Optimization of Fracture Spacing and Well Spacing in Utica Shale Play Using Fast Analytical Flow-Cell Model (FCM) Calibrated with Numerical Reservoir Simulator

Abstract

1. Introduction

2. Field Data and Reservoir Model Predictions

2.1. Outline of Field Data Used

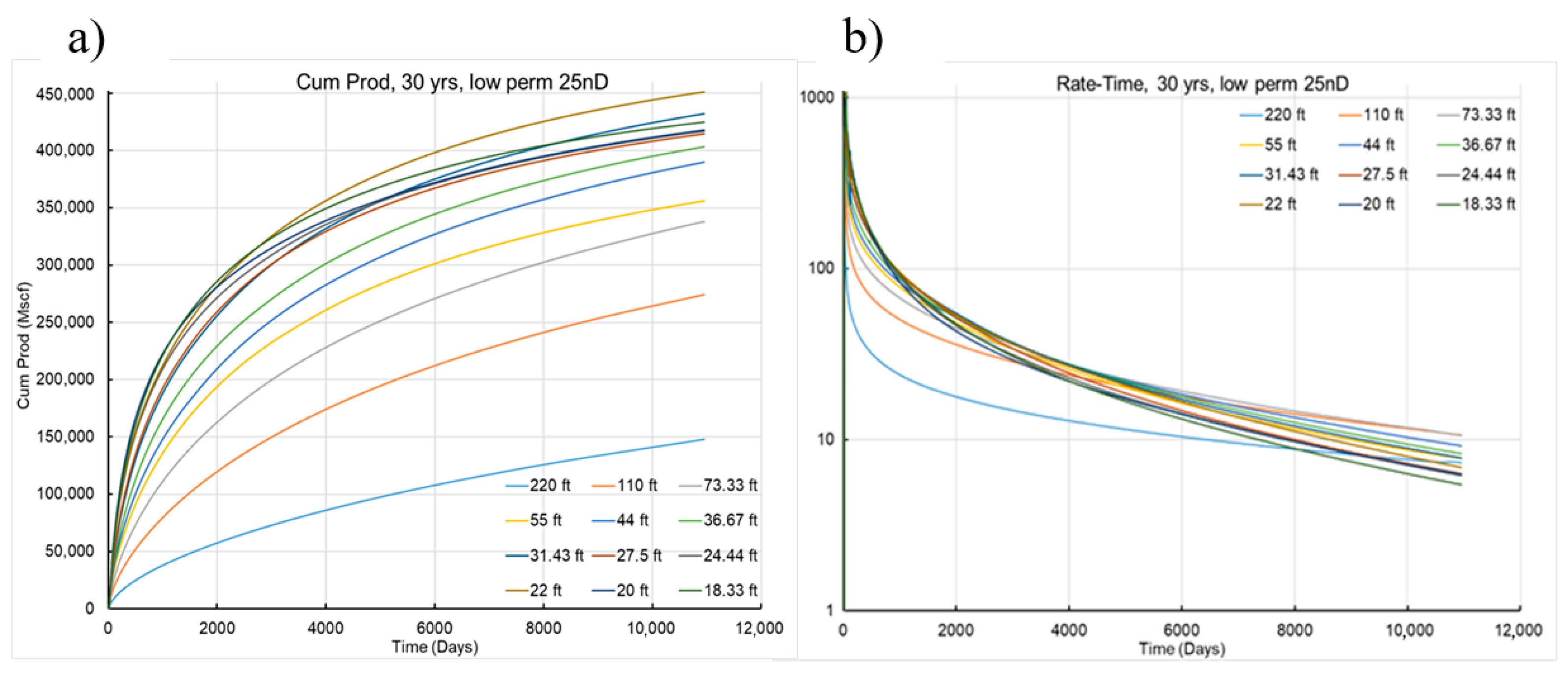

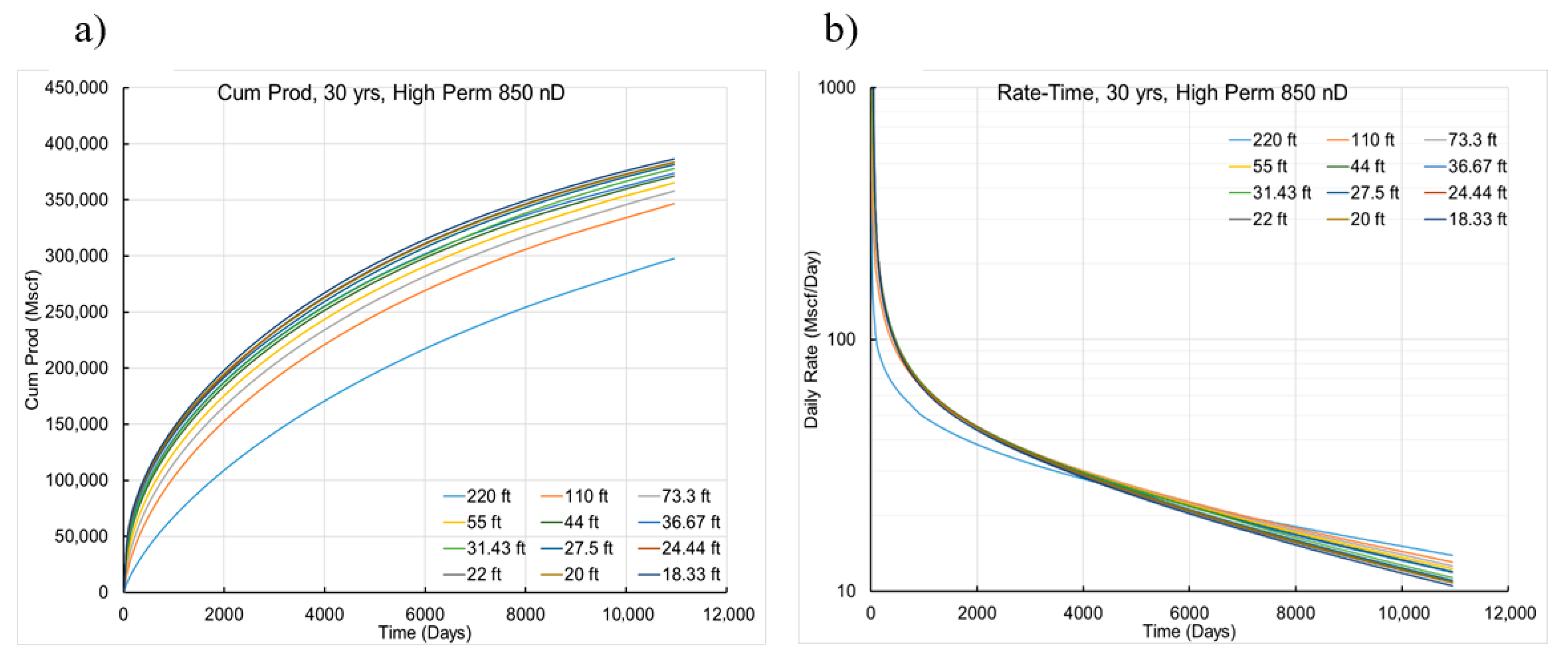

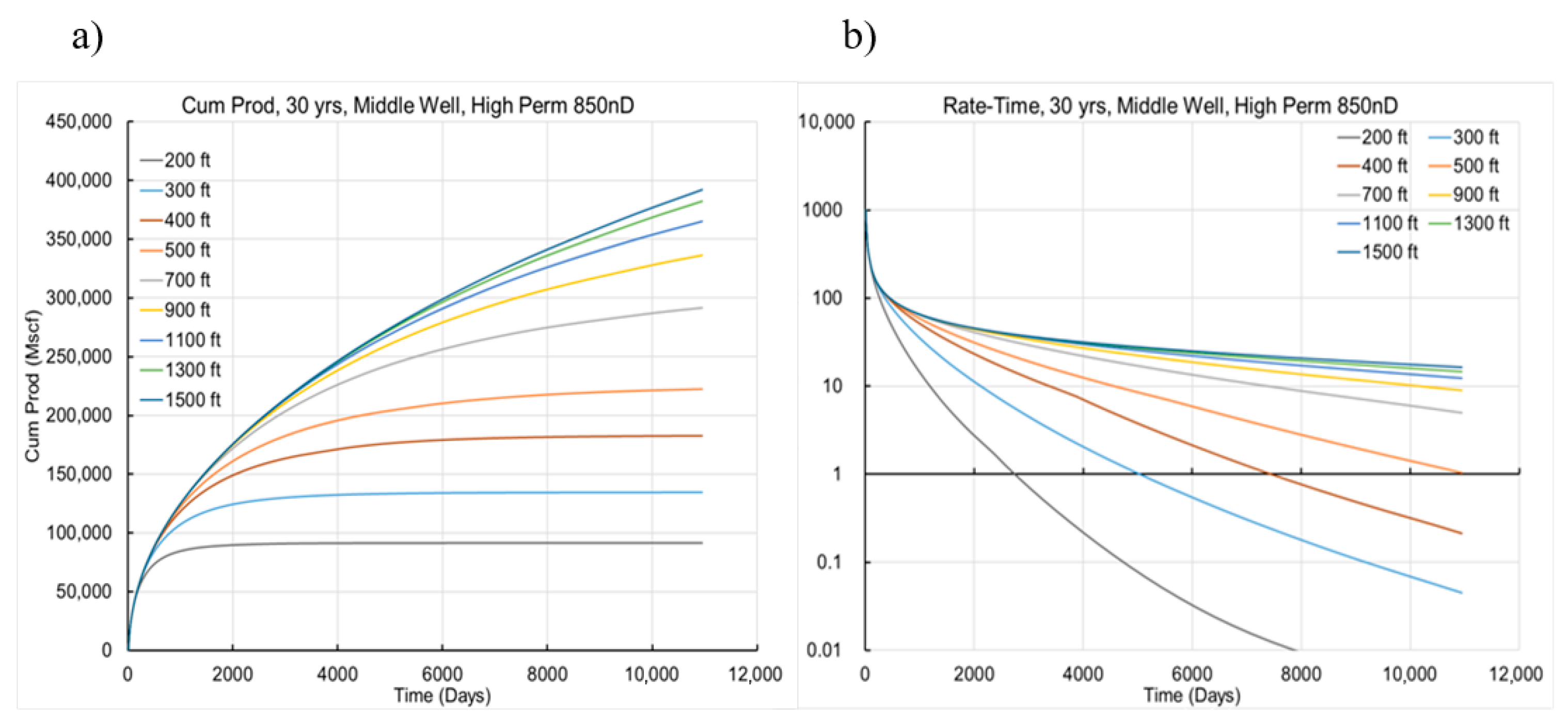

2.2. Numerical Reservoir Simulator (High Permeability Case)-Sensitivity to Fracture Spacing

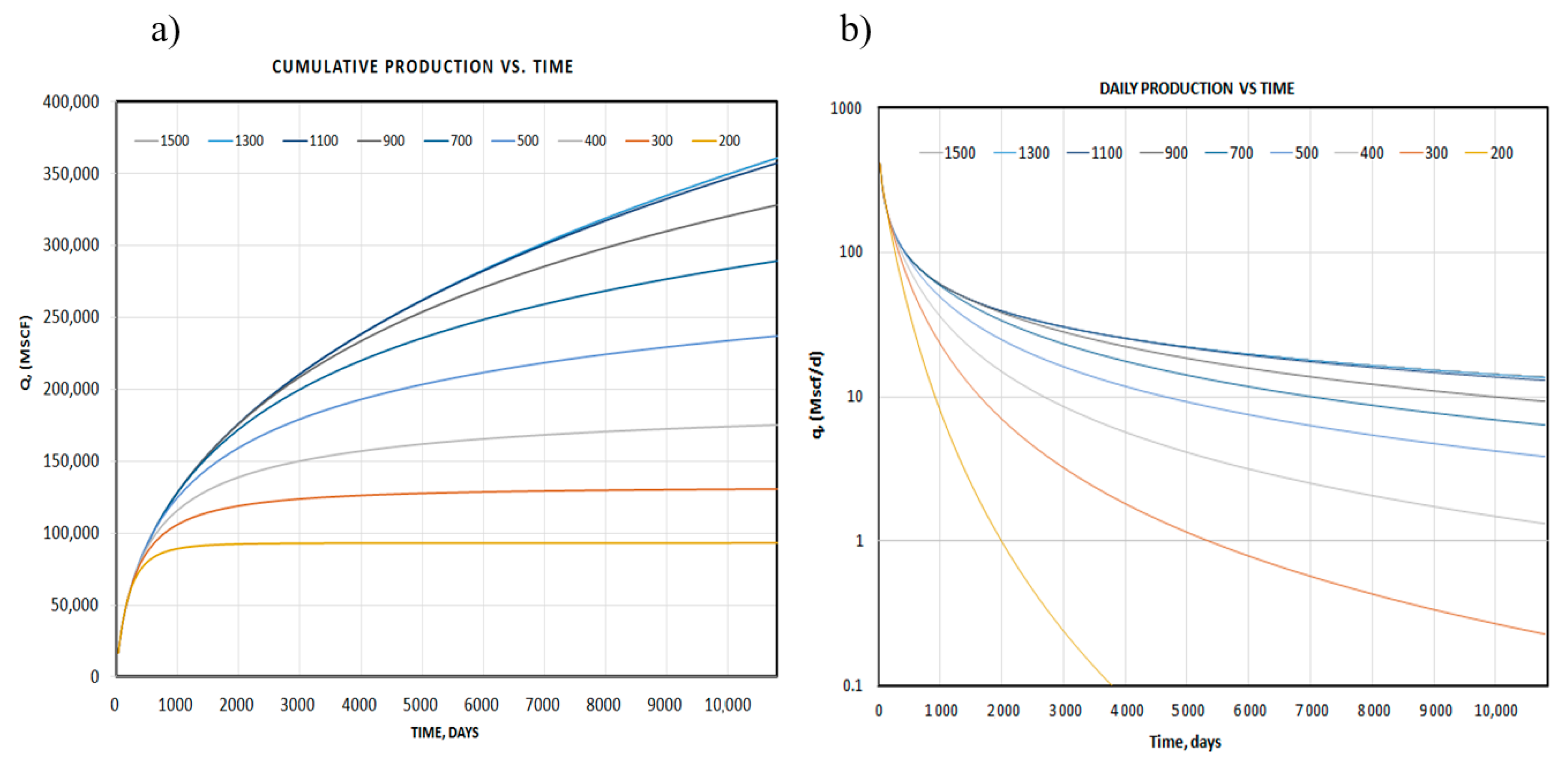

