Conjugated Numerical Approach for Modelling DBHE in High Geothermal Gradient Environments

Abstract

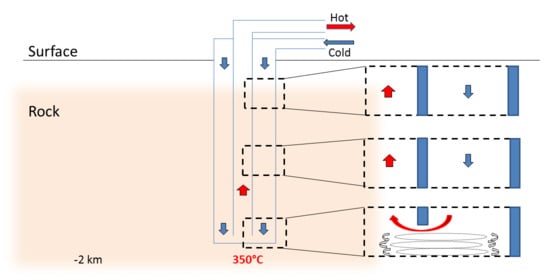

1. Introduction

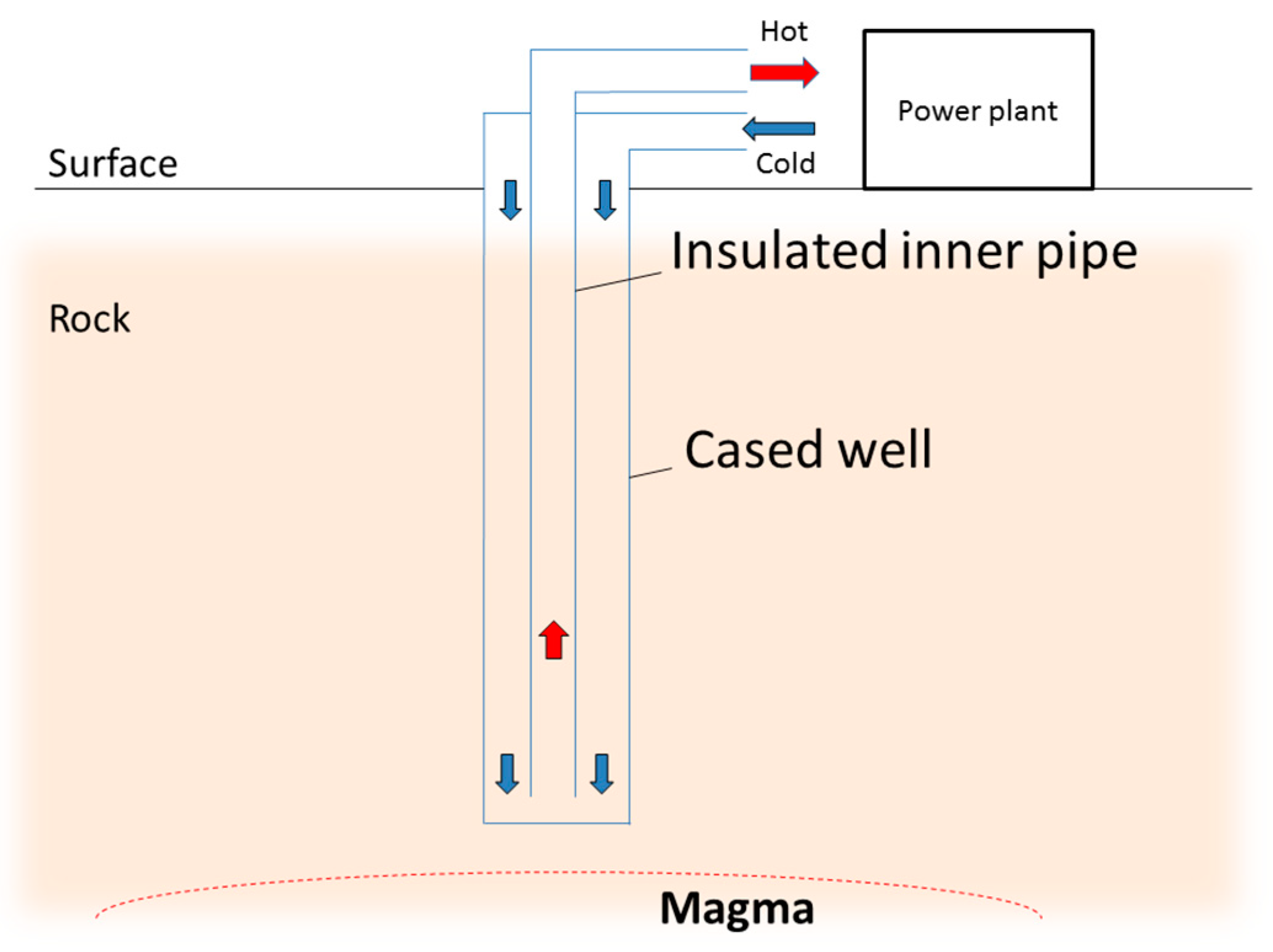

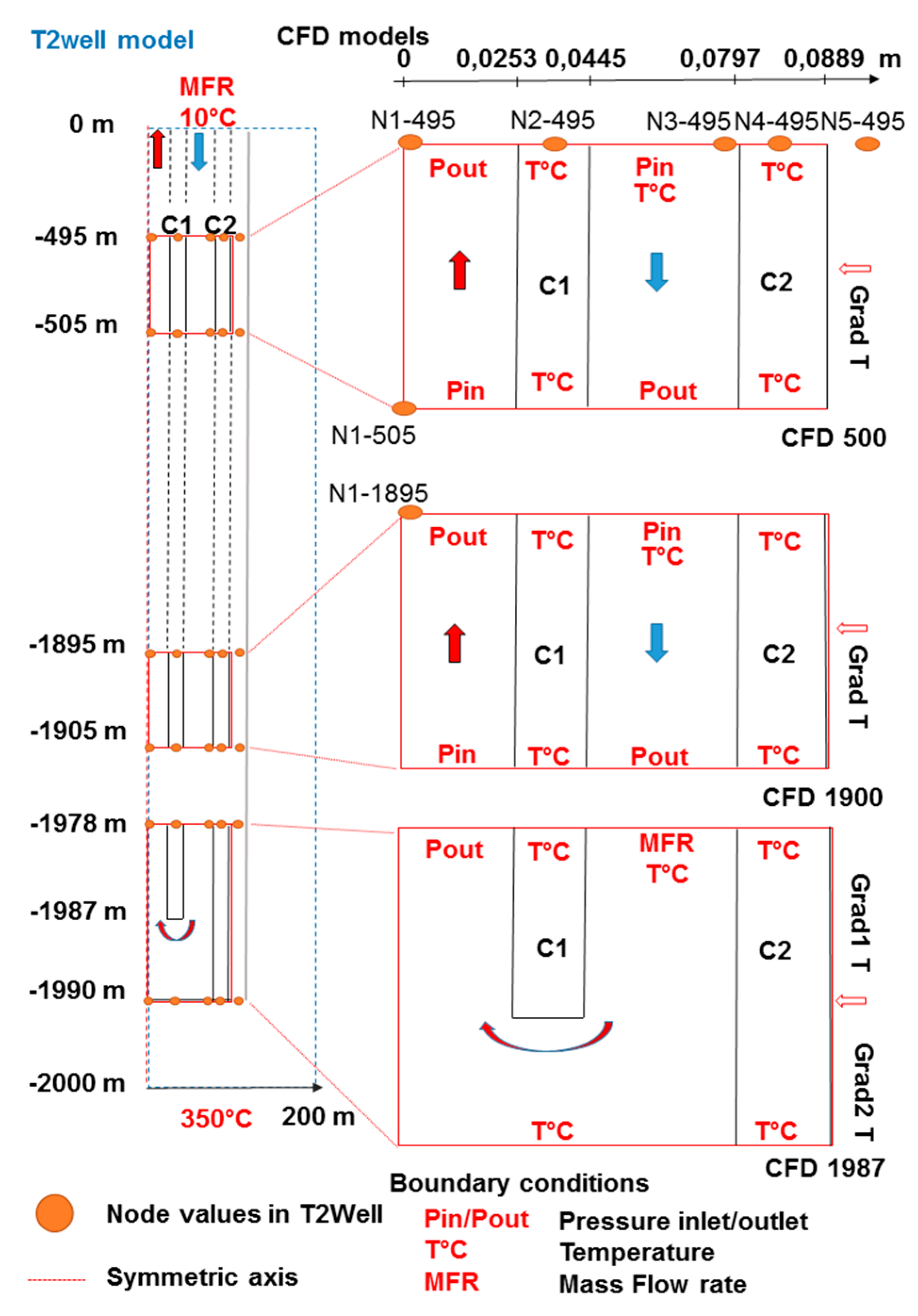

2. Materials and Methods

2.1. Model Parameters

2.2. Mathematical Model of T2well

2.3. Mathematical CFD Model

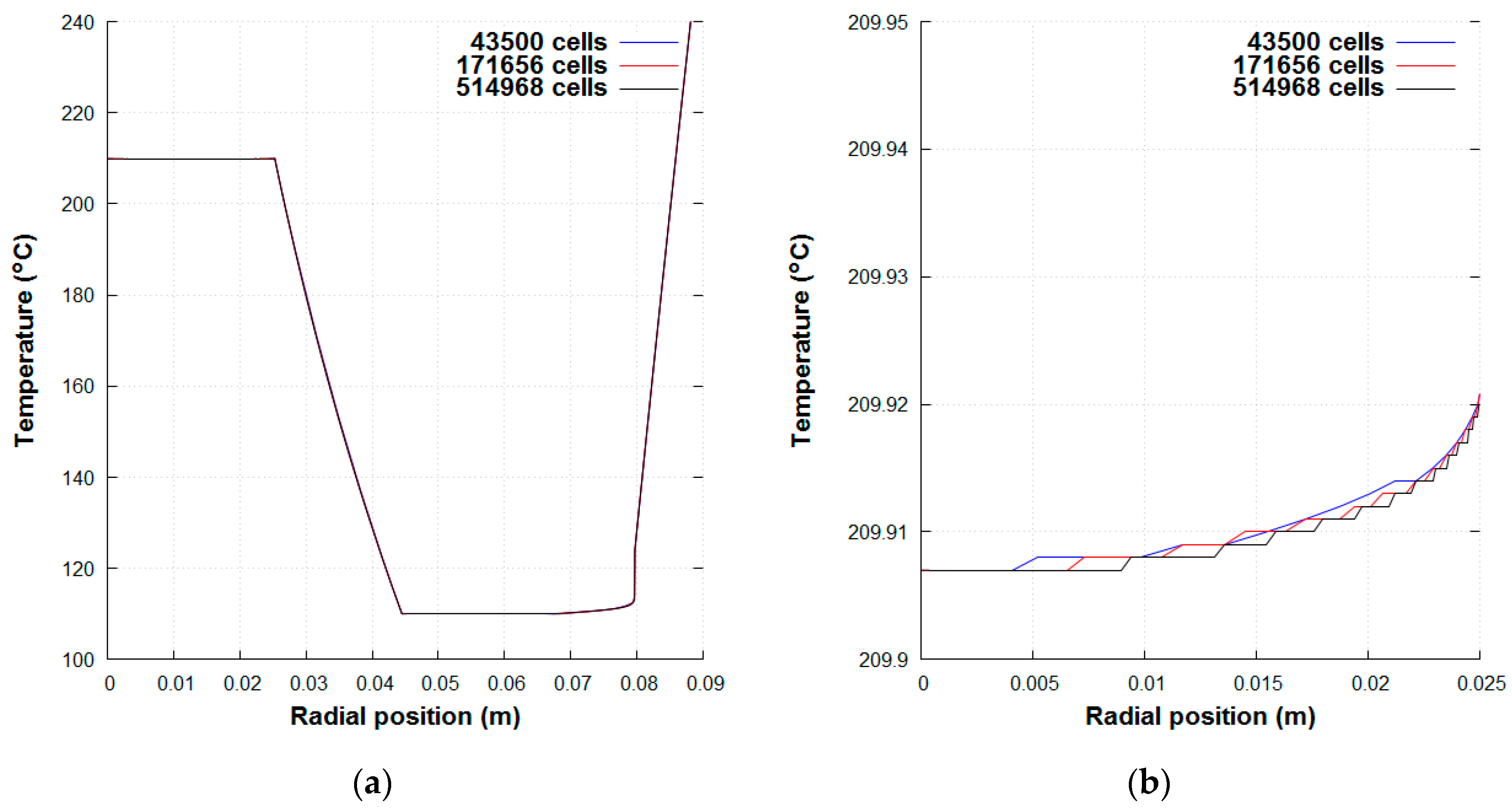

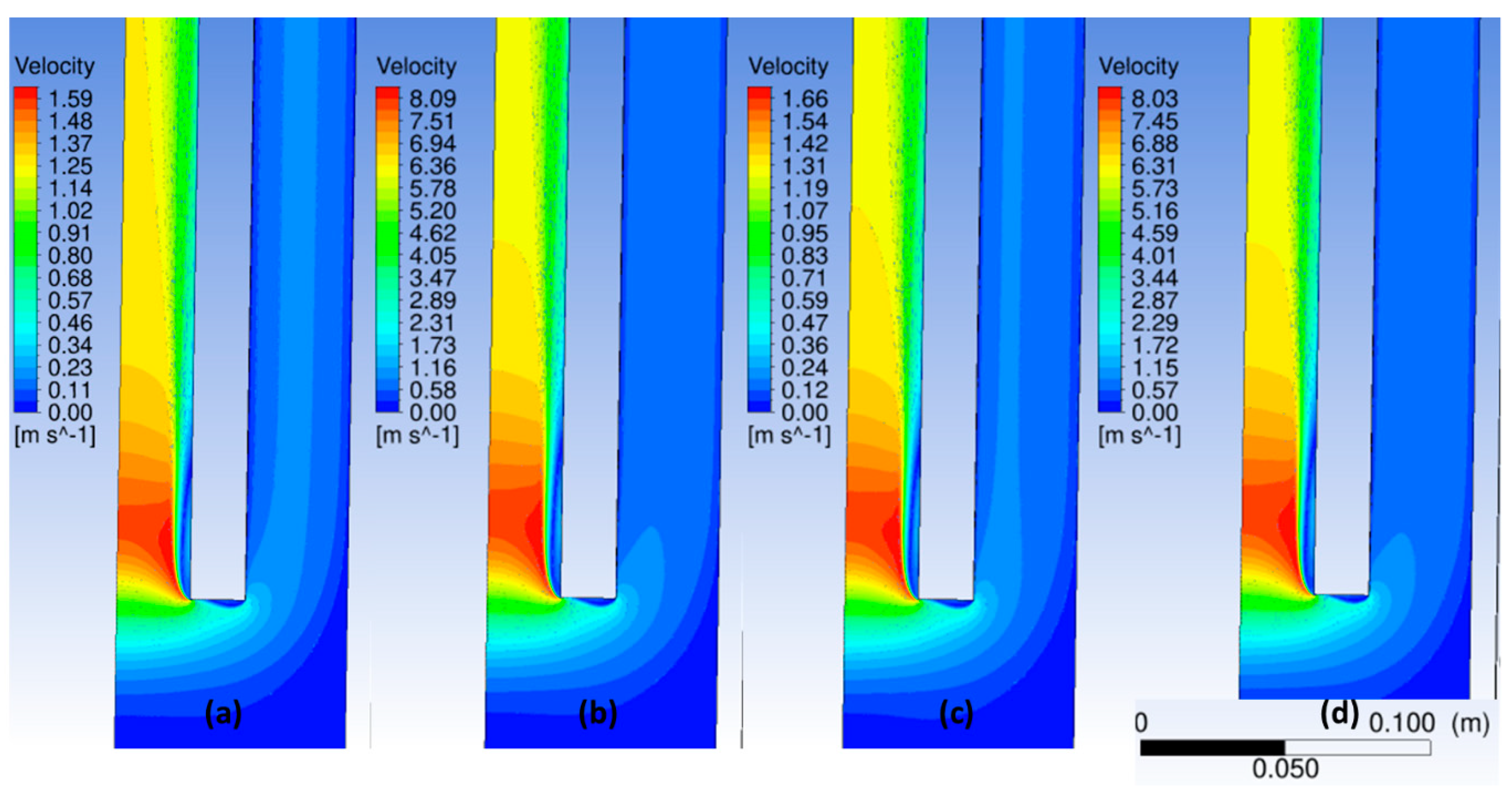

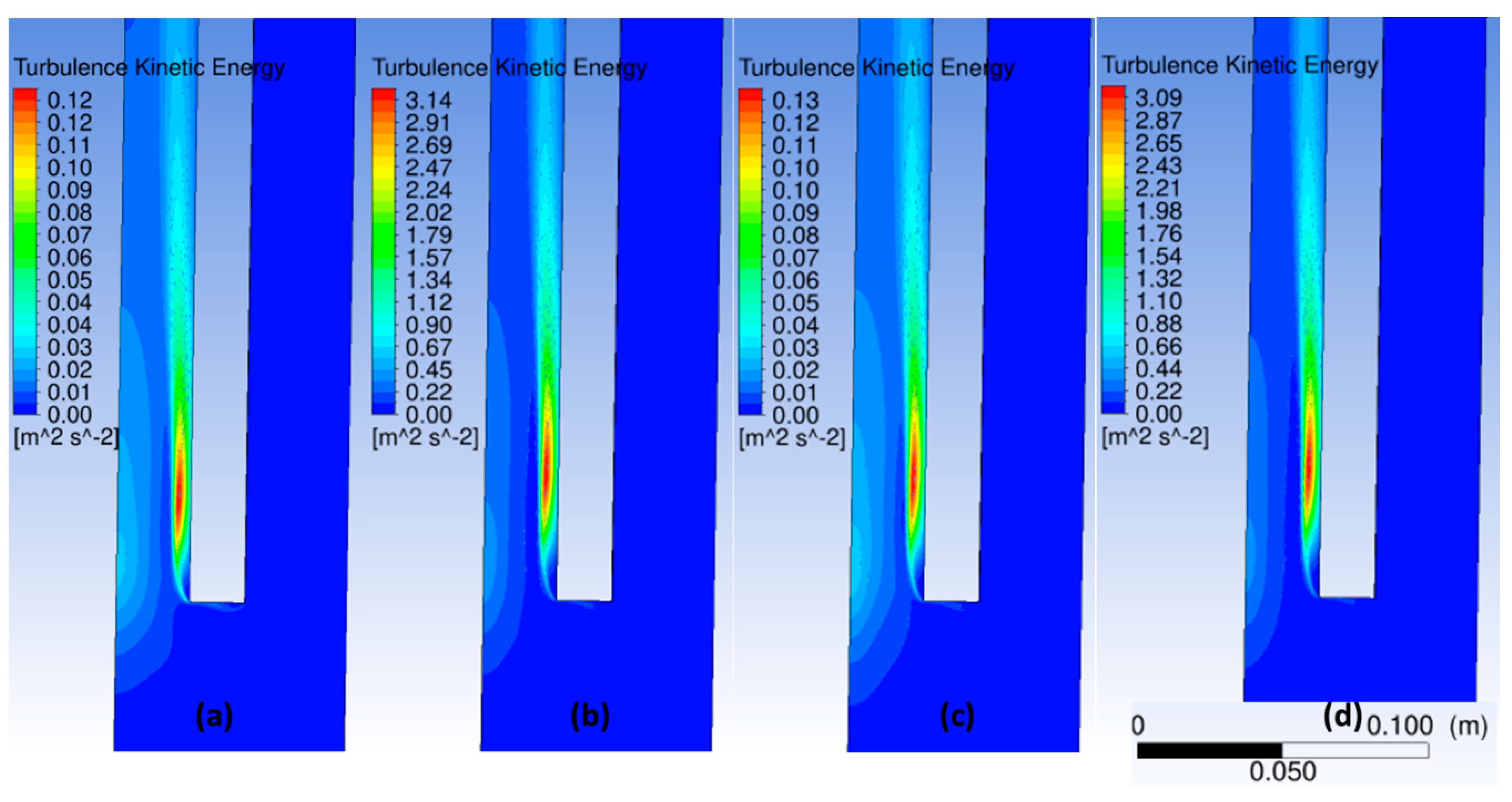

2.4. Mesh Independence Study

3. Results

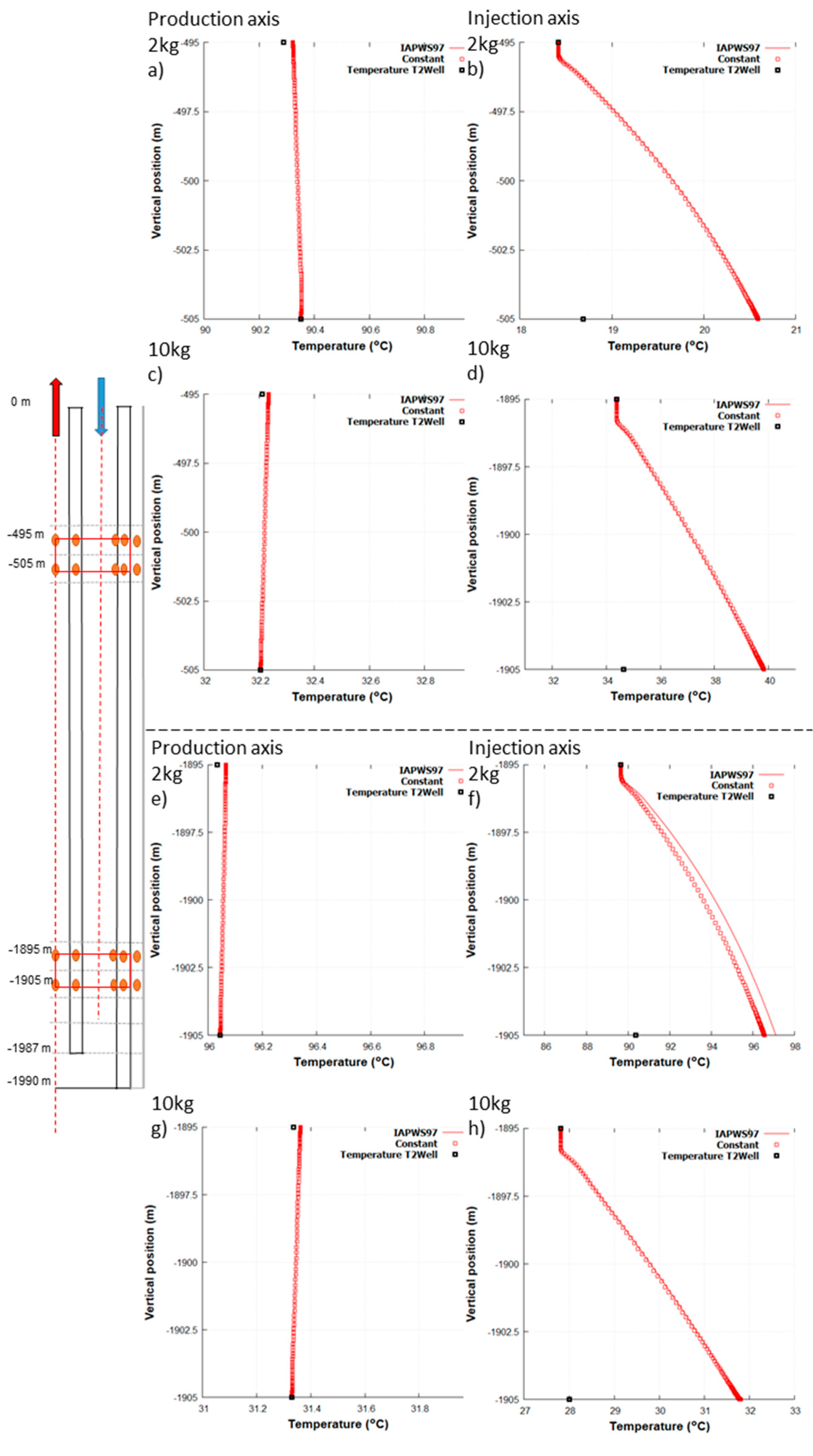

3.1. Vertical Comparison Analysis at −500 m and −1900 m

3.1.1. Thermal Analysis

3.1.2. Fluid Properties Analysis

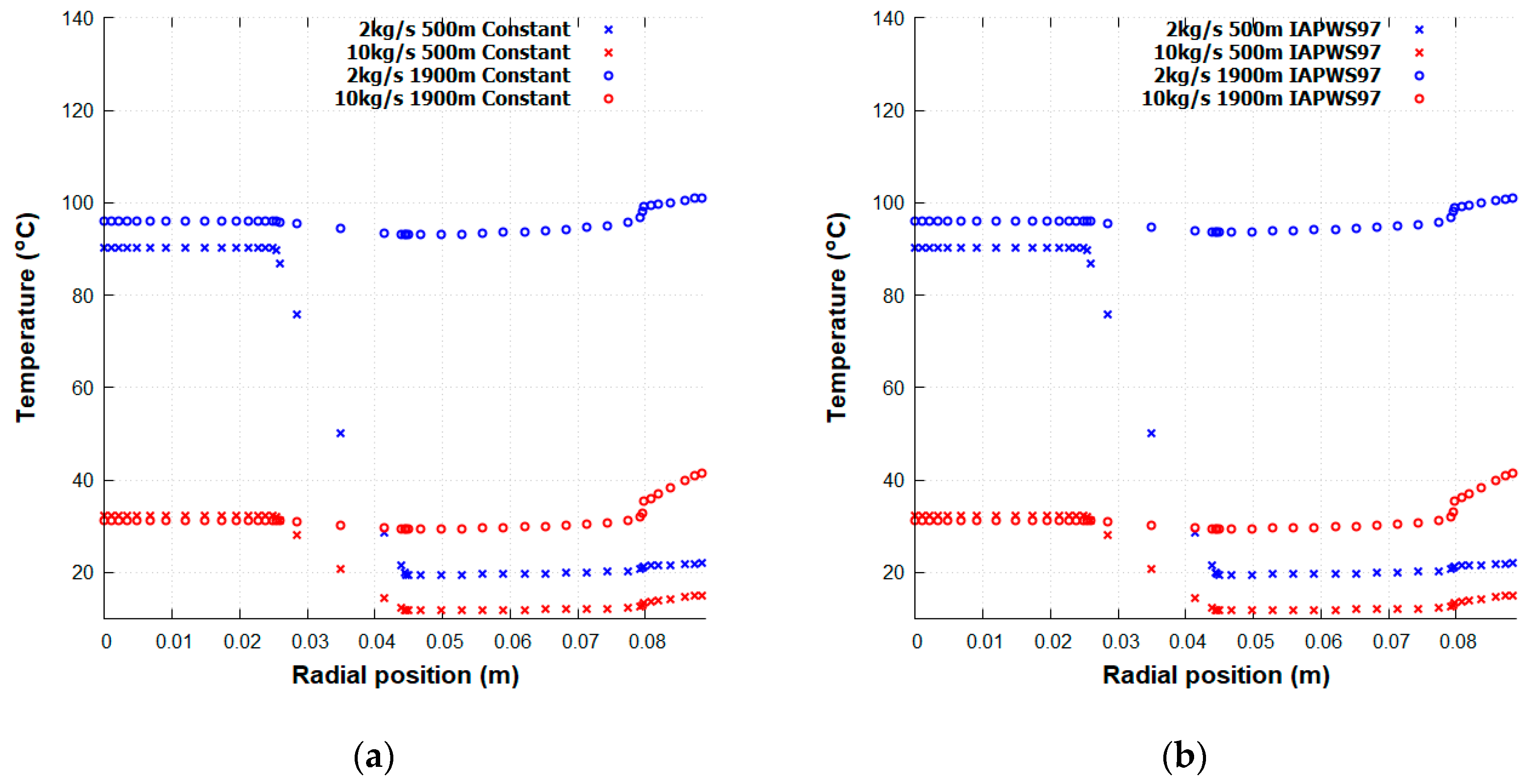

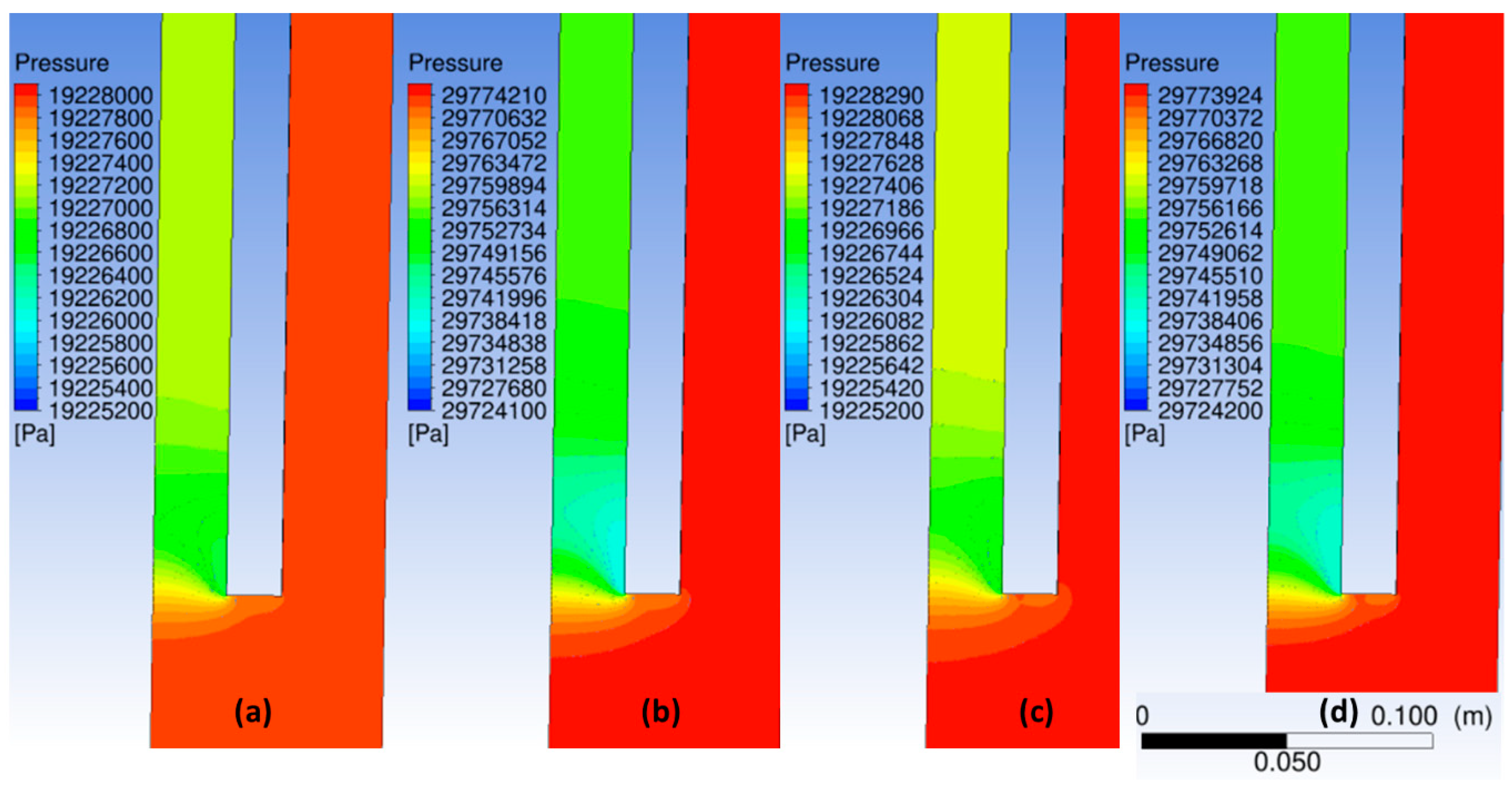

3.2. Radial Comparison Analysis at −500 m and −1900 m

3.2.1. Thermal Analysis

3.2.2. Heat Transfer Analysis

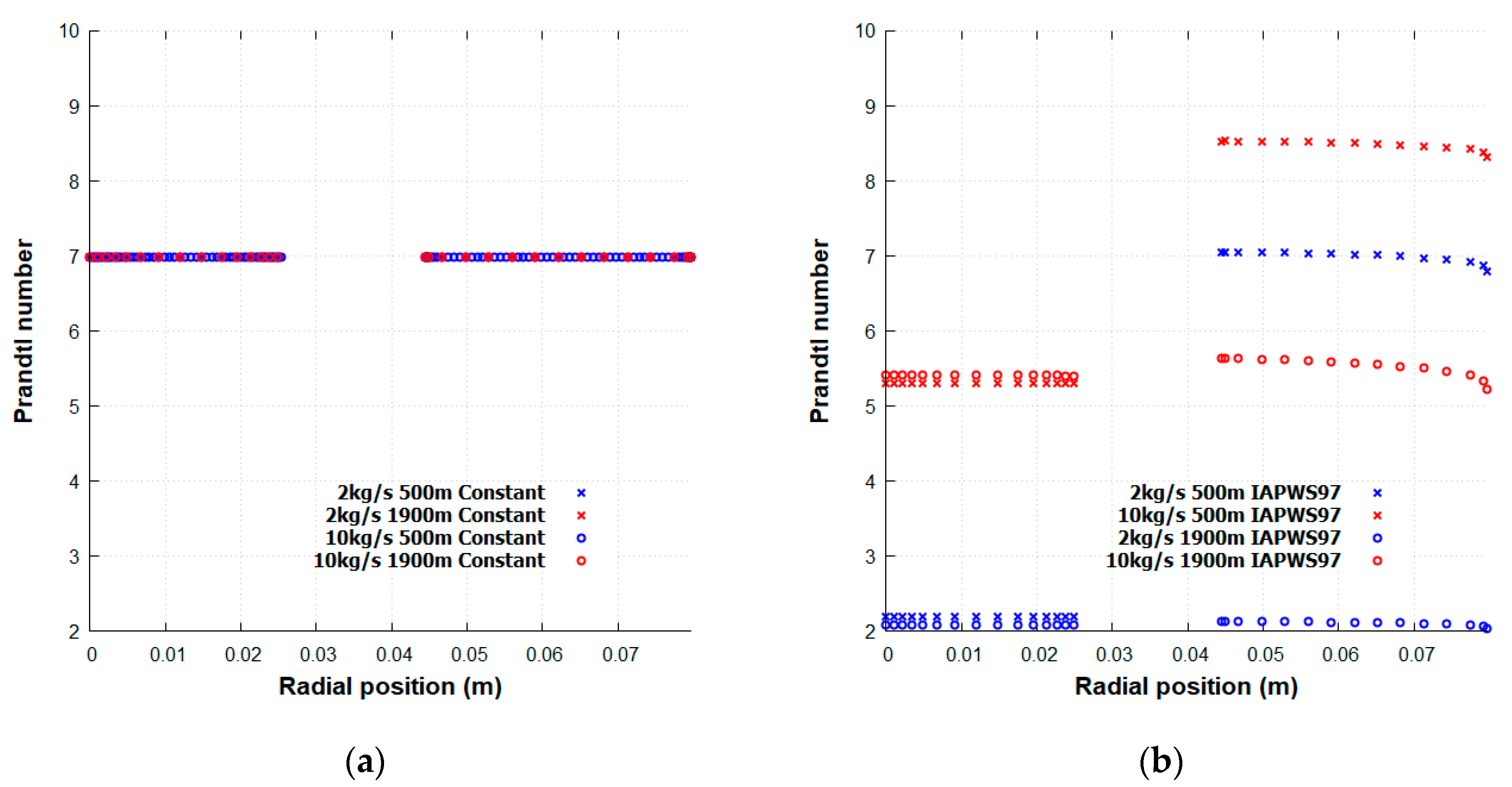

3.3. Return Flow Analysis

3.3.1. Pressure and Temperature Comparison

