Streaming Electrification of Nycodiel 1255 Synthetic Ester and Trafo EN Mineral Oil Mixtures by Using Rotating Disc Method

Abstract

1. Introduction

1.1. Research of Insulating Liquids Mixtures

1.2. Streaming Electrification Measurement Methods

1.3. Purpose and Scope of Research

2. Materials and Methods

Mathematical Model of the Streaming Electrification Phenomenon

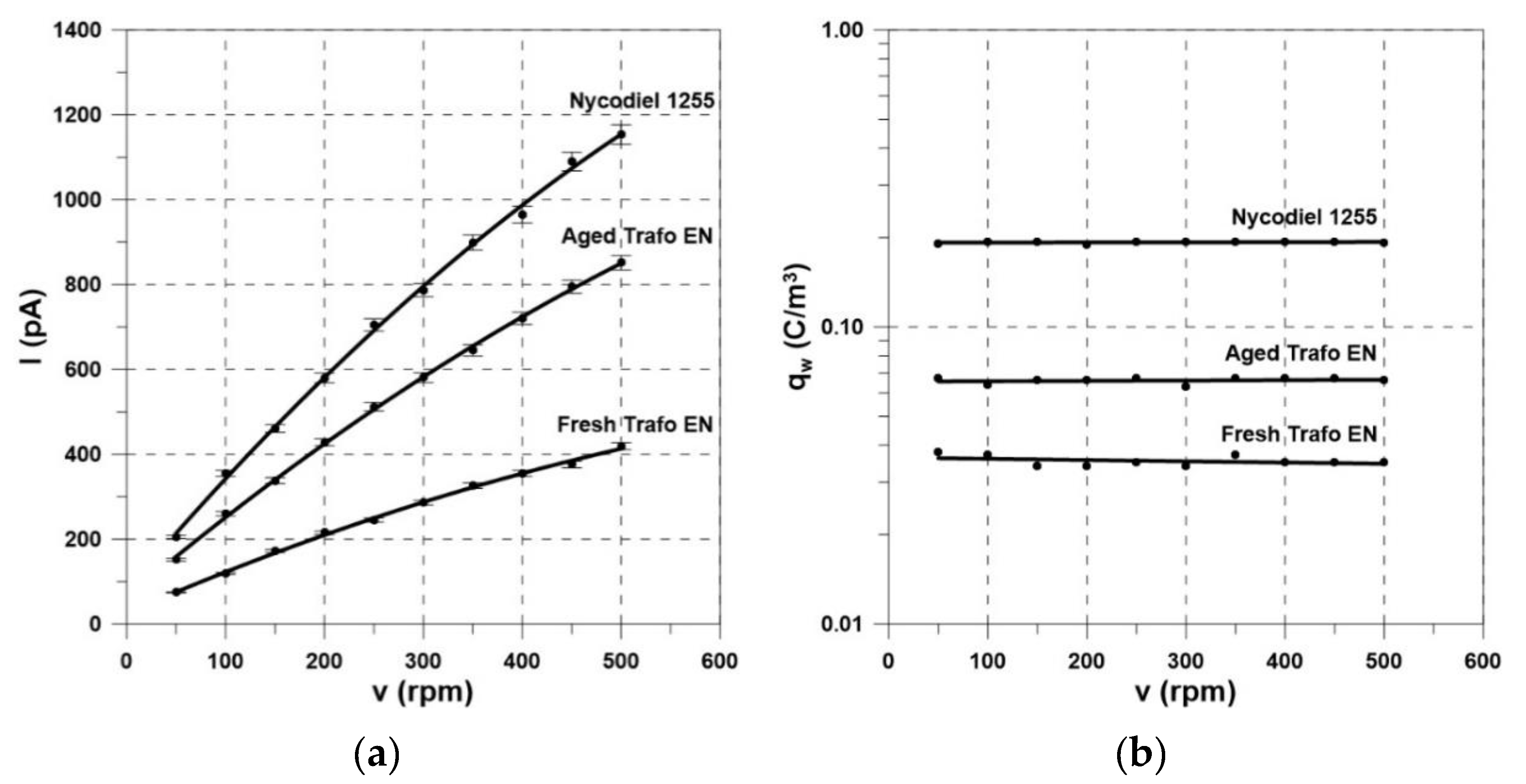

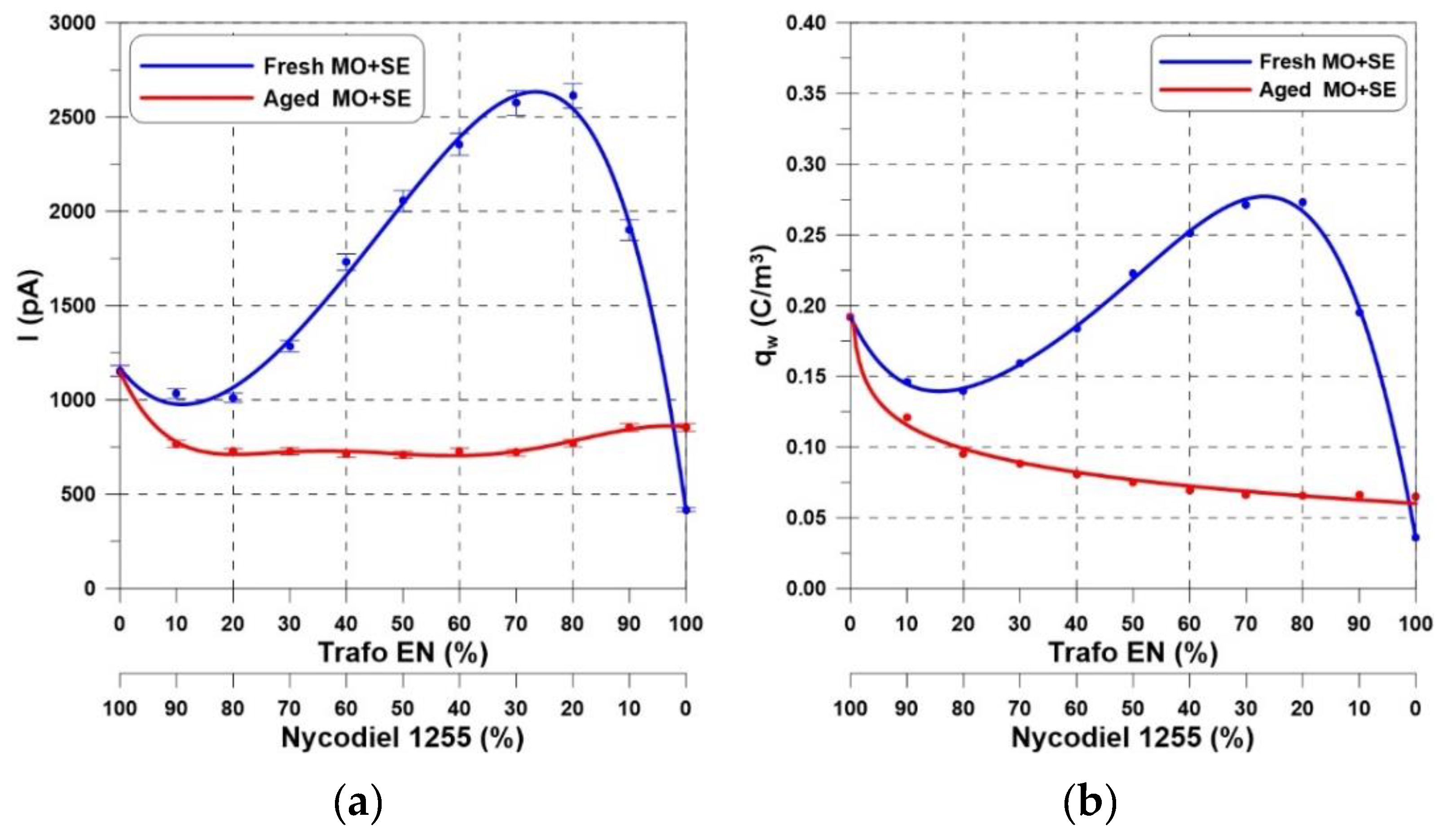

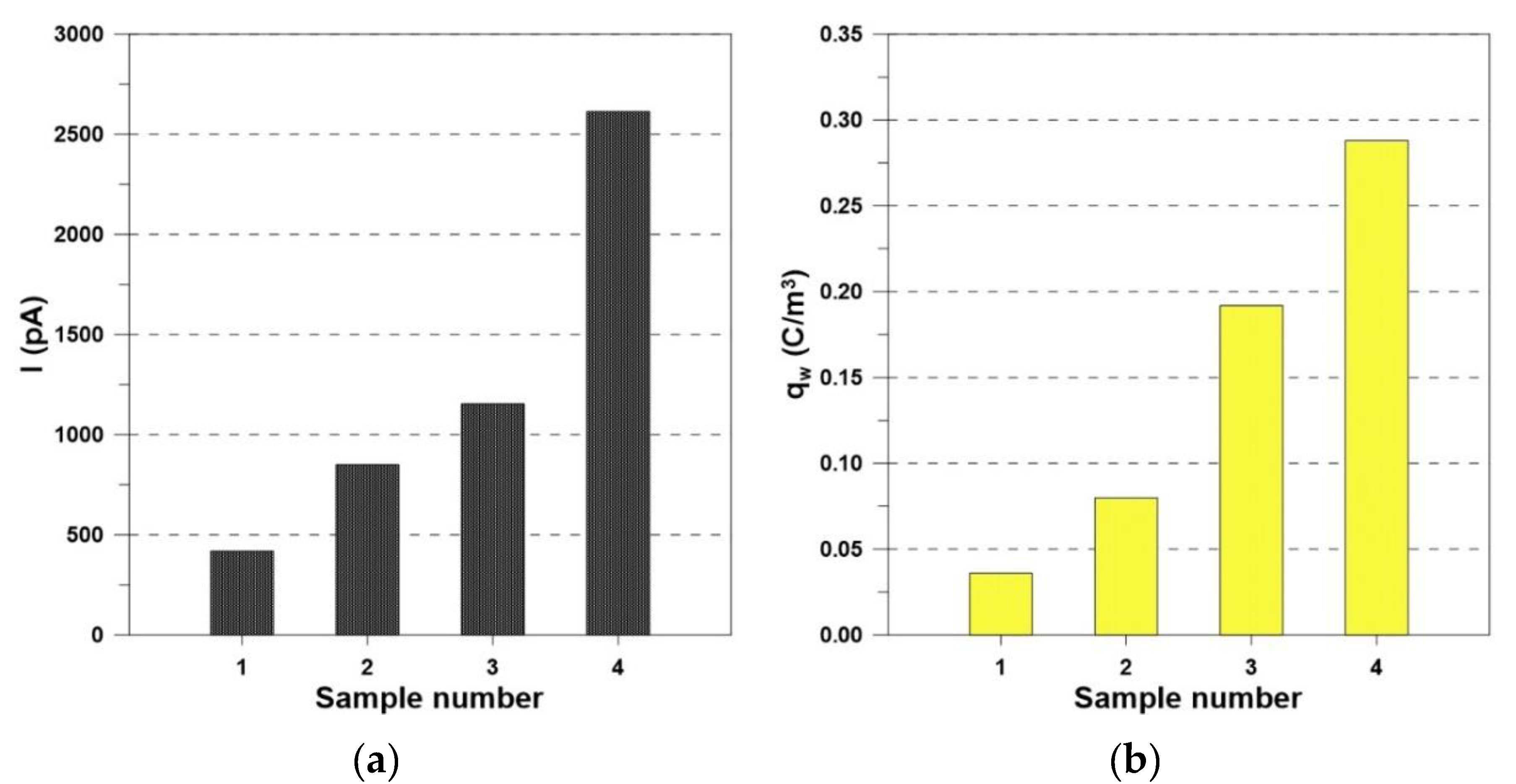

3. Results

4. Conclusions

Funding

Conflicts of Interest

References

- Boss, P.; Lorin, P.; Viscardi, A.; Harley, J.W.; Isecke, J. Economical aspects and experiences of power transformer on-line monitoring. In CIGRE Session 2000; CIGRE: Paris, France, 2000. [Google Scholar]

- The Council on Large Electric Systems (CIGRE). CIGRE Technical Brochure 248; Economics of Transformer Management; CIGRE: Paris, France, 2004. [Google Scholar]

- Fofana, I.; Borsi, H.; Gockenbach, E.; Farzaneh, M. Aging of transformer insulating materials under selective conditions. Electr. Energy Syst. 2007, 17, 450–470. [Google Scholar] [CrossRef]

