1.2. State of the Art Review

Traditional HP technologies include the vapour compression heat pump (VCHP) [

2], absorption heat pump [

3], and transcritical heat pump [

4]. Pavlas et al. [

5] developed a Process Integration methodology for an HP integrated with a biomass gasification process of a wood processing plant. Liew and Walmsley [

6] adopted a Total Site targeting method to integrate open cycle VCHP for enhancing overall site energy efficiency. Walmsley [

7] presented a Total Site Heat Integration (TSHI) method for integrated evaporation systems using a HP (vapour recompression) effectively with application to milk concentrating. Walmsley et al. [

8] performed a Pinch Analysis of hybrid compression–absorption HP process for convective dryers by employing to simulation and optimisation tools. Stampfli et al. [

9] adapted Pinch Analysis to integrating VCHP for HPs in batch processes. A hybrid method [

10] that unifies the insight-based and mathematical programming approaches has been proposed for industrial HP integration in batch processes to avoid long computation times. Another criterion EPC (i.e., the coefficient of performance in exergy per total annual cost) was proposed [

11] for selecting HPs, modelling diverse types of HPs for operating conditions. This criterion can both evaluate the thermodynamic and economic performances of HPs.

Urbanucci et al. [

12] proposed a two-level optimisation algorithm for the high-temperature HP integration in a trigeneration system. The proposed model allowed them to analyse the HP performance for various working fluids and operating conditions. Schlosser et al. [

13] developed a model for evaluation of the efficiency gains of combining HP storage and intelligent system control for integrating multiple heat sources and sinks, reporting a significant reduction in energy demand. To integrate heat-upgrading technologies in process sites, Oluleye et al. [

14] developed a systems-oriented criterion for conceptual screening and selection of HPs. A Mixed Integer Linear Programming (MILP) framework has been developed [

15]. The screening criterion measured the exergy degradation of technology options. However, the techniques presented in that work are only applicable to conceptual system design. Goumba et al. [

16] considered the different waste heat sources and proposed the “Recov’Heat” tool, for minimising the utility demands, which makes the heat pumping task easier.

The above studies only use known models to consider the integration of VCHP and processes. Some of the older HP types used Freon as a working fluid. However, Freon is no longer used because of its negative impact on the Earth’s atmospheric ozone [

17]. In addition to the improvement the Coefficient of Performance (COP) of HPs and effective utilisation of the energy input, to further improve the environmental protection, engineers are committed to the development of new working fluids and HP technologies. HP applications are also in continuous development, is widely used in air conditioning and industrial fields and playing a significant role in terms of energy-saving and environmental protection.

Another type of HP with a commercial application is the TCHP, which uses CO

2 as a working fluid. CO

2 is a natural refrigerant, commonly known under the label “R744”. It has a relatively low global warming potential (GWP) value of only 1 and does not cause damage to the ozone layer. It is non-toxic, non-flammable, low-cost and easy to obtain. At present, hot water systems with CO

2 HPs usually adopt a transcritical cycle. In the early 1990s, Lorentzen [

4] proposed a transcritical CO

2 cycle based on the specific physical properties of CO

2, which significantly promoted the development of CO

2 systems in the field of refrigeration. Over the past twenty years, research institutions and enterprises in many countries around the world have done a lot of research on TCHP, which has become a research hotspot in the field of refrigeration. The exothermic process of significant temperature change (~80–100 °C) on the high-pressure side of the transcritical CO

2 system is very suitable for hot water heating. As a result, research on transcritical CO

2 HPs (TCHP) started as a hot water heater. Nekså et al. [

18] built a test device for a hot water HP system. The first demonstration TCHP water heater [

19] was established for industrial use. Kim et al. [

20] used a combined scroll expander–compressor unit in a two-stage compression CO

2 transcritical cycle to improve the cycle COP. Van de Bor et al. [

21] compared several heat recovery technologies based on HPs and heat engines. Integration schemes with processes are not considered.

