Early Fault Detection of Gas Turbine Hot Components Based on Exhaust Gas Temperature Profile Continuous Distribution Estimation

Abstract

:1. Introduction

2. Early Fault Detection Method

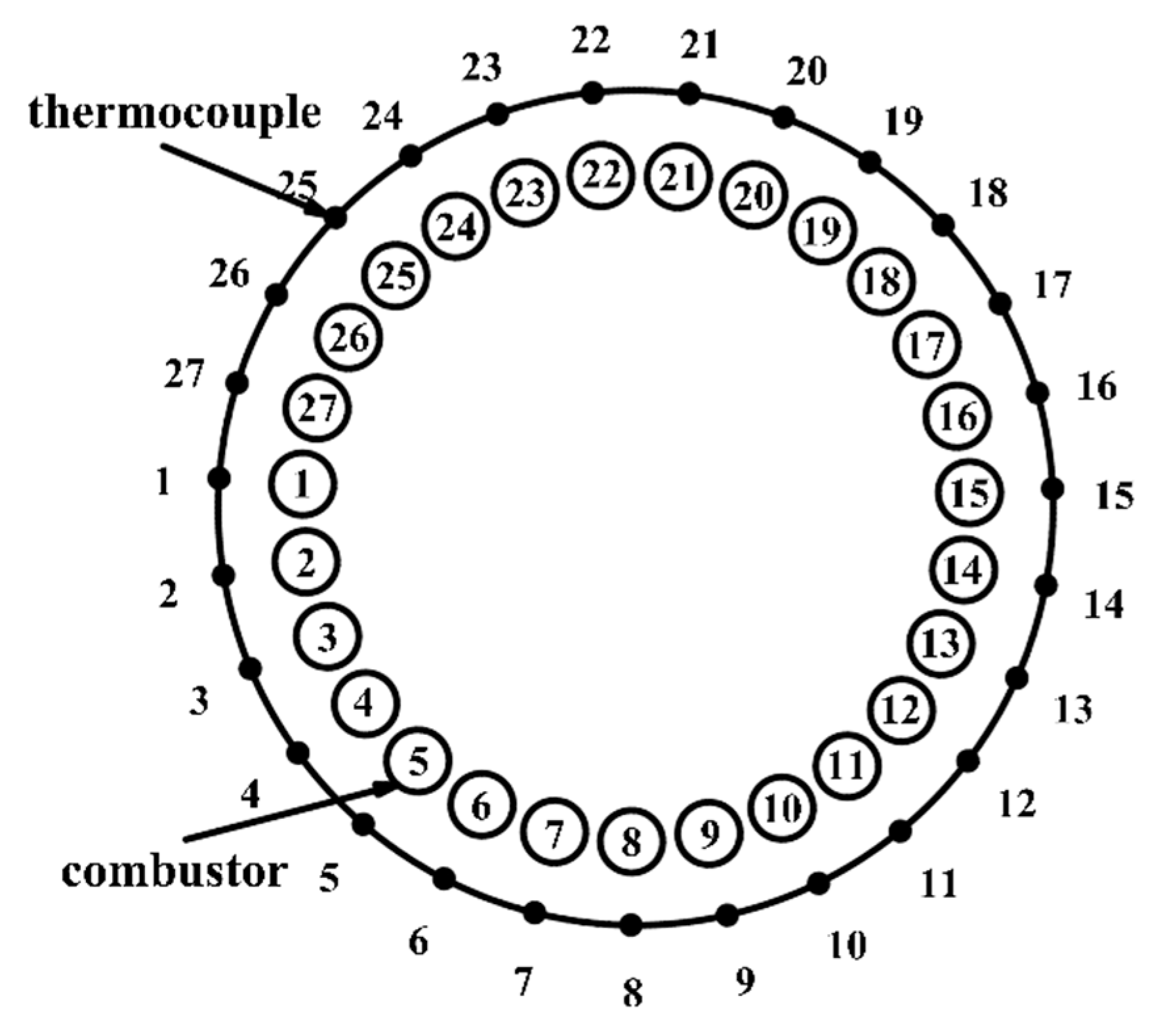

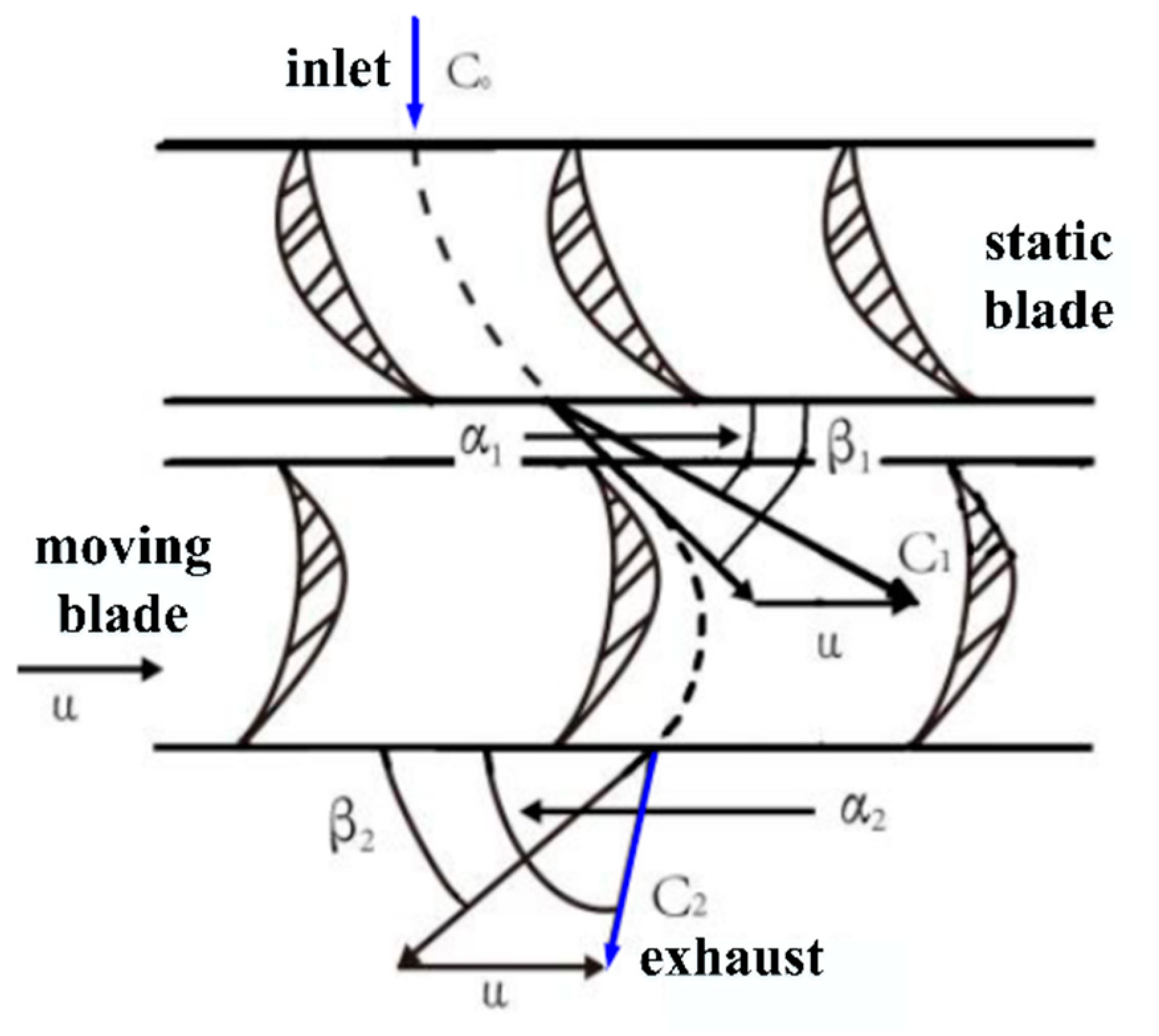

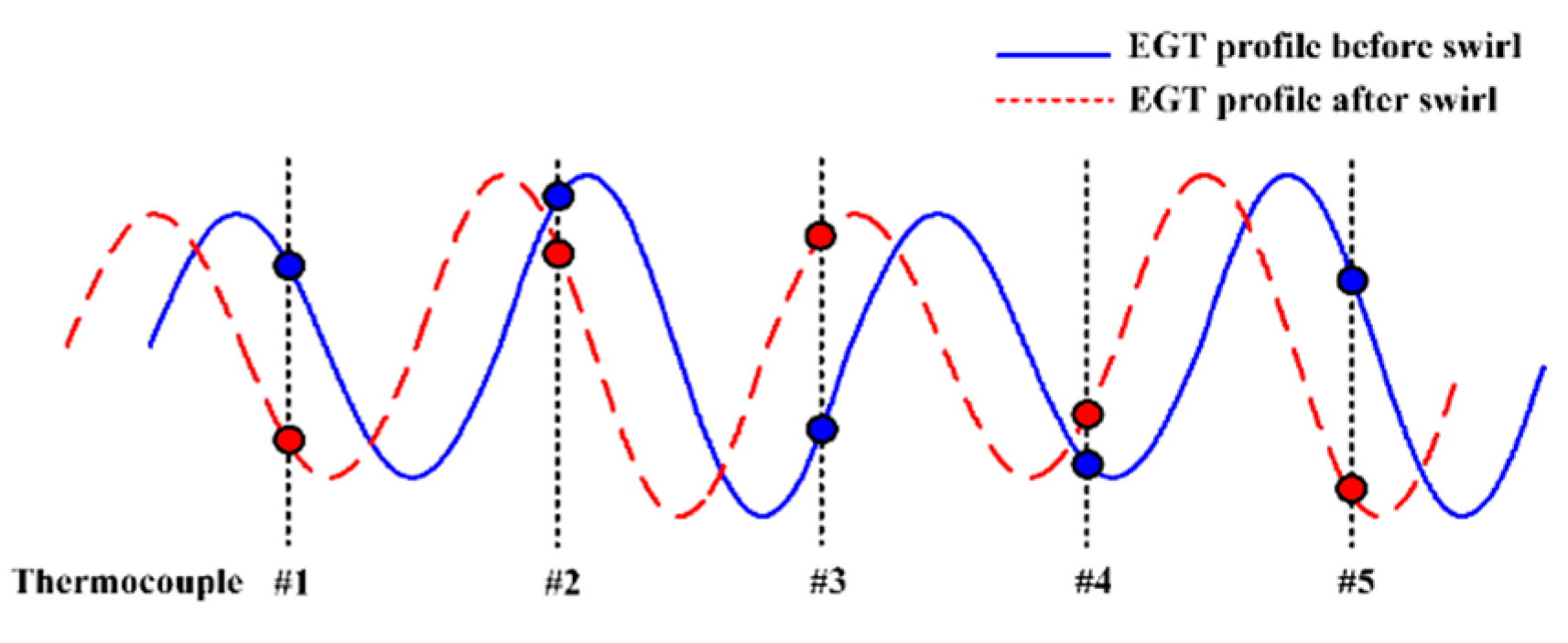

2.1. Influence of Gas Rotation on EGT Profile

2.2. EGT Profile Continuous Distribution Estimation

2.2.1. EGT Profile Model

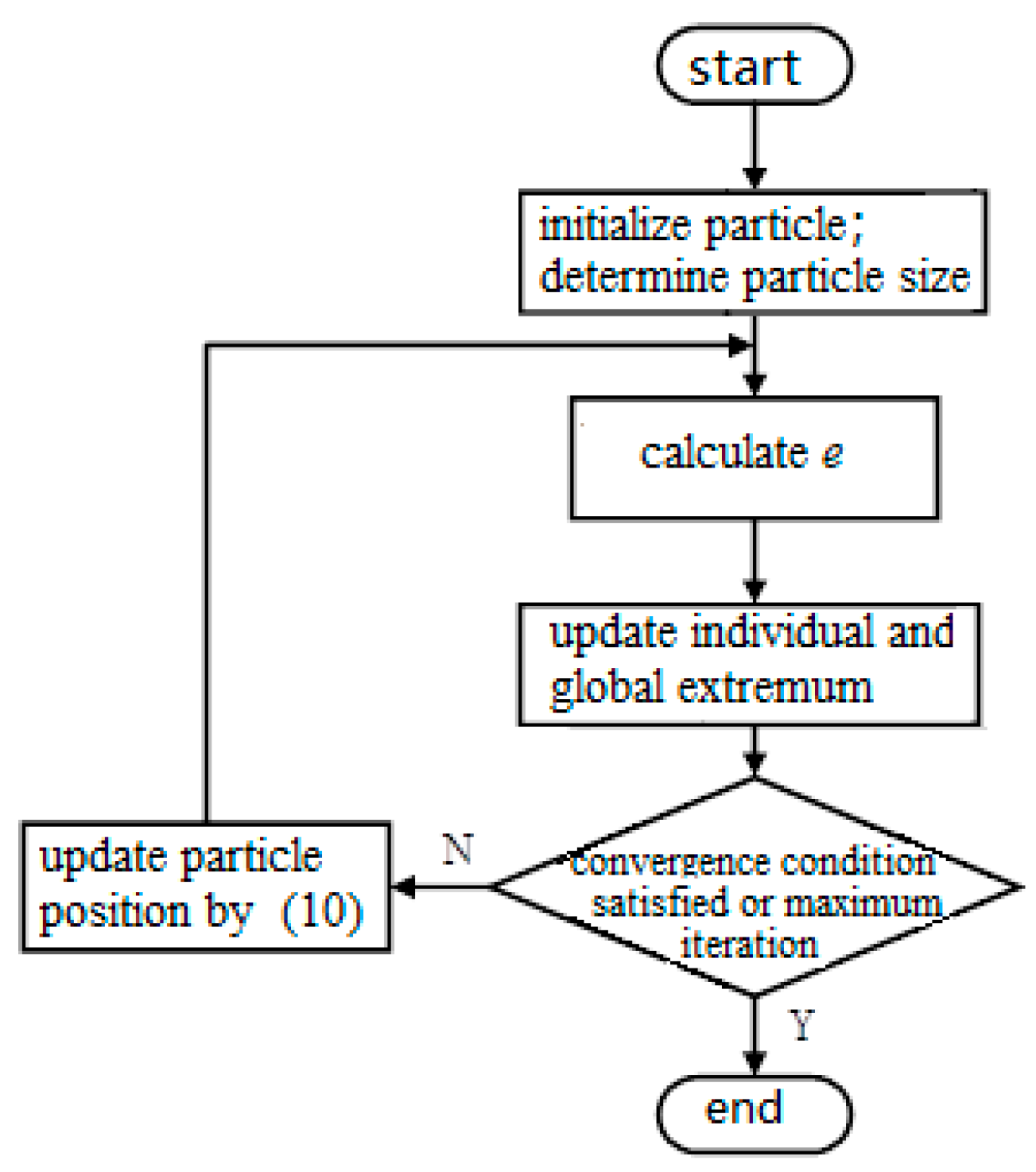

