Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods †

Abstract

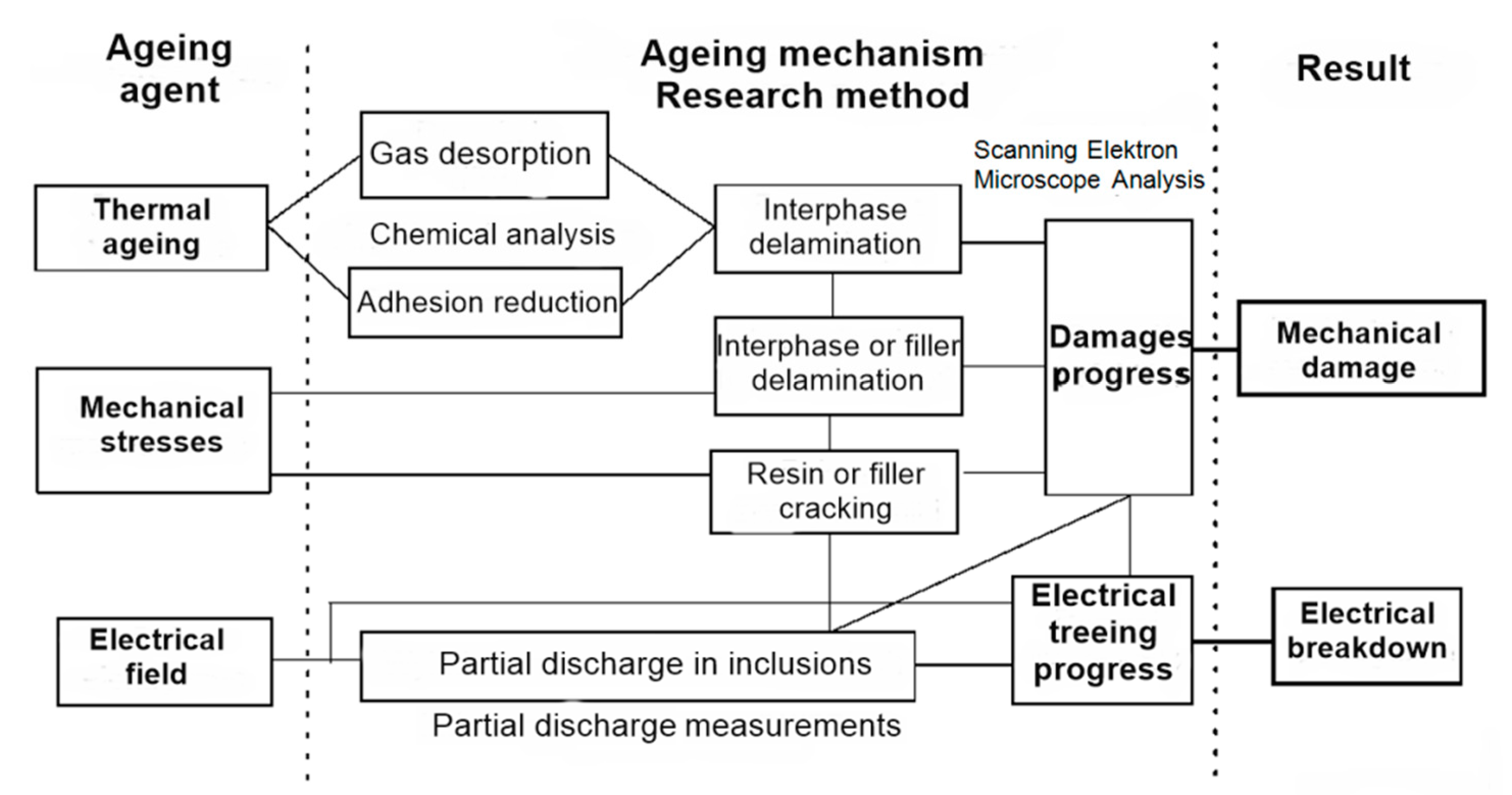

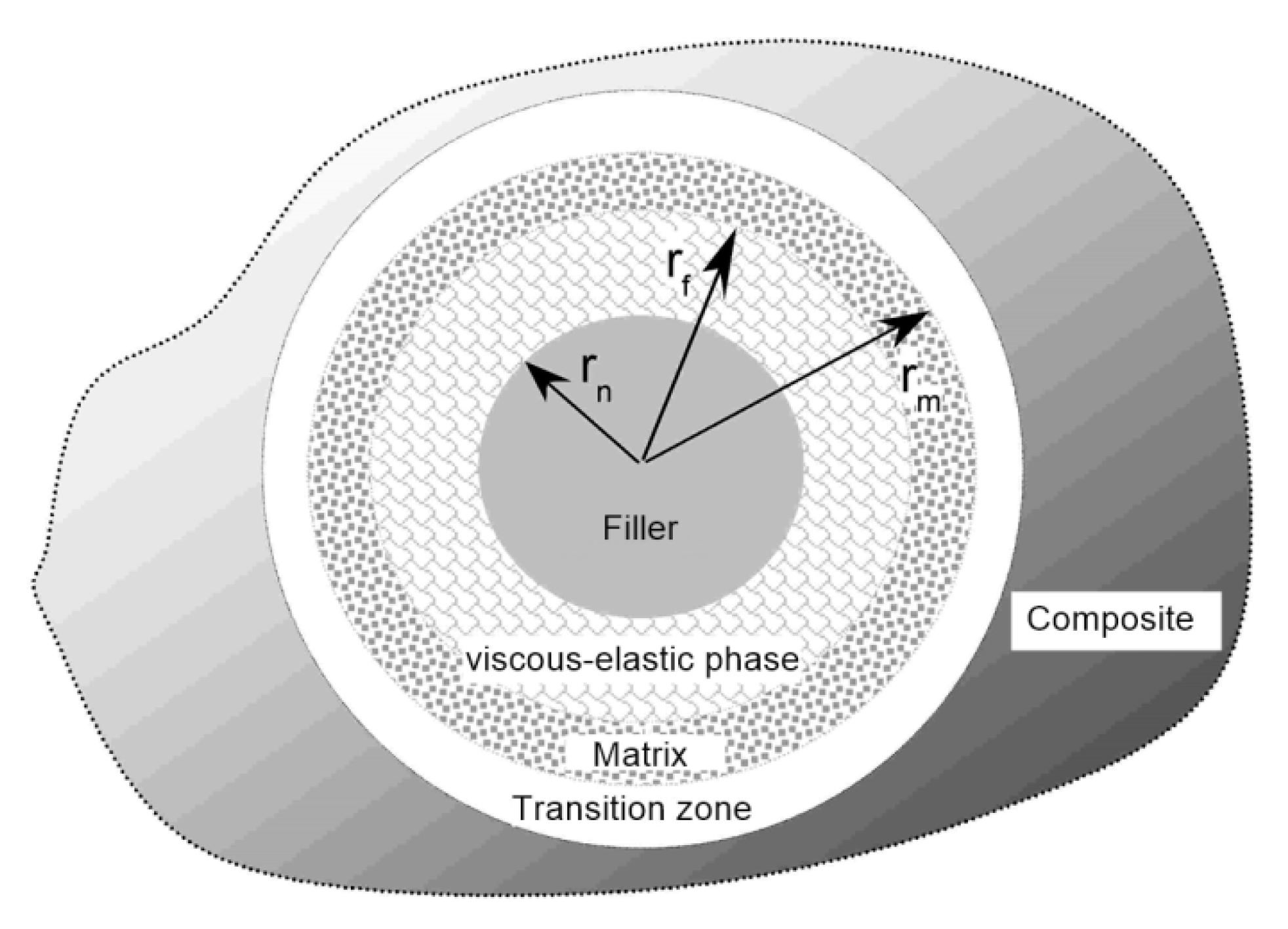

:1. Introduction

- LE—the “lifetime” for the electric field strength E,

- L0—the “lifetime” for the electric field strength E0,

- n—the coefficient of the voltage durability (VEC).

- T0—the reference temperature,

- LT—the lifetime for the temperature T,

- B—the coefficient associated with the activation energy of the major chemical reactions.

- M—the coefficient of mechanical durability (MEC),

- L0, M0 correspond to Equation (1).