In VCHP and TCHP, the working fluid undergoes a phase change in at least one of the constituent processes, during which it absorbs or releases heat from the heat source to the heat exchanger (HX). This dependence on latent heat transfer may be a problem in some applications where average temperature variation is significant, exergy transfer efficiency is low, and COP is low. Fu and Gundersen [

22] developed a HP for industrial applications based on the Joule cycle (which they called a reversed Brayton cycle). The operating parameters are investigated by thermodynamic and mathematical models, applying Pinch Analysis and Appropriate Placement rules. The provided case studies also illustrate the Hest Exchanger Network (HEN) synthesis conforming to the Heat Integration targets.

ECOP (Ecop Technologies GmbH) [

23] applied a HP process based on a reverse Joule cycle (also known as Joule–Brayton or Brayton cycle) with the rotation HP implementation. Compared with the traditional HP, the Joule cycle heat pump (JCHP) features sensible heat exchange between the working fluid and process heat source/sink, which is an advantage when the process streams do not condense or evaporate or have smaller Specific Heat Capacity (CP). This provides more flexibility in accommodating process streams and achieving a higher temperature lift.

A recent work [

24] has presented a system synthesis method for HP integration in the industry. The method uses a superstructure-based mathematical model, resulting in a Mixed Integer Nonlinear Programming (MINLP) formulation, achieving performance improvements over similar previous methods of up to 30%. The model considers phase-change based HPs (mainly VCHP). As is shown in this paper, the correct choice of HP type bears the significance of an order of magnitude higher than such improvements.

Many processes need heat transfer in industrial processing and power generation. Some need heating, and some need cooling or condensation. If the heat exchange network can be appropriately designed, the utility can be minimised, and the capital investment can be reduced to achieve energy saving. Pinch Analysis, pioneered by Linnhoff and Hindmarsh [

25], has become a widely used method for the comprehensive design of heat exchange networks. The heat exchange network with minimum energy consumption can be obtained by optimising the heat recovery system, energy supply and process operation. Energy targeting is a powerful aid to process design and integration. Stampfli et al. [

9] suggested the COP equation/curve for Process Integration with VCHP. According to the COP equation, when the condensation duty provided by the process sink is known, the evaporative duty of the HP can be obtained, and the COP curve can be drawn in Grand Composite Curve (GCC). The condensation duty can also be obtained when the process is used as a source. Gai et al. [

26] extended the COP curve when the process was integrated with the JCHP. However, the COP curve for the Process Integration with a HP is derived under some assumptions or ideal conditions. Also, in the TCHP, the working fluid CO

2 is a transcritical cycle and the physical property changes substantially, so it is difficult to express the COP curve with an equation accurately.

1.3. Contributions and Novelty of This Study

A JCHP is more likely to obtain higher COP than a traditional HP under certain circumstances. However, there have been so far just a few studies on the use of JCHP and industrial processes. There is also a gap in the literature for a comparative analysis of different HP types, including the emerging JCHP. The COP equations of HP have some ideal assumptions. These results are in some deviation from the actual performance of the HP, which cannot well represent the real performance of the HP.

This study simulates and optimises the operation of the main classes of HPs in a process simulation software—Petro-SIM [

27]—to get the performance of the HP, as much close to the reality as possible. These classes include the VCHP, TCHP and the JCHP.

The setting of various parameters considers possible process configurations. All COP curves and heat duties in the GCC for process and HP integration will be plotted against the actual data calculated in Petro-SIM. The choice of HP type should be performed based on the temperature–enthalpy profile of the considered industrial process for obtaining optimal performance. In this paper, the performance and application scope of three different HP systems—JCHP, VCHP, and TCHP—are discussed and compared to understand the energy-saving potential of applying the HP.