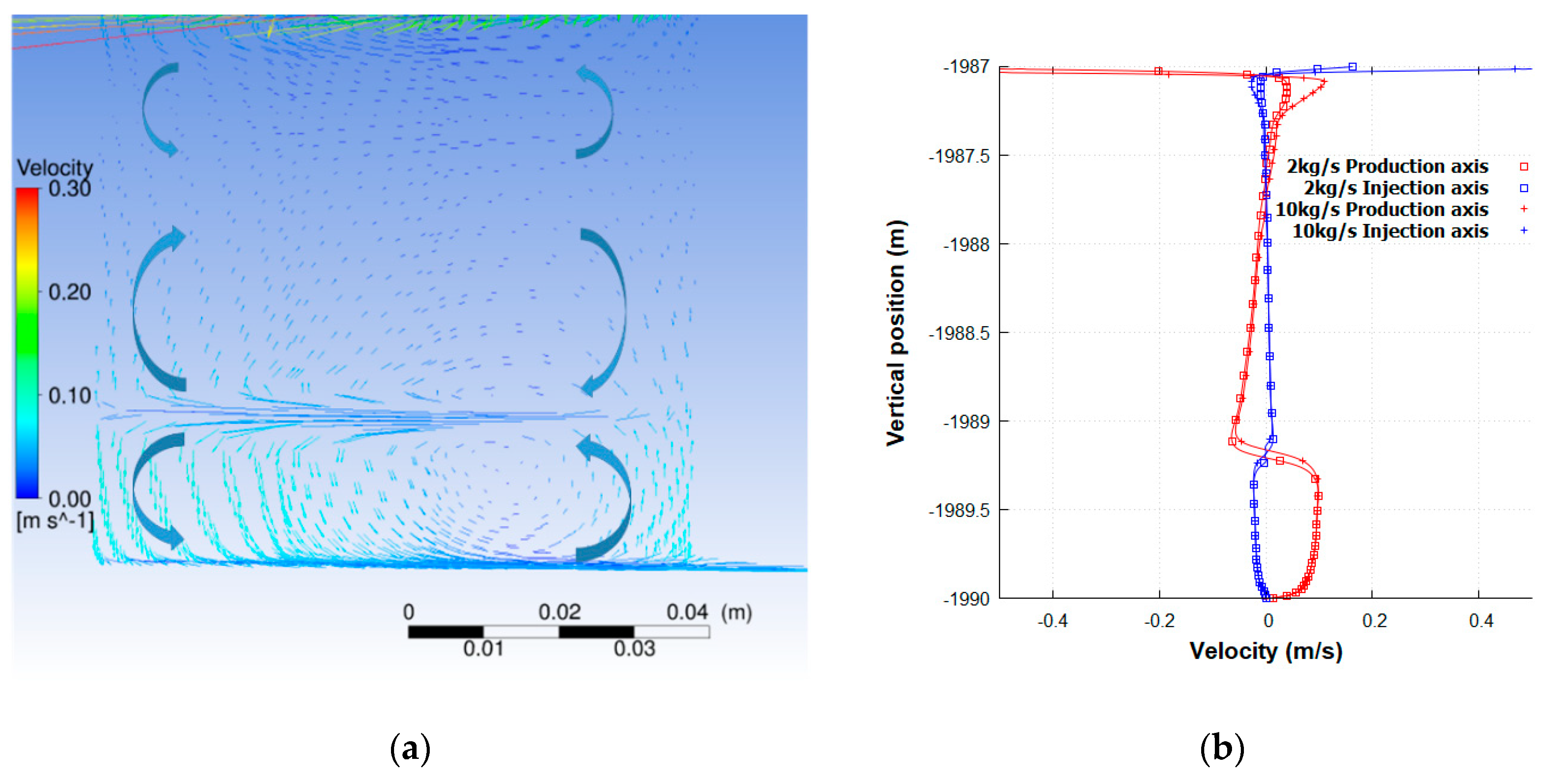

3.3.2. Velocity Field Analysis

3.3.3. Convection Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Greek Letters | ||

| α | Speed of sound | m/s |

| δ | Roughness | m |

| ε | Dissipation rate | m2/s2 |

| Γ | Surface well area | m2 |

| λ | Thermal conductivity | W/m.K |

| Ω | Perimeter of the cross section | m |

| μ, μt | Molecular, eddy viscosity | Pa.s |

| ρ | Density | kg/m3 |

| τ | Stress tensor | Pa |

| θ | Angle between the vertical axis and the wellbore section | ° |

| Roman letters | ||

| A | Cross sectional area | m2 |

| c | Specific heat capacity | J/kg.K |

| C1ε, C2, C3ε | Constants | |

| d | Diameter | m |

| E | Energy | J |

| f | Apparent friction | |

| g, | Gravitational constant, vector | 9.81 m.s−2 |

| h | Specific enthalpy | kJ/kg.K |

| J | Diffusion | kg/m2.s |

| k | Turbulence | m2/s2 |

| p | Pressure | Pa |

| q | Source, sink term | kg/s, J/s |

| r | Radial coordinate | m |

| R | Molecular gas constant | |

