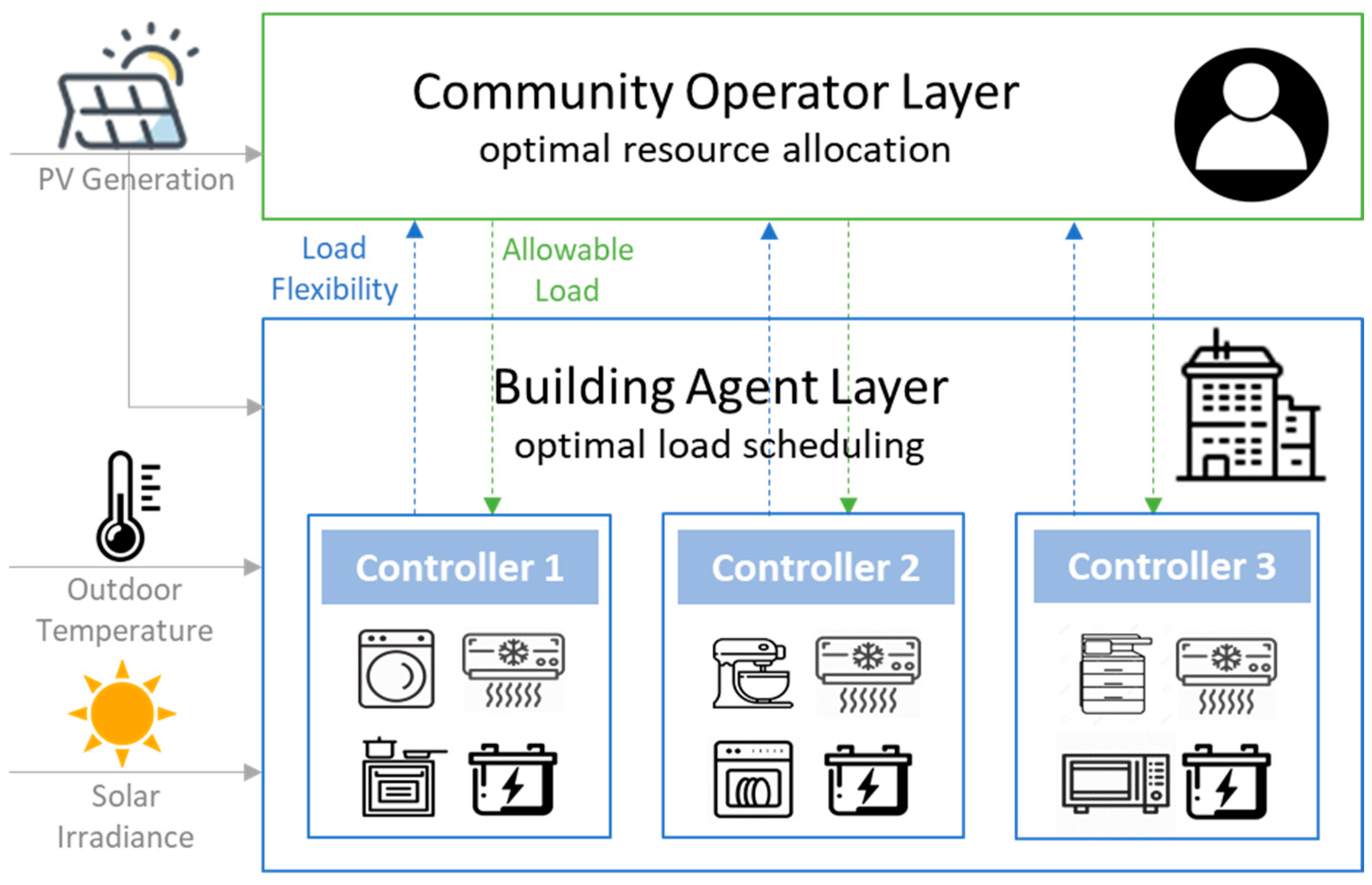

The proposed architecture has been tested with a case study based on a real-world community located in Anna Maria Island, FL [

28]. It is a net-zero energy community made up of residential units and small commercial buildings with on-site PV panels. To demonstrate the idea of dynamic power sharing among buildings, the data for three buildings of different types are used in the case study [

27]. The selected buildings are: one residential building (area: 93.8 m

2), one ice cream shop (area: 160.5 m

2), and one bakery (area: 410 m

2). All buildings use heat pumps as the HVAC equipment. All data for the case study have been exported from a validated physics-based model of the studied community [

29]. The weather file embedded in the model is typical meteorological year (TMY) data for the weather station at Tampa International Airport [

30]. The load data consists of power submetering data provided by the community [

27]. The solar irradiance data are collected through a local solar station. The indoor temperature data are simulation results generated by the physics-based room models [

31]. The simulations are run in Python 2.7 with Gurobi 9.0 [

32] as the optimization engine. The average simulation time of each scenario is about 20 s in Windows 7 operating system on a DELL T5810 workstation with 32 GB RAM and a 3.50 GHz Intel Xeon CPU (E5-1620 v4) processor.

4.1. Simulation Scenario Design

The optimal resource allocation and load scheduling MPC algorithm for the community when disconnected from the grid was simulated for 48 h within Florida’s hurricane season on August 4 and 5. The timestep

for both COL and BAL is 1 h and the MPC horizon

h to balance the trade-off between forecast information and computational time.

Table 1 lists the 10 scenarios covering various weighting methods at the operator layer and two different objectives at the building layer. In the following discussion, R stands for Residential, I stands for Ice Cream Shop, and B stands for Bakery. Each scenario was run for all three buildings. In total, 30 simulations were run and analyzed.

In the room temperature constraints, the lower and upper temperature limits

and

are governed by ASHRAE Standard 55–2017 [

33], which recommends the temperature range for thermal comfort to be approximately between 67

and 82

(20–28

). Thus,

is 20

and

is 28

.

Table 2 summarizes the coefficients of the HVAC linear regression models. The prediction accuracy is measured with the root mean square error (RMSE). The nominal power of each heat pump is listed in the last row of

Table 2.

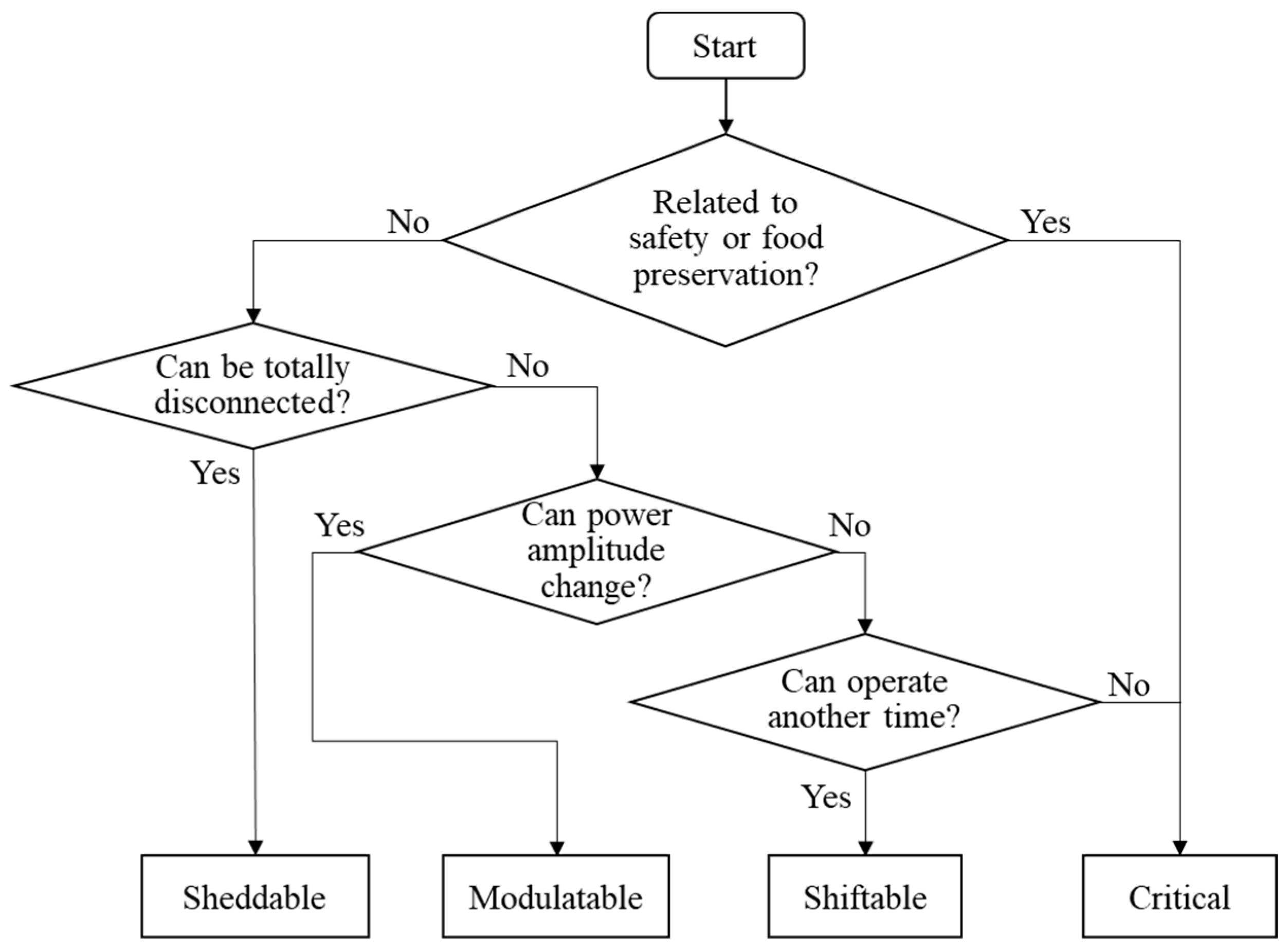

Table 3 summarizes the load categorization results following the classification proposed in

Section 2.2. In this study, we determine whether a load is sheddable from the building owner’s perspective. For instance, the coffee maker and the soda dispenser in the ice cream shop are classified as sheddable during the outage. Mixers with variable speed options, as well as the HVAC system, are classified as modulatable loads due to their varying power amplitudes. Since some plug loads in the dataset are unspecified, we sum those loads into one modulatable load. The washer, dryer, and stovetop range are considered shiftable loads in this work as their operation schedules can be flexible if needed. Lights, coolers, and display cases are classified as critical because they are related with occupants’ need for safety and food preservation. Due to the islanded circumstances, some loads commonly categorized as critical are considered to be sheddable (e.g., computer) in this paper.

Parameters related to battery configuration and penalty coefficients are summarized in

Table 4. We assumed the maximum charging/discharging power

to be 40% of the battery energy bound

. Further, the initial battery SOC is assumed to be 50% of

. The charging/discharging efficiencies are

.

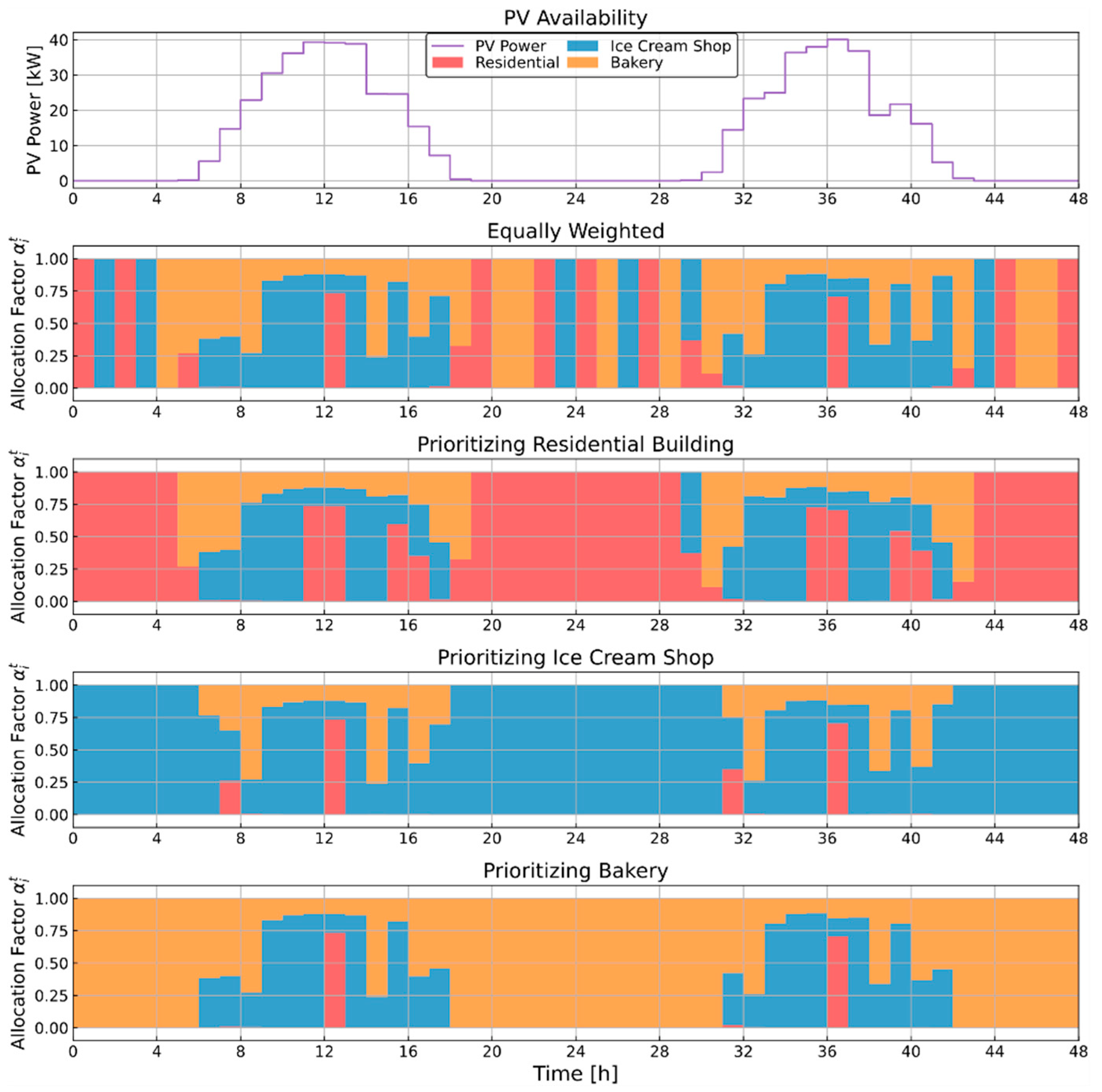

4.3. Impact of Weighting Factor

This section first discusses the allocation factors generated by the operator layer, which later serves as the input for the smart controllers at the building layer. Then, we compare the scheduled load shapes, battery behavior, and indoor temperature of each building in different scenarios to further discuss the impact of weighting factors on the KPIs.

