1. Introduction

Economic dispatch (ED) is one of the most important issues pertaining to the operation and control of power systems [

1,

2]. It involves finding an optimal scheduling for all committed generators to minimize fuel costs, while satisfying various constraints such as load demand balance and generation capacity constraints. However, owing to increasing global concerns regarding the environmental issues caused by the combustion of fossil fuels, ED has become a significant concern from an economical perspective and for dealing with pollutant emissions from fossil fuel combustion [

3]. Some countries have set maximum emission limits and impose fines when these limits are exceeded [

4]. Thus, emission constraints should also be considered during operational scheduling. Economic emission dispatch (EED) has been proposed for scheduling to account for the emission of harmful gases such as carbon dioxide (CO

2), sulfur oxides (SO

x), and nitrogen oxides (NO

x), which pollute the air and exacerbate global warming [

5]. The objective function of the EED usually adds emission criteria to the fuel cost of the thermal unit. To integrate the emission component with ED, Dhillon et al. [

6] and Kulkarni et al. [

7] presented a method whereby a penalty factor is multiplied to the emission term in the objective function. This technique allows both components to become commensurately involved in the optimization.

Demand response (DR) is expected to help solve environmental problems, as it is environmentally friendly and offers several benefits to the entire system [

8,

9]. This is because DR resources are one of the most inexpensive resources and can react quickly to the commands of the system operator [

10]. Furthermore, they do not emit pollutants and help reduce peak loads. In a DR program, consumers sign a contract with the local utility to reduce their demand when requested by the system operator. The utility possesses the advantage of reducing the maximum demand and consequently decreasing operation costs. Moreover, the system operator can use the DR program to satisfy constraints such as maximum pollutant emissions. DR programs are commonly used in small power systems such as microgrids (MGs), because they are difficult to implement in large power systems due to communication problems [

11,

12].