2.3. Sensitivity to Well Spacing: ResFrac Model

2.4. Reservoir Simulator Results (High Permeability Case)

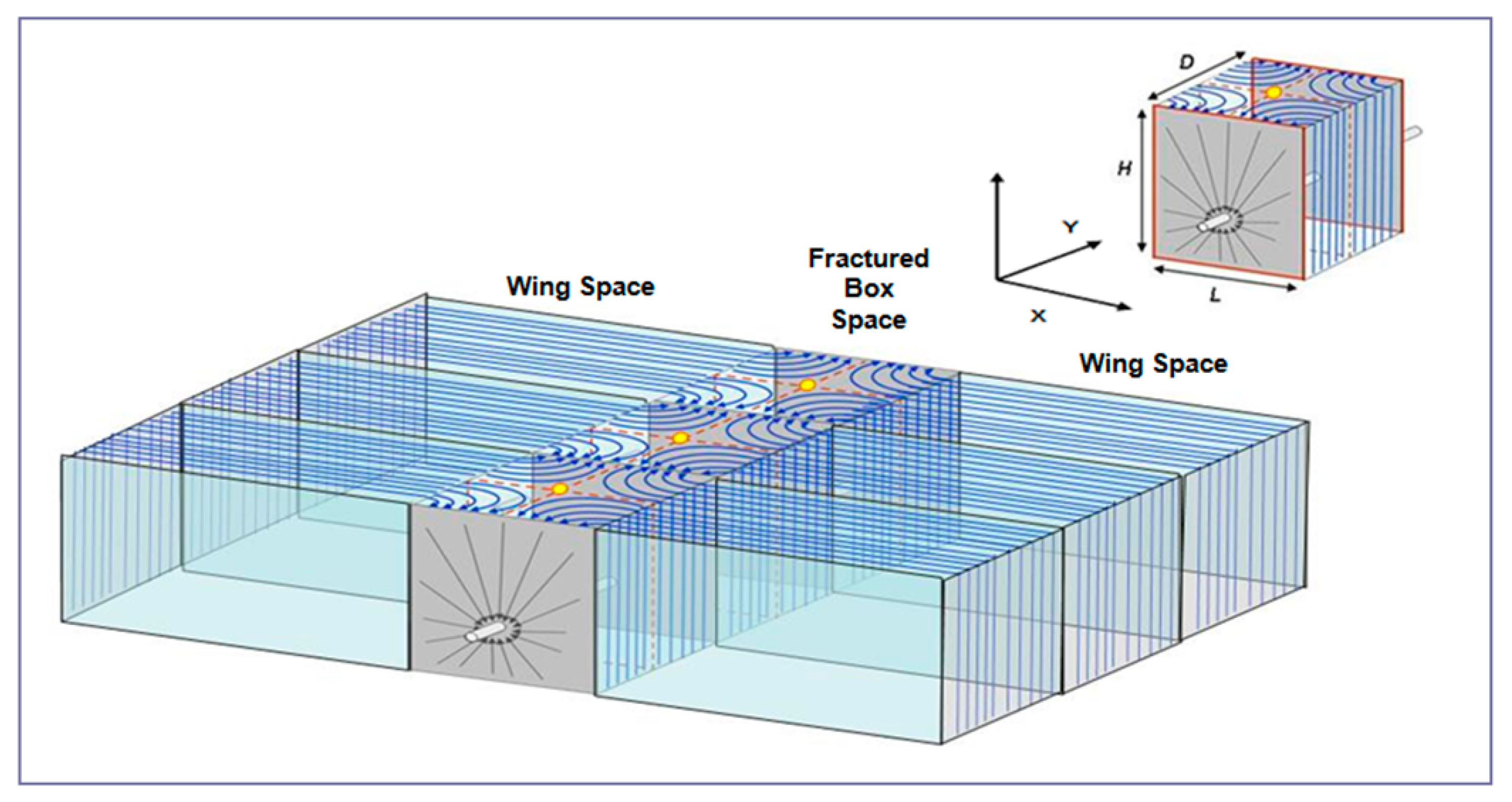

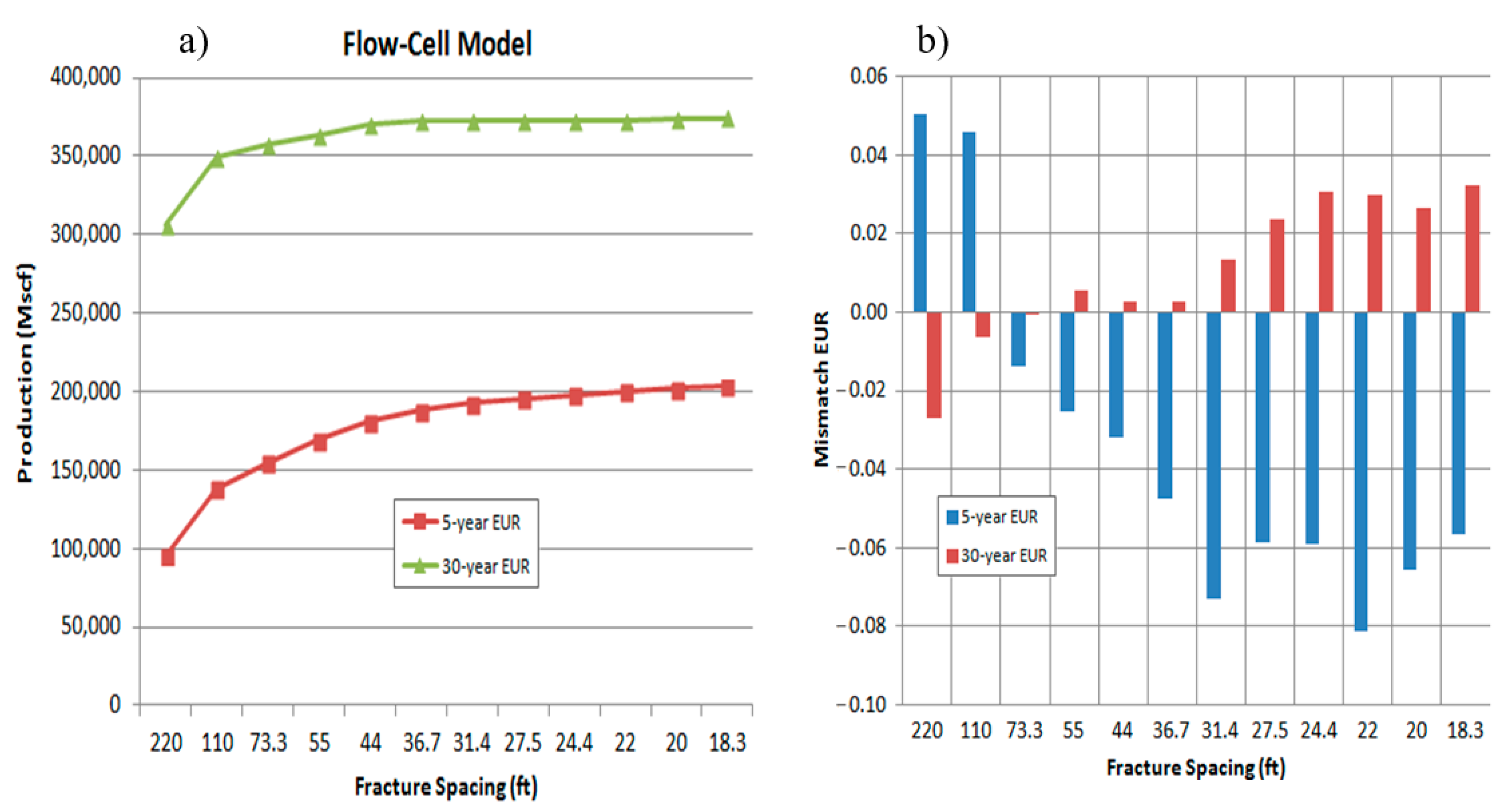

3. Flow-Cell Model Results: Fracture-Spacing Effects

3.1. Basic Assumptions

3.2. Key Algorithms

