Thermo-Fluid Dynamics Analysis of Fire Smoke Dispersion and Control Strategy in Buildings

Abstract

1. Introduction

2. Methodology

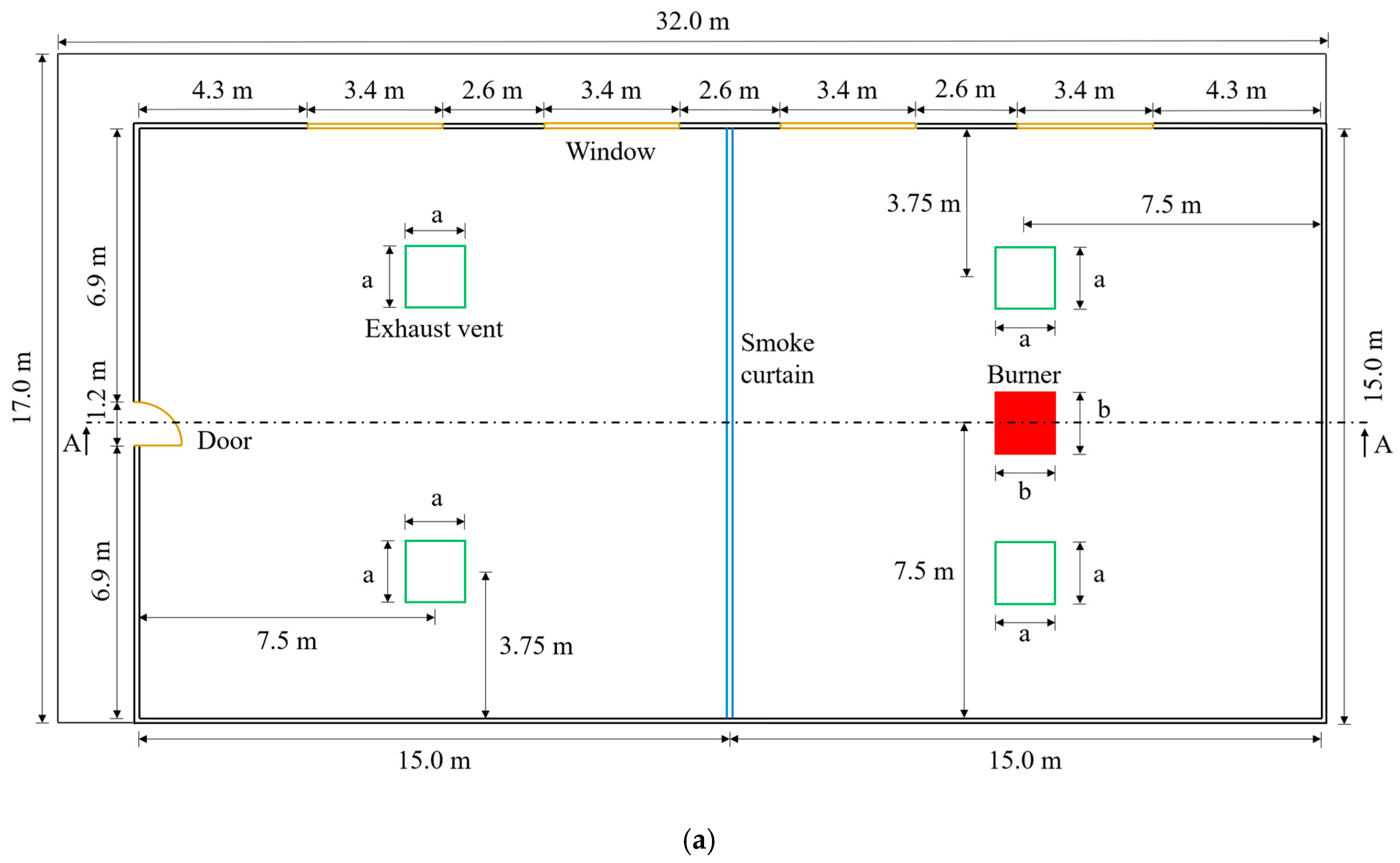

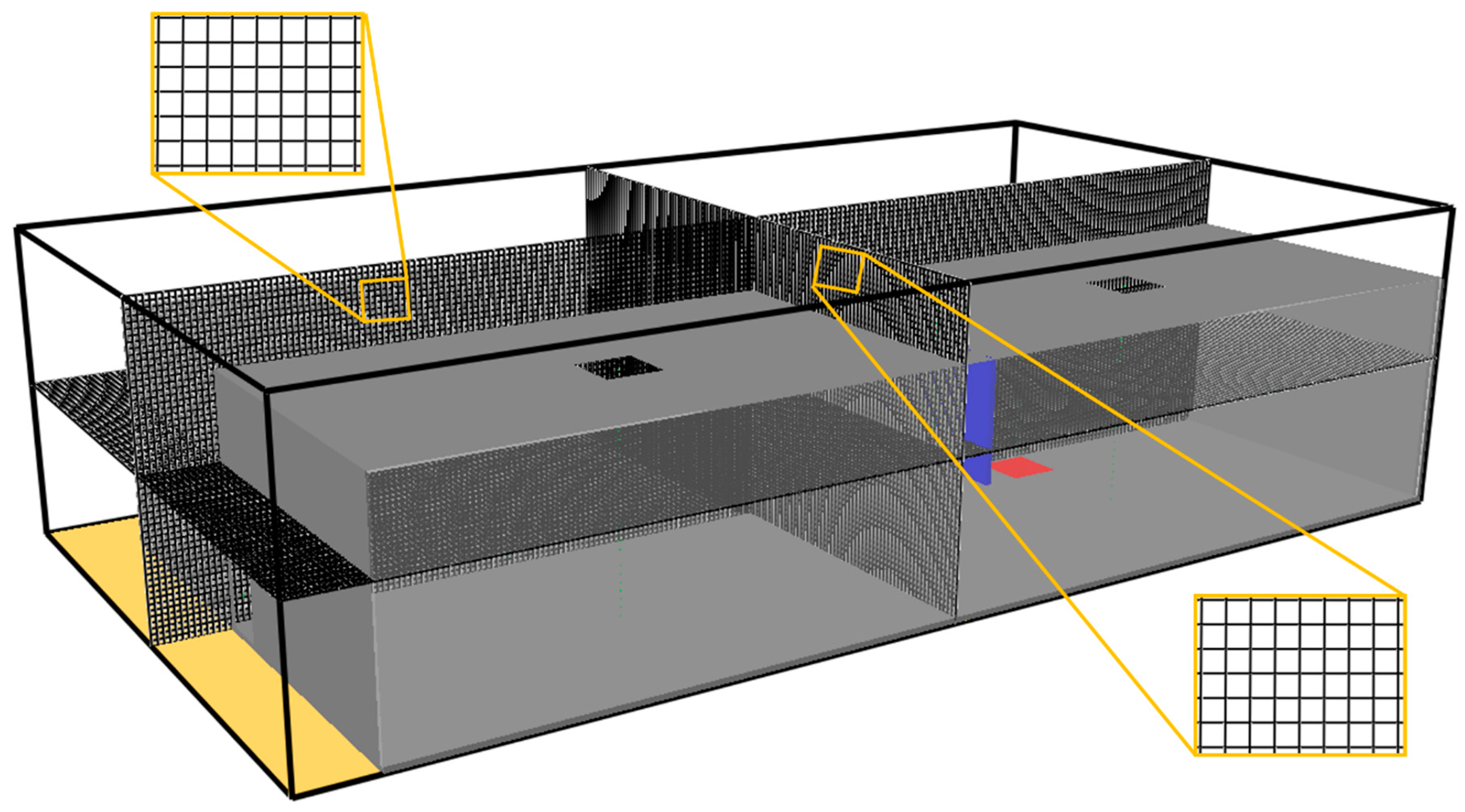

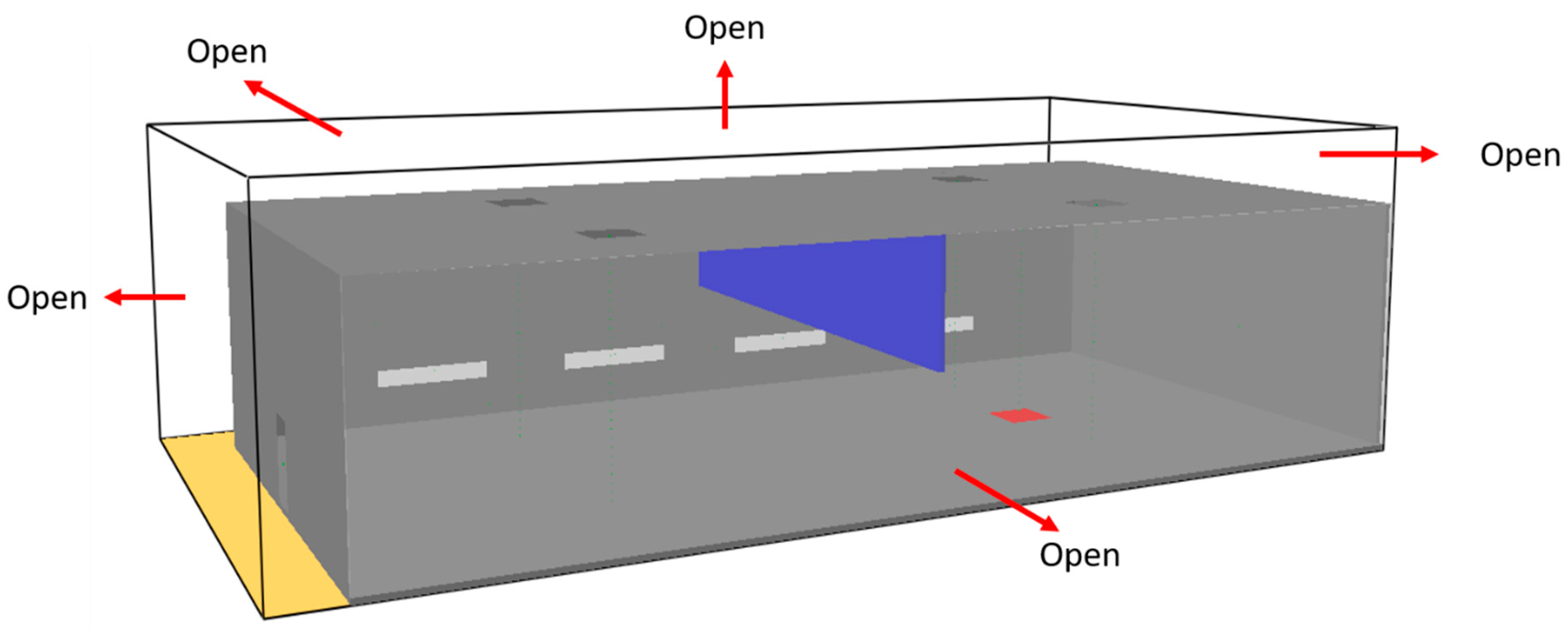

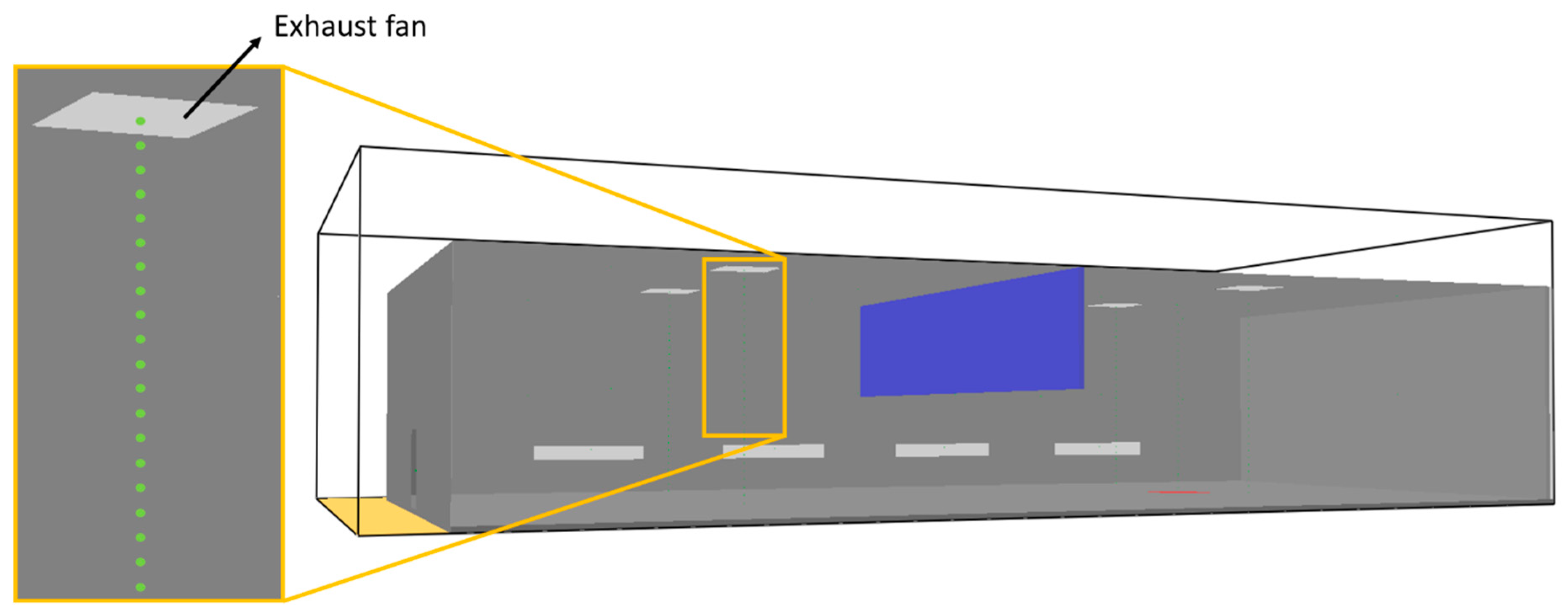

2.1. The Physical Problem and the Computational Domain

2.2. The Mathematical Model

2.2.1. The Governing Equations

- (a)

- Mass conservation:where is the density, is the velocity vector and is the source term associated with the addition of mass from evaporating droplets or other subgrid-scale particles that represent, for example, sprinkler and fuel sprays, vegetation, and any other type of small, unresolvable object.

- (b)

- Species conservation:where and are the mass fraction and diffusivity of species . and are the mass production rate per unit volume of species by chemical reactions and evaporating droplets/particles, respectively.

- (c)

- Linear momentum conservation:where is the pressure, is the gravitational acceleration vector, is the external force vector (excluding gravity) and is the viscous stress tensor.

- (d)

- Energy conservation:where is the enthalpy, is the heat release rate per unit volume from a chemical reaction and is the energy transferred to subgrid-scale droplets and particles (for example, sprinkler), and represents the conductive, diffusive and radiative heat fluxes.

- (e)

- Equation of state (ideal gas law):where is the universal constant, is the absolute temperature and is the molecular weight of the gas mixture.