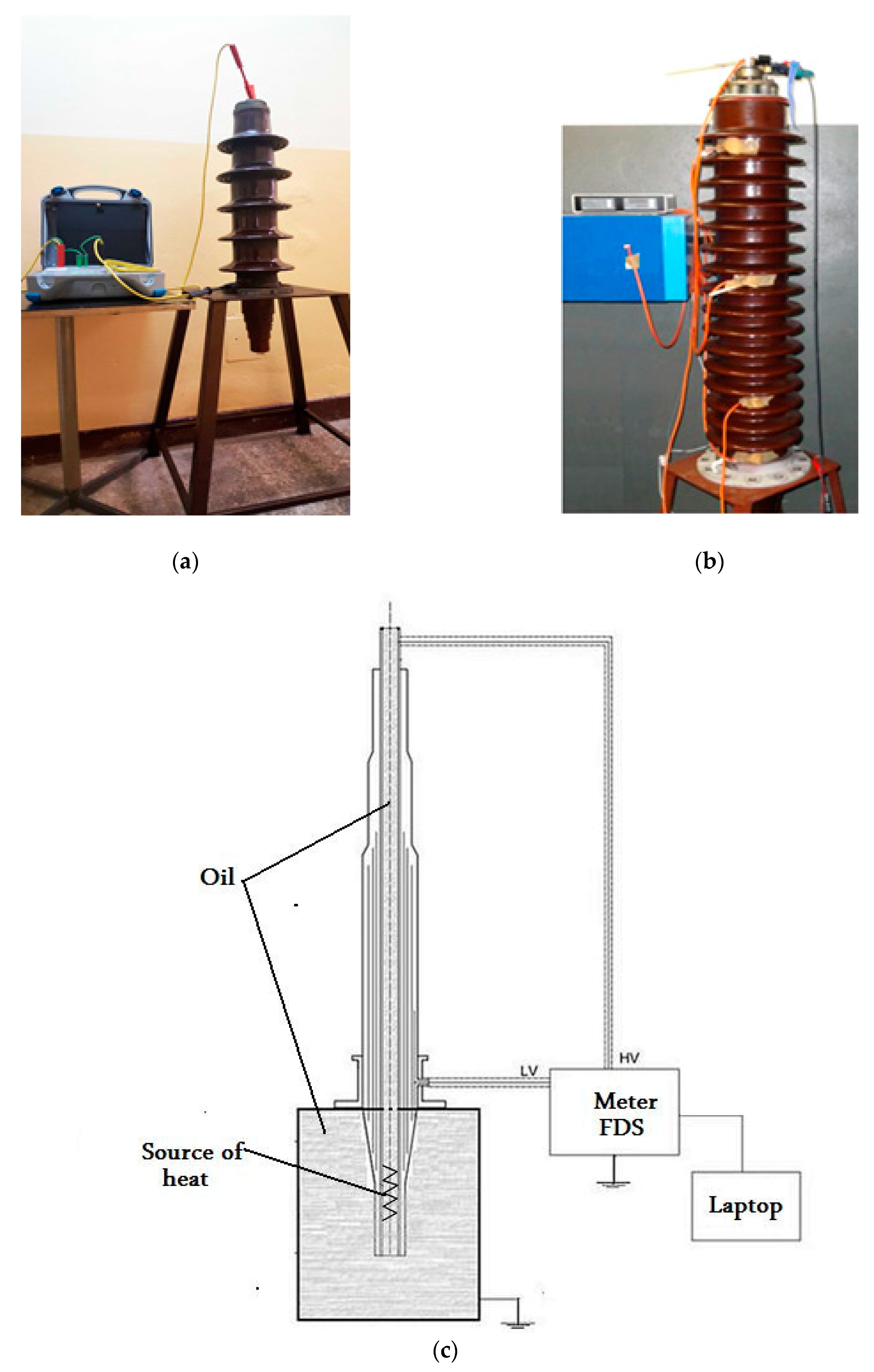

2. Test Subject and Research Methodology

3. Results

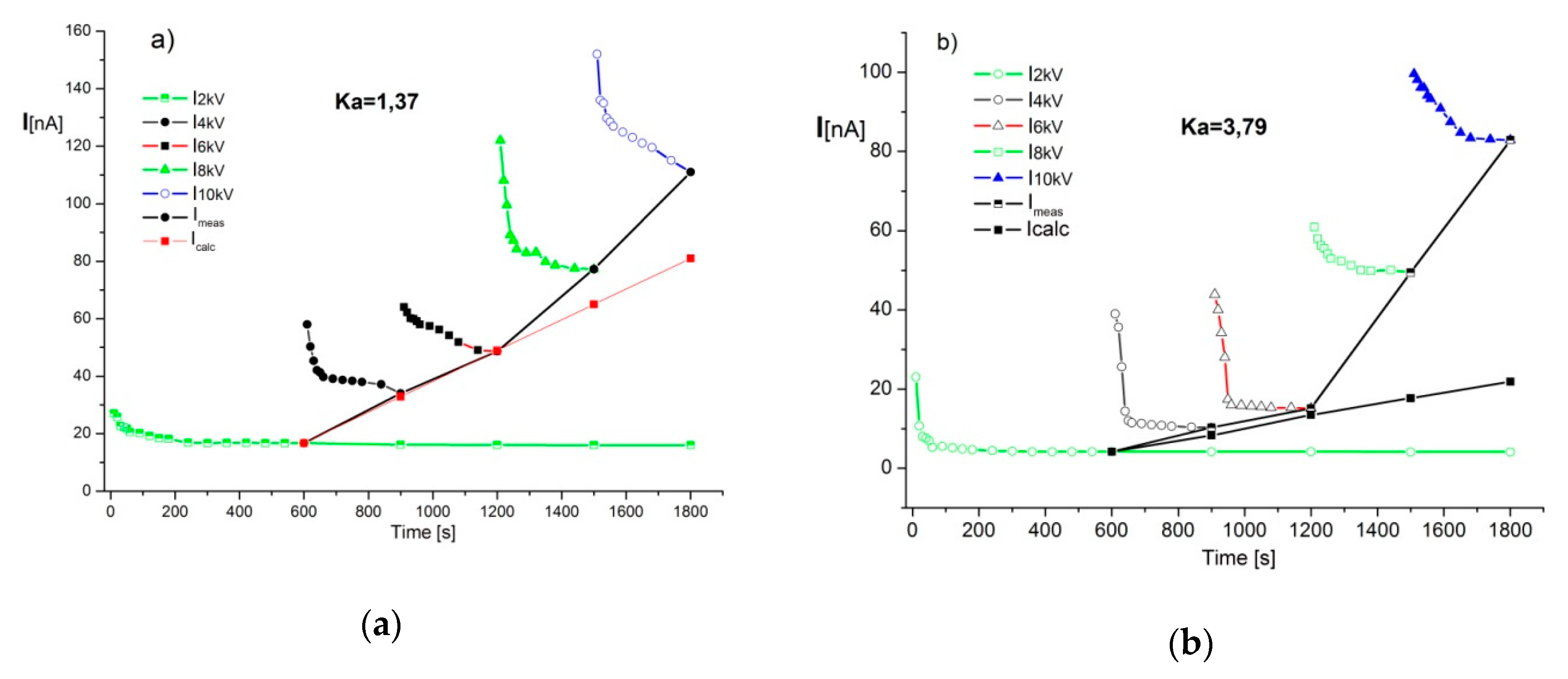

