Comparison of the Electromagnetic Characteristics of a Novel Gramme Winding and a Concentrated Winding Tubular Permanent-Magnet Linear Generator

Abstract

:1. Introduction

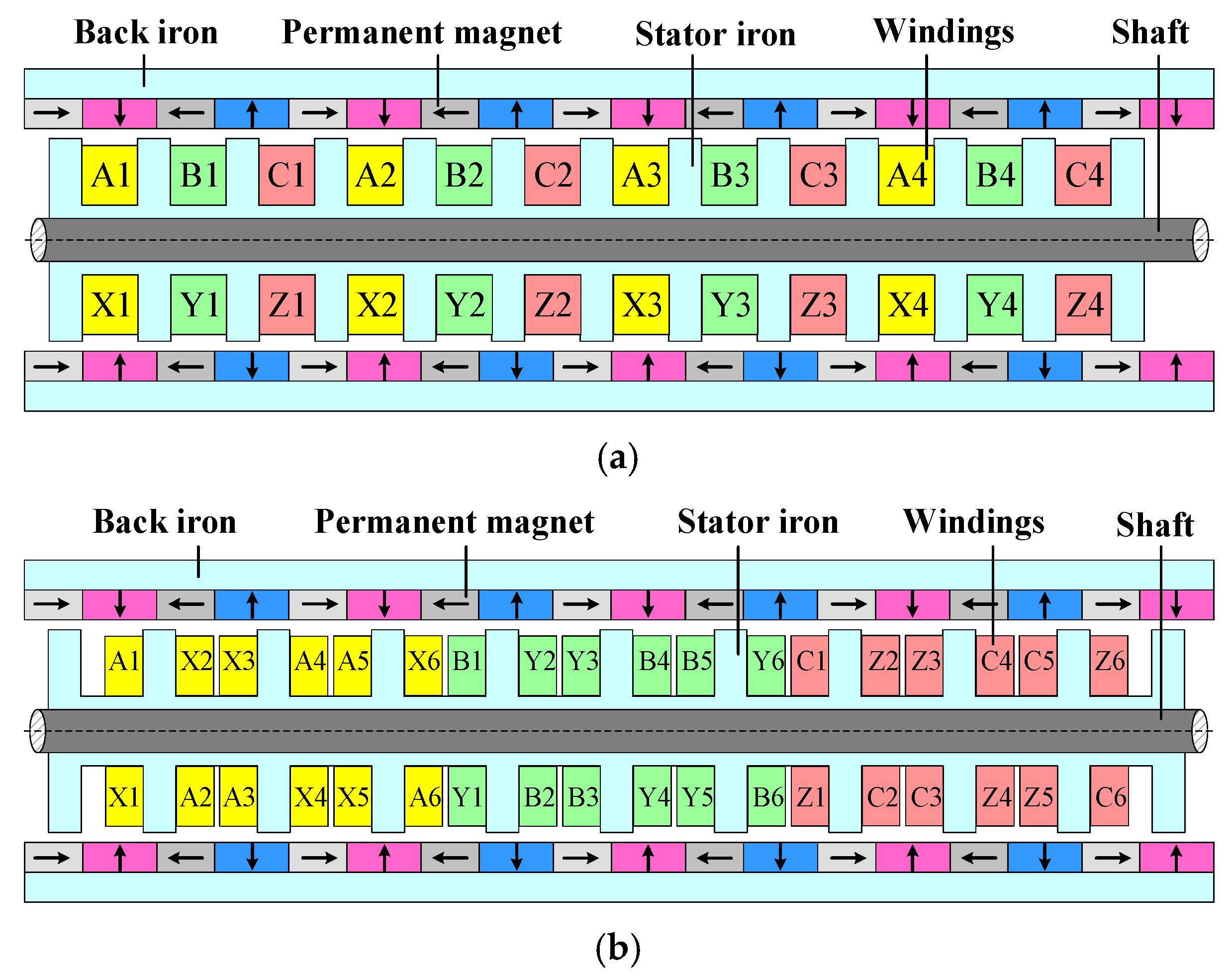

2. Structures and Operation Principle of Generators

2.1. Structures of GW and CW

- All coils are wound in the same direction.

- The minimum unit module of the GW is two poles and three slots.

- Only one phase coil is embedded in each stator slot. Each phase coil is arranged in sequence to facilitate expansion into a multiphase generator.