- Martin, D.; Cui, Y.; Ekanayake, C.; Ma, H.; Saha, T. An updated model to determine the life remaining of transformer insulation. IEEE Trans. Power Deliv. 2015, 30, 395–402. [Google Scholar] [CrossRef]

- Ruan, J.; Jin, S.; Du, Z.; Xie, Y.; Zhu, L.; Tian, Y.; Gong, R.; Li, G.; Xiong, M. Condition assessment of paper insulation in oil-immersed power transformers based on the iterative inversion of resistivity. Energies 2017, 10, 509. [Google Scholar] [CrossRef]

- Wolny, S. Analysis of high-frequency dispersion characteristics of capacitance and loss factor of aramid paper impregnated with various dielectric liquids. Energies 2019, 12, 1063. [Google Scholar] [CrossRef]

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- N’cho, J.S.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of physicochemical-based diagnostic techniques for assessing insulation condition in aged transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Wang, X.; Tang, C.; Huang, B.; Hao, J.; Chen, G. Review of research progress on the electrical properties and modification of mineral insulating oils used in power transformers. Energies 2018, 11, 487. [Google Scholar] [CrossRef]

- Fernández, I.; Ortiz, A.; Delgado, F.; Renedo, C.; Pérez, S. Comparative evaluation of alternative fluids for power transformers. Electr. Power Syst. Res. 2013, 98, 58–69. [Google Scholar] [CrossRef]

- Mohan Rao, U.; Fofana, I.; Jaya, T.; Rodriguez-Celis, E.M.; Jalbert, J.; Picher, P. Alternative dielectric fluids for transformer insulation system: Progress, challenges, and future prospects. IEEE Access 2019, 7, 184552–184571. [Google Scholar] [CrossRef]

- Mehta, D.M.; Kundu, P.; Chowdhury, A.; Lakhiani, V.K.; Jhala, A.S. A review on critical evaluation of natural ester vis-a-vis mineral oil insulating liquid for use in transformers: Part 1. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 873–880. [Google Scholar] [CrossRef]

- Mehta, D.M.; Kundu, P.; Chowdhury, A.; Lakhiani, V.K.; Jhala, A.S. A review on critical evaluation of natural ester vis-a-vis mineral oil insulating liquid for use in transformers: Part II. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1705–1712. [Google Scholar] [CrossRef]

- Shinde, R. Condition monitoring of a retro-filled power transformer by natural ester Envirotemp FR3 fluid. In Proceedings of the 3rd International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Rupnagar, India, 16–18 November 2017; pp. 265–269. [Google Scholar]

