Effects of Reservoir Parameters on Separation Behaviors of the Spiral Separator for Purifying Natural Gas Hydrate

Abstract

1. Introduction

2. Materials and Methods

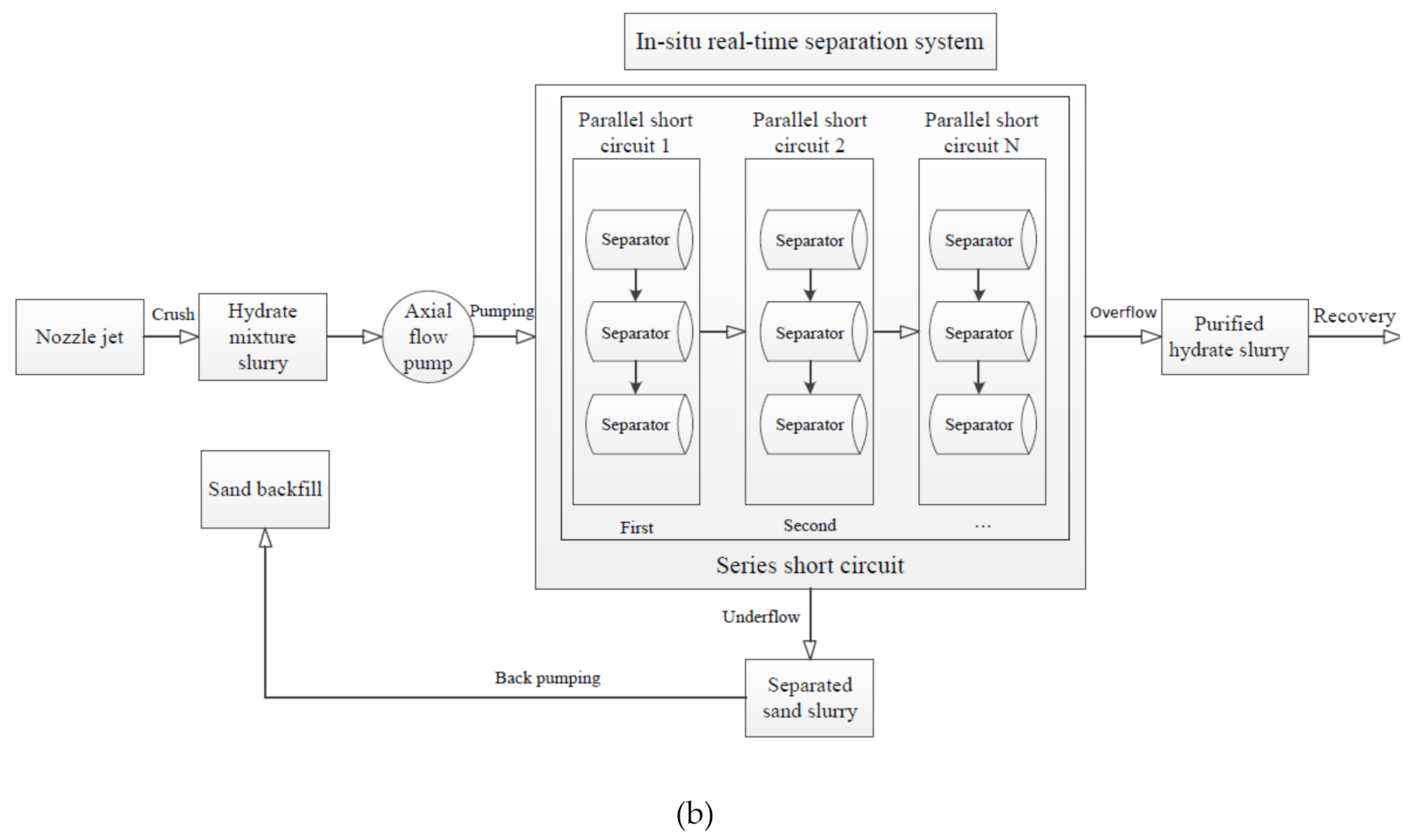

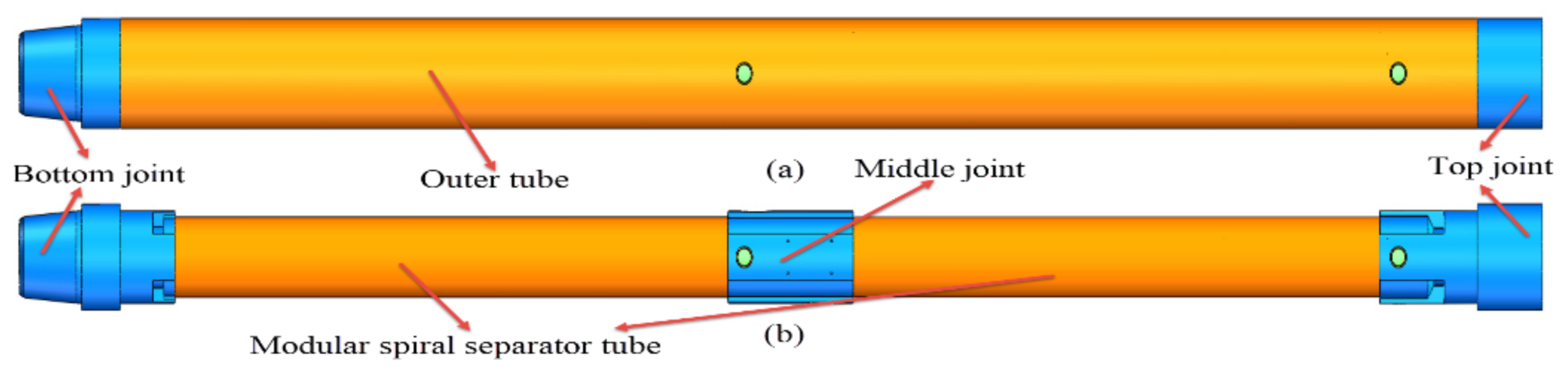