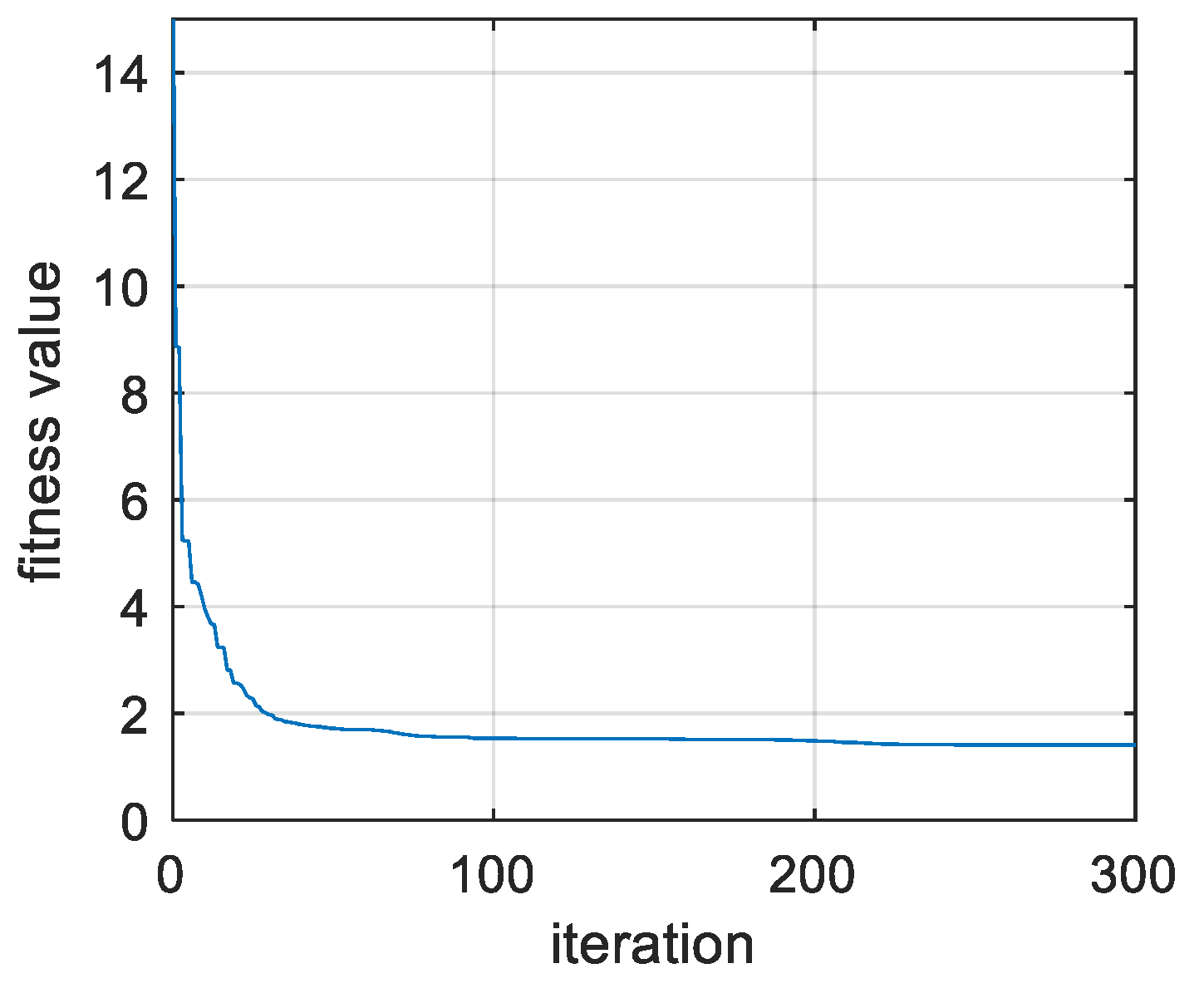

2.2.2. Parameter Evaluation

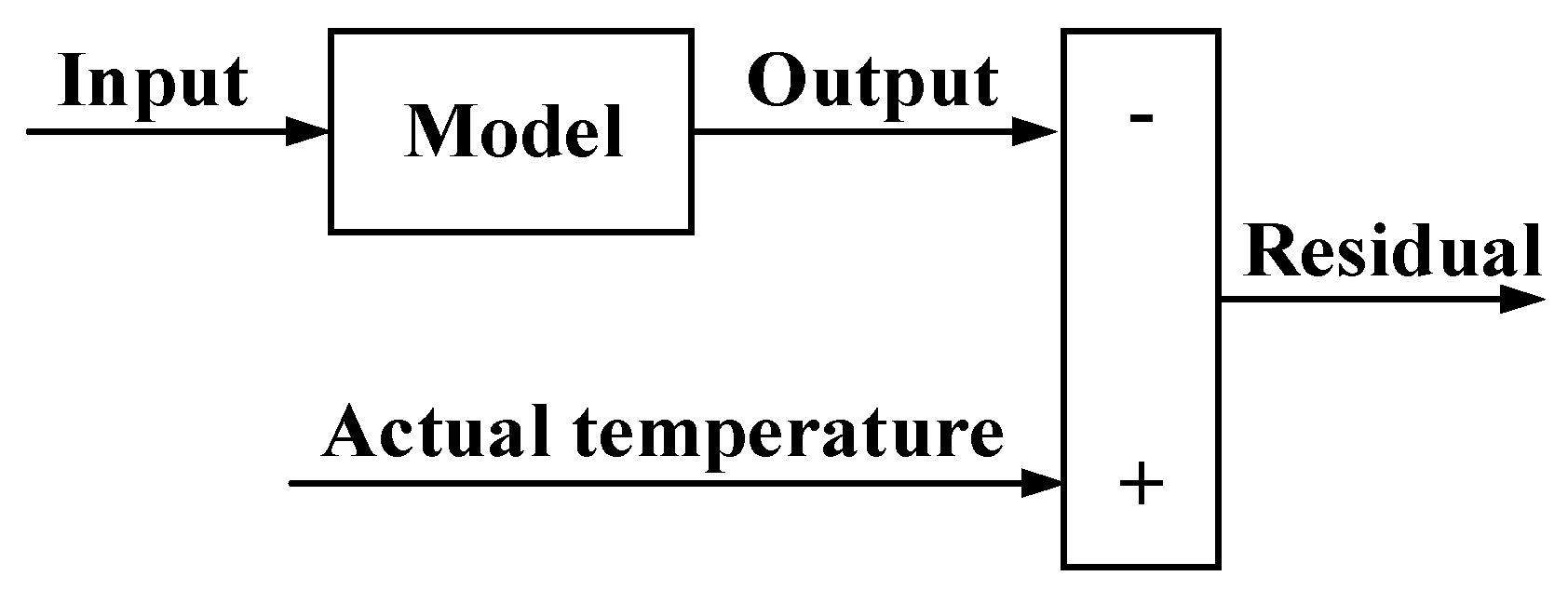

2.3. Gas Turbine Hot Components Early Fault Detection

3. Experiments

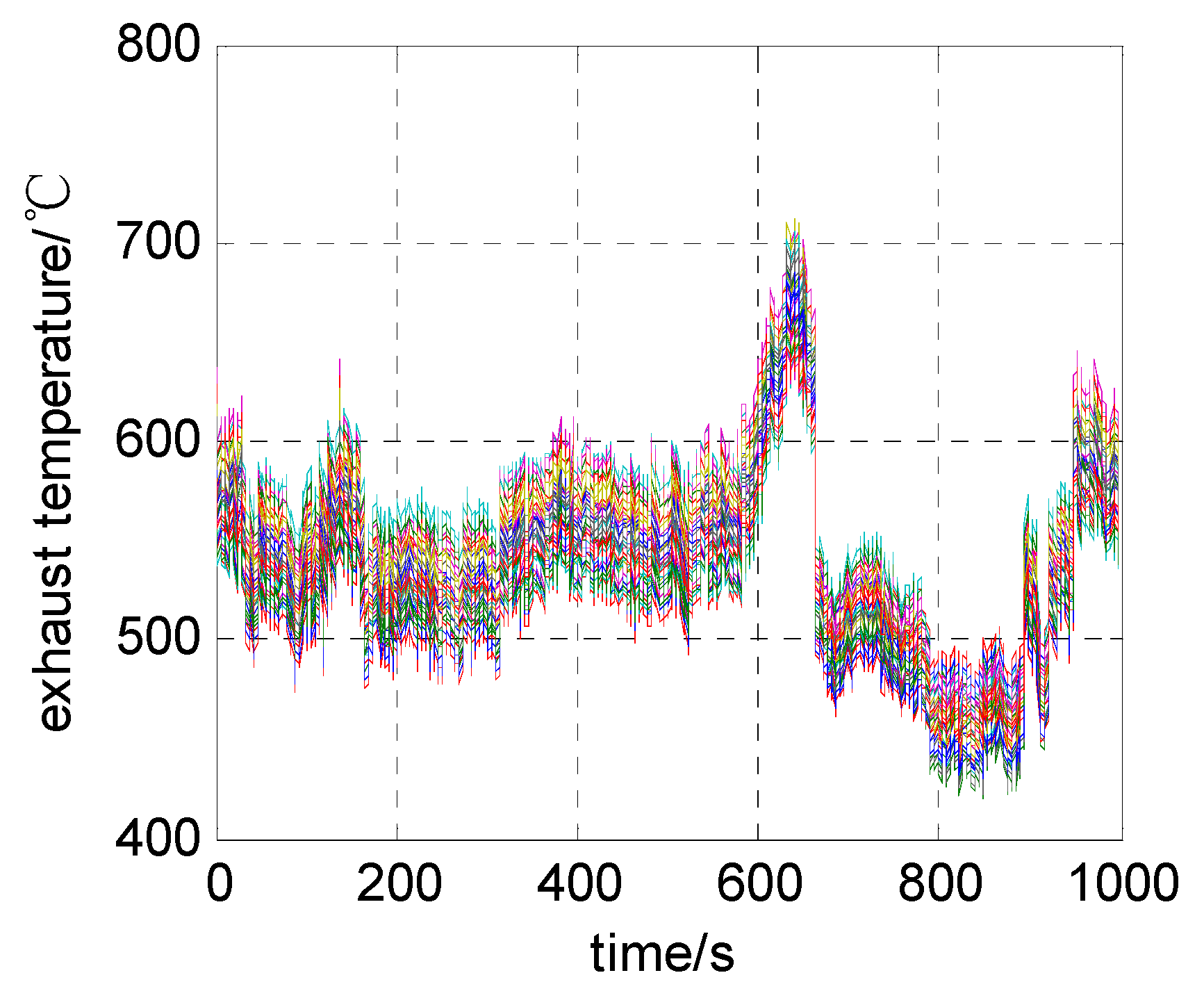

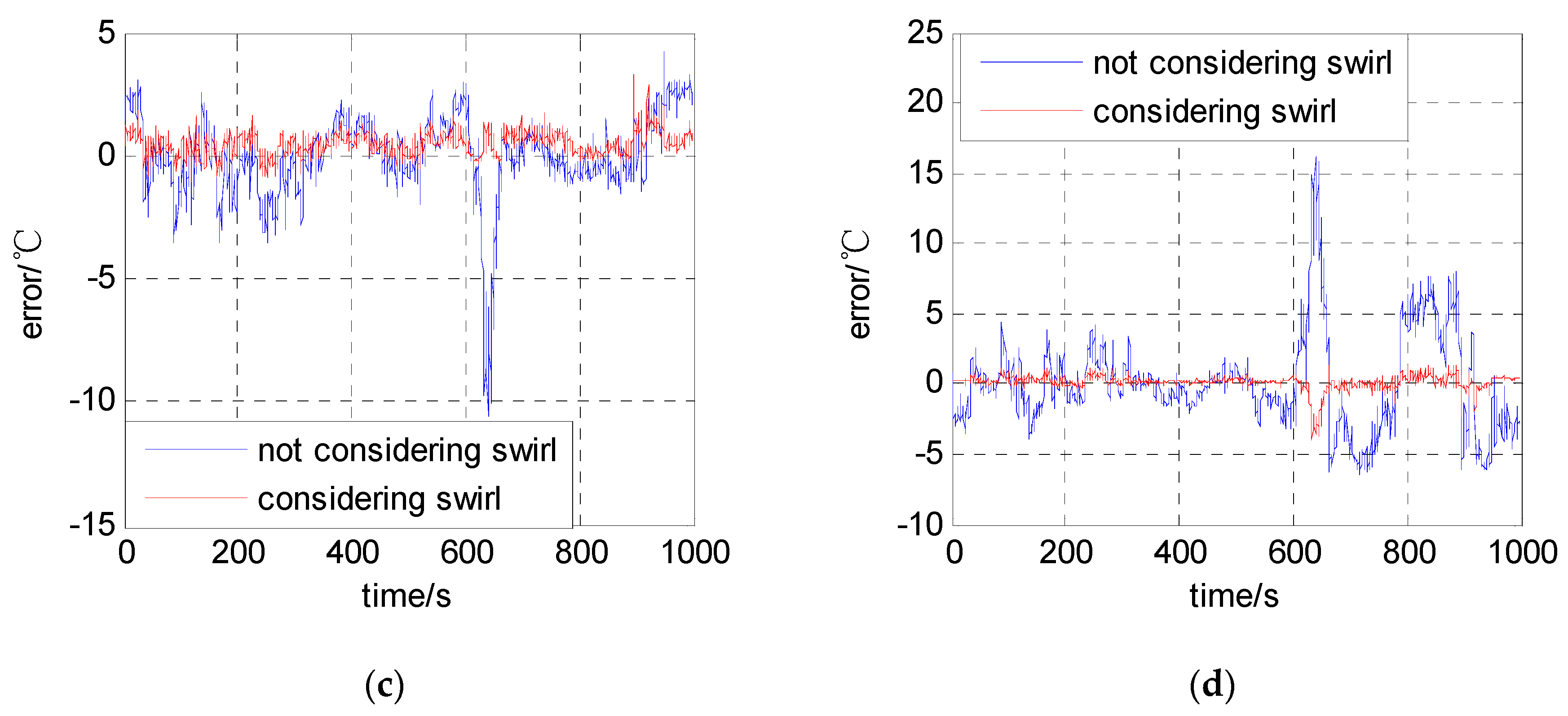

3.1. EGT Profile Estimation Result

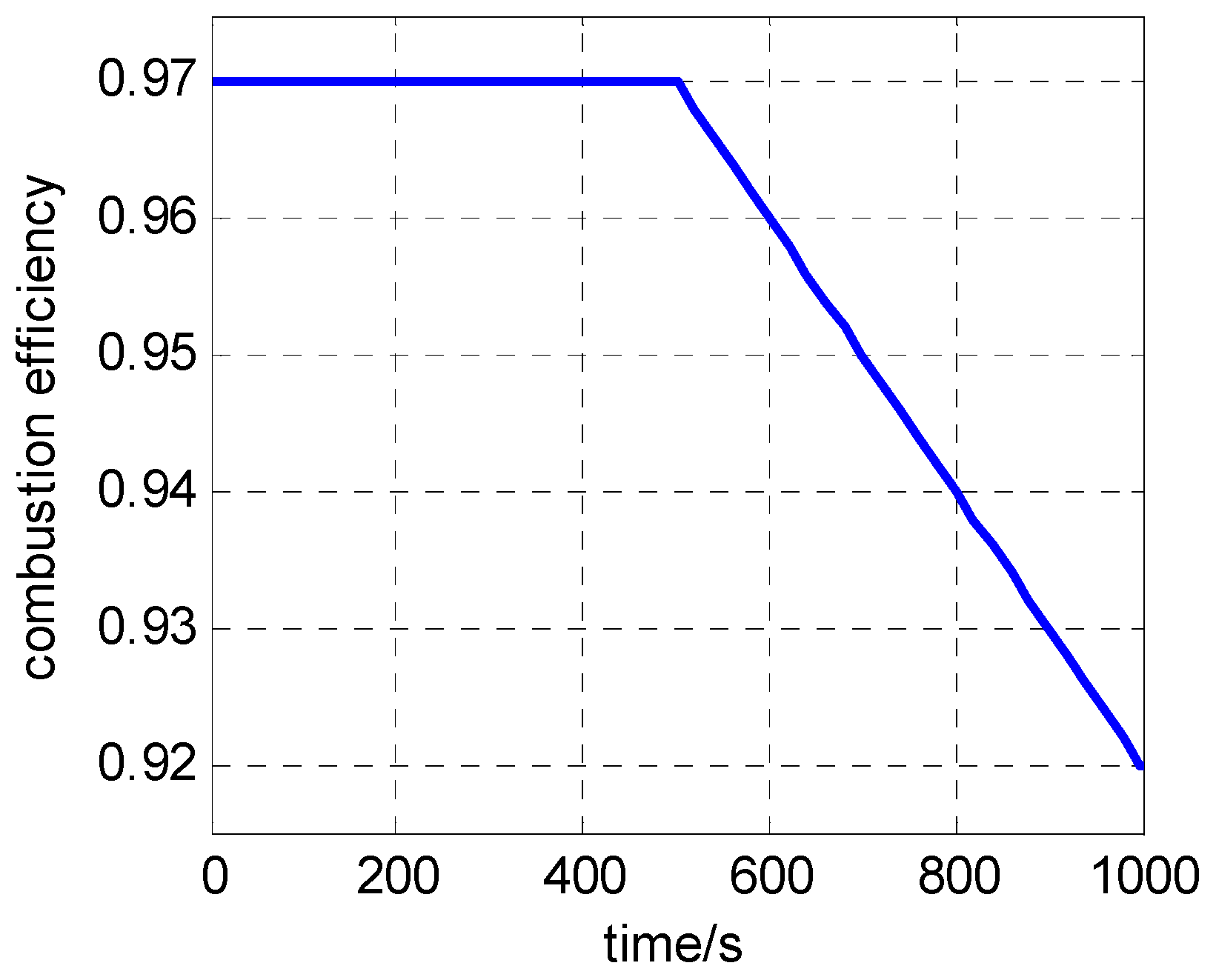

3.2. Fault Detection Result

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- General Electric