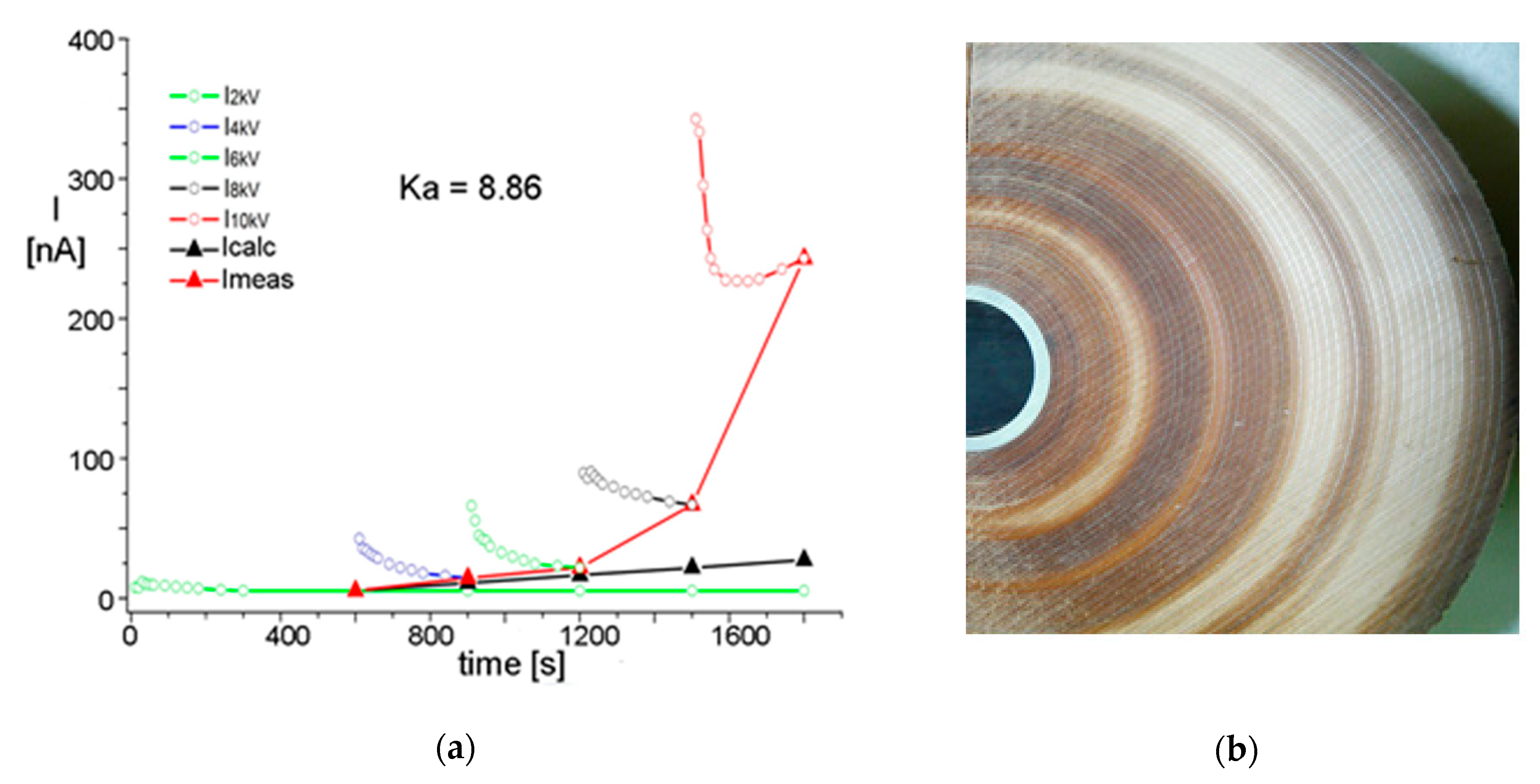

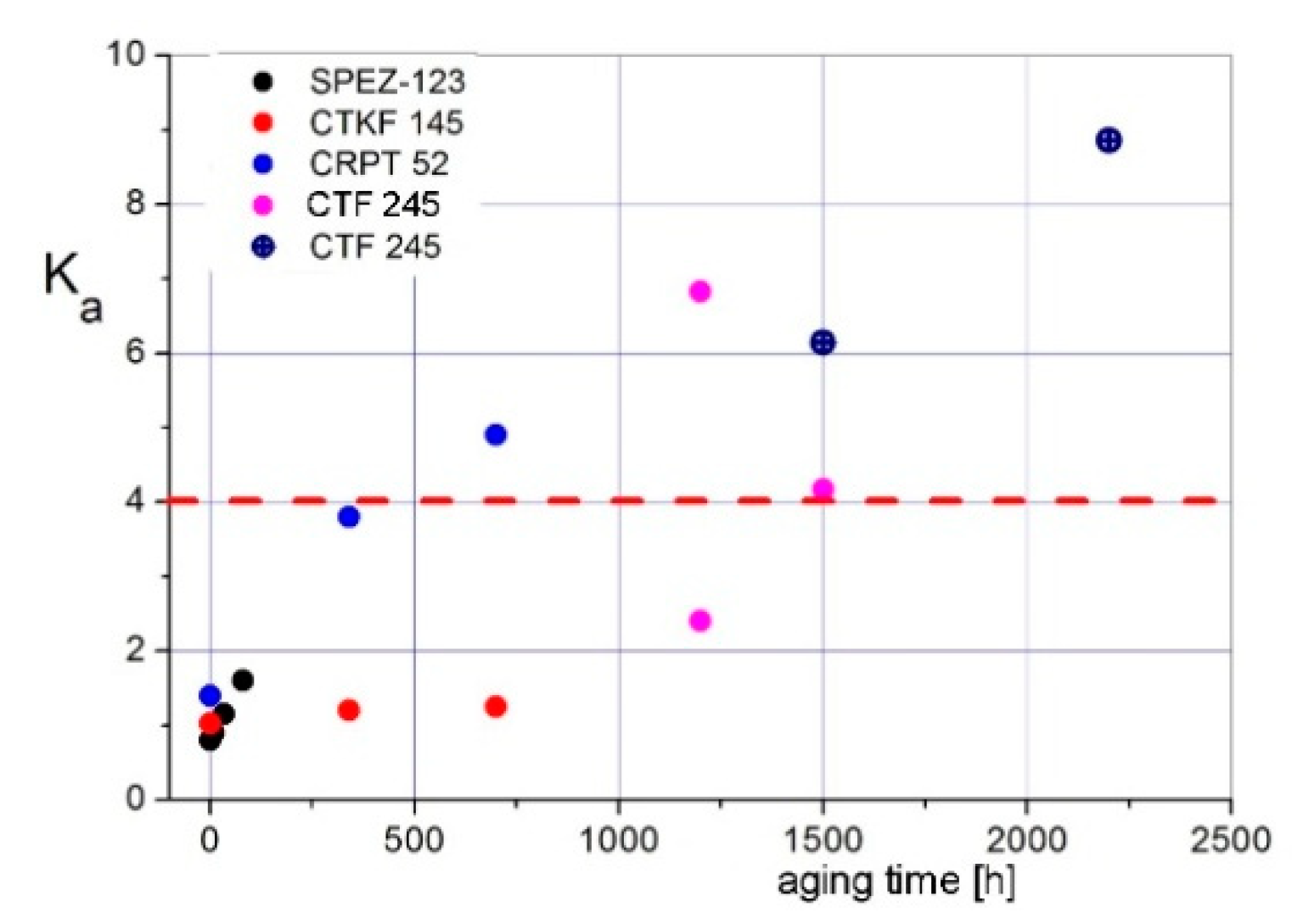

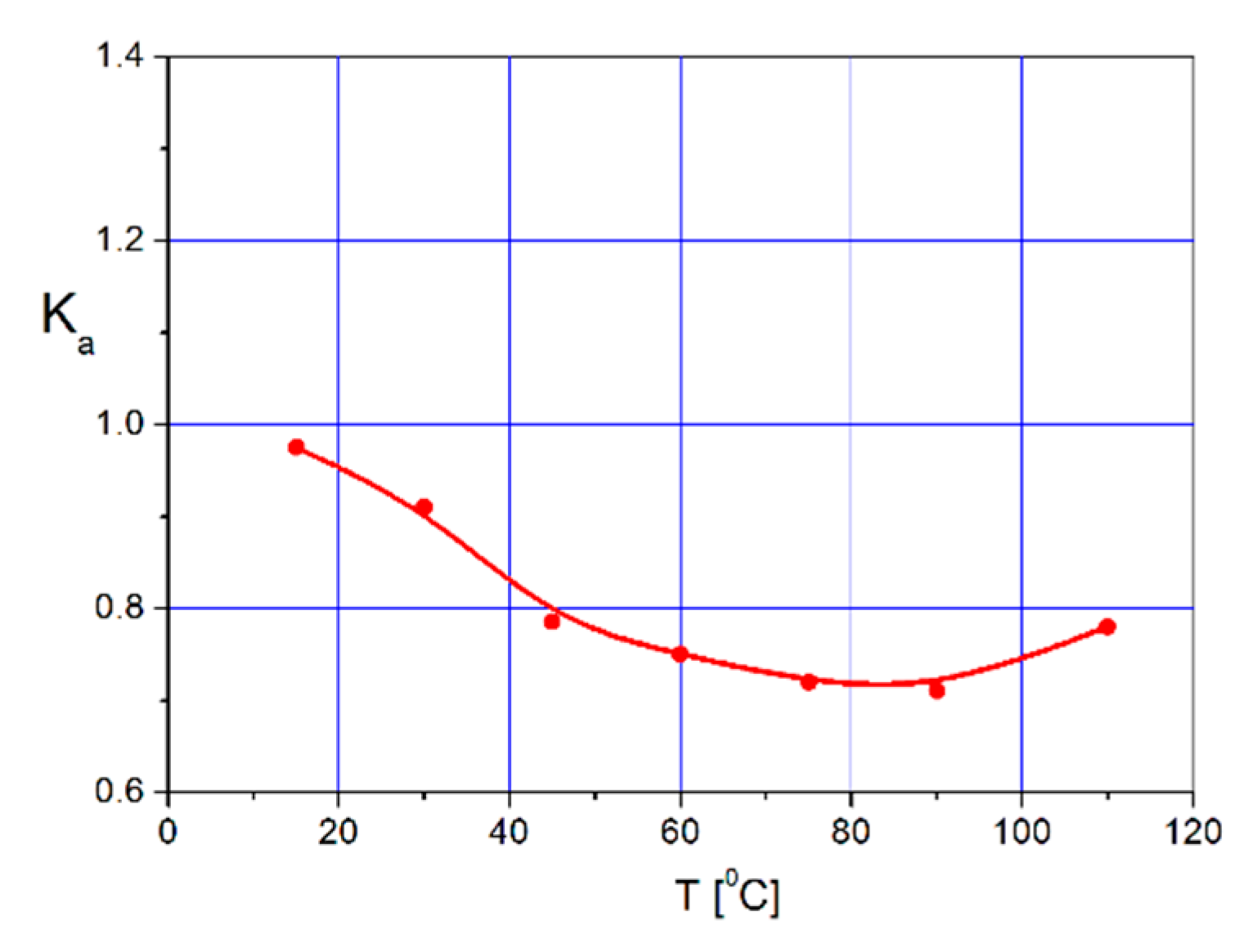

3.1. Impact of Thermal Aging on SVM Test Results