Effects on Erosion of Polymeric Coatings in Sea Water Conditions. In Proceedings of the Asian Wave and Tidal Energy Conference (AWTEC), Marina Bay Sands, Singapore, 24–28 October 2016. [Google Scholar]

- Walker, J.M.; Flack, K.A.; Lust, E.E.; Schultz, M.P.; Luznik, L. Experimental and numerical studies of blade roughness and fouling on marine current turbine performance. Renew. Energy 2014, 66, 257–267. [Google Scholar] [CrossRef]

- Maruzewski, P.; Hasmatuchi, V.; Mombelli, H.P.; Burggraeve, D.; Iosfin, J.; Finnegan, P.; Avellan, F. Surface roughness impact on Francis turbine performances and prediction of efficiency step up. Int. J. Fluid Mach. Syst. 2009, 2, 353–362. [Google Scholar] [CrossRef]

- Priegue, L.; Stoesser, T. The influence of blade roughness on the performance of a vertical axis tidal turbine. Int. J. Mar. Energy 2017, 17, 136–146. [Google Scholar] [CrossRef]

- Mehmood, N. Study of naca 0015 for diffuser design in tidal current turbine applications. Int. J. Eng. 2012, 25, 373–380. [Google Scholar] [CrossRef]

- Coiro, D.; Nicolosi, F.; De Marco, A.; Melone, S.; Montella, F. Flow curvature effect on dynamic behaviour of a novel vertical axis tidal current turbine: Numerical and experimental analysis. In ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering; American Society of Mechanical Engineers Digital Collection, 2005. [Google Scholar]

- Xiao, Q.; Zhu, Q. A review on flow energy harvesters based on flapping foils. J. Fluids Struct. 2014, 46, 174–191. [Google Scholar] [CrossRef]

- Lanzafame, R.; Mauro, S.; Messina, M. Wind turbine CFD modeling using a correlation-based transitional model. Renew. Energy 2013, 52, 31–39. [Google Scholar] [CrossRef]

- Nabavi, Y. Numerical Study of the duct Shape Effect on the Performance of a Ducted Vertical Axis Tidal Turbine; University of British Columbia: Vancouver, BC, Canada, 2008. [Google Scholar]

- Yang, W.; Wu, Y.; Liu, S. An optimization method on runner blades in bulb turbine based on CFD analysis. Sci. China Technol. Sci. 2011, 54, 338–344. [Google Scholar] [CrossRef]

- Castelli, M.; De Betta, S.; Benini, E. Numerical investigation of the optimal spatial domain discretization for the 2-D analysis of a Darrieus vertical-axis water turbine. In Proceedings of the World Academy of Science, Engineering and Technology, Paris, France, 25–26 April 2012. [Google Scholar]

- Lain, S.; Osorio, C. Simulation and Evaluation of a Straight-Bladed Darrieus-Type cross Flow Marine Turbine. J. Sci. Industr. Res. 2010, 69, 906–912. [Google Scholar]

- Balduzzi, F.; Bianchini, A.; Maleci, R.; Ferrara, G.; Ferrari, L. Critical issues in the CFD simulation of Darrieus wind turbines. Renew. Energy 2016, 85, 419–435. [Google Scholar] [CrossRef]

- Nobile, R.; Vahdati, M.; Barlow, J.F.; Mewburn-Crook, A. Unsteady flow simulation of a vertical axis augmented wind turbine: A two-dimensional study. J. Wind Eng. Ind. Aerodyn. 2014, 125, 168–179. [Google Scholar] [CrossRef]

- Dai, Y.; Lam, W. Numerical study of straight-bladed Darrieus-type tidal turbine. Proc. Inst. Civil Eng. -Energy 2009, 162, 67–76. [Google Scholar] [CrossRef]

- Liu, Z.; Qu, H.; Shi, H. Numerical Study on Self-Starting Performance of Darrieus Vertical Axis Turbine for Tidal Stream Energy Conversion. Energies 2016, 9, 789. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Pang, A.L.J.; Skote, M.; Lim, S.Y. Modelling high Re flow around a 2D cylindrical bluff body using the k-ω (SST) turbulence model. Prog. Comput. Fluid Dyn. Int. J. 2016, 16, 48–57. [Google Scholar] [CrossRef]

- Adedeji, O.E.; Yu, W.; Sanders, R.S. Analysis of local wear variables for high-precision erosion modelling in complex geometries. Wear 2019, 426, 562–569. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Huber, N. Experimental analysis and modelling of particle-wall collisions. Int. J. Multiph. Flow 1999, 25, 1457–1489. [Google Scholar] [CrossRef]

- Fluent, A. 19.2 Theory Guide; ANSYS. Inc.: Canonsburg, PA, USA, 2018. [Google Scholar]

- Pattanapol, W.; Wakes, S.J.; Hilton, M.J.; Dickinson, K.J. Modeling of surface roughness for flow over a complex vegetated surface. Int. J. Math. Phys. Eng. Sci. 2008, 2, 18–26. [Google Scholar]

- Menter, F. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 2002, 40, 254–266. [Google Scholar] [CrossRef]

- Cebeci, T.; Bradshaw, P. Momentum Transfer in Boundary Layers; Hemisphere Publishing Corp.: Washington, DC, USA; McGraw-Hill Book Co.: New York, NY, USA, 1977; Volume 407, p. 1977. [Google Scholar]

- TAN, M.G.; LIU, H.L.; WU, X.F.; WANG, Y.; WANG, K.; FU, M. The Effect of Roughness on the Numerical Prediction of the Characteristics of Centrifugal Pumps. China Rural Water Hydropower 2011, 2. [Google Scholar]