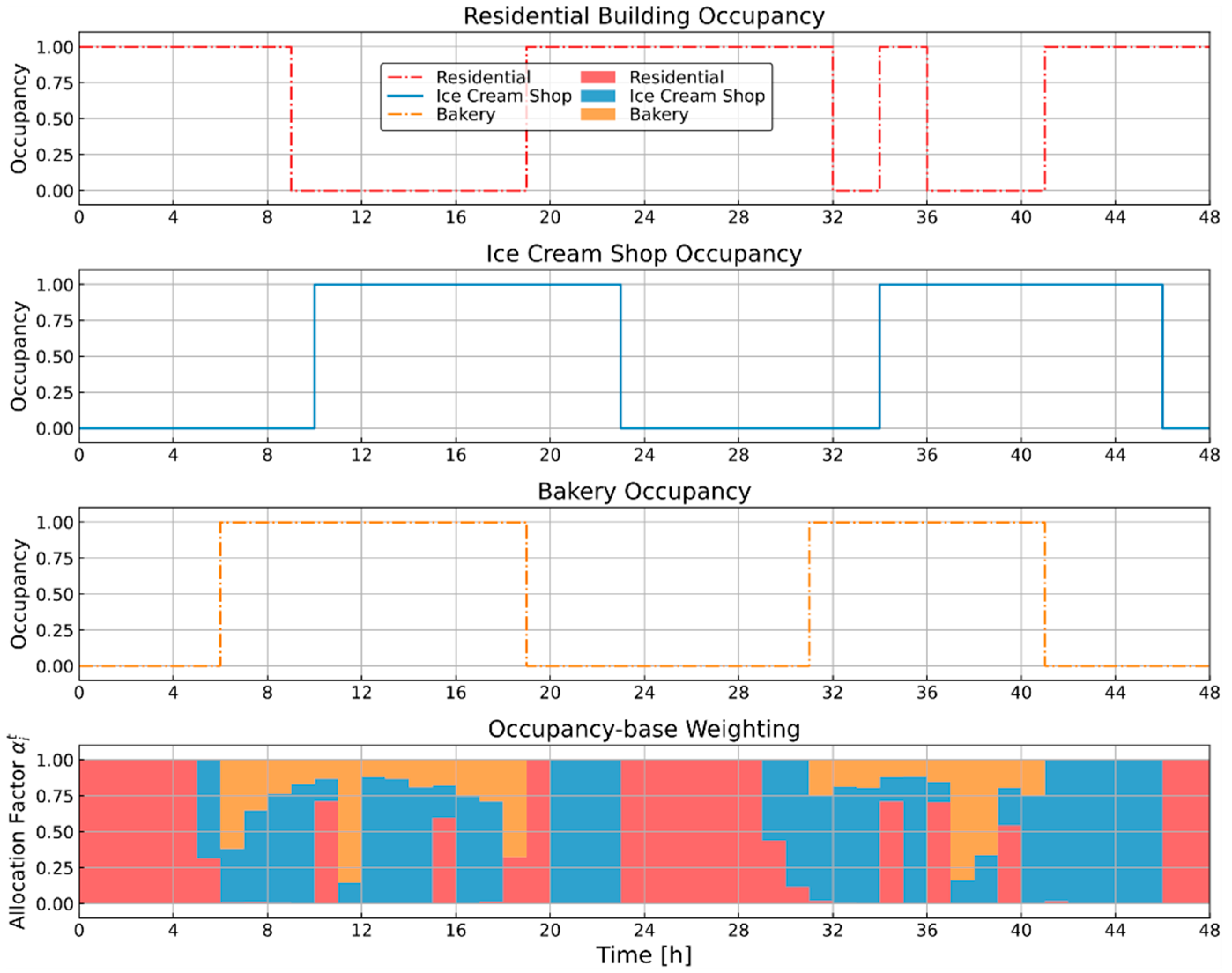

Figure 4 compares the allocation factors for equally weighted buildings (baseline) with weightings that prioritize each building over the others. Qualitatively, when all buildings are equally weighted in the allocation process (second plot from top), we see a rather random behavior for the PV allocation during the nighttime when no PV power is available. All three buildings take turn to get full PV power (

) because they have the same objective function value. On the contrary, for the scenarios when single building is prioritized, the prioritized building gets full PV power alone during the nighttime (bottom three plots). During the daytime, when more PV generation is available, the allocation results follow similar trends for all scenarios regardless of the weighting method. Although generally we see less load shedding in the prioritized building, as well as a higher value of the allocation factor, the allocation process is mostly constrained by the building load flexibility ranges. More specifically, buildings with a higher load flexibility lower bound (i.e., ice cream shop) tend to get more allowable load than other buildings.

Figure 5 plots the allocation factors for occupancy-based weighting method against building occupancy. Here, occupancy indicates whether the building is occupied. In this work, we do not consider number of people in the building as we don’t have access to this level of data. From the middle plot, we see that the residential building is mostly occupied during the night from about 7 P.M. to 8 A.M. Ice cream shop and bakery are occupied during the day from 10 A.M.–11 P.M. and 6 A.M.–7 P.M., respectively. From the bottom plot, we see that similar to single building prioritized scenarios, when at night only residential building is occupied, it gets full PV allocation. However, when the time reaches 5 A.M., the allocation factor of the residential building starts to decrease and during the day only a few hours will it get PV power due to its unoccupied status. During the daytime, when both the bakery and ice cream shop are occupied, the allocation basically follows the buildings’ power flexibility lower bounds as discussed before.

To further quantify the impact of different weighting methods, the mean values of the allocation factors

, as well as the total allocated PV energy are listed in

Table 5. Due to the highly stochastic allocation during nighttime when no PV power is available, we only counted hours when PV generation is greater than zero in the calculation of

. From the table, we noticed that having a lower mean allocation factor does not necessarily mean less PV energy allocation. For example, in the scenario where the residential building is prioritized, its

is less than 22% while for the bakery it is almost 33%. However, the total PV energy allocated to the residential building is 33.42% more than that allocated to the bakery. This is because the residential building has higher

values during hours with the most PV generation (i.e., around noon). This indicates that having a higher allocation factor when more PV power is generated is more crucial. When looking at the occupancy-based weighting scenario, the residential building PV energy exceeds that of the equal weighting scenario since the shortly occupied hours during the day (e.g., hours 34–36) bring more allocation. Overall, no matter which weighting method is adopted, the ice cream shop is always allocated the most PV energy due to its large refrigeration loads, while the residential building is always allocated the least amount of PV energy (except when it is prioritized in scenarios S21_R and S22_R). This indicates that the impact of power flexibility is more prominent than the weighting factors during the resource allocation.

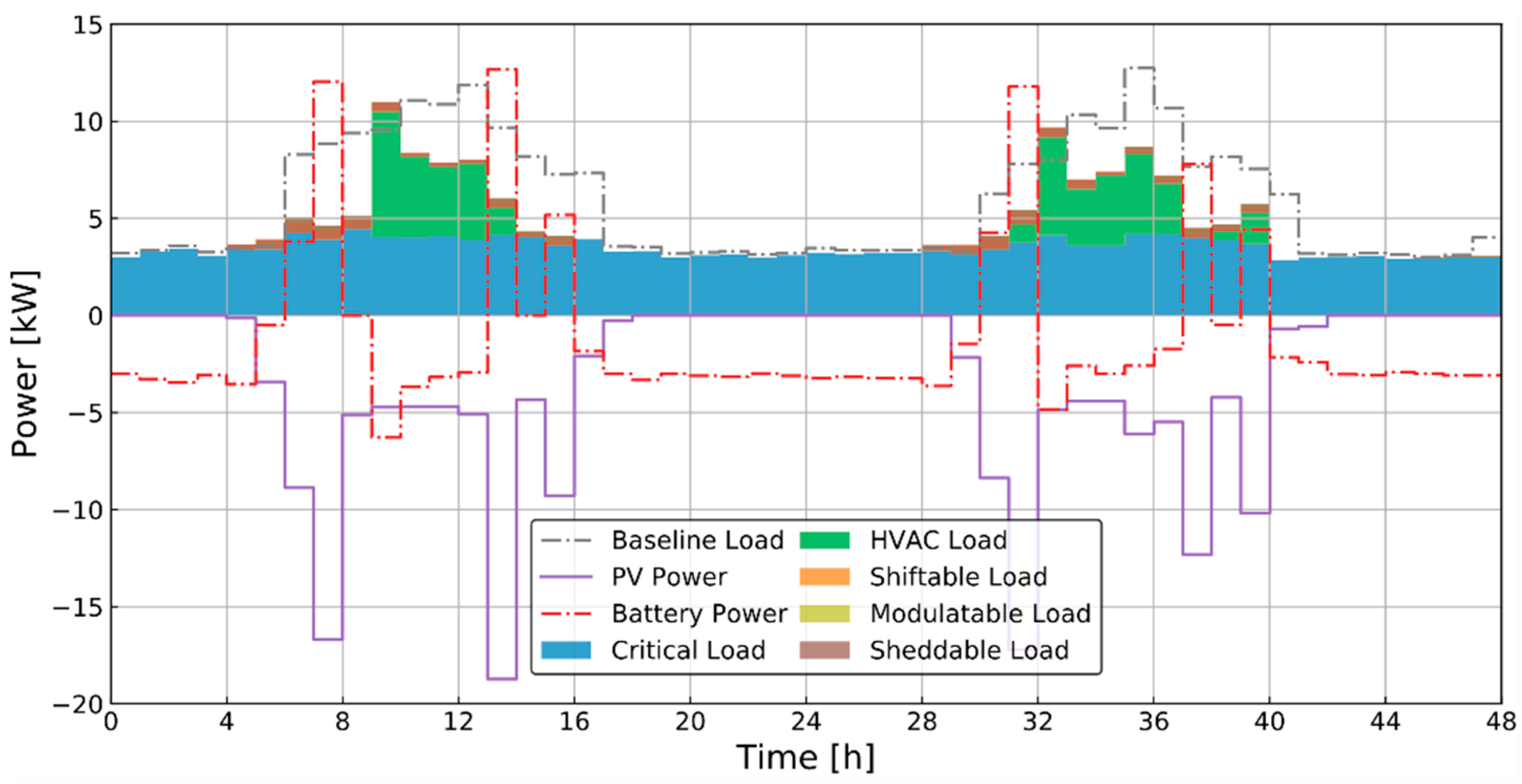

Next, the simulation results will be discussed for the various PV allocation methods. In the following discussion, we highlight a subset of the results; however, the complete set of results are available in

Appendix A and quantitative results for all 30 simulations are summarized in

Table A1. In the following simulation results, the baseline power is the original load shape from data. The positive battery power means charging and negative means discharging. The scheduled sheddable, modulatable, shiftable loads, and critical loads are represented by color blocks. When evaluating the thermal comfort results, the baseline temperature is the original indoor temperature with a setpoint of 24 °C without optimization. For clarity, the label S21 in the temperature plots represents the scenario of the discussed building being prioritized, as described in

Table 1.