- Rajaram, S.; Naveen, J. Maintenance of natural ester (Envirotemp FR3 dielectric fluid) filled transformer. J. Int. Assoc. Electr. Gener. Trans. Distr. 2018, 31, 22–25. [Google Scholar]

- Zhao, Y.; Qian, Y.; Wei, B.; Wang, R.; Rapp, K.J.; Xu, Y. In-service ageing comparison study of natural ester and mineral oil filled distribution transformers. In Proceedings of the IEEE International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019. [Google Scholar]

- Breazeal, R.C.; Sbravati, A.; Robalino, D.M. Evaluation of natural ester retrofilled transformers after one year of continuous overload. In Proceedings of the Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019; pp. 115–119. [Google Scholar]

- McShane, C.P.; Luksich, J.; Rapp, K.J. Retrofilling aging transformers with natural ester based dielectric coolant for safety and life extension. In Proceedings of the Cement Industry Technical Conference, Conference Record IEEE-IAS/PCA, Dallas, TX, USA, 4–9 May 2003; pp. 141–147. [Google Scholar]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Challenge of mixed insulating liquids for use in high-voltage transformers Part 1: Investigation of mixed liquids. IEEE Electr. Insul. Mag. 2002, 18, 18–31. [Google Scholar] [CrossRef]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Challenge of mixed insulating liquids for use in high-voltage transformers Part 2: Investigations of mixed liquid impregnated paper insulation. IEEE Electr. Insul. Mag. 2002, 18, 5–16. [Google Scholar] [CrossRef]

- Perrier, C.; Beroual, A.; Bessede, J.L. Improvement of power transformers by using mixtures of mineral oil with synthetic esters. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 556–564. [Google Scholar] [CrossRef]

- Rao, U.M.; Sood, Y.R.; Jarial, R.K. Oxidation stability enhancement of a blend of mineral and synthetic ester oils. IEEE Elect. Insul. Mag. 2016, 32, 43–47. [Google Scholar] [CrossRef]

- Yu, H.; Chen, R.; Hu, X.; Xu, X.; Xu, Y. Dielectric and physicochemical properties of mineral and vegetable oils mixtures. In Proceedings of the 19th IEEE International Conference on Dielectric Liquids (ICDL), Manchester, UK, 25–29 June 2017. [Google Scholar]

- Beroual, A.; Khaled, U.; Noah, P.S.M.; Sitorus, H. Comparative study of breakdown voltage of mineral, synthetic and natural oils and based mineral oil mixtures under AC and DC voltages. Energies 2017, 10, 511. [Google Scholar] [CrossRef]

- Hamadi, A.; Fofana, I.; Djillali, M. Stability of mineral oil and oil-ester mixtures under thermal aging and electrical discharges. IET Gener. Transm. Distrib. 2017, 11, 2384–2392. [Google Scholar] [CrossRef]

- Dombek, G.; Gielniak, J. Fire safety and electrical properties of mixtures of synthetic ester/mineral oil and synthetic ester/natural ester. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1846–1852. [Google Scholar] [CrossRef]

- Nadolny, Z.; Dombek, G. Thermal properties of mixtures of mineral oil and natural ester in terms of their application in the transformer. In Proceedings of the International Conference on Energy, Environment and Material Systems (EEMS), Polanica-Zdrój, Poland, 13–15 September 2017; pp. 1–6. [Google Scholar]

- Nadolny, Z.; Dombek, G.; Przybylek, P. Thermal properties of a mixture of mineral oil and synthetic ester in terms of its applications in the transformer. In Proceedings of the IEEE International Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 857–860. [Google Scholar]

- Gao, Y.; Li, F.; Lu, W.; Zhao, W. Effect of temperature on flow electrification under DC electrical field. J. Eng. 2019, 2019, 2893–2896. [Google Scholar] [CrossRef]

- Zdanowski, M. Streaming electrification phenomenon of electrical insulating oils for power transformers. Energies 2020, 13, 3225. [Google Scholar] [CrossRef]

- Zmarzły, D.; Frącz, P. Streaming electrification in the swinging plate system. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3217–3225. [Google Scholar] [CrossRef]

- Zmarzły, D.; Frącz, P. Dynamics of impulse response of streaming electrification current in swinging cylinder system insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 713–720. [Google Scholar] [CrossRef]

- Ren, S.; Liu, Q.; Zhong, L.; Yu, Q.; Xu, Y.; Cao, X.; Hanai, M.; Yamada, S.; Mori, S. Electrostatic charging tendency and correlation analysis of mineral insulation oils under thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 499–505. [Google Scholar]

- Leblanc, P.; Paillat, T.; Cabaleiro, J.M.; Touchard, G. Flow electrification investigation under the effect of the flow parameters. Int. J. Plasma Environ. Sci. Technol. 2018, 11, 156–160. [Google Scholar]

- Zmarzły, D.; Kędzia, J. A noise analyzer for monitoring static electrification current. J. Electrost. 2005, 63, 409–422. [Google Scholar] [CrossRef]