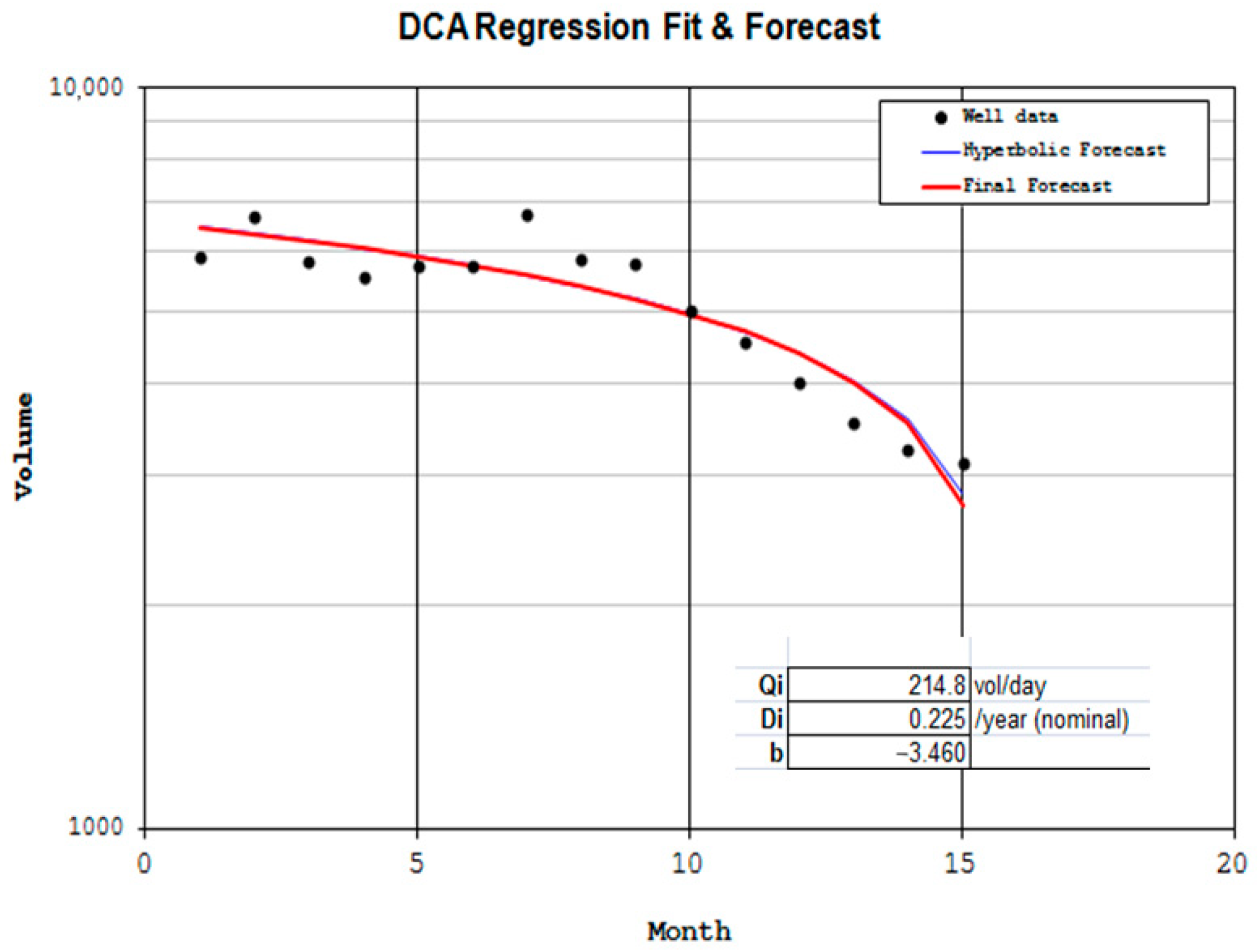

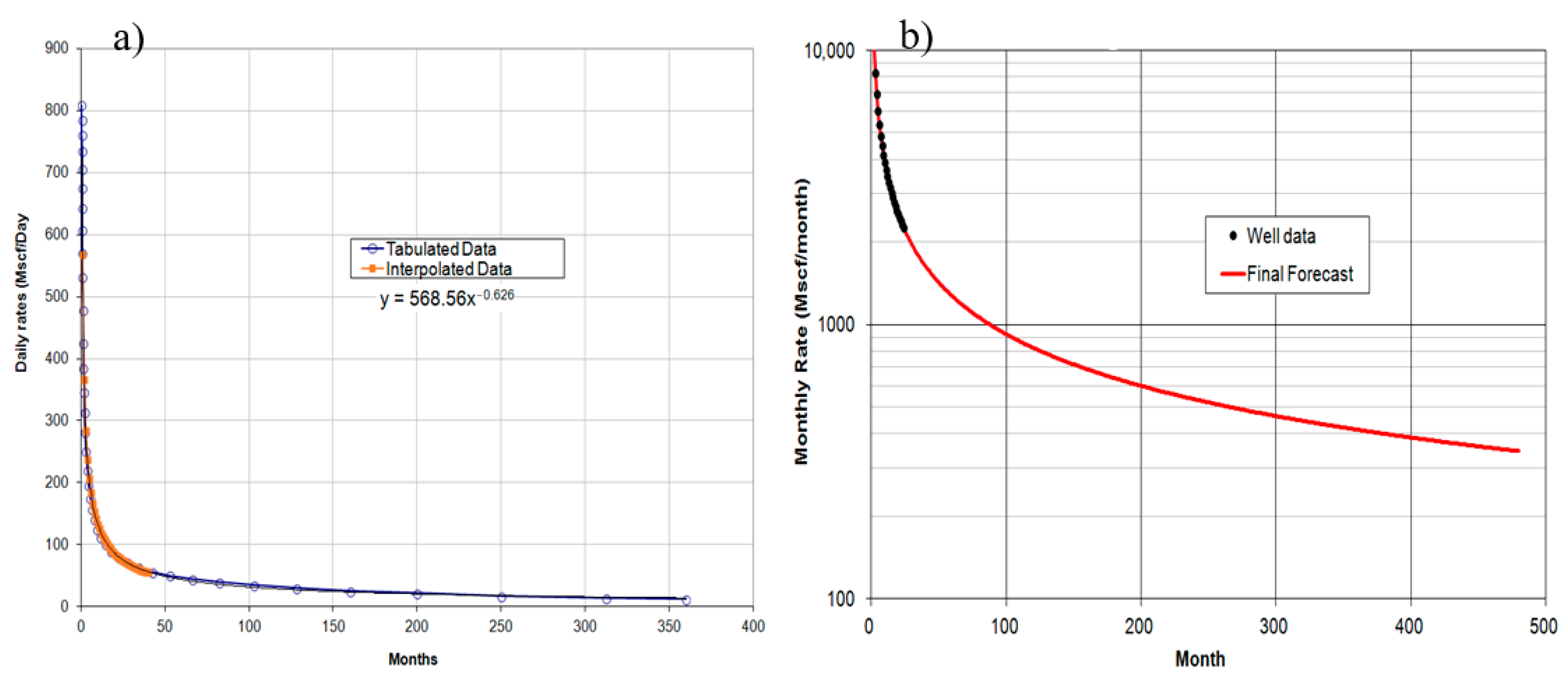

3.3. Type-Well Selection

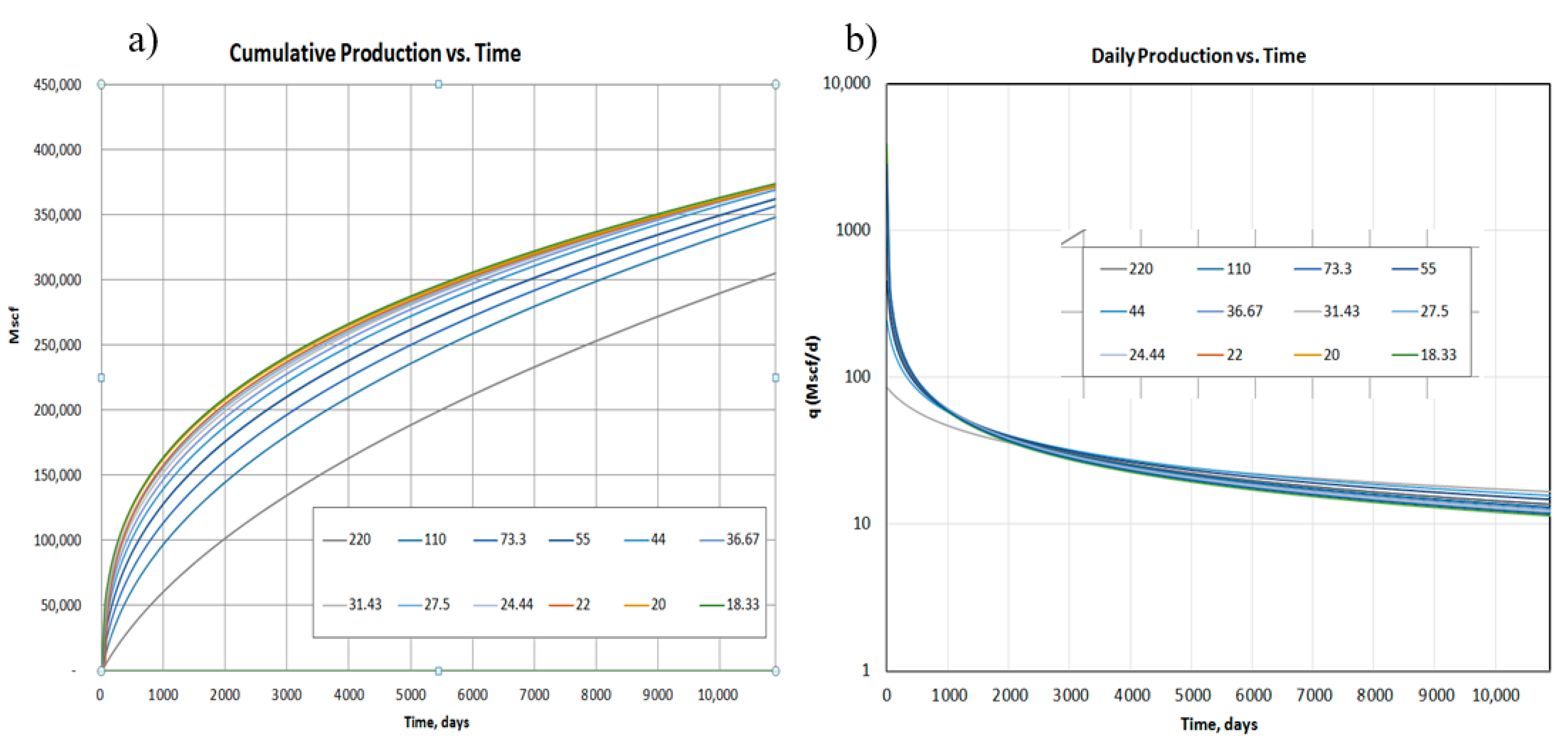

3.4. Fracture-Spacing Effects with Flow-Cell Model

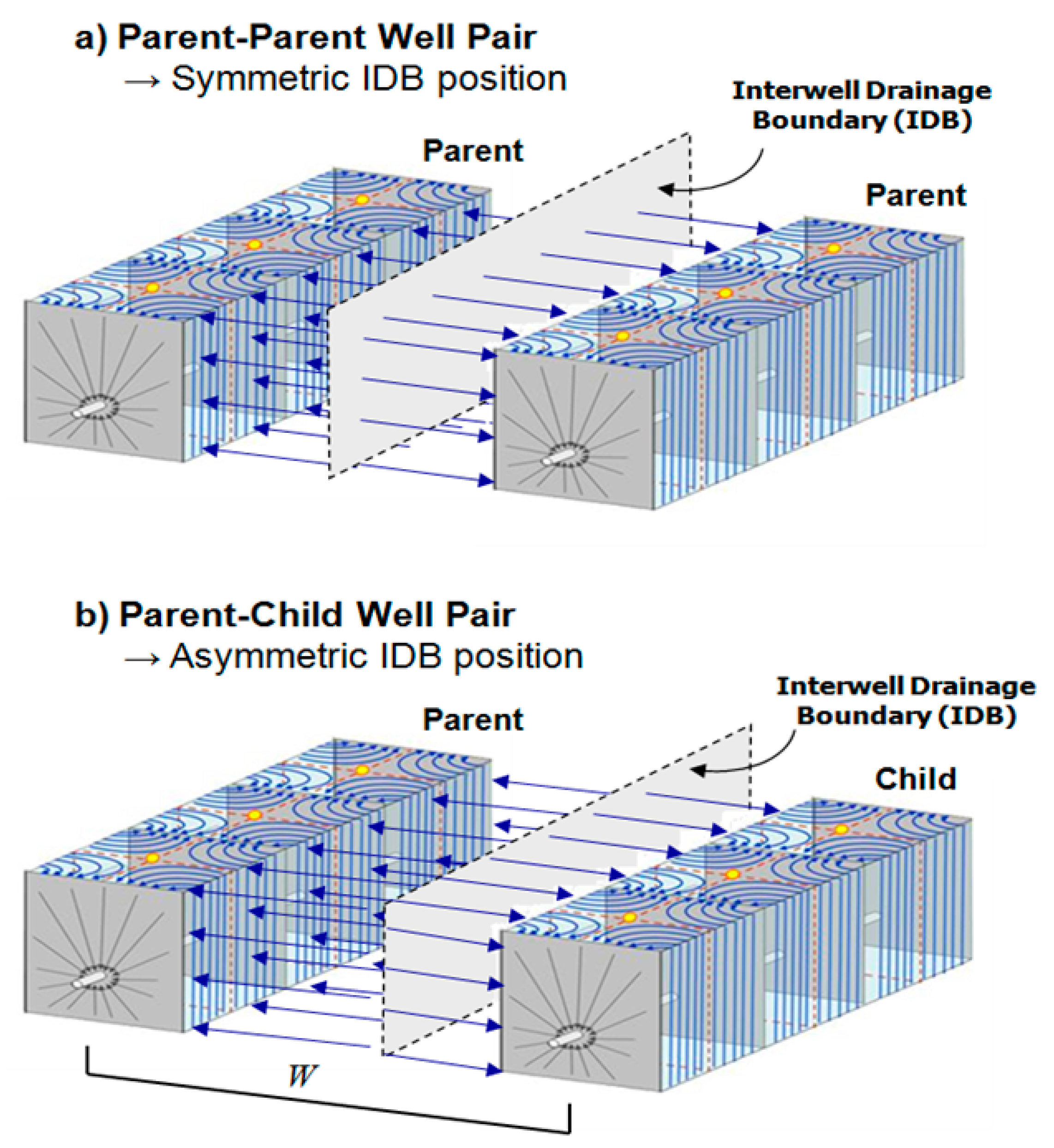

4. Flow-Cell Model: Well-Spacing Effects

