The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland

Abstract

1. Introduction

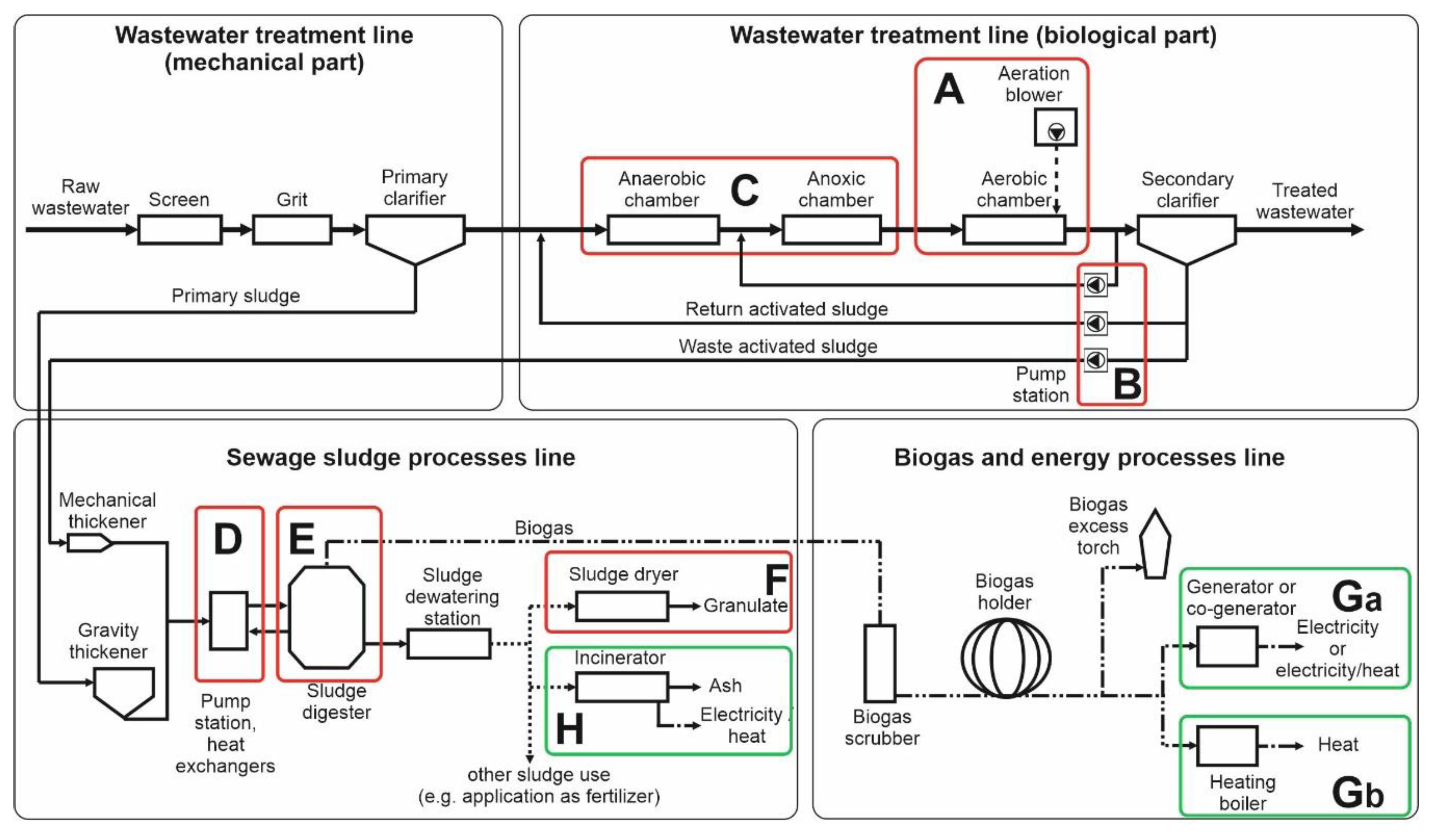

2. Energy Intensity and Biogas Energy Technology of WWTPs

2.1. Energy Consumption in the Technological Wastewater Treatment Processes

2.2. Biogas Production from Sewage Sludge in a Wastewater Treatment Plant

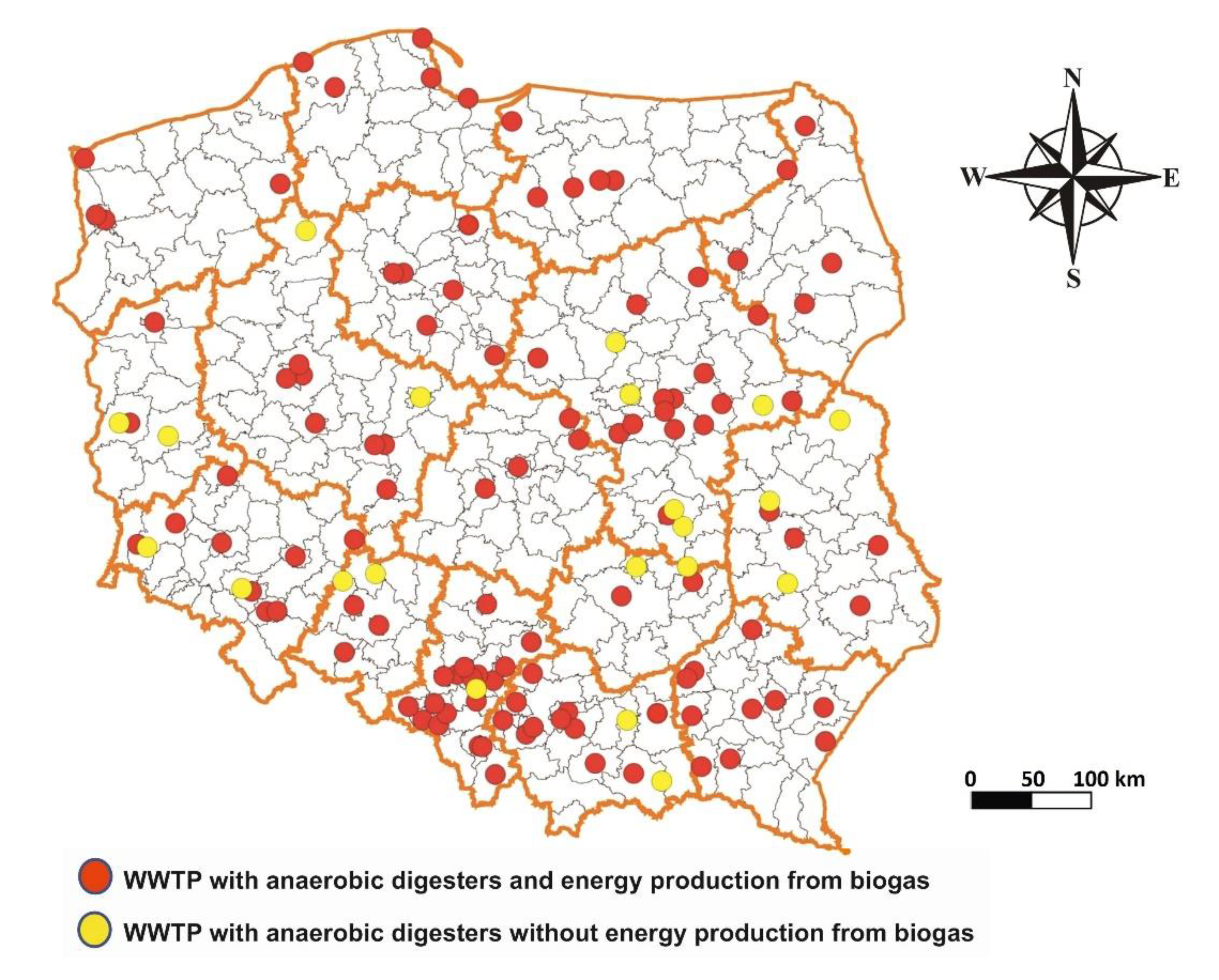

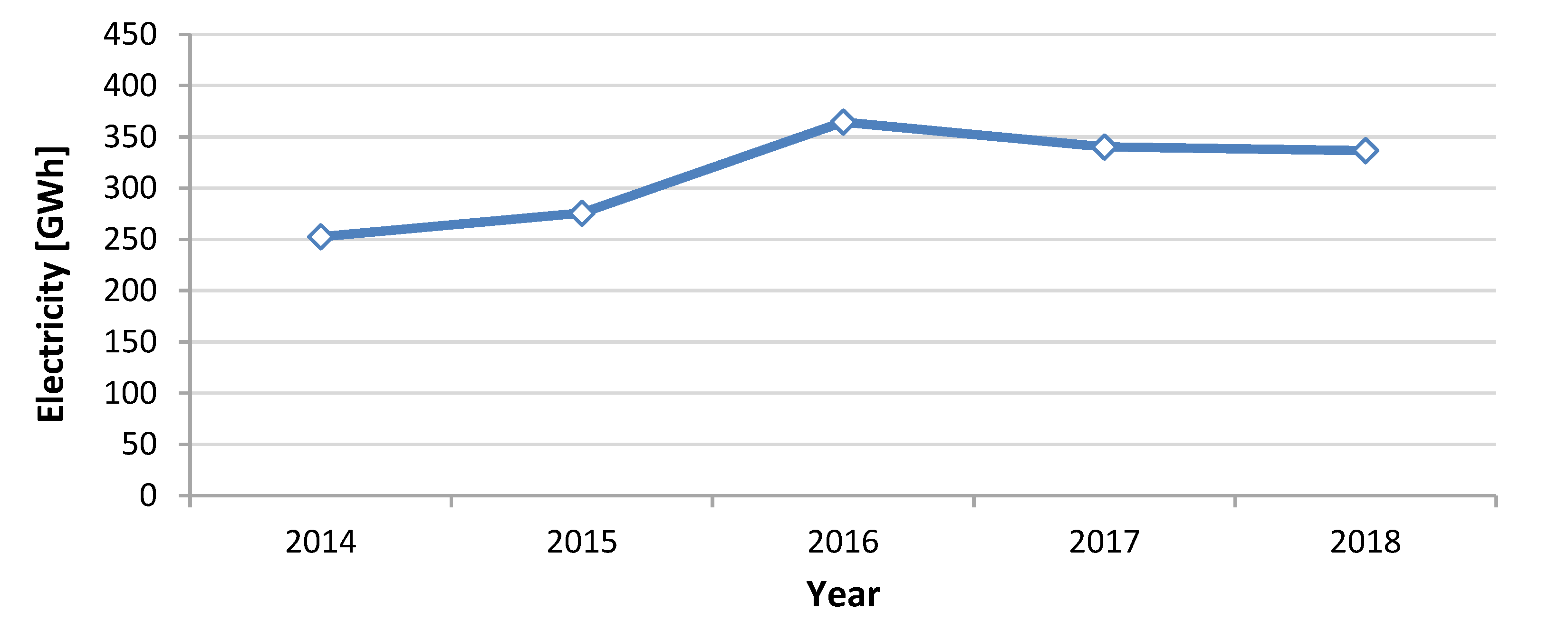

3. Biogas Utilization at WWTPs in Poland

4. Materials and Methods

4.1. Description of the Plant

4.1.1. General Characteristics of the Wastewater Treatment Plant in Iława

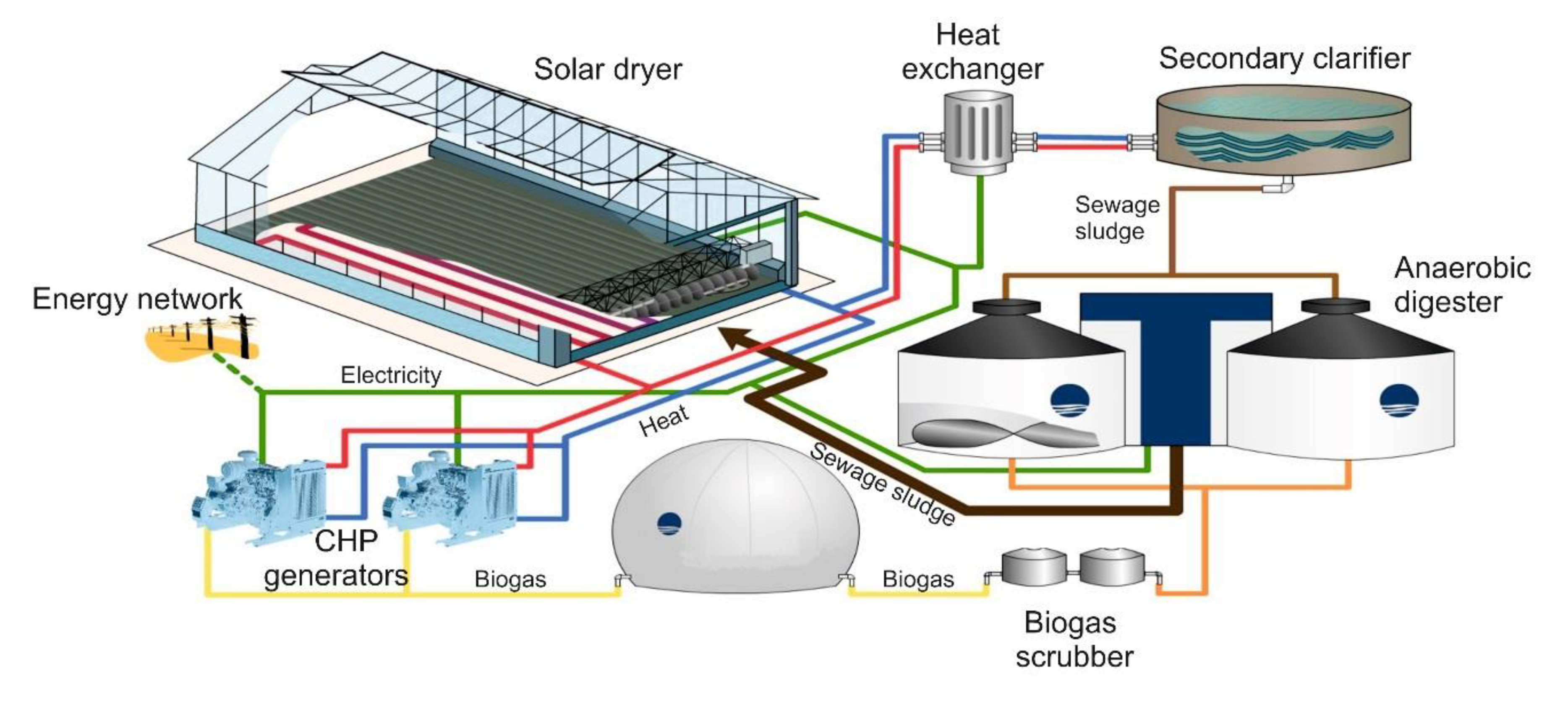

4.1.2. Sludge-Energy System in the WWTP

4.2. Methods

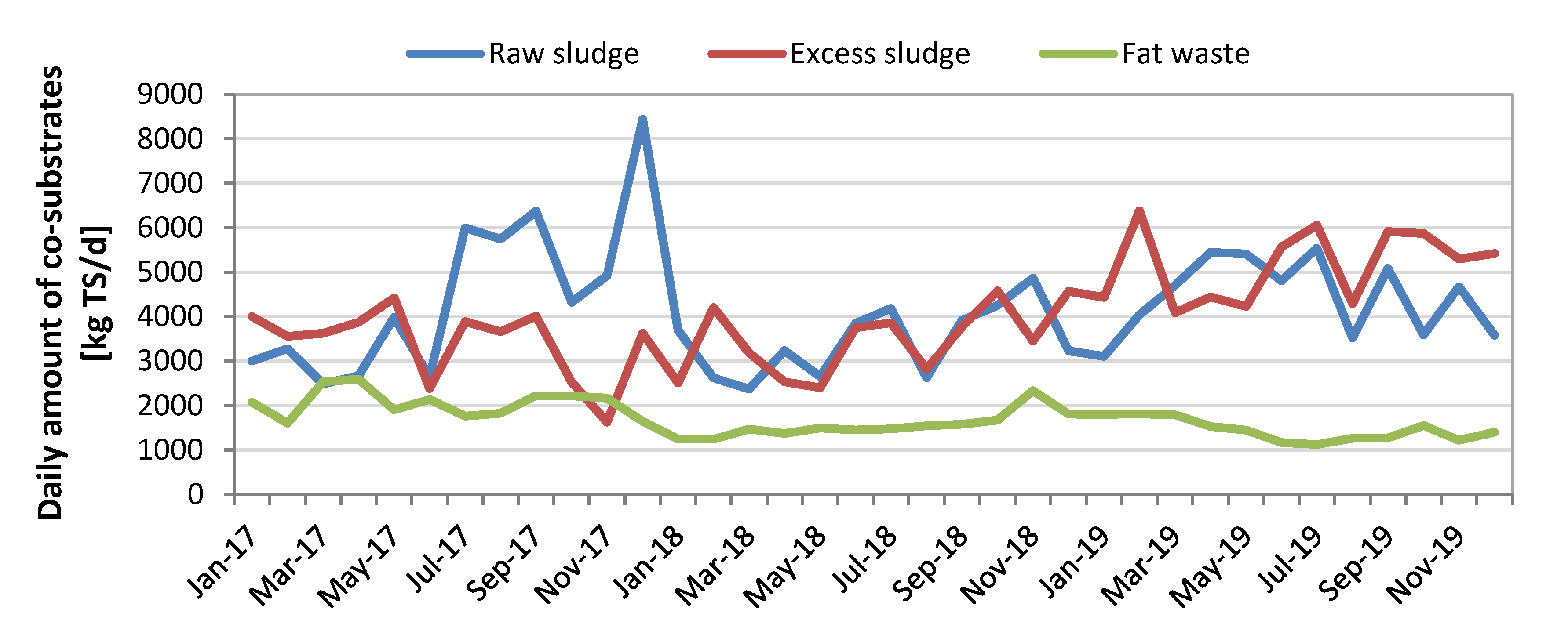

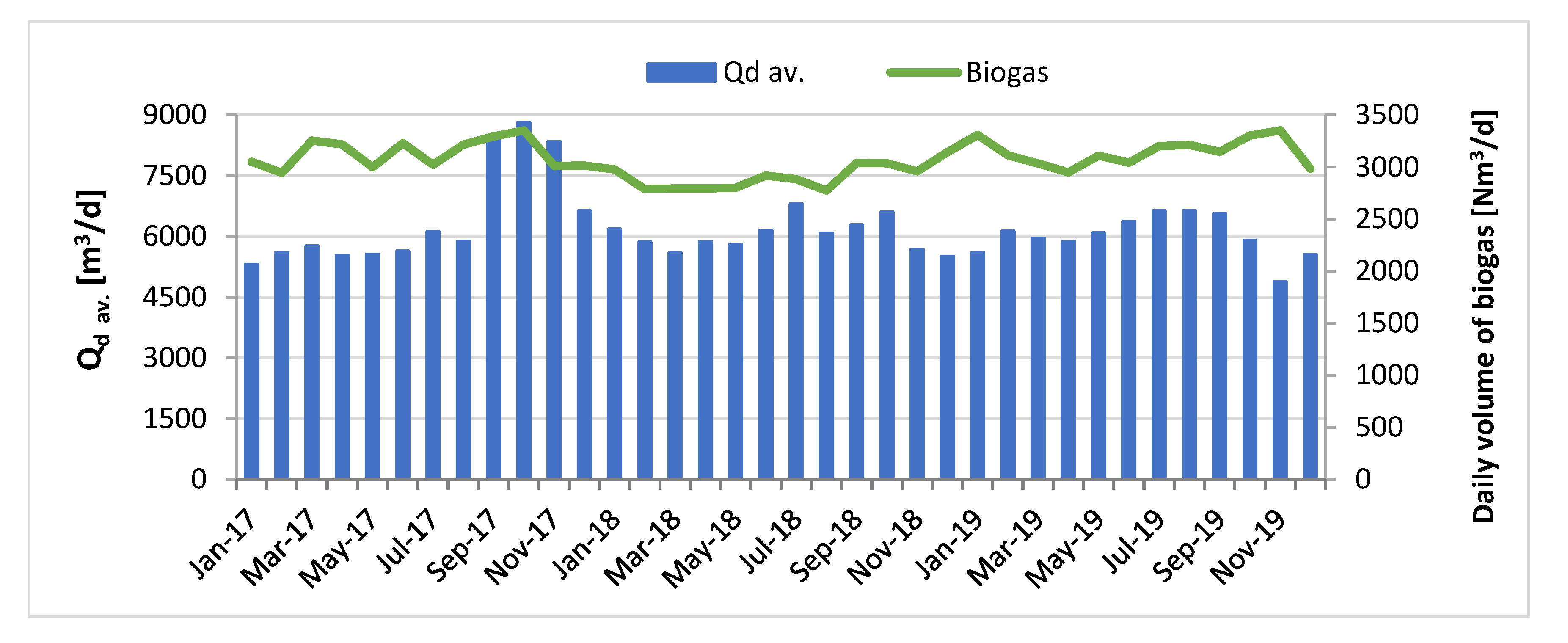

