Determination of the Theoretical and Actual Working Volume of a Hydraulic Motor

Abstract

1. Introduction

- (a)

- the volumetric efficiency:

- (b)

- the hydraulic-mechanical efficiency:

- Qv—the volumetric losses in the motor;

- n—rotational speed of the motor shaft;

- M—load of the motor;

- Δp—pressure drop measured in the motor ports.

- (a)

- known methods to determine the theoretical working volume;

- (b)

- the proposed method of determining the theoretical qt and actual working volume qr (taking into account the effect of the flow meter position in the measurement system, the compressibility of liquid, and the pressure drop Δpich in the internal channel of a motor).

2. Known Method to Determine the Theoretical Working Volume

2.1. Flow Rate in Hydraulic Motor

- Qg—the positive displacement component:

- Qu—the liquid lifted in the gaps:

- qu—the liquid flow rate Qu per one revolution of the shaft at Δp = 0;

- QC—the expansion/compression component (taken into account when the flow meter is located at the low-pressure side and the liquid is not aerated):

- QL—leakage in the working mechanism gaps;

- ρo—density at atmospheric pressure;

- ρ—density of liquid at pressure p;

- K1, K2, K3, K4, K5—constants.

- Δpi—the pressure drop in the motor working chambers;

- α—the coefficient of linear expansion of materials of the motor working mechanism;

- ΔT—the increase in the motor temperature;

- K6, K7, K8—constants;

- Ks—the isentropic secant modulus of liquid compressibility;

- λ—the relative harmful volume.

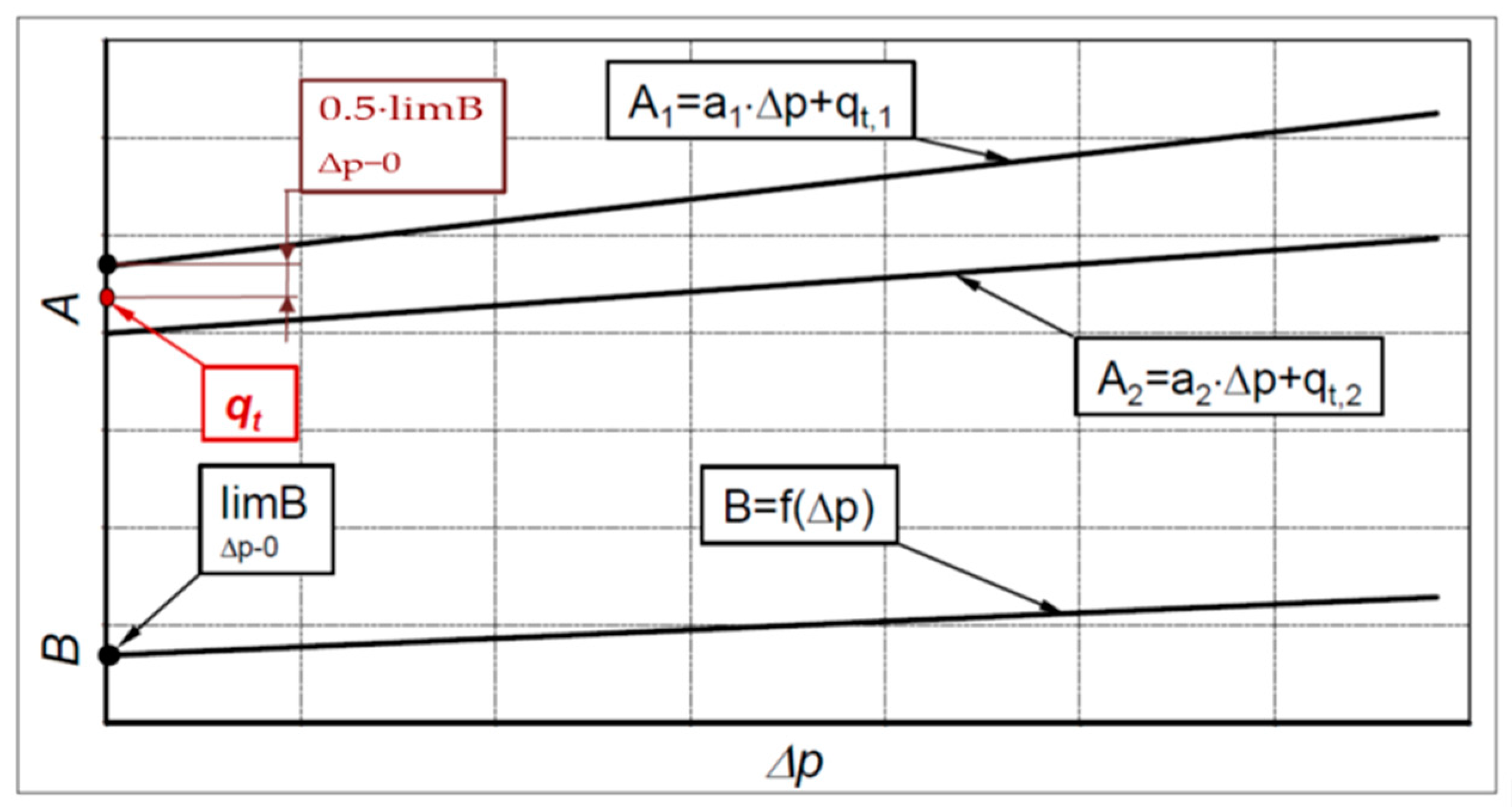

2.2. Theoretical Working Volume from the Method Defined in ISO 8426

2.3. Toet’s Method

- (a)

- qt is independent of n and Δp;

- (b)

- besides and the other effects (not expressed by formulas) have influence on the leakage QL;

- (c)

- there is no way for separation of qg and qu;

- (d)

- if the volumetric efficiency is greater than 100% then only the qg was applied (omitting the qu);

- (e)

- for some types of positive displacement machines (screw pumps and motors), where qg is very precisely determinable and qu ≈ 0 is ≈ qt (for the same of T1).

2.4. Balawender’s Method

- The notation of the theoretical working volume given by Equation (16) is incorrect as it suggests a measurement at Δp = 0. In real conditions, the motor does not run at Δp = 0;

- In fact, in order to determine the theoretical working volume qt the limit values of the working volume for the internal pressure drop Δpi going to zero should be taken into account;

- The function can be unspecified in the mathematical sense at Δp = 0 due to the unspecified displacements of the motor working mechanism elements;

- The flow component caused by the compressibility of liquid was incorrectly interpreted.

- (a)

- qt is independent of n and Δp;

- (b)

- the temperature of liquid can have influence on qt,

- (c)

- there is no way for of qg and qu.

3. New Method of Determining the Theoretical and Actual Working Volume

3.1. The Flow Rate Caused by Liquid Lifting in Gaps

3.2. The Actual Working Volume qr

3.3. The Effect of the Flow Meter Position in the Measurement System on the Actual Working Volume Value

- K—the bulk modulus of non-aerated oil at atmospheric pressure po;

- Xo—the amount of non-dissolved air in the oil at atmospheric pressure po;

- p—the absolute pressure;

- n—the polytrophic exponent;

- m—the coefficient of the influence of pressure p on the bulk modulus K.

