Image Characteristic Extraction of Ice-Covered Outdoor Insulator for Monitoring Icing Degree

Abstract

1. Introduction

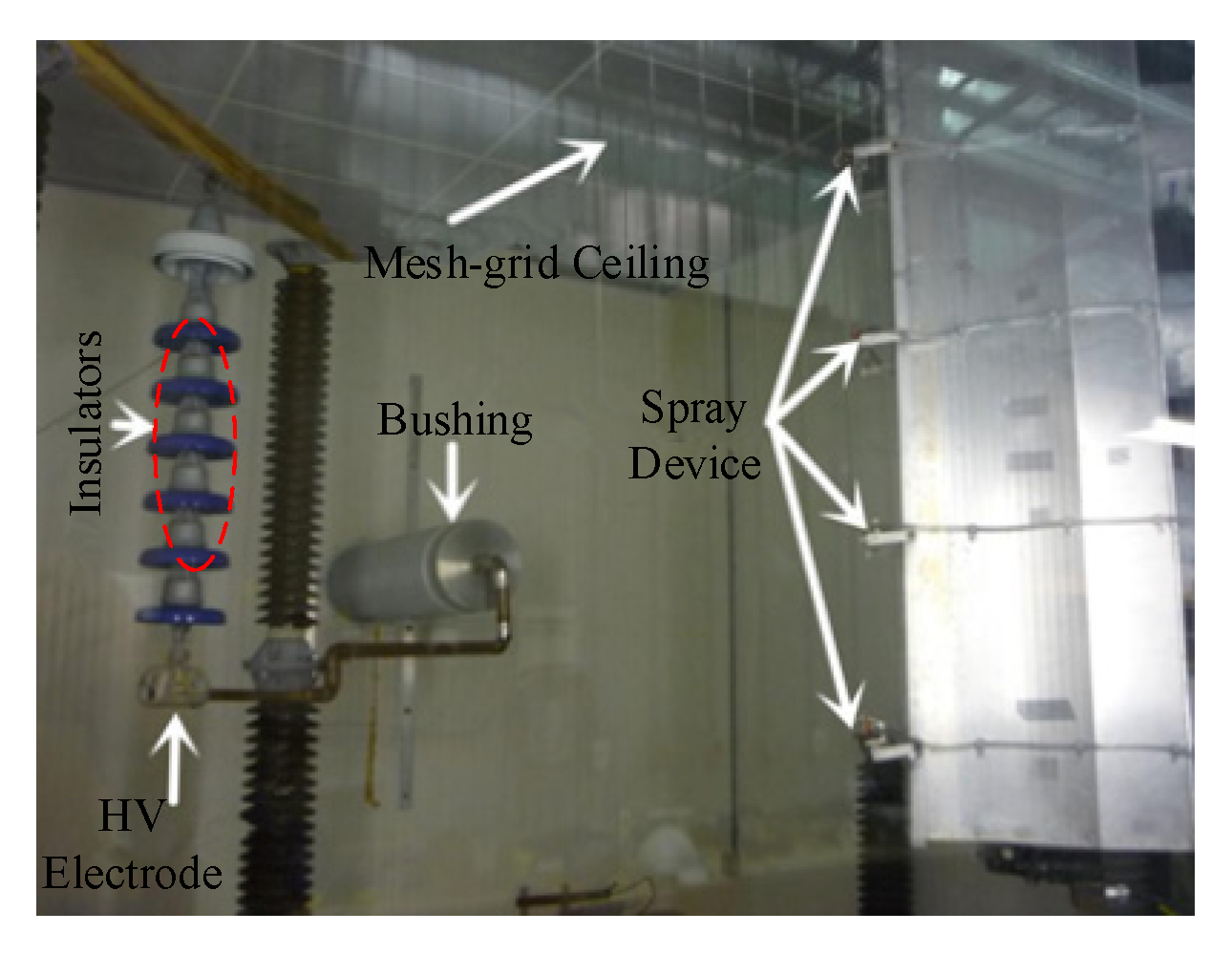

2. Test Setup and Procedures

