Novel Uninterruptible Phase-Separation Passing and Power Quality Compensation Scheme Based on Modular Multilevel Converter for Double-Track Electrified Railway

Abstract

:1. Introduction

- (1)

- This paper puts forward a novel uninterruptible phase separation passing and power quality compensation scheme for double-track electrified railway. It can comprehensively solve the problem of over-voltages and current during locomotive passing phase separation and negative sequence current due to three-phase unbalance seen from public power systems.

- (2)

- Three working modes are proposed for the UPSP-PQC scheme, including UPSP mode, PQC mode and UPSP priority, and PQC optimum mode. These working modes can ensure that the locomotive passes PS without a loss of power supply and realize optimal power quality compensation at the same time.

- (3)

- The three-leg modular multilevel converter (MMC) topology of UPSP-PQC is proposed. The corresponding control double-loop control strategies are designed. The PSCAD/EMTDC simulation model is built to verify the effectiveness of the proposed PSP-PQC scheme and its control strategies.

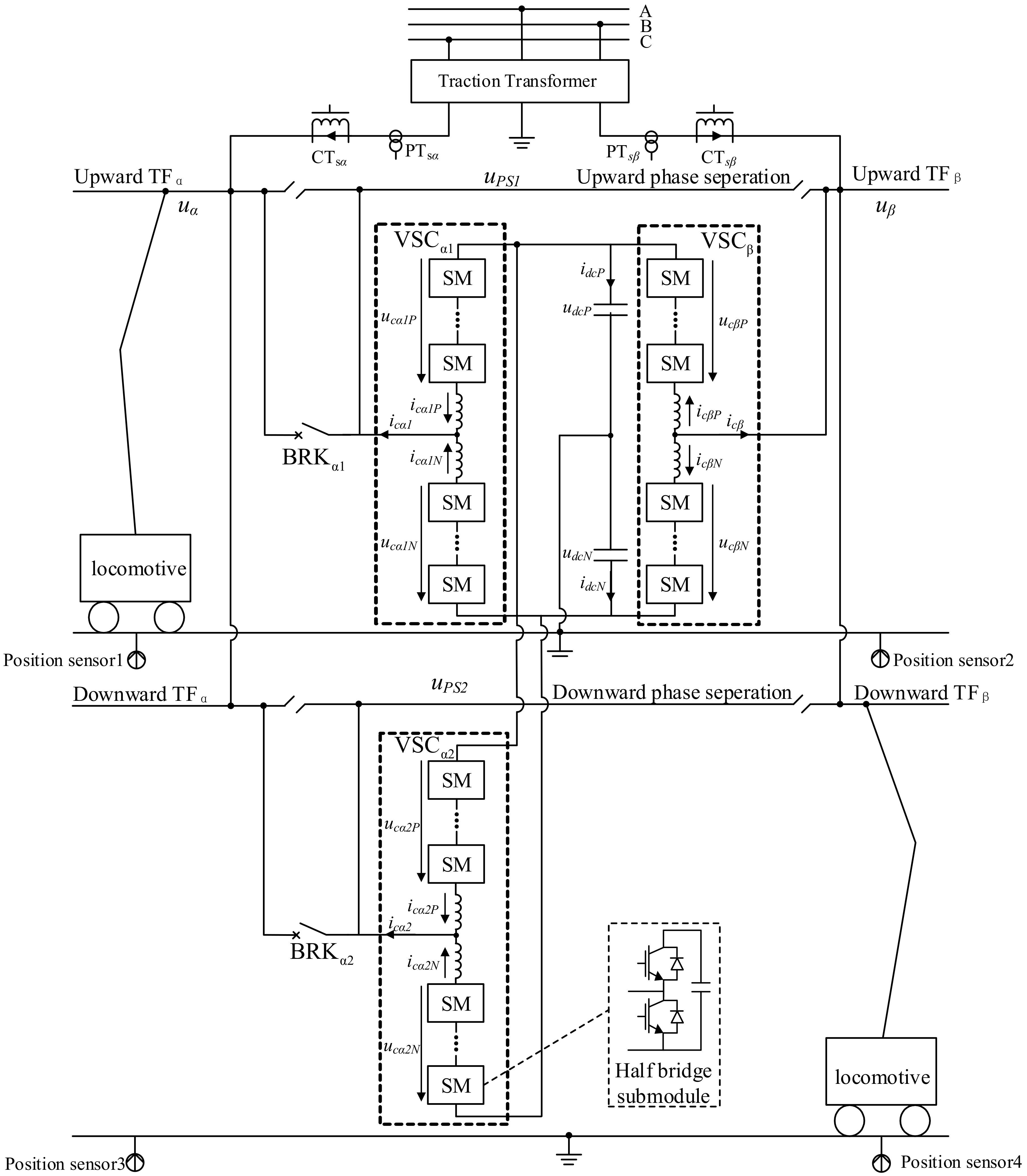

2. System Diagram of UPSP-PQC for Double-Track Electrified Railway

3. Working Modes and Principle Analysis of UPSP-PQC

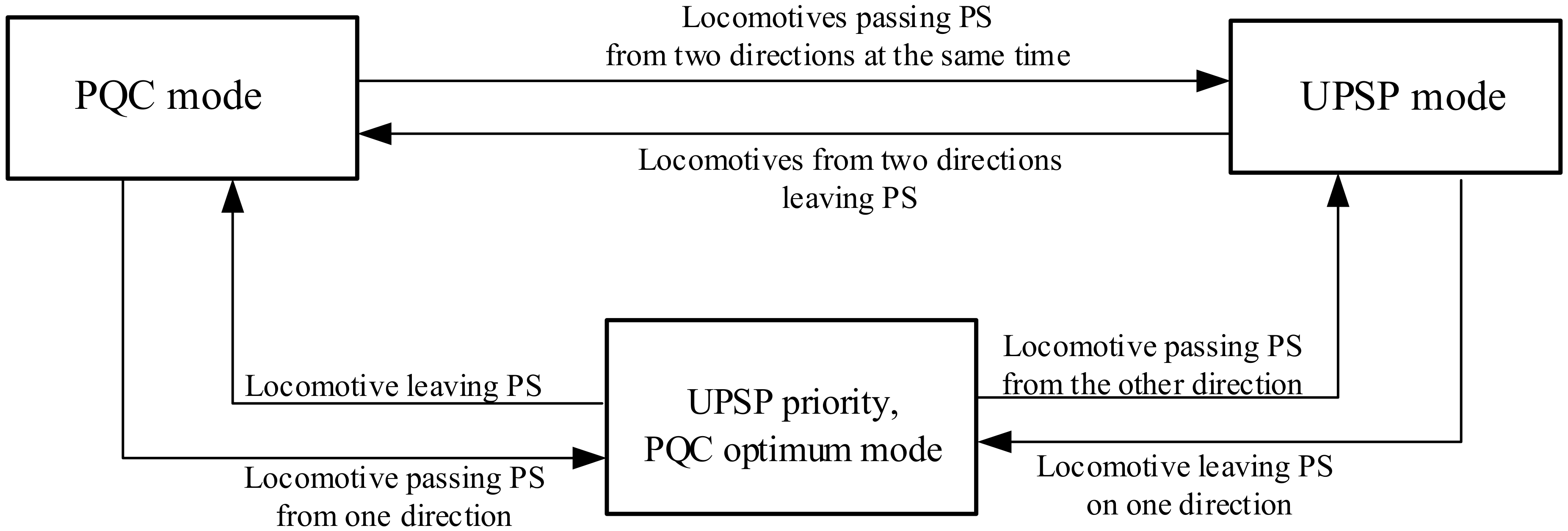

3.1. Analysis of Working Modes

- (1)

- UPSP mode: The UPSP-PQC scheme works in the UPSP mode when there are locomotives passing PS from both upward and downward direction at the same time. Under this mode, and are all disconnected. absorbs active power from TFβ. and transfer active power to upward and downward TFα and make locomotives pass PS without power loss according to the principle given in Section 3.2.

- (2)

- PQC mode: When there is no locomotive passing PS from either directions, UPSP-PQC works in PQC mode. and are both closed. The output power of is equal to the compensation power required by the phase, but the output power of and is half the compensation power required by the phase.

- (3)

- UPSP priority, PQC optimum mode: If there is a locomotive passing through PS from only one direction, UPSP-PQC scheme works in UPSP priority, PQC optimum mode. The circuit breaker on the direction of the locomotive passing through PS is disconnected, and the corresponding converter works in UPSP mode, providing power to the locomotive. The circuit breaker of the other direction is closed. The converter on this direction and works in the power quality compensation mode, and the output power is equal to the compensation power required by the phase and phase respectively. The switching conditions in three working modes of UPSP-PQC scheme are shown in Figure 3.