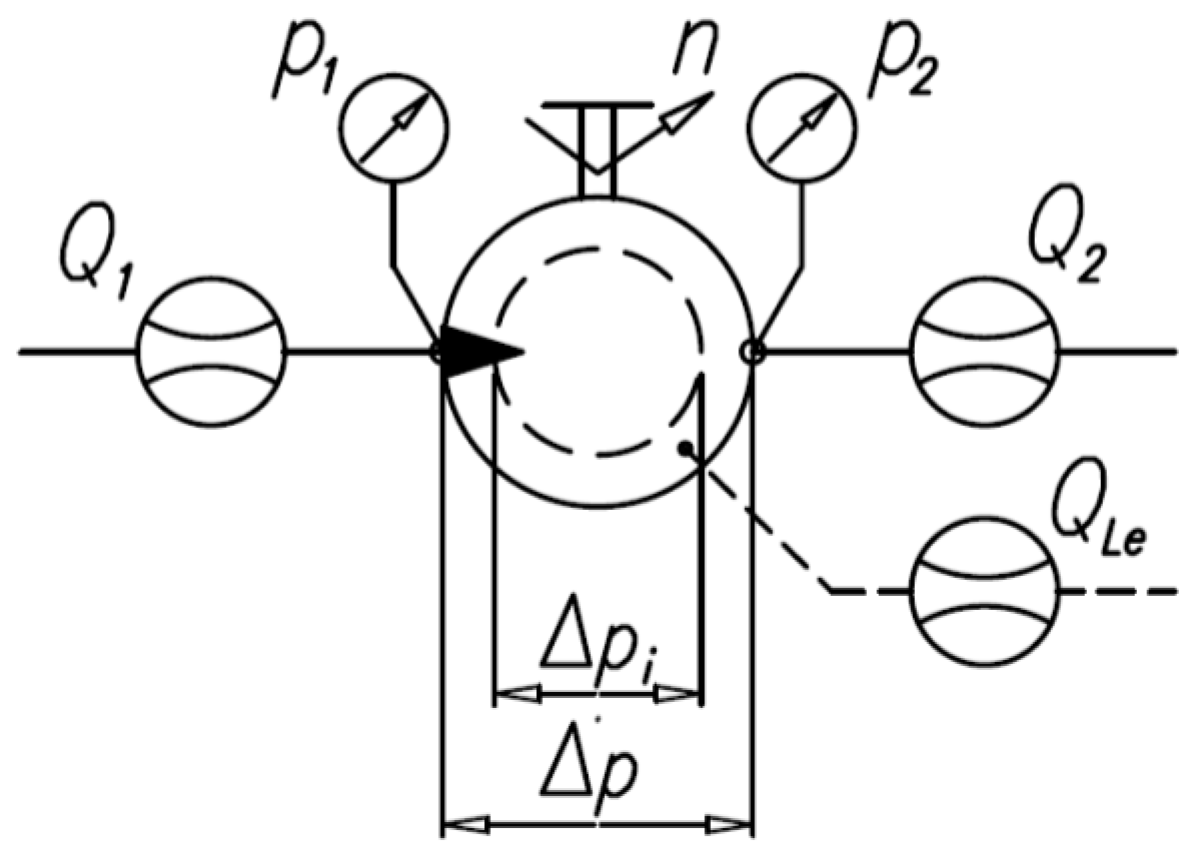

3.4. Method of Pressure Drop Measurement in Motor Internal Channels

- (a)

- the pressure p1 in the motor port;

- (b)

- the pressure pH in the motor working chamber;

- (c)

- the motor output flow rate Q2;

- (d)

- the rotational speed n of the motor shaft.

- Ct—the constant of the turbulent flow component;

- Cl—the constant of the laminar flow component;

- ν—the kinematic viscosity;

- ρ—the density of liquid.

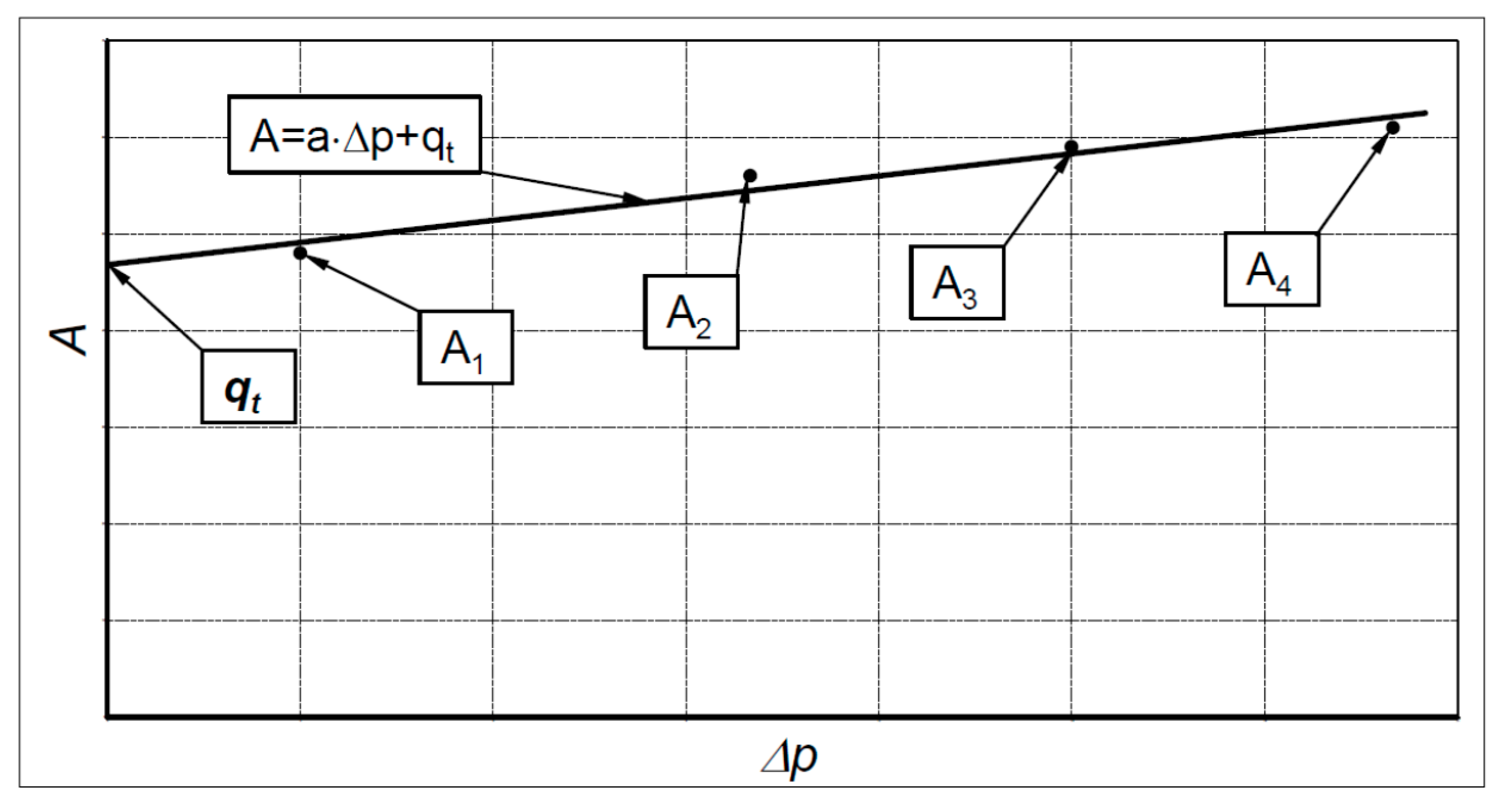

3.5. Model of Flow Rate in Hydraulic Motor

3.6. Practical Implementation of the Method

- (a)

- To measure the flow Q1 or Q2 at a constant inlet temperature T1 and a constant pressure drop Δp for several values of n (no less than five). The measurement has to be taken once again using at least five different pressure drops Δp;

- (b)

- To measure the pressure drop Δpich in the internal channel of the motor according to the method described in Section 3.4;

- (c)

- To calculate the pressure drop Δpi in the working chamber of the motor for data from item (a);

- (d)

- If the flow meter is located in the low-pressure line, the influence of the liquid compressibility should be taken into account and the flow rate Q(pH) corresponding the value of high-pressure pH in the working chamber should be calculated;

- (e)

- To plot the characteristics Q(pH) = f(n)Δpi=const and calculate the coefficients A in the Formula (17).