4.1. Well Pressure Interference Via the Matrix

4.2. Kick-off Times and Final Segment b-Values

4.3. Well-Spacing Effects with Flow-Cell Model

4.4. Well-Spacing Effects (Parent-Child Wells)

5. Discussion

5.1. Merits of Reserves Reporting Based on Flow-Cell Model

5.2. Back-Casting Completion Failures

5.3. Strengths and Weaknesses of the Flow-Cell Model

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

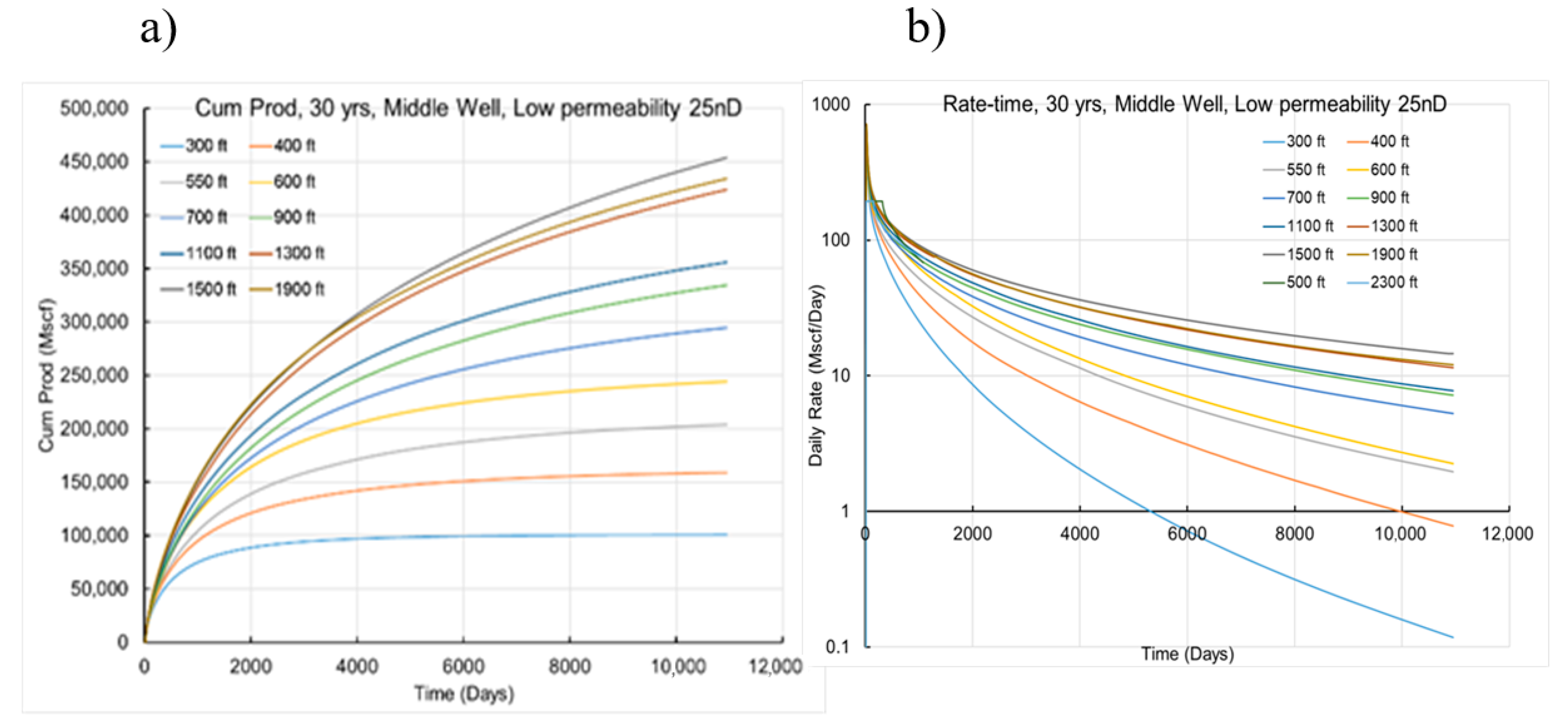

Appendix A. Numerical Reservoir Simulator Results (Low Permeability Case)

