The Development Strategies and Technology Roadmap of Bioenergy for a Typical Region: A Case Study in the Beijing-Tianjin-Hebei Region in China

Abstract

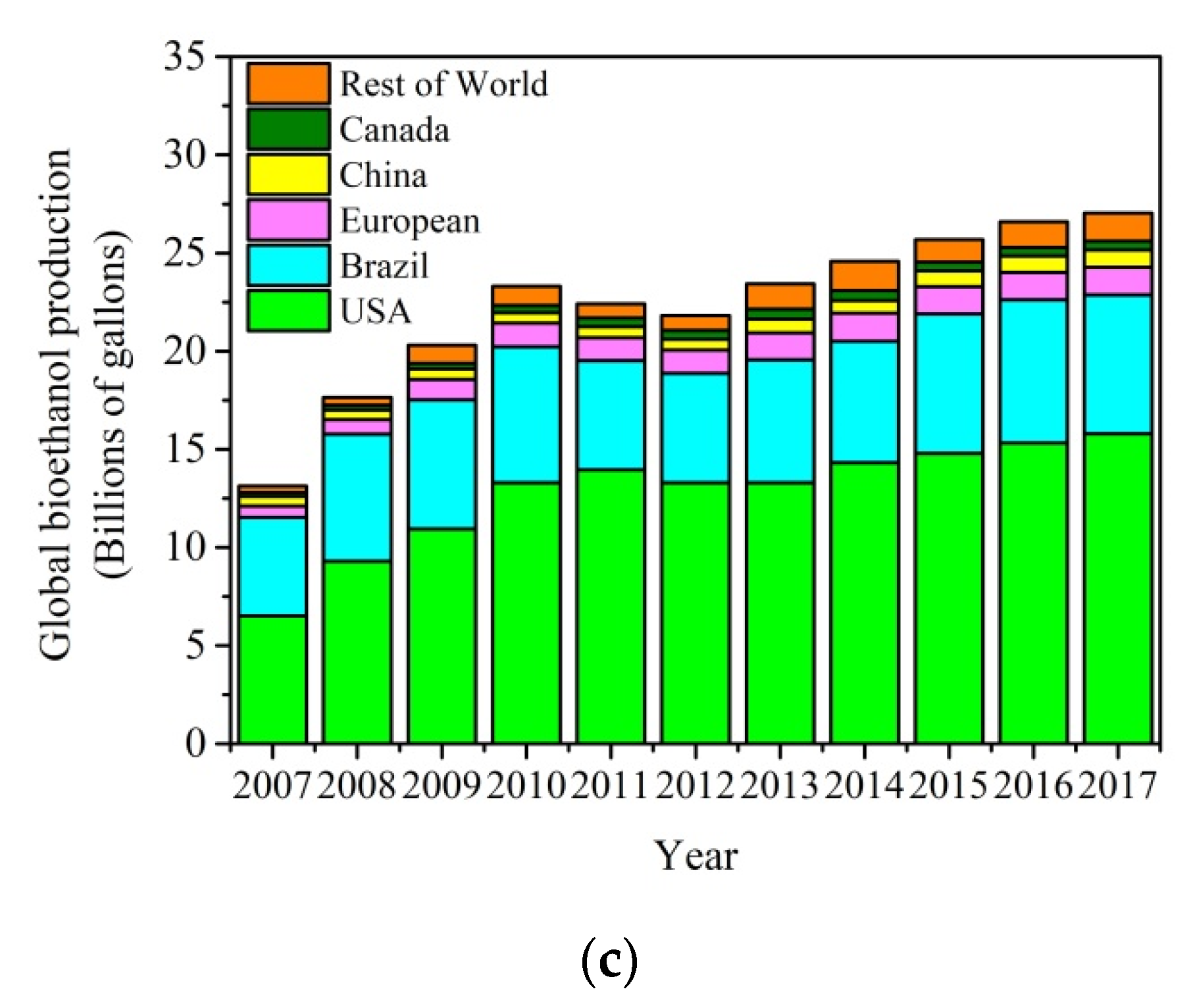

1. Introduction

2. The Description of the Technology Roadmap and Case Information

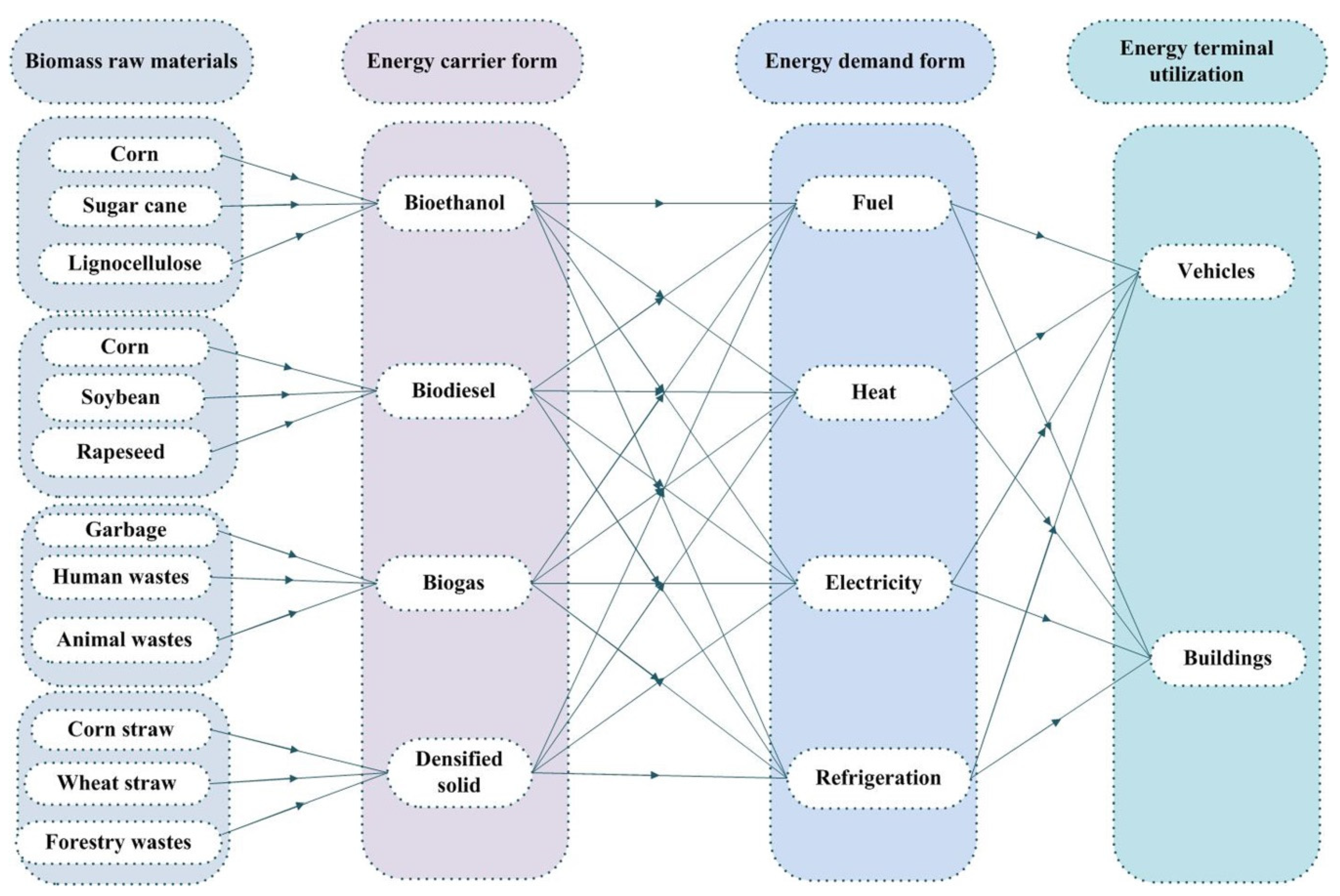

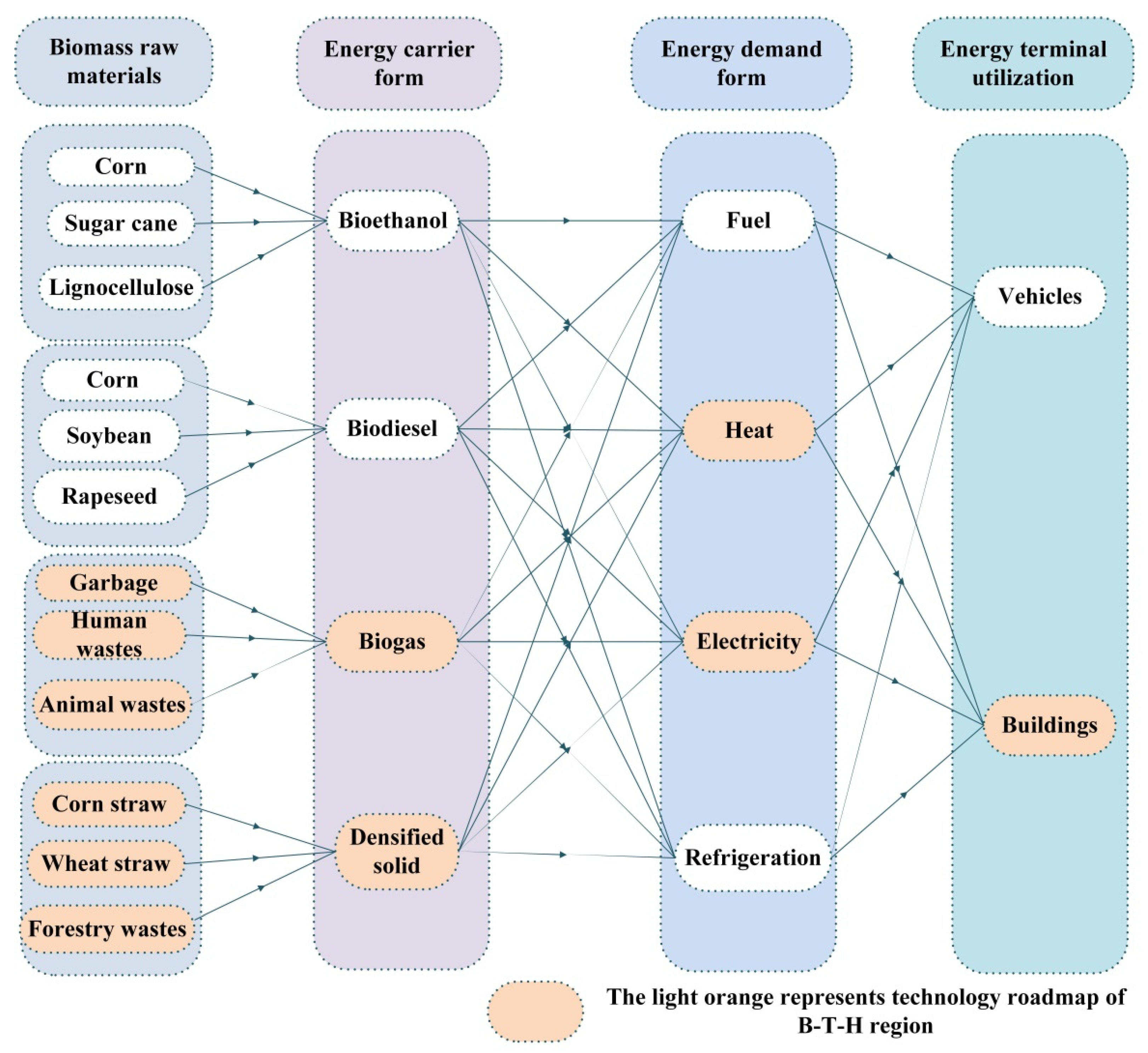

2.1. The Description of the Technology Roadmap

2.2. The Description of Case Information

2.3. The Limitations of This Work

3. The Potential Estimation of Bioenergy in the B-T-H Region

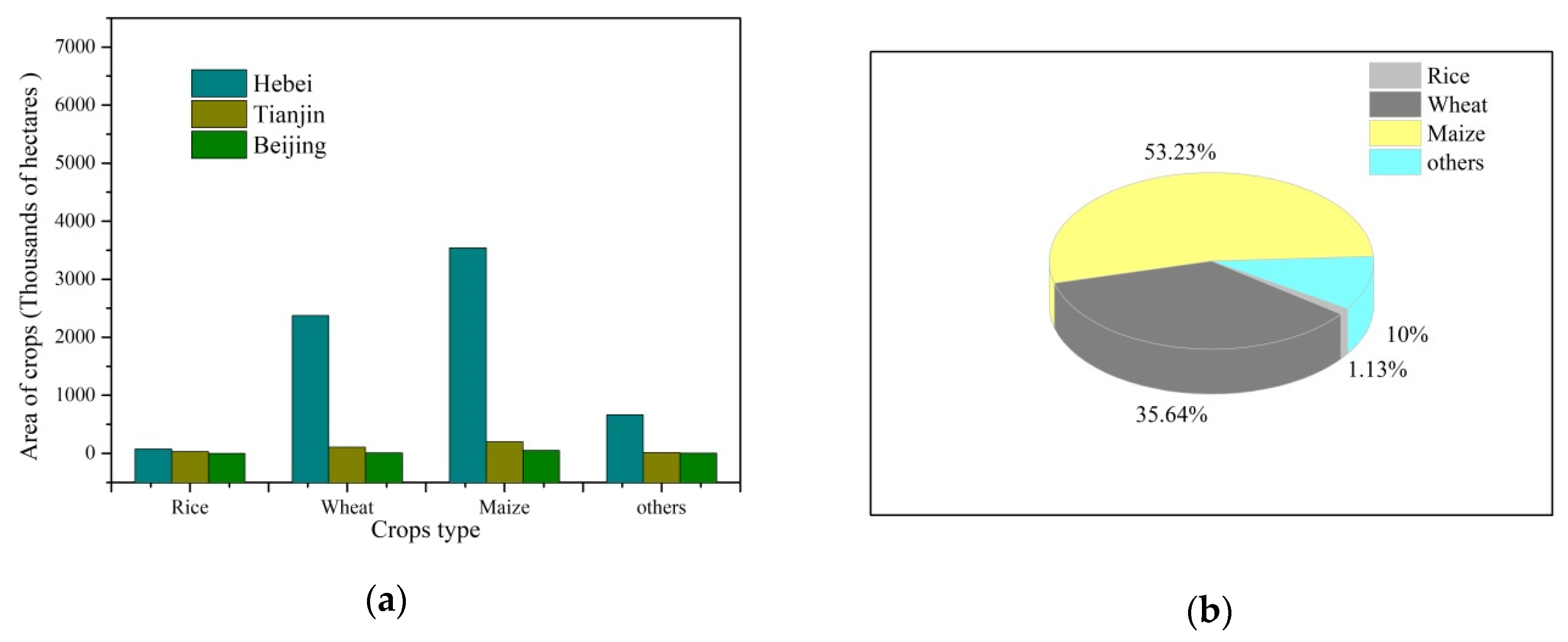

3.1. The Estimation of Crops Straw Bioenergy Potential

3.1.1. Crop Residues

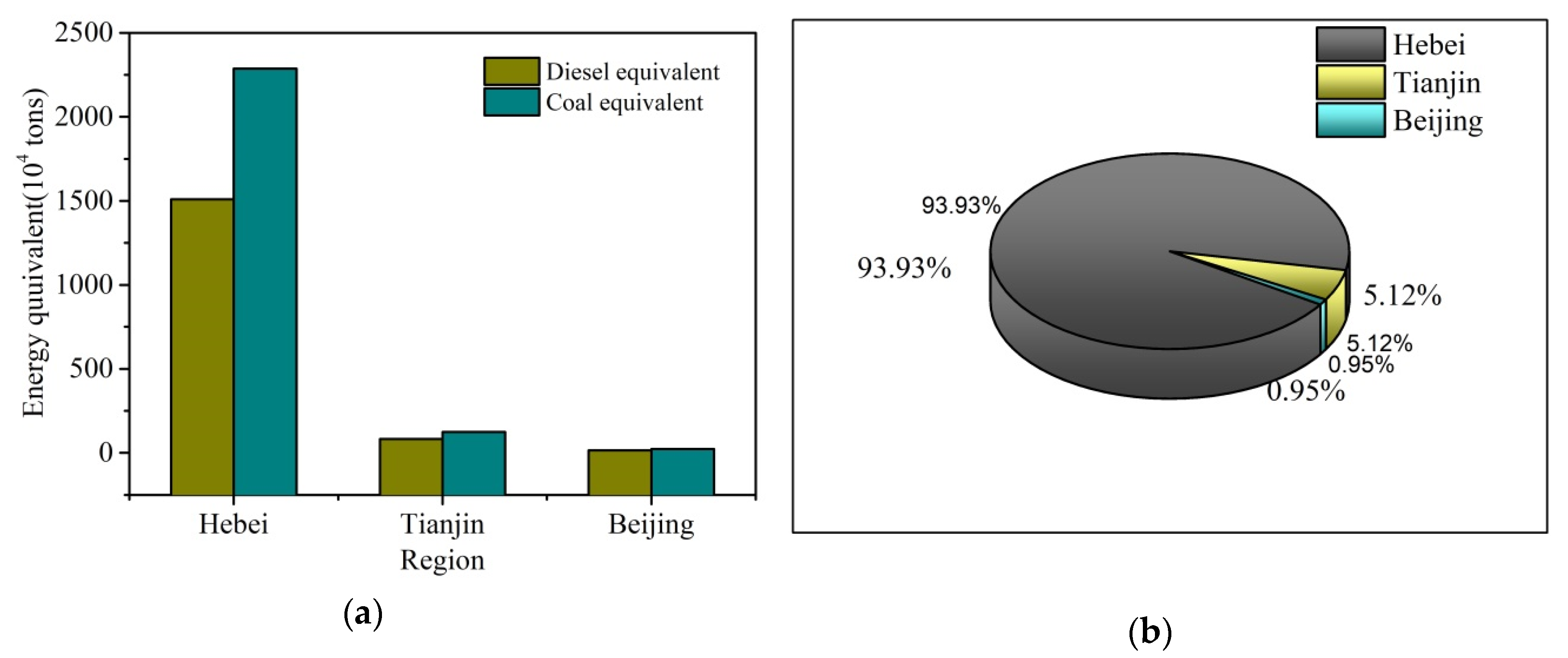

3.1.2. The Energy Potential Estimation of Crops Residues

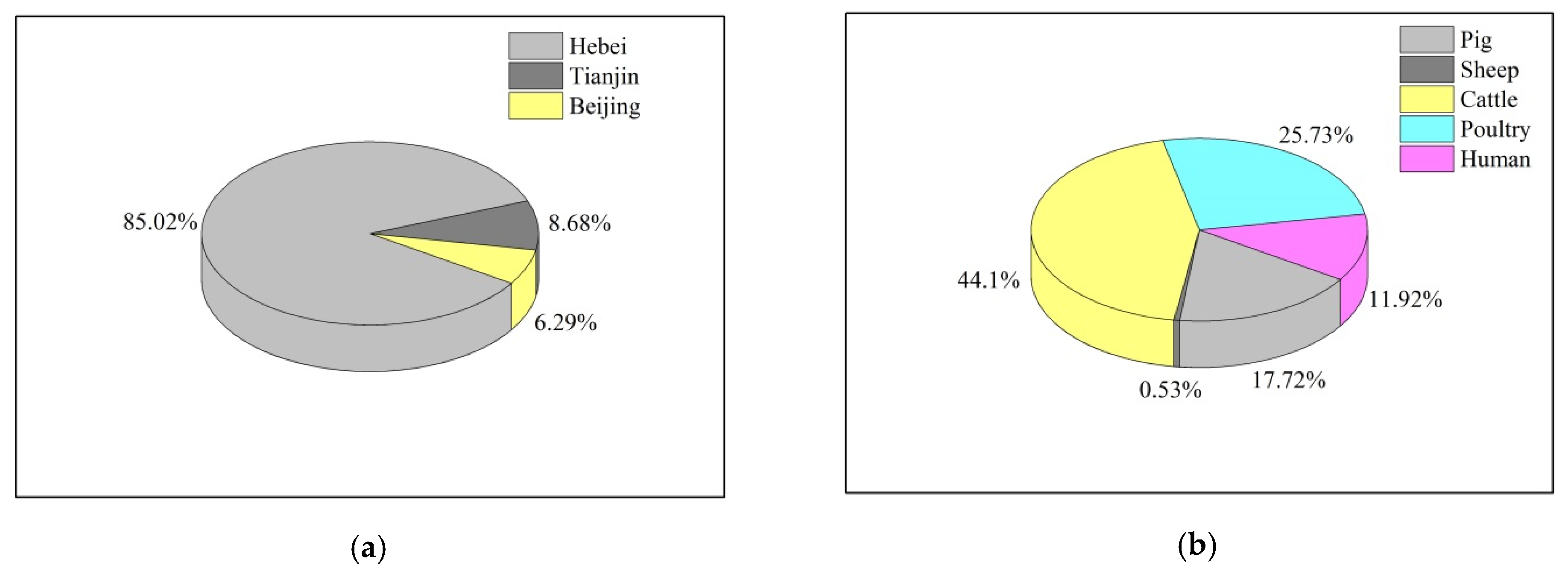

3.2. The Estimation of Human, Poultry, and Livestock Manure Bioenergy Potential

3.2.1. The Estimation of Human, Poultry, and Livestock Manure Production

3.2.2. The Energy Potential Estimation of Human, Livestock, and Poultry Waste

3.3. The Estimation of Municipal Solid Waste (MSW) Bioenergy Potential

3.3.1. The Production of MSW

3.3.2. The Energy Potential Estimation of MSW

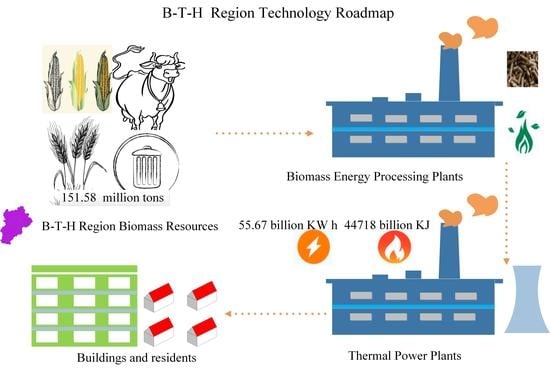

4. The Technology Roadmap of the B-T-H Region

5. Conclusions

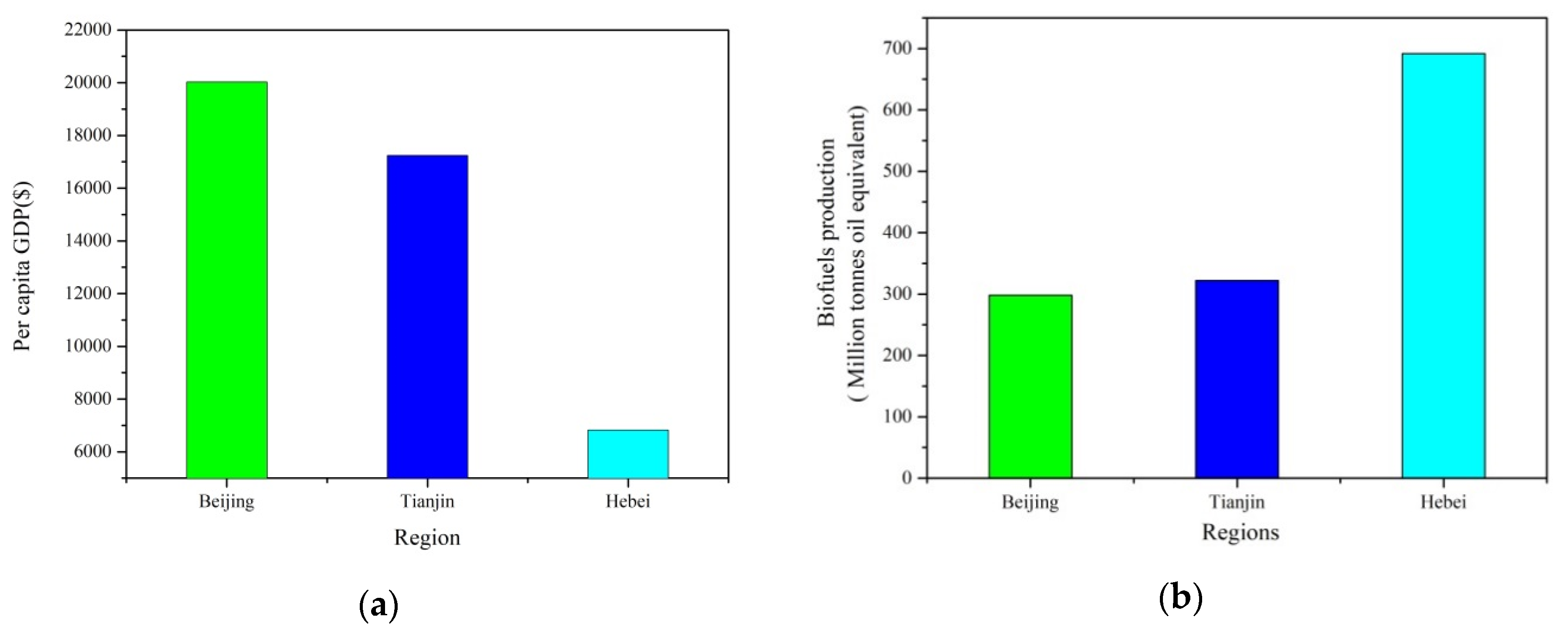