4. Results of Experimental Research

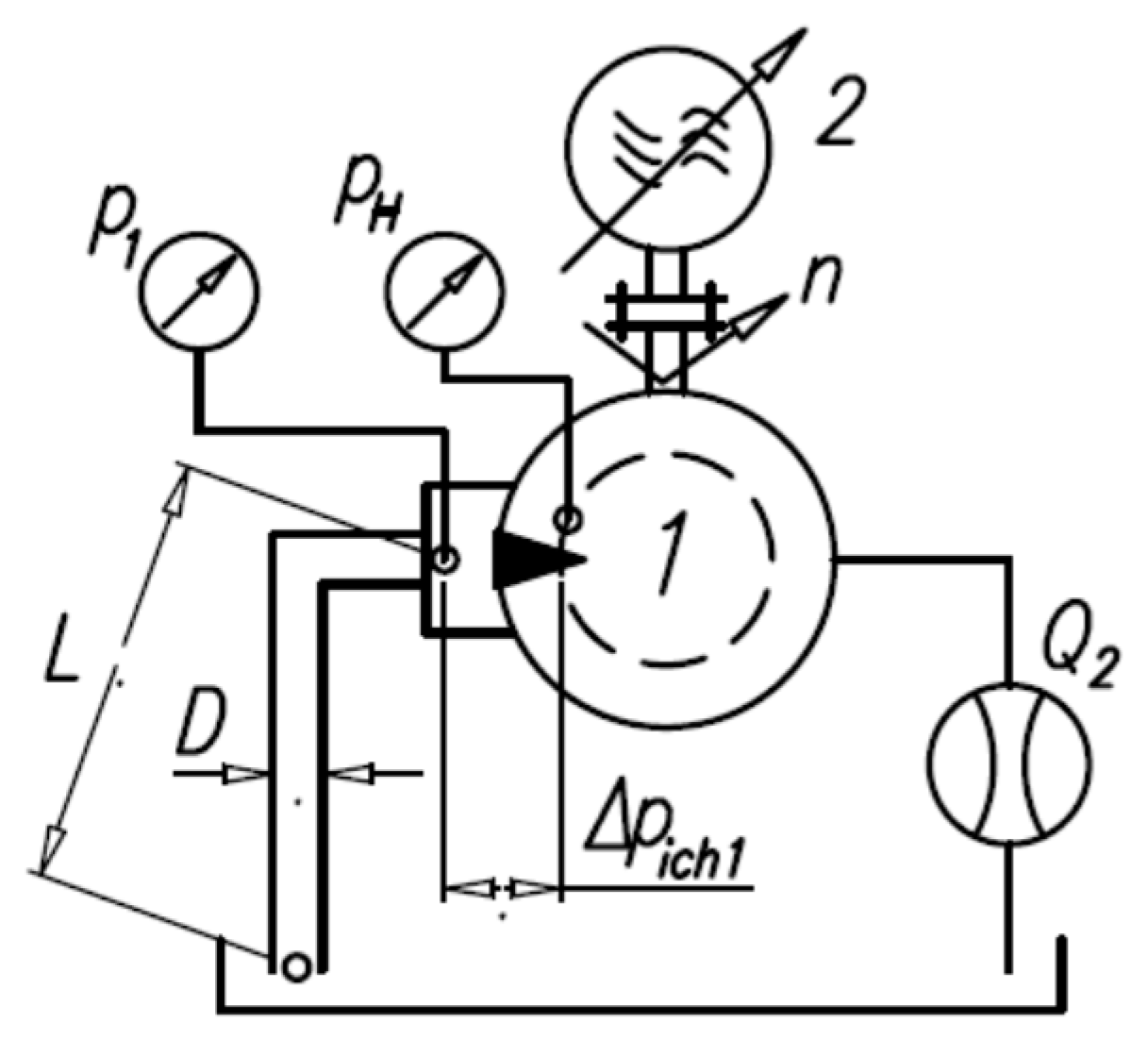

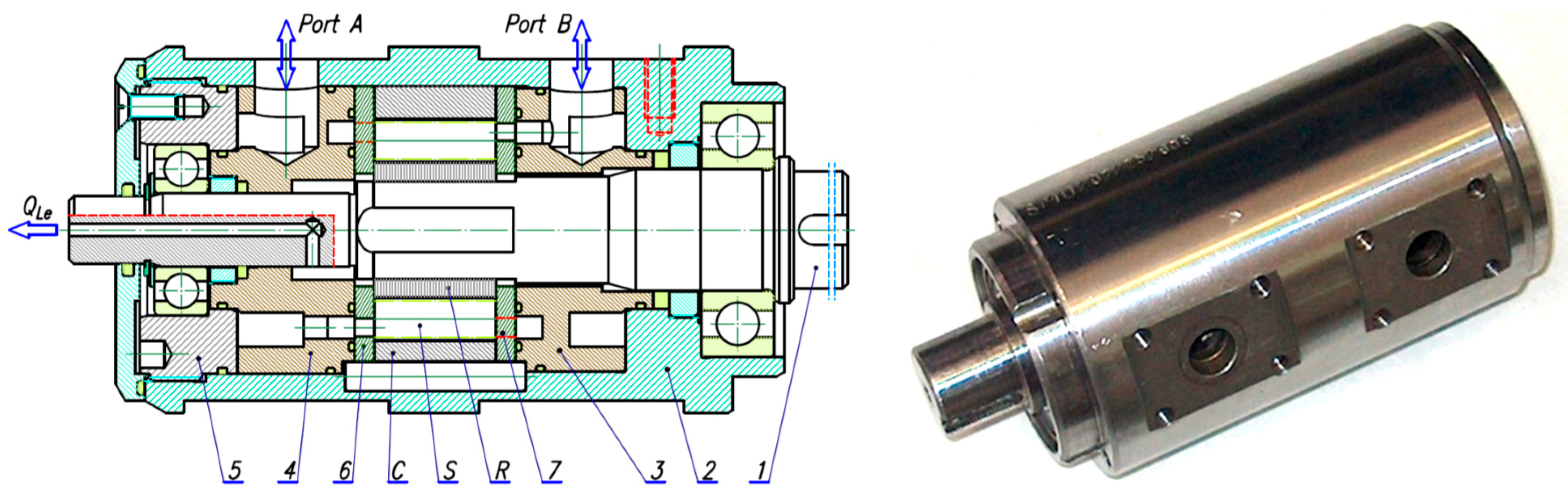

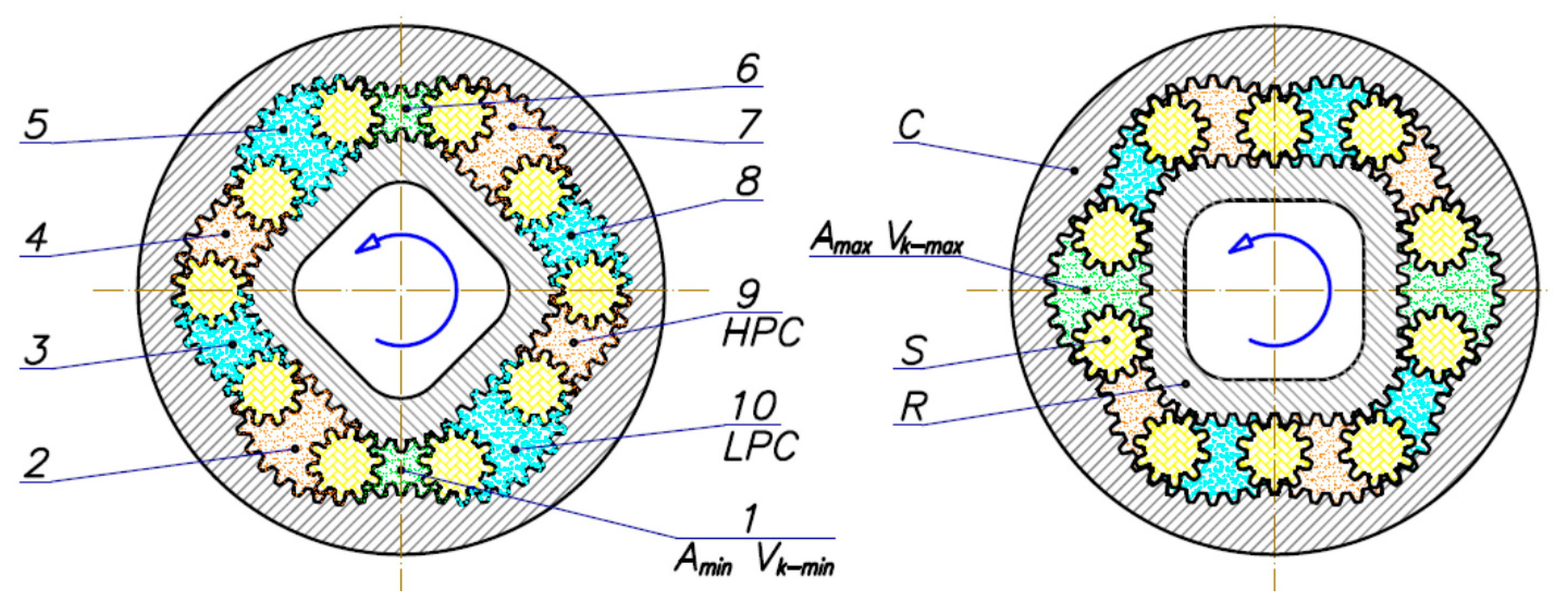

4.1. Tested Motor

- the height of the working mechanism H = 25 mm;

- the minimum area of the working chamber Amin = 26.11 mm2;

- the maximum area of the working chamber Amax = 83.51 mm2.

- Thus, the geometric working volume of the satellite mechanism was qg = 34.44 cm3/rev. Other motor parameters were:

- the tooth module m = 0.75 mm;

- the difference in the height of the satellites and the rotor in relations to the curvature was Δh = 5 μm.

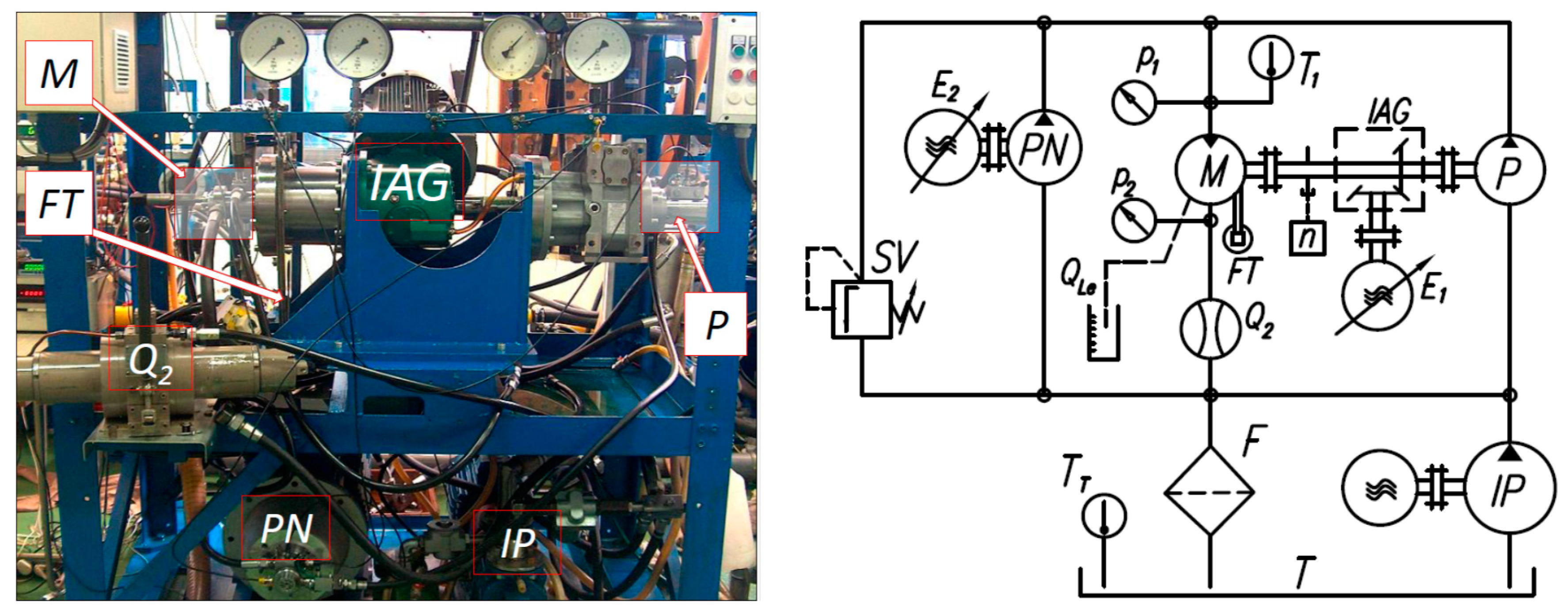

4.2. The Test Stand and Measuring Apparatus

- pressure p1 in the inflow port (strain gauge pressure transducer, range 0–10 MPa and 0–40MPa, class 0.3);

- pressure p2 in the outflow port (strain gauge pressure transducers, range 0–2.5 MPa, class 0.3);

- flow rate Q2 (piston flowmeter, the flowmeter chamber volume 0.63 dm3, range 0–200 L/min, class 0.2, accuracy of reading 0.01 L/min, maximum measurement error 0.41 L/min);

- torque M (strain gauge force transducer FT mounted on the arm 0.5 m (the arm attached to the motor body), range 0–100 N, class 0.1);

- rotational speed of shaft n (inductive sensor, accuracy of measurement ±0.01 rpm);

- temperature T1 of liquid in the inflow port of the motor (RTD temperature sensor, class A, max. measurement error 0.5 °C).

- the rotational speed n was maintained with a deviation of ±0.1 rpm;

- the pressure drop Δp was maintained with a deviation of ±0.05 MPa;

- the temperature in inflow port T1 was maintained with a deviation of ±1.0 °C.