3.2. Working Principle of UPSP Mode

3.3. Working Principle of PQC Mode

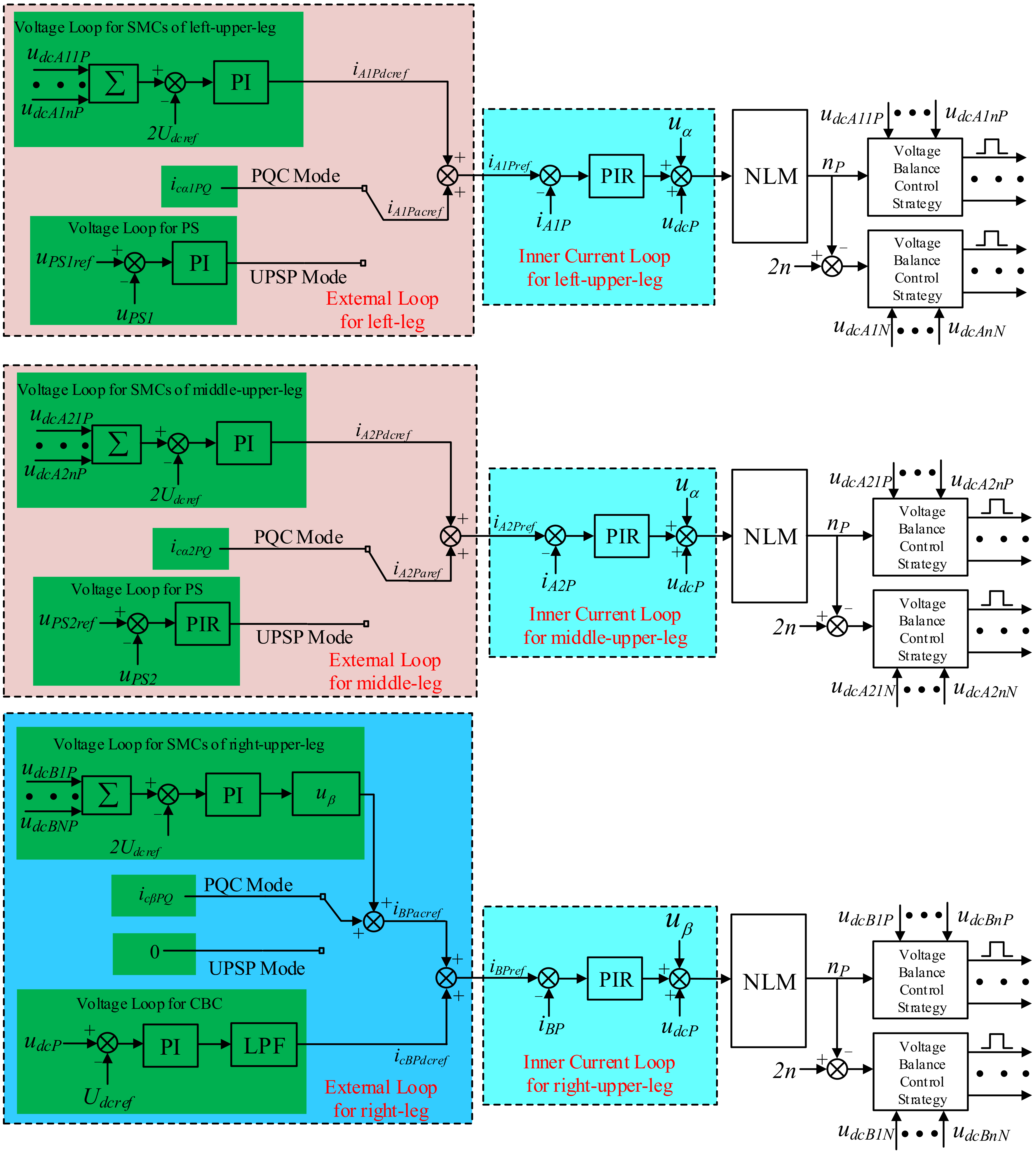

4. Control Strategy of Three-Leg MMC-Based UPSP-PQC Scheme

- (I)

- When it works in the UPSP mode, the right leg converter absorbs active power from TFβ by controlling the AC current and transfers power to the left leg and middle leg. The output voltage of the left-leg and middle-leg converter are regulated according to the principle given above during the phase-shifting process. When UPSP-PQC operates in the PQC mode, the currents in the left, middle and right legs correspond to Equation (2) to minimize the negative sequence current flowing into the PPS.

- (II)

- The DC voltages of the common bus capacitors remain stable, and the DC voltages of the sub-module capacitors (SMCs) are equal.