2.2.2. Initial and Boundary Conditions

2.2.3. Heat Release Rate

2.3. Numerical Solution Method

2.4. Thermo-Physical Properties of Materials

2.5. Cases Studied

3. Results and Discussion

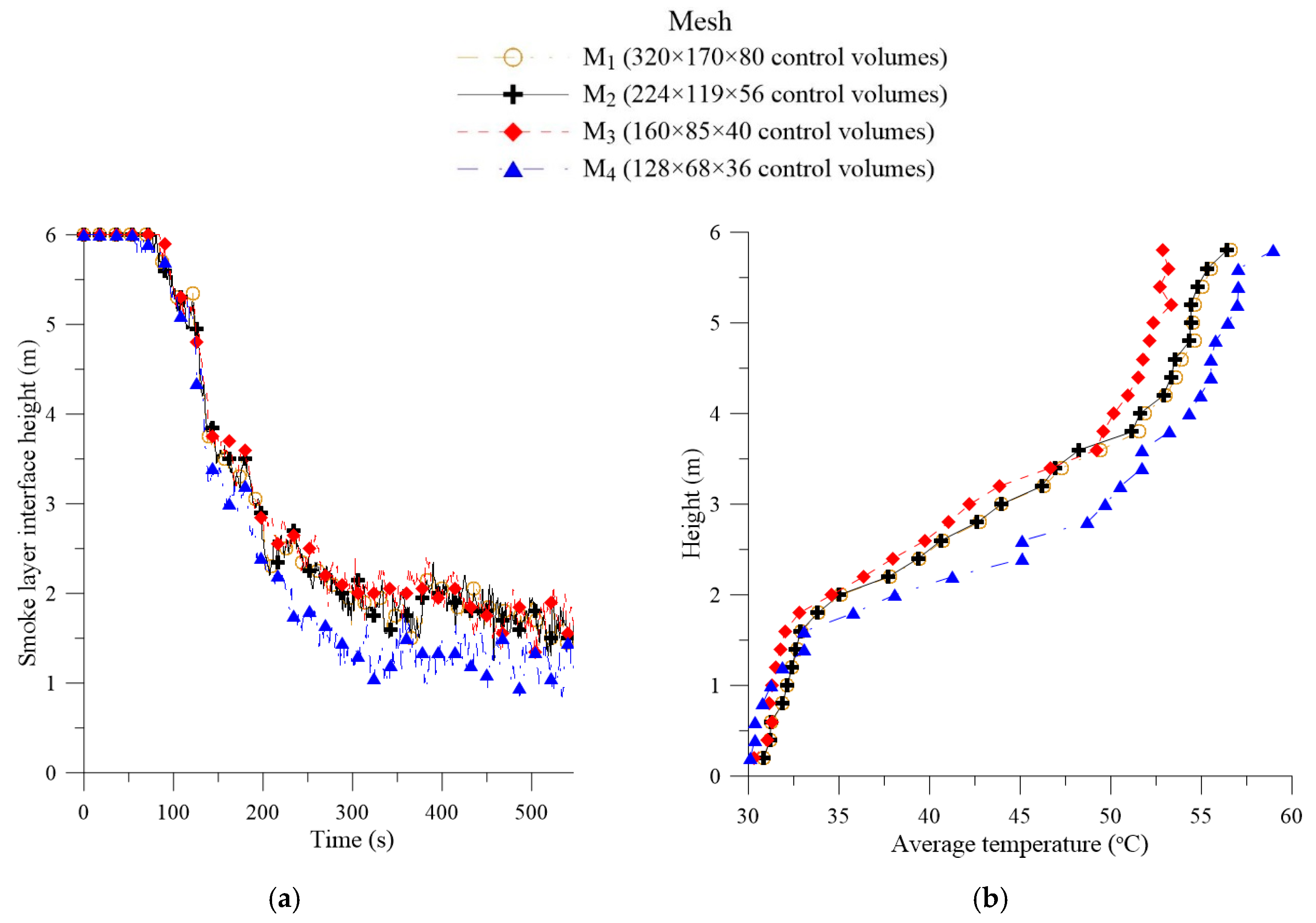

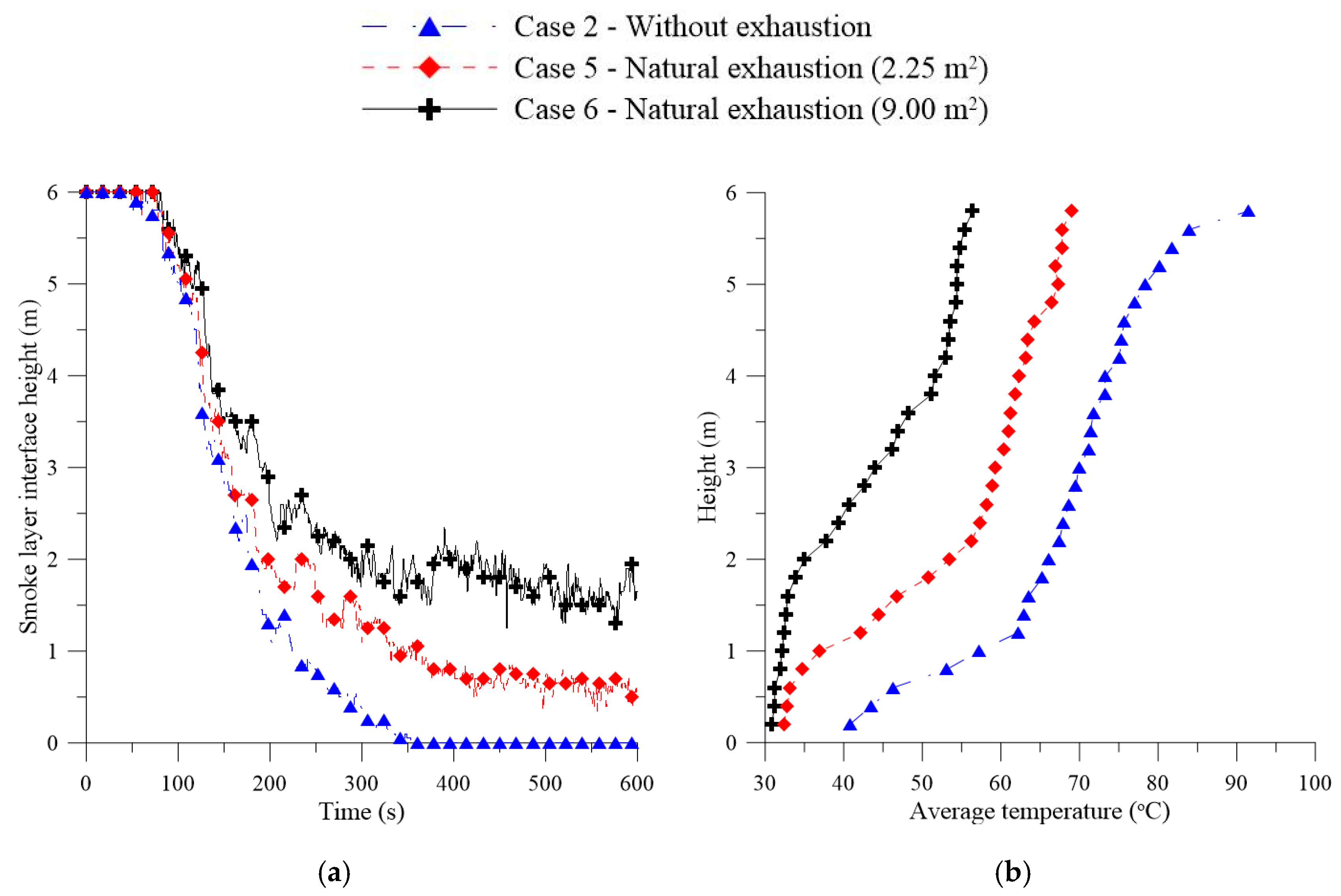

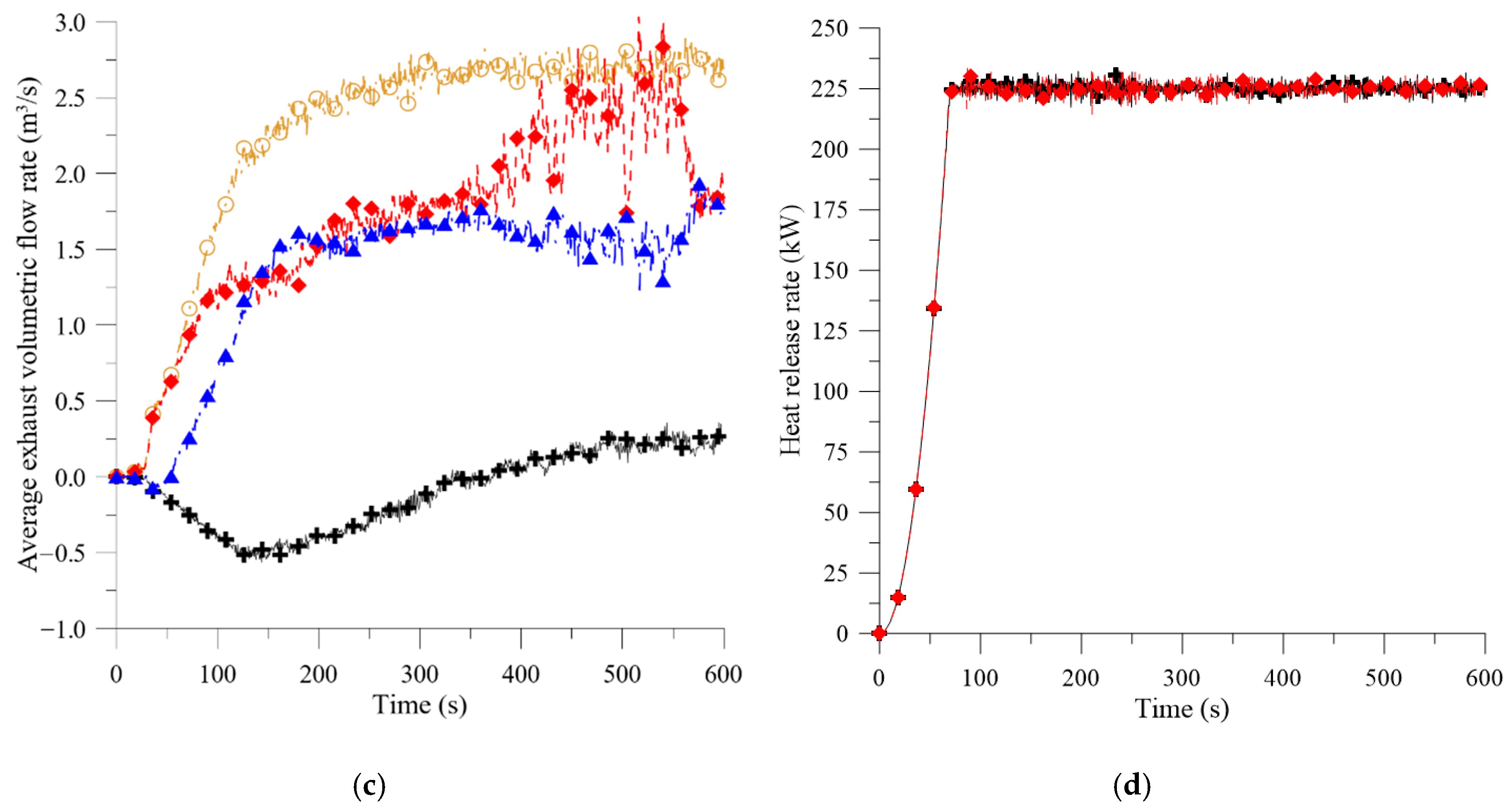

3.1. Mesh Convergence Analysis

3.2. Thermo-Fluid Dynamic Analysis of Processes

3.2.1. Natural Exhaust with Closed Windows

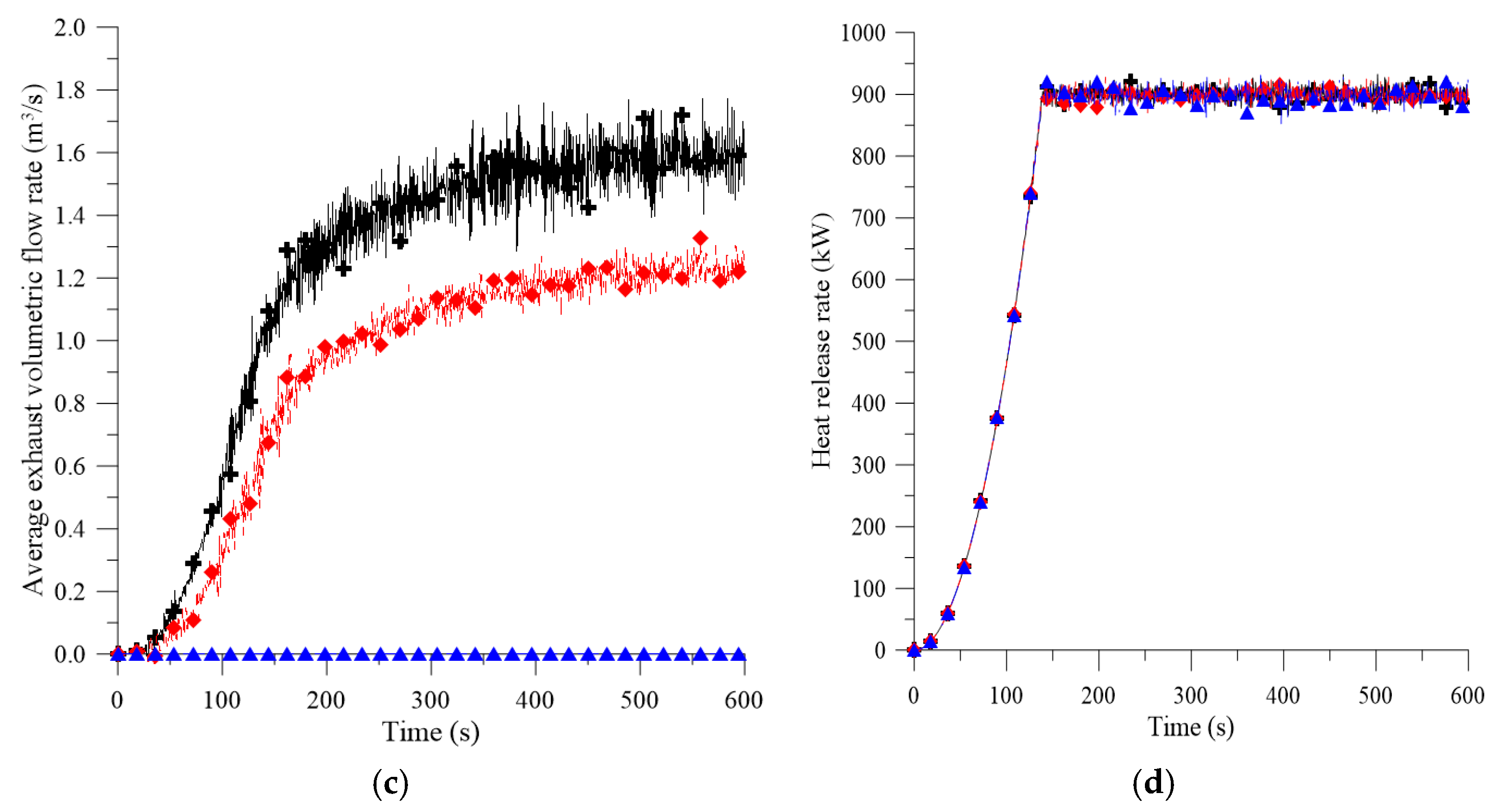