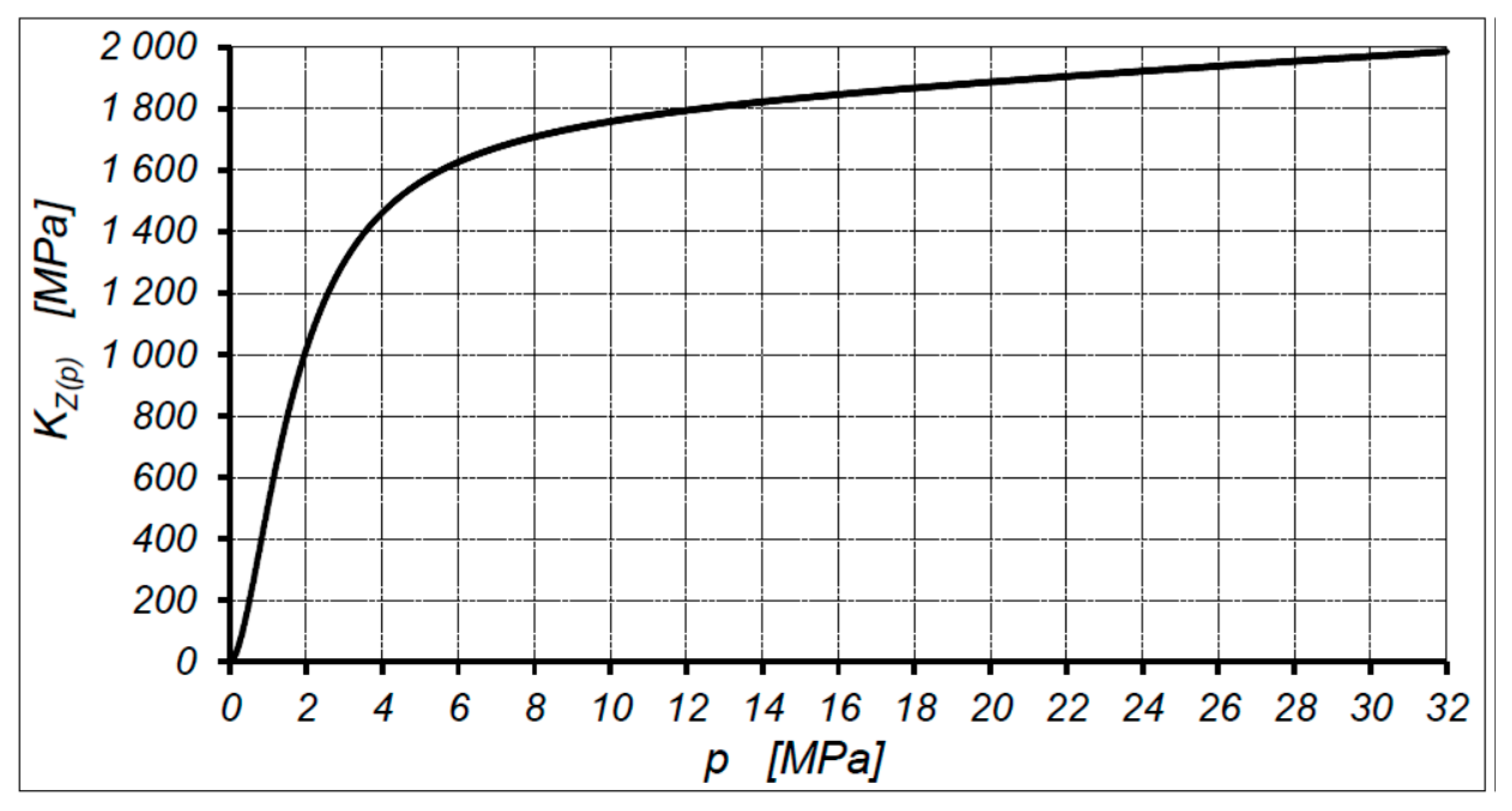

4.3. Working Liquid Parameters

- the bulk modulus of non-aerated oil at atmospheric pressure K = 1775 MPa;

- the content in oil of non-dissolved air at atmospheric pressure Xo = 0.01;

- the politrophic exponent n = 1.4;

- the coefficient of the effect of pressure p on the bulk modulus m = 9.19;

- the atmospheric pressure po = 0.1 MPa.