3. Image Processing of Ice-Covered Insulator

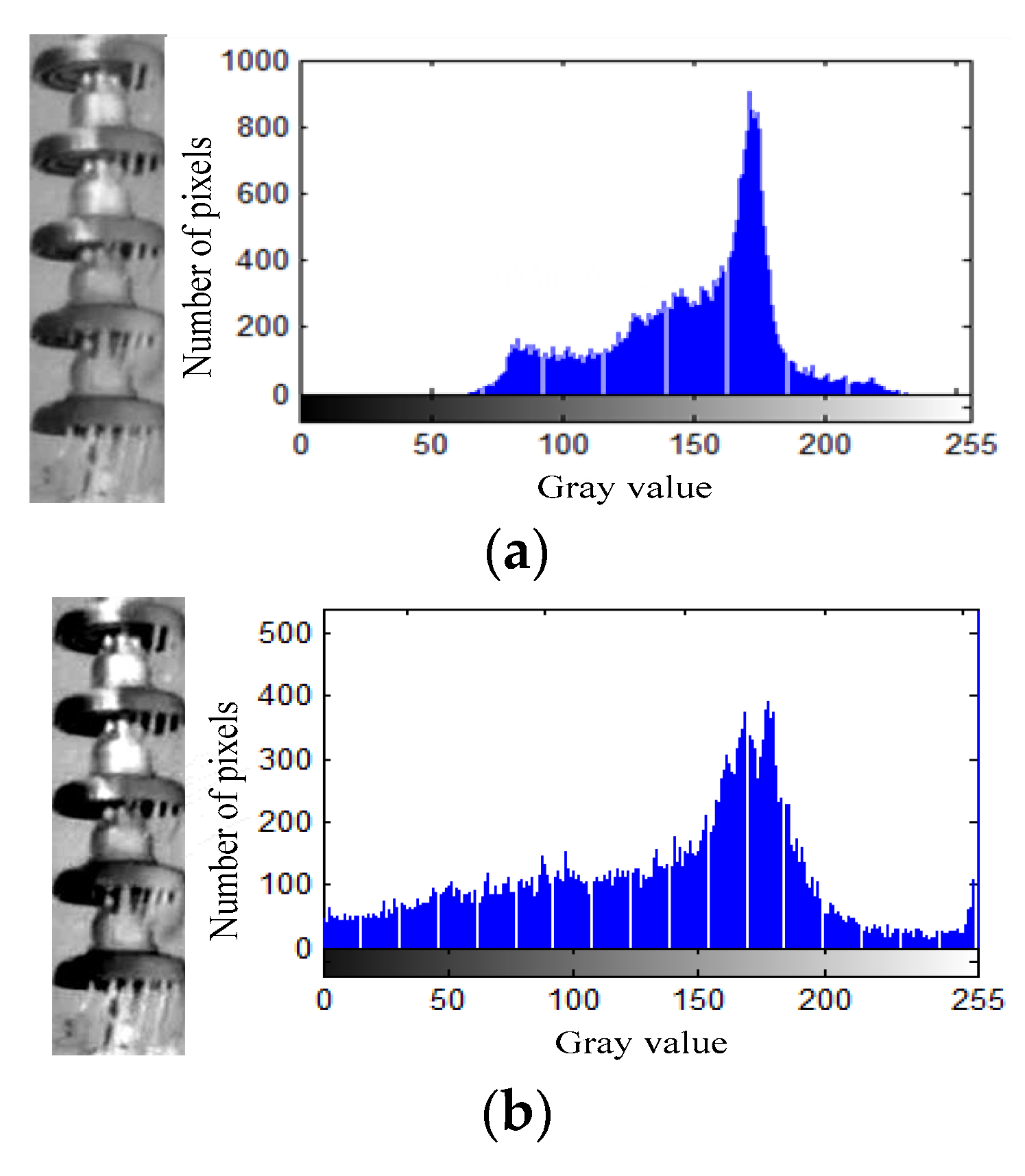

3.1. Enhancement of Image

- (1)

- Image grayscale

- (2)

- Gray Stretch

- (3)