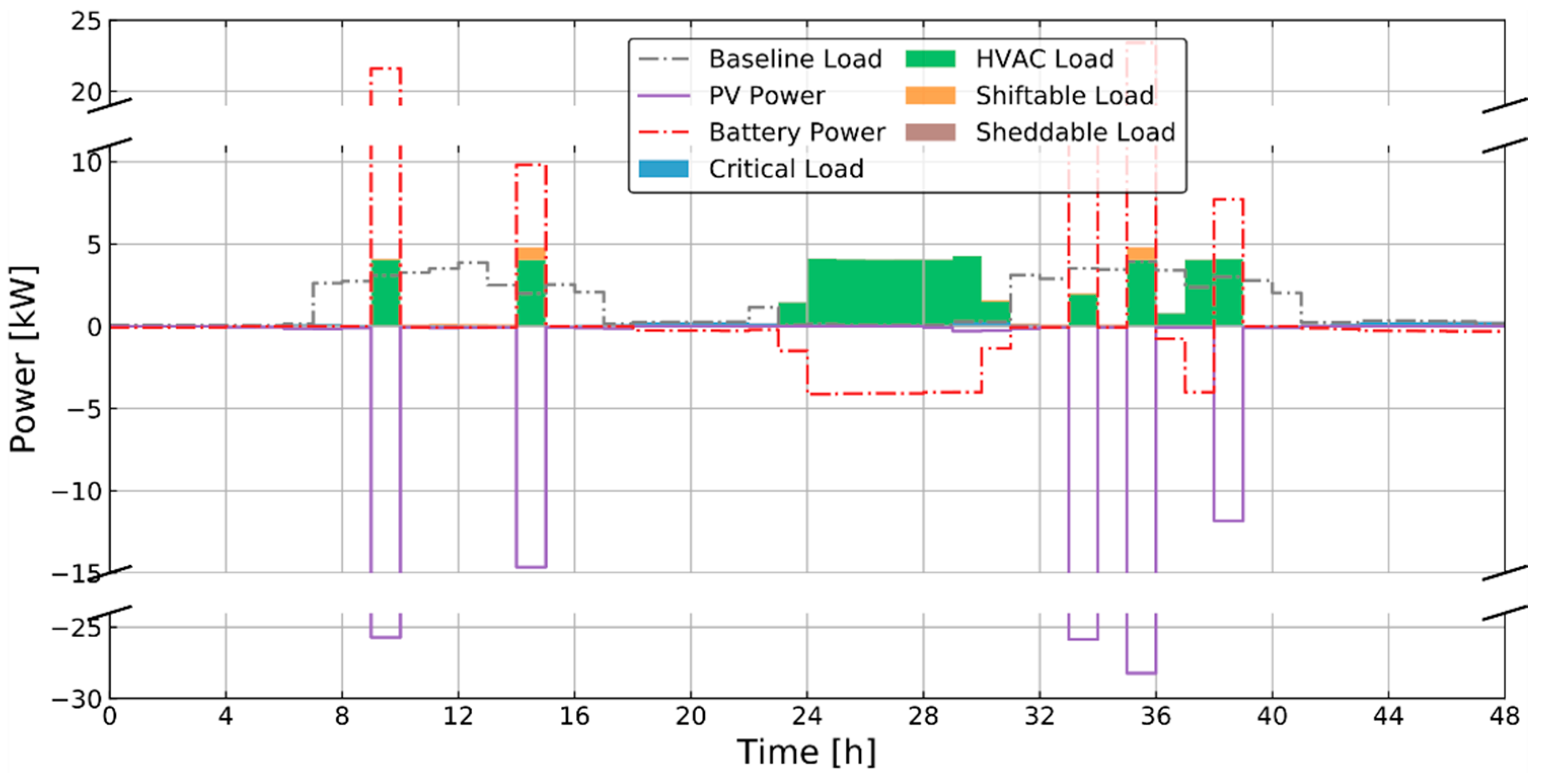

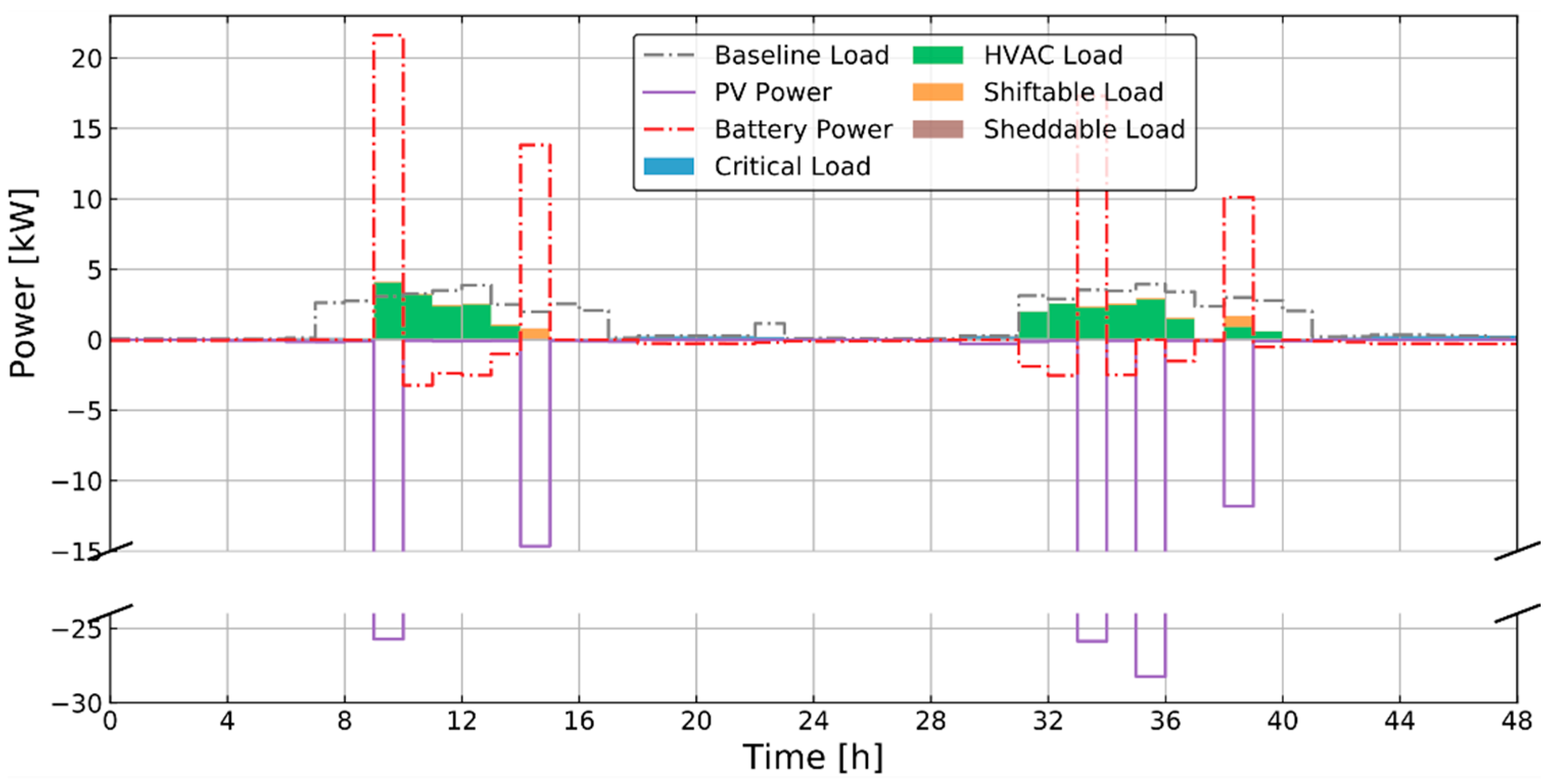

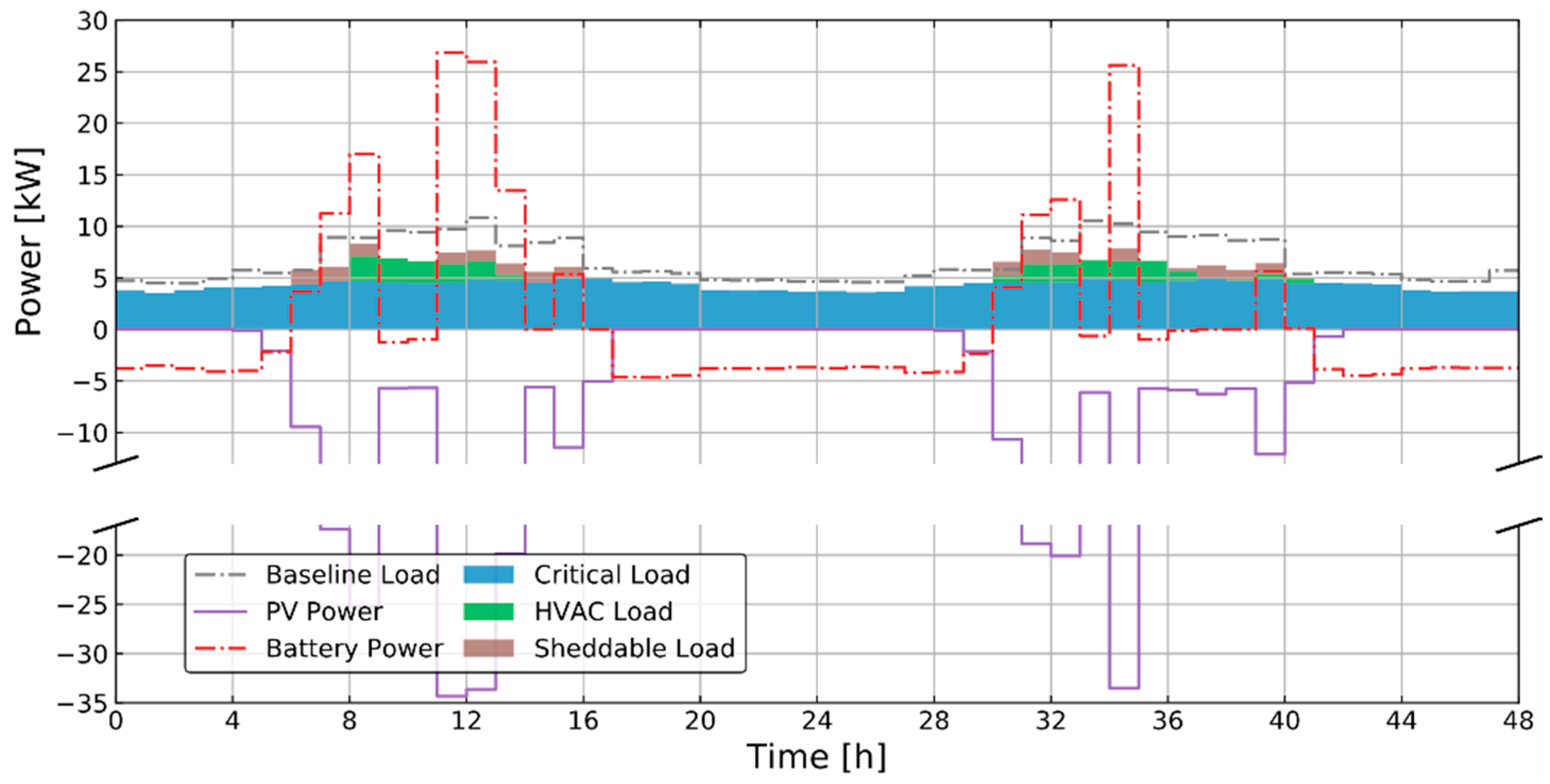

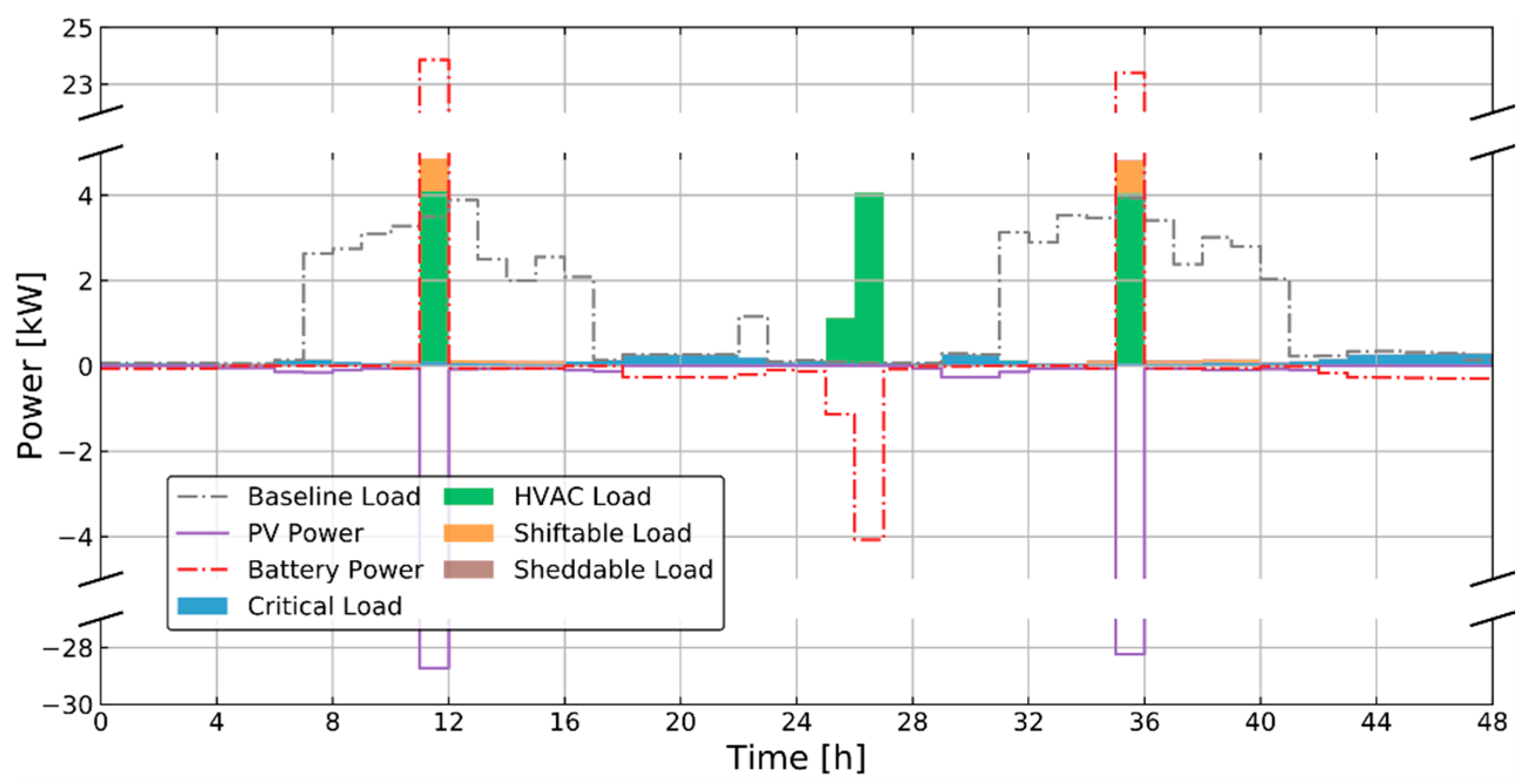

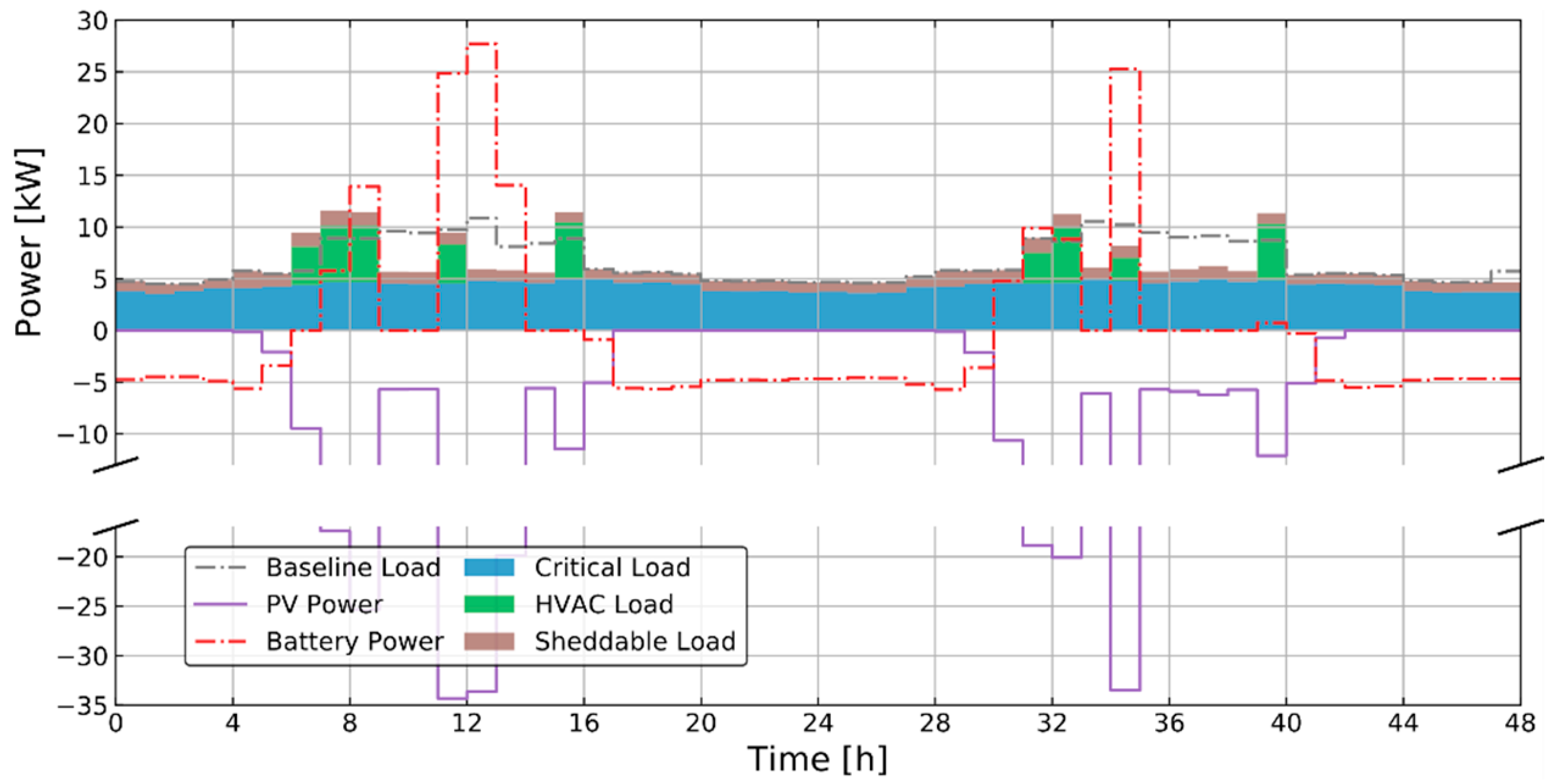

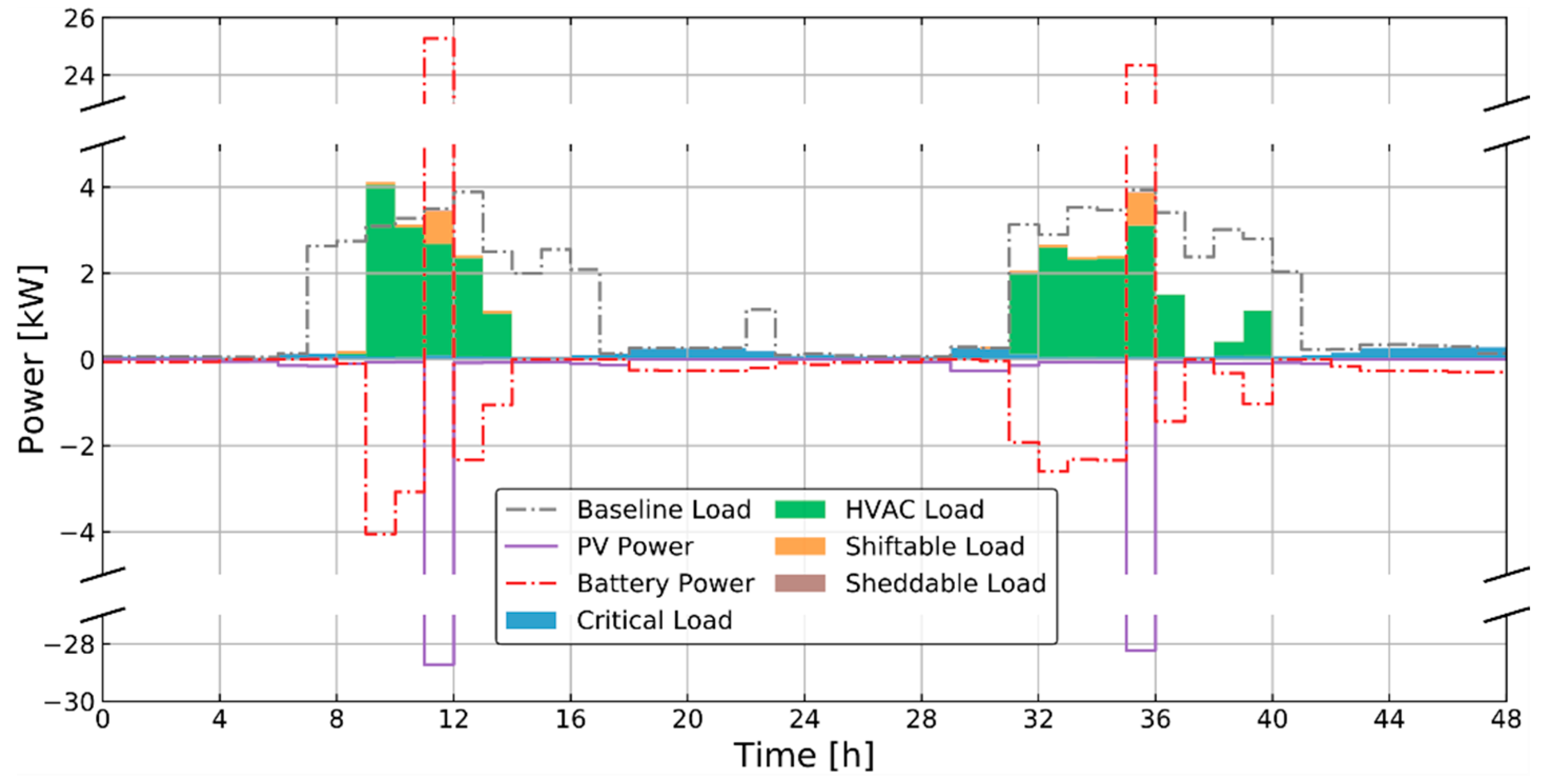

The residential building operation is compared in the scenario where all buildings are equally weighted and where the residential building is prioritized in

Figure 6 and

Figure 7, respectively. In both scenarios, we see that shiftable loads are scheduled during the day when more PV power is available. All sheddable and modulatable loads are satisfied in both cases (see

Table A1 for details). When the allocated PV power is more than doubled in the residential building due to it being prioritized, we see more battery charging and discharging in

Figure 7. However, more than enough PV power is allocated to the residential building in this case due to its high priority, resulting in 31.25% of the allocated PV power being curtailed. Additionally, more power is allocated to the HVAC system in