- Through statistical data analysis, the total available biomass resource is 90.60 million tons, of which 36.52 million tons come from crop residue, 15.46 million tons from manure, and 38.62 million tons from MSW. The crops residue potential of Heibei region is enormous, accounting for 93% of the B-T-H region total, which is equal to 0.10 × 1015 kcal of total energy of crops residues in this area. Therefore, a huge energy development market in Hebei may exist.

- The potentials of crops residue and livestock and human manure in the different components of the B-T-H region have significant regional difference, which may be ascribed to the level of economic development, population base, and topography. From a resource perspective, the suitable technology roadmaps are the biogas development roadmap and the densified solid development roadmap.

- Taking into conversion efficiency and energy use efficiency account, an estimate of the final energy use of available biomass energy is obtained. The total available bioenergy of heat is 44,718 billion KJ, the total available bioenergy of power is 55.67 billion KW h and the total available bioenergy of coal equivalent is 23.91 million tons.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

Appendix B.1. Crop Residue Economic Value

| Category | Agricultural Machinery Capital Recovery | Operation and Maintenance Costs | Human Resources Cost | Management Fees | Corn Straw Price |

|---|---|---|---|---|---|

| Unit price($/t) | 3.0 | 6.9 | 2.9 | 1.1 | 22.85 |

| Total corp residue economic value (million USD) | 318 | ||||

Appendix B.2. Excrements Economic Value

| Category | Biogas |

|---|---|

| Unit price ($ USD/m3) | 1.047 |