4.4. Pressure Drop in Motor Internal Channels

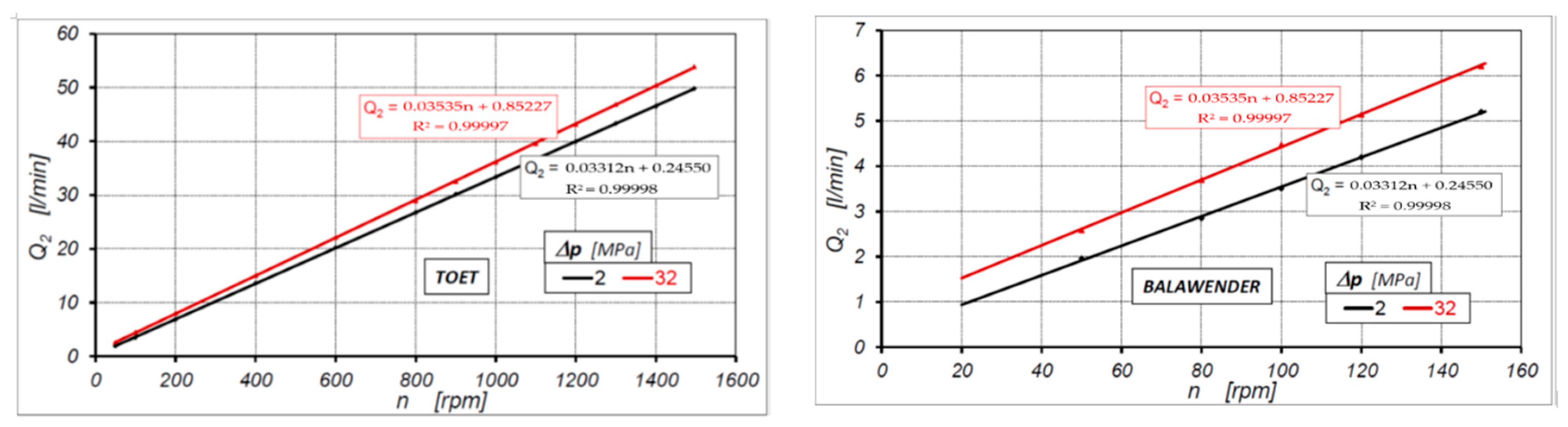

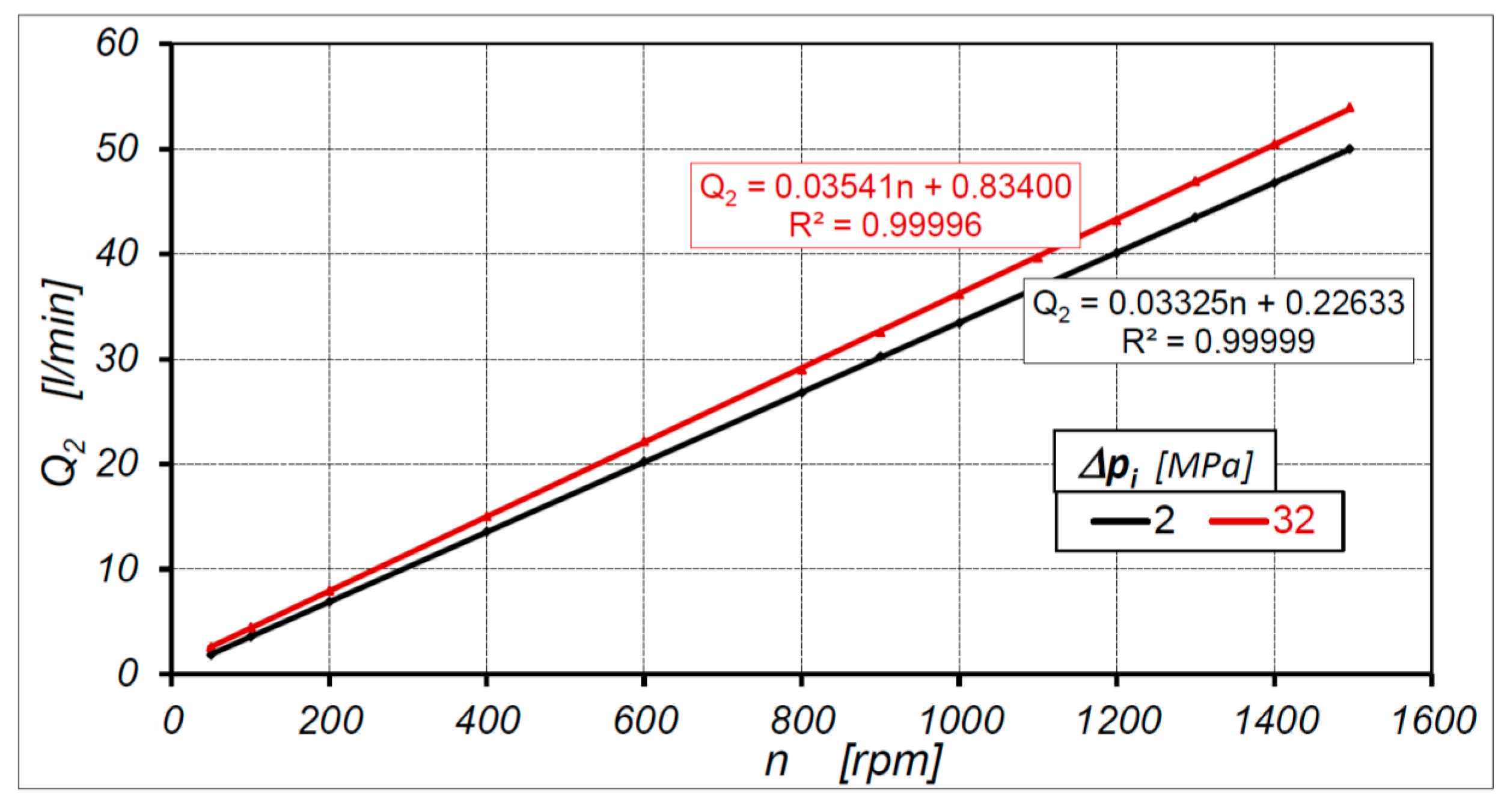

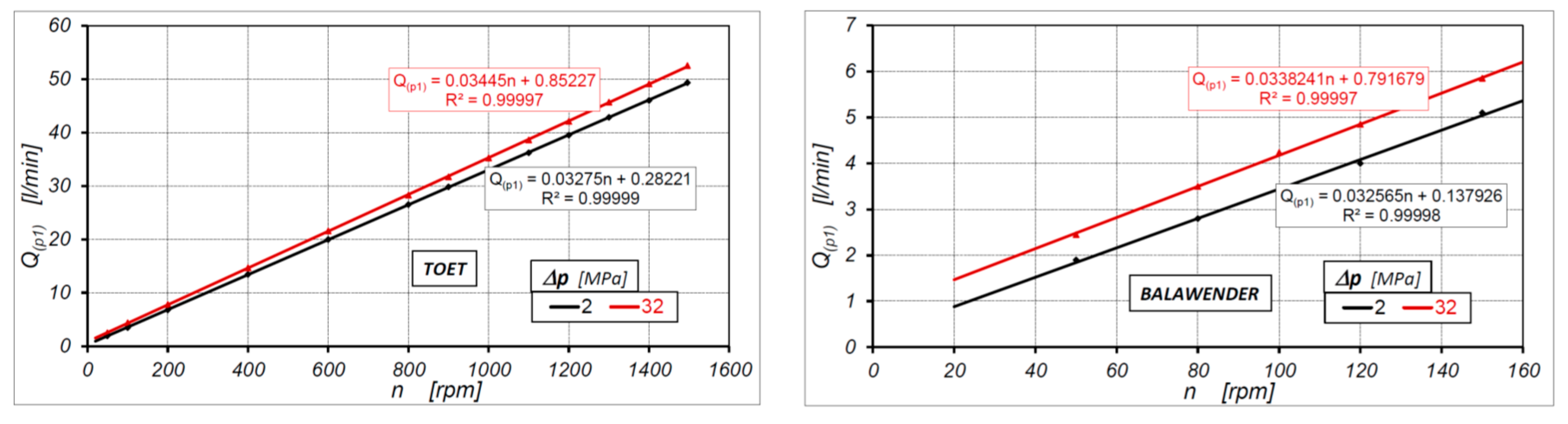

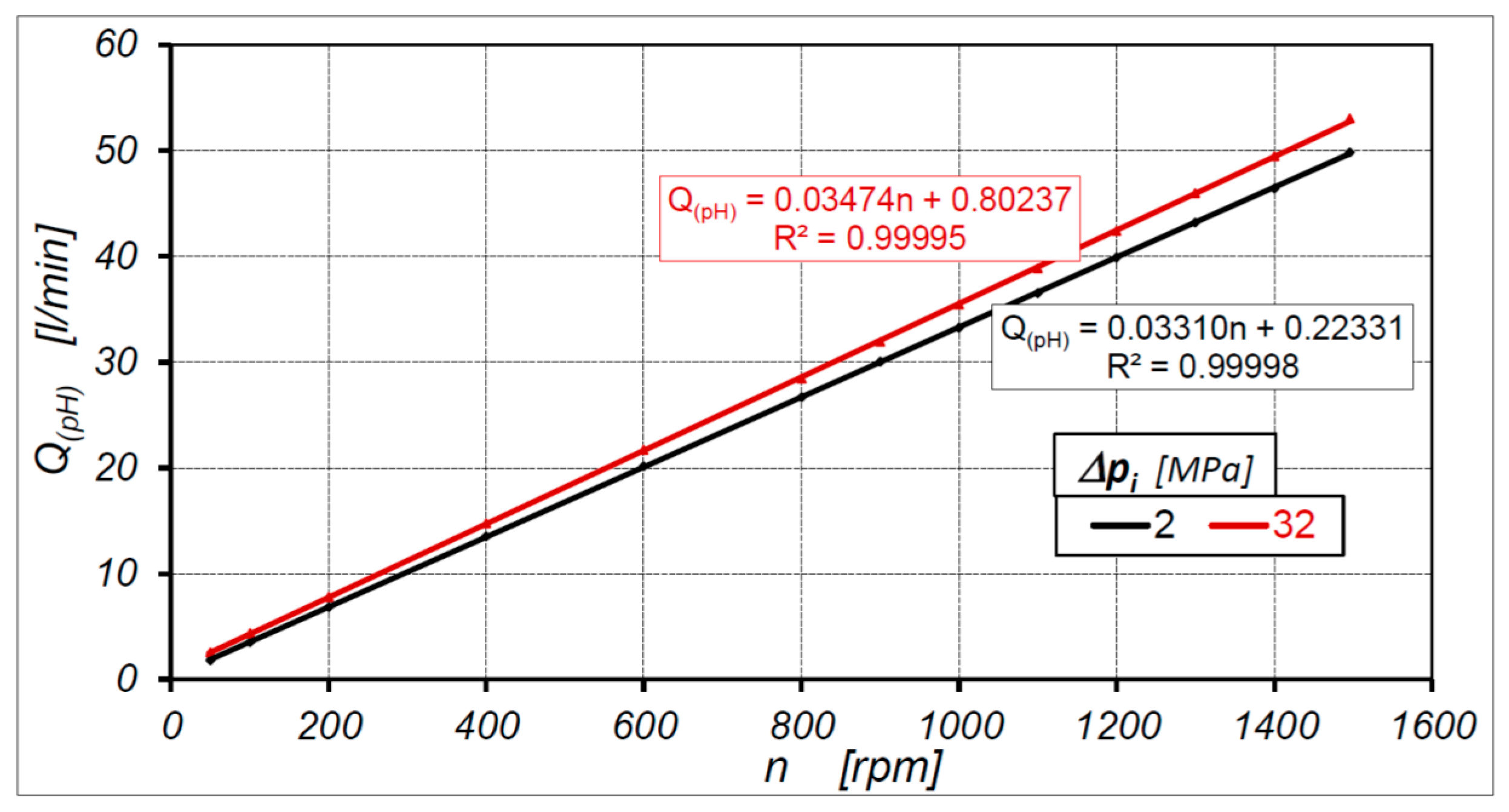