Figure 7, causing the indoor temperature to be closer to the lower bound (

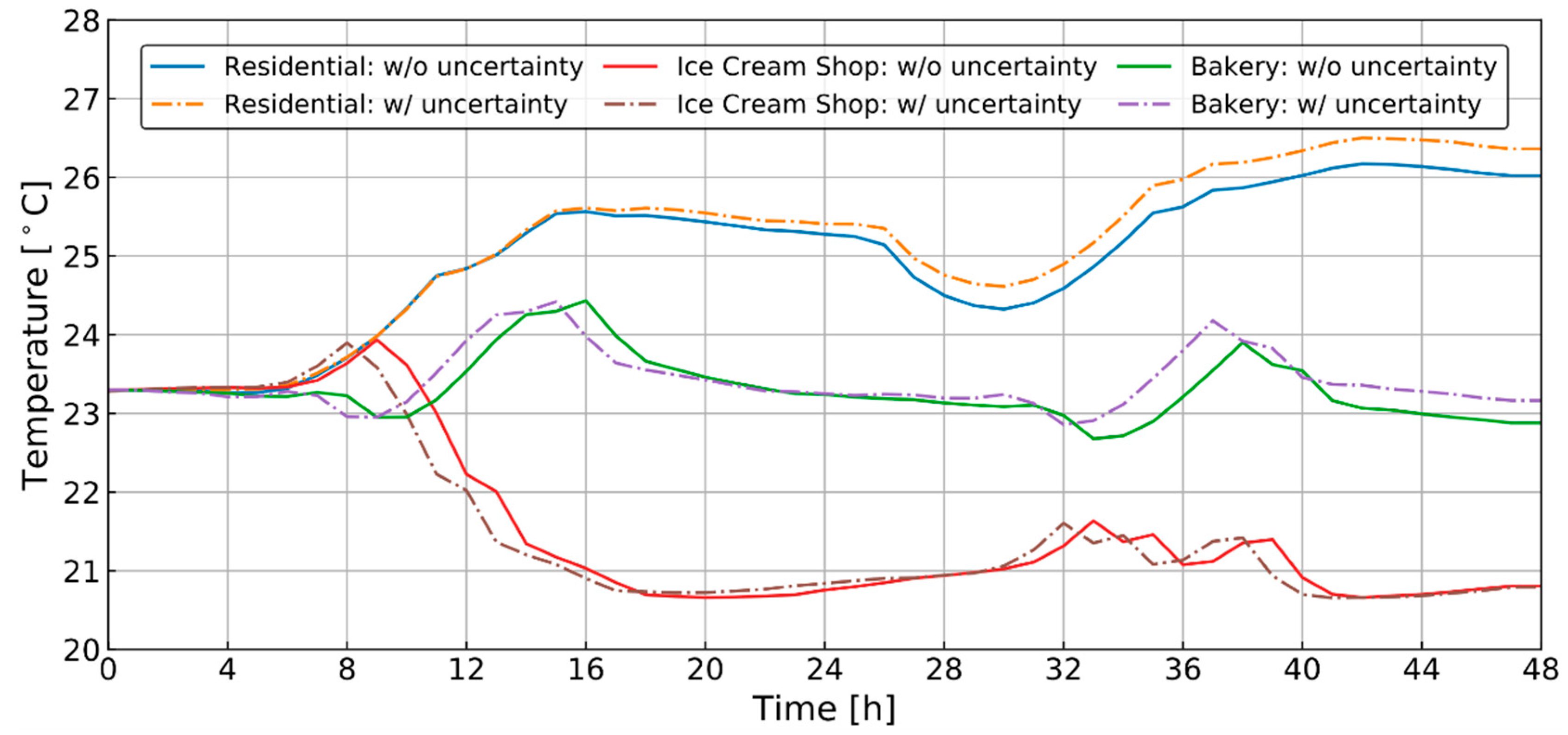

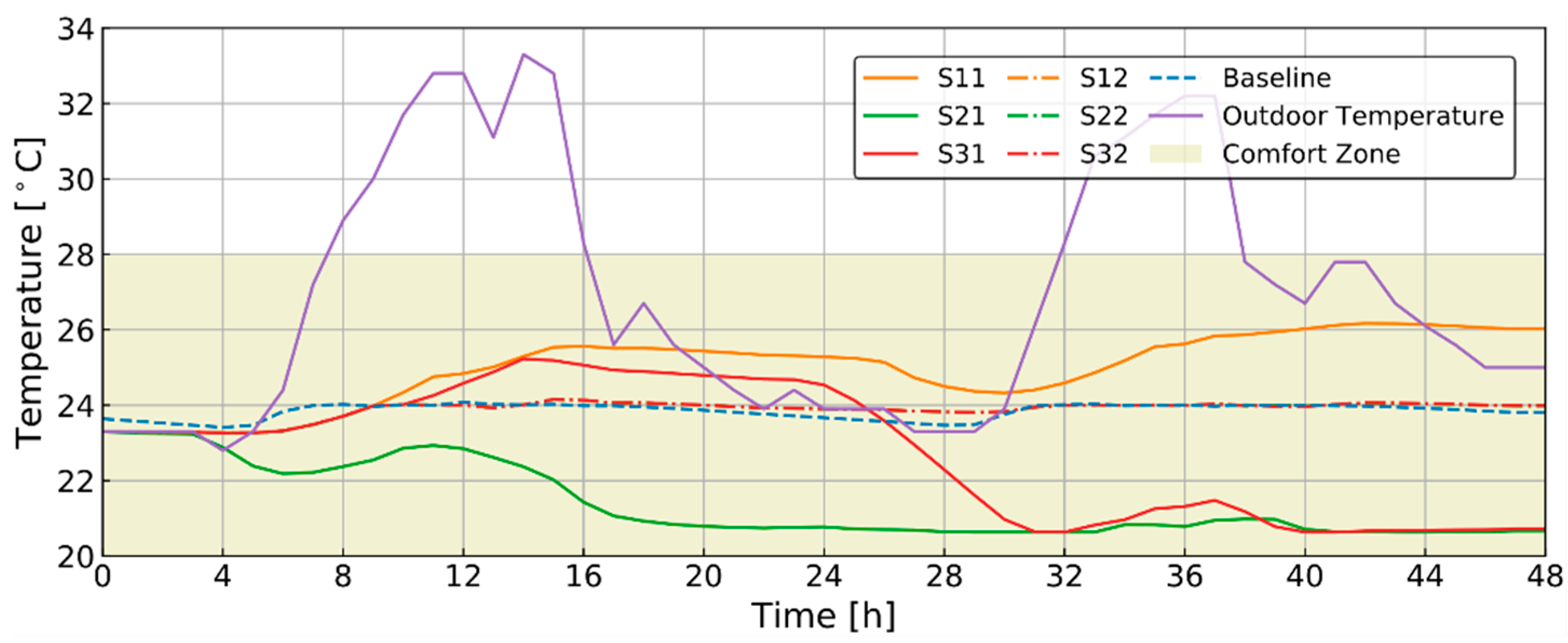

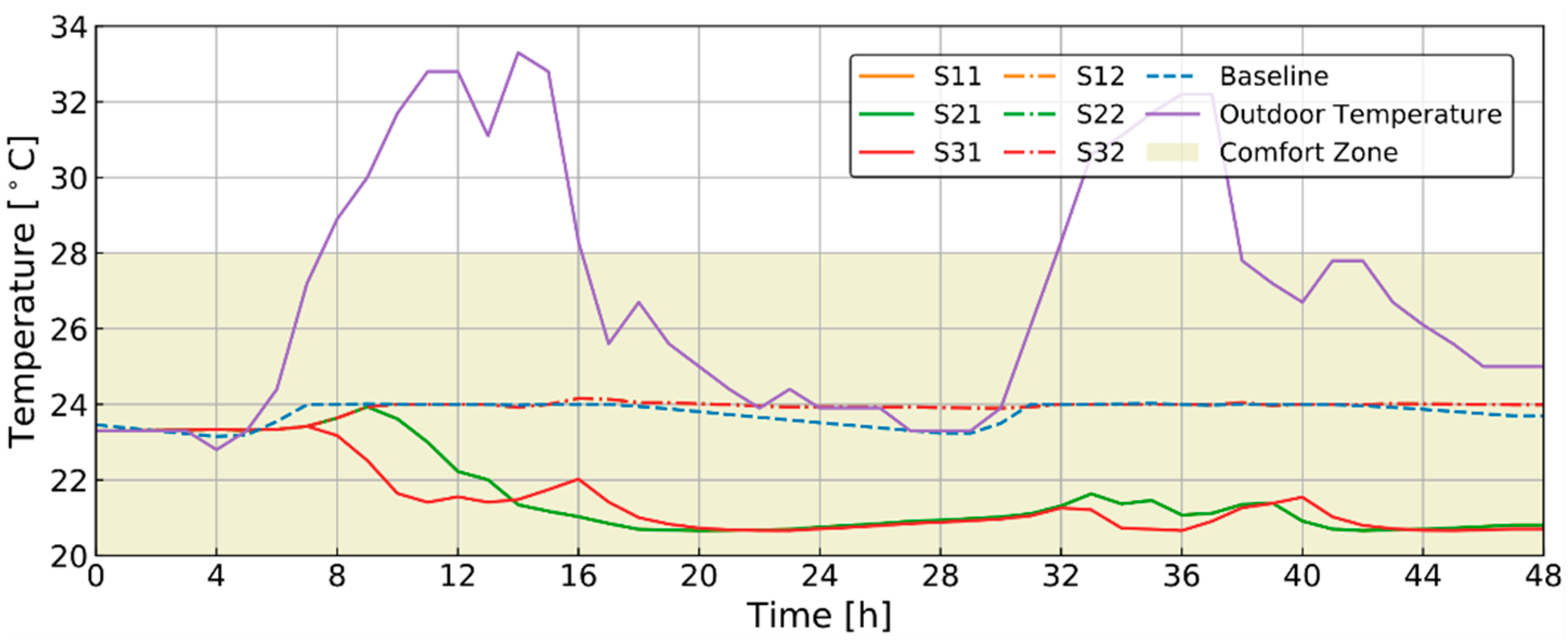

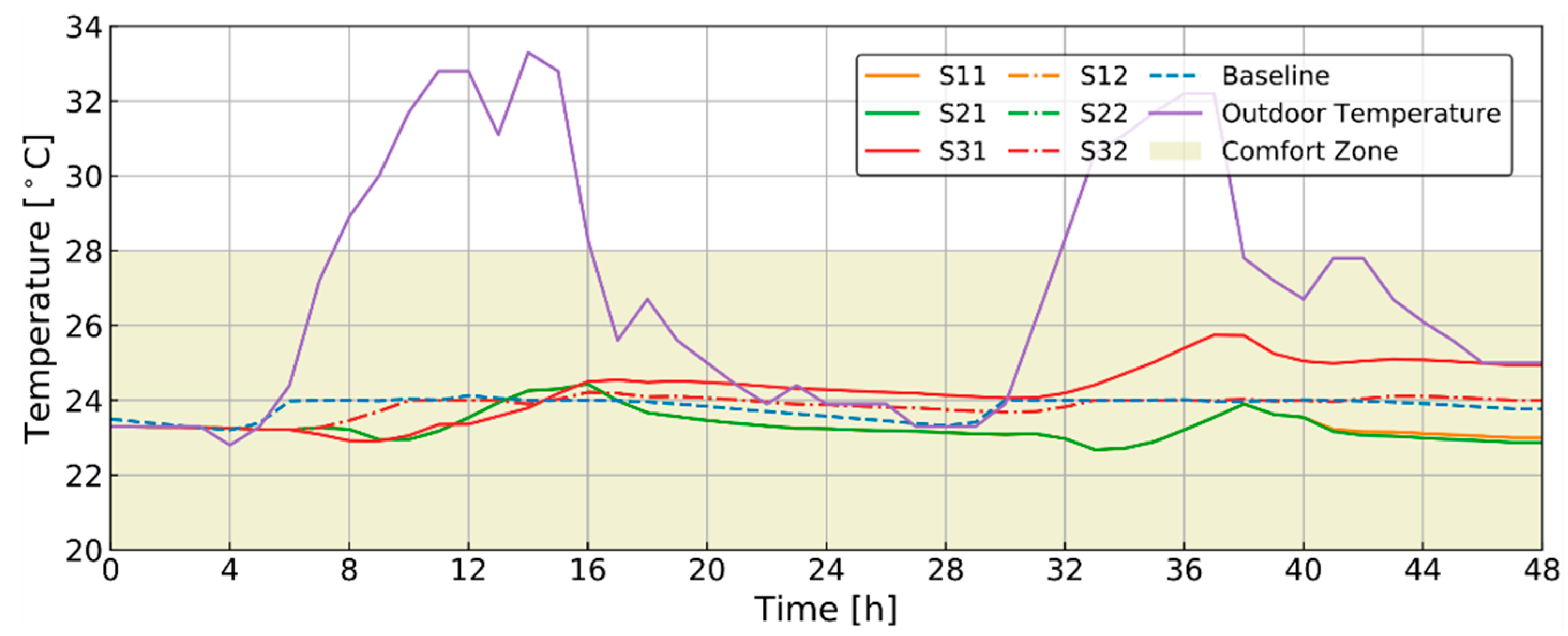

Figure 8). Comparing S11, S21, S31 with various weighting factors in

Figure 8, we see that scenarios with more allocated PV power results in a lower indoor temperature since more power is available for the HVAC load. In

Figure 8, all temperatures are within the comfort bounds. It is noted that in

Figure 8, S12, S22, and S32 temperature curves have almost the same trend that they cannot be differentiated from the plot.