4.1. External Control Loop

4.2. Internal Control Loop

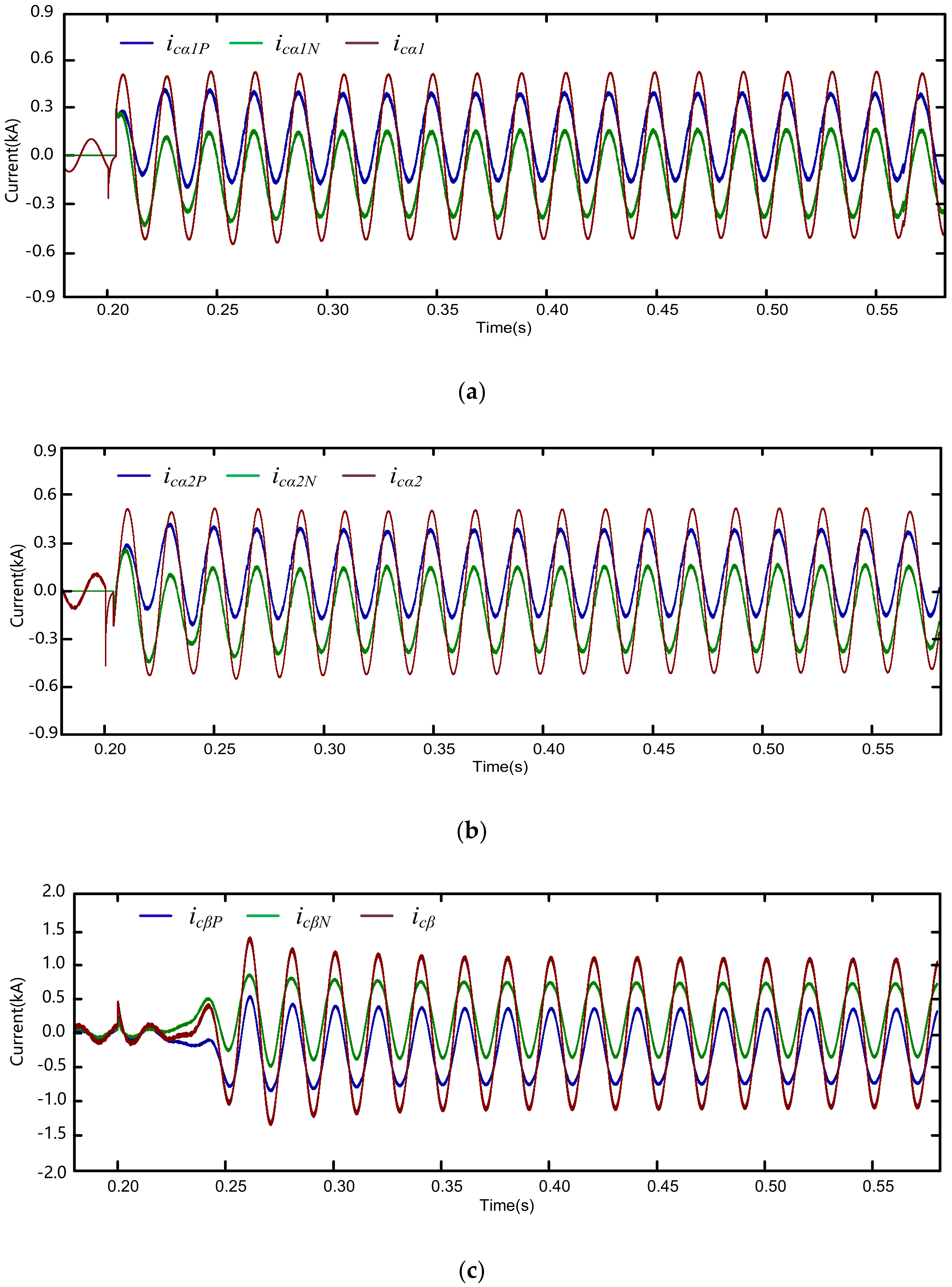

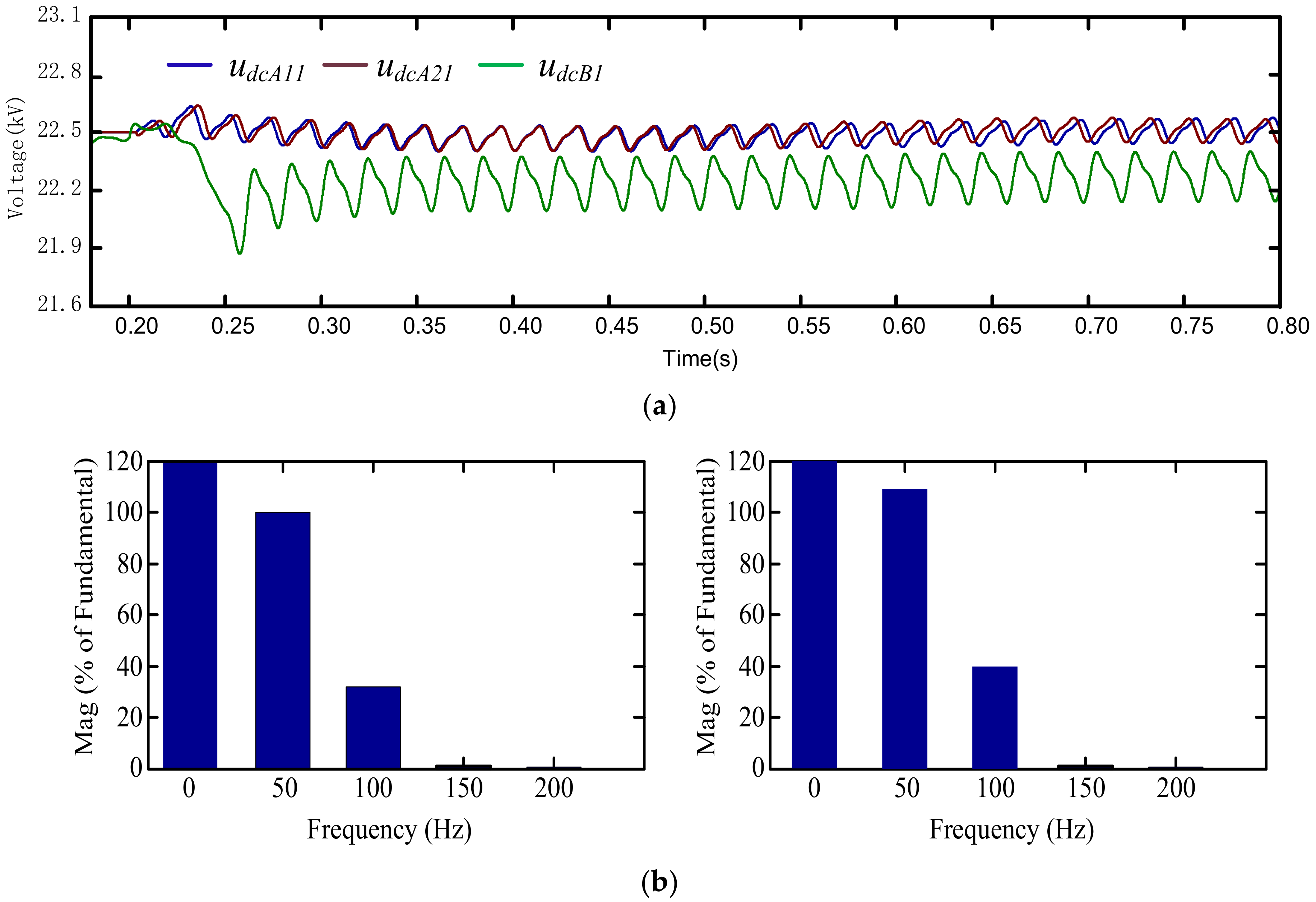

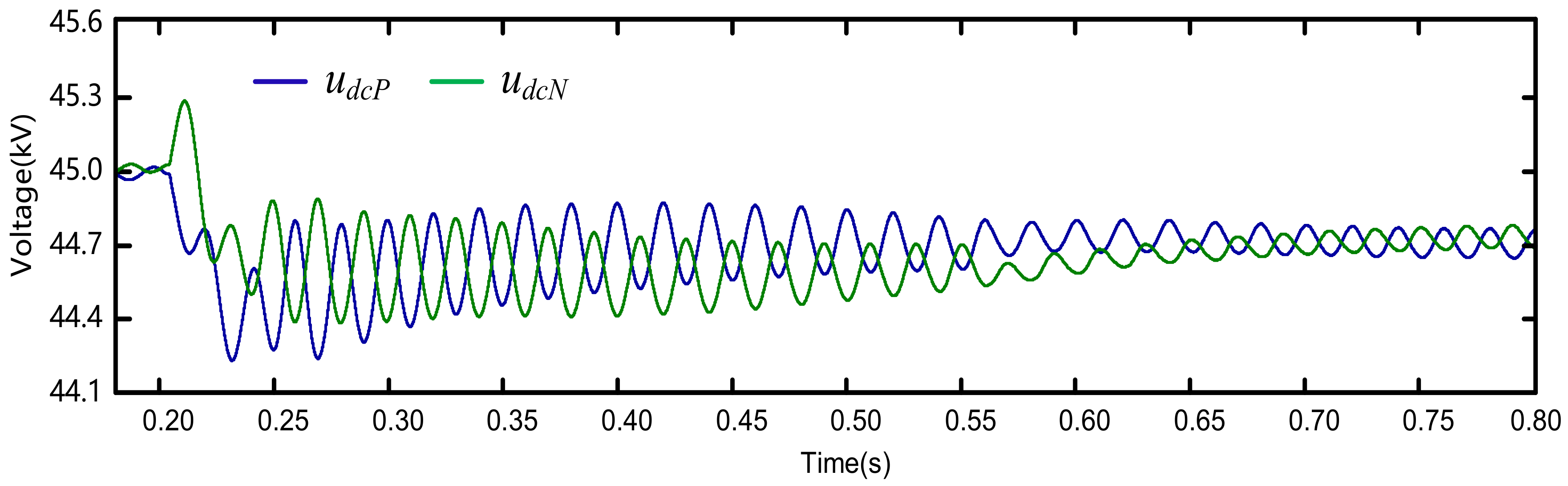

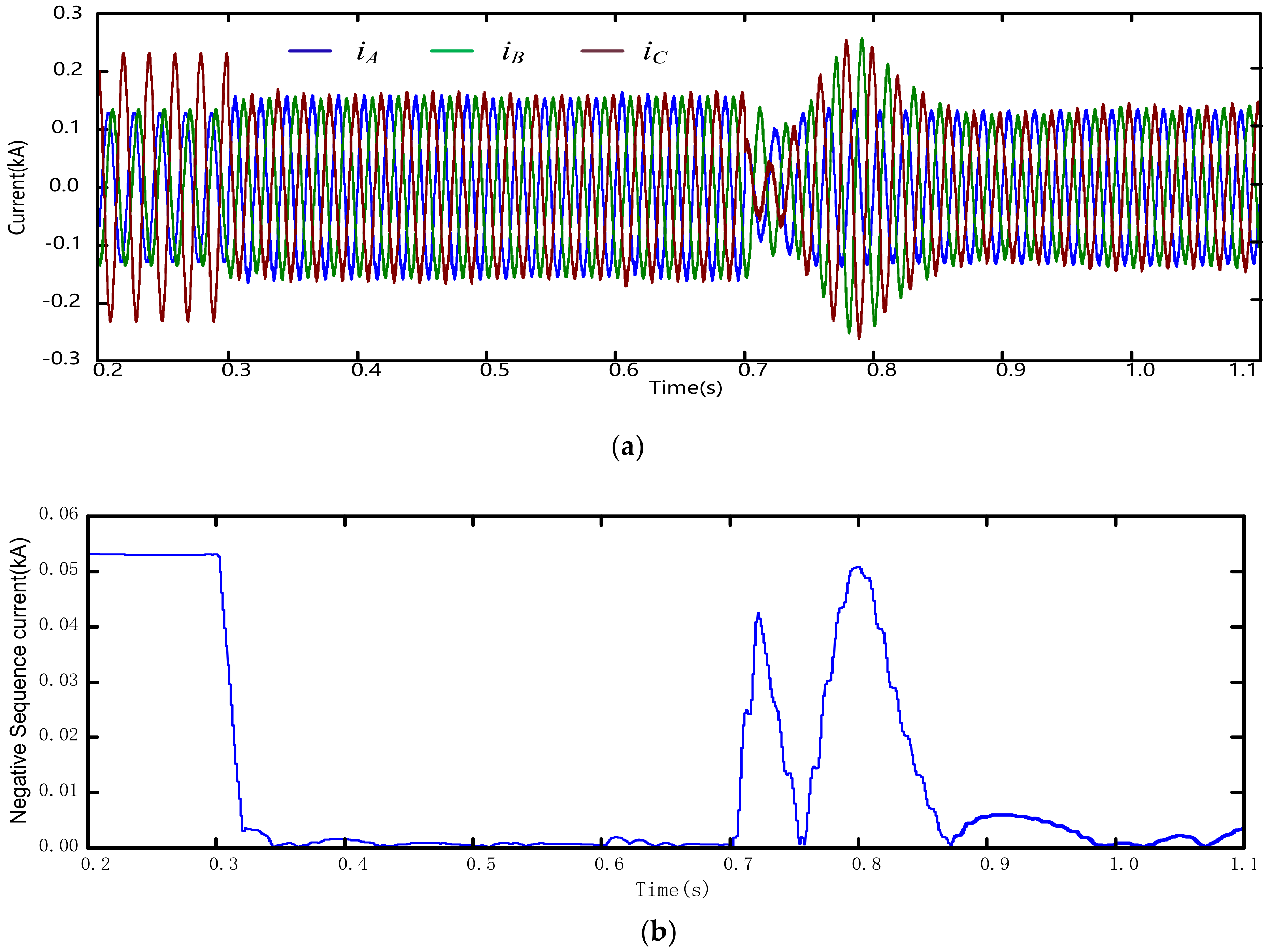

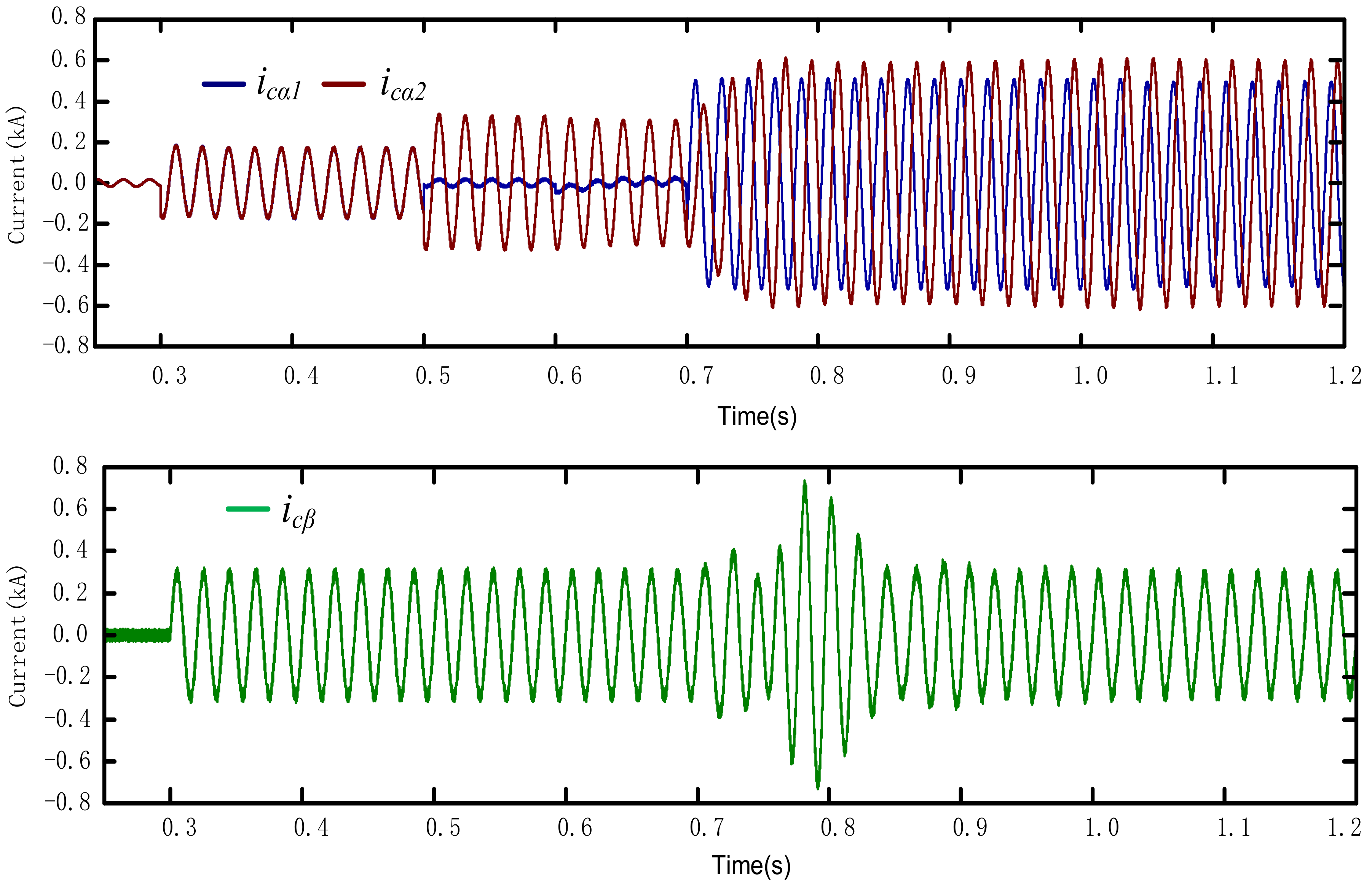

5. Simulation Verification

5.1. Simulation Result of UPSP Mode

5.2. Simulation Result for UPSP Priority, PQC Optimum Mode

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Unit | Definition |

| Hz | Frequency of phase traction feeder voltages | |

| Hz | Frequencies of phase separation voltages | |

| rad | Phases of phase traction feeder voltages | |

| kV | Instantaneous value of phase traction feeder voltage | |

| kV | delay of and by a quarter of voltage period | |

| kV | Instantaneous value of the phase-separation voltage | |

| kV | Instantaneous value reference of the phase-separation voltage | |

| s | Transition time of phase shifting | |

| kA | Output current of , and | |

| kA | Compensation current reference under power compensation mode | |