4.5. Motor Output Flow Rate Characteristics

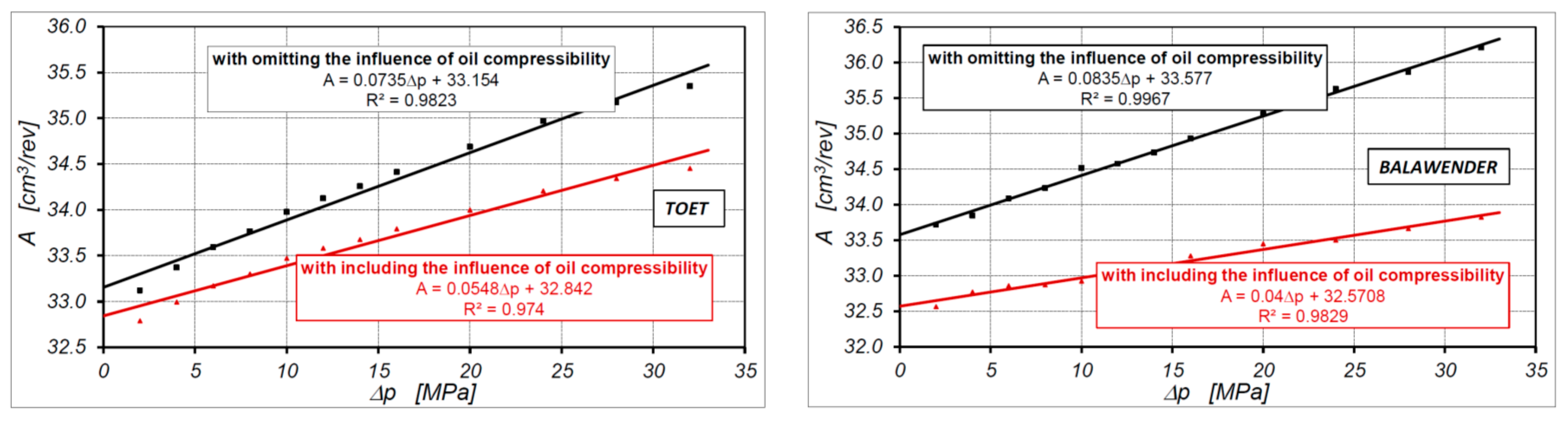

4.6. Motor Theoretical Working Volume According to Known Methods

4.7. Motor Theoretical Working Volume According to Proposed Method

- (a)