| Total cattle excrement economic value (million USD) | 7400 |

| Total excrement economic value (million USD) | 3261 |

Appendix B.3. Economic Feasibility of the Available Biomass

Appendix C

Appendix C.1. Range of Straw/Grain Ratio

Appendix C.2. Range of Collection Coefficient

| Crops | Range of Collection Coefficient |

|---|---|

| Crops | 0.75–0.9 |

| Livestock excretion | 0.6–0.9 |

| Municipal solid waste | 0.9 |

References

- Bilan, Y.; Streimikiene, D.; Vasylieva, T.; Lyulyov, O.; Pimonenko, T.; Pavlyk, A. Linking between Renewable Energy, CO2 Emissions, and Economic Growth: Challenges for Candidates and Potential Candidates for the EU Membership. Sustainability 2019, 11, 1528. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Paramati, S.R.; Ozturk, I.; Bhattacharya, S. The effect of renewable energy consumption on economic growth: Evidence from top 38 countries. Appl. Energy 2016, 162, 733–741. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Rafiq, S.; Bhattacharya, S. The role of technology on the dynamics of coal consumption-economic growth: New evidence from China. Appl. Energy 2015, 154, 686–695. [Google Scholar] [CrossRef]

- Wolde-Rufael, Y. Energy consumption and economic growth: The experience of African countries revisited. Energy Econ. 2009, 31, 217–224. [Google Scholar] [CrossRef]

- Costantini, V.; Martini, C. The causality between energy consumption and economic growth: A multi-sectoral analysis using non-stationary cointegrated panel data. Energy Econ. 2010, 32, 591–603. [Google Scholar] [CrossRef]