- Image denoise

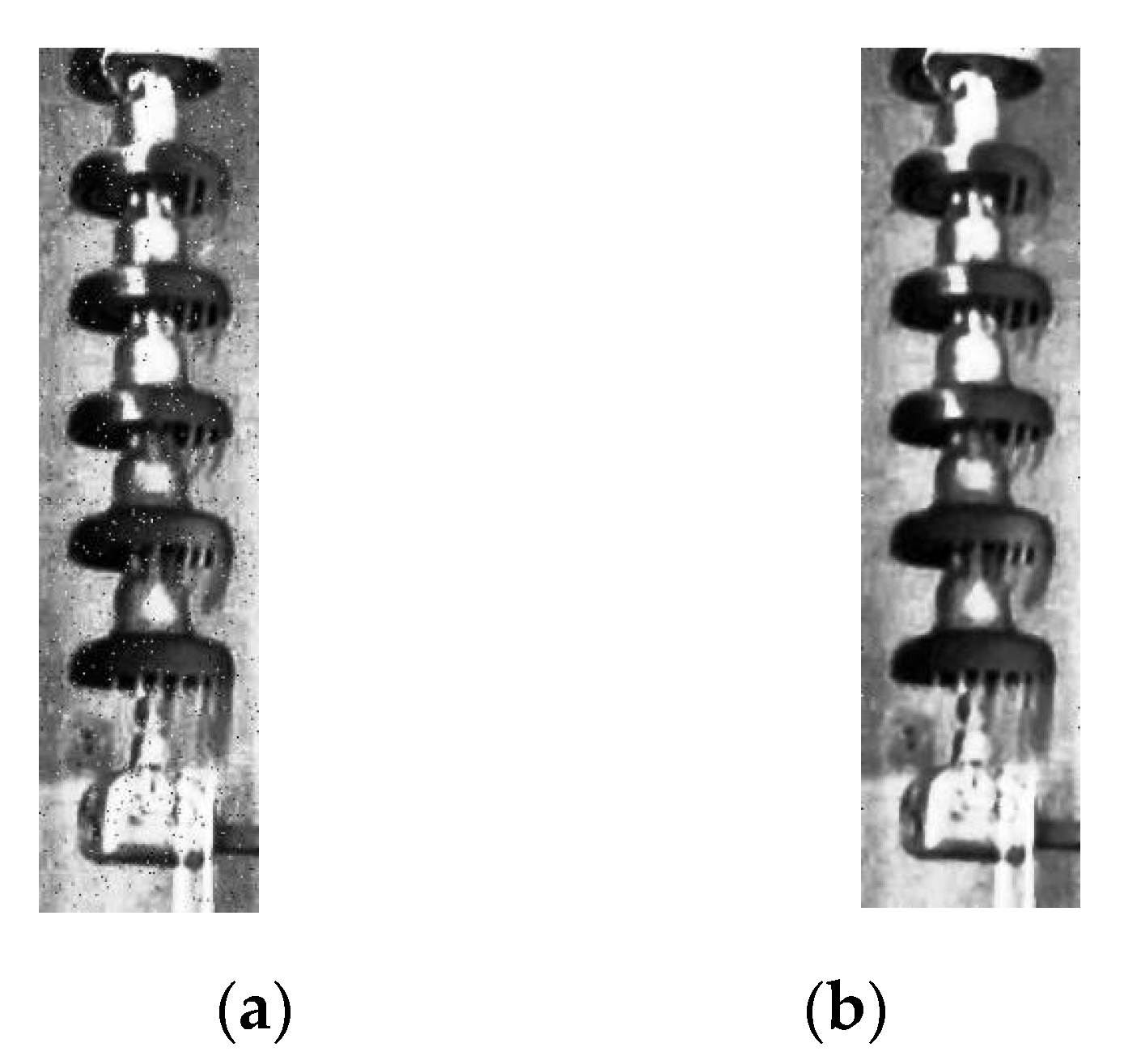

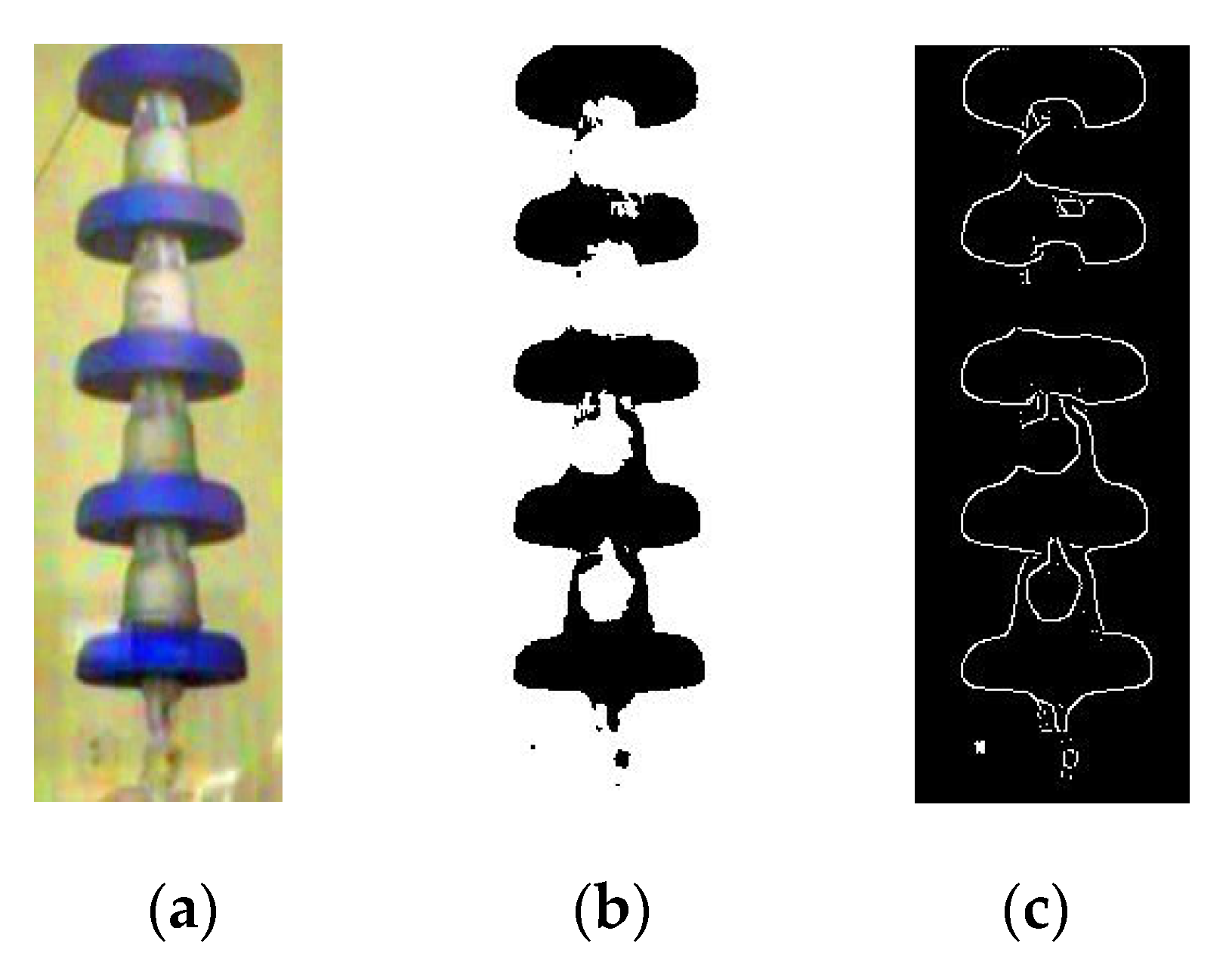

3.2. Image Segmentation

- (1)

- Maximum entropy threshold segmentation

- (2)

- Edge detection

- (3)