- Sagol, E.; Reggio, M.; Ilinca, A. Issues concerning roughness on wind turbine blades. Renew. Sustain. Energy Rev. 2013, 23, 514–525. [Google Scholar] [CrossRef]

- Villalpando, F.; Reggio, M.; Ilinca, A. Numerical study of flow around iced wind turbine airfoil. Eng. Appl. Comput. Fluid Mech. 2012, 6, 39–45. [Google Scholar] [CrossRef]

- Ehrmann, R.S. Effect of Surface Roughness on Wind Turbine Performance. J. Phys. 2014, 1037. [Google Scholar]

- Hodson, H.; Dominy, R. Three-Dimensional Flow in a Low-Pressure Turbine Cascade at its Design Condition. J. Turbomach. 1987, 109, 177–185. [Google Scholar] [CrossRef]

- Li, D.; Li, R.; Yang, C.; Wang, X. Effects of surface roughness on aerodynamic performance of a wind turbine airfoil. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, China, 28–31 March 2010. [Google Scholar]

- Ahmed, M.R. Blade sections for wind turbine and tidal current turbine applications–current status and future challenges. Int. J. Energy Res. 2012, 36, 829–844. [Google Scholar] [CrossRef]

- Cruz, A.G.B.d.; Mesquita, A.L.A.; Blanco, C.J.C. Minimum pressure coefficient criterion applied in axial-flow hydraulic turbines. J. Braz. Soc. Mech. Sci. Eng. 2008, 30, 30–38. [Google Scholar] [CrossRef]

- Ren, N.; Ou, J. Numerical simulation of surface roughness effect on wind turbine thick airfoils. In Proceedings of the 2009 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 28–31 March 2009. [Google Scholar]

- Freudenreich, K.; Kaiser, K.; Schaffarczyk, A.P.; Winkler, H.; Stahl, B. Reynolds number and roughness effects on thick airfoils for wind turbines. Wind Eng. 2004, 28, 529–546. [Google Scholar] [CrossRef]

- Montomoli, F.; Hodson, H.; Haselbach, F. Effect of roughness and unsteadiness on the performance of a new low pressure turbine blade at low Reynolds numbers. J. Turbomach. 2010, 132, 031018. [Google Scholar] [CrossRef]

- Timmer, W.; Schaffarczyk, A. The effect of roughness at high Reynolds numbers on the performance of aerofoil DU 97-W-300Mod. Wind Energy Int. J. Prog. Appl. Wind Power Convers. Technol. 2004, 7, 295–307. [Google Scholar] [CrossRef]

- Blair, M.F. The Effects of Reynolds Number, Rotor Incidence Angle and Surface Roughness on the Heat Transfer Distribution in a Large-Scale Turbine Rotor Passage; NASA: East Hartford, CT, USA, 1991. [Google Scholar]

- Virk, M.S.; Homola, M.C.; Nicklasson, P.J. Effect of rime ice accretion on aerodynamic characteristics of wind turbine blade profiles. Wind Eng. 2010, 34, 207–218. [Google Scholar] [CrossRef]

- Laakso, T.; Baring-Gould, I.; Cattin, R.; Durstewitz, M.; Hulkkonen, M.; Krenn, A.; Lacroix, A.; Peltola, E.; Ronsten, G.; Tallhaug, L.; et al. Wind energy projects in cold climates. Int. Energy Agency 2005, 36. [Google Scholar]

- Dalili, N.; Edrisy, A.; Carriveau, R. A review of surface engineering issues critical to wind turbine performance. Renew. Sustain. Energy Rev. 2009, 13, 428–438. [Google Scholar] [CrossRef]

- Corten, G.P.; Veldkamp, H.F. Insects Cause Double Stall; Netherlands Energy Research Foundation: Petten, The Netherlands, 2001. [Google Scholar]

- Corten, G.P.; Veldkamp, H.F. Aerodynamics: Insects can halve wind-turbine power. Nature 2001, 412, 41. [Google Scholar] [CrossRef]

- Lachmann, G.V. Aspects of Insect Contamination in Relation to Laminar flow Aircraft; Ministry of Aviation, Aeronautical Research Council, 1960. [Google Scholar]

- Zhang, Y.; Igarashi, T.; Hu, H. Experimental investigations on the performance degradation of a low-Reynolds-number airfoil with distributed leading edge roughness. In Proceedings of the 49th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

| Height of blade | 0.45 m |

| Length of chord | 0.3 m |

| Number of blades | 3 |

| Type of airfoil | NACA 0015 |

| Velocity of water | 1 m/s |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanjanpour, M.H.; Javadi, A.A. Experimental and CFD Analysis of Impact of Surface Roughness on Hydrodynamic Performance of a Darrieus Hydro (DH) Turbine. Energies 2020, 13, 928. https://doi.org/10.3390/en13040928

Khanjanpour MH, Javadi AA. Experimental and CFD Analysis of Impact of Surface Roughness on Hydrodynamic Performance of a Darrieus Hydro (DH) Turbine. Energies. 2020; 13(4):928. https://doi.org/10.3390/en13040928

Chicago/Turabian StyleKhanjanpour, Mohammad Hassan, and Akbar A. Javadi. 2020. "Experimental and CFD Analysis of Impact of Surface Roughness on Hydrodynamic Performance of a Darrieus Hydro (DH) Turbine" Energies 13, no. 4: 928. https://doi.org/10.3390/en13040928

APA StyleKhanjanpour, M. H., & Javadi, A. A. (2020). Experimental and CFD Analysis of Impact of Surface Roughness on Hydrodynamic Performance of a Darrieus Hydro (DH) Turbine. Energies, 13(4), 928. https://doi.org/10.3390/en13040928