2.2. Operation Principle of GW

3. Parameter Design and Analytical Model

4. Analysis of Electromagnetic Characteristics

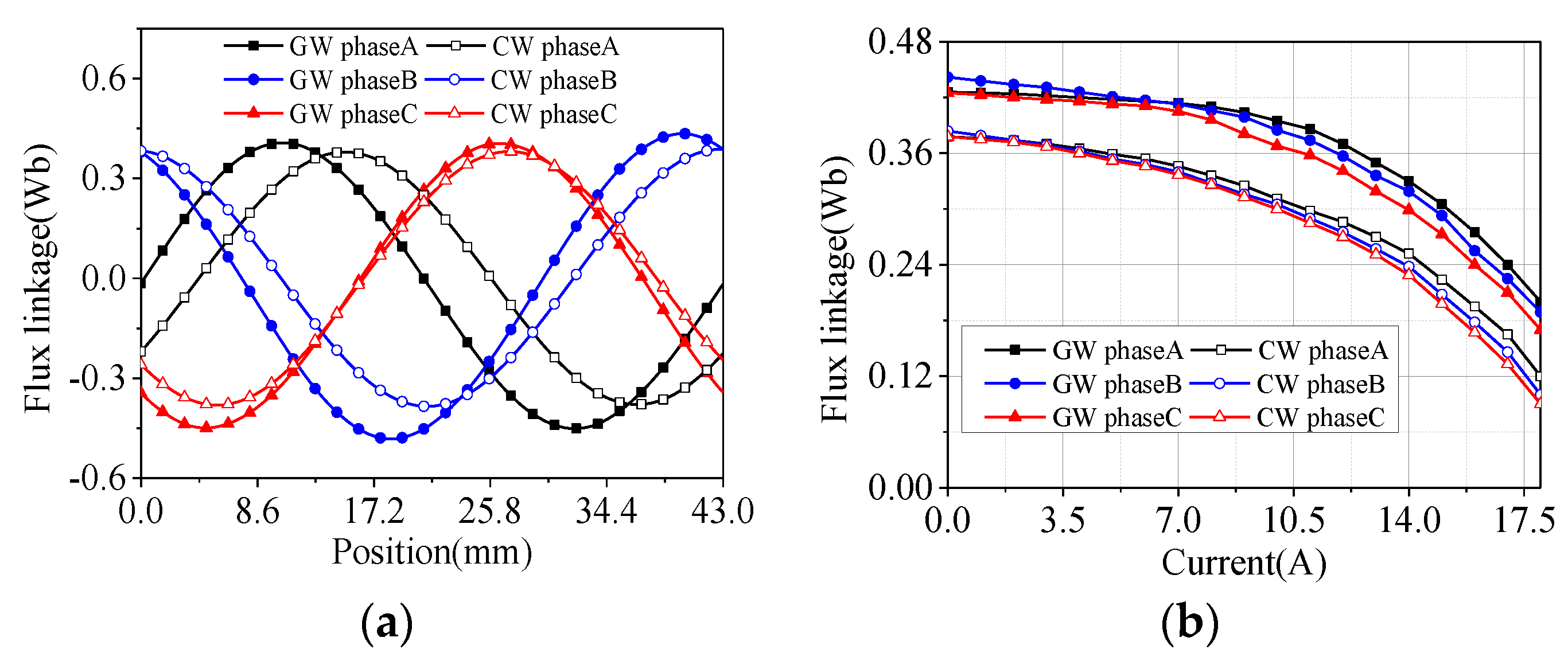

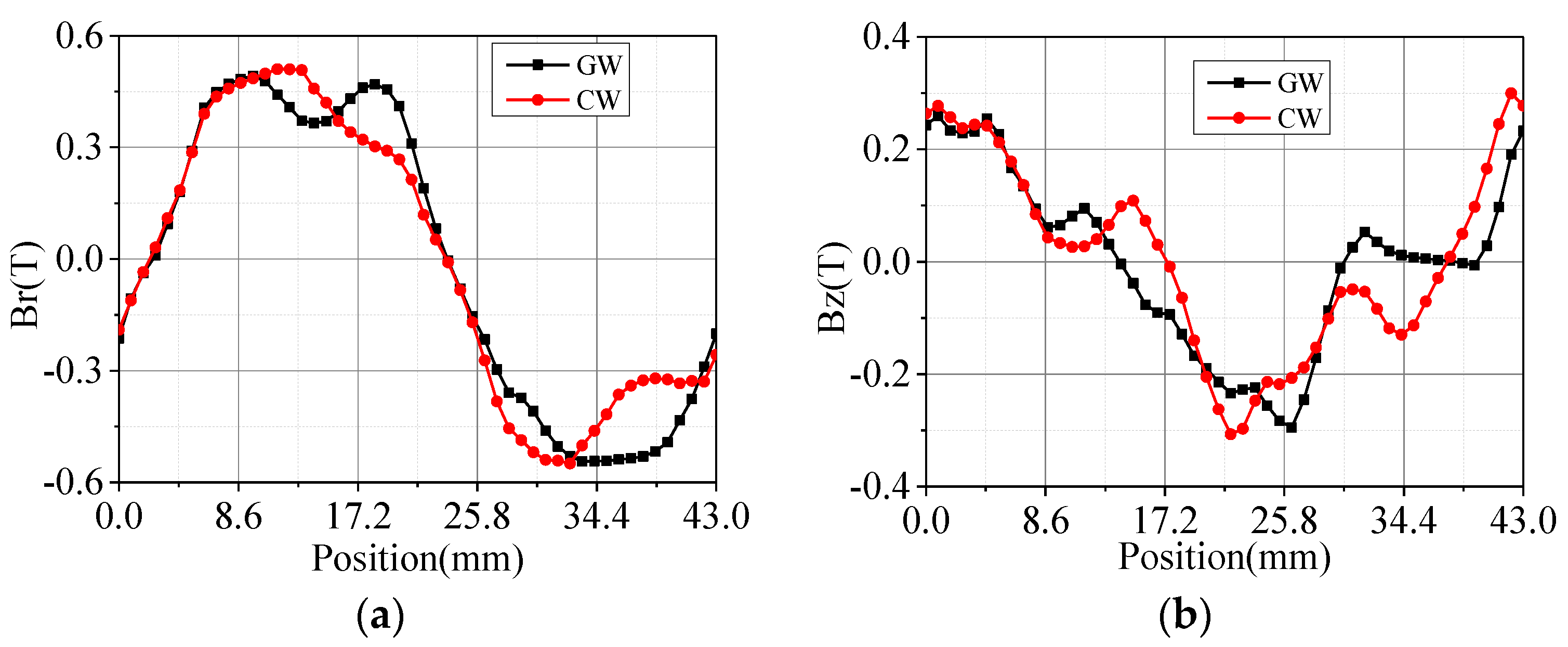

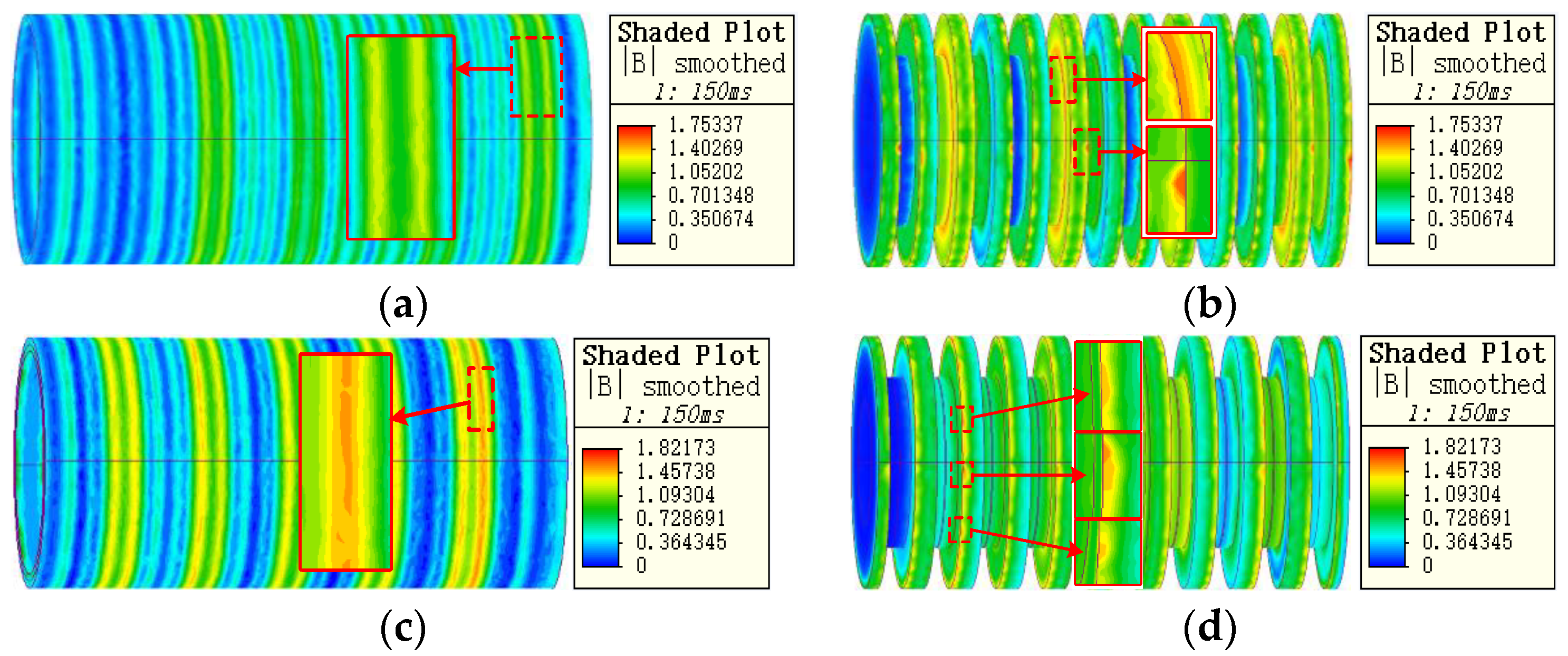

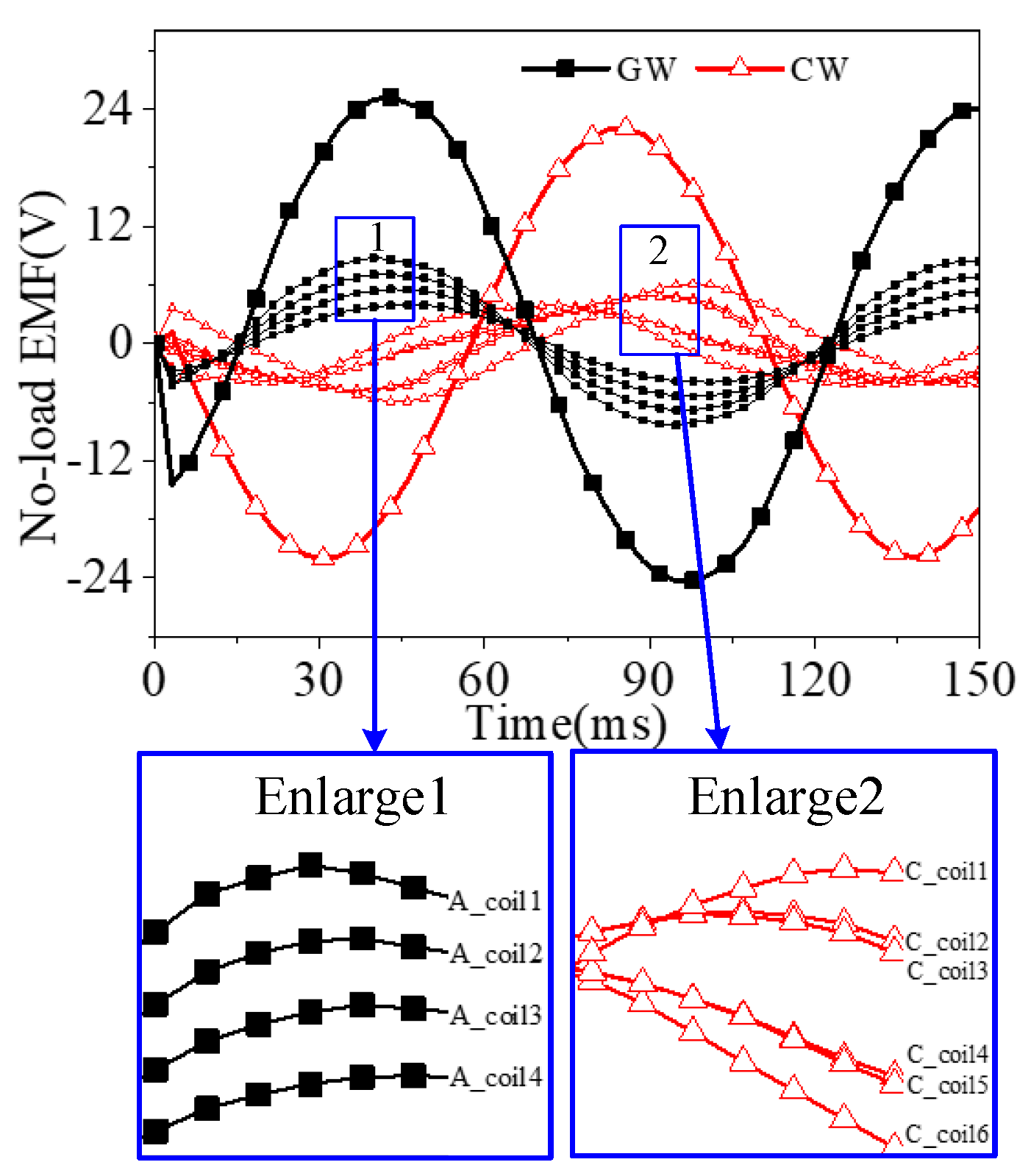

4.1. Analysis of No-Load Characteristics

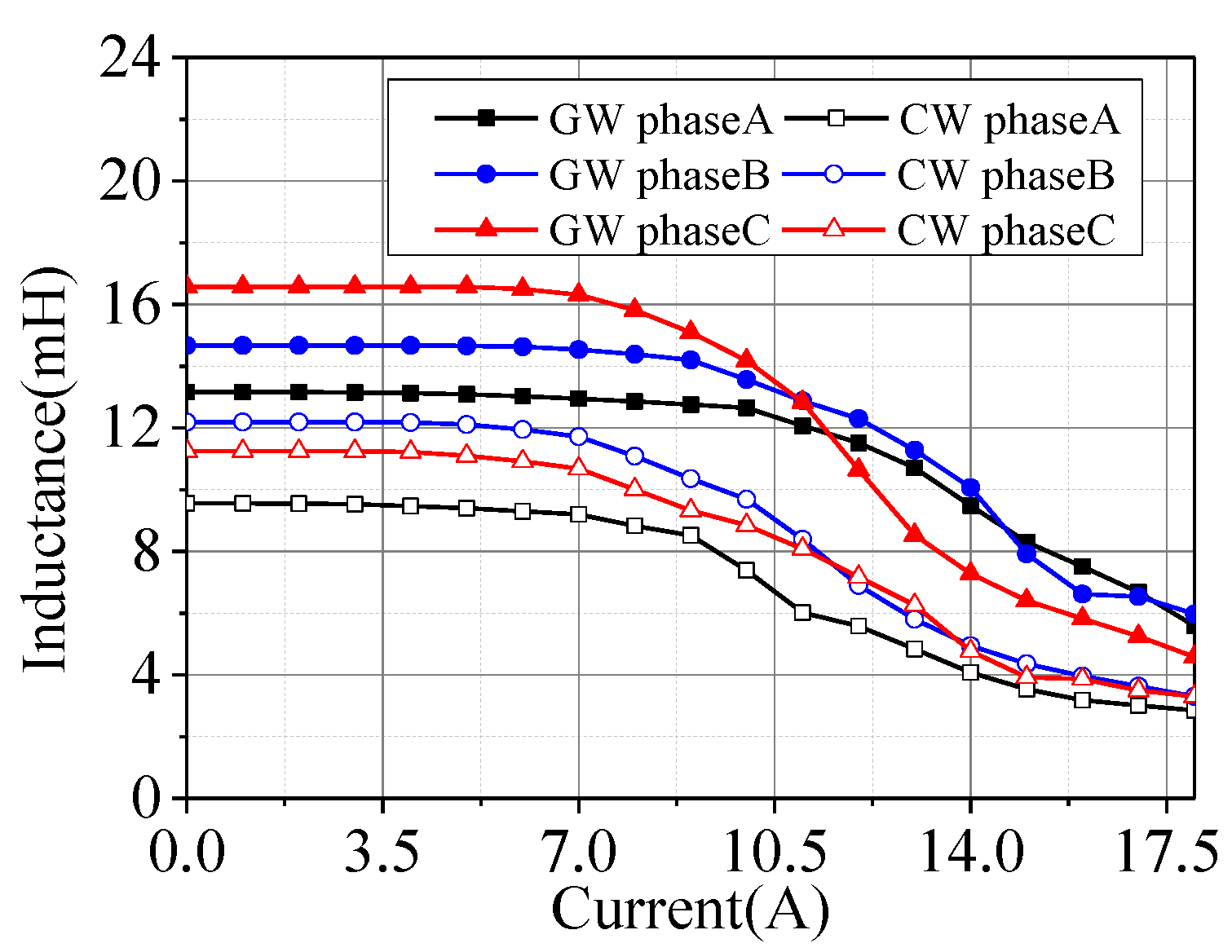

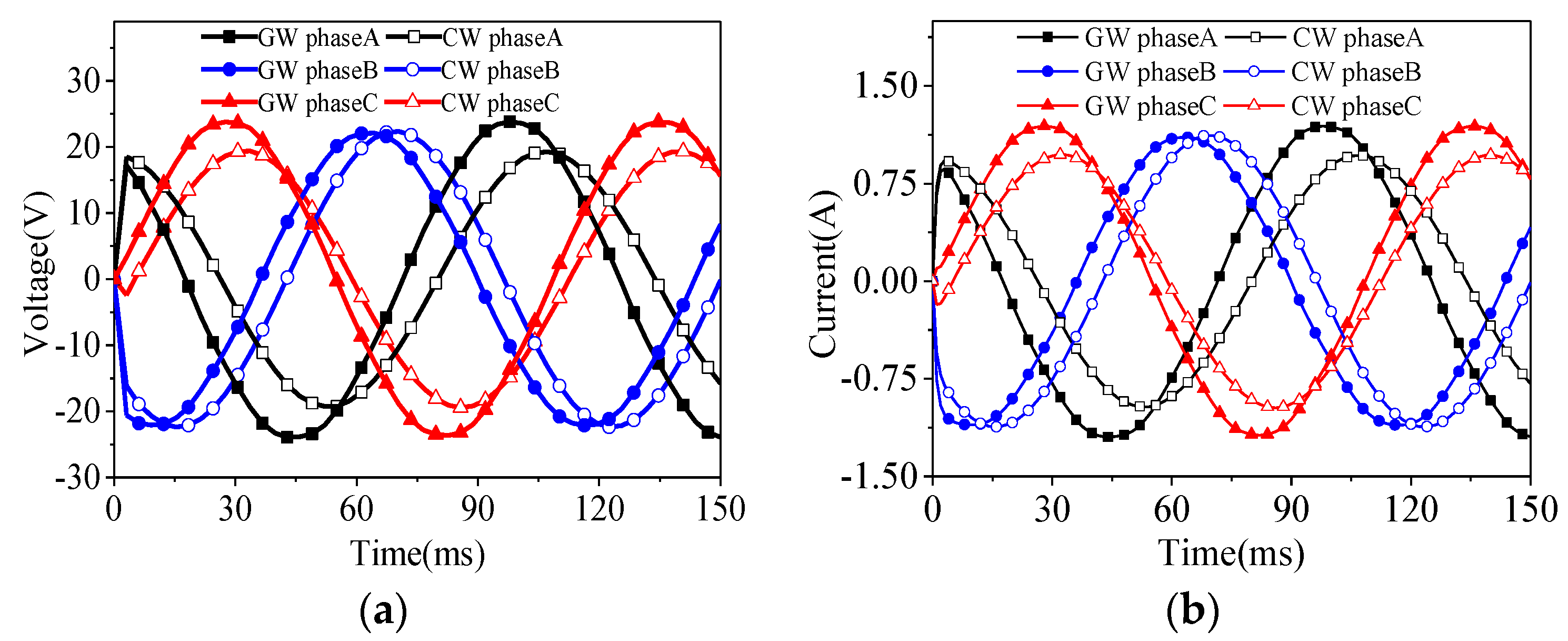

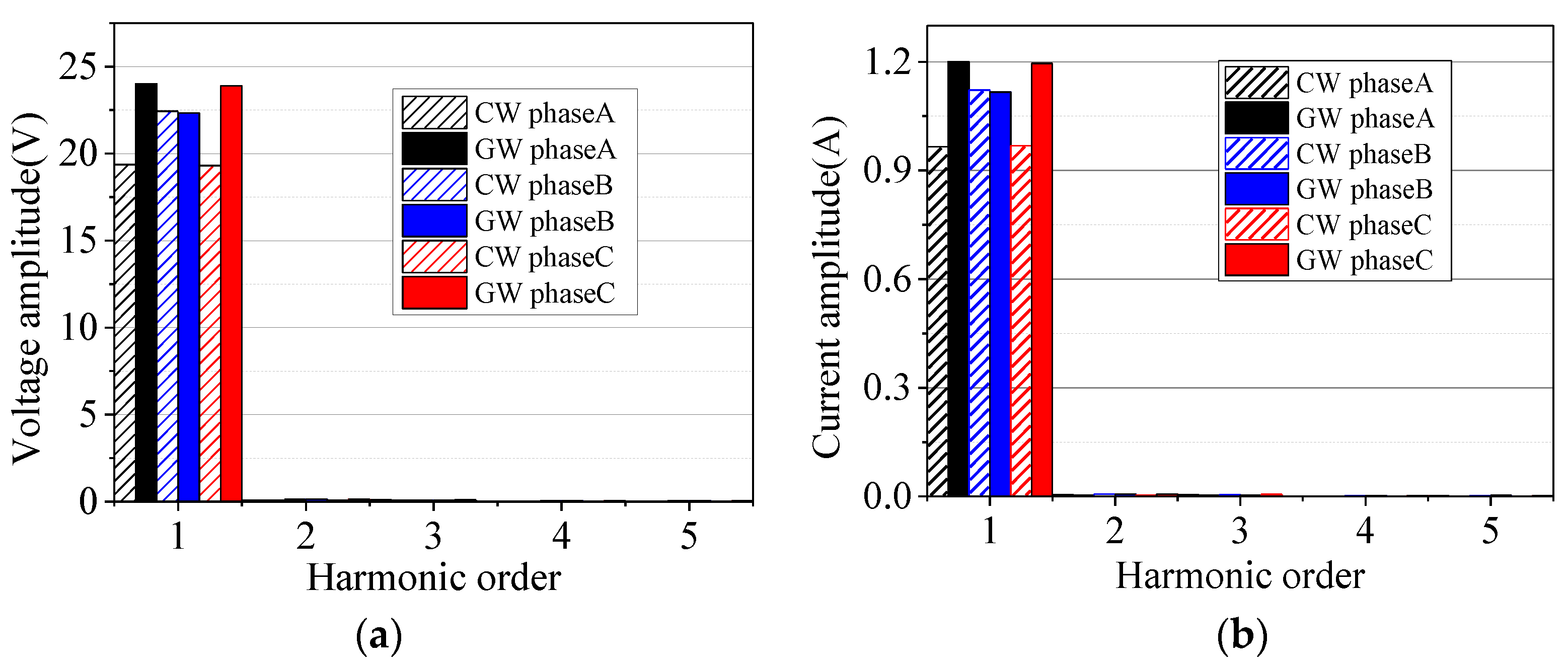

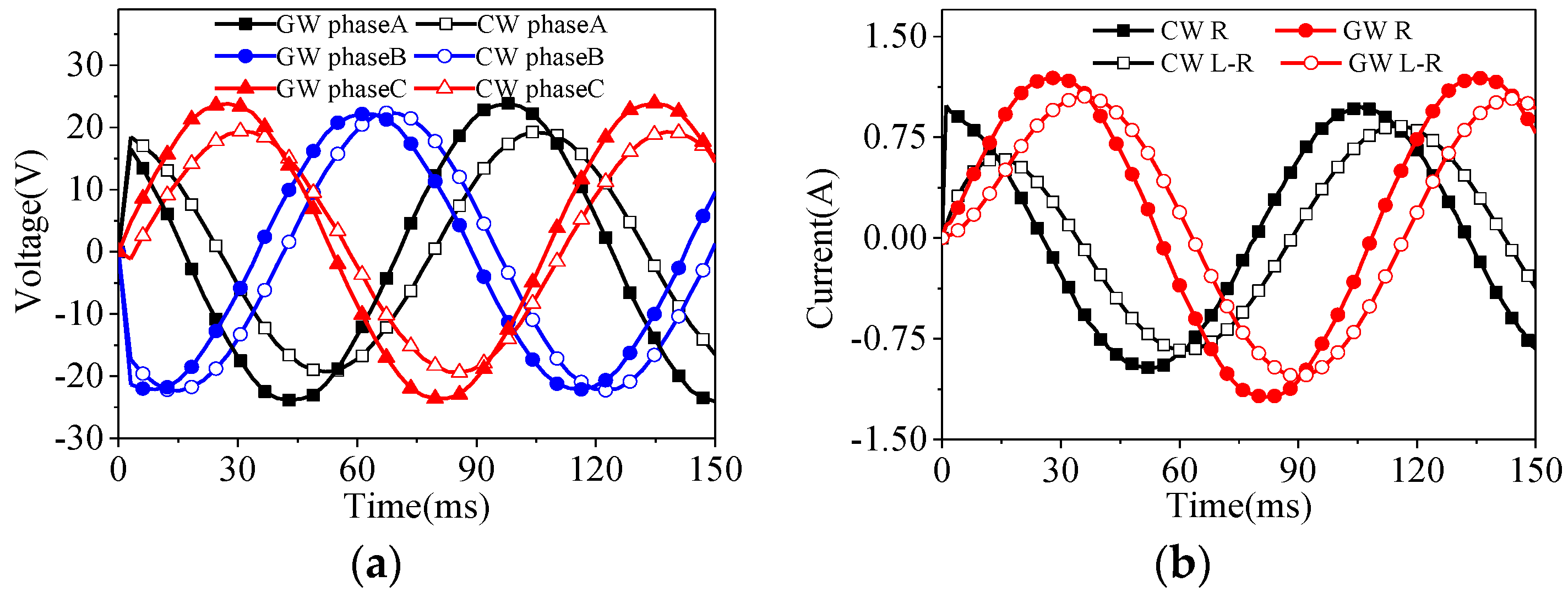

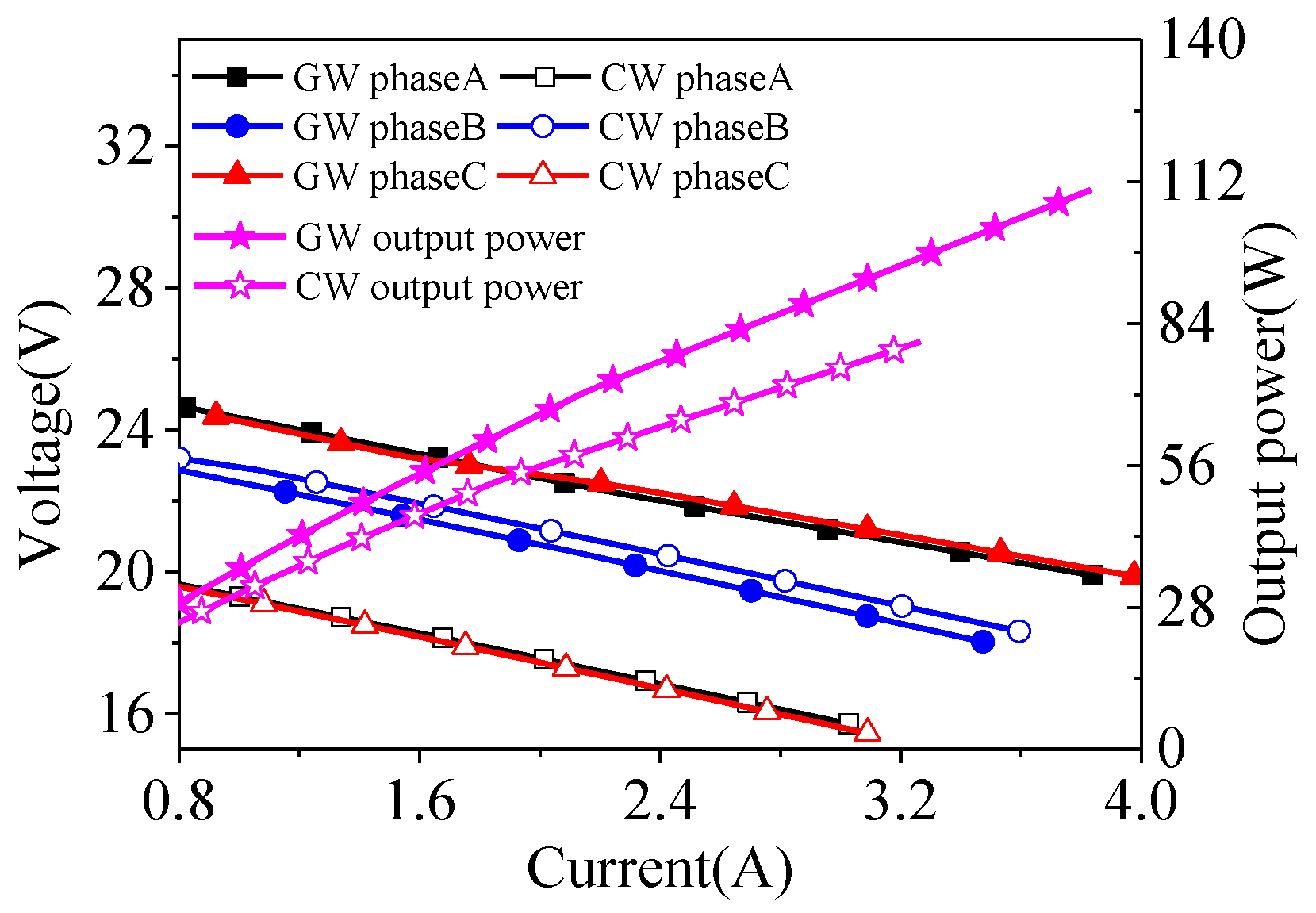

4.2. Analysis of Load Characteristics

4.3. Loss and Efficiency

4.4. Voltage Regulation

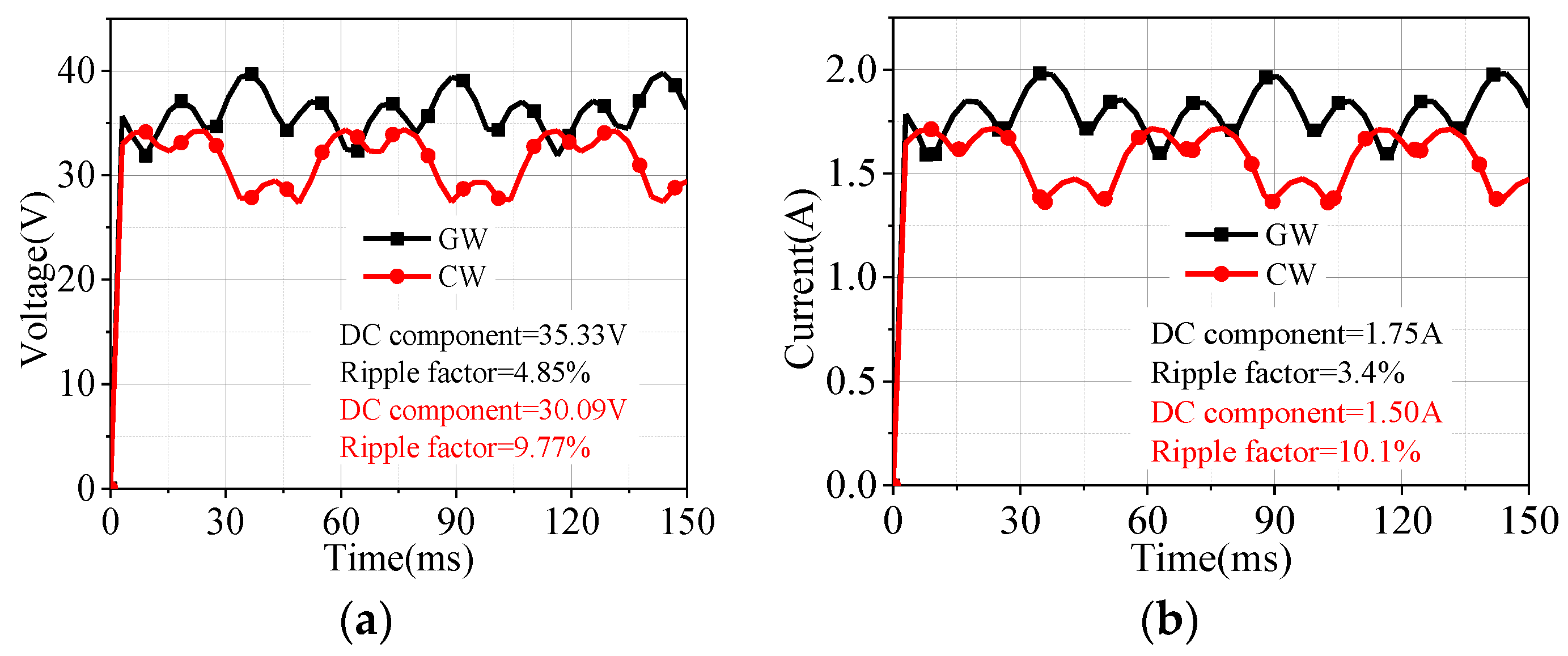

5. DC Load Characteristics