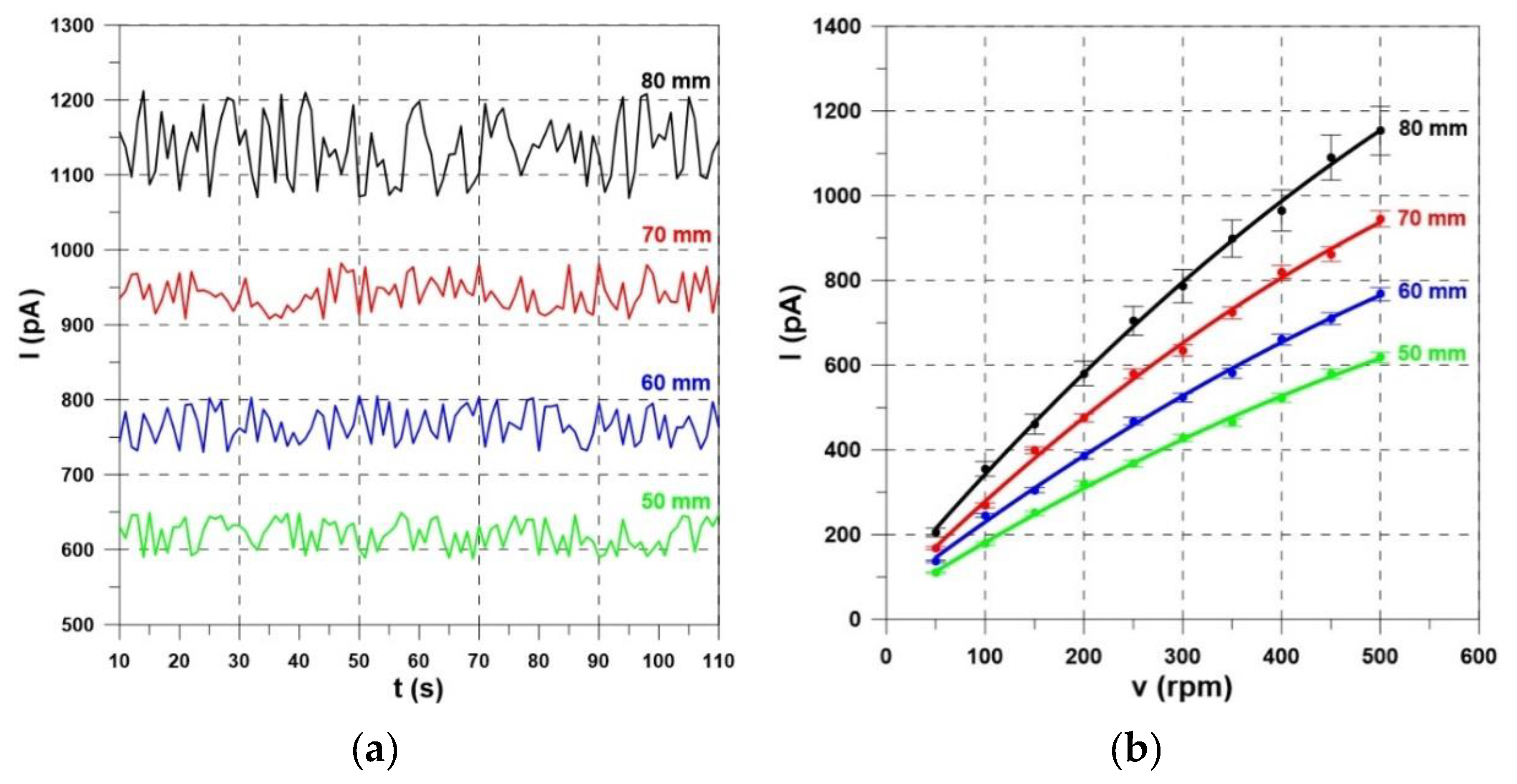

- Zdanowski, M.; Wolny, S.; Zmarzły, D.; Kędzia, J. The analysis and selection of the spinning disk system parameters for the measurement of static electrification of insulation oils. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 480–486. [Google Scholar] [CrossRef]

- Zdanowski, M. Electrostatic charging tendency analysis concerning retrofilling power transformers with Envirotemp FR3 natural ester. Energies 2020, 13, 4420. [Google Scholar] [CrossRef]

- Zdanowski, M.; Maleska, M. Streaming electrification of insulating liquid mixtures. Arch. Electr. Eng. 2019, 68, 387–397. [Google Scholar]

- Adamczewski, J. Ionization and Conductivity of Liquid Dielectric; Polish Scientific Publishers (PWN): Warsaw, Poland, 1965. (In Polish) [Google Scholar]