of the Insulation of Bushings

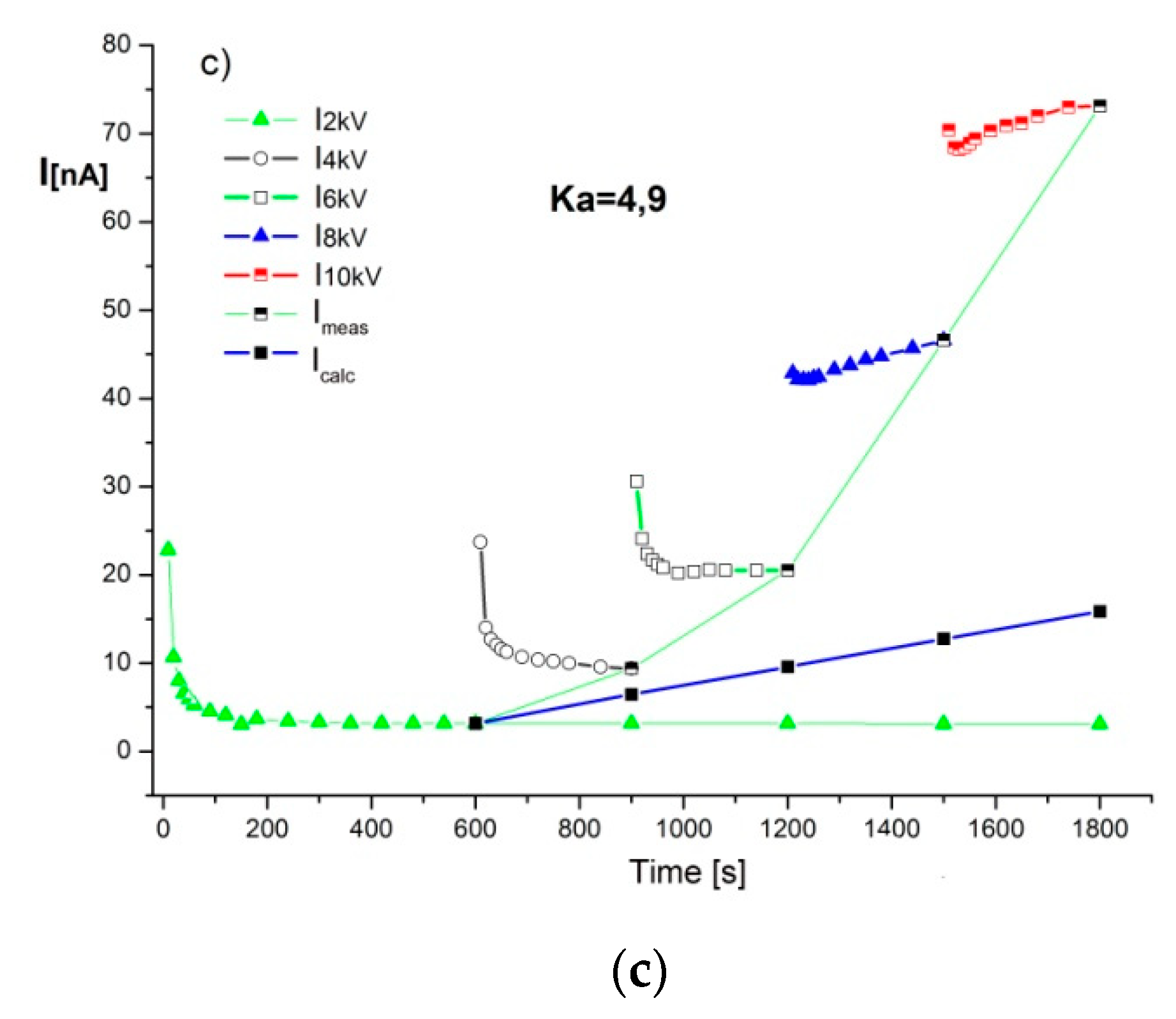

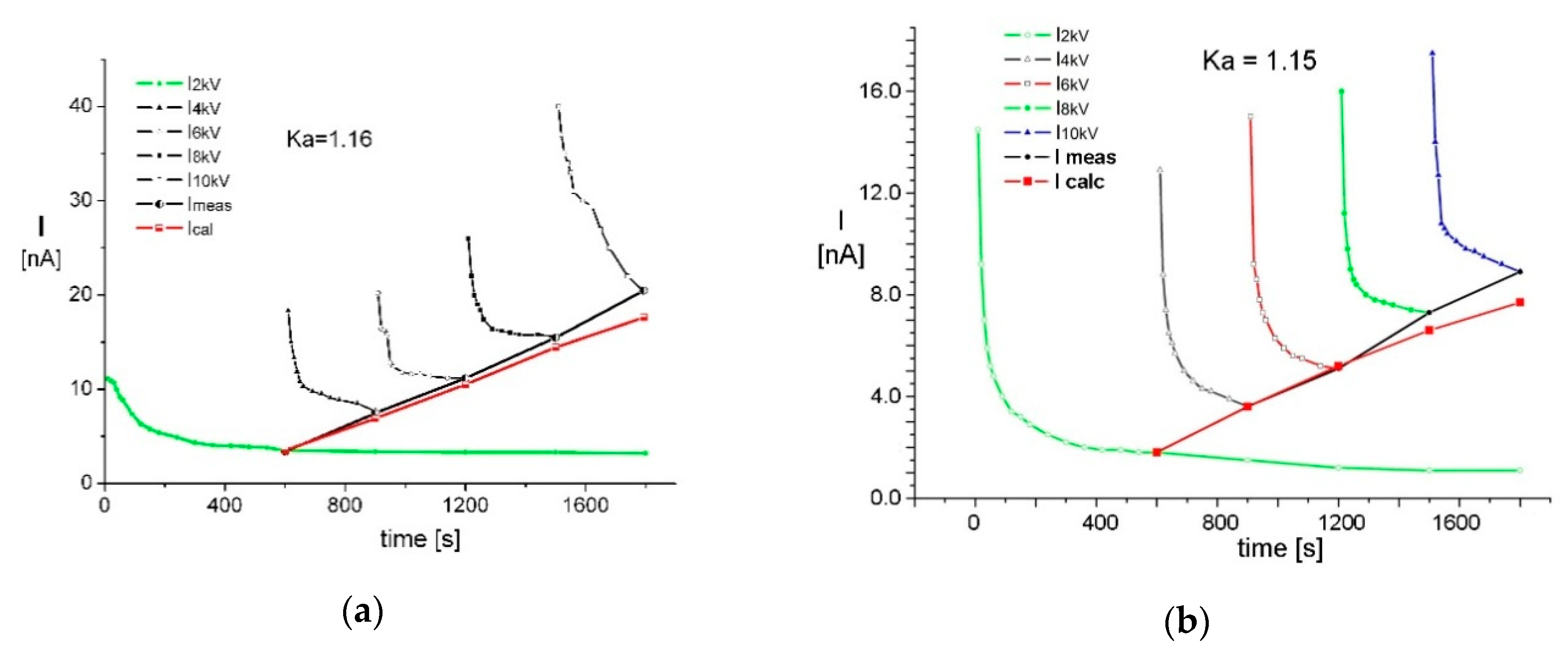

3.2. SVM Test of RIP Type Bushings after Long-Term Operation