| kV | Voltages of common DC capacitors | |

| kV | Voltages of one sub-module capacitor in , , | |

| , | MW | Total active power of the locomotive powered by TFα, TFβ |

| MVar | Total reactive power of the locomotive powered by TFα, TFβ | |

| MW | Active power output of | |

| MVar | Reactive power output of |

References

- Lucca, G. Influence of railway line characteristics in inductive interference on railway track circuits. IET Sci. Meas. Technol. 2019, 13, 9–16. [Google Scholar]

- Madane, S.; Deokar, S.A. Harmonic mitigation in traction supply system by using half bridge converter. In Proceedings of the 2017 International Conference on Data Management, Analytics and Innovation (ICDMAI), Pune, India, 24–26 February 2017; pp. 161–165. [Google Scholar]

- Kandaev, V.A.; Avdeeva, K.V.; Utkina, A.V. Determination of Electrical Quantities in the Traction Rail Network and Buried Pipelines Located Under the Influence of Stray Currents from Electrified Railway Transport. In Proceedings of the 2018 Dynamics of Systems, Mechanisms and Machines (Dynamics), Omsk, Russia, 13–15 November 2018; pp. 1–8. [Google Scholar]

- Kong, W.; Ma, K.; Wu, Q. Three-Phase Power Imbalance Decomposition into Systematic Imbalance and Random Imbalance. IEEE Trans. Power Syst. 2018, 33, 3001–3012. [Google Scholar]

- Ma, F.; Xu, Q.; He, Z.; Tu, C.; Shuai, Z.; Luo, A.; Li, Y.; Ma, F.; Shuai, Z. A Railway Traction Power Conditioner Using Modular Multilevel Converter and Its Control Strategy for High-Speed Railway System. IEEE Trans. Transp. Electrif. 2016, 2, 96–109. [Google Scholar]

- Yeh, C.; Manjrekar, M.D. A Reconfigurable Uninterruptible Power Supply System for Multiple Power Quality Applications. IEEE Trans. Power Electron. 2007, 22, 1361–1372. [Google Scholar]

- Liu, M.; Lu, Y.; Wei, H.; Zhu, X.; Kong, Z.; Zhao, L.; Zhao, S.; Bai, M. Experimental Research on Articulated Electric Phase Separation Overvoltage. Electrified Railw. 2007, 14, 15–17. [Google Scholar]

- Lao, K.-W.; Wong, M.-C.; Dai, N.Y.; Wong, C.-K.; Lam, C.-S. Analysis of DC-Link Operation Voltage of a Hybrid Railway Power Quality Conditioner and Its PQ Compensation Capability in High-Speed Cophase Traction Power Supply. IEEE Trans. Power Electron. 2016, 31, 1643–1656. [Google Scholar]

- Long, Y.; Xiao, X.; Xu, Y.; Baolai, Y.; Xu, Y.; Hao, J. MMC-UPQC: Application of Modular Multilevel Converter on Unified Power Quality Conditioner. In Proceedings of the 2013 IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013; pp. 1–5. [Google Scholar]

- Fu, G.; Qiu, L.; Hu, J. Research on Flexible Ground Automatic Neutral-Section Passing Technology Base on Voltage Compensation. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; pp. 1–7. [Google Scholar]

- Hu, H.; He, Z.; Li, X.; Wang, K.; Gao, S. Power-Quality Impact Assessment for High-Speed Railway Associated With High-Speed Trains Using Train Timetable—Part I: Methodology and Modeling. IEEE Trans. Power Deliv. 2015, 31, 693–703. [Google Scholar]