2.1. The Structure of the Downhole Spiral Separator

2.2. CFD Numerical Simulation

2.2.1. Mesh and Model Description

2.2.2. Boundary Conditions

3. Results and Discussion

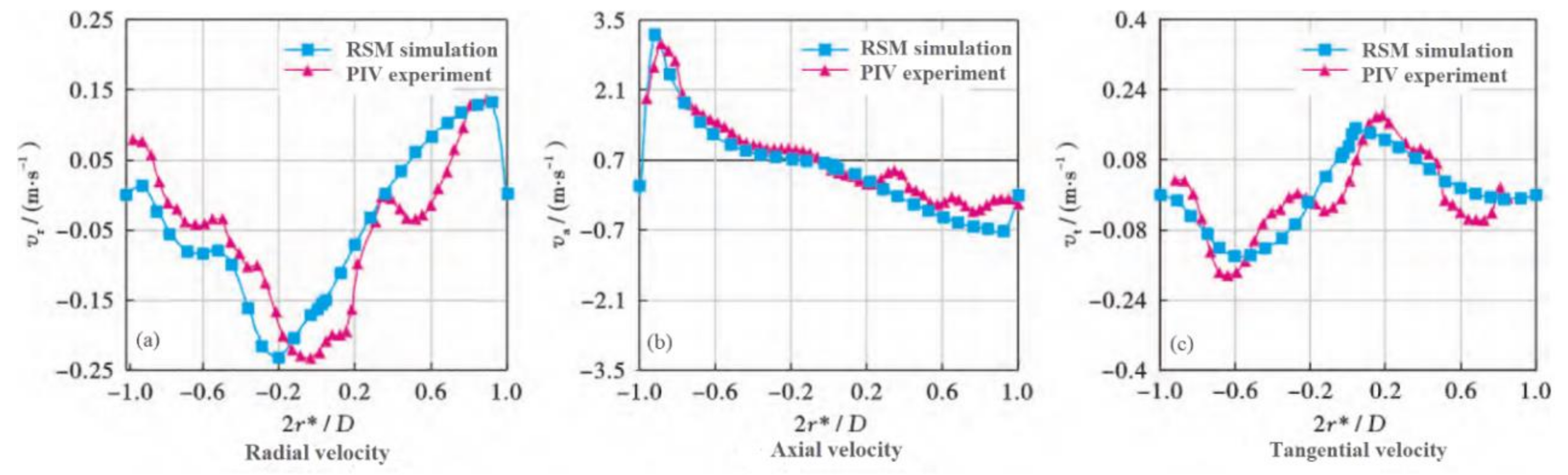

3.1. Model Validation and Grid Independency