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xiao, X.; Bai, N.Z.; Kang, Q.; Nie, Z.X.; Huang, X.R. A Review of the Development of Wave Power System and the Research on Direct-Drive Wave Power System. Trans. China Electrotech. Soc. 2014, 29, 1–11. [Google Scholar]

- Faiz, J.; Nematsaberi, A. Linear Electrical Generator Topologies for Direct-Drive Marine Wave Energy Conversion—An Overview. IET Renew. Power Gener. 2017, 11, 1163–1176. [Google Scholar]

- DelliColli, V.; Cancelliere, P.; Marignetti, F. A Tubular-Generator Drive for Wave Energy Conversion. IEEE Trans. Ind. Electron. 2006, 53, 1152–1159. [Google Scholar]

- Wahyudie, A.; Jama, M.; Susilo, T.B. Design and Testing of a Laboratory Scale Test Rig for Wave Energy Converters Using a Double-Sided Permanent Magnet Linear Generator. IET Renew. Power Gener. 2017, 11, 922–930. [Google Scholar] [CrossRef]

- Polinder, H.; Damen, M.; Gardner, F. Linear PM Generator System for Wave Energy Conversion in the AWS. IEEE Trans. Energy Convers. 2004, 19, 583–589. [Google Scholar] [CrossRef] [Green Version]

- Polinder, H.; Mecrow, B.C.; Jack, A.G. Conventional and TFPM Linear Generators for Direct-Drive Wave Energy Conversion. IEEE Trans. Energy Convers. 2005, 20, 260–267. [Google Scholar] [CrossRef]

- Dobzhanskyi, O. Comparison Analysis of Cylindrical and Rectangular Linear Permanent Magnet Transverse-Flux Machines for Wave Energy Applications. In Proceedings of the 2019 12th International Symposium on Linear Drives for Industry Applications (LDIA), Neuchatel, Switzerland, 1–3 July 2019; pp. 1–5. [Google Scholar]

- Musolino, A.; Raugi, M.; Rizzo, R.; Sani, L. A Semi-Analytical Model for the Analysis of a Permanent Magnet Tubular Linear Generator. IEEE Trans. Ind. Appl. 2018, 54, 204–212. [Google Scholar] [CrossRef]