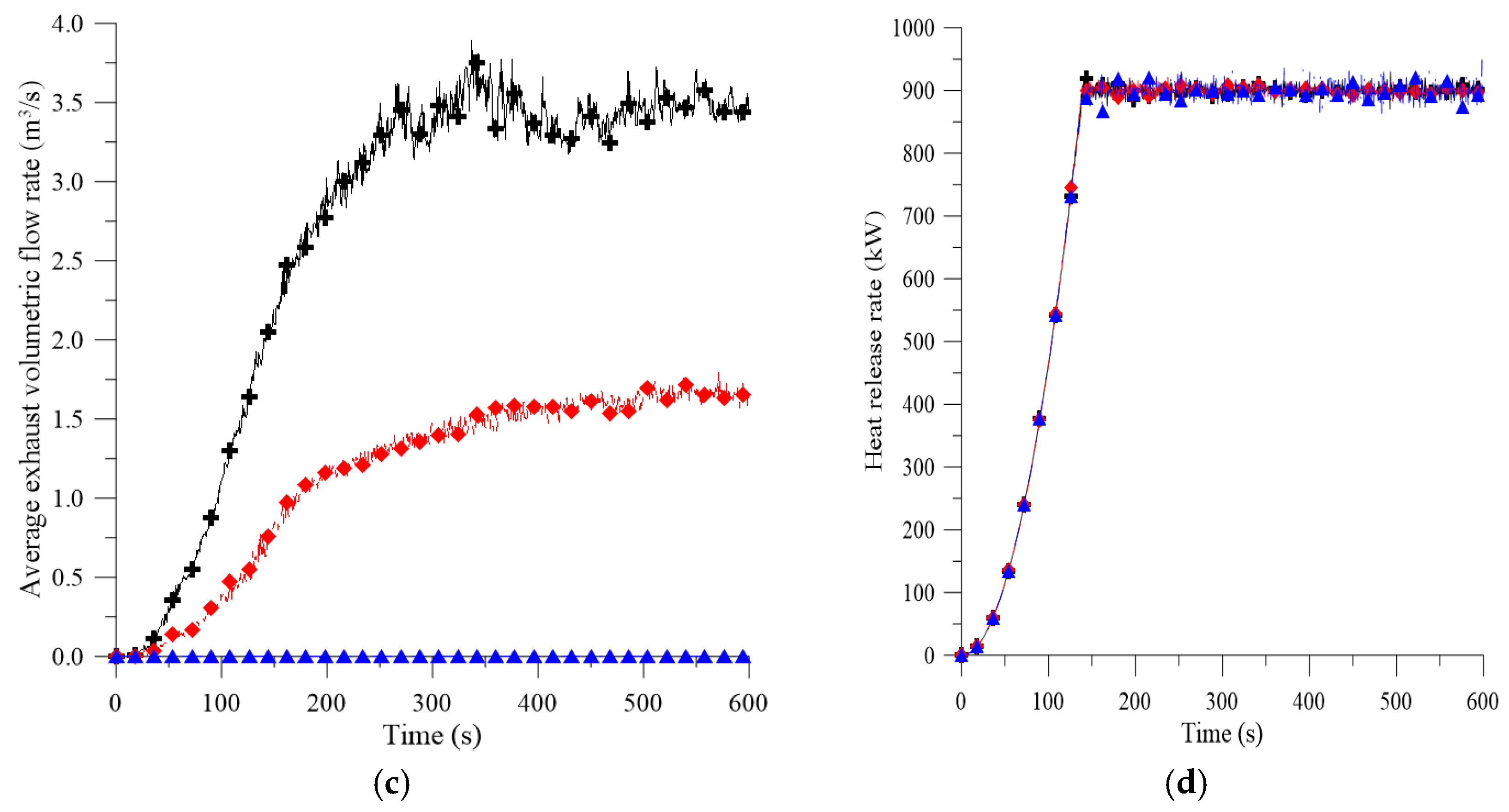

3.2.2. Natural Exhaust with Open Windows

3.2.3. Natural Exhaust with Different Heat Release Rates

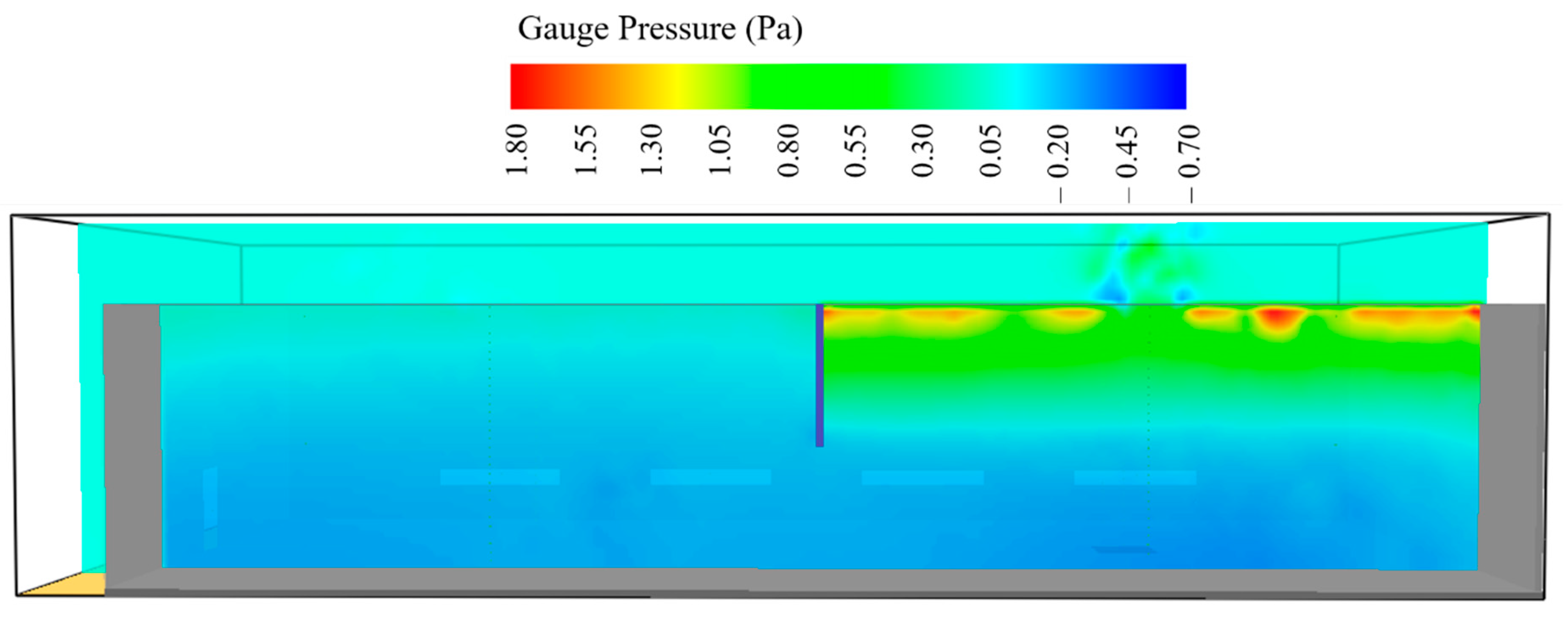

3.2.4. Natural Exhaust with Smoke Curtain and Closed Windows

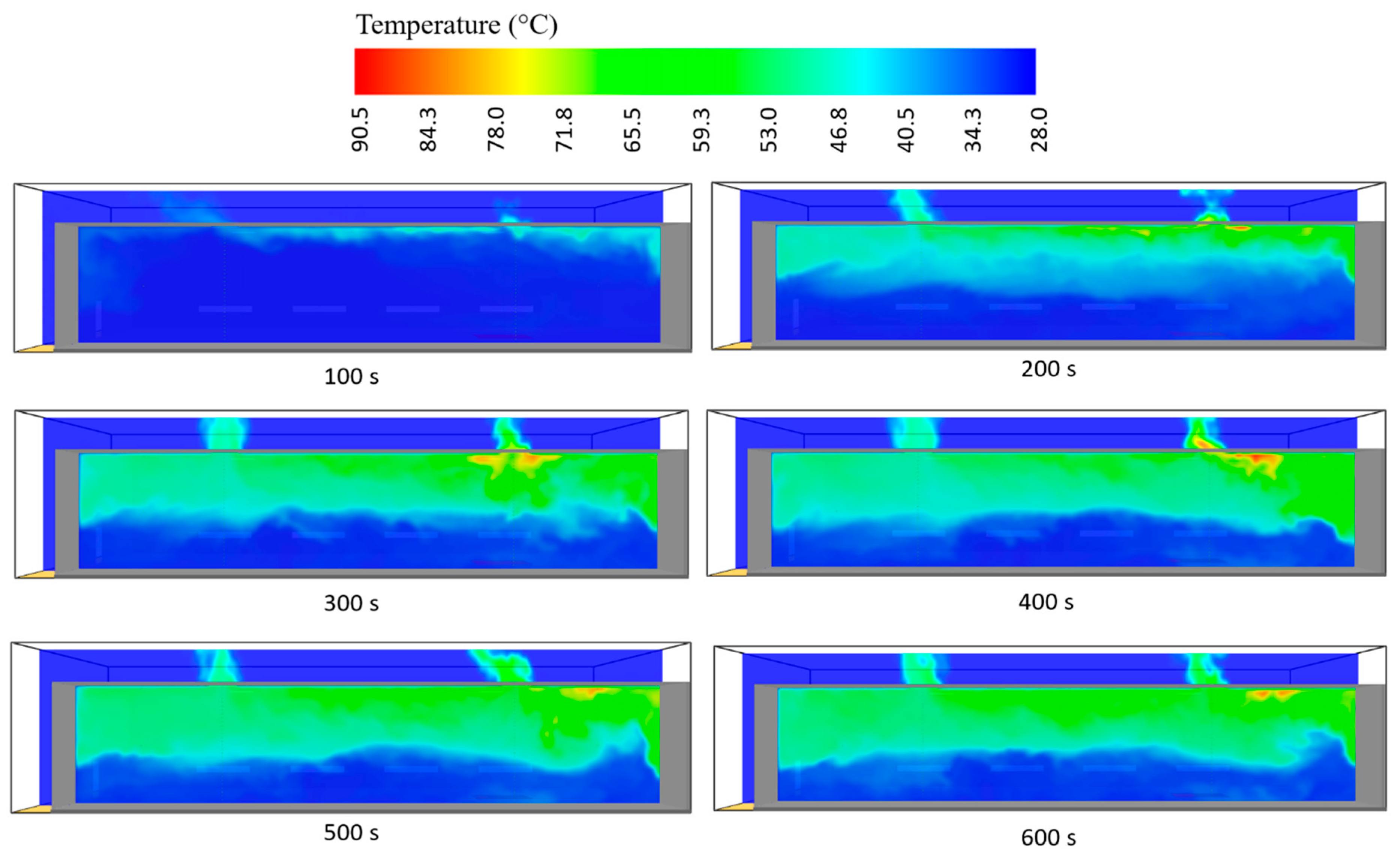

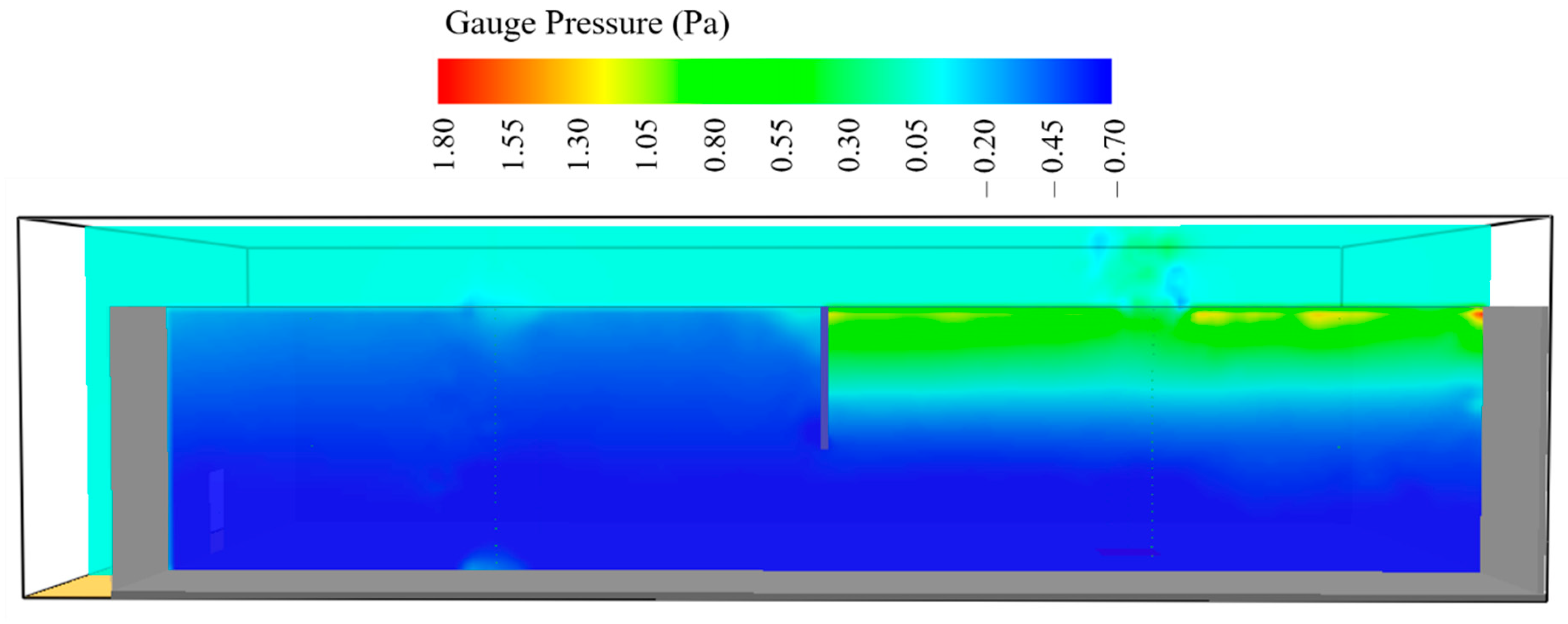

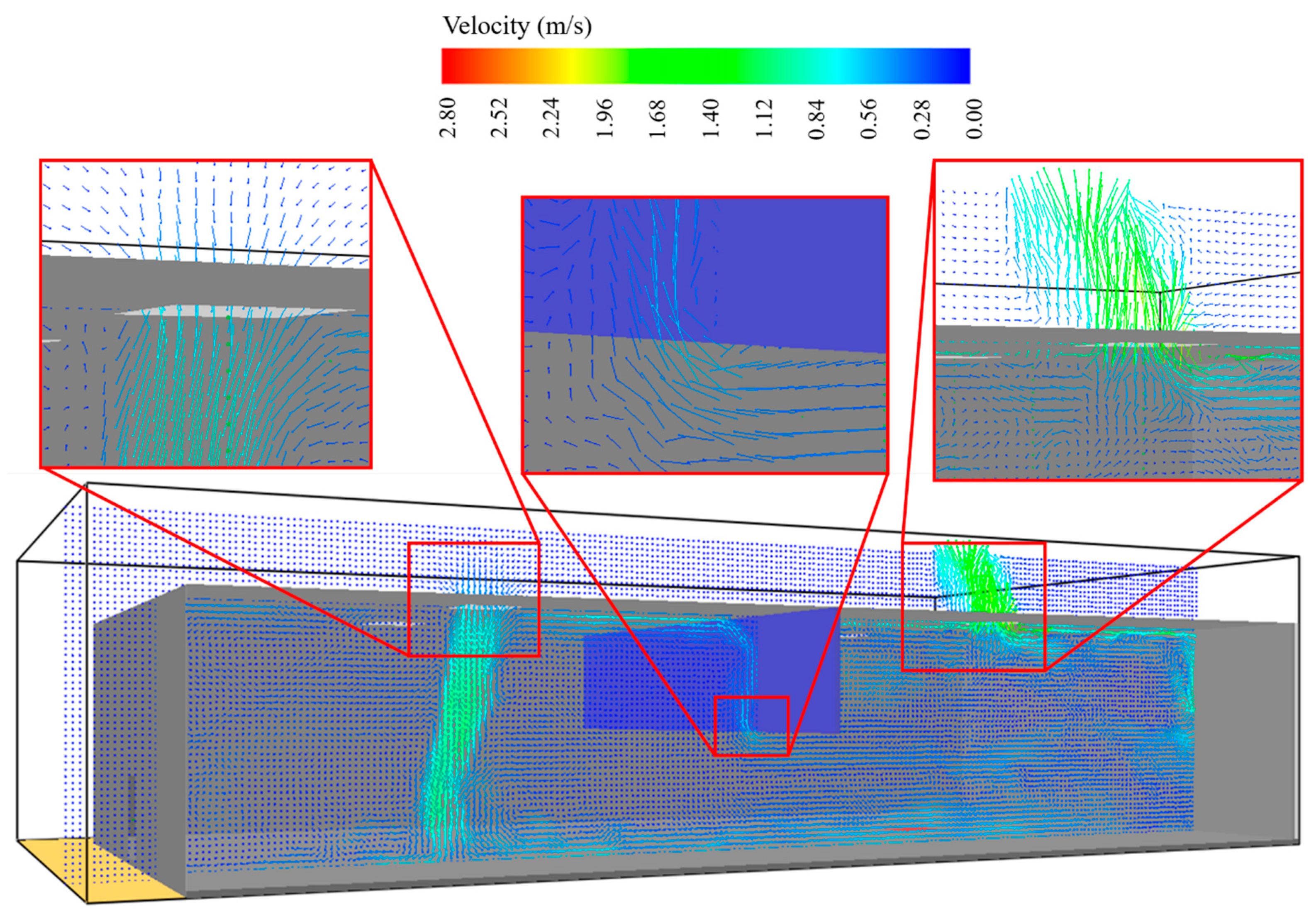

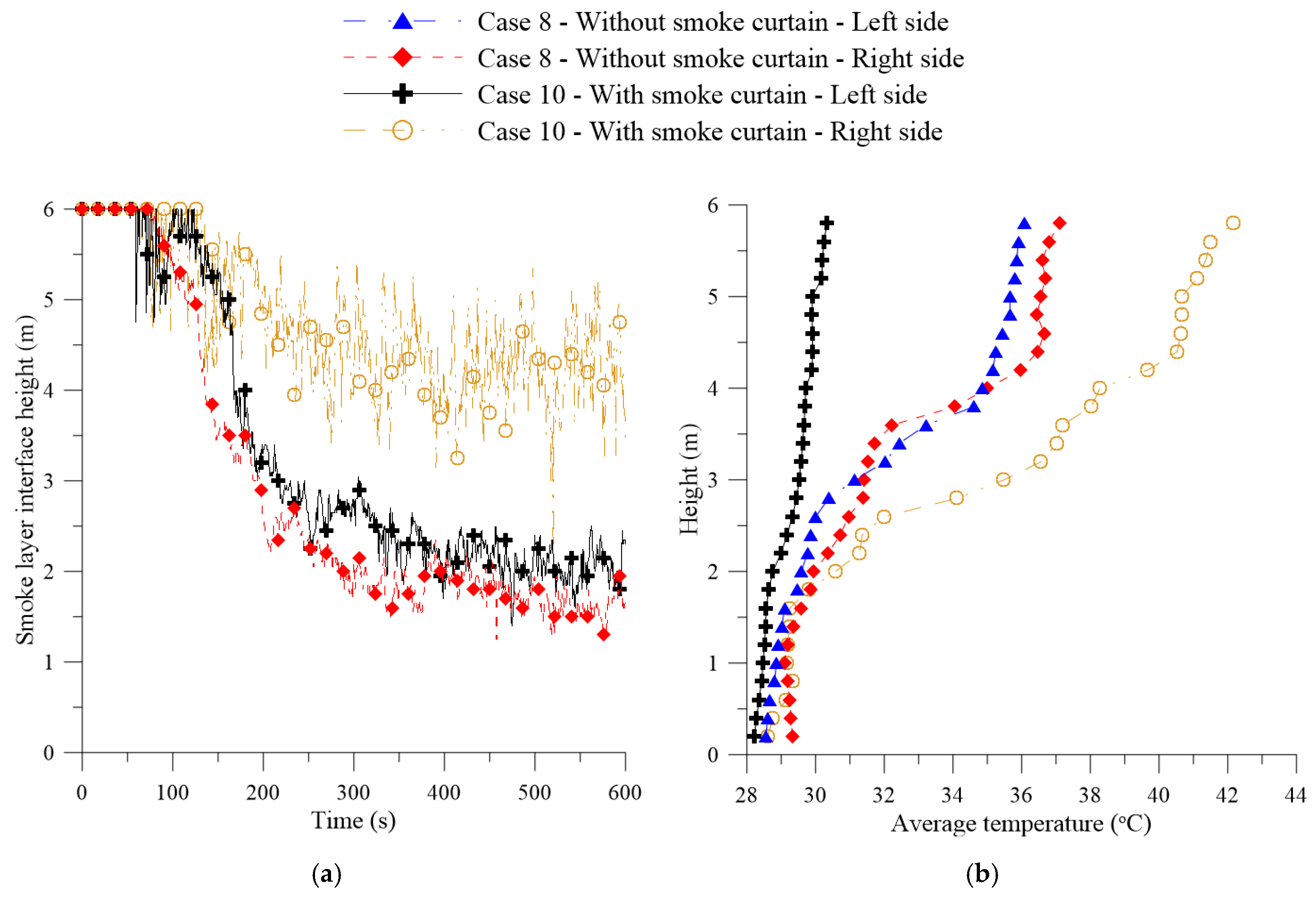

3.2.5. Natural Exhaust with Smoke Curtain and Open Windows

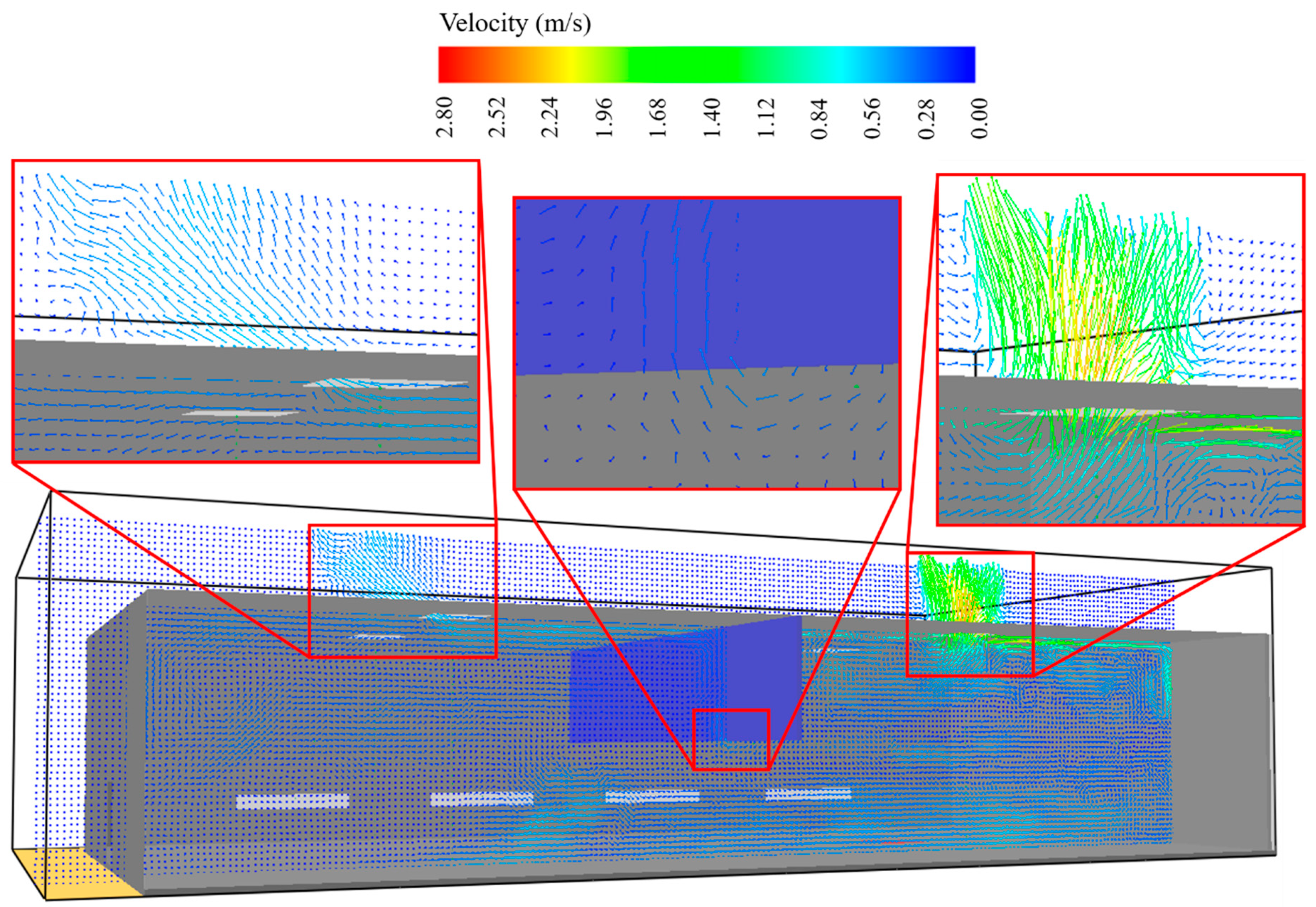

3.2.6. Mechanical Exhaust without Smoke Curtain and Open Windows

4. Conclusions

- (a)

- For a poorly ventilated compartment (closed windows) and a HRR of 900 kW, the increase in the natural exhaust area did not improve the smoke layer interface height. In all cases, the smoke reached the floor in less than 450 s and when using any of the natural exhaust systems, there was a delay of only 15 s in the time necessary for the smoke to reach a height of 1.80 m from the floor.

- (b)

- For the well-ventilated compartment (open windows) and HRR of 900 kW, the increase in the natural exhaust area significantly increased the volume of gases exhausted, delaying the vertical displacement of the smoke layer and reducing the temperature in the entire compartment. For the case without an exhaust system, smoke reaches the floor and, for the cases with natural exhaust areas of 2.25 and 9.00 m2, the minimum values obtained for the smoke layer interface height were 0.35 and 1.25 m, respectively.