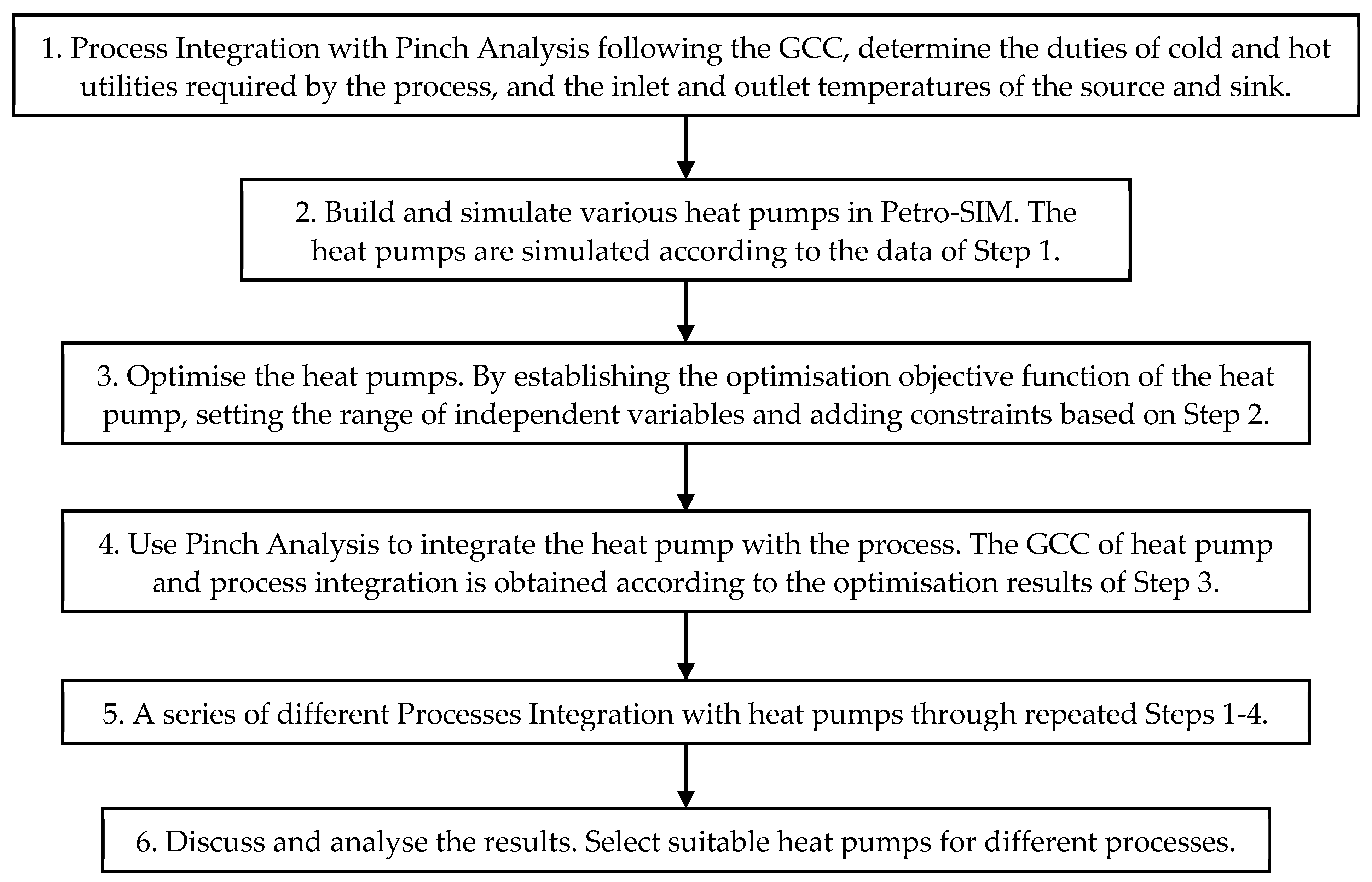

Section 2 introduces the simulation and optimisation of the considered HP types and the method of integration with the process for achieving heat recover. In

Section 3, the suitability of the HP types to different temperature–enthalpy (T–H) profiles is evaluated, aiming at the minimisation of power consumption. The optimal COP of each integration case was obtained by optimising the operating parameters of the HP when given source and sink at different temperatures. In

Section 4, the model is further applied to the integration of HP and different industrial process cases using Pinch Analysis, and the energy-saving potential of different types of HP is evaluated using the GCC [

28].