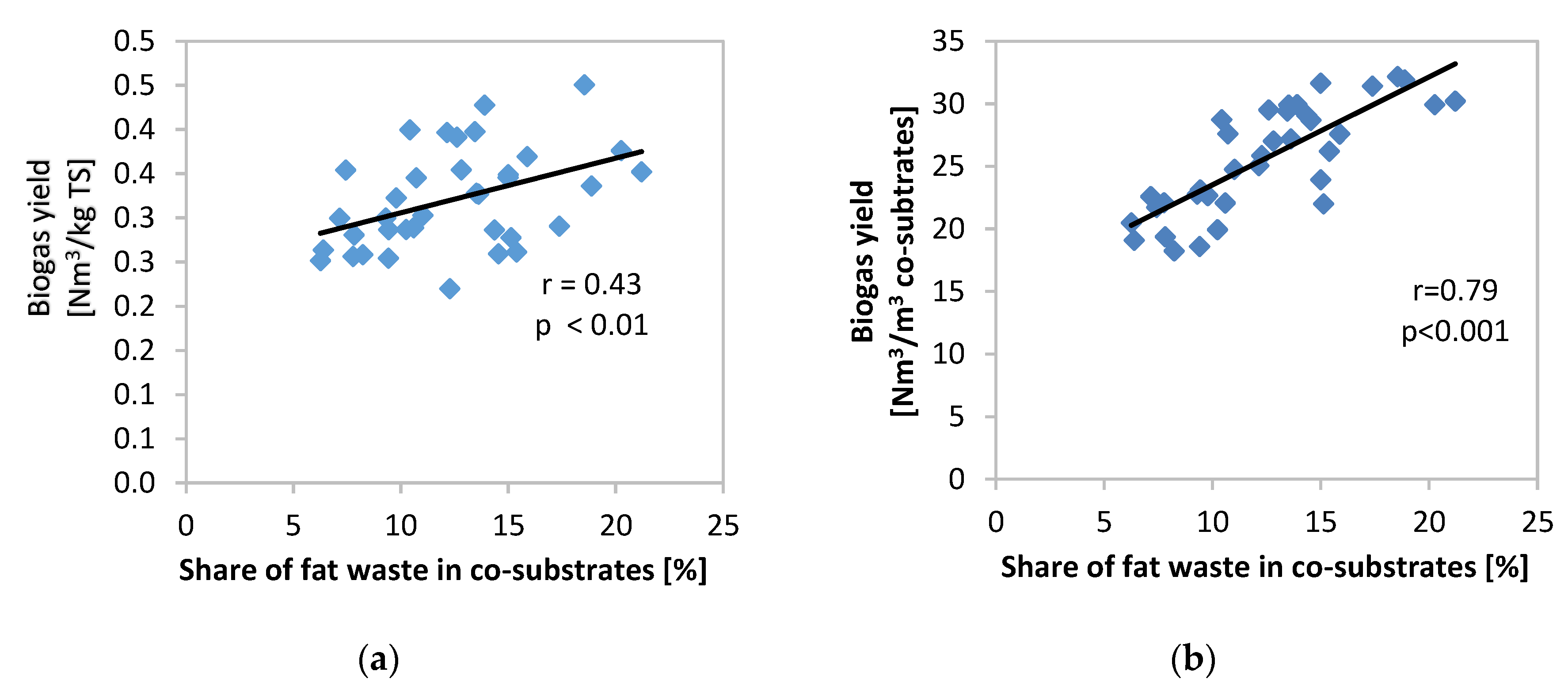

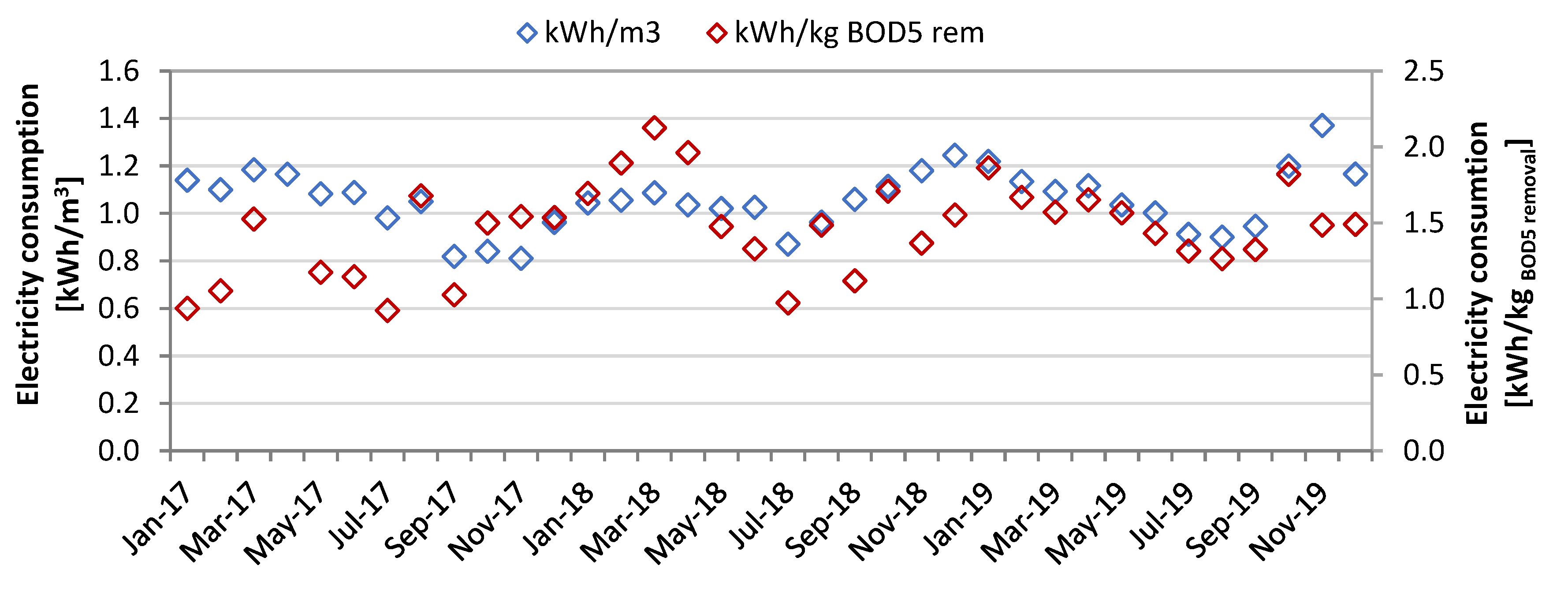

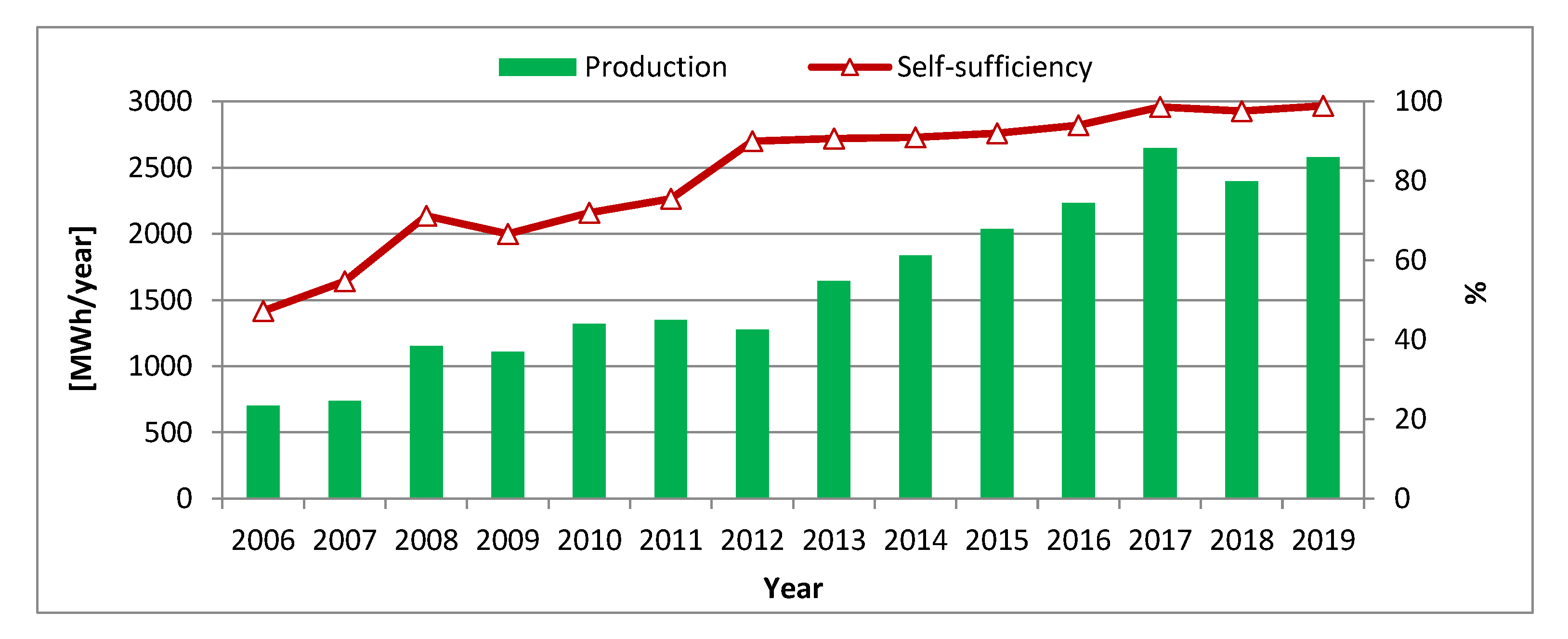

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AcoD | anaerobic co-digestion process |

| AD | anaerobic digestion |

| BOD5 | Biochemical Oxygen Demand |

| CHP | combined heat and power |

| ES | excess sludge |

| FOG | fat, oil, and grease wastes |

| HRT | hydraulic retention time |

| LCFA | long-chain fatty acids |

| MWel | megawatts electric |

| OFMSW | organic fraction of municipal solid waste |

| OLR | organic loading rate |

| PE | population equivalent |

| PS | population equivalent |

| TS | total solids content |

| VS | volatile solids |

| WWTP | wastewater treatment plant |

References