- Wang, J.B.; Howe, D.; Jewell, G.W. Fringing in Tubular Permanent-Magnet Machines: Part I. Magnetic Field Distribution, Flux Linkage, and Thrust Force. IEEE Trans. Magn. 2003, 39, 3507–3516. [Google Scholar] [CrossRef]

- Wang, J.B.; Howe, D.; Jewell, G.W. Fringing in Tubular Permanent-Magnet Machines: Part II. Cogging Force and its Minimization. IEEE Trans. Magn. 2003, 39, 3517–3522. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.B.; West, M.; Howe, D. Design and Experimental Verification of a Linear Permanent Magnet Generator for a Free-Piston Energy Converter. IEEE Trans. Energy Convers. 2007, 22, 299–306. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yu, H.T.; Hu, M.Q. Research on a Permanent Magnet Tubular Linear Generator for Direct Drive Wave Energy Conversion. IET Renew. Power Gener. 2014, 8, 281–288. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yu, H.T.; Liu, Q. Research on a Double Float System for Direct Drive Wave Power Conversion. IET Renew. Power Gener. 2017, 11, 1026–1032. [Google Scholar] [CrossRef]

- Huang, L.; Hu, M.Q.; Chen, Z. Research on a Direct-Drive Wave Energy Converter Using an Outer-PM Linear Tubular Generator. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Guo, R.; Yu, H.T.; Xia, T. A Simplified Subdomain Analytical Model for the Design and Analysis of a Tubular Linear Permanent Magnet Oscillation Generator. IEEE Access. 2018, 6, 42355–42367. [Google Scholar] [CrossRef]

- Qiu, H.; Zhao, X.; Wei, Y. Influence of Inter-Turn Short-Circuit Fault on the Loss of High Speed Permanent Magnet Generator with Gramme Ring Windings. IET Power Electron. 2019, 12, 1256–1262. [Google Scholar] [CrossRef]

- Dong, J.N.; Huang, Y.K.; Jin, L. Electromagnetic and Thermal Analysis of Open-Circuit Air Cooled High-Speed Permanent Magnet Machines with Gramme Ring Windings. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Nukki, R.; Kilk, A.; Kallaste, A. Generator Mode Analysis of Exterior-Rotor PM Synchronous Machine with Gramme’s Winding. In Proceedings of the IEEE 5th International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Riga, Latvia, 11–13 May 2015; pp. 347–352. [Google Scholar]

- Pirisi, A.; Gruosso, G.; Zich, R.E. Novel Modeling Design of Three Phase Tubular Permanent Magnet Linear Generator for Marine Applications. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, Lisbon, Portugal, 18–20 March 2009; pp. 78–83. [Google Scholar]