- determined taking into account the influence of oil compressibility;

- (b)

- determined omitting the influence of oil compressibility.

5. Discussion

- an overestimation of volumetric losses and an underestimation of volumetric efficiency ηv;

- an underestimation of mechanical losses and an overestimation of mechanical efficiency ηm.

Funding

Conflicts of Interest

Appendix A

| No. | Δp [MPa] | Q2 = A n + B | A [cm3/rev] | R2 |

|---|---|---|---|---|

| 1 | 2 | Q2 = 0.033120·n + 0.245496 | 33.120 | 0.999984 |

| 2 | 4 | Q2 = 0.033369·n + 0.379312 | 33.369 | 0.999982 |

| 3 | 6 | Q2 = 0.033590·n + 0.441141 | 33.590 | 0.999974 |

| 4 | 8 | Q2 = 0.033762·n + 0.462461 | 33.762 | 0.999988 |

| 5 | 10 | Q2 = 0.033973·n + 0.476327 | 33.973 | 0.999979 |

| 6 | 12 | Q2 = 0.034124·n + 0.498480 | 34.124 | 0.999990 |

| 7 | 14 | Q2 = 0.034256·n + 0.518116 | 34.256 | 0.999970 |

| 8 | 16 | Q2 = 0.034411·n + 0.566370 | 34.411 | 0.999989 |

| 9 | 20 | Q2 = 0.034689·n + 0.649842 | 34.689 | 0.999989 |

| 10 | 24 | Q2 = 0.034968·n + 0.735564 | 34.968 | 0.999992 |

| 11 | 28 | Q2 = 0.035170·n + 0.800050 | 35.170 | 0.999986 |

| 12 | 32 | Q2 = 0.035349·n + 0.852268 | 35.349 | 0.999966 |

| No. | Δp [MPa] | Q2 = A·n + B | A [cm3/rev] | R2 |

|---|---|---|---|---|

| 1 | 2 | Q2 = 0.033715·n + 0.145474 | 33.715 | 0.999960 |

| 2 | 4 | Q2 = 0.033844·n + 0.256944 | 33.844 | 0.999785 |

| 3 | 6 | Q2 = 0.034086·n + 0.327206 | 34.086 | 0.999926 |

| 4 | 8 | Q2 = 0.034232·n + 0.372550 | 34.232 | 0.999909 |

| 5 | 10 | Q2 = 0.034517·n + 0.388903 | 34.517 | 0.999904 |

| 6 | 12 | Q2 = 0.034577·n + 0.429866 | 34.577 | 0.999537 |

| 7 | 14 | Q2 = 0.034732·n + 0.430350 | 34.732 | 0.999907 |

| 8 | 16 | Q2 = 0.034931·n + 0.486725 | 34.931 | 0.999677 |

| 9 | 20 | Q2 = 0.035275·n + 0.540842 | 35.275 | 0.999824 |

| 10 | 24 | Q2 = 0.035629·n + 0.664698 | 35.629 | 0.999920 |

| 11 | 28 | Q2 = 0.035868·n + 0.742994 | 35.868 | 0.999823 |

| 12 | 32 | Q2 = 0.036213·n + 0.801073 | 36.213 | 0.999438 |

| No. | Δp [MPa] | Q2 = A·n + B | A [cm3/rev] | R2 |

|---|---|---|---|---|

| 1 | 2 | Q2 = 0.033251·n + 0.226334 | 33.251 | 0.999992 |

| 2 | 4 | Q2 = 0.033513·n + 0.291487 | 33.513 | 0.999989 |

| 3 | 6 | Q2 = 0.033714·n + 0.347383 | 33.714 | 0.999992 |

| 4 | 8 | Q2 = 0.033881·n + 0.397161 | 33.881 | 0.999995 |

| 5 | 10 | Q2 = 0.034034·n + 0.442995 | 34.034 | 0.999996 |

| 6 | 12 | Q2 = 0.034183·n + 0.486303 | 34.183 | 0.999995 |

| 7 | 14 | Q2 = 0.034333·n + 0.527925 | 34.333 | 0.999994 |

| 8 | 16 | Q2 = 0.034484·n + 0.568284 | 34.484 | 0.999995 |

| 9 | 20 | Q2 = 0.034778·n + 0.645530 | 34.778 | 0.999996 |

| 10 | 24 | Q2 = 0.035035·n + 0.717189 | 35.035 | 0.999992 |

| 11 | 28 | Q2 = 0.035235·n + 0.781090 | 35.235 | 0.999979 |

| 12 | 32 | Q2 = 0.035408·n + 0.834000 | 35.408 | 0.999957 |

| No. | Δp [MPa] | Q(p1) = A·n + B | A [cm3/rev] | R2 |

|---|---|---|---|---|

| 1 | 2 | Q(p1) = 0.032787·n + 0.245497 | 32.788 | 0.999984 |

| 2 | 4 | Q(p1) = 0.032991·n + 0.379312 | 32.991 | 0.999983 |

| 3 | 6 | Q(p1) = 0.033168·n + 0.441141 | 33.168 | 0.999974 |

| 4 | 8 | Q(p1) = 0.033298·n + 0.462462 | 33.298 | 0.999988 |

| 5 | 10 | Q(p1) = 0.033468·n + 0.476328 | 33.468 | 0.999978 |

| 6 | 12 | Q(p1) = 0.033580·n + 0.498481 | 33.580 | 0.999991 |

| 7 | 14 | Q(p1) = 0.033674·n + 0.518116 | 33.674 | 0.999969 |

| 8 | 16 | Q(p1) = 0.033791·n + 0.566370 | 33.791 | 0.999989 |

| 9 | 20 | Q(p1) = 0.033996·n + 0.649842 | 33.996 | 0.999989 |

| 10 | 24 | Q(p1) = 0.034207·n + 0.735564 | 34.207 | 0.999992 |

| 11 | 28 | Q(p1) = 0.034340·n + 0.800050 | 34.340 | 0.999986 |

| 12 | 32 | Q(p1) = 0.034452·n + 0.852269 | 34.452 | 0.999965 |

| No. | Δp [MPa] | Q(p1) = A·n + B | A [cm3/rev] | R2 |

|---|---|---|---|---|

| 1 | 2 | Q(p1) = 0.032566·n + 0.137926 | 32.566 | 0.999848 |

| 2 | 4 | Q(p1) = 0.032770·n + 0.248459 | 32.770 | 0.999924 |

| 3 | 6 | Q(p1) = 0.032906·n + 0.316588 | 32.906 | 0.999977 |

| 4 | 8 | Q(p1) = 0.032797·n + 0.373599 | 32.797 | 0.999991 |

| 5 | 10 | Q(p1) = 0.032923·n + 0.404549 | 32.923 | 0.999977 |

| 6 | 12 | Q(p1) = 0.032867·n + 0.452474 | 32.867 | 0.999993 |

| 7 | 14 | Q(p1) = 0.033010·n + 0.443626 | 33.010 | 0.999967 |

| 8 | 16 | Q(p1) = 0.033279·n + 0.452977 | 33.279 | 0.999982 |

| 9 | 20 | Q(p1) = 0.033603·n + 0.509748 | 33.603 | 0.999537 |

| 10 | 24 | Q(p1) = 0.033501·n + 0.682885 | 33.501 | 0.999856 |

| 11 | 28 | Q(p1) = 0.033663·n + 0.722821 | 33.663 | 0.999790 |

| 12 | 32 | Q(p1) = 0.033824·n + 0.791678 | 33.824 | 0.999661 |

| No. | Δpi [MPa] | Q(pH) = A·n + B | A [cm3/rev] | R2 |

|---|---|---|---|---|

| 1 | 2 | Q(pH) = 0.033095·n + 0.223310 | 33.095 | 0.999982 |

| 2 | 4 | Q(pH) = 0.033308·n + 0.346180 | 33.308 | 0.999991 |

| 3 | 6 | Q(pH) = 0.033487·n + 0.404302 | 33.487 | 0.999993 |

| 4 | 8 | Q(pH) = 0.033638·n + 0.431194 | 33.638 | 0.999992 |

| 5 | 10 | Q(pH) = 0.033769·n + 0.448067 | 33.769 | 0.999990 |

| 6 | 12 | Q(pH) = 0.033886·n + 0.466857 | 33.886 | 0.999988 |

| 7 | 14 | Q(pH) = 0.033997·n + 0.492843 | 33.997 | 0.999988 |

| 8 | 16 | Q(pH) = 0.034105·n + 0.526875 | 34.105 | 0.999989 |

| 9 | 20 | Q(pH) = 0.034315·n + 0.610846 | 34.315 | 0.999990 |

| 10 | 24 | Q(pH) = 0.034497·n + 0.696203 | 34.497 | 0.999988 |