- Di Fraia, S.; Massarotti, N.; Vanoli, L. A novel energy assessment of urban wastewater treatment plants. Energy Convers. Manag. 2018, 163, 304–313. [Google Scholar] [CrossRef]

- Masłoń, A.; Wójcik, M.; Chmielowski, K. Efficient use of energy in wastewater treatment plants. Energy Policy Stud. 2018, 1, 12–26. [Google Scholar]

- Roots, P.; Sabba, F.; Rosenthal, A.F.; Wang, Y.; Yuan, Q.; Rieger, L.; Yang, F.; Kozak, J.A.; Zhang, H.; Wells, G.F. Integrated shortcut nitrogen and biological phosphorus removal from mainstream wastewater: Process operation and modeling. Environ. Sci. Water Res. Technol. 2020, 6, 566–580. [Google Scholar] [CrossRef]

- Wang, B.; Guo, Y.; Zhao, M.; Li, B.; Peng, Y. Achieving Energy-Efficient Nitrogen Removal and Excess Sludge Reutilization by Partial Nitritation and Simultaneous Anammox Denitrification and Sludge Fermentation Process. Chemosphere 2019, 218, 705–714. [Google Scholar] [CrossRef] [PubMed]

- Czarnota, J.; Masłoń, A.; Zdeb, M.; Łagód, G. The impact of different powdered mineral materials on selected properties of aerobic granular sludge. Molecules 2020, 25, 386. [Google Scholar] [CrossRef]

- Drewnowski, J.; Mąkinia, J.; Szaja, A.; Łagód, G.; Kopeć, Ł.; Aguilar, J.A. Comparative Study of Balancing SRT by Using Modified ASM2d in Control and Operation Strategy at Full-Scale WWTP. Water 2019, 11, 485. [Google Scholar] [CrossRef]

- Drewnowski, J.; Remiszewska-Skwarek, A.; Duda, S.; Łagód, G. Aeration Process in Bioreactors as the Main Energy Consumer in a Wastewater Treatment Plant. Review of Solutions and Methods of Process Optimization. Processes 2019, 7, 311. [Google Scholar] [CrossRef]

- Szeląg, B.; Drewnowski, J.; Łagód, G.; Majerek, D.; Dacewicz, E.; Fatone, F. Soft Sensor Application in Identification of the Activated Sludge Bulking Considering the Technological and Economical Aspects of Smart Systems Functioning. Sensors 2020, 20, 1941. [Google Scholar] [CrossRef]

- Silvestre, G.; Fernández, B.; Bonmatí, A. Significance of anaerobic digestion as a source of clean energy in wastewater treatment plants. Energy Convers. Manag. 2015, 101, 255–262. [Google Scholar] [CrossRef]

- De Vrieze, J.; Smet, D.; Klok, J.; Colsen, J.; Angenent, L.T.; Vlaeminck, S.E. Thermophilic sludge digestion improves energy balance and nutrient recovery potential in full-scale municipal wastewater treatment plants. Bioresour. Technol. 2016, 218, 1237–1245. [Google Scholar] [CrossRef]