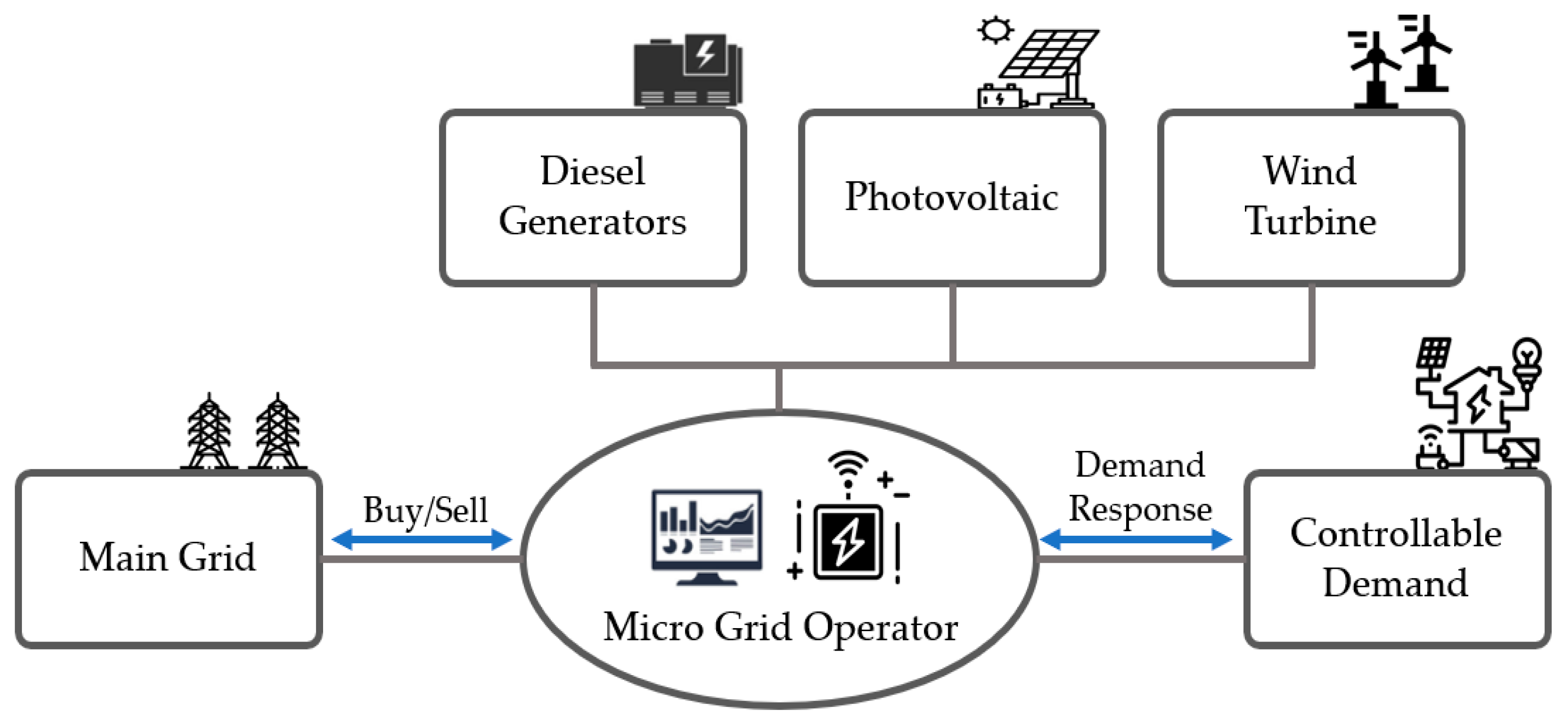

MGs can be defined as a small-scale form of the centralized power system and typically consist of diesel generation (DG) units, renewable energy resources, and loads that are designed and situated close to customers in small communities [

13]. MG operators (MGOs) manage a cluster of loads and power resources, conducting operations to control power locally. MGOs also create contracts with the utility service to meet environmental constraints of the EED, and they take the maximum emission constraints into account in the context of MG operation. To satisfy such constraints, ecofriendly energy resources such as DR should be used appropriately.

Various approaches have been recently adopted to address environmental problems in MG operation. In [

14], emissions of harmful gases such as CO

2, SO

x, and NO

x were reduced by installing additional ecofriendly generators that consume less fuel. In [

15], a differential evolution technique that combines heat and power was proposed to solve the microgrid economic and emission dispatch problem. In [

16], both emission and fuel costs were implemented through different variants of particle swarm optimization. A hybrid algorithm that combines the differential evolution algorithm and particle cluster optimization was used to solve the EED problem [

17]. In [

18], a price penalty factor, which is the ratio between the maximum fuel cost and the maximum emission of the corresponding generator, was applied for solving the EED problem. However, the studies mentioned above did not take the DR program into account, and the optimal operations were insufficient under environmental considerations. In [

19], a multi-objective approach was proposed to optimize microgrid in a short-term with renewable energy sources with a randomized natural behavior. However, pollutant emissions was not considered. Through the implementation of the DR program, in [

20], a balanced solution was obtained where a sample hub energy system containing conventional and renewable energy sources was solved with a mixed integer linear program for optimizing operation costs and reducing pollutant emission. In [

21], extended game theory was incorporated into the multiobjective dynamic EED optimization problem through a DR model. In [

22,

23], DR was considered for spinning reserves to solve the EED problem. However, the cost of interruptions and the incentives of the participating subjects were not considered.