- (c)

- The increase in the HRR from the burner accelerates the downward vertical displacement of the smoke layer and increases the volume of gases exhausted and the compartment temperature, regardless of the ventilation (open or closed windows).

- (d)

- Although the use of the 3.00 m smoke curtain was sufficient to restrict the smoke on the right side of the compartment, with HRR = 225 kW, for both cases analyzed. The use of a smoke curtain was efficient in smoke exhaustion, only for the case of poorly ventilated environment (closed windows), in which the exhaust fans on the left side acted as air intakes.

- (e)

- Although the mechanical exhaust system with a total volumetric flow rate of 36.00 m3/h has shown good results in the downward displacement of the smoke layer and in the reduction of the internal temperature; it promotes very high speeds in the occupation area of people inside the compartment.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| FDS | Fire Dynamic Simulator |

| CFD | Computational Fluid Dynamic |

| Courant-Friedrichs-Lewy constraint | |

| Maximum allowed value for CFL | |

| cp | Specific heat |

| External force vector (excluding gravity) | |

| Gravitational acceleration vector | |

| HRR | Heat Release Rate |

| HRRPUA | Heat Release Rate Per Unit Area |

| Heat Release Rate in the growth phase | |

| Enthalpy | |

| K | Thermal conductivity |

| Mass production rate per unit volume by evaporating droplets/particles | |

| Mass production rate per unit volume of species by chemical reactions | |

| Mass production rate per unit volume of species by evaporating droplets/particles | |

| NIST | National Institute for Standards and Technology |

| Pressure | |

| P0 | Initial pressure |

| Heat release rate per unit volume from a chemical reaction | |

| Energy transferred to subgrid-scale droplets/particles | |

| Heat flux vector | |

| RH0 | Initial relative humidity |

| Temperature | |

| T0 | Initial temperature |

| T | Time |

| Velocity vector | |

| u0 | Initial velocity vector |

| u | Velocity component in the x direction |

| v | Velocity component in the y direction |

| w | Velocity component in the z direction |

| Mass fraction of species | |

| Yair,0 | Initial mass fraction of air |

| Ysoot,0 | Initial mass fraction of soot |

| Fire growth coefficient | |

| Δh | Heat of combustion |

| ε | Emissivity |

| Density | |

| Viscous stress tensor |

References

- Khan, E.A.; Ahmed, M.A.; Khan, E.H.; Majumder, S.C. Fire Emergency Evacuation Simulation of a shopping mall using Fire Dynamic Simulator (FDS). J. Chem. Eng. 2017, 30, 32–36. [Google Scholar] [CrossRef][Green Version]

- Stefanidou, M.; Athanaselis, S.; Spiliopoulou, C. Health impacts of fire smoke inhalation. Inhal. Toxicol. 2008, 20, 761–766. [Google Scholar] [CrossRef] [PubMed]

- Thompson, O.F.; Galea, E.R.; Hulse, L.M. A review of the literature on human behaviour in dwelling fires. Saf. Sci. 2018, 109, 303–312. [Google Scholar] [CrossRef]

- Xiong, L.; Bruck, D.; Ball, M. Preventing accidental residential fires: The role of human involvement in non-injury house fires. Fire Mater. 2017, 41, 3–16. [Google Scholar] [CrossRef]

- Mihailidou, E.K.; Antoniadis, K.D.; Assael, M.J. The 319 major industrial accidents since 1917. Int. Rev. Chem. Eng. 2012, 4, 529–540. [Google Scholar]

- Miller, I. Human Behaviour Contributing to Unintentional Residential Fire Deaths, 1997–2003; New Zealand Fire Service Commission, 2005; Available online: https://fireandemergency.nz/assets/Documents/Research-and-reports/Report-47-Human-Behaviour-Contributing-to-Unintentional-Residential-Fire-Deaths-1997-2003.pdf (accessed on 30 July 2020).

- Shen, T.-S.; Huang, Y.-H.; Chien, S.-W. Using fire dynamic simulation (FDS) to reconstruct an arson fire scene. Build. Environ. 2008, 43, 1036–1045. [Google Scholar] [CrossRef]

- Hu, L.H.; Huo, R.; Li, Y.Z.; Wang, H.B.; Chow, W.K. Full-scale burning tests on studying smoke temperature and velocity along a corridor. Tunn. Undergr. Space Technol. 2005, 20, 223–229. [Google Scholar] [CrossRef]

- Barillo, D.J.; Goode, R. Fire fatality study: Demographics of fire victims. Burns 1996, 22, 85–88. [Google Scholar] [CrossRef]

- Antonio, A.C.P.; Castro, P.S.; Freire, L.O. Smoke inhalation injury during enclosed-space fires: An update. J. Bras. Pneumol. 2013, 39, 373–381. [Google Scholar] [CrossRef]

- Black, W.Z. Smoke movement in elevator shafts during a high-rise structural fire. Fire Saf. J. 2009, 44, 168–182. [Google Scholar] [CrossRef]

- Qin, T.X.; Guo, Y.C.; Chan, C.K.; Lin, W.Y. Numerical simulation of the spread of smoke in an atrium under fire scenario. Build. Environ. 2009, 44, 56–65. [Google Scholar] [CrossRef]

- Klote, J.H.; Ferreira, M.J.; Kashef, A.; Turnbull, P.G.; Milke, J.A. Handbook of Smoke Control Engineering; American Society of Heating Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2012; ISBN 1936504243. [Google Scholar]

- Anseeuw, K.; Delvau, N.; Burillo-Putze, G.; De Iaco, F.; Geldner, G.; Holmström, P.; Lambert, Y.; Sabbe, M. Cyanide poisoning by fire smoke inhalation: A European expert consensus. Eur. J. Emerg. Med. 2013, 20, 2–9. [Google Scholar] [CrossRef] [PubMed]

- Król, M.; Król, A. Multi-criteria numerical analysis of factors influencing the efficiency of natural smoke venting of atria. J. Wind Eng. Ind. Aerodyn. 2017, 170, 149–161. [Google Scholar] [CrossRef]

- Abotaleb, H.A. Numerical study on smoke exhaust system in a mall with mechanical make-up techniques. Alexandria Eng. J. 2018, 57, 2961–2974. [Google Scholar] [CrossRef]

- Yuen, A.C.Y.; Chen, T.B.Y.; Yang, W.; Wang, C.; Li, A.; Yeoh, G.H.; Chan, Q.N.; Chan, M.C. Natural ventilated smoke control simulation case study using different settings of smoke vents and curtains in a large Atrium. Fire 2019, 2, 7. [Google Scholar] [CrossRef]

- Gupta, K.; Mehrotra, M.; Kumar, P.; Gogia, A.R.; Prasad, A.; Fisher, J.A. Smoke inhalation injury: Etiopathogenesis, diagnosis, and management. Indian J. Crit. Care Med. Peer-Rev. Off. Publ. Indian Soc. Crit. Care Med. 2018, 22, 180. [Google Scholar] [CrossRef]

- Chen, T.B.Y.; Yuen, A.C.Y.; Yeoh, G.H.; Timchenko, V.; Cheung, S.C.P.; Chan, Q.N.; Yang, W.; Lu, H. Numerical study of fire spread using the level-set method with large eddy simulation incorporating detailed chemical kinetics gas-phase combustion model. J. Comput. Sci. 2018, 24, 8–23. [Google Scholar] [CrossRef]

- Qin, T.X.; Guo, Y.C.; Chan, C.K.; Lin, W.Y. Numerical investigation of smoke exhaust mechanism in a gymnasium under fire scenarios. Build. Environ. 2006, 41, 1203–1213. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Vanella, M.; Weinschenk, C.; Overholt, K. Fire Dynamics Simulator Technical Reference Guide Volume 2: Verification, 6th ed.; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2017. [Google Scholar]

- Zalok, E.; Hadjisophocleous, G.V. Assessment of the use of fire dynamics simulator in performance-based design. Fire Technol. 2011, 47, 1081–1100. [Google Scholar] [CrossRef]

- Gutiérrez-Montes, C.; Sanmiguel-Rojas, E.; Viedma, A.; Rein, G. Experimental data and numerical modelling of 1.3 and 2.3 MW fires in a 20 m cubic atrium. Build. Environ. 2009, 44, 1827–1839. [Google Scholar] [CrossRef]

- Xiao, B. Comparison of numerical and experimental results of fire induced doorway flows. Fire Technol. 2012, 48, 595–614. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overholt, K. Fire Dynamics Simulator Technical Reference Guide Volume 3: Validation, 6th ed.; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2017. [Google Scholar]

- Ayala, P.; Cantizano, A.; Gutiérrez-Montes, C.; Rein, G. Influence of atrium roof geometries on the numerical predictions of fire tests under natural ventilation conditions. Energy Build. 2013, 65, 382–390. [Google Scholar] [CrossRef]

- Liu, Y.; Moser, A.; Sinai, Y. Comparison of a CFD fire model against a ventilated fire experiment in an enclosure. Int. J. Vent. 2004, 3, 169–181. [Google Scholar] [CrossRef]

- Hasib, R.; Kumar, R.; Kumar, S. Simulation of an experimental compartment fire by CFD. Build. Environ. 2007, 42, 3149–3160. [Google Scholar] [CrossRef]

- Barsim, M.M.; Bassily, M.A.; El-Batsh, H.M.; Rihan, Y.A.; Sherif, M.M. Numerical simulation of an experimental atrium fires in combined natural and forced ventilation by CFD. Int. J. Vent. 2020, 19, 1–24. [Google Scholar] [CrossRef]