3.2. Separation Performance

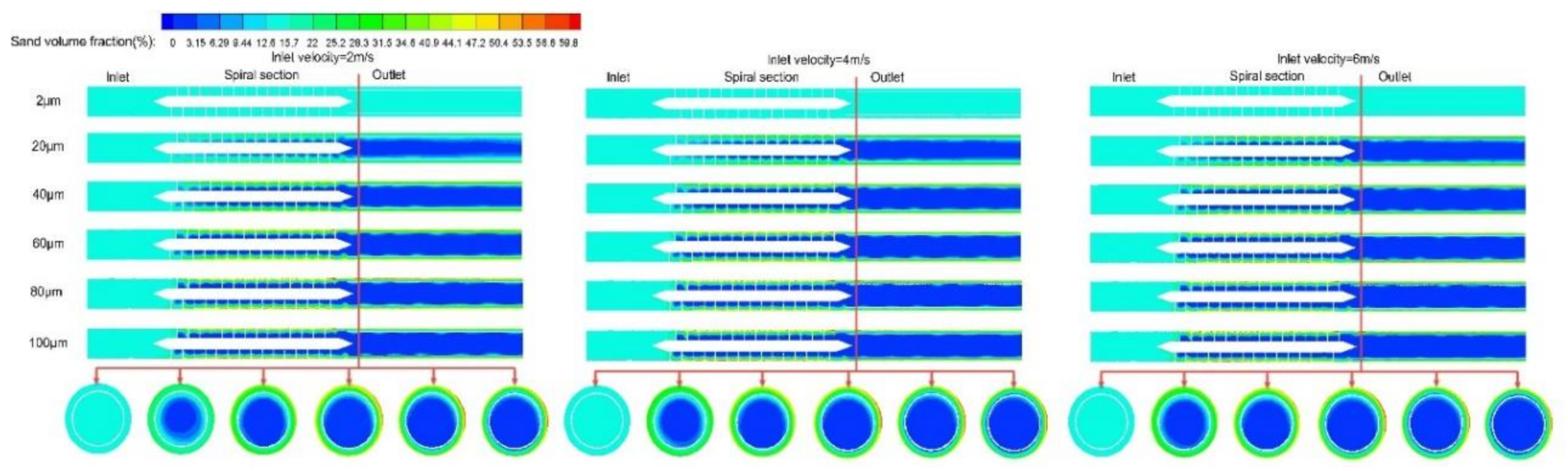

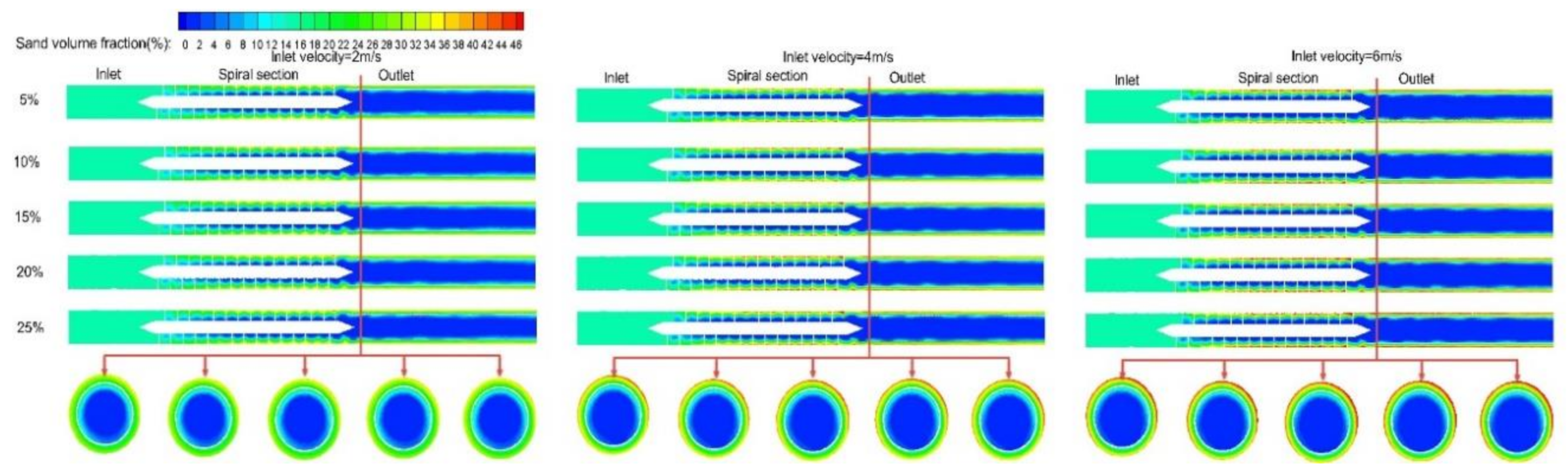

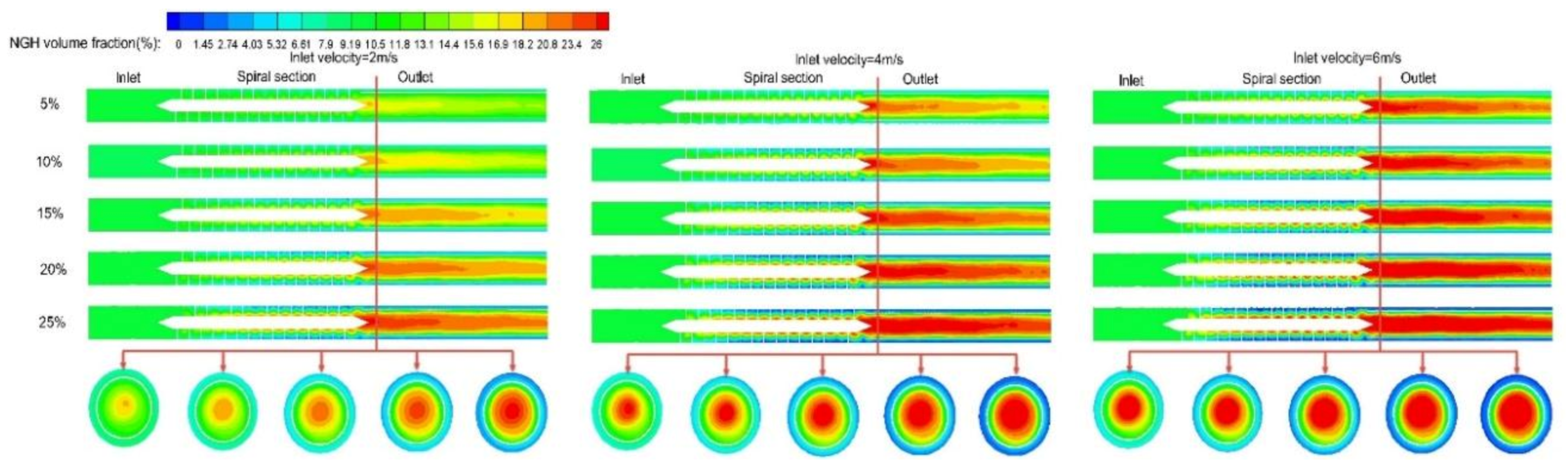

3.2.1. Discrete Phase Distribution

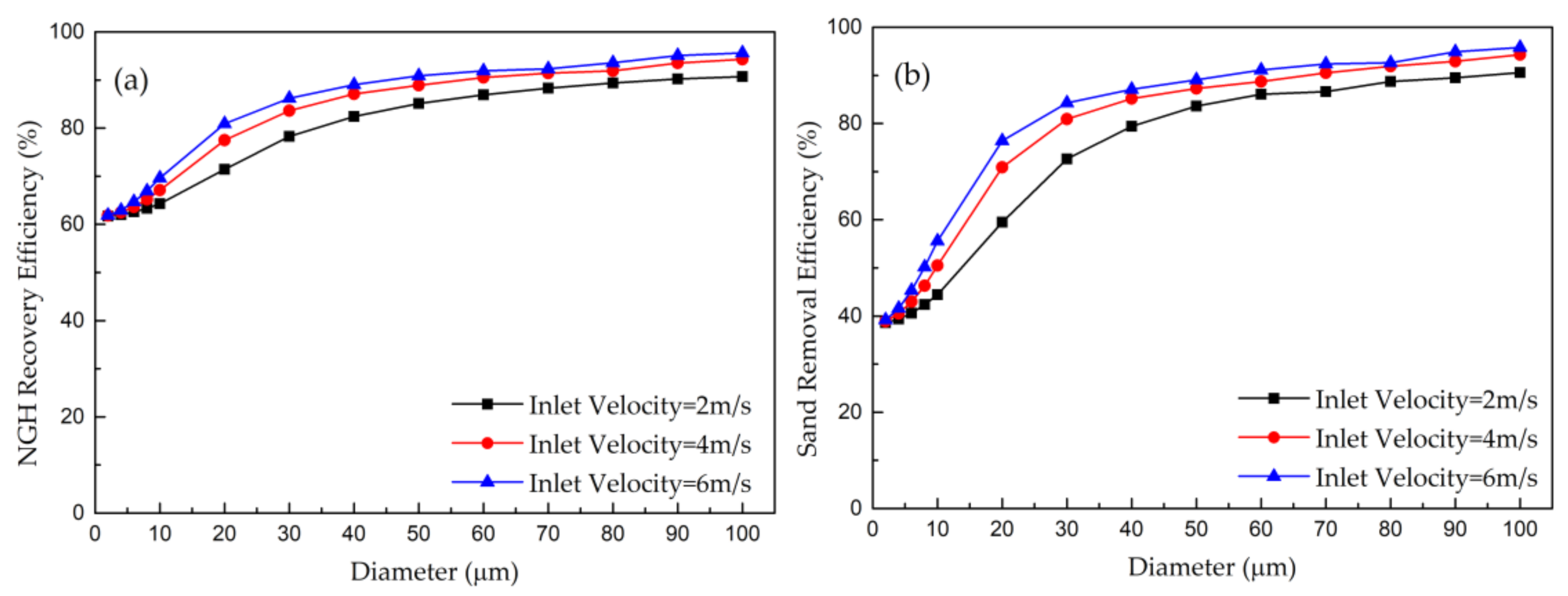