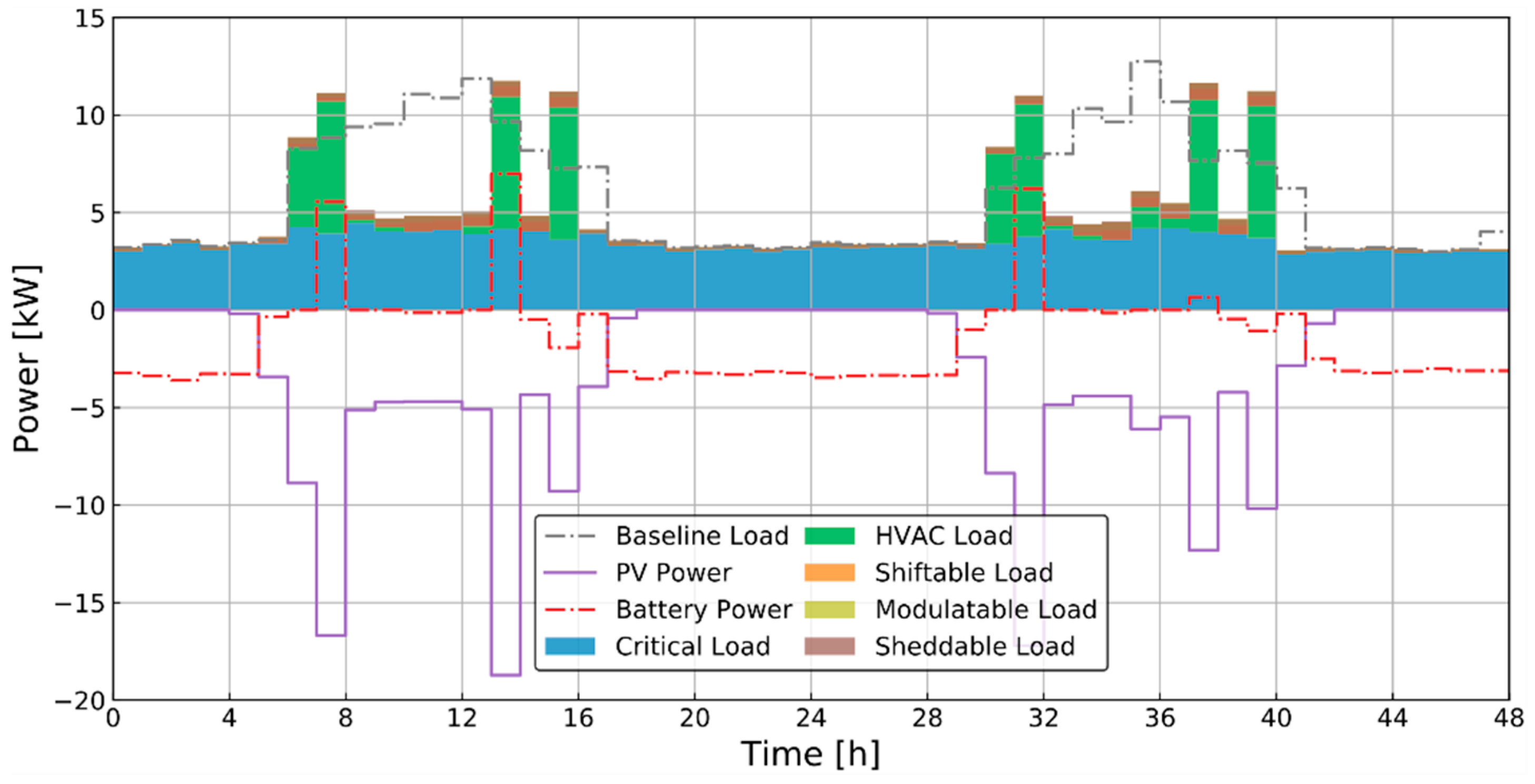

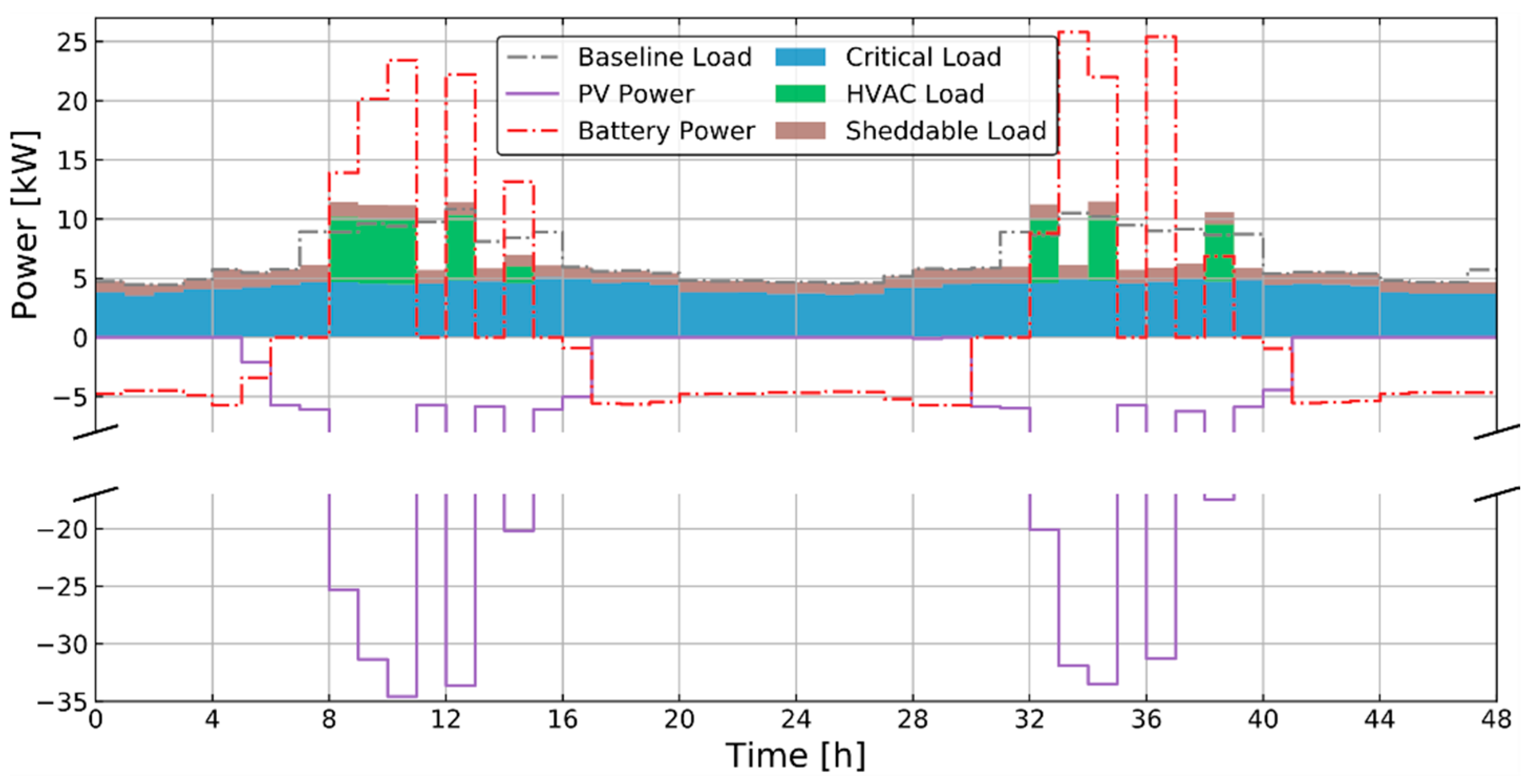

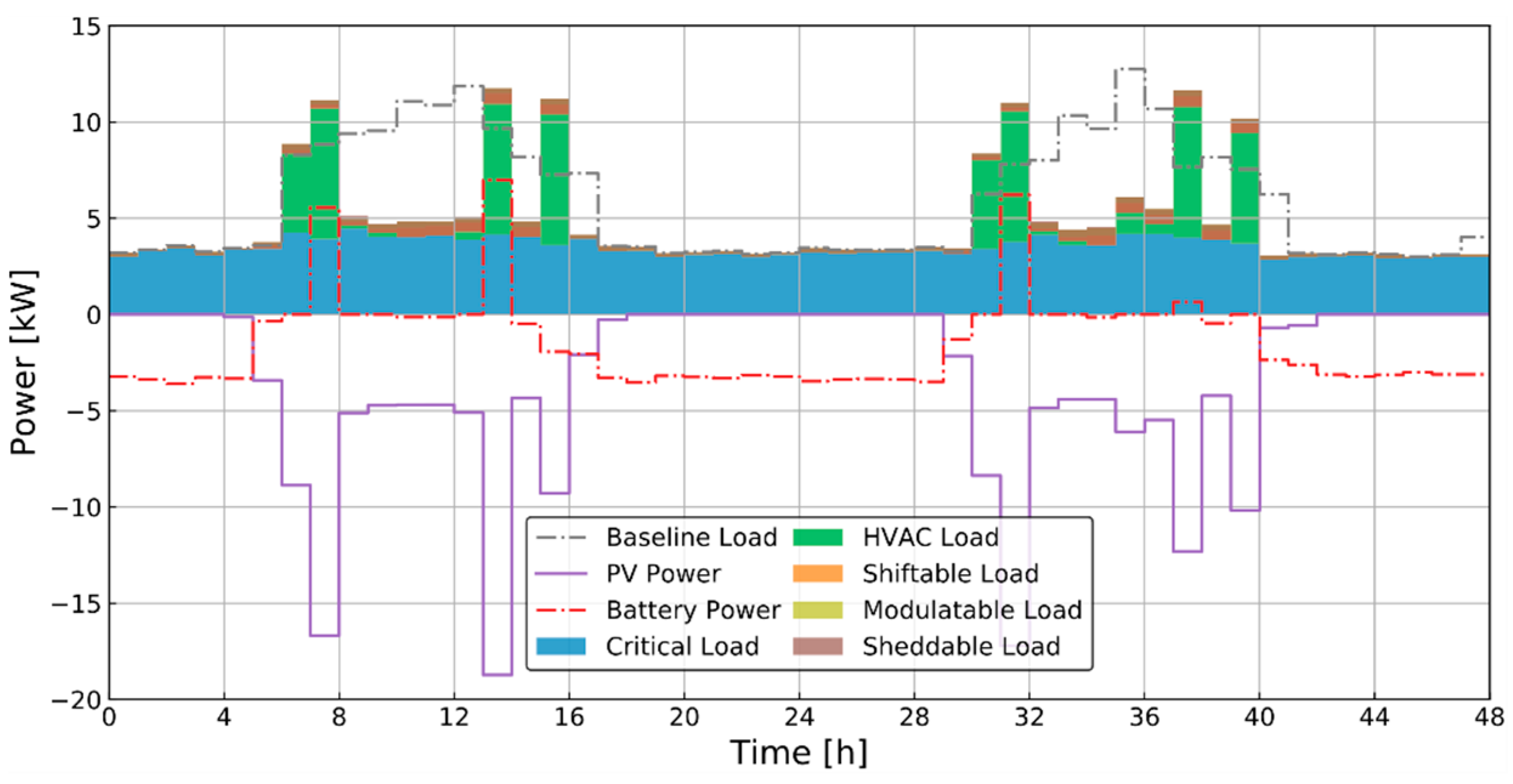

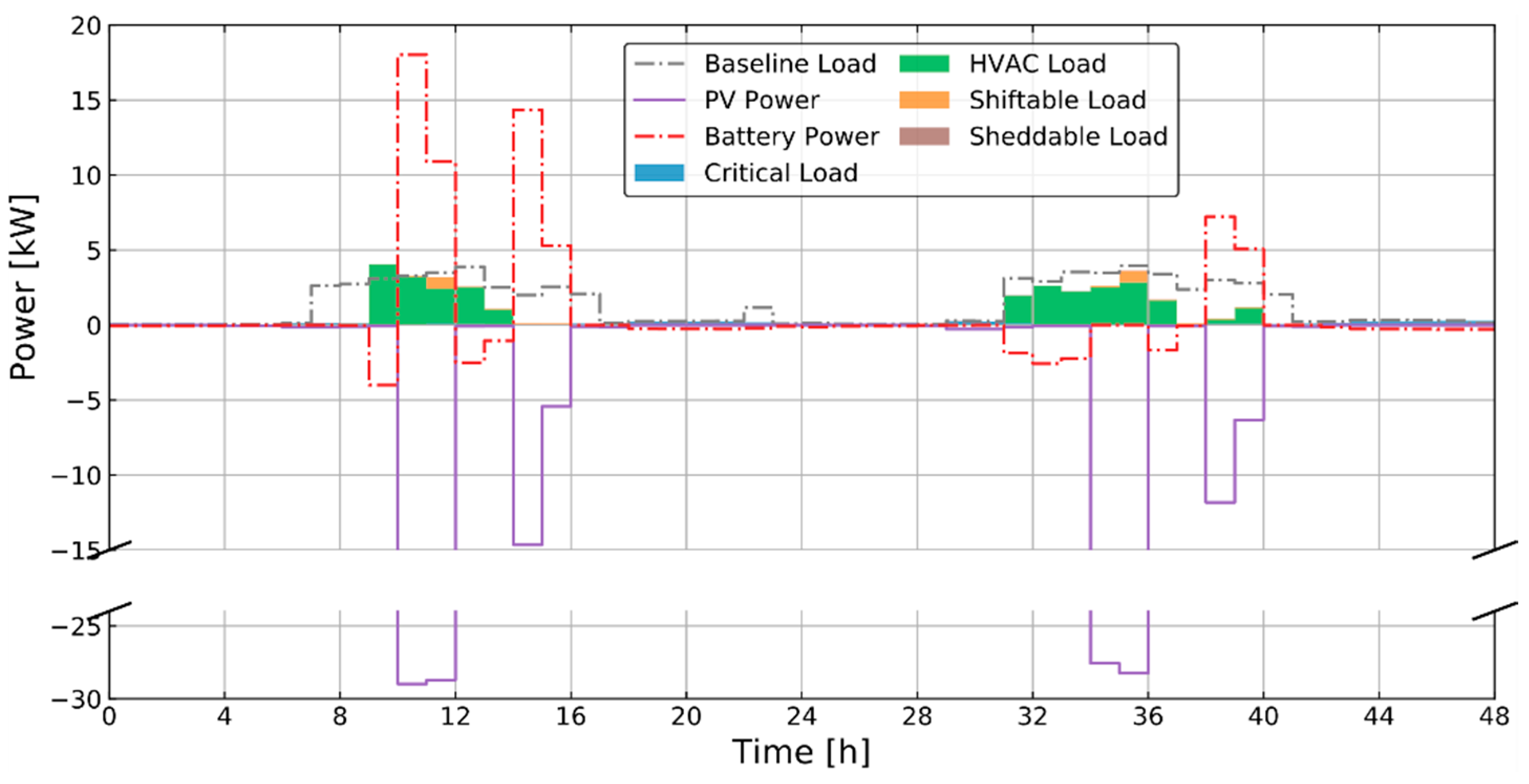

Figure 9 depicts the results for the ice cream shop with equal weighting while

Figure 10 shows the results with occupancy-based weighting. Since the total allocated PV energy in

Figure 10 is reduced by about 12% that compared to

Figure 9, we see much less battery charging and a slight reduction of HVAC power in

Figure 10. All sheddable loads are satisfied in both cases (see

Table A1 for details). In

Figure 11, the indoor temperature trajectories of S11 and S21 overlap with each other as almost the same amount of PV power is allocated to the ice cream shop in these two scenarios. The indoor temperature in simulation scenario S31 first drops below those of scenarios S11 and S21 in the morning due to a precooling between 6 to 9 A.M., and then exceeds them in the afternoon due to less power available to operate the HVAC system. A similar trend is also seen in the following simulation day. As in the residential building,

Figure 11 shows that the indoor thermal comfort of the ice cream shop was maintained within the given temperature bounds. It is noted that in

Figure 11, S12, S22, and S32 temperature curves have almost the same trend that they cannot be differentiated from the plot.