- Wu, N.; Moreira, C.; Zhang, Y.; Doan, N.; Yang, S.; Phlips, E.; Svoronos, S.; Pullammanappallil, P. Techno-Economic Analysis of Biogas Production from Microalgae through Anaerobic Digestion. In Anaerobic Digestion; Banu, J.R., Ed.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Pellera, F.; Gidarakos, E. Anaerobic digestion of solid agroindustrial waste in semi-continuous mode: Evaluation of mono-digestion and co-digestion systems. Waste Manag. 2017, 68, 103–119. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.Q.; Yang, S.S.; Xiang, W.S.; Wang, X.J.; Ren, N.Q. Minimization of excess sludge production by in-situ activated sludge treatment processes - A comprehensive review. Biotechnol. Adv. 2013, 31, 1386–1396. [Google Scholar] [CrossRef] [PubMed]

- Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant–Challenges and Barriers. Proceedings 2018, 2, 614. [Google Scholar] [CrossRef]

- Mata-Álvares, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Rabii, A.; Aldin, S.; Dahman, Y.; Elbeshbishy, E. A review on anaerobic co-digestion with a focus on the microbial populations and the effect of multi-stage digester configuration. Energies 2019, 12, 1106. [Google Scholar] [CrossRef]

- Alrawashdeh, K.A.B.; Pugliese, A.; Slopiecka, K.; Pistolesi, V.; Massoli, S.; Bartocci, P.; Bidini, G.; Fantozzi, F. Codigestion of untreated and treated sewage sludge with the organic fraction of municipal solid wastes. Fermentation 2017, 3, 35. [Google Scholar] [CrossRef]

- Xie, S.; Wickham, R.; Nghiem, L.D. Synergistic effect from anaerobic co-digestion of sewage sludge and organic wastes. Int. Biodeterior. Biodegrad. 2017, 116, 191–197. [Google Scholar] [CrossRef]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Longo, S.; d’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and diagnosis of Energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl. Energy 2016, 176, 1251–1268. [Google Scholar] [CrossRef]

- Kiselev, A.; Magaril, E.; Magaril, R.; Panepinto, D.; Ravina, M.; Zanetti, M.C. Towards Circular Economy: Evaluation of Sewage Sludge Biogas Solutions. Resources 2019, 8, 91. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, T.; Li, X.; Huang, J.; Peng, D.; Maurer, C.; Kranert, M. Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge. Energies 2020, 13, 818. [Google Scholar] [CrossRef]

- Spellman, F.R. Water & Wastewater Infrastructure: Energy Efficiency and Sustainability, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 1–463. [Google Scholar]

- Orchowski, M.; Masłoń, A.; Heidrich, Z. Energy consumption of the Sandomierz wastewater treatment plant. Gas Water Sanit. Eng. 2018, 2, 72–77. [Google Scholar] [CrossRef]

- Bodík, I.; Kubaská, M. Energy and sustainability of operation of a wastewater treatment plant. Environ. Protect. Eng. 2013, 39, 15–24. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Lo, S.L. Sludge: A waste or renewable source for energy and resources recovery? Renew. Sustain. Energy Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Koniuszewska, I.; Korzeniewska, E.; Harnisz, M.; Czatzkowska, M. Intensification of biogas production using various technologies: A review. Int. J. Energy Res. 2020, 44, 6240–6258. [Google Scholar] [CrossRef]

- Dymaczewski, Z.; Szulc, P. The modern wastewater treatment plant in the concept of sustainable development. In Proceedings of the Technical Conference “Innovative Solutions in Wastewater Treatment and Sludge Management”, Piła, Poland, 10–11 October 2017. [Google Scholar]

- Caposciutti, G.; Baccioli, A.; Ferrari, L.; Desideri, U. Biogas from Anaerobic Digestion: Power Generation or Biomethane Production? Energies 2020, 13, 743. [Google Scholar] [CrossRef]

- Parsons, D.; Marcet, E.C.; Jeffrey, P. Carbon Sensitive Urban Water Futures. D 21.1; E.U: Tansitions to the Urban Water Services of Tomorrow (TRUST), 2012; Available online: https://ita.upv.es/TRUST/downloads/index.php?iddesc=1 (accessed on 16 June 2020).

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: Challenges and opportunities towards energy-neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef]

- Dzene, I.; Slotina, L. Efficient Heat Use from Biogas CHP Plants. Case Studies from Biogas Plants in Latvia. Environ. Clim. Technol. 2013, 3, 45–48. [Google Scholar] [CrossRef]

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A review of biogas utilization, purification and upgrading technologies. Waste Biomass Valori. 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Grosser, A.; Neczaj, E. Sewage sludge and fat rich materials co-digestion-Performance and energy potential. J. Clean. Prod. 2018, 198, 1076–1089. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Szaja, A.; Montusiewicz, A. Enhancing the co-digestion efficiency of sewage sludge and cheese whey using brewery spent grain as an additional substrate. Bioresour. Technol. 2019, 291, 121863. [Google Scholar] [CrossRef] [PubMed]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Choi, J.-M.; Han, S.-K.; Lee, C.-Y. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Biores. Technol. 2018, 259, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Svensson, K.; Kjørlaug, O.; Higgins, M.J.; Linjordet, R.; Horn, S. Post-anaerobic digestion thermal hydrolysis of sewage sludge and food waste: Effect on methane yields, dewaterability and solids reduction. Wat. Res. 2018, 132, 158–166. [Google Scholar] [CrossRef]

- Yang, D.; Hu, C.; Dai, L.; Liu, Z.; Dong, B.; Dai, X. Post-thermal hydrolysis and centrate recirculation for enhancing anaerobic digestion of sewage sludge. Waste Manag. 2019, 92, 39–48. [Google Scholar] [CrossRef]

- Grübel, K.; Wacławek, S.; Kuglarz, M.; Wacławek, M.; Černík, M. Improvement of the thermophilic anaerobic digestion and hygienisation of waste activated sludge by synergistic pretreatment. J. Environ. Sci. Health—Part A Toxic/Hazardous Subst. Environ. Eng. 2019, 54, 694–700. [Google Scholar] [CrossRef]

- Waclawek, S.; Grübel, K.; Silvestri, D.; Padil, V.V.T.; Waclawek, M.; Cerník, M.; Varma, R.S. Disintegration of wastewater activated sludge (WAS) for improved biogas production. Energies 2019, 12, 21. [Google Scholar] [CrossRef]

- Xie, S.; Higgins, M.J.; Bustamante, H.; Galway, B.; Nghiem, L.D. Current status and perspectives on anaerobic co-digestion and associated downstream processes. Environ. Sci. Water Res. Technol. 2018, 4, 1759–1770. [Google Scholar] [CrossRef]

- Widomski, M.K. Selected methods of water resources accounting in the aspect of sustainable development. Probl. Ekorozw./Probl. Sustain. Dev. 2014, 9, 141–150. [Google Scholar]

- Pawłowski, A.; Pawłowski, L. Impact of energy acquisition methods on the implementation of sustainable development paradigms (In Polish). Rocz. Ochr. Sr. 2016, 18, 19–37. [Google Scholar]

- Werle, S. Sewage Sludge-To-Energy Management in Eastern Europe: A Polish Perspective. Ecol. Chem. Eng. S 2015, 22, 459–469. [Google Scholar] [CrossRef]