| S | Modulus of the mean rate of stress tensor | |

| T | Temperature | K |

| U | Internal energy | J/kg |

| uz,r, | Axial, radial velocity, velocity field | m/s |

| V | Volume | m3 |

| z | Axial coordinate, depth | m |

| Subscripts | ||

| b | Buoyancy | |

| eff | Effective | |

| i | Inner | |

| k | Turbulence | |

| o | Outer | |

| r | Radial component | |

| t | Turbulent | |

| z | Axial component, depth |

References

- Davies, J.H.; Davies, D.R. Earth’s surface heat flux. Solid Earth Discuss. 2009, 1, 1–45. [Google Scholar] [CrossRef]

- Bertani, R. Geothermal power generation in the world 2005–2010 update report. Geothermics 2012, 41, 1–29. [Google Scholar] [CrossRef]

- Tester, J.; Morris, G.; Cummings, R.; Bivins, R. Electricity from Hot Dry Rock geothermal Energy: Technical and Economic Issues; Los Alamos Scientific, Laboratory: Los Alamos, NM, USA, 1979. [Google Scholar]

- Alimonti, C.; Conti, P.; Soldo, E. A comprehensive exergy evaluation of a deep borehole heat exchanger coupled with a ORC plant: The case study of Campi Flegrei. Energy 2019, 189, 116100. [Google Scholar] [CrossRef]

- Falcone, G.; Liu, X.; Okech, R.R.; Seyidov, F.; Teodoriu, C. Assessment of deep geothermal energy exploitation methods: The need for novel single-well solutions. Energy 2018, 160, 54–63. [Google Scholar] [CrossRef]

- Song, X.; Shi, Y.; Li, G.; Shen, Z.; Hu, X.; Lyu, Z.; Zheng, R.; Wang, G. Numerical analysis of the heat production performance of a closed loop geothermal system. Renew. Energy 2018, 120, 365–378. [Google Scholar] [CrossRef]

- Westaway, R. Deep Geothermal Single Well heat production: Critical appraisal under UK conditions. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 424–449. [Google Scholar] [CrossRef]

- Alimonti, C.; Soldo, E.; Bocchetti, D.; Berardi, D. The wellbore heat exchangers: A technical review. Renew. Energy 2018, 123, 353–381. [Google Scholar] [CrossRef]