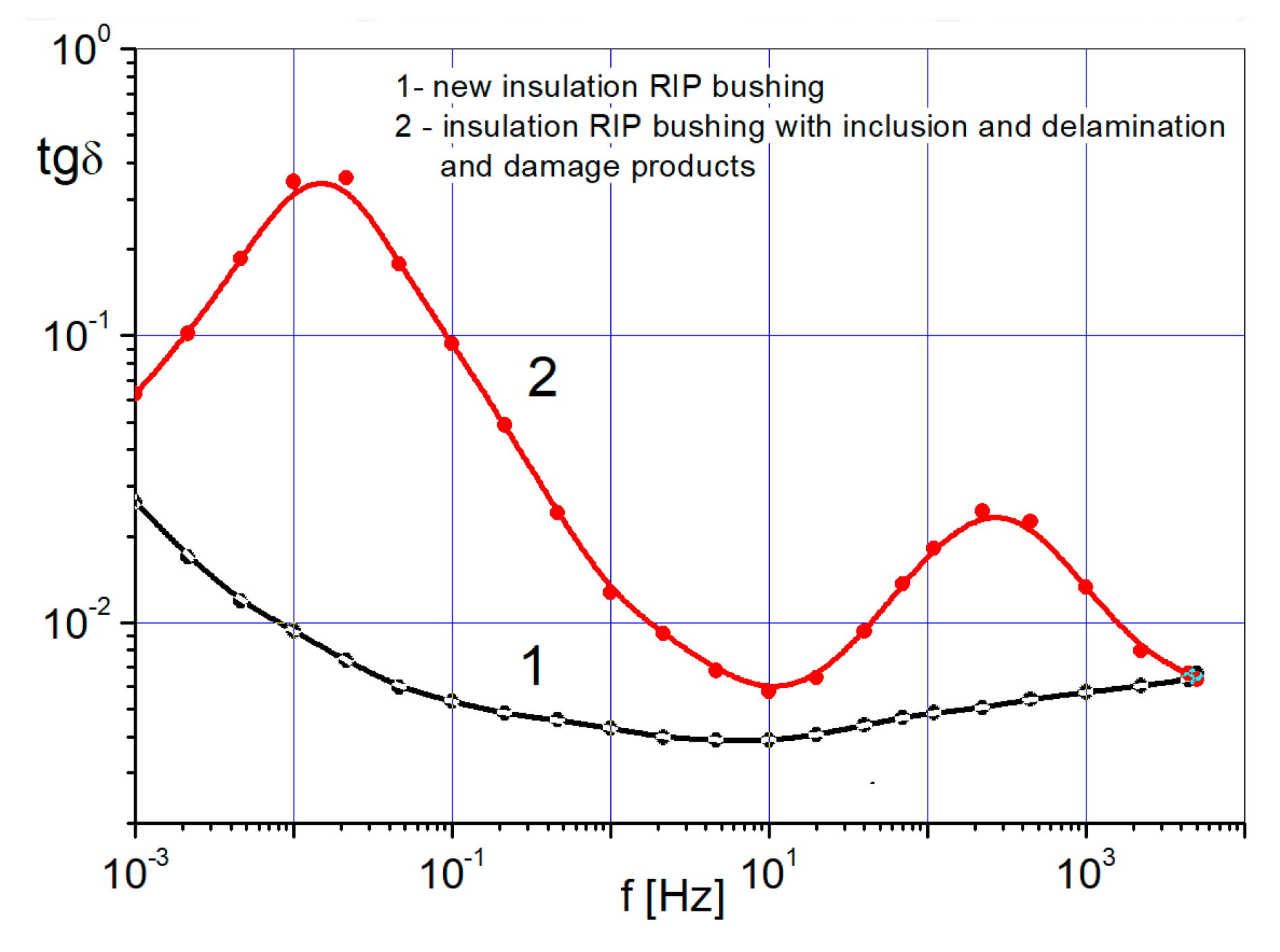

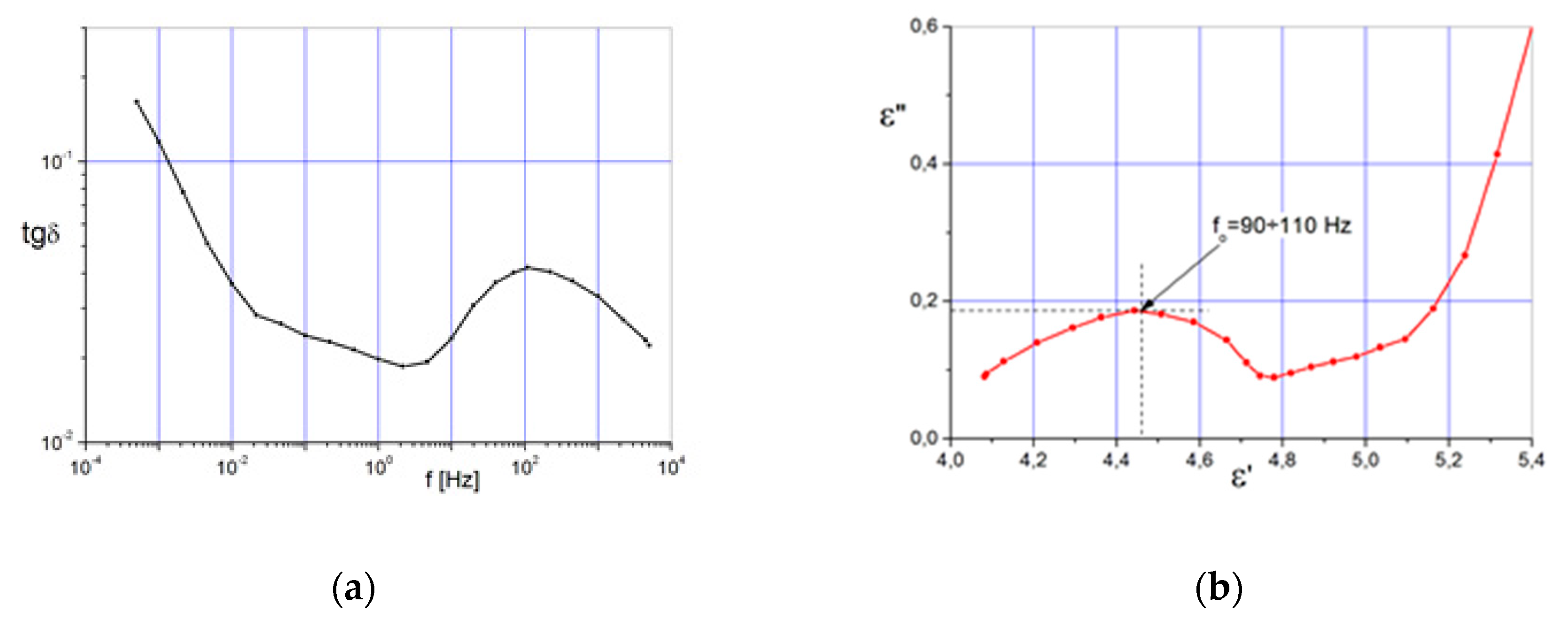

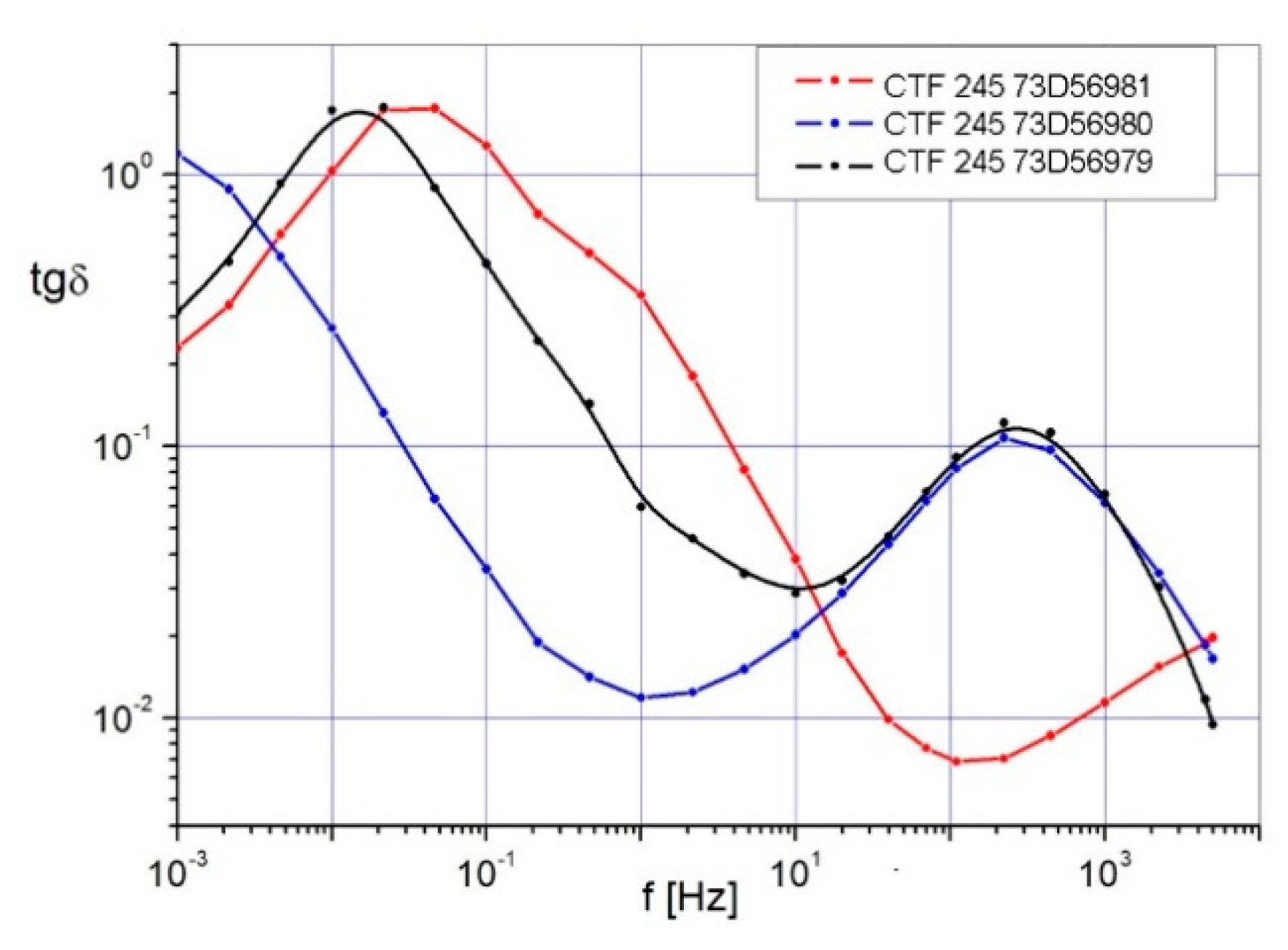

3.3. FDS Analysis of Bushings Insulation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akbari, M.; Allahbakhshi, M.; Mahmoodian, R. Heat analysis of the power transformer bushings in the transient and steady states considering the load variations. Appl. Therm. Eng. 2017, 121, 999–1010. [Google Scholar] [CrossRef]