- Siddique, M.N.I.; Wahid, Z.A. Achievements and perspectives of anaerobic co-digestion: A review. J. Clean. Prod. 2018, 194, 359–371. [Google Scholar] [CrossRef]

- Cano, R.; Pérez-Elvira, S.I.; Fdz-Polanco, F. Energy feasibility study of sludge pretreatments: A review. Appl. Energy 2015, 149, 176–185. [Google Scholar] [CrossRef]

- Silvestre, G.; Rodríguez-Abalde, A.; Fernández, B.; Flotats, X.; Bonmatí, A. Biomass adaptation over anaerobic co-digestion of sewage sludge and trapped grease waste. Bioresour. Technol. 2011, 102, 6830–6836. [Google Scholar] [CrossRef]

- Astals, S.; Esteban-Gutiérrez, M.; Fernández-Arévalo, T.; Aymerich, E.; García-Heras, J.L.; Mata-Alvarez, J. Anaerobic digestion of seven different sewage sludges: A biodegradability and modelling study. Water Res. 2013, 47, 6033–6043. [Google Scholar] [CrossRef]

- Bulak, P.; Proc, K.; Pawłowska, M.; Kasprzycka, A.; Berus, W.; Bieganowski, A. Biogas generation from insects breeding post production wastes. J. Clean. Prod. 2020, 244, 118777. [Google Scholar] [CrossRef]

- Zubrowska-Sudol, M.; Dzido, A.; Garlicka, A.; Krawczyk, P.; Stępień, M.; Umiejewska, K.; Walczak, J.; Wołowicz, M.; Sytek-Szmeichel, K. Innovative Hydrodynamic Disintegrator Adjusted to Agricultural Substrates Pre-treatment Aimed at Methane Production Intensification—CFD Modelling and Batch Tests. Energies 2020, 13, 4256. [Google Scholar] [CrossRef]

- Drzewicki, A.; Bułkowska, K.; Tomczykowska, M. Intensification of the biomethanisation process in wastewater treatment plant. Int. J. Environ. Res. 2015, 9, 805–812. [Google Scholar] [CrossRef]

- Grosser, A.; Neczaj, E.; Singh, B.R.; Almås, R.; Brattebø, H.; Kacprzak, M. Anaerobic digestion of sewage sludge with grease trap sludge and municipal solid waste as co-substrates. Environ. Res. 2017, 155, 249–260. [Google Scholar] [CrossRef] [PubMed]

- Long, J.H.; Aziz, T.N.; Reyes, F.L.D.L.; Ducoste, J.J. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process. Saf. Environ. Prot. 2012, 90, 231–245. [Google Scholar] [CrossRef]

- Palatsi, J.; Laureni, M.; Andrés, M.V.; Flotats, X.; Nielsen, H.B.; Angelidaki, I. Strategies for recovering inhibition caused by long chain fatty acids on anaerobic thermophilic biogas reactors. Bioresour. Technol. 2009, 100, 4588–4596. [Google Scholar] [CrossRef] [PubMed]

- Zonta, Ž.; Alves, M.M.; Flotats, X.; Palatsi, J. Modelling inhibitory effects of long chain fatty acids in the anaerobic digestion process. Water Res. 2013, 47, 1369–1380. [Google Scholar] [CrossRef]

- Davidsson, Å.; Lövstedt, C.; la Cour Jansen, J.; Gruvberger, C.; Aspegren, H. Co-digestion of grease trap sludge and sewage sludge. Waste Manag. 2008, 28, 986–992. [Google Scholar] [CrossRef]

- Kalemba, K.; Barbusiński, K. Anaerobic co-digestion of sewage sludge and molasses. In Proceedings of the International Conference on Advances in Energy Systems and Environmental Engineering (ASEE17), E3S Web Conf, Wrocław, Poland, 2–5 July 2017; Volume 22, p. 00075. [Google Scholar] [CrossRef]

- MosayebNezhad, M.; Mehr, A.S.; Gandiglio, M.; Lanzini, A.; Santarelli, M. Techno-economic assessment of biogas-fed CHP hybrid systems in a real wastewater treatment plant. Appl. Therm. Eng. 2018, 129, 1263–1280. [Google Scholar] [CrossRef]

- Central Statistical Office of Poland (GUS). 2019. Available online: http://www.gus.pl/ (accessed on 6 August 2020).

- Council Directive 86/278/EEC of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge Is Used in Agriculture. Available online: https://eur-lex.europa.eu/ (accessed on 10 June 2020).

- Council Directive 91/271/EEC of 21 May 1991 Concerning Urban Waste-Water Treatment. Available online: https://eur-lex.europa.eu/ (accessed on 10 June 2020).

- Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Available online: https://eur-lex.europa.eu/ (accessed on 10 June 2020).

- Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the Incineration of Waste. Available online: https://eur-lex.europa.eu/ (accessed on 10 June 2020).

- Sun, Y.; Lu, M.; Sun, Y.; Chen, Z.; Duan, H.; Liu, D. Application and Evaluation of Energy Conservation Technologies in Wastewater Treatment Plants. Appl. Sci. 2019, 9, 4501. [Google Scholar] [CrossRef]

- Rzepecki, T. A self-sufficient water supply and sewage company—A dream or a real possibility. In Proceedings of the 4th Scientific Conference “Energy Security–Pillars and Development Perspective”, Rzeszów, Poland, 1–2 April 2019. [Google Scholar]

- Chamber of Commerce “Polish Waterworks” (IGWP). Information Materials. 2020. Available online: https://www.igwp.org.pl/ (accessed on 12 June 2020).

- Durdevic, Đ.; Blecich, P.; Zelijko, J. Energy Recovery from Sewage Sludge: The Case. Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- Polish Oil and Gas Company (PGNiG). Annual Report. 2019. Available online: http://http://en.pgnig.pl/ (accessed on 12 August 2020).

- BP Statistical Review of World Energy. 2019. Available online: https://www.bp.com/ (accessed on 10 August 2020).

- German ATV-DVWK Rules and Standards ATV-DVWK-A 131, E. Dimensioning of Single-Stage Activated Sludge Plants. May 2000. Available online: https://kupdf.net/download/atv-dvwk-a-131e_58ff62c7dc0d60307d959e98_pdf (accessed on 12 June 2020).