- Oldenburg, C.M.; Pan, L.; Muir, M.P.; Eastman, A.D.; Higgins, B.S. Numerical simulation of critical factors controlling heat extraction from geothermal systems using a closed-loop heat exchange method. In Proceedings of the 41st Workshop on the Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 22–24 February 2016. [Google Scholar]

- Templeton, J.; Ghoreishi-Madiseh, S.; Hassani, F.P.; Al-Khawaja, M. Abandoned petroleum wells as sustainable sources of geothermal energy. Energy 2014, 70, 366–373. [Google Scholar] [CrossRef]

- Nian, Y.-L.; Cheng, W.-L.; Yang, X.-Y.; Xie, K. Simulation of a novel deep ground source heat pump system using abandoned oil wells with coaxial BHE. Int. J. Heat Mass Transf. 2019, 137, 400–412. [Google Scholar] [CrossRef]

- Watson, S.; Falcone, G.; Westaway, R. Repurposing Hydrocarbon Wells for Geothermal Use in the UK: The Onshore Fields with the Greatest Potential. Energies 2020, 13, 3541. [Google Scholar] [CrossRef]

- Morita, K.; Bollmeier, W.S.; Mizogami, H. An Experiment to Prove the Concept of the Downhole Coaxial Heat Exchanger (DCHE) in Hawaii; Geothermal Resources Council: Davis, CA, USA, 1992. [Google Scholar]

- Dai, C.; Li, J.; Shi, Y.; Zeng, L.; Lei, H. An experiment on heat extraction from a deep geothermal well using a downhole coaxial open loop design. Appl. Energy 2019, 252, 113447. [Google Scholar] [CrossRef]

- Renaud, T.; Verdin, P.; Falcone, G. Numerical simulation of a Deep Borehole Heat Exchanger in the Krafla geothermal system. Int. J. Heat Mass Transf. 2019, 143, 118496. [Google Scholar] [CrossRef]

- Bu, X.; Ma, W.; Li, H. Geothermal energy production utilizing abandoned oil and gas wells. Renew. Energy 2012, 41, 80–85. [Google Scholar] [CrossRef]

- Le Lous, M.; Larroque, F.; Dupuy, A.; Moignard, A. Thermal performance of a deep borehole heat exchanger: Insights from a synthetic coupled heat and flow model. Geothermics 2015, 57, 157–172. [Google Scholar] [CrossRef]