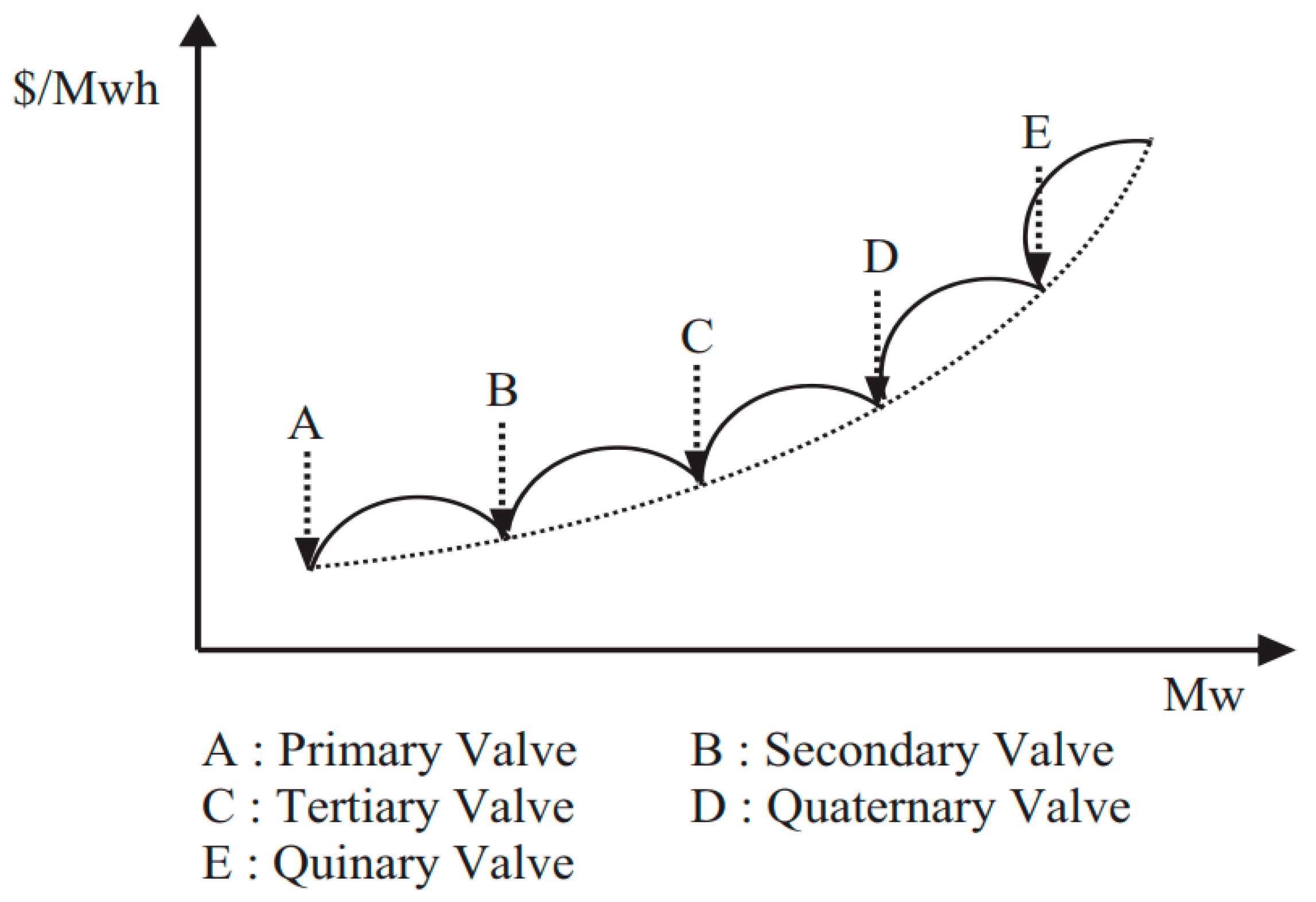

Several methods have been considered to solve the EED problem. A flower pollination algorithm was used to solve economic load dispatch and EED problems by considering the power limits of the generator [

24]. In [

25], economic load and emission dispatch were determined with a bioinspired algorithm in a renewable integrated islanded MG. A converted single objective function comprising fuel cost and emission was optimized using a gravitational search algorithm in [

26]. In [

27], quantification of the impacts of the CO2 emission has been considered on the planning, economic and scheduling decisions. While most EED problems include pollutant emissions in the objective function, there were no maximum emission constraints on the power system. To operate MGs while accounting for environmental concerns, because maximum emission constraints are practically essential, the optimal operation approach for these problems must be studied. In addition, DR is a considerably ecofriendly energy resource; however, very few studies focus on it to determine volume with respect to environmental constraints. Therefore, it is essential to conduct a study on the optimization of MG operation by utilizing a DR program and considering emission constraints for combined economic emission dispatch (CEED) problems.