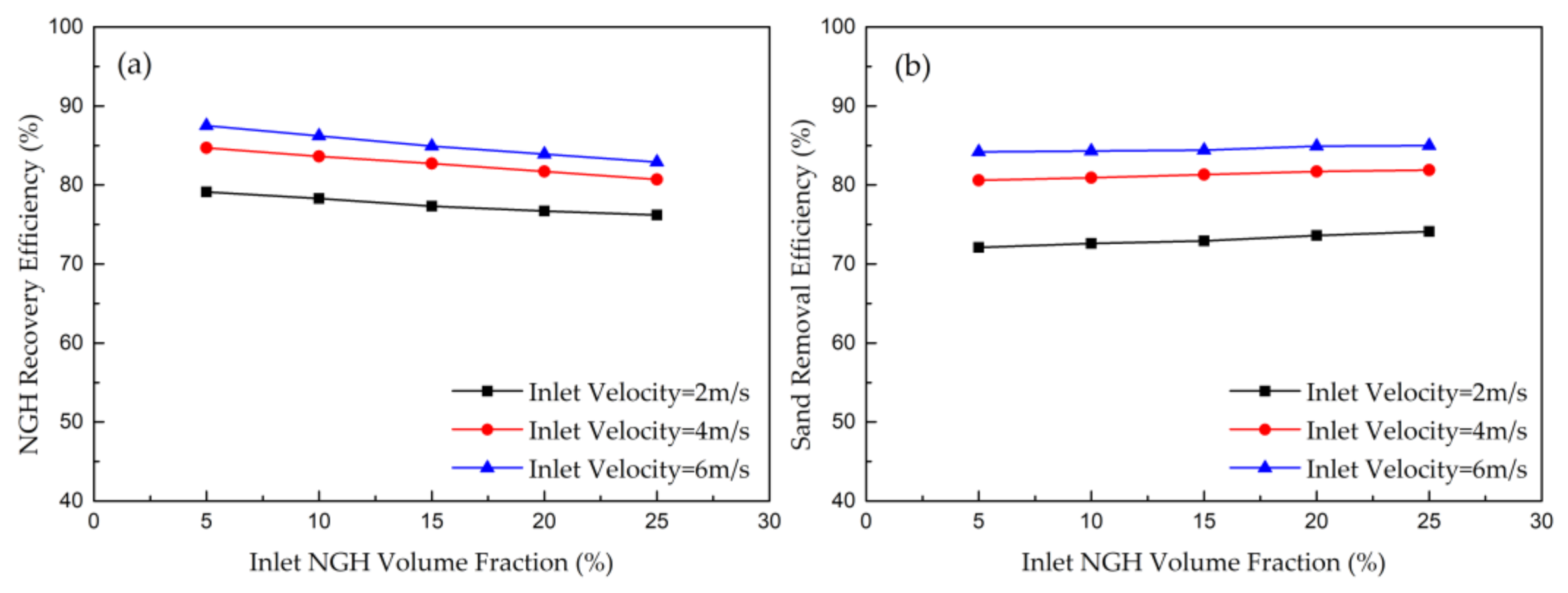

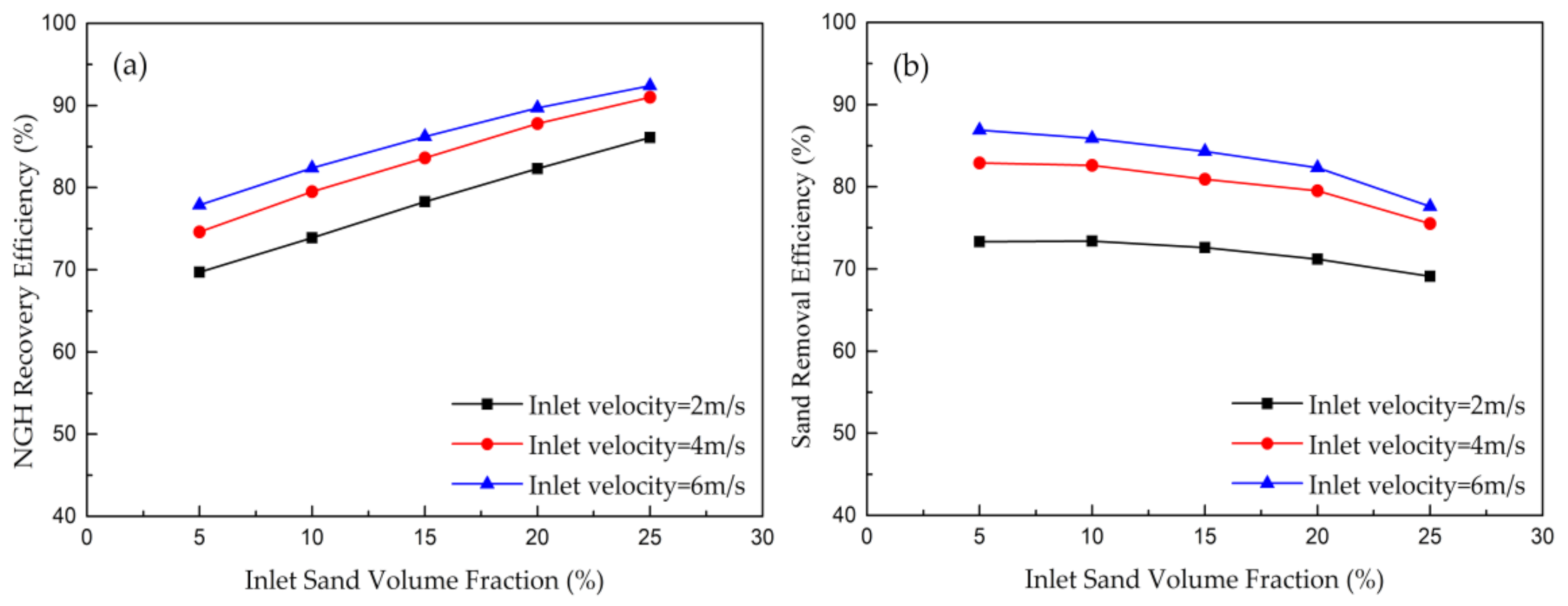

3.2.2. Separation Efficiency

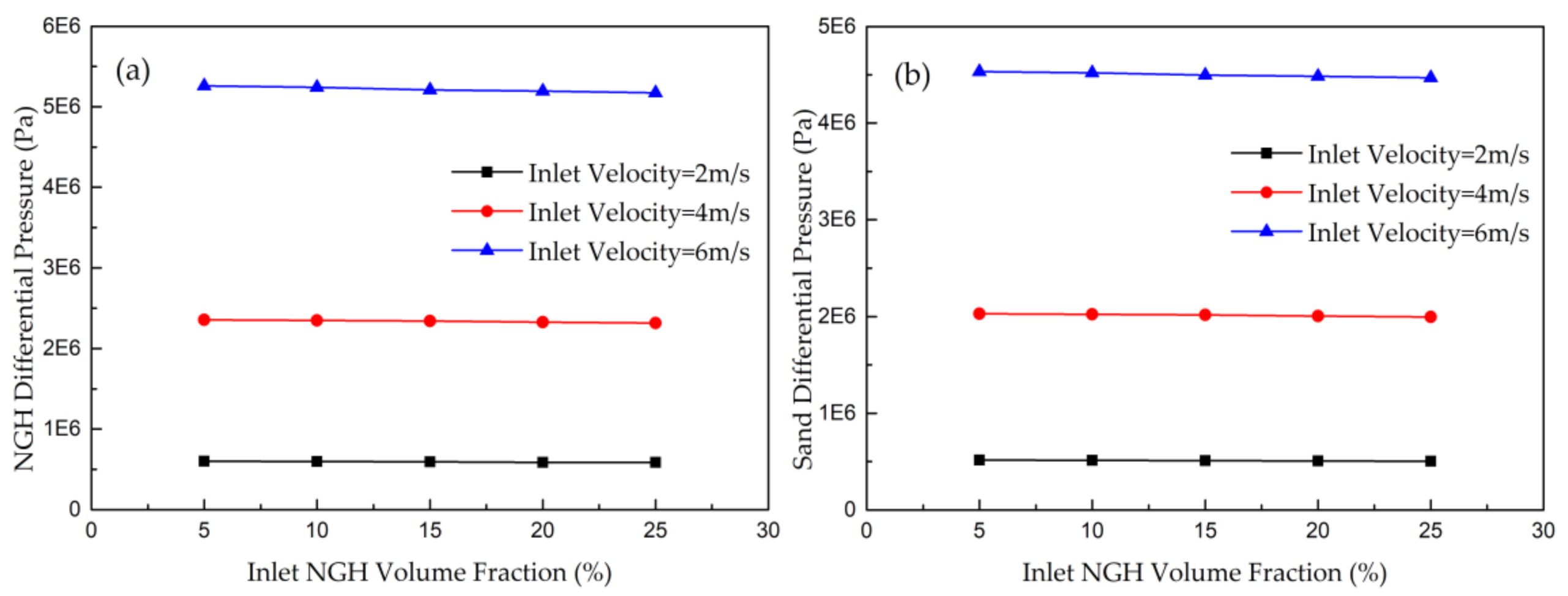

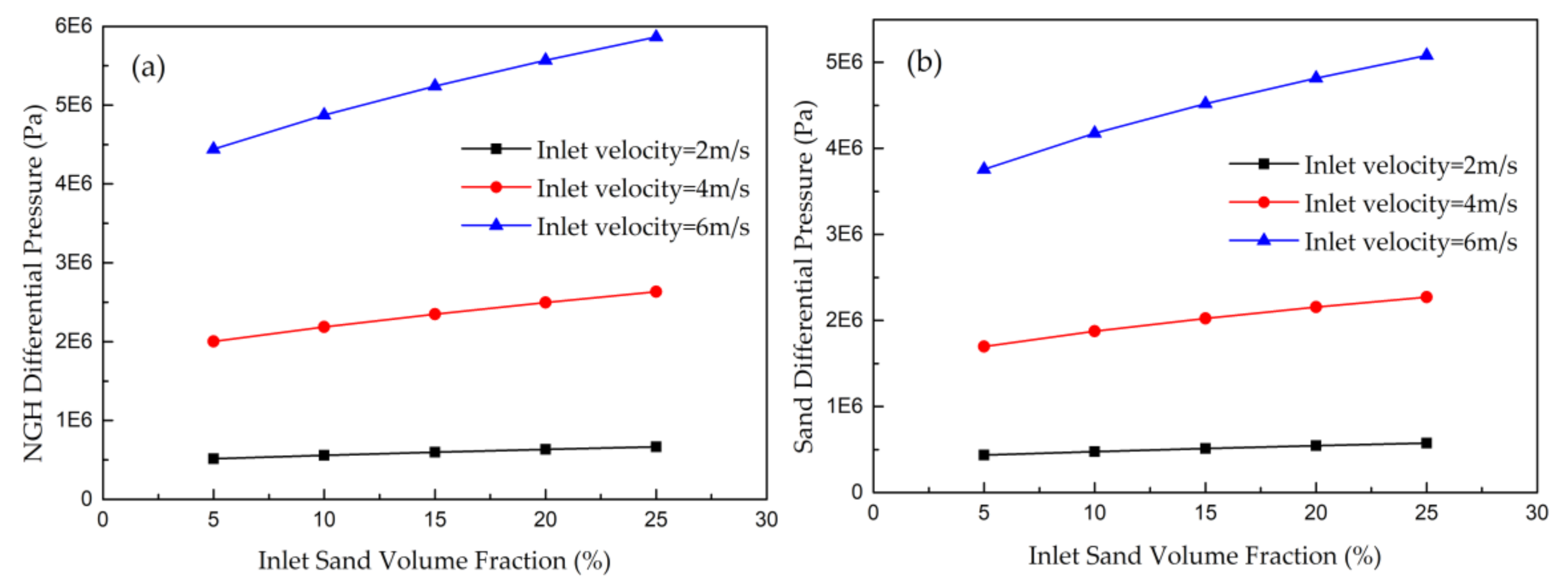

3.2.3. Differential Pressure

4. Conclusions

- (1)

- The distribution of each phase is uniform in the inlet, and the NGH phase volume fraction decreases along the center to the wall in the spiral section and outlet while that in the sand phase increases. With increasing particle diameter and inlet sand volume fraction, the NGH volume fraction increases at the center of the spiral separator, and the sand volume fraction increases at the wall of the spiral separator. It shows that the spiral separator shows good performance in the recovery of NGH and sand removal.