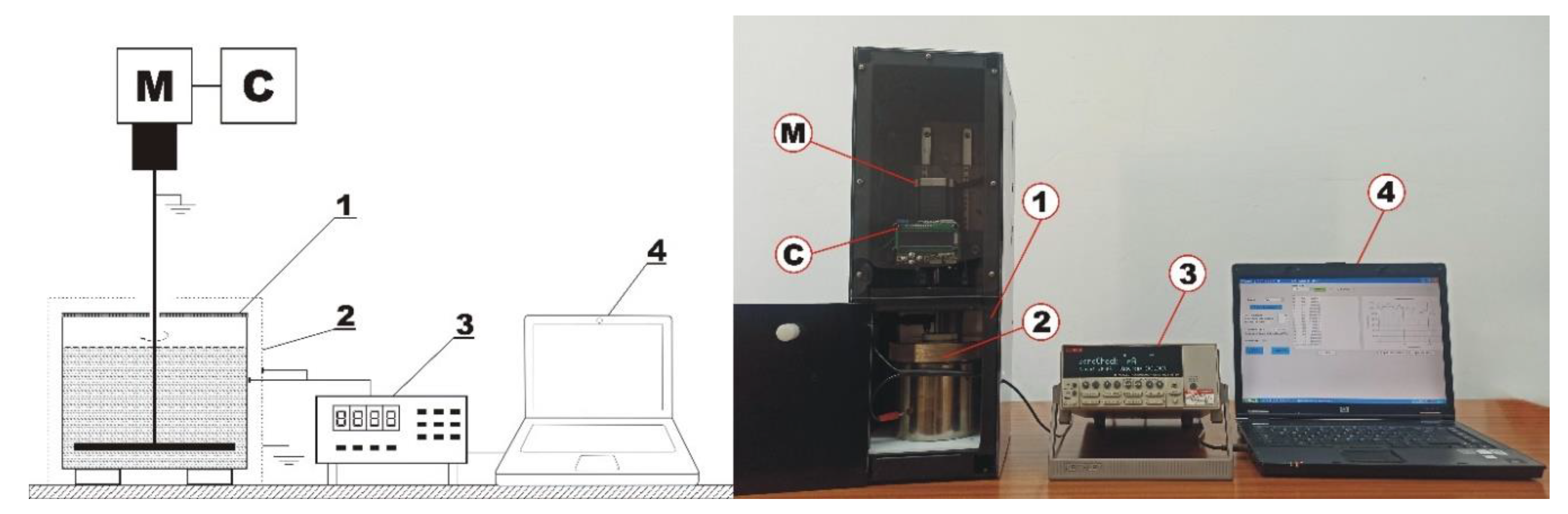

- Zdanowski, M.; Ozon, T. Measuring system for a streaming electrification tests of insulating liquids. Poznan Univ. Technol. Acad. J. Electr. Eng. 2016, 86, 393–403. (In Polish) [Google Scholar]

- Kędzia, J.; Willner, B. Electrification current in the spinning disc system. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 58–62. [Google Scholar] [CrossRef]

- Rajab, A.; Gumilang, H.; Tsuchie, M.; Kozako, M.; Hikita, M.; Suzuki, T. Study on static electrification of the PFAE-mineral oil mixture. IOP Conf. Ser. Mater. Sci. Eng. 2019, 602, 012016. [Google Scholar] [CrossRef]