- Eliss, K. Bushings for Power Transformers: A Handbook for Power Engineers; Author House: Bloomington, IN, USA, 2011. [Google Scholar]

- Kassihin, S.D.; Lizunov, S.D.; Lipstein, G.R.; Lokhanin, A.K.; Morozova, T.I. Service experience and reasons of bushing failures of EHV transformers and shunt reactors. Trans. CIGRE 1996, 12–105. [Google Scholar]

- Marques, A.P.; de Jesus Ribeiro, C.; Azevedo, C.H.B.; Lopes dos Santos, J.A.; de Carvalho Sousa, F.R.; da Cunha Brito, L. Power transformer distruptions—A case study. IEEE Electr. Insul. Mag. 2014, 30, 17–21. [Google Scholar] [CrossRef]

- Mehta, A.K.; Sharma, R.N.; Chauhan, S.; Agnihotri, S.D. Study and diagnosis of the power transformer bushing insulation system. In Proceedings of the 2011 IEEE Pulsed Power Conference, Chicago, IL, USA, 19–23 June 2011; pp. 700–705. [Google Scholar] [CrossRef]

- Zink, M.; Klipfel, V.; Berger, F. Ageing—Condition Assessment of Generator Transformer Buhings by means of Dielectric Simulation Models. In Proceedings of the IEEE International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012; pp. 137–140. [Google Scholar]

- Tenbohlen, S.; Jagers, J.; Vahidi, F.; Müller, P.; Lapworth, J.; Yukiyasu, S.; Desai, B.; McIntosh, A.; Bastos, G.; Bo, L. Transformer Realiability Survey; CIGRE: Paris, France, 2015. [Google Scholar]

- Smith, D.J.; Mcmeekin, S.G.; Stewart, B.G.; Wallace, P.A. The modelling of electric field, capacitance and dissipation factor of a high voltage bushing over varying frequency. In Proceedings of the 2012 47th International Universities Power Engineering Conference (UPEC), London, UK, 4–7 September 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Seifert, J.M.; Stietzel, U.; Kärner, H.C. The Aging of Composite Insulating Materials—New possibilities to detect and classify ageing phenomena with dielectric diagnosis tools. In Proceedings of the IEEE International Symposium on Electrical Insulation, Arlington, VA, USA, 7–10 June 1998. [Google Scholar] [CrossRef]

- Helgeson, A. Analysis of Dielectric Response Measurement Methods and Dielectric Properties of Resin-Rich Insulation during Processing. Depart. Electr. Power Eng. Stockh. 2000, 1100–1593. [Google Scholar]

- IEC Report. Publication 505, Guide for Evaluation and Identification of Insulation Systems of Electrical Equipment; 1975. Available online: https://webstore.iec.ch/publication/16396 (accessed on 5 February 2020).

- Kimura, K.; Kaneda, Y. The Role of Microscopic Defects in Multistress Aging of Micaceous Insulation. IEEE Trans. 1995, 2, 426–432. [Google Scholar] [CrossRef]

- Theocaris, P.S.; Varias, A.G. Thermal Expansion Properties of Particulates Based on the Concept of Mesophase. J. Appl. Polym. Sci. 1985, 30, 2979–2995. [Google Scholar] [CrossRef]

- Ban, D.; Cettolo, M.; Miletic, B. Electrical Motor Insulation Conditons dc Testing. IEEE Trans. 1998, 5, 917–921. [Google Scholar]

- Subocz, J.; Zenker, M.; Mrozik, A. The Analysis of Relaxation Processes in Thermally Aged Solid Insulation Bushing (in Polish—Analiza procesów relaksacyjnych w starzonym termicznie przepuście z izolacją stałą). Prz. Elektrotech. 2012, 88, 212–214. [Google Scholar]

- Subocz, J.; Zenker, M.; Mrozik, A.; Bohatyrewicz, P. The Effect of Thermal Aging Process on Dielectric Response of Bushings with RBP and RIP Insulation. In Proceedings of the 2018 Innovative Materials and Technologies in Electrical Engineering (i-MITEL), Sulecin, Poland, 18–20 April 2018. [Google Scholar]

- IEEE Standard for Performance Characteristics and Dimensions for Power Transformer and Reactor Bushings. IEEE Stand. 2018. [CrossRef]

- Przybyłek, P.; Morańda, H.; Walczak, K.; Mościcka-Grzesiak, H. The bubble effect in bushings—Investigations on models. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3405–3412. [Google Scholar] [CrossRef]

- Polish Institute of Meteorology and Water Management—National Research Institute (in Polish—Instytut Meteorologii I Gospodarki Wodnej—Państwowy Instytut Badawczy). Available online: http://klimat.imgw.pl/wp-content/uploads/2013/01/1_25.pdf (accessed on 14 December 2019).

- Weather and Climate (in Polish—Pogoda I Klimat). Available online: http://meteomodel.pl/BLOG/?p=10757 (accessed on 14 December 2019).

- Subocz, J. Dielectric Conductivity and Relaxation of Layered Insulation Systems (in Polish—Przewodnictwo I Relaksacja Warstwowych Układów Izolacyjnych); West Pomeranian University of Technology: Szczecin, Poland, 2012; ISBN 978-83-7663-113-4. [Google Scholar]

| Voltage Level | Time Interval |

|---|---|

| 2 kV | 10 min |

| 4 kV | 5 min |

| 6 kV | 5 min |

| 8 kV | 5 min |

| 10 kV | 5 min |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subocz, J.; Mrozik, A.; Bohatyrewicz, P.; Zenker, M. Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods. Energies 2020, 13, 853. https://doi.org/10.3390/en13040853

Subocz J, Mrozik A, Bohatyrewicz P, Zenker M. Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods. Energies. 2020; 13(4):853. https://doi.org/10.3390/en13040853

Chicago/Turabian StyleSubocz, Jan, Andrzej Mrozik, Patryk Bohatyrewicz, and Marek Zenker. 2020. "Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods" Energies 13, no. 4: 853. https://doi.org/10.3390/en13040853

APA StyleSubocz, J., Mrozik, A., Bohatyrewicz, P., & Zenker, M. (2020). Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods. Energies, 13(4), 853. https://doi.org/10.3390/en13040853