| 11 | 28 | Q(pH) = 0.034626·n + 0.764548 | 34.626 | 0.999979 |

| 12 | 32 | Q(pH) = 0.034744·n + 0.802372 | 34.744 | 0.999947 |

References

- Wilson, W.E. Positive Displacement Pumps and Fluid Motors; Publication Corporation: New York, NY, USA, 1950. [Google Scholar]

- Schlosser, W.M.J. Meten aan Verdringerpompen. Ph.D. Thesis, Technical Hogeschool Delft, Delft, The Netherlands, 1957. [Google Scholar]

- Schlosser, W.M.J.; Hilbrands, J.W. Das Theoretische Hubvolumen von Verdrangerpumpen; No. 4. Olhydraul. und Pneum. 1963, 7, 133–138. [Google Scholar]

- Schlosser, W.M.J.; Hilbrands, J.W. Das Volumetrische Wirkungsgrad von Verdrongerpumpen; No. 12. Olhydraul. und Pneum. 1963, 7, 469–476. [Google Scholar]

- Toet, G. Die Bestimmung des Theoretischen Hubvolumens von hydrostatischen Verdrangerpumen und Motoren aus Volumetrischen Messungen; No 14. Olhydraul. und Pnaum. 1970, 14, 185–190. [Google Scholar]

- Toet, G.; Johnson, J.; Montague, J.; Torres, K.; Garcia-Bravo, J. The determination of the theoretical stroke volume of hydrostatic positive displacement pumps and motors from volumetric measurements. Energies 2019, 12, 415. [Google Scholar] [CrossRef]

- Balawender, A. Opracowanie Metodyki Wyznaczania Teoretycznej Objętości Roboczej Pomp i Silników Hydraulicznych Wyporowych (The Development of the Methodology for the Determination of the Theoretical Working Volume of Positive Displacement Pumps and Hydraulic Motors). Ph.D. Thesis, Gdansk University of Technology, Gdansk, Poland, 1974. [Google Scholar]

- Balawender, A. Analiza energetyczna i metodyka badań silników hydraulicznych wolnoobrotowych (Energy analysis and methodics of testing of low-speed hydraulic motors). In Scientific Book of the Gdansk University of Technology; Mechanika No. 54; Gdansk University of Technology Publishing House: Gdansk, Poland, 1988. [Google Scholar]

- Garcia-Bravo, J.; Nicholson, J. What is the real size of that pump? Fluid Power J. 2018. Available online: https://fluidpowerjournal.com/real-size-pump/ (accessed on 1 September 2020).

- Manring, N.; Williamson, C. The theoretical Volumetric Displacement of a check-valve type, digital displacement pump. J. Dyn. Syst. Meas. Control 2019, 141, 12–14. [Google Scholar]

- Myszkowski, A. Energy analysis of an ideal suction-pressure unit. Arch. Mech. Technol. Mater. 2015, 35, 51–60. [Google Scholar]

- Post, W. Models for steady-state performance of hydraulic pumps: Determination of displacement. In Proceedings of the 9th Bath International Fluid Power Workshop, University of Bath, Bath, UK, 9–11 September 1996; Volume 9. [Google Scholar]

- International Organisation for Standardization. ISO 8426:2008: Hydraulic Fluid Power. Positive Displacement Pumps and Motors. Determination of Derived Capacity; ISO Copyright Office: Geneva, Switzerland, 2008. [Google Scholar]

- Kim, T.; Kalbfleisch, P.; Ivantysynova, M. The effect of cross porting on derived displacement volume. Int. J. Fluid Power 2014, 15. [Google Scholar] [CrossRef]

- Stryczek, S. Napęd Hydrostatyczny; WNT: Warszawa, Poland, 2005. [Google Scholar]

- Sliwinski, P. Satellite Displacement Machines. Basic of Design and Analysis of Power Loss; Gdansk University of Technology Publishers: Gdansk, Poland, 2016. [Google Scholar]

- Osiecki, L. Commutation Units of Hydraulics Axial Piston Machines; Gdansk University of Technology Publishers: Gdansk, Poland, 2006. [Google Scholar]

- Zaluski, P. Influence of the Position of the Swash Plate Rotation Axis on the Volumetric Efficiency of Axial Piston Pumps. Ph.D. Thesis, Gdansk University of Technology, Gdansk, Poland, 2017. [Google Scholar]

- Sliwinski, P.; Patrosz, P. Satellite Operating Mechanism of the Hydraulic Displacement Machine. Patent PL218888, 27 February 2015. [Google Scholar]

- Sliwinski, P. The methodology of design of axial clearances compensation unit in hydraulic satellite displacement machine and their experimental verification. Arch. Civ. Mech. Eng. 2019, 19. [Google Scholar] [CrossRef]

- Sliwinski, P. The influence of water and mineral oil on mechanical losses in a hydraulic motor for offshore and marine application. Pol. Marit. Res. 2020, 27. [Google Scholar] [CrossRef]

| Method | qt [cm3/rev] | |

|---|---|---|

| From project—qg | 34.440 | |

| Omitting the influence of oil compressibility | Toet | 33.105 |

| Balawender | 33.577 | |

| Proposed method | 33.076 | |

| Including the influence of oil compressibility | Toet | 32.842 |

| Balawender | 32.571 | |

| proposed method | 32.916 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sliwinski, P. Determination of the Theoretical and Actual Working Volume of a Hydraulic Motor. Energies 2020, 13, 5933. https://doi.org/10.3390/en13225933

Sliwinski P. Determination of the Theoretical and Actual Working Volume of a Hydraulic Motor. Energies. 2020; 13(22):5933. https://doi.org/10.3390/en13225933

Chicago/Turabian StyleSliwinski, Pawel. 2020. "Determination of the Theoretical and Actual Working Volume of a Hydraulic Motor" Energies 13, no. 22: 5933. https://doi.org/10.3390/en13225933

APA StyleSliwinski, P. (2020). Determination of the Theoretical and Actual Working Volume of a Hydraulic Motor. Energies, 13(22), 5933. https://doi.org/10.3390/en13225933