References

- Izadi, G.; Guises, R.; Barton, C.; Randazzo, S.; Mahrooqi, S.; Shaibani, M.; Dobroskok, A. Advanced Integrated Subsurface 3D Reservoir Model for Multistage Full-Physics Hydraulic Fracturing Simulation. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar] [CrossRef]

- Yu, W.; Xu, Y.; Weijermars, R.; Wu, K.; Sepehrnoori, K. A numerical model for simulating pressure response of well interference and well performance in tight oil reservoirs with complex fracture geometries using the fast embedded discrete fracture model method. SPE Reserv. Eval. Eng. 2018, 21, 489–502. [Google Scholar] [CrossRef]

- Garza, M.; Baumbach, J.; Prosser, J.; Pettigrew, S.; Elvig, K. An Eagle Ford Case Study: Improving an Infill Well Completion through Optimized Refracturing Treatment of the Offset Parent Wells. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019. [Google Scholar] [CrossRef]

- Yu, W.; Wu, K.; Zuo, L.; Tan, X.; Weijermars, R. Physical Models for Inter-Well Interference in Shale Reservoirs: Relative Impacts of Fracture Hits and Matrix Permeability. In Proceedings of the SPE Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016. SPE-URTeC 2457663. [Google Scholar] [CrossRef]

- SPE Taskforce Final Report, 2016. Unconventional Reserves Task Force, The Woodlands, TX, USA, 18–19 August 2015. Available online: https://www.spwla.org/Documents/SPWLA/TEMP/Unconventional%20Taskforce%20Final%20Report.pdf (accessed on 13 December 2020).

- Zhao, P.; Dong, R.; Liang, Y. Regional to Local Machine-Learning Analysis for Unconventional Formation Reserve Estimation: Eagle Ford Case Study; Society of Petroleum Engineers: Houston, USA, 2020. [Google Scholar] [CrossRef]

- Cipolla, C.; Gilbert, C.; Sharma, A.; LeBas, J. Case History of Completion Optimization in the Utica; Society of Petroleum Engineers: Houston, TX, USA, 2018. [Google Scholar] [CrossRef]

- McClure, M.; Picone, M.; Fowler, G.; Ratcliff, D.; Kang, C.; Medam, S.; Frantz, J. Nuances and Frequently Asked Questions in Field-Scale Hydraulic Fracture Modeling. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar] [CrossRef]

- Weijermars, R.; Tugan, F.M.; Khanal, A. Production Rates and EUR Forecasts for Interfering Parent-Parent Wells and Parent-Child Wells: Fast Analytical Solutions and Validation with Numerical Reservoir Simulators. J. Pet. Sci. Eng. 2020, 190, 107032. [Google Scholar] [CrossRef]

- Weijermars, R.; Khanal, A. Production Interference of Hydraulically Fractured Hydrocarbon Wells: New Tools for Optimization of Productivity and Economic Performance of Parent and Child Wells. In Proceedings of the SPE Europec featured at 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019. SPE-195544-MS. [Google Scholar]

- Weijermars, R.; Nandlal, K. Pre-Drilling Production Forecasting of Parent and Child Wells Using a 2-Segment DCA Method Based on an Analytical Flow-Cell Model Scaled by a Single Type Well. Energies 2020, 23, 1525. [Google Scholar] [CrossRef]

- Waters, D.; Weijermars, R. Predicting the Performance of Undeveloped Multi-Fractured Marcellus Gas Wells Using an Analytical Flow-Cell Model (FCM). Energies 2021. work in review. [Google Scholar]

- Fowler, G.; McClure, M.; Cipolla, C. A Utica Case Study: The Impact of Permeability Estimates on History Matching, Fracture Length, and Well Spacing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar] [CrossRef]

- Weijermars, R.; Nandlal, K.; Khanal, A.; Tugan, M.F. Comparison of Pressure Front with Tracer Front Advance and Principal Flow Regimes in Hydraulically Fractured Wells in Unconventional Reservoirs. J. Pet. Sci. Eng. 2019, 183, 106407. [Google Scholar] [CrossRef]

- Tugan, M.F.; Weijermars, R. Variation in b-sigmoids with flow regime transitions in support of a New 3-Segment DCA Method: Improved Production Forecasting for tight oil and gas wells. J. Pet. Sci. Eng. 2020, 192, 107243. [Google Scholar] [CrossRef]

- Weijermars, R.; Nascentes Alves, I. High-Resolution Visualization of Flow Velocities Near Frac-Tips and Flow Interference of Multi-Fracked Eagle Ford Wells, Brazos County, Texas. J. Pet. Sci. Eng. 2018, 165, 946–961. [Google Scholar] [CrossRef]

- Tugan, M.F. Deliquification techniques for conventional and unconventional gas wells: Review, field cases and lessons learned for mitigation of liquid loading. J. Nat. Gas Sci. Eng. 2020, 83, 103568. [Google Scholar] [CrossRef]

- Weijermars, R.; Nandlal, K.; Tugan, M.F.; Dusterhoft, R.; Stegent, N. Hydraulic Fracture Test Site Drained Rock Volume and Recovery Factors Visualized by Scaled Complex Analysis Models: Emulating Multiple Data Sources (production rates, Water Cuts, Pressure Gauges, Flow Regime Changes, and b-sigmoids). In Proceedings of the Unconventional Resources Technology Conference, Austin, TX, USA, 20–22 June 2020. URTeC 2020–2434. [Google Scholar]

- Sukumar, S.; Weijermars, R.; Nascentes Alves, I.; Noynaert, S. Analysis of Pressure Communication between Austin Chalk and Eagle Ford Wells during a Zipper Frac Operation. MDPI Energies—Special Issue: “Improved Reservoir Models and Production Forecasting Techniques for Multi-Stage Fractured Hydrocarbon Wells”. Energies 2019, 12, 1469. [Google Scholar] [CrossRef]

- Yang, X.; Yu, W.; Weijermars, R.; Wu, K. Fracture hits via diagnostic charts to assess production interference level. SPE J. 2020, 1–27. [Google Scholar] [CrossRef]

- Maley, S. The Use of Conventional Decline Curve Analysis in Tight Gas Well Applications. In Proceedings of the SPE/DOE (Society of Petroleum Engineers and U.S. Department of Energy), Low Permeability Gas Reservoirs, Denver, CO, USA, 19–22 May 1985. [Google Scholar] [CrossRef]

- Weijermars, R.; Johnson, A.; Denman, J.; Salinas, K.; Kennedy, M.; Williams, J. Creditworthiness of North American Oil Companies and Minsky Effects of the (2014–2016) Oil Price Shock. J. Financ. Account 2018, 6, 162–180. [Google Scholar] [CrossRef]

- Weijermars, R. Jumps in Proved Unconventional Gas Reserves Present Challenges to Reserves Auditing. SPE Econ. Manag. 2012, 4, 131–146. [Google Scholar] [CrossRef]

- SPEE Monograph 3. Guidelines for the Practical Evaluation of Undeveloped Reserves in Resource Plays; Society of Petroleum Evaluation Engineers: SPE Houston, TX, USA, 2011; Available online: https://spee.org/ (accessed on 13 December 2020).