- (2)

- The NGH recovery efficiency and sand removal efficiency increase first and then tend to be steady. With the increasing of the inlet sand volume fraction, the NGH recovery efficiency increases, but the sand removal efficiency decreases. When the inlet NGH volume fraction increases, the separation efficiency change law is opposite to that when the inlet sand volume fraction increases.

- (3)

- The differential pressure increases when the particle diameter and inlet sand volume fraction increase, whereas it decreases with increasing of the inlet NGH volume fraction. Therefore, the saturation and porosity of hydrate reservoir are one of the decisive factors of energy loss of the spiral separator.

- (4)

- Effects degree of reservoir parameters is in order from large to small: sand phase volume fraction, particle size, and hydrate volume fraction. The results show that the reservoir saturation and porosity can balance NGH recovery efficiency and sand removal efficiency. Furthermore, the spiral separator has good performance under the change of reservoir parameters. When inlet velocity increases, the NGH recovery efficiency, sand removal efficiency, and differential pressure increase continuously. Therefore, increasing the inlet velocity is helpful to improve separation performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kezirian, M.T.; Phoenix, S.L. Natural Gas Hydrate as a Storage Mechanism for Safe, Sustainable and Economical Production from Offshore Petroleum Reserves. Energies 2017, 10, 828. [Google Scholar] [CrossRef]

- Boswell, R.; Collett, T.S. Current perspectives on gas hydrate resources. Energy Environ. Sci. 2011, 4, 1206–1215. [Google Scholar] [CrossRef]

- Chong, Z.R.; Yang, S.H.B.; Babu, P.; Linga, P.; Li, X.-S. Review of natural gas hydrates as an energy resource: Prospects and challenges. Appl. Energy 2016, 162, 1633–1652. [Google Scholar] [CrossRef]

- Collett, T.S.; Johnson, A.H.; Knapp, C.C.; Boswell, R. Natural gas hydrates—A review. Brows. Collect. 2009, 89, 146–219. [Google Scholar]

- Ruppel, C. Methane Hydrates and the Future of Natural Gas. Future Nat. Gas. Interdiscip. Mit. Study 2011, S4, 25. [Google Scholar]

- Uddin, M.; Coombe, D.A.; Law, D.H.; Gunter, B. Numerical Studies of Gas Hydrate Formation and Decomposition in a Geological Reservoir. J. Energy Res. Tech. 2008, 130, 1–14. [Google Scholar] [CrossRef]

- Lu, J.; Xiong, Y.; Li, D.-L.; Shen, X.; Wu, Q.; Liang, D. Experimental Investigation of Characteristics of Sand Production in Wellbore during Hydrate Exploitation by the Depressurization Method. Energies 2018, 11, 1673. [Google Scholar] [CrossRef]

- Masui, A.; Haneda, H.; Ogata, Y.; Aoki, K. Mechanical Properties of Sandy Sediment Containing Marine Gas Hydrates in Deep Sea Offshore Japan. In Proceedings of the Seventh ISOPE Ocean Mining Symposium, Lisbon, Portugal, 1–6 July 2007; International Society of Offshore and Polar Engineers: Mountain View, CA, USA; pp. 53–56. [Google Scholar]

- Zhang, W.; Shao, M.J.; Tian, Q.L. Technical Progress of a Pilot Project to Produce Natural Gas Hydrate in Japanese Waters. Pet. Drill. Tech. 2017, 45, 101–105. [Google Scholar]

- Feng, J.C.; Wang, Y.; Li, X.S. Entropy generation analysis of hydrate dissociation by depressurization with horizontal well in different scales of hydrate reservoirs. Energy 2017, 125, 62–71. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.C.; Li, X.S.; Zhang, Y. Experimental and modeling analyses of scaling criteria for methane hydrate dissociation in sediment by depressurization. Appl. Energy 2016, 181, 299–309. [Google Scholar] [CrossRef]

- Zhou, S.W.; Chen, W.; Li, Q.P.; Zhou, J.L.; Shi, H.S. Research on the solid fluidization well testing and production for shallow non-diagenetic natural gas hydrate in deep water area. Offshore Oil Gas China 2017, 29, 1. [Google Scholar]

- Zhou, S.W.; Zhao, J.Z.; Li, Q.P. Optimal Design of the Engineering Parameters for the first Global Trial Production of Marine Natural Gas Hydrates through Solid Fluidization. Nat. Gas Ind. 2017, 37, 118–131. [Google Scholar] [CrossRef]