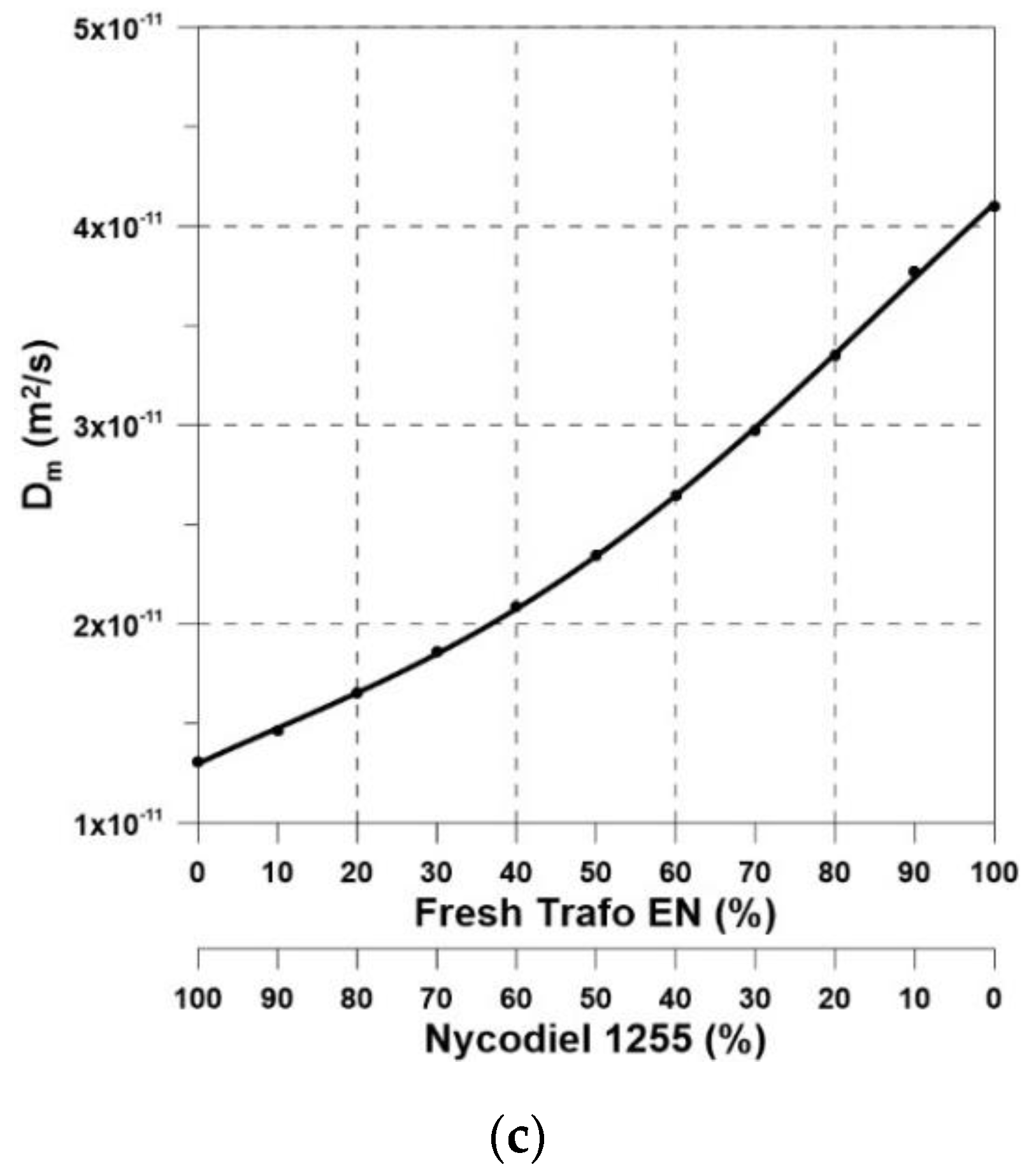

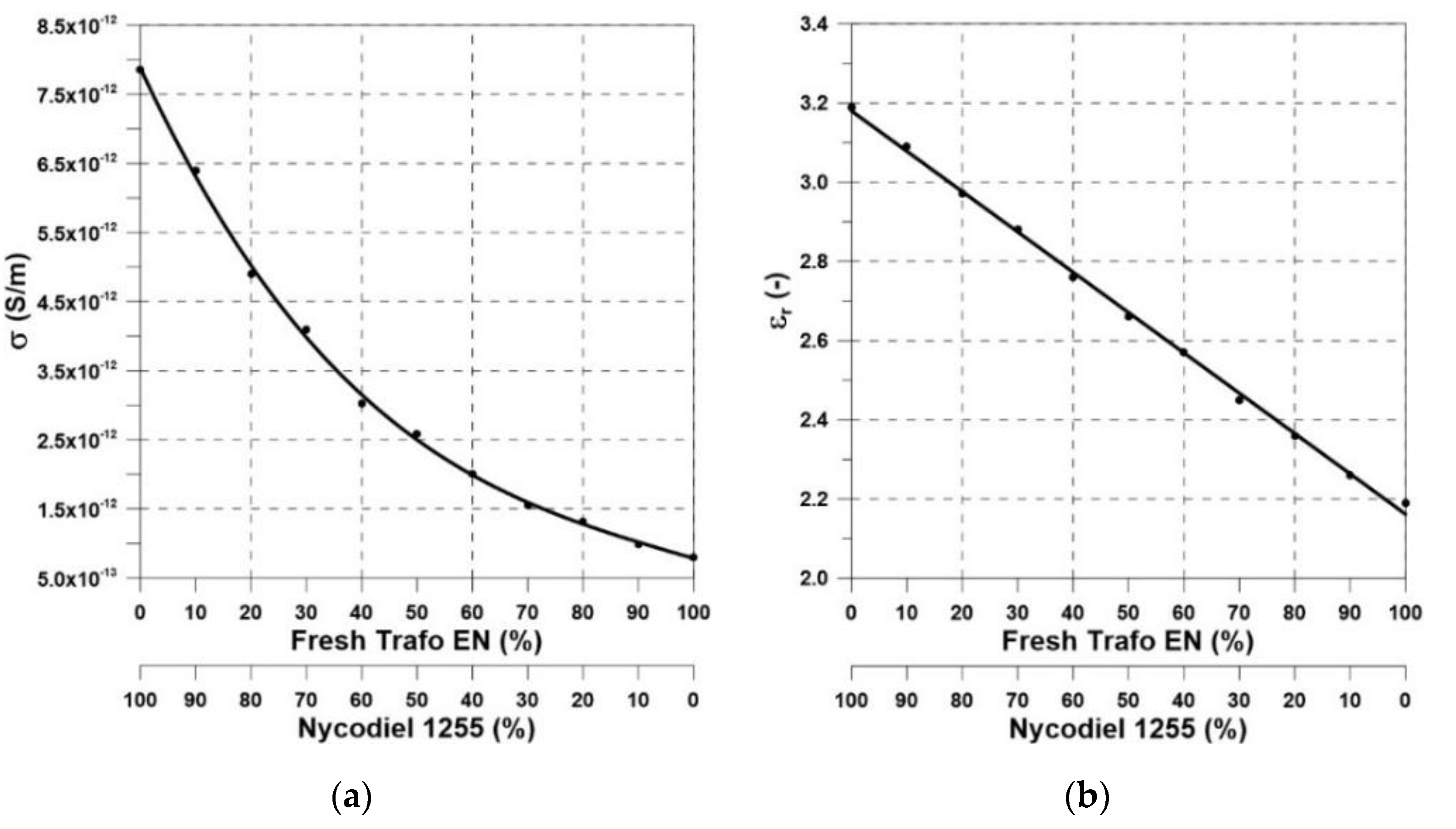

| Mixture Content | ρ (kg/m3) | νk (m2/s) | Dm (m2/s) | σ (S/m) | εr (–) |

|---|---|---|---|---|---|

| SE 100% | 970 | 6.21 × 10−5 | 1.31 × 10−11 | 7.85 × 10−12 | 3.19 |

| 90% SE + 10% MO | 963 | 5.63 × 10−5 | 1.45 × 10−11 | 6.41 × 10−12 | 3.09 |

| 80% SE + 20% MO | 952 | 4.95 × 10−5 | 1.67 × 10−11 | 4.90 × 10−12 | 2.97 |

| 70% SE + 30% MO | 941 | 4.55 × 10−5 | 1.84 × 10−11 | 4.02 × 10−12 | 2.88 |

| 60% SE + 40% MO | 932 | 3.99 × 10−5 | 2.11 × 10−11 | 3.02 × 10−12 | 2.76 |

| 50% SE + 50% MO | 923 | 3.63 × 10−5 | 2.35 × 10−11 | 2.58 × 10−12 | 2.66 |

| 40% SE + 60% MO | 911 | 3.19 × 10−5 | 2.70 × 10−11 | 2.01 × 10−12 | 2.57 |

| 30% SE + 70% MO | 902 | 2.93 × 10−5 | 2.97 × 10−11 | 1.55 × 10−12 | 2.45 |

| 20% SE + 80% MO | 891 | 2.69 × 10−5 | 3.28 × 10−11 | 1.32 × 10−12 | 2.36 |

| 10% SE + 90% MO | 881 | 2.37 × 10−5 | 3.77 × 10−11 | 9.88 × 10−13 | 2.26 |

| MO 100% | 871 | 2.21 × 10−5 | 4.11 × 10−11 | 7.97 × 10−13 | 2.19 |

| Mixture Content | ρ (kg/m3) | νk (m2/s) | Dm (m2/s) | σ (S/m) | εr (–) |

|---|---|---|---|---|---|

| SE 100% | 970 | 6.21 × 10−5 | 1.31 × 10−11 | 7.85 × 10−12 | 3.19 |

| 90% SE + 10% MO | 962 | 5.65 × 10−5 | 1.45 × 10−11 | 8.29 × 10−12 | 3.11 |

| 80% SE + 20% MO | 951 | 5.29 × 10−5 | 1.56 × 10−11 | 8.61 × 10−12 | 2.99 |

| 70% SE + 30% MO | 940 | 4.71 × 10−5 | 1.78 × 10−11 | 9.21 × 10−12 | 2.92 |