- Wang, Q.; Lu, J.; Wang, Q.; Duan, J. Transient overvoltage study of auto-passing neutral section in high-speed railway. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–5. [Google Scholar]

- Liu, Z.; Hu, X.; Liao, Y. Vehicle-Grid System Stability Analysis Based on Norm Criterion and Suppression of Low-Frequency Oscillation with MMC-STATCOM. IEEE Trans. Transp. Electrif. 2018, 4, 757–766. [Google Scholar]

- Rodrigues, P.; Morais, V.A.; Martins, A.; Carvalho, A. STATCOM Simulation Models for Analysis of Electrified Railways. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 2257–2262. [Google Scholar]

- Chen, M.; Chen, Y.; Wei, M. Modeling and Control of a Novel Hybrid Power Quality Compensation System for 25-kV Electrified Railway. Energies 2019, 12, 3303. [Google Scholar]

- Ma, Q.; Guo, X.; Luo, P.; Zhang, Z. Coordinated Control Strategy Design of New Railway Power Conditioner Based on Super Capacitor Energy Storage. Trans. China Electrotech. Soc. 2019, 34, 765–776. [Google Scholar]

- Ma, Q.; Tan, L.; Luo, P. Negative sequence optimization compensation strategy for hybrid power quality control system of V/v traction power supply station. Electr. Power Autom. Equip. 2017, 37, 128–132. [Google Scholar]

- Luo, P.; Li, Q.; Ma, Q. Multi-scenario Capacity Optimization Design of Railway Power Conditioner Considering Load Uncertainty. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 2714–2719. [Google Scholar]

- Park, S.; Salkuti, S.R. Optimal Energy Management of Railroad Electrical Systems with Renewable Energy and Energy Storage Systems. Sustainability 2019, 11, 6293. [Google Scholar]

- Hosseini, S.M.; Carli, R.; Dotoli, M. Robust Day-Ahead Energy Scheduling of a Smart Residential User Under Uncertainty. In Proceedings of the 2019 18th European Control Conference (ECC), Naples, Italy, 25–28 June 2019; pp. 935–940. [Google Scholar]

- Carli, R.; Dotoli, M. Decentralized control for residential energy management of a smart users’ microgrid with renewable energy exchange. IEEE CAA J. Autom. Sin. 2019, 6, 641–656. [Google Scholar]

- Geidl, M.; Koeppel, G.; Favre-Perrod, P.; Klockl, B.; Andersson, G.; Frohlich, K. Energy hubs for the future. IEEE Power Energy Mag. 2007, 5, 24–30. [Google Scholar]

- Dai, N.; Wong, C.; Wong, M.; Lao, K. Hybrid power quality conditioner for co-phase power supply system in electrified railway. IET Power Electron. 2012, 5, 1084–1094. [Google Scholar]

- Ricco, M.; Mathe, L.; Monmasson, E.; Teodorescu, R. FPGA-Based Implementation of MMC Control Based on Sorting Networks. Energies 2018, 11, 2394. [Google Scholar]

- Moranchel, M.; Huerta, F.; Sanz, I.; Bueno, E.; Rodríguez, F. A Comparison of Modulation Techniques for Modular Multilevel Converters. Energies 2016, 9, 1091. [Google Scholar]

- Zhou, F.; Luo, A.; Li, Y.; Xu, Q.; He, Z.; Guerrero, J.M. Double-Carrier Phase-Disposition Pulse Width Modulation Method for Modular Multilevel Converters. Energies 2017, 10, 581. [Google Scholar]

| V/V and YNd11 | Scott and Impedance Matching Balance |

|---|---|

| Symbol | Description | Value |

|---|---|---|

| RMS voltage of TF | 27.5 kV | |

| Voltage frequency of PPS | 50 Hz | |

| N | Number of SMs in each arm | 4 |

| , | Voltage of common DC capacitor | 22.5 kV |

| SM capacitance | ||

| Arm inductance | 18 mH | |

| Control frequency (selecting and sorting) | 10 kHz | |

| Carrier frequency | 10 kHz |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, X.; Li, X.; Zhou, Z. Novel Uninterruptible Phase-Separation Passing and Power Quality Compensation Scheme Based on Modular Multilevel Converter for Double-Track Electrified Railway. Energies 2020, 13, 738. https://doi.org/10.3390/en13030738

Tian X, Li X, Zhou Z. Novel Uninterruptible Phase-Separation Passing and Power Quality Compensation Scheme Based on Modular Multilevel Converter for Double-Track Electrified Railway. Energies. 2020; 13(3):738. https://doi.org/10.3390/en13030738

Chicago/Turabian StyleTian, Xu, Xingcheng Li, and Zibo Zhou. 2020. "Novel Uninterruptible Phase-Separation Passing and Power Quality Compensation Scheme Based on Modular Multilevel Converter for Double-Track Electrified Railway" Energies 13, no. 3: 738. https://doi.org/10.3390/en13030738

APA StyleTian, X., Li, X., & Zhou, Z. (2020). Novel Uninterruptible Phase-Separation Passing and Power Quality Compensation Scheme Based on Modular Multilevel Converter for Double-Track Electrified Railway. Energies, 13(3), 738. https://doi.org/10.3390/en13030738