- Chen, H.; Lv, B.; Fu, L.Q.; Wu, W.K. Separation and purification of natural gas hydrate slurry mixture by hydrocyclone. Mod. Chem. Ind. 2017, 1, 155–159. [Google Scholar]

- Wu, K.S.; Dai, M.L. Hydrocyclone for Separating Silt in Gas Hydrate Mixed Slurry on the Seabed. J. Beijing Univ. Technol. 2015, 41, 973–979. [Google Scholar]

- Dai, M.L. Study on Multiphase Flow and Separation of Hydrate Slurry Spiral Tube. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2017. [Google Scholar]

- Tian, J.; Ni, L.; Song, T.; Shen, C.; Yao, Y.; Zhao, J. Numerical study of foulant-water separation using hydrocyclones enhanced by reflux device: Effect of underflow pipe diameter. Sep. Purif. Technol. 2019, 215, 10–24. [Google Scholar] [CrossRef]

- Dai, S.; Yuan, H.; Hualin, W.; Yuan, W.; Fu, P. Deoiling of oil-coated catalyst using high-speed suspending self-rotation in cyclone. Sep. Purif. Technol. 2019, 210, 117–124. [Google Scholar]

- Xu, B.R.; Jiang, M.H.; Zhao, L.X.; Wang, Y.W.; Zhang, X.G.; Deng, X. CFD Simulation and PIV Test of Water Flow Characteristics in Helix Separator. Acta Pet. Sin. 2018, 39, 223–231. [Google Scholar]

- Zhou, X.J.; Liu, X.G. Velocity Characteristics of the Flow Field in Double Helix and Variable Pitch Separator. Ind. Control Comput. 2017, 30, 130–131. [Google Scholar]

- Ji, Y.; Chen, J.; Jiao, X.; Cai, X.; Li, P. Theoretical Modeling and Numerical Simulation of Axial-Vortex Separation Technology Used for Oily Water Treatment. Sep. Sci. 2015, 50, 1870–1881. [Google Scholar] [CrossRef]

- Zhao, L.; Xu, B.; Jiang, M.; Li, F.; Hua, Z. Flow-field distribution and parametric-optimisation analysis of spiral-tube separators. Chem. Eng. Res. Des. 2012, 90, 1011–1018. [Google Scholar] [CrossRef]

- Zhang, N. Simulation and Optimization of Downhole Gas-liquid Separator. Master’s Thesis, Southwest Petroleum University, Chengdu, China, June 2015. [Google Scholar]

- Wang, Q.W. The Design Research and Application of the Downhole Gas-Liquid Helix Separator. Master’s Thesis, Northeast Petroleum University, DaQing, China, 5 March 2011. [Google Scholar]

- Doheim, M.A.; Gawad, A.F.A.; Mahran, G.M.A.; Abu-Ali, M.; Rizk, A. Numerical simulation of particulate-flow in spiral separators: Part I. Low solids concentration (0.3% & 3% solids). Appl. Math. Model. 2013, 37, 198–215. [Google Scholar]

- Dixit, P.; Tiwari, R.; Mukherjee, A.K.; Banerjee, P.K. Application of response surface methodology for modeling and optimization of spiral separator for processing of iron ore slime. Powder Technol. 2015, 275, 105–112. [Google Scholar] [CrossRef]

| Parameter | Symbol | Dimension (mm) |

|---|---|---|

| Diameter of inlet | D | 100 |

| Diameter of helical blades | d | 38 |

| Pitch of helical blades | B | 40 |

| Cycle number of helical blades | - | 15 |

| Diameter of NGH recovery outlet | d1 | 72 |

| Diameter of sand removal outlet | d2 | 10 |

| Media | Density (kg/m3) | Viscosity (kg/m/s) |

|---|---|---|

| Seawater | 1025 | 0.0017 |

| Sand | 2600 | - |

| NGH | 910 | - |

| MESH SIZES | Maximum Static Pressure (MPa) |

|---|---|

| 150,000 | 0.381542 |

| 200,000 | 0.493760 |

| 250,000 | 0.661696 |

| 300,000 | 0.663254 |

| 350,000 | 0.660915 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, S.; Wang, G. Effects of Reservoir Parameters on Separation Behaviors of the Spiral Separator for Purifying Natural Gas Hydrate. Energies 2020, 13, 5346. https://doi.org/10.3390/en13205346

Qiu S, Wang G. Effects of Reservoir Parameters on Separation Behaviors of the Spiral Separator for Purifying Natural Gas Hydrate. Energies. 2020; 13(20):5346. https://doi.org/10.3390/en13205346

Chicago/Turabian StyleQiu, Shunzuo, and Guorong Wang. 2020. "Effects of Reservoir Parameters on Separation Behaviors of the Spiral Separator for Purifying Natural Gas Hydrate" Energies 13, no. 20: 5346. https://doi.org/10.3390/en13205346

APA StyleQiu, S., & Wang, G. (2020). Effects of Reservoir Parameters on Separation Behaviors of the Spiral Separator for Purifying Natural Gas Hydrate. Energies, 13(20), 5346. https://doi.org/10.3390/en13205346