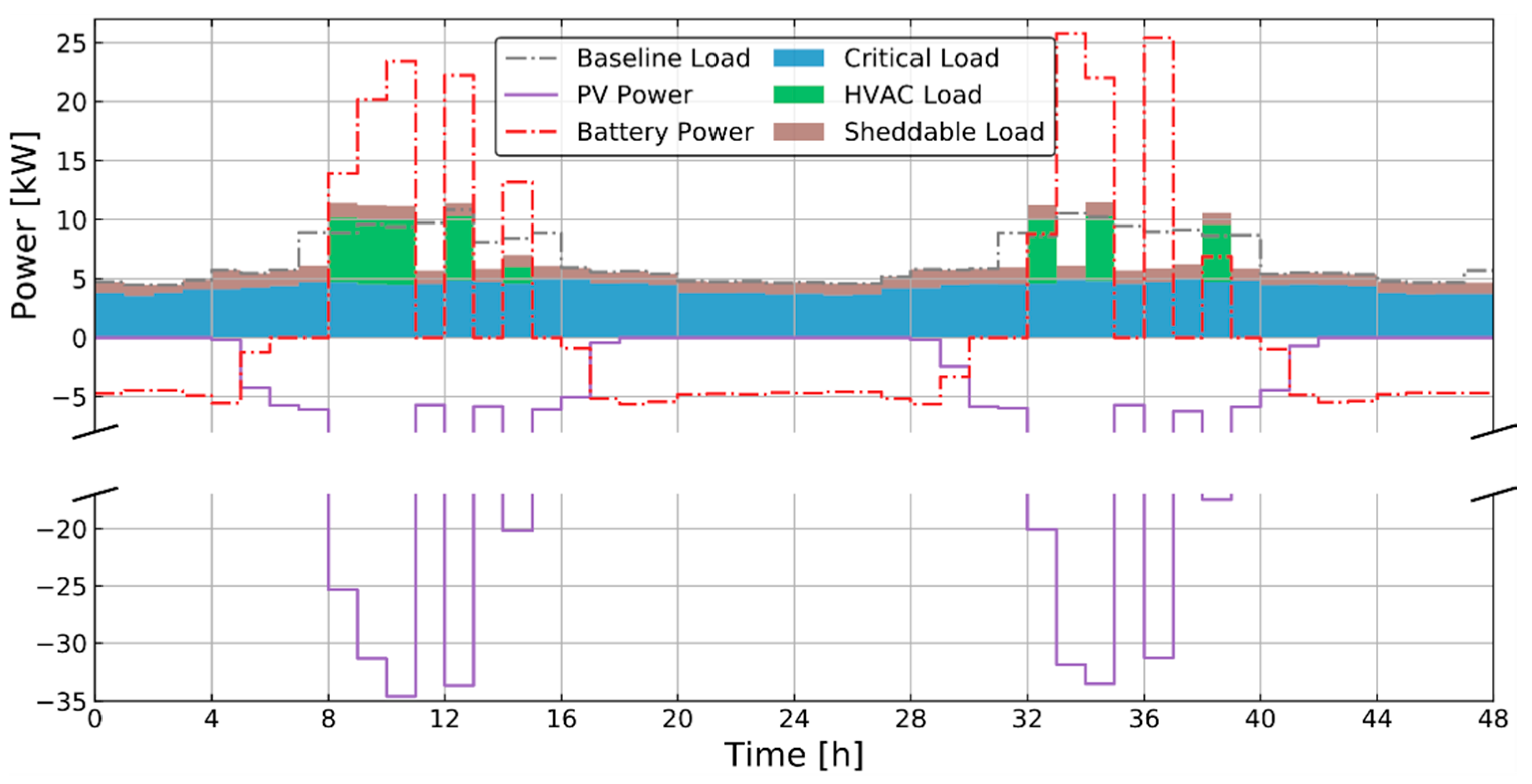

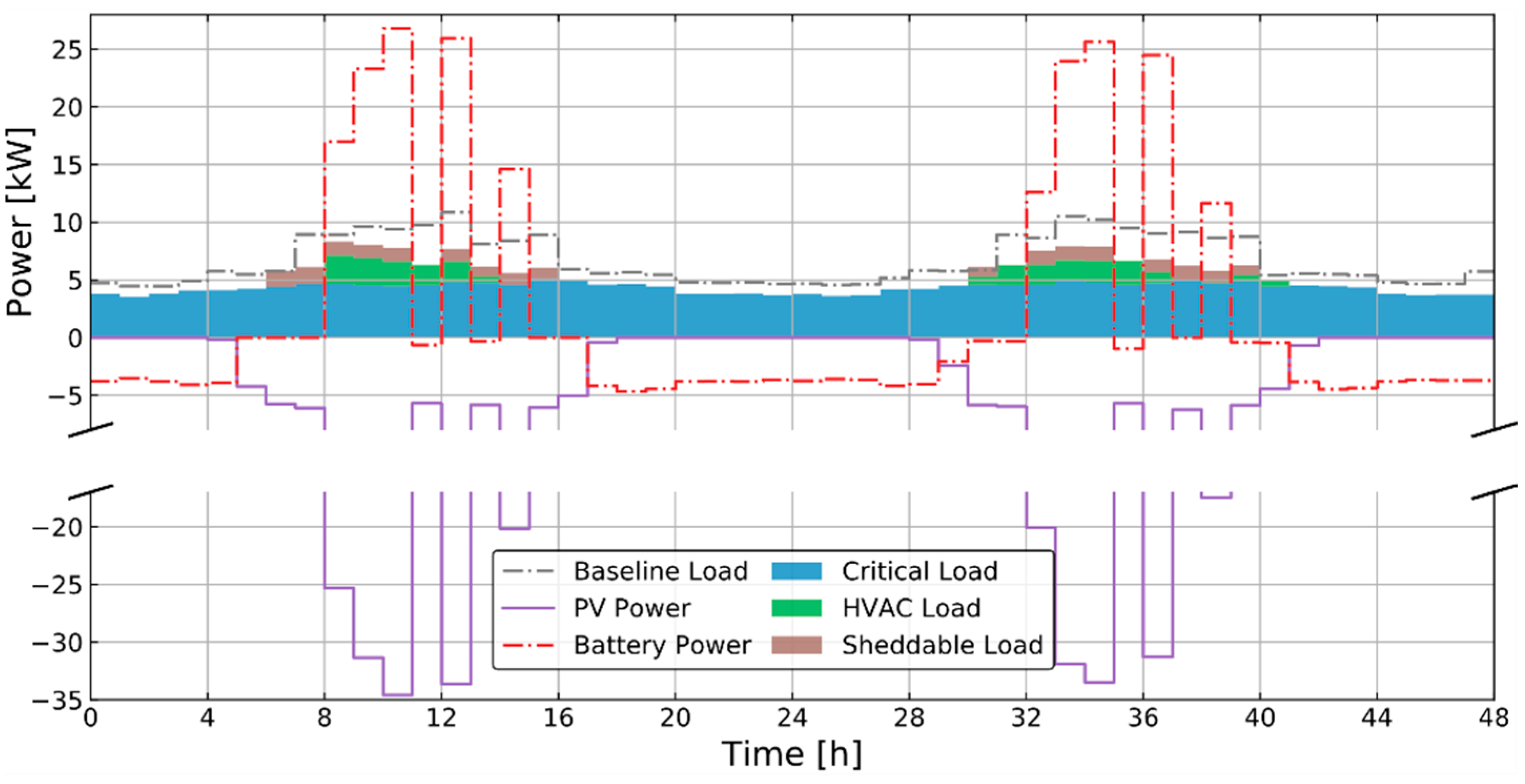

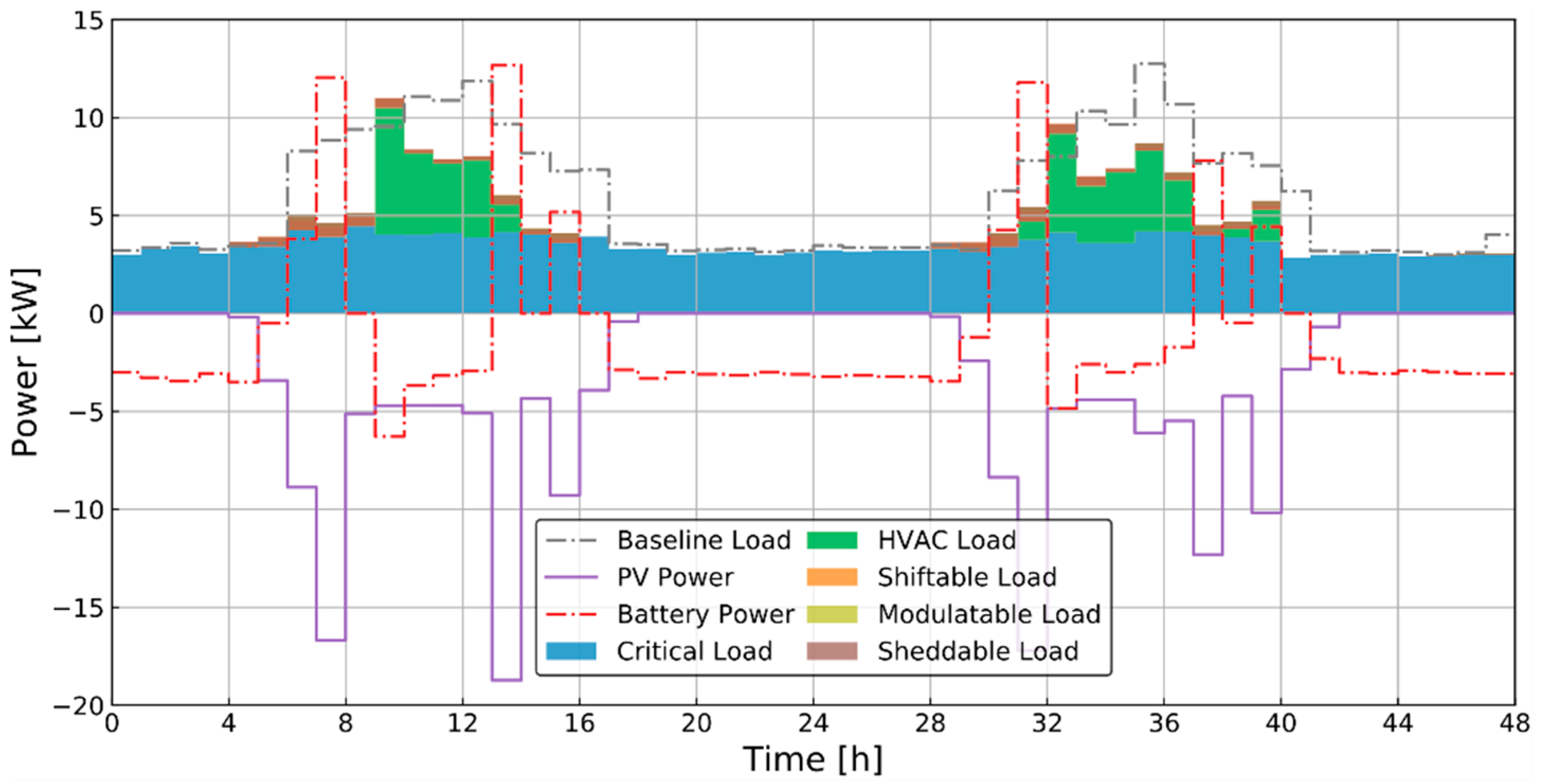

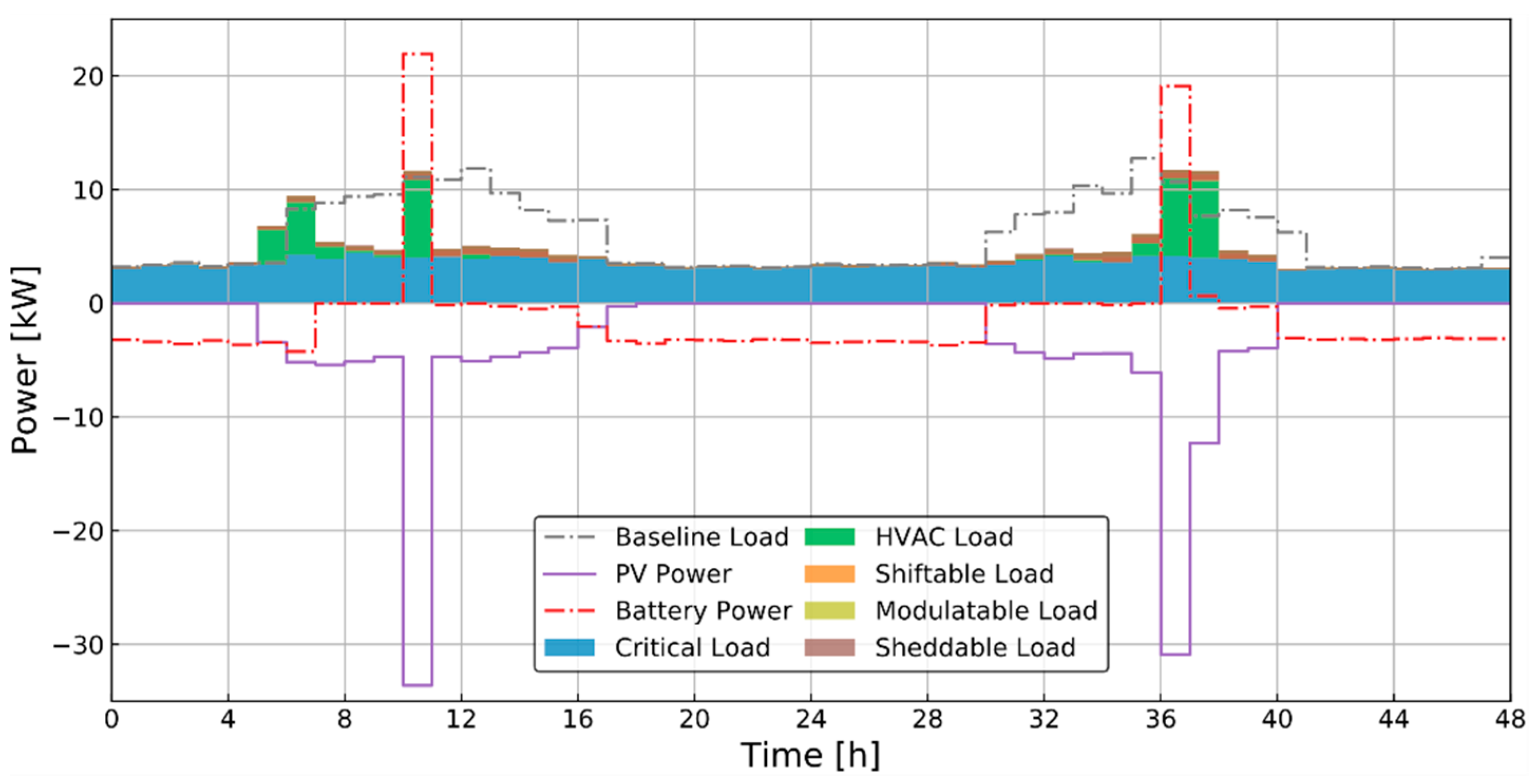

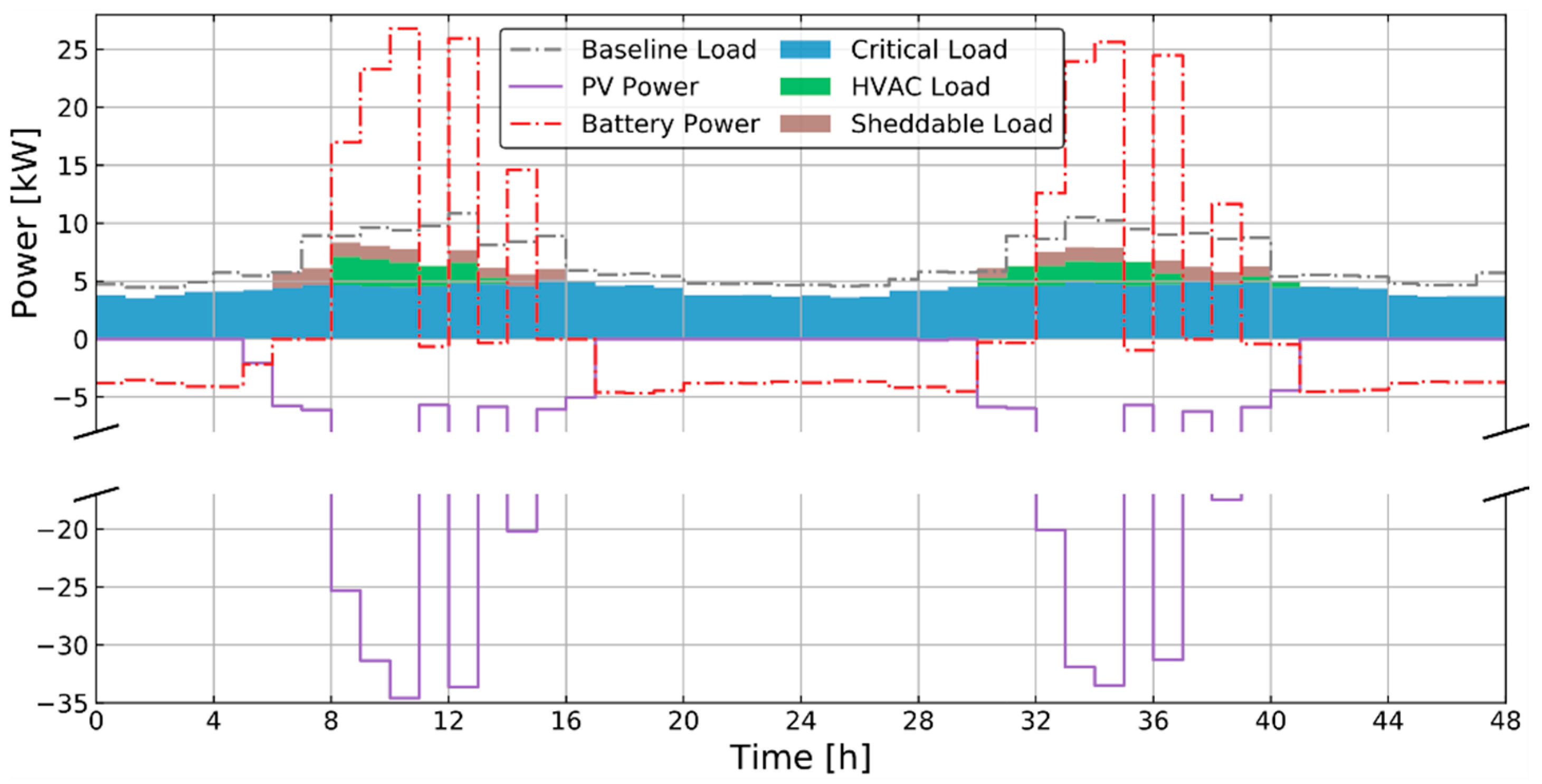

Figure 12 plots the results for bakery with equal weighting while

Figure 13 with occupancy-based weighting. Due to a reduction of PV power in

Figure 13, much less power is allocated to the HVAC system, especially during late afternoon (e.g., hour 16 and 40). The battery discharging is almost the same in the two scenarios, both to satisfy the four types of loads present in this building. All sheddable and modulatable loads are satisfied in both cases (see

Table A1 for details). However, battery charging only happens about once a day in scenario S31 given the focused allocated PV power shape. In

Figure 14, the indoor temperature for S31 is higher than S11 due to less power available to operate the HVAC system. All temperatures are within the comfort temperature bounds. It is noted that in

Figure 14, S12, S22, and S32 temperature curves have almost the same trend that they cannot be differentiated from the plot.

To summarize, in this section, we discussed the PV resource allocation results under different weighting methods. The resulted load shape, battery behavior, and indoor temperatures are also discussed qualitatively. From the discussion, we found that the weighting method of the operator layer directly affects the mean allocation factor of each building. When one building is prioritized, we see an obvious increase of . However, a higher does not necessarily mean more PV energy allocation. A higher allocation factor during time periods with more PV generation (e.g., around noon) is more crucial than a higher mean value of the allocation factor overall. Additionally, we noticed that the allocation process is mostly constrained by the building load flexibility ranges. More specifically, buildings with a higher load flexibility lower bound (i.e., ice cream shop with large critical loads) tend to get more allowable load than other buildings. Additionally, when prioritizing buildings according to occupancy status, the building with longer occupant presence gets more PV power, which is not necessarily a fair allocation method. For instance, in S31, 5.5% of the PV energy allocated to the residential building was curtailed. Since the allocation process was according to building occupancy time, more than enough power is allocated to the residential building in this case. Lastly, the resulting load schedule, battery behavior, and indoor temperature are directly correlated with the available PV power when other system settings are the same (e.g., battery charging constraints and penalty coefficients).

4.4. Impact of Objective Function

This section discusses the impact of different objective functions on the scheduled load shapes, battery behavior, and indoor temperature. Similar to the last section, qualitative discussions will first be provided.

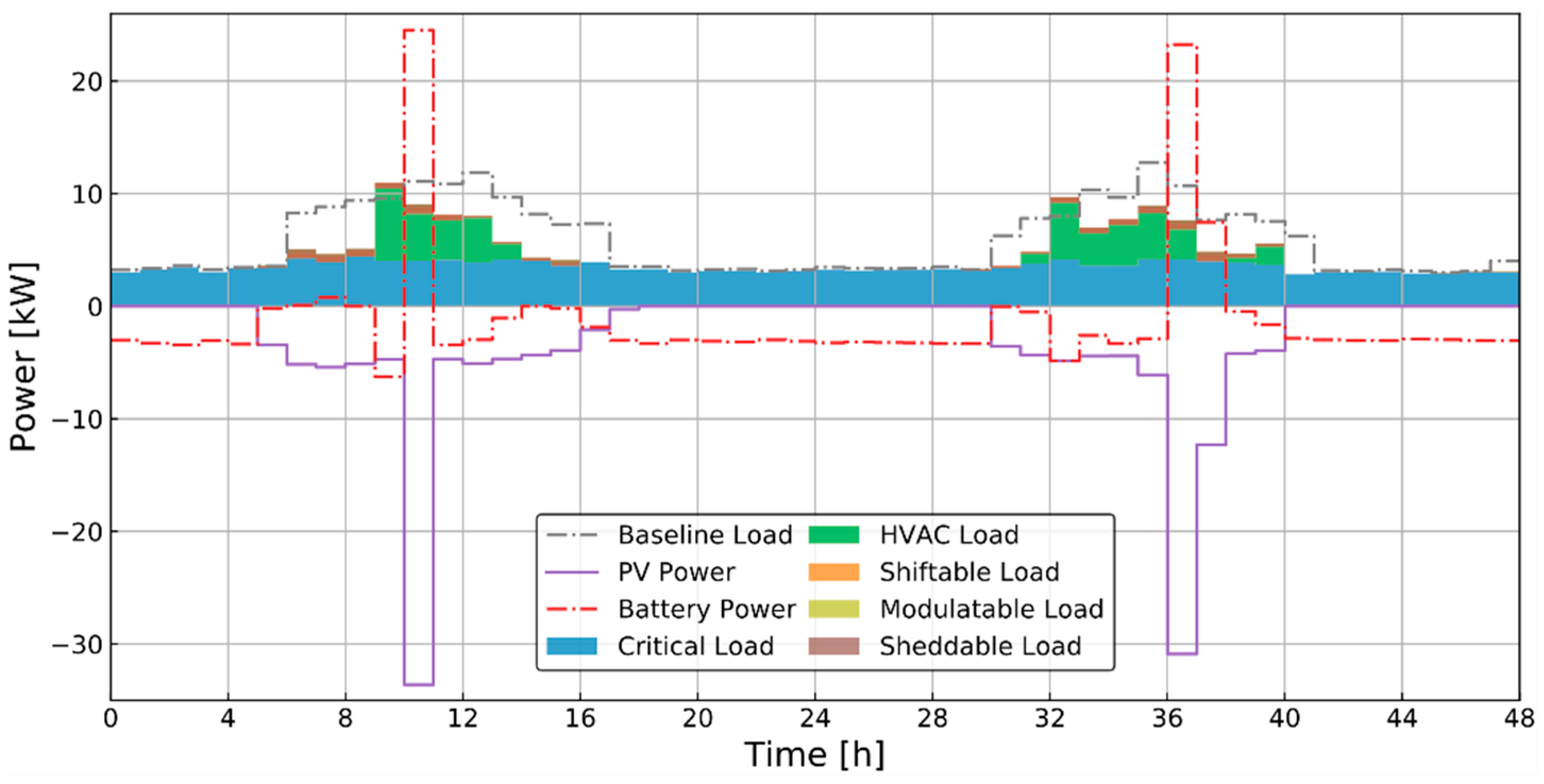

Figure 15 plots the results of the residential building with equal weighting and the objective is to maximize thermal comfort. Compared with

Figure 6, we see that when the objective switches from minimizing unserved load to maximizing comfort, there is an obvious increase of HVAC power and the temperature gets closer to the temperature setpoint of 24

(

Figure 8). When comparing

Figure 16 with

Figure 7, we see a decrease of HVAC power usage because before (S21 in

Figure 8), the indoor temperature was below 24

; when the objective is to minimize the temperature deviation from 24

, the required cooling power is actually less. The HVAC power is saved to get the indoor temperature closer to the temperature setpoint.

Comparing

Figure 17 with

Figure 9, we see a decrease of serving in sheddable load when the objective switches from minimizing unserved load to maximizing comfort. As a result, 63.72% of sheddable load is unserved in this scenario (

Table A1). However, the HVAC power also decreases in order to increase the indoor temperature to the temperature setpoint. The saved PV power is charged into the battery as we see an increase of battery charging in

Figure 17. Similar observation can be found if we compare

Figure 18 with

Figure 12, where unserved ratio of sheddable load increases to 99.03% and modulatable to 68.89% due to the change of objective function (

Table A1).

To further quantify the impact of weighting factor and objective function, we summarized the community overall KPIs in