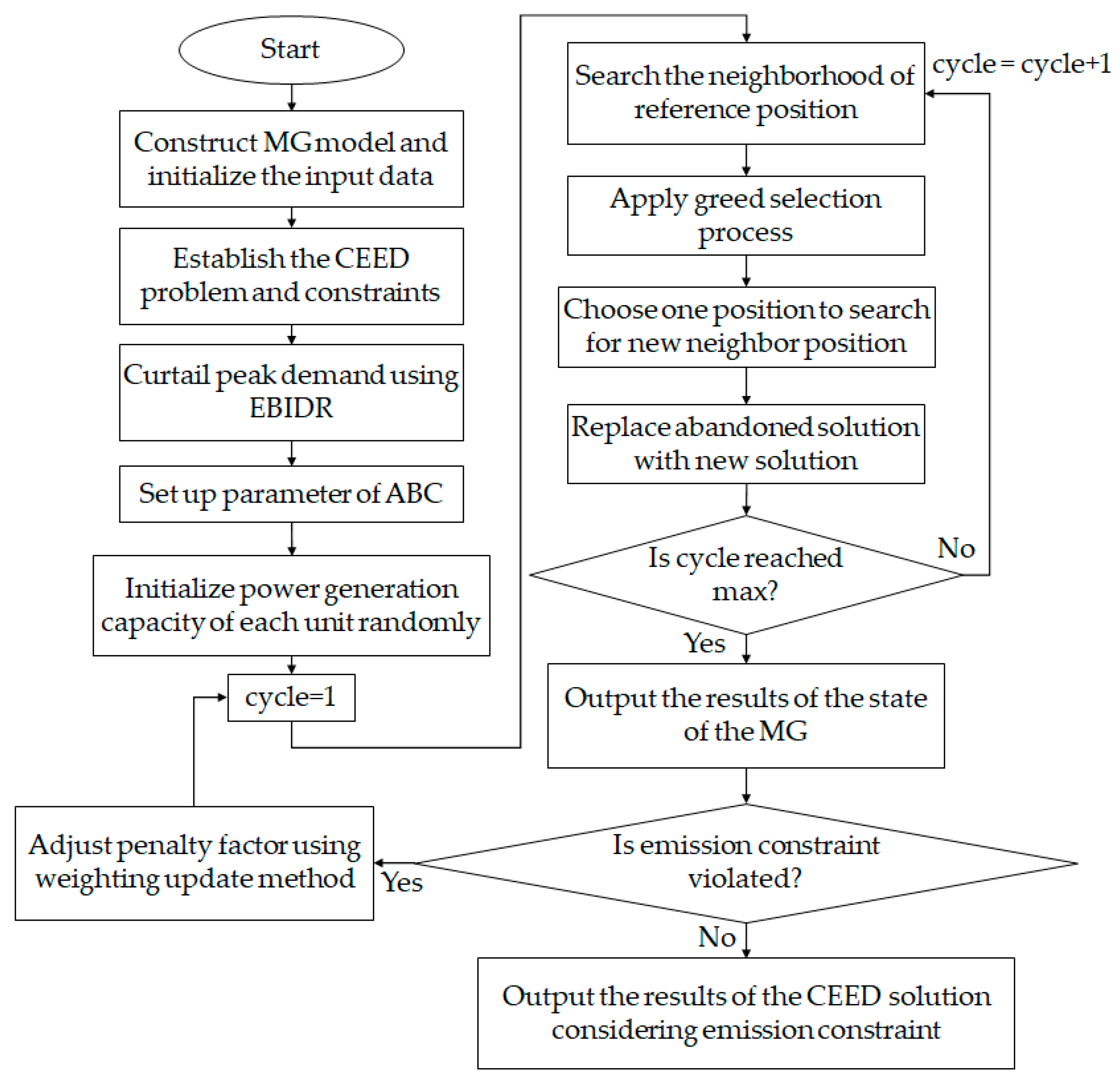

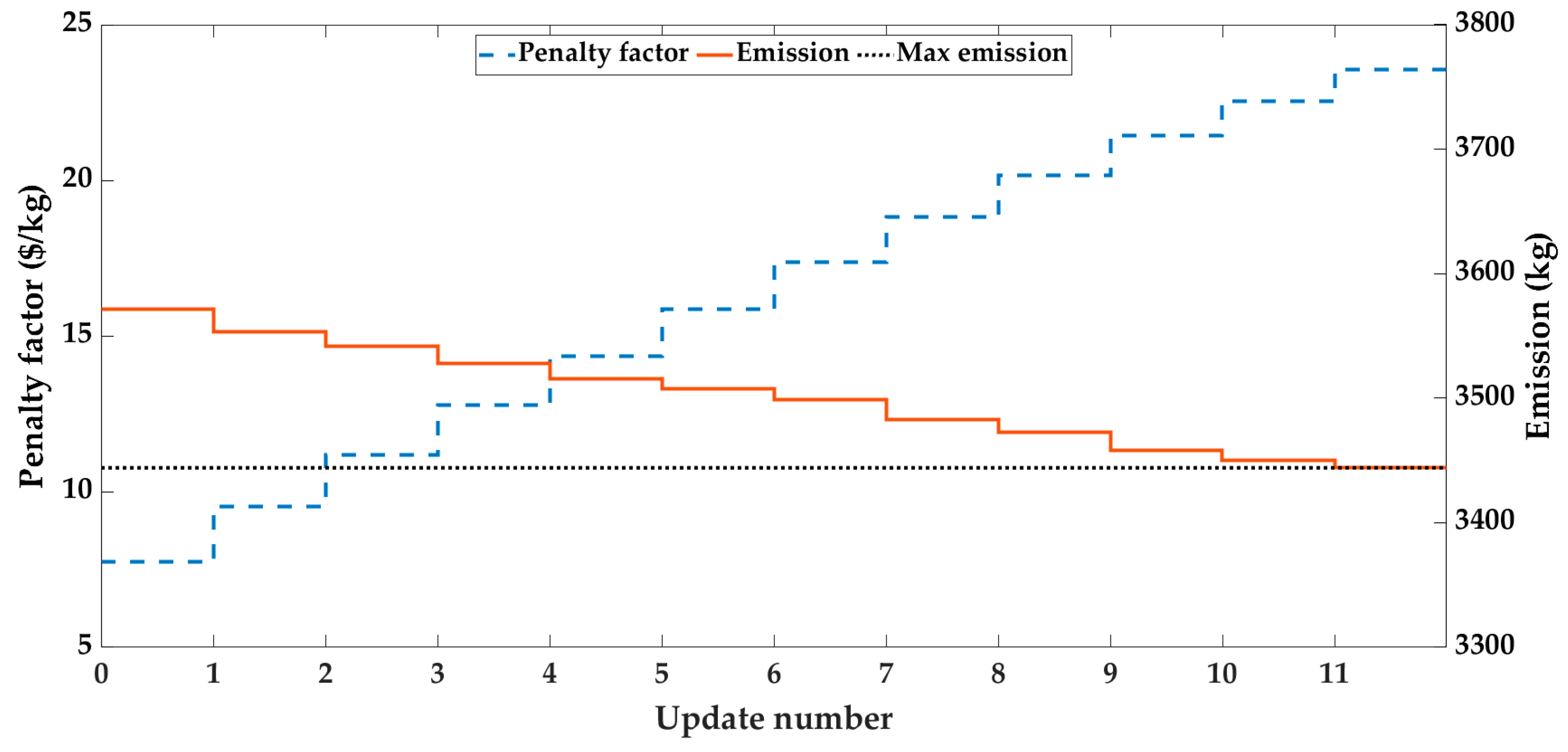

In this study, we propose an approach to solve the CEED problem while considering maximum emission constraints. The CEED function consists of the operation costs and pollutant emissions. Here, the penalty factor is used to convert the emission into an equivalent cost value. Various constraints are considered in solving the problem. In particular, the maximum emission constraint is additionally considered. To solve this problem optimally, we propose an environment-based demand response (EBDR) program that determines volume by optimizing economics and reducing the degree of pollutant emissions from the system. A weighting update artificial bee colony algorithm (WU-ABC) is applied to solve the CEED problem under a maximum emission constraint. Here, the penalty factor is updated using the weighting update method until all the constraints are satisfied. By using WU-ABC algorithm, the proposed approach becomes capable of finding the optimal CEED solution of the MG.