Company. Heavy Duty Gas Turbine Monitoring & Protection; General Electric Company: Reno, NV, USA, 2015. [Google Scholar]

- Yu, L.; Jin, J. Study on Deflection Laws of 9FA Gas-Turbine Exhaust Temperature Field. Electr. Power Constr. 2009, 3, 26. [Google Scholar] [CrossRef]

- Gulen, S.C.; Griffin, P.R.; Paolucci, S. Real-time on-line Performance Diagnostics of Heavy-duty Industrial Gas Turbines. ASME J. Eng. Gas Turbines Power 2002, 124, 910–921. [Google Scholar] [CrossRef]

- Liu, J. The Research for Exhaust Temperature Anomaly Detection in Gas Turbine. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Yılmaz, İ. Evaluation of the relationship between exhaust gas temperature and operational parameters in CFM56-7B engines. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 433–440. [Google Scholar] [CrossRef]

- Song, Y.X.; Zhang, K.X.; Shi, Y.S. Research on Aeroengine Performance Parameters Forecast Based on Multiple Linear Regression Forecasting Method. J. Aerosp. Power 2009, 24, 427–431. [Google Scholar]

- Tarassenko, L.; Nairac, A.; Townsend, N.; Buxton, I.; Cowley, P. Novelty detection for the identification of abnormalities. Int. J. Syst. Sci. 2000, 31, 1427–1439. [Google Scholar] [CrossRef]

- Yan, W. Detecting Gas Turbine Combustor Anomalies Using Semi-supervised Anomaly Detection with Deep Representation Learning. Cognit. Comput. 2020, 12, 398–411. [Google Scholar] [CrossRef]

- Basseville, M.; Benveniste, A.; Mathis, G.; Zhang, Q. Monitoring the Combustion Set of a Gas Turbine. IFAC Proc. Vol. 1994, 27, 375–380. [Google Scholar] [CrossRef]

- Zhang, Q.; Basseville, M.; Benveniste, A. Early warning of slight changes in systems. Automatica 1994, 30, 95–113. [Google Scholar] [CrossRef]

- Medina, P.; Saez, D.; Roman, R. On Line Fault Detection and Isolation in Gas Turbine Combustors; ASME Paper No. GT2008-51316; ASME: New York, NY, USA, 2008. [Google Scholar]

- Jinfu, L.; Jiao, L.; Jie, W.; Zhongqi, W.; Daren, Y. Early Fault Detection of Hot Components in Gas Turbines. ASME J. Eng. Gas Turbines Power 2017, 139, 021201. [Google Scholar] [CrossRef]

- Talaat, M.; Gobran, M.H.; Wasfi, M. A hybrid model of an artificial neural network with thermodynamic model for system diagnosis of electrical power plant gas turbine. Eng. Appl. Artif. Intell. 2018, 68, 222–235. [Google Scholar] [CrossRef]