- Grosser, A. The influence of decreased hydraulic retention time on the performance and stability of co-digestion of sewage sludge with grease trap sludge and organic fraction of municipal waste. J. Environ. Manage. 2017, 203, 1143–1157. [Google Scholar] [CrossRef]

- Björn, A.; ShakeriYekta, S.; Ziels, R.M.; Gustafsson, K.; Svenssom, B.H.; Karlsson, A. Feasibility of OFMSW co-digestion with sewage sludge for increasing biogas production at wastewater treatment plants. Euro-Mediterr. J. Environ. Integr. 2017, 2, 21. [Google Scholar] [CrossRef]

- Koch, K.; Helmreich, B.; Drewes, J.E. Co-digestion of food waste in municipal wastewater treatment plants: Effect of different mixtures on methane yield and hydrolysis rate constant. Appl. Energy 2015, 137, 250–255. [Google Scholar] [CrossRef]

- Yoon, Y.-M.; Kim, S.-H.; Oh, S.-Y.; Kim, C.-H. Potential of anaerobic digestion for material recovery and energy production in waste biomass from a poultry slaughterhouse. Waste Manag. 2014, 34, 204–209. [Google Scholar] [CrossRef] [PubMed]

- Pitk, P.; Kaparaju, P.; Vilu, R. Methane potential of sterilized solid slaughterhouse wastes. Biores. Technol. 2012, 116, 42–46. [Google Scholar] [CrossRef]

- Latifi, P.; Karrabi, M.; Danesh, S. Anaerobic co-digestion of poultry slaughterhouse wastes with sewage sludge in batch-mode bioreactors (effect of inoculum-substrate ratio and total solids). Renew. Sustain. Energ. Rev. 2019, 107, 288–296. [Google Scholar] [CrossRef]

- Budych-Gorzna, M.; Smoczyński, M.; Oleskowicz-Popiel, P. Enhancement of biogas production at the municipal wastewater treatment plant by co-digestion with poultry industry waste. Appl. Energy 2016, 161, 387–394. [Google Scholar] [CrossRef]

- Masłoń, A.; Tendera, K. Sewage sludge management at the Rzeszów WWTP. Forum Eksploatatora 2017, 1, 38–45. (In Polish) [Google Scholar]

- Masłoń, A.; Pazdro, S.; Mroczek, W. Sewage sludge management in wastewater treatment plant in Mielec. Forum Eksploatatora 2015, 4, 47–54. (In Polish) [Google Scholar]

- Gazda, M.; Rak, A.; Sudak, M. Research on cofermentation of sewage sludge with waste fats for the wastewater treatment plant in Brzeg. Infrastr. Ecol. Rural Ar. 2012, 3, 79–90. (In Polish) [Google Scholar]

- Trojanowicz, K.; Karamus, Ł. Energy utilization of biogas as an element of sewage sludge management in the wastewater treatment plant in Krosno. Forum Eksploatatora 2016, 4, 46–53. (In Polish) [Google Scholar]

- Masłoń, A. Analysis of energy consumption at the Rzeszów Wastewater Treatment Plant. In Proceedings of the International Conference on Advances in Energy Systems and Environmental Engineering (ASEE17), E3S Web Conf, Wrocław, Poland, 2–5 July 2017; Volume 22, p. 00115. [Google Scholar] [CrossRef]

- Szczyrba, P.; Masłoń, A.; Czarnota, J.; Olszewski, K. Analysis of sewage sludge and biogas-energy management at the Opole wastewater treatment plant. Ecol. Eng. 2020, 21, 26–34. [Google Scholar] [CrossRef]

- Masłoń, A.; Czarnota, J. Biogas production from sewage sludge as an energy balance element of the wastewater treatment plant. In Proceedings of the VI International Scientific and Technical Conference “Pure Water. Fundamental, Applied and Industrial Aspects”, Kiev, Ukraine, 14–15 November 2019; pp. 46–48. [Google Scholar]

- Masłoń, A. An Analysis of Sewage Sludge and Biogas Production at the Zamość WWTP. Lect. Notes Civ. Eng. 2020, 7, 291–298. [Google Scholar] [CrossRef]

- Poland’s National Inventory Report 2018; National Centre for Emission Management (KOBiZE) at the Institute of Environmental Protection–National Research Institute: Warsaw, Poland, 2018. Available online: http://www.kobize (accessed on 2 September 2020).

| Treatment Stage | Share in Energy Consumption [%] | Potential for Energy Saving | Comments |

|---|---|---|---|

| Wastewater Pumping (Pumping Station) | 10 | 5–10% through the modification of the existing pumps; up to 30% through better conservation and adjustment to the throughput | depending on the topography where WWTP is located |

| Biological Treatment of Wastewater | 55 | 20–50% through the optimization of technological parameters, optimization of aeration and mixing in biological reactors implementation of online control | mainly pertains to aeration and mixing in the reactor |

| Processing and Disposal of Sewage Sludge (Dewatering and Transport of Sludge) | 35 | 30% of energy efficiency can be achieved through the application of mesophilic anaerobic digestion with implementation of additional substrate | determined by operating conditions and the type of selected substrate |

| Organic Co-Substrates | Maximum Biogas Production (mL/g VS) | Methane Content in Biogas (%) | Content of Substrate in the Feedstock (v/v %) |

|---|---|---|---|

| Waste meat | 170.3 | 76 | 3 |

| Soapstock | 117.17 | 73 | 10 |

| By-products after biodiesel production | 99.91 | 72 | 10 |

| Molasses | 95.69 | 73 | 0.5 |

| Waste from fat separator | 88.68 | 70 | 3 |

| Hydraulic Load | |||||

|---|---|---|---|---|---|

| Parameter | Minimum | Maximum | Average | SD | |

| Total wastewater, m3/d | 4886.0 | 8816.0 | 6176.0 | 837.0 | |

| Physicochemical Parameters | |||||

| Parameter | Minimum | Maximum | Average | SD | |

| Biochemical oxygen demand (BOD5) | mg/L | 519.5 | 1220.0 | 752.4 | 165.4 |

| kg/d | 2908.7 | 6736.0 | 4613.9 | 947.1 | |

| Chemical oxygen demand (COD) | mg/L | 1057.0 | 2301.0 | 1559.4 | 320.8 |

| kg/d | 6116.9 | 15,108.4 | 9595.5 | 2032.5 | |

| Total suspended solids (TSS) | mg/L | 182.5 | 815.0 | 542.8 | 139.5 |

| kg/d | 1119.3 | 5220.4 | 3353.9 | 926.4 | |

| Total nitrogen (TN) | mg/L | 68.2 | 128.5 | 101.4 | 14.8 |

| kg/d | 453.2 | 992.3 | 623.6 | 101.1 | |

| Total phosphorous (TP) | mg/L | 8.9 | 69.3 | 16.0 | 10.0 |

| kg/d | 62.4 | 338.6 | 96.5 | 48.9 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masłoń, A.; Czarnota, J.; Szaja, A.; Szulżyk-Cieplak, J.; Łagód, G. The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies 2020, 13, 6056. https://doi.org/10.3390/en13226056

Masłoń A, Czarnota J, Szaja A, Szulżyk-Cieplak J, Łagód G. The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies. 2020; 13(22):6056. https://doi.org/10.3390/en13226056

Chicago/Turabian StyleMasłoń, Adam, Joanna Czarnota, Aleksandra Szaja, Joanna Szulżyk-Cieplak, and Grzegorz Łagód. 2020. "The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland" Energies 13, no. 22: 6056. https://doi.org/10.3390/en13226056

APA StyleMasłoń, A., Czarnota, J., Szaja, A., Szulżyk-Cieplak, J., & Łagód, G. (2020). The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies, 13(22), 6056. https://doi.org/10.3390/en13226056