The primary contributions of this paper can be summarized as follows:

The CEED problem, with a maximum emission constraint on the MG, involves the minimization of operation costs and pollutant emissions. A penalty factor is used by the MGO to control the importance of both objective functions with respect to pollutant emissions. This approach is sufficiently effective to satisfy the maximum emission constraints on MG operation.

EBDR is applied and both economic and environmental factors are considered. Through the concept of elasticity, the MGO can command demand shifts and reduction, and participants in the DR program are provided appropriate incentives. Through this EBDR program, economics can be improved and environmental hazards can be reduced.

To solve the CEED problem, we propose the use of the WU-ABC algorithm. This algorithm can efficiently update the penalty factor according to the maximum emission constraint by using the weighting update method in combination with the ABC algorithm, which has been widely used for the optimal operation of power systems of late.

The proposed approach provides an optimal power scheduling using EBDR for MG systems in CEED problems with maximum emission constraints. In this regard, MGOs can be provided with more reasonable and flexible solutions for optimal operation with environmental constraints.

The remainder of this paper is organized as follows.

Section 2 introduces the grid-connected MG system model.

Section 3 presents the formulation of the problem for the CEED with a maximum emission constraint.

Section 4 outlines the proposed EBDR strategy.

Section 5 presents the solution of the WU-ABC algorithm and summarizes the overall process.