- Sadorsky, P. Renewable energy consumption and income in emerging economies. Energy Policy 2009, 37, 4021–4028. [Google Scholar] [CrossRef]

- Bowden, N.; Payne, J.E. Sectoral analysis of the causal relationship between renewable and non-renewable energy consumption and real output in the US. Energy Sources Part B Econ. Plan Policy 2010, 5, 400–408. [Google Scholar] [CrossRef]

- Ozturk, I.; Bilgili, F. Economic growth and biomass consumption nexus: Dynamic panel analysis for Sub-Sahara African countries. Appl. Energy 2015, 137, 110–116. [Google Scholar] [CrossRef]

- British Petroleum UK. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2019-full-report.pdf (accessed on 21 November 2019).

- Landman, W. Climate change 2007: The physical science basis. S. Afr. Geogr. J. 2010, 92, 86–87. [Google Scholar] [CrossRef]

- Okkerse, C.; Van Bekkum, H. From fossil to green. Green Chem. 1999, 1, 107–114. [Google Scholar] [CrossRef]

- Conference of the Parties Twenty-First Session. Available online: http://unfccc.int/resource/docs/2015/cop21/eng/l09.pdf (accessed on 10 November 2019).

- European Environment Agency (EEA). Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&init=1&plugin=1&language=en&pcode=t2020_31 (accessed on 26 November 2019).

- Ruddiman, W.F. The anthropogenic greenhouse era began thousands of years ago. Clim. Chang. 2003, 61, 261–293. [Google Scholar] [CrossRef]

- United Nations Sustainable Development Goal. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 15 November 2019).