- Meroney, R.N. Wind effects on atria fires. J. Wind Eng. Ind. Aerodyn. 2011, 99, 443–447. [Google Scholar] [CrossRef]

- Gutiérrez-Montes, C.; Sanmiguel-Rojas, E.; Kaiser, A.S.; Viedma, A. Numerical model and validation experiments of atrium enclosure fire in a new fire test facility. Build. Environ. 2008, 43, 1912–1928. [Google Scholar] [CrossRef]

- Lapuerta, C.; Suard, S.; Babik, F.; Rigollet, L. Validation process of ISIS CFD software for fire simulation. Nucl. Eng. Des. 2012, 253, 367–373. [Google Scholar] [CrossRef]

- Suard, S.; Koched, A.; Pretrel, H.; Audouin, L. Numerical simulations of fire-induced doorway flows in a small scale enclosure. Int. J. Heat Mass Transf. 2015, 81, 578–590. [Google Scholar] [CrossRef]

- Pretrel, H.; Suard, S.; Audouin, L. Experimental and numerical study of low frequency oscillatory behaviour of a large-scale hydrocarbon pool fire in a mechanically ventilated compartment. Fire Saf. J. 2016, 83, 38–53. [Google Scholar] [CrossRef]

- Shih, C.; Chen, Y.; Su, C.; Wang, S.; Yang, Y. Analysis of makeup air in a natural smoke vent system in a tall space using numerical simulation and Schlieren technique. Int. J. Numer. Methods Heat Fluid Flow 2019. [Google Scholar] [CrossRef]

- Hagglund, B. Effects of Inlets on Natural Fire Vents: An Experimental Study; DIANE Publishing: Stockholm, Sweden, 1996; ISBN 0788137298. [Google Scholar]

- Huang, Y.; Chen, X.; Zhang, C. Numerical simulation of the variation of obscuration ratio at the fire early phase with various soot yield rate. Case Stud. Therm. Eng. 2020, 18, 100572. [Google Scholar] [CrossRef]

- Tan, T.; Yu, L.; Ding, L.; Gao, Z.; Ji, J. Numerical investigation on the effect of ambient pressure on mechanical smoke extraction efficiency in tunnel fires. Fire Saf. J. 2020, 103136. [Google Scholar] [CrossRef]

- Wang, K.; Cai, W.; Zhang, Y.; Hao, H.; Wang, Z. Numerical simulation of fire smoke control methods in subway stations and collaborative control system for emergency rescue. Process Saf. Environ. Prot. 2021, 147, 146–161. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Vanella, M. Fire Dynamics Simulator: User’s Guide, 6th ed.; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2017. [Google Scholar]

- Wang, L.; Lim, J.; Quintiere, J.G. On the prediction of fire-induced vent flows using FDS. J. Fire Sci. 2011, 30, 110–121. [Google Scholar] [CrossRef]

- Rehm, R.G.; Baum, H.R. The equations of motion for thermally driven, buoyant flows. J. Res. NBS 1978, 83, 297–308. [Google Scholar] [CrossRef]

- Deardorff, J.W. Stratocumulus-capped mixed layers derived from a three-dimensional model. Boundary-Layer Meteorol. 1980, 18, 495–527. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; McDermott, R.; Vanella, M. Fire Dynamics Simulator Technical Reference Guide Volumes 1: Mathematical Model, 6th ed.; National Institute of Standards and Technology, Building and Fire Research: Gaithersburg, MD, USA, 2017. [Google Scholar]

- Chisum, W.J.; Turvey, B.E. Crime Reconstruction; Academic Press: Waltham, MA, USA, 2011; ISBN 0123864615. [Google Scholar]

- Maevski, I.Y. Design Fires in Road Tunnels; National Academy of Sciences: Washington, DC, USA, 2011; ISBN 0309143306. [Google Scholar]

- Wu, G.-Y.; Chen, R.-C. The analysis of the natural smoke filling times in an atrium. J. Combust. 2010, 2010. [Google Scholar] [CrossRef]

- Hurley, M.J.; Rosenbaum, E.R. Performance-Based Fire Safety Design; CRC Press: Boca Raton, FL, USA, 2015; ISBN 1482246562. [Google Scholar]

- Harlow, F.H.; Welch, J.E. Numerical calculation of time-dependent viscous incompressible flow of fluid with free surface. Phys. Fluids 1965, 8, 2182–2189. [Google Scholar] [CrossRef]

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Watts, J.M., Jr.; WIECZOREK, C.J. SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2015; ISBN 1493925652. [Google Scholar]

- Yang, J.; Wong, M.S.; Menenti, M.; Nichol, J. Modeling the effective emissivity of the urban canopy using sky view factor. ISPRS J. Photogramm. Remote Sens. 2015, 105, 211–219. [Google Scholar] [CrossRef]

- Tewarson, A. Generation of heat and gaseous, liquid, and solid products in fires. In The SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2008; Volume 4, pp. 3–109. [Google Scholar]

- de Freitas Rocha, M.A.; Landesmann, A. Combustion properties of Brazilian natural wood species. Fire Mater. 2016, 40, 219–228. [Google Scholar] [CrossRef]

- Alpert, R.L. Ceiling jet flows. In SFPE handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 429–454. [Google Scholar]

- Sinclair, R. CFD simulation in atrium smoke management system design. ASHRAE Trans. 2001, 107, 711. [Google Scholar]

| P0 (Pa) | T0 (°C) | RH0 (%) | u0 (m/s) | Yair,0 (-) | Ysoot,0 (-) |

|---|---|---|---|---|---|

| 101,325 | 28 | 70 | 0 | 1 | 0 |

| Parameter | Material | Source | |

|---|---|---|---|

| Concrete | Wood (Fuel) | ||

| (kg/m3) | 2100 | - | [50] |

| cp (kJ/(kg·K)) | 0.88 | - | [50] |

| k (W/(m·K)) | 1.37 | - | [50] |

| ε (-) | 0.92 | - | [51] |

| ysoot (kg/kg) | - | 0.0015 | [52] |

| yCO (kg/kg) | - | 0.004 | [52] |

| Δh | - | 16,400 | [52] |

| HRRPUA (kW/m2) | - | 100 | [53] |

| Case | Door (2.20 m2) | Windows (6.80 m2 Total) | Exhaust System | Smoke Curtain | HRR (kW) | a * (m) | b * (m) |

|---|---|---|---|---|---|---|---|

| 1 | Open | Closed | Without | Without | 900 | 0.00 | 3.0 |

| 2 | Open | Open | Without | Without | 900 | 0.00 | 3.0 |

| 3 | Open | Closed | Natural (2.25 m2 total) | Without | 900 | 0.75 | 3.0 |

| 4 | Open | Closed | Natural (9.00 m2 total) | Without | 900 | 1.50 | 3.0 |

| 5 | Open | Open | Natural (2.25 m2 total) | Without | 900 | 0.75 | 3.0 |

| 6 | Open | Open | Natural (9.00 m2 total) | Without | 900 | 1.50 | 3.0 |

| 7 | Open | Closed | Natural (9.00 m2 total) | Without | 225 | 1.50 | 1.5 |

| 8 | Open | Open | Natural (9.00 m2 total) | Without | 225 | 1.50 | 1.5 |

| 9 | Open | Closed | Natural (9.00 m2 total) | With | 225 | 1.50 | 1.5 |

| 10 | Open | Open | Natural (9.00 m2 total) | With | 225 | 1.50 | 1.5 |

| 11 | Open | Open | Mechanical (18.00 m3/h total) | Without | 900 | 1.50 | 3.0 |

| 12 | Open | Open | Mechanical (36.00 m3/h total) | Without | 900 | 1.50 | 3.0 |

| Mesh | Number of Elements in Each Direction | Total Number of Elements | Element Size (cm) |

|---|---|---|---|

| M1 | 320 × 170 × 80 | 4,352,000 | 10.00 |

| M2 | 224 × 119 × 56 | 1,492,736 | 14.26 |

| M3 | 160 × 85 × 40 | 544,000 | 20.00 |

| M4 | 128 × 68 × 32 | 378,528 | 25.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gomez, R.S.; Porto, T.R.N.; Magalhães, H.L.F.; Santos, A.C.Q.; Viana, V.H.V.; Gomes, K.C.; Lima, A.G.B. Thermo-Fluid Dynamics Analysis of Fire Smoke Dispersion and Control Strategy in Buildings. Energies 2020, 13, 6000. https://doi.org/10.3390/en13226000

Gomez RS, Porto TRN, Magalhães HLF, Santos ACQ, Viana VHV, Gomes KC, Lima AGB. Thermo-Fluid Dynamics Analysis of Fire Smoke Dispersion and Control Strategy in Buildings. Energies. 2020; 13(22):6000. https://doi.org/10.3390/en13226000

Chicago/Turabian StyleGomez, Ricardo S., Túlio R. N. Porto, Hortência L. F. Magalhães, Antonio C. Q. Santos, Victor H. V. Viana, Kelly C. Gomes, and Antonio G. B. Lima. 2020. "Thermo-Fluid Dynamics Analysis of Fire Smoke Dispersion and Control Strategy in Buildings" Energies 13, no. 22: 6000. https://doi.org/10.3390/en13226000

APA StyleGomez, R. S., Porto, T. R. N., Magalhães, H. L. F., Santos, A. C. Q., Viana, V. H. V., Gomes, K. C., & Lima, A. G. B. (2020). Thermo-Fluid Dynamics Analysis of Fire Smoke Dispersion and Control Strategy in Buildings. Energies, 13(22), 6000. https://doi.org/10.3390/en13226000