- Renaud, T. Forced Convection Heat Transfer in Unconventional Geothermal Systems Numerical Investigation of Complex Flow Processes Neat Magmatic Chambers. Ph.D. Thesis, Cranfield University, Cranfield, UK, February 2020. [Google Scholar]

- Renaud, T.; Verdin, P.; Falcone, G.; Pan, L. Heat transfer modelling of an unconventional, closed-loop geothermal well. In Proceedings of the World Geothermal Congress, Reykjavik, Iceland, 26 April–2 May 2020. [Google Scholar]

- Noorollahi, Y.; Pourarshad, M.; Jalilinasrabady, S.; Yousefi, H. Numerical simulation of power production from abandoned oil wells in Ahwaz oil field in southern Iran. Geothermics 2015, 55, 16–23. [Google Scholar] [CrossRef]

- Tang, H.; Xu, B.; Hasan, A.R.; Sun, Z.; Killough, J. Modeling wellbore heat exchangers: Fully numerical to fully analytical solutions. Renew. Energy 2019, 133, 1124–1135. [Google Scholar] [CrossRef]

- Alimonti, C.; Soldo, E. Study of geothermal power generation from a very deep oil well with a wellbore heat exchanger. Renew. Energy 2016, 86, 292–301. [Google Scholar] [CrossRef]