- Energy Information Administration (EIA), International Energy Outlook. Available online: https://www.eia.gov/pressroom/presentations/sieminski_07252013.pdf (accessed on 15 November 2019).

- Energy and Climate Goals of China’s 12th Five-Year Plan. Available online: https://www.c2es.org/site/assets/uploads/2011/03/energy-climate-goals-chinas-twelfth-five-year-plan.pdf (accessed on 22 November 2019).

- REN21. Available online: https://www.ren21.net/wp-content/uploads/2019/05/gsr_2019_full_report_en.pdf (accessed on 10 November 2019).

- Lal, R. World crop residues production and implications of its use as a biofuel. Environ. Int. 2005, 31, 575–584. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae beats bioethanol. Trends Biotechnol. 2008, 26, 126–131. [Google Scholar] [CrossRef] [PubMed]

- Ferreira-Leitão, V.; Gottschalk, L.M.F.; Ferrara, M.A.; Nepomuceno, A.L.; Molinari, H.B.C.; Bon, E.P.S. Biomass Residues in Brazil: Availability and Potential Uses. In Waste Biomass Valorization; Springer: Berlin/Heidelberg, Germany, 2010; Volume 1, pp. 65–76. [Google Scholar]

- Balogun, A.O.; Lasode, O.A.; McDonald, A.G. Thermo-physical, Chemical and Structural Modifications in Torrefied Biomass Residues. In Waste Biomass Valorization; Springer: Berlin/Heidelberg, Germany, 2016; Volume 9, pp. 131–138. [Google Scholar]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Abdullah, B.; Syed Muhammad, S.A.F.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- International Energy Agency. Available online: https://www.iea.org/publications/freepublications/publication/Technology_Roadmap_Delivering_Sustainable_Bioenergy.pdf (accessed on 25 November 2019).

- Diamantis, V.I.; Kapagiannidis, A.G.; Ntougias, S.; Tataki, V.; Melidis, P.; Aivasidis, A. Two-stage CSTR–UASB digestion enables superior and alkali addition-free cheese whey treatment. Biochem. Eng. J. 2014, 84, 45–52. [Google Scholar] [CrossRef]

- Long, H.; Li, X.; Wang, H.; Jia, J. Biomass resources and their bioenergy potential estimation: A review. Renew. Sustain. Energy Rev. 2013, 26, 344–352. [Google Scholar] [CrossRef]

- Ahorsu, R.; Medina, F.; Constantí, M. Significance and Challenges of Biomass as a Suitable Feedstock for Bioenergy and Biochemical Production: A Review. Energies 2018, 11, 3366. [Google Scholar] [CrossRef]

- Alternative Fuels Data Center. Available online: https://afdc.energy.gov/fuels/ethanol.html (accessed on 15 November 2019).

- Forbord, M.; Vik, J.; Hillring, B.G. Development of local and regional forest based bioenergy in Norway—Supply networks, financial support and political commitment. Biomass Bioenergy 2012, 47, 164–176. [Google Scholar] [CrossRef][Green Version]

- Kraxner, F.; Nordström, E.-M.; Havlík, P.; Gusti, M.; Mosnier, A.; Frank, S.; Obersteiner, M. Global bioenergy scenarios—Future forest development, land-use implications, and trade-offs. Biomass Bioenergy 2013, 57, 86–96. [Google Scholar] [CrossRef]

- Perez-Verdin, G.; Grebner, D.L.; Sun, C.; Munn, I.A.; Schultz, E.B.; Matney, T.G. Woody biomass availability for bioethanol conversion in Mississippi. Biomass Bioenergy 2009, 33, 492–503. [Google Scholar] [CrossRef]

- Duku, M.H.; Gu, S.; Hagan, E.B. A comprehensive review of biomass resources and biofuels potential in Ghana. Renew. Sustain. Energy Rev. 2011, 15, 404–415. [Google Scholar] [CrossRef]

- Wicke, B.; Smeets, E.; Watson, H.; Faaij, A. The current bioenergy production potential of semi-arid and arid regions in sub-Saharan Africa. Biomass Bioenergy 2011, 35, 2773–2786. [Google Scholar] [CrossRef]

- Cai, J.; Liu, R.; Deng, C. An assessment of biomass resources availability in Shanghai: 2005 analysis. Renew. Sustain. Energy Rev. 2008, 12, 1997–2004. [Google Scholar] [CrossRef]

- Steubing, B.; Ballmer, I.; Gassner, M.; Gerber, L.; Pampuri, L.; Bischof, S.; Zah, R. Identifying environmentally and economically optimal bioenergy plant sizes and locations: A spatial model of wood-based SNG value chains. Renew. Energy 2014, 61, 57–68. [Google Scholar] [CrossRef]

- Jasinskas, A.; Sakalauskas, A.; Domeika, R. Evaluation of physical–mechanical properties of herbaceous bioenergy plants. Biomass Bioenergy 2008, 32, 952–958. [Google Scholar] [CrossRef]

- Niblick, B.; Monnell, J.D.; Zhao, X.; Landis, A.E. Using geographic information systems to assess potential biofuel crop production on urban marginal lands. Appl. Energy 2013, 103, 234–242. [Google Scholar] [CrossRef]

- Sliz-Szkliniarz, B.; Vogt, J. A GIS-based approach for evaluating the potential of biogas production from livestock manure and crops at a regional scale: A case study for the Kujawsko-Pomorskie Voivodeship. Renew. Sustain. Energy Rev. 2012, 16, 752–763. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenergy 2004, 26, 361–375. [Google Scholar] [CrossRef]

- Smeets, E.M.W.; Faaij, A.P.C.; Lewandowski, I.M.; Turkenburg, W.C. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. Sci. 2007, 33, 56–106. [Google Scholar] [CrossRef]

- Thrän, D.; Seidenberger, T.; Zeddies, J.; Offermann, R. Global biomass potentials—Resources, drivers and scenario results. Energy Sustain. Dev. 2010, 14, 200–205. [Google Scholar] [CrossRef]

- De Wit, M.; Londo, M.; Faaij, A. Productivity developments in European agriculture: Relations to and opportunities for biomass production. Renew. Sustain. Energy Rev. 2011, 15, 2397–2412. [Google Scholar] [CrossRef]

- De Wit, M.; Faaij, A. European biomass resource potential and costs. Biomass Bioenergy 2010, 34, 188–202. [Google Scholar] [CrossRef]

- Banowetz, G.M.; Boateng, A.; Steiner, J.J.; Griffith, S.M.; Sethi, V.; El-Nashaar, H. Assessment of straw biomass feedstock resources in the Pacific Northwest. Biomass Bioenergy 2008, 32, 629–634. [Google Scholar] [CrossRef]

- Karaj, S.H.; Rehl, T.; Leis, H.; Müller, J. Analysis of biomass residues potential for electrical energy generation in Albania. Renew. Sustain. Energy Rev. 2010, 14, 493–499. [Google Scholar] [CrossRef]

- Steubing, B.; Zah, R.; Waeger, P.; Ludwig, C. Bioenergy in Switzerland: Assessing the domestic sustainable biomass potential. Renew. Sustain. Energy Rev. 2010, 14, 2256–2265. [Google Scholar] [CrossRef]

- Szymańska, D.; Chodkowska-Miszczuk, J. Endogenous resources utilization of rural areas in shaping sustainable development in Poland. Renew. Sustain. Energy Rev. 2011, 15, 1497–1501. [Google Scholar] [CrossRef]

- Zhuang, D.; Jiang, D.; Liu, L.; Huang, Y. Assessment of bioenergy potential on marginal land in China. Renew. Sustain. Energy Rev. 2011, 15, 1050–1056. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Safari, A.; Mustaffa, W.E.S.B. Biomass energy in Malaysia: Current state and prospects. Renew. Sustain. Energy Rev. 2011, 15, 3360–3370. [Google Scholar] [CrossRef]

- Minowa, T.; Kojima, T.; Matsuoka, Y. Study for utilization of municipal residues as bioenergy resource in Japan. Biomass Bioenergy 2005, 29, 360–366. [Google Scholar] [CrossRef]

- Energy Information Administration (IEA). Available online: https://www.iea.org/publications/freepublications/publication/Biofuels_Roadmap_WEB.pdf (accessed on 29 November 2019).