Table 6 and

Table 7. The KPIs include PV curtailment ratio, unserved load ratio, temperature deviation from setpoint, and required battery size. The definition of the PV curtailment ratio is the total curtailed PV energy over the generated energy during the simulation horizon. The unserved load ratio is calculated by dividing the total unserved load by the total original load over the simulation horizon. The definition of the temperature deviation from setpoint is adapted from the root mean square deviation (RMSD), which is the root mean of the square of the deviation between the indoor temperature and the temperature setpoint over the 48-h simulation denoted by:

where

is the simulation horizon. Here, the temperature setpoint is selected to be the middle of the comfort temperature range: 24

. Lastly, the required battery size is obtained by subtracting the minimum battery SOC from the maximum value. This gives us a sense of how much of the battery capacity has been utilized under different scenarios. Further, this could help to guide the battery sizing to enhance community resilience.

From

Table 6, we see that PV curtailment only happens when the residential building is prioritized (S21_R and S22_R) or when occupancy-based weighting is implemented (S31 and S32). This is because the residential building has a relatively small power demand compared to the other two commercial buildings. When it is prioritized by the operator layer, more PV generation is allocated than needed, resulting in PV curtailment. This also echoes our discussions above that allocating purely based on building occupancy status could lead to unfair allocation situations. In the table, the shiftable load unserved load ratio is the same for all scenarios. This is because of our assumption that each shiftable load operates once and only once every day. However, in the original data, some loads might have operated more than once, causing “unserved load” for shiftable loads. Given this, we can consider that all loads are satisfied for the scenarios to minimize unserved load (S11 to S31 in

Table 6). When looking at scenarios S12–S32 in

Table 6, we see an increase of unserved load as the objective switches to maximizing comfort. The largest unserved load ratio appears in the scenario where residential building is prioritized. From

Table 6, the scenarios that perform the best would be S11, S21_I, and S21_B if we only consider PV curtailment and unserved load ratio. In these scenarios, the PV allocation is either equally weighting all buildings or prioritizing those with larger power demand while minimizing the unserved load ratio.

Next, we analyze the temperature deviation and necessary battery size shown in

Table 7. We see that all scenarios with the thermal comfort objective experience the fewest temperature deviations. This means that the indoor temperature is well controlled to stay near the temperature setpoint. In the remaining scenarios with the unserved load objective, large deviations in temperature can be seen. For many scenarios, this is due to lower indoor temperatures than the temperature setpoint. Hence, setting the temperature setpoint appropriately can save HVAC energy. However, in our case, the saved energy was either curtailed or charged into the battery instead of satisfying the other loads. This also leads to larger battery sizes in scenarios to maximize comfort (average size: 221.5 kWh) than scenarios to minimize unserved load (average size: 200.5 kWh). Therefore, a co-optimization of thermal comfort and unserved load is necessary with the benefit of less curtailment, smaller unserved load ratio, assured thermal comfort, as well as smaller battery size.

The above simulation results highlight the impact of the objective function on KPI outcomes. From the above discussions, we identified that if only PV curtailment and unserved load ratio are considered, the best option is to allocate the PV resource either equally weighting or prioritizing buildings with larger power demand while minimizing unserved load ratio. After further looking at other indices, we noticed that choosing the optimization objective to track an appropriately selected indoor room temperature setpoint will save HVAC energy. However, this will not lead to lower unserved ratio for other load types. Instead, the PV curtailment could increase. The two objectives have a competitive relationship: serving more HVAC power to increase thermal comfort will decrease the other served load.