- Chen, Q.; Li, H.; Li, M.; Xie, Z.; Xiu, J. Prediction of Aeroengine Exhaust Gas Temperature Based on RBF Neural Networks. J. Ordnance Equip. Eng. 2019, 6, 183. [Google Scholar]

- Pi, J.; Huang, J.; Huang, L.; Gao, S.; Liu, G. Aeroengine Exhaust Gas Temperature Prediction Based on IQPSO-SVR. J. Vib. Meas. Diagn. 2019, 2, 18. [Google Scholar]

- Zhang, Q. Contribution à la Surveillance de Procédés Industriels. Ph.D. Thesis, University of Rennes 1, Rennes, France, 1991. [Google Scholar]

- Sun, J.; Feng, B.; Xu, W. Particle swarm optimization with particles having quantum behavior. In Proceedings of the 2004 Congress on Evolutionary Computation, Portland, OR, USA, 19–23 June 2004. [Google Scholar]

- Camporeale, S.M.; Fortunato, B.; Mastrovito, M. A Modular Code for Real Time Dynamic Simulation of Gas Turbines in Simulink. J. Eng. Gas Turbines Power 2006, 128, 506–517. [Google Scholar] [CrossRef]

| Parameters | Initial Value |

|---|---|

| a | |

| b | |

| c | |

| d | |

| Number of evolutions | 300 |

| Particle group size | 300 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 1.006 | 0.987 | ||

| 0.977 | a | −0.318 | |

| 0.994 | b | −0.397 | |

| 1.022 | c | −0.254 | |

| 1.012 | b | 1.497 |

| Measuring Point NO. | Not Considering Swirl Effect | Considering Swirl Effect | Measuring Point NO. | Not Considering Swirl Effect | Considering Swirl Effect | ||||

|---|---|---|---|---|---|---|---|---|---|

| Upper Limit /°C | Lower Limit /°C | Upper Limit/°C | Lower Limit/°C | Upper Limit /°C | Lower Limit /°C | Upper Limit /°C | Lower Limit /°C | ||

| 12.74 | −6.95 | 1.86 | −5.40 | 14.49 | −5.10 | 2.82 | −2.08 | ||

| 5.55 | −3.84 | 2.45 | −4.35 | 5.92 | −9.43 | 3.76 | −2.43 | ||

| 6.92 | −10.77 | 2.10 | −2.75 | 8.13 | −14.24 | 5.65 | −2.02 | ||

| 5.03 | −14.63 | 2.12 | −2.83 | 3.83 | −9.32 | 2.40 | −2.26 | ||

| 8.68 | −5.37 | 2.60 | −3.46 | 9.99 | −6.88 | 1.51 | −3.20 | ||

| 13.34 | −8.11 | 1.58 | −5.31 | 12.91 | −5.05 | 1.50 | −4.13 | ||

| 8.97 | −3.71 | 1.51 | −2.50 | 3.74 | −7.47 | 1.89 | −2.64 | ||

| 6.57 | −10.37 | 2.84 | −1.27 | 7.20 | −13.85 | 3.16 | −1.19 | ||

| 5.72 | −14.52 | 4.25 | −2.27 | 4.23 | −10.61 | 3.25 | −1.52 | ||

| 7.72 | −4.04 | 4.18 | −3.14 | 11.17 | −7.33 | 2.75 | −3.02 | ||

| 14.64 | −8.29 | 3.81 | −4.00 | 16.20 | −6.53 | 1.41 | −3.84 | ||

| 13.93 | −4.93 | 3.98 | −3.42 | 5.76 | −5.75 | 3.05 | −3.20 | ||

| 7.01 | −10.46 | 4.16 | −3.35 | 8.38 | −11.29 | 4.72 | −2.90 | ||

| 7.44 | −14.22 | 5.92 | −2.29 | 4.64 | −13.25 | 3.39 | −3.43 | ||

| 4.51 | −5.43 | 3.65 | −2.37 | 8.71 | −5.26 | 2.18 | −4.06 | ||

| 11.53 | −7.28 | 2.45 | −2.48 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Bai, M.; Long, Z.; Liu, J.; Ma, Y.; Yu, D. Early Fault Detection of Gas Turbine Hot Components Based on Exhaust Gas Temperature Profile Continuous Distribution Estimation. Energies 2020, 13, 5950. https://doi.org/10.3390/en13225950

Liu J, Bai M, Long Z, Liu J, Ma Y, Yu D. Early Fault Detection of Gas Turbine Hot Components Based on Exhaust Gas Temperature Profile Continuous Distribution Estimation. Energies. 2020; 13(22):5950. https://doi.org/10.3390/en13225950

Chicago/Turabian StyleLiu, Jinfu, Mingliang Bai, Zhenhua Long, Jiao Liu, Yujia Ma, and Daren Yu. 2020. "Early Fault Detection of Gas Turbine Hot Components Based on Exhaust Gas Temperature Profile Continuous Distribution Estimation" Energies 13, no. 22: 5950. https://doi.org/10.3390/en13225950

APA StyleLiu, J., Bai, M., Long, Z., Liu, J., Ma, Y., & Yu, D. (2020). Early Fault Detection of Gas Turbine Hot Components Based on Exhaust Gas Temperature Profile Continuous Distribution Estimation. Energies, 13(22), 5950. https://doi.org/10.3390/en13225950