- Energy Information Administration (IEA). Available online: https://www.iea.org/publications/freepublications/publication/2012_Bioenergy_Roadmap_2nd_Edition_WEB.pdf (accessed on 29 November 2019).

- How2Guide for Bioenergy Roadmap Development and Implementation. Available online: https://www.iea.org/publications/freepublications/publication/How2GuideforBioenergyRoadmapDevelopmentandImplementation.pdf (accessed on 29 November 2019).

- Mitchell, C.P.; Bridgwater, A.V.; Mackie, K.L. Bioenergy Systems. In Developments in Thermochemical Biomass Conversion, 1st ed.; Bridgwater, A.V., Boocock, D.G.B., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 1997; Volume 1, pp. 1509–1524. [Google Scholar]

- Manochio, C.; Andrade, B.R.; Rodriguez, R.P.; Moraes, B.S. Ethanol from biomass: A comparative overview. Renew. Sustain. Energy Rev. 2017, 80, 743–755. [Google Scholar] [CrossRef]

- Azadi, P.; Inderwildi, O.R.; Farnood, R.; King, D.A. Liquid fuels, hydrogen and chemicals from lignin: A critical review. Renew. Sustain. Energy Rev. 2013, 21, 506–523. [Google Scholar] [CrossRef]

- Rawat, I.; Ranjith Kumar, R.; Mutanda, T.; Bux, F. Biodiesel from microalgae: A critical evaluation from laboratory to large scale production. Appl. Energy 2013, 103, 444–467. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Wang, W.; Ouyang, W.; Hao, F. A Supply-Chain Analysis Framework for Assessing Densified Biomass Solid Fuel Utilization Policies in China. Energies 2015, 8, 7122–7139. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z.; Zhang, Y.; Wang, Y.; Yu, Y.; Ji, F.; Dong, R. A comprehensive review on densified solid biofuel industry in China. Renew. Sustain. Energy Rev. 2016, 54, 1412–1428. [Google Scholar] [CrossRef]

- Chen, L.J.; Li, X.; Han, L.J. Renewable energy from agro-residues in China: Solid biofuels and biomass briquetting technology. Renew. Sustain. Energy Rev. 2009, 13, 2689–2695. [Google Scholar] [CrossRef]

- Castrillón Mendoza, R.; Rey Hernández, J.; Velasco Gómez, E.; San José Alonso, J.; Rey Martínez, F. Analysis of the Methodology to Obtain Several Key Indicators Performance (KIP), by Energy Retrofitting of the Actual Building to the District Heating Fuelled by Biomass, Focusing on nZEB Goal: Case of Study. Energies 2019, 12, 93. [Google Scholar] [CrossRef]

- Song, S.; Liu, P.; Xu, J.; Ma, L.; Chong, C.; He, M.; Huang, X.Z.; Li, Z.; Ni, W. An Economic and Policy Analysis of a District Heating System Using Corn Straw Densified Fuel: A Case Study in Nong’an County in Jilin Province, China. Energies 2016, 10, 8. [Google Scholar] [CrossRef]

- Dwivedi, P.; Khanna, M.; Fuller, M. Is wood pellet-based electricity less carbon-intensive than coal-based electricity? It depends on perspectives, baselines, feedstocks, and forest management practices. Environ. Res. Lett. 2019, 14, 024006. [Google Scholar] [CrossRef]

- Inayat, A.; Raza, M. District cooling system via renewable energy sources: A review. Renew. Sustain. Energy Rev. 2019, 107, 360–373. [Google Scholar] [CrossRef]

- Vallios, I.; Tsoutsos, T.; Papadakis, G. Design of biomass district heating systems. Biomass Bioenergy 2009, 33, 659–678. [Google Scholar] [CrossRef]

- Thomson, H.; Liddell, C. The suitability of wood pellet heating for domestic households: A review of literature. Renew. Sustain. Energy Rev. 2015, 42, 1362–1369. [Google Scholar] [CrossRef]

- Complied by National Bureau of Statistics of China, Chinese Statistical Yearbook in 2017. Available online: http://www.stats.gov.cn/tjsj/ndsj/2017/indexch.htm (accessed on 3 December 2019).

- Ministry of Ecology and Environment of the People’s Republic of China (MEP). Chinese Environment status bulletin in 2015. Available online: http://www.mee.gov.cn/hjzl/zghjzkgb/lnzghjzkgb/201606/P020160602333160471955.pdf (accessed on 12 December 2019).

- Ministry of Ecology and Environment of the People’s Republic of China (MEP). Chinese Environment Status Bulletin in 2016. Available online: http://www.mee.gov.cn/hjzl/zghjzkgb/lnzghjzkgb/201706/P020170605833655914077.pdf (accessed on 12 December 2019).

- Zhang, B.B. Assessment of Raw Material Supply Capability and Energy Potential of Biomass Resources in China. Ph.D. Thesis, China Agricultural University, Beijing, China, 2018. (In Chinese). [Google Scholar]

- Larson, W.E. Crop residue: Energy production on erosion control. J. Soil Water Conserv. 1979, 34, 74–76. [Google Scholar]

- Yanli, Y.; Peidong, Z.; Wenlong, Z.; Yongsheng, T.; Yonghong, Z.; Lisheng, W. Quantitative appraisal and potential analysis for primary biomass resources for energy utilization in China. Renew. Sustain. Energy Rev. 2010, 14, 3050–3058. [Google Scholar] [CrossRef]

- Stout, B.A. Energy from Biomass. In Handbook of Energy for World Agriculture, 1st ed.; Elsevier Science: New York, NY, USA, 1990; pp. 1–504. [Google Scholar]

- Lal, R. The role of residues management in sustainable agricultural systems. J. Sustain. Agric. 1995, 5, 51–78. [Google Scholar] [CrossRef]

- Wang, F.H.; Ma, W.Q.; Dou, Z.X.; Ma, L.; Liu, X.L.; Xu, J.X.; Zhang, F.S. The estimation of the production amount of animal manure and its environmental effect in China. China Environ. Sci. 2006, 26, 614–617. [Google Scholar]

- Peng, L.; Wang, D.Y. Estimation of annual quantity of total excretion from livestock and poultry in Chongqing Municipality. Trans. CSAE 2004, 20, 288–291. (In Chinese) [Google Scholar]

- Zhu, L.; Zhang, L.; Fan, J.; Jiang, P.; Li, L. MSW to synthetic natural gas: System modeling and thermodynamics assessment. Waste Manag. 2016, 48, 257–264. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A.; Alamoudı, R.H.; Ahmad, W.; Sheıkh, M.H. Optimization of municipal solid waste (MSW) disposal in Saudi Arabia. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 1929–1937. [Google Scholar] [CrossRef]

- Lima, R.M.; Santos, A.H.M.; Pereira, C.R.S.; Flauzino, B.K.; Pereira, A.C.O.S.; Nogueira, F.J.H.; Valverde, J.A.R. Spatially distributed potential of landfill biogas production and electric power generation in Brazil. Waste Manag. 2018, 74, 323–334. [Google Scholar] [CrossRef]

- Yao, X.; Guo, Z.; Liu, Y.; Li, J.; Feng, W.; Lei, H.; Gao, Y. Reduction potential of GHG emissions from municipal solid waste incineration for power generation in Beijing. J. Clean. Prod. 2019, 241, 118283–118297. [Google Scholar] [CrossRef]

- Complied by Beijing Bureau of Statistics, National Bureau of Statistics Beijing Investigation Team, Beijing Statistical Yearbook of 2019. Available online: http://navi.cnki.net/KNavi/YearbookDetail?pcode=CYFD&pykm=YOFGE&bh= (accessed on 1 January 2020).