- Mishra, S. A New Approach to Reserves Estimation in Shale Gas Reservoirs Using Multiple Decline Curve Analysis Models; Society of Petroleum Engineers: Houston, TX, USA, 2012. [Google Scholar] [CrossRef]

- Hu, Y.; Weijermars, R.; Lihua, Z.; Yu, W. Benchmarking EUR Estimates for Hydraulically Fractured Wells with and without Fracture Hits Using Various DCA Methods. J. Pet. Sci. Eng. 2017, 162, 617–632. [Google Scholar] [CrossRef]

- Tugan, F.M.; Weijermars, R. Improved EUR Prediction for Multi-Fractured Hydrocarbon Wells Based on 3-Segment DCA: Implication for Production Forecasting of Parent and Child Wells. J. Pet. Sci. Eng. 2020, 187, 106692. [Google Scholar] [CrossRef]

| Number of Peroration Clusters | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cluster Spacing (ft) | 220 | 110 | 73.3 | 55 | 44 | 36.7 | 31.4 | 27.5 | 24.4 | 22 | 20 | 18.3 |

| Fracure Spacing (ft) | 220 | 110 | 73.3 | 55 | 44 | 36.7 | 31.4 | 27.5 | 24.4 | 22 | 20 | 18.3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5-year EUR (Mscf) | 100,265 | 144,231 | 152,459 | 165,000 | 175,000 | 179,012 | 178,516 | 184,377 | 186,485 | 183,886 | 188,622 | 191,686 |

| 30-year EUR (Mscf) | 297,716 | 346,644 | 357,876 | 365,223 | 371,253 | 373,733 | 377,912 | 381,429 | 383,622 | 383,713 | 383,338 | 386,465 |

| Well Spacing (ft) | 200 | 300 | 400 | 500 | 700 | 900 | 1100 | 1300 | 1500 |

|---|---|---|---|---|---|---|---|---|---|

| 5-year EUR (Mscf) | 89,000 | 122,672 | 144,396 | 157,323 | 166,882 | 169,414 | 167,273 | 168,847 | 167,141 |

| 30-year EUR (Mscf) | 91,491 | 134,589 | 182,713 | 222,431 | 291,651 | 336,381 | 365,223 | 382,353 | 392,114 |

| Fracture Spacing (ft) | 220 | 110 | 73.3 | 55 | 44 | 36.7 | 31.4 | 27.5 | 24.4 | 22 | 20 | 18.3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| qi-Adj | 1.75 | 1.25 | 1.04 | 1.00 | 0.98 | 0.96 | 0.94 | 0.92 | 0.90 | 0.88 | 0.86 | 0.84 |

| Di_adj | 1.10 | 1.05 | 1.00 | 1.00 | 0.99 | 0.98 | 0.97 | 0.96 | 0.95 | 0.94 | 0.93 | 0.92 |

| Fracture Spacing (ft) | 220 | 110 | 73.3 | 55 | 44 | 36.7 | 31.4 | 27.5 | 24.4 | 22 | 20 | 18.3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5-year EUR (Mscf) | 95,437 | 137,905 | 154,607 | 169,319 | 180,781 | 187,962 | 192,623 | 195,833 | 198,152 | 200,147 | 201,845 | 203,213 |

| 30-year EUR (Mscf) | 305,971 | 348,841 | 357,951 | 363,150 | 370,254 | 372,679 | 372,982 | 372,633 | 372,226 | 372,616 | 373,401 | 374,312 |

| Physical Quantity | Magnitude | Unit |

|---|---|---|

| Lateral length | 7000 | ft |

| Well spacing | 100 | ft |

| Total frac length | 95 | ft |

| Effective fracture height (payzone thickness) | 121 | ft |

| Number of stages | 32 | - |

| Stage length | 220 | ft |

| Fracture spacing base case | 55 | ft |

| Porosity | 0.07 | - |

| Water saturation | 0.12 | - |

| Matrix permeability | 850 | nDarcy |

| Fracture permeability | → ∞ | nDarcy |

| Rock compressibility | 2 × 10−6 | psi−1 |

| Gas average viscosity (*) | 0.015 | cPoise |

| Temperature | 170 | F |

| Original reservoir pressure | 6830 | psi |

| Minimum horizontal stress | 7800 | psi |

| Well Spacing (ft) | 200 | 300 | 400 | 500 | 700 | 900 | 1100 | 1300 | 1500 |

|---|---|---|---|---|---|---|---|---|---|

| 5-year EUR | 92,195 | 117,685 | 136,452 | 154,858 | 166,390 | 169,344 | 169,485 | 169,485 | 169,485 |

| 30-year EUR | 93,154 | 130,902 | 175,472 | 236,189 | 288,990 | 327,996 | 356,543 | 358,641 | 372,226 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weijermars, R. Optimization of Fracture Spacing and Well Spacing in Utica Shale Play Using Fast Analytical Flow-Cell Model (FCM) Calibrated with Numerical Reservoir Simulator. Energies 2020, 13, 6736. https://doi.org/10.3390/en13246736

Weijermars R. Optimization of Fracture Spacing and Well Spacing in Utica Shale Play Using Fast Analytical Flow-Cell Model (FCM) Calibrated with Numerical Reservoir Simulator. Energies. 2020; 13(24):6736. https://doi.org/10.3390/en13246736

Chicago/Turabian StyleWeijermars, Ruud. 2020. "Optimization of Fracture Spacing and Well Spacing in Utica Shale Play Using Fast Analytical Flow-Cell Model (FCM) Calibrated with Numerical Reservoir Simulator" Energies 13, no. 24: 6736. https://doi.org/10.3390/en13246736

APA StyleWeijermars, R. (2020). Optimization of Fracture Spacing and Well Spacing in Utica Shale Play Using Fast Analytical Flow-Cell Model (FCM) Calibrated with Numerical Reservoir Simulator. Energies, 13(24), 6736. https://doi.org/10.3390/en13246736