| 60% SE + 40% MO | 931 | 4.35 × 10−5 | 1.94 × 10−11 | 9.72 × 10−12 | 2.81 |

| 50% SE + 50% MO | 922 | 3.99 × 10−5 | 2.14 × 10−11 | 1.02 × 10−11 | 2.72 |

| 40% SE + 60% MO | 910 | 3.62 × 10−5 | 2.40 × 10−11 | 1.07 × 10−11 | 2.63 |

| 30% SE + 70% MO | 901 | 3.21 × 10−5 | 2.72 × 10−11 | 1.14 × 10−11 | 2.52 |

| 20% SE + 80% MO | 889 | 2.98 × 10−5 | 2.97 × 10−11 | 1.19 × 10−11 | 2.41 |

| 10% SE + 90% MO | 880 | 2.75 × 10−5 | 3.25 × 10−11 | 1.27 × 10−11 | 2.35 |

| MO 100% | 870 | 2.41 × 10−5 | 3.77 × 10−11 | 1.33 × 10−11 | 2.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zdanowski, M. Streaming Electrification of Nycodiel 1255 Synthetic Ester and Trafo EN Mineral Oil Mixtures by Using Rotating Disc Method. Energies 2020, 13, 6159. https://doi.org/10.3390/en13236159

Zdanowski M. Streaming Electrification of Nycodiel 1255 Synthetic Ester and Trafo EN Mineral Oil Mixtures by Using Rotating Disc Method. Energies. 2020; 13(23):6159. https://doi.org/10.3390/en13236159

Chicago/Turabian StyleZdanowski, Maciej. 2020. "Streaming Electrification of Nycodiel 1255 Synthetic Ester and Trafo EN Mineral Oil Mixtures by Using Rotating Disc Method" Energies 13, no. 23: 6159. https://doi.org/10.3390/en13236159

APA StyleZdanowski, M. (2020). Streaming Electrification of Nycodiel 1255 Synthetic Ester and Trafo EN Mineral Oil Mixtures by Using Rotating Disc Method. Energies, 13(23), 6159. https://doi.org/10.3390/en13236159