- Complied by Tianjin Bureau of Statistics, National Bureau of Statistics Tianjin Investigation Team, Tianjin Statistical Yearbook of 2019. Available online: http://navi.cnki.net/KNavi/YearbookDetail?pcode=CYFD&pykm=YTJTJ&bh= (accessed on 1 January 2020).

- Complied by Hebei Provincial Bureau of Statistics, Hebei Economic Yearbook of 2018. Available online: http://navi.cnki.net/KNavi/YearbookDetail?pcode=CYFD&pykm=YMAWW&bh= (accessed on 1 January 2020).

| Crops | Straw/Grain Ratio |

|---|---|

| Rice | 1.00 |

| Wheat | 1.28 |

| Maize | 1.10 |

| Legumes | 1.50 |

| Potato | 0.50 |

| Peanut | 1.01 |

| Rapeseed | 1.01 |

| Cotton | 3.62 |

| Sugar beet | 0.10 |

| Tobacco | 0.66 |

| Crops | Category | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|---|

| Rice | Production | 0.50 | 0.26 | 0.00 | 0.76 |

| Per land area amount | 0.03 | 0.23 | 0.00 | 0.26 | |

| Per capita amount | 6.71 | 14.97 | 0.03 | 21.71 | |

| Wheat | Production | 15.04 | 0.62 | 0.06 | 15.72 |

| Per land area amount | 0.80 | 0.55 | 0.04 | 1.39 | |

| Per capita amount | 200.02 | 35.47 | 2.85 | 238.34 | |

| Maize | Production | 20.35 | 1.19 | 0.33 | 21.88 |

| Per land area amount | 1.08 | 1.06 | 0.20 | 2.33 | |

| Per capita amount | 270.68 | 67.81 | 15.30 | 353.79 | |

| Legumes | Production | 0.20 | 0.01 | 0.01 | 0.22 |

| Per land area amount | 0.01 | 0.01 | 0.00 | 0.02 | |

| Per capita amount | 2.77 | 0.49 | 0.27 | 3.53 | |

| Potato | Production | 13.40 | 0.15 | 0.0 | 1.36 |

| Per land area amount | 0.07 | 0.01 | 0.00 | 0.08 | |

| Per capita amount | 17.81 | 0.85 | 0.28 | 18.94 | |

| Peanut | Production | 1.03 | 0.01 | N/A 1 | 1.04 |

| Per land area amount | 0.06 | 0.01 | 0.00 | 0.07 | |

| Per capita amount | 13.75 | 0.30 | 0.19 | 14.24 | |

| Rapeseed | Production | 0.00 | N/A 1 | N/A 1 | 0.00 |

| Per land area amount | 0.00 | N/A 1 | N/A 1 | 0.00 | |

| Per capita amount | 0.55 | N/A 1 | N/A 1 | 0.55 | |

| Cotton | Production | 0.02 | 0.02 | N/A 1 | 0.04 |

| Per land area amount | 0.01 | 0.02 | N/A 1 | 0.03 | |

| Per capita amount | 3.19 | 1.42 | N/A 1 | 4.61 | |

| Sugar beet | Production | 0.06 | N/A 1 | N/A 1 | 0.06 |

| Per land area amount | 0.03 | N/A 1 | N/A 1 | 0.03 | |

| Per capita amount | 8.30 | N/A 1 | N/A 1 | 8.30 | |

| Tobacco | Production | 0.00 | N/A 1 | N/A 1 | 0.00 |

| Per land area amount | 0.00 | N/A 1 | N/A 1 | 0.00 | |

| Per capita amount | 0.00 | N/A 1 | N/A 1 | 0.03 |

| Crops | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|

| Rice | 0.38 | 0.20 | 0.00 | 0.58 |

| Wheat | 14.44 | 0.60 | 0.06 | 15.10 |

| Maize | 16.79 | 0.98 | 0.27 | 18.05 |

| Legumes | 0.23 | 0.01 | 0.01 | 0.25 |

| Potato | 0.50 | 0.01 | 0.00 | 0.51 |

| Peanut | 1.16 | 0.01 | 0.00 | 1.17 |

| Rapeseed | 0.09 | N/A 1 | N/A 1 | 0.09 |

| Cotton | 0.65 | 0.07 | N/A 1 | 0.72 |

| Sugar beet | 0.05 | N/A 1 | N/A 1 | 0.05 |

| Tobacco | 0.00 | N/A 1 | N/A 1 | 0.00 |

| Total | 34.30 | 1.87 | 0.35 | 36.52 |

| Crops | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|

| Rice | 0.19 | 0.10 | 0.00 | 0.29 |

| Wheat | 7.22 | 0.30 | 0.03 | 7.55 |

| Maize | 8.40 | 0.49 | 0.14 | 9.03 |

| Legumes | 0.12 | 0.00 | 0.00 | 0.13 |

| Potato | 0.25 | 0.00 | 0.00 | 0.26 |

| Peanut | 0.58 | 0.00 | 0.00 | 0.59 |

| Rapeseed | 0.05 | N/A 1 | N/A 1 | 0.05 |

| Cotton | 0.33 | 0.03 | N/A 1 | 0.36 |

| Sugar beet | 0.02 | N/A 1 | N/A 1 | 0.02 |

| Tobacco | 0.00 | N/A 1 | N/A 1 | 0.00 |

| Total | 17.15 | 0.93 | 0.17 | 18.26 |

| Species | Excretion Coefficient (kg/day) | COD Production Coefficient (kg/day) | Feeding Cycle (day) |

|---|---|---|---|

| Pig | 3.39 | 0.36 | 199 |

| Sheep | 2.60 | 0.01 | 365 |

| Cattle | 30.40 | 4.09 | 365 |

| Poultry | 0.37 | 0.025 | 365 |

| Horse | 15 | N/A 1 | 365 |

| Donkey | 13 | N/A 1 | 365 |

| Mule | 13 | N/A 1 | 365 |

| Human | 0.08 | 0.075 | 365 |

| Species | Situation | Hebei | Tianjin | Beijing |

|---|---|---|---|---|

| Pig | Marketable stock | 34.34 | 3.75 | 2.75 |

| Standing stock | 19.58 | 1.80 | 1.65 | |

| Sheep | Marketable stock | 23.04 | 0.69 | 0.70 |

| Standing stock | 12.28 | 0.43 | 0.60 | |

| Cattle | Marketable stock | 3.32 | 0.20 | 0.07 |

| Standing stock | 3.60 | 0.26 | 0.16 | |

| Poultry | Marketable stock | 607.72 | 79.11 | 38.83 |

| Horse | Standing stock | 0.06 | 0.00 | 0.00 |

| Donkey | Standing stock | 0.17 | 0.01 | 0.00 |

| Mule | Standing stock | 0.05 | 0.00 | 0.00 |

| Human | Year-end residents | 74.70 | 15.62 | 21.73 |

| Species | Situation | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|---|