- Chen, C.; Shao, H.; Naumov, D.; Kong, Y.; Tu, K.; Kolditz, O. Numerical investigation on the performance, sustainability, and efficiency of the deep borehole heat exchanger system for building heating. Geotherm. Energy 2019, 7, 18. [Google Scholar] [CrossRef]

- Hu, X.; Banks, J.; Wu, L.; Liu, W.V. Numerical modeling of a coaxial borehole heat exchanger to exploit geothermal energy from abandoned petroleum wells in Hinton, Alberta. Renew. Energy 2020, 148, 1110–1123. [Google Scholar] [CrossRef]

- Sui, D.; Wiktorski, E.; Røksland, M.; Basmoen, T.A. Review and investigations on geothermal energy extraction from abandoned petroleum wells. J. Pet. Explor. Prod. Technol. 2019, 9, 1135–1147. [Google Scholar] [CrossRef]

- Heller, K.; Teodoriu, C.; Falcone, G. A new deep geothermal concept based on the geyser principle. In Proceedings of the 39th Workshop Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 24–26 February 2014. [Google Scholar]

- Hara, H. Geothermal Well Using Graphite as Solid Conductor. U.S. Patent Application US20110232858A1, 29 September 2011. [Google Scholar]

- Cheng, W.-L.; Li, T.-T.; Nian, Y.-L.; Xie, K. Evaluation of working fluids for geothermal power generation from abandoned oil wells. Appl. Energy 2014, 118, 238–245. [Google Scholar] [CrossRef]

- Pan, L.; Oldenburg, C.M. T2Well—An integrated wellbore–reservoir simulator. Comput. Geosci. 2014, 65, 46–55. [Google Scholar] [CrossRef]

- ANSYS. Ansys Fluent Theory Guide; Volume Release 17; ANSYS: Canonsburg, PA, USA, 2016. [Google Scholar]

- Wagner, W.; Cooper, J.R.; Dittmann, A.; Kijima, J.; Kretzschmar, H.-J.; Kruse, A.; Mares, R.; Oguchi, K.; Sato, H.; Sto¨cker, I.; et al. The IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and Steam. J. Eng. Gas Turbines Power 2000, 122, 150–184. [Google Scholar] [CrossRef]

- Pruess, K.; Oldenburg, C.; Moridis, G. TOUGH2 User’s Guide. Earth Sciences Division; Lawrence Berkeley National Laboratory, University of California: Berkeley, CA, USA, 2012.

| Properties | Water | C1 | C2 |

|---|---|---|---|

| Density (kg/m3) | 998.2 | 7850 | 7850 |

| Thermal Conductivity (W/m.K) | 0.6 | 0.06 | 46.1 |

| Specific heat (J/kg.K) | 4182 | 470 | 470 |

| Viscosity (kg/m.s) | 0.001003 | ||

| Inner/Outer radius (m) | 0.0253/0.0445 | 0.0797/0.0889 |

| CFD Models | Mass Flow Rate (kg/s) | N1 | N2 | N3 | N4 | N5 |

|---|---|---|---|---|---|---|

| 495 m/505 m | ||||||

| 1895 m/1905 m | ||||||

| 1978 m/1990 m | ||||||

| CFD 500 | 2 | 90.29/90.35 | 49.33/49.5 | 11.91/11.98 | 18.45/18.725 | 21.85/22.18 |

| 4,799,675/4,896,675 | 4,868,875/4,967,075 | |||||

| 10 | 32.21/32.20 | 20.36/20.38 | 11.41/11.46 | 11.45/11.50 | 15.15/15.28 | |

| 7,382,175/7,530,275 | 23,168,675/23,266,675 | |||||

| CFD 1900 | 2 | 96.03/96.04 | 92.39/92.80 | 89.65/90.36 | 89.76/90.47 | 100.87/101.63 |

| 18,393,675/28,217,675 | 18,488,675/18,583,675 | |||||

| 10 | 31.34/31.33 | 29.33/29.43 | 27.82/28 | 27.96/28.14 | 41.85/42.10 | |

| 28,143,675/28,291,675 | 36,921,675/37,019,675 | |||||

| CFD 1987 | 2 | 96.11/337.71 | 95.69/337.71 | 29.28/337.71 | 95.49/337.71 | 107.01/108.10 |

| 19,195,973 | 108.35/337.71 | |||||

| 10 | 31.27/336.51 | 30.15/336.51 | 29.28/336.51 | 29.43/336.51 | 43.93/44.73 | |

| 2,9368,858 | 44.91/336.51 |

| Depth | Density | Thermal | Conductivity | Viscosity | ||

|---|---|---|---|---|---|---|

| 2 kg/s | 10 kg/s | 2 kg/s | 10 kg/s | 2 kg/s | 10 kg/s | |

| 500 m | 3.10/−0.22 | 0/0.2 | −12.62/−0.26 | −3.66/0.30 | 68.66/−0.52 | 24.11/−21.71 |

| 1900 m | 2.87/2.74 | −0.91/−1.33 | −14.32/−14.17 | −5.23/−5.59 | 70.22/69.61 | 22.63/20.11 |

| Pressure in the Annular at −1987 m (Pa/bar) | Temperature in the Internal tubing at −1987 m (K) | |||

|---|---|---|---|---|

| 2 kg/s | 10 kg/s | 2 kg/s | 10 kg/s | |

| CFD constant | 1.92281 × 107/192 | 2.97761 × 107/297 | 375.08 | 305.39 |

| CFD IAPWS-IF97 | 1.92272 × 107/192 | 2.97752 × 107/297 | 375.43 | 302.43 |

| T2Well | 1.92748 × 107/192 | 3.77324 × 107/377 | 369.26 | 304.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renaud, T.; Verdin, P.G.; Falcone, G. Conjugated Numerical Approach for Modelling DBHE in High Geothermal Gradient Environments. Energies 2020, 13, 6107. https://doi.org/10.3390/en13226107

Renaud T, Verdin PG, Falcone G. Conjugated Numerical Approach for Modelling DBHE in High Geothermal Gradient Environments. Energies. 2020; 13(22):6107. https://doi.org/10.3390/en13226107

Chicago/Turabian StyleRenaud, Theo, Patrick G. Verdin, and Gioia Falcone. 2020. "Conjugated Numerical Approach for Modelling DBHE in High Geothermal Gradient Environments" Energies 13, no. 22: 6107. https://doi.org/10.3390/en13226107

APA StyleRenaud, T., Verdin, P. G., & Falcone, G. (2020). Conjugated Numerical Approach for Modelling DBHE in High Geothermal Gradient Environments. Energies, 13(22), 6107. https://doi.org/10.3390/en13226107