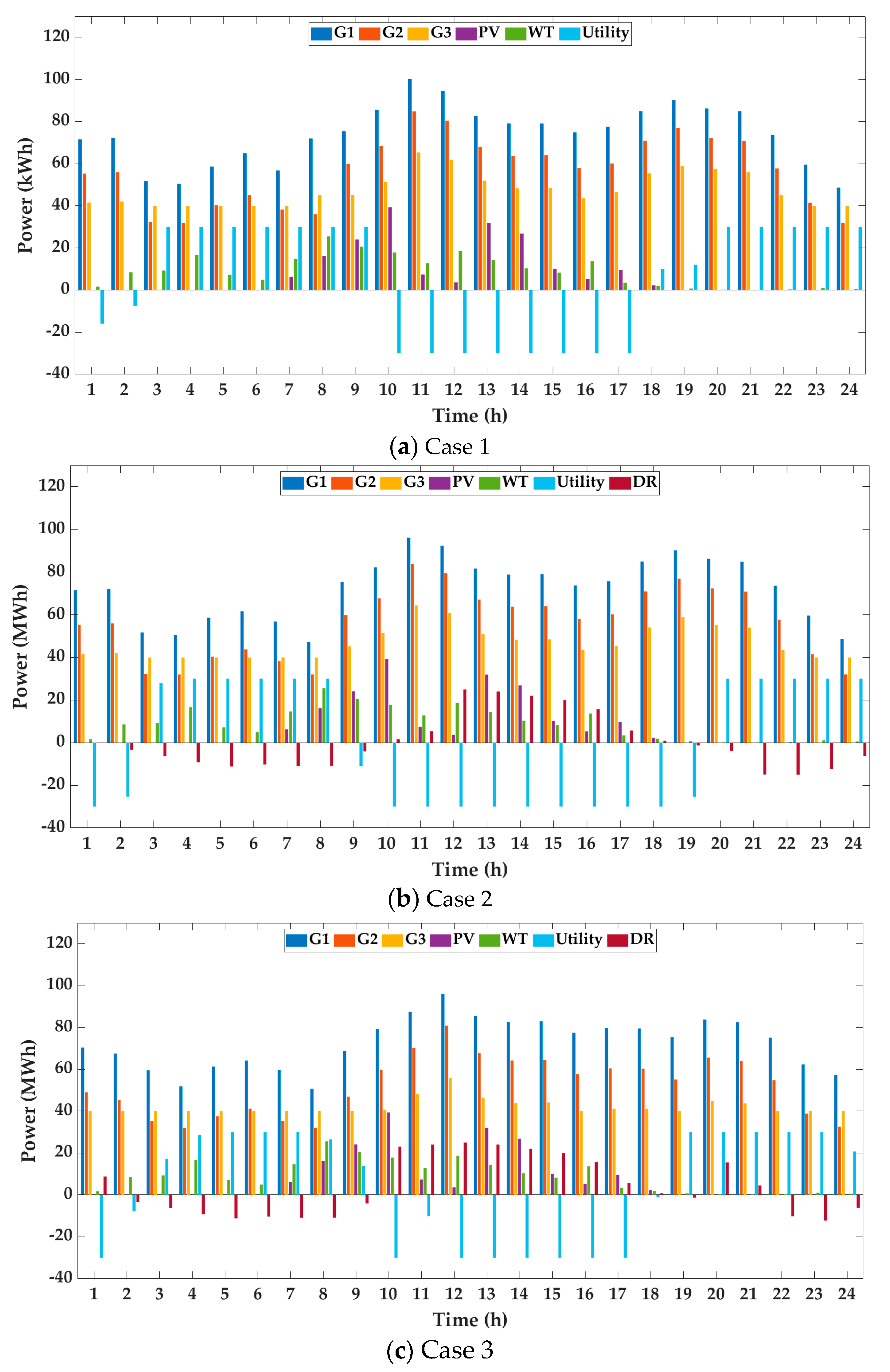

Section 6 presents the simulation results, and

Section 7 presents the conclusions of this study.

7. Conclusions

This paper proposed a CEED approach with the EBDR program by using the WU-ABC algorithm. The objective function was constructed in consideration of generation costs and pollutant emission. The emission function took the emitted quantities of CO2, SOx, and NOx, into account and converts their sum into operation costs through unit conversion, using a penalty factor. To meet the maximum emission constraint considered in addition to the CEED in our work, the EBDR program was proposed to balance economics and environmental issues. The EBDR program is based on the concept of elasticity, and the participation volume changes depending on the violation of emission constraints. To solve the multiobjective optimization problem, we proposed the use of the WU-ABC algorithm, a combination of the weighting update method and the conventional ABC algorithm. To demonstrate the effectiveness of the proposed CEED approach, simulations were conducted on the modified grid-connected MG system. Three cases were considered depending on the maximum emission constraint and the application of a DR program. The proposed approach was able to reduce operation costs compared to the conventional solution without DR program. Furthermore, it was easy to satisfy the maximum emission constraints by updating the penalty factor. In summary, the use of the EBDR program reduced operation costs and pollutant emissions, and the maximum emission constraints were satisfied through the WU-ABC algorithm. Although operation costs were slightly increased compared to that of a conventional economic DR, an emission violation fee was not imposed. In addition, the performance test results indicated that the WU-ABC algorithm outperformed other algorithms in terms of cost and CPU time. Therefore, the proposed CEED approach can assist MGOs in optimizing MG operations under environmental constraints. Our future work will be under way to focus on solving the sensitivity problem in MG when the consumers do not comply with the command of MGO in the CEED problem.