| Pig | Marketable stock | 13.90 | 1.52 | 1.11 | 16.53 |

| Standing stock | 7.92 | 0.73 | 0.67 | 9.32 | |

| Sheep | Marketable stock | 13.12 | 0.39 | 0.40 | 13.91 |

| Standing stock | 6.99 | 0.25 | 0.34 | 7.58 | |

| Cattle | Marketable stock | 22.10 | 1.34 | 0.49 | 23.93 |

| Standing stock | 23.93 | 1.72 | 1.08 | 26.73 | |

| Poultry | Marketable stock | 49.24 | 6.41 | 3.15 | 58.80 |

| Horse | Standing stock | 0.19 | 0.00 | 0.01 | 0.20 |

| Donkey | Standing stock | 0.49 | 0.02 | 0.01 | 0.52 |

| Mule | Standing stock | 0.15 | 0.00 | 0.00 | 0.15 |

| Human | Year-end resident | 1.31 | 0.27 | 0.38 | 1.96 |

| Total | 139.35 | 12.65 | 7.63 | 159.63 | |

| Species | Situation | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|---|

| Pig | Marketable stock | 1.48 | 0.16 | 0.12 | 1.76 |

| Standing stock | 0.84 | 0.08 | 0.07 | 0.99 | |

| Sheep | Marketable stock | 0.05 | 0.00 | 0.00 | 0.05 |

| Standing stock | 0.03 | 0.00 | 0.00 | 0.03 | |

| Cattle | Marketable stock | 2.97 | 0.18 | 0.07 | 3.22 |

| Standing stock | 3.22 | 0.23 | 0.14 | 3.60 | |

| Poultry | Marketable stock | 3.33 | 0.43 | 0.21 | 3.97 |

| Human | Year-end resident | 1.23 | 0.26 | 0.36 | 1.84 |

| Total | 13.14 | 1.34 | 0.97 | 15.46 | |

| Species | Situation | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|---|

| Pig | Marketable stock | 6.75 | 0.74 | 0.54 | 8.03 |

| Standing stock | 3.85 | 0.35 | 0.32 | 4.52 | |

| Sheep | Marketable stock | 0.23 | 0.01 | 0.01 | 0.25 |

| Standing stock | 0.12 | 0.01 | 0.01 | 0.13 | |

| Cattle | Marketable stock | 13.60 | 0.82 | 0.30 | 14.72 |

| Standing stock | 14.72 | 1.06 | 0.66 | 16.45 | |

| Poultry | Marketable stock | 15.22 | 1.98 | 0.97 | 18.17 |

| Human | Year-end resident | 5.61 | 1.18 | 1.63 | 8.42 |

| Total | 60.10 | 6.14 | 4.45 | 70.68 | |

| Species | Situation | Hebei | Tianjin | Beijing | Total |

|---|---|---|---|---|---|

| Pig | Marketable stock | 0.49 | 0.05 | 0.04 | 0.59 |

| Standing stock | 0.28 | 0.03 | 0.02 | 0.33 | |

| Sheep | Marketable stock | 0.02 | 0.00 | 0.00 | 0.02 |

| Standing stock | 0.01 | 0.00 | 0.00 | 0.01 | |

| Cattle | Marketable stock | 1.00 | 0.06 | 0.02 | 1.08 |

| Standing stock | 1.08 | 0.08 | 0.05 | 1.21 | |

| Poultry | Marketable stock | 1.12 | 0.15 | 0.07 | 1.33 |

| Human | Year-end resident | 0.41 | 0.09 | 0.12 | 0.62 |

| Total | 4.41 | 0.45 | 0.33 | 5.18 | |

| Category | Beijing | Hebei | Tianjin | Total |

|---|---|---|---|---|

| Wastes clearance volume (106 tons) | 9.24 | 7.00 | 3.07 | 1.93 |

| Harmless disposal volume (106 tons) | 9.24 | 7.00 | 2.90 | 1.93 |

| Sanitary landfill wastes (106 tons) | 4.38 | 3.91 | 1.52 | 38.62 |

| Burning wastes | 326.50 | 284.80 | 137.6 | 7724.84 |

| Harmless treatment rate | 99.00% | 99.80% | 99.40% | None |

| Category | Beijing | Hebei | Tianjin | Total |

|---|---|---|---|---|

| Methane production from landfill treatment (106 tons) | 0.12 | 0.11 | 0.41 | 0.27 |

| Methane coal equivalent produced by landfill treatment (106 tons) | 0.21 | 0.19 | 0.73 | 0.47 |

| Methane produced by landfill treatment (hundred million m3) | 1.71 | 1.53 | 0.60 | 3.84 |

| Biomass Raw Materials | Collection Coefficient | Energy Carrier Form | Energy Loss in Infrastructure | Machining Efficiency | Energy Demand form | Energy Conversion Efficiency | Caloric Value (KJ/Kg) | Energy Utilization Efficiency |

|---|---|---|---|---|---|---|---|---|

| Crops | 75% | Biogas | 5% | 0.30 m3/kg | Heating | 75.83% | 12,572.70 | 55% |

| Power (central) | N/A3 | N/A 1 | ||||||

| Densification | 5% | 92% | Heating | 75.83% | 12572.70 | 45% | ||

| Power (central) | 0.56KW h/Kg | N/A 1 | ||||||

| MSW | 90% | Biogas | N/A 1 | N/A 1 | Heating | 75.83% | 25.58 | 55% |

| Power (central) | 1.25 KW h/m3 | N/A 1 | 55% | |||||

| Excrement | 60% | Biogas | 15% | 0.54 m3/kg | Heating | 75.83% | 25.58 | 55% |

| Power (central) | 1.25 KW h/m3 | N/A 1 | 55% |

| Energy | Hebei | Tianjin | Beijing | |

|---|---|---|---|---|

| Total energy demand (106 tons coal equivalent) | 303.85 | 80.11 | 71.32 | |

| Coal percentage of total energy demand (%) | 83.71 | 48.00 | 5.65 | |

| Petroleum percentage of total energy demand (%) | 7.97 | N/A 1 | 33.8 | |

| Natural gas percentage of total energy demand (%) | 4.23 | 1.02 | 31.8 | |

| Total residential demand (106 tons coal equivalent) | N/A 1 | 11.02 | 16.97 | |

| Residential demand | Heat (106 million KJ) | N/A 1 | 102.18 | N/A 1 |

| Electricity (102 million KW h) | N/A 1 | 99.68 | N/A 1 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, Y.-Z.; Wang, A.-B.; Gao, L.-J.; Xu, H.-J.; Ning, X.-W. The Development Strategies and Technology Roadmap of Bioenergy for a Typical Region: A Case Study in the Beijing-Tianjin-Hebei Region in China. Energies 2020, 13, 844. https://doi.org/10.3390/en13040844

Zhang X, Li Y-Z, Wang A-B, Gao L-J, Xu H-J, Ning X-W. The Development Strategies and Technology Roadmap of Bioenergy for a Typical Region: A Case Study in the Beijing-Tianjin-Hebei Region in China. Energies. 2020; 13(4):844. https://doi.org/10.3390/en13040844

Chicago/Turabian StyleZhang, Xin, Yun-Ze Li, Ao-Bing Wang, Li-Jun Gao, Hui-Juan Xu, and Xian-Wen Ning. 2020. "The Development Strategies and Technology Roadmap of Bioenergy for a Typical Region: A Case Study in the Beijing-Tianjin-Hebei Region in China" Energies 13, no. 4: 844. https://doi.org/10.3390/en13040844

APA StyleZhang, X., Li, Y.-Z., Wang, A.-B., Gao, L.-J., Xu, H.-J., & Ning, X.-W. (2020). The Development Strategies and Technology Roadmap of Bioenergy for a Typical Region: A Case Study in the Beijing-Tianjin-Hebei Region in China. Energies, 13(4), 844. https://doi.org/10.3390/en13040844