- Lu, J.Y.; Ma, W.M. Investigation of Phase Unbalance Characteristics in the Linear Induction Coil Launcher. IEEE Trans. Plasma Sci. 2011, 39, 110–115. [Google Scholar] [CrossRef]

- Trapanese, M.; Boscaino, V.; Cipriani, G. A Permanent Magnet Linear Generator for the Enhancement of the Reliability of a Wave Energy Conversion System. IEEE Trans. Ind. Electron. 2019, 66, 4934–4944. [Google Scholar] [CrossRef]

| Parameters | CW | GW |

|---|---|---|

| Pole pitch | 21.5 mm | 21.5 mm |

| Magnet length for r direction | 14.5 mm | 14.5 mm |

| Magnet length for z direction | 7 mm | 7 mm |

| Thickness of PM | 3 mm | 3 mm |

| Thickness of back iron | 3 mm | 3 mm |

| Outer radius of stator | 92 mm | 92 mm |

| Tooth width | 9 mm | 6.9 mm |

| Slot width | 10.5 mm | 7.5 mm |

| Slot depth | 15 mm | 15 mm |

| Air gap | 3 mm | 3 mm |

| Number of turns | 60 | 90 |

| Number of coils | 6 | 4 |

| Type of the PM | NdFeB35 | NdFeB35 |

| Type of the core | M600 | M600 |

| GW | CW | |

|---|---|---|

| Radial | 0.55 T | 0.51 T |

| Axial | 0.20 T | 0.21 T |

| Phase | CW | GW | Increases |

|---|---|---|---|

| A | 22.09 V | 25 V | 13.17% |

| B | 22.49 V | 26.6 V | 18.27% |

| C | 22.12 V | 24.97 V | 12.88% |

| Phase | CW | GW |

|---|---|---|

| A | 2.96% | 9.49% |

| B | 2.91% | 6.46% |

| C | 3.48% | 12.13% |

| Load | Copper Loss | Hysteresis Loss | Output Power | Efficiency |

|---|---|---|---|---|

| 5 Ω | 37.29 W | 10.4 W | 110.35 W | 69.82% |

| 10 Ω | 12.04 W | 4.02 W | 71.29 W | 81.61% |

| 15 Ω | 5.86 W | 2.32 W | 52.02 W | 86.41% |

| 20 Ω | 3.47 W | 1.38 W | 41.14 W | 89.44% |

| 25 Ω | 2.29 W | 1.22 W | 33.99 W | 90.62% |

| 30 Ω | 1.63 W | 0.97 W | 28.95 W | 91.76% |

| Load | Copper Loss | Hysteresis Loss | Output Power | Efficiency |

|---|---|---|---|---|

| 5 Ω | 27.17 W | 10.26 W | 80.39 W | 68.23% |

| 10 Ω | 9.04 W | 3.91 W | 53.52 W | 80.51% |

| 15 Ω | 4.45 W | 2.16 W | 39.54 W | 85.67% |

| 20 Ω | 2.64 W | 1.12 W | 31.26 W | 89.26% |

| 25 Ω | 1.74 W | 1.05 W | 25.83 W | 90.23% |

| 30 Ω | 1.23 W | 0.92 W | 21.99 W | 91.06% |

| Load | A | B | C | ΔUA | ΔUB | ΔUC |

|---|---|---|---|---|---|---|

| 5 Ω | 19.74 V | 17.85 V | 19.88 V | 21.9% | 39.1% | 21.3% |

| 10 Ω | 22.26 V | 20.65 V | 22.45 V | 11.4% | 26.6% | 10.5% |

| 15 Ω | 23.39 V | 21.74 V | 23.25 V | 6.7% | 21.7% | 7.1% |

| 20 Ω | 24.00 V | 22.32 V | 23.89 V | 4.1% | 19.1% | 4.4% |

| 25 Ω | 24.38 V | 22.68 V | 24.30 V | 2.5% | 17.5% | 2.7% |

| 30 Ω | 24.63 V | 22.93 V | 24.57 V | 1.5% | 16.4% | 1.6% |

| Load | A | B | C | ΔUA | ΔUB | ΔUC |

|---|---|---|---|---|---|---|

| 5 Ω | 15.56 V | 17.97 V | 15.45 V | 33.7% | 20.1% | 34.5% |

| 10 Ω | 17.93 V | 20.74 V | 17.84 V | 21.4% | 7.7% | 22.1% |

| 15 Ω | 18.86 V | 21.84 V | 18.79 V | 16.6% | 2.8% | 17.2% |

| 20 Ω | 19.36 V | 22.42 V | 19.3 V | 14.0% | 0.2% | 14.6% |

| 25 Ω | 19.67 V | 22.79 V | 19.61 V | 12.4% | −1.3% | 12.9% |

| 30 Ω | 19.89 V | 23.04 V | 19.83 V | 11.3% | −2.4% | 11.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, H.; Wei, J.; Si, J.; Cheng, Z.; Gan, C.; Xu, X. Comparison of the Electromagnetic Characteristics of a Novel Gramme Winding and a Concentrated Winding Tubular Permanent-Magnet Linear Generator. Energies 2020, 13, 5943. https://doi.org/10.3390/en13225943

Feng H, Wei J, Si J, Cheng Z, Gan C, Xu X. Comparison of the Electromagnetic Characteristics of a Novel Gramme Winding and a Concentrated Winding Tubular Permanent-Magnet Linear Generator. Energies. 2020; 13(22):5943. https://doi.org/10.3390/en13225943

Chicago/Turabian StyleFeng, Haichao, Jinsong Wei, Jikai Si, Zhiping Cheng, Chun Gan, and Xiaozhuo Xu. 2020. "Comparison of the Electromagnetic Characteristics of a Novel Gramme Winding and a Concentrated Winding Tubular Permanent-Magnet Linear Generator" Energies 13, no. 22: 5943. https://doi.org/10.3390/en13225943

APA StyleFeng, H., Wei, J., Si, J., Cheng, Z., Gan, C., & Xu, X. (2020). Comparison of the Electromagnetic Characteristics of a Novel Gramme Winding and a Concentrated Winding Tubular Permanent-Magnet Linear Generator. Energies, 13(22), 5943. https://doi.org/10.3390/en13225943