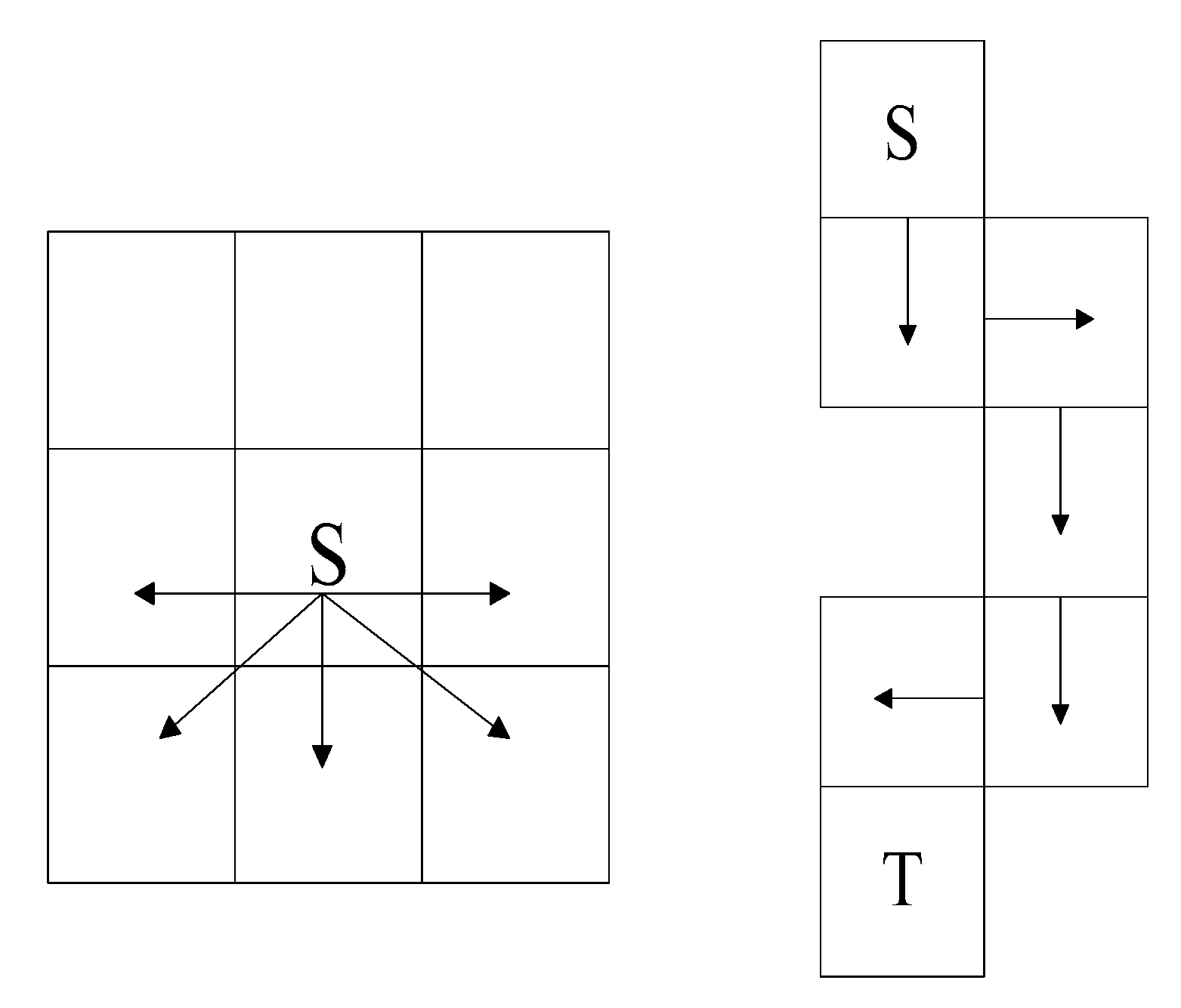

- Region growth method

4. Analyze the Results of Characteristic Extraction

5. Conclusions

- (1)

- Aiming at the problems of fuzzy background and noise interference of the iced insulator image, the direct equalization method, and median filter method are proposed to preprocess the image. The method can effectively reduce the noise and enhance the contrast of the image, which is of great significance for further processing the image of the iced insulator.

- (2)

- The maximum entropy threshold segmentation algorithm is used to extract the insulator and its surface ice from the image, and the key information is accurately screened out from the image. An improved Canny operator edge detection algorithm is used to track the edge of the non-icing insulator image and calculate the icing thickness of icing insulator image edge, which can accurately detect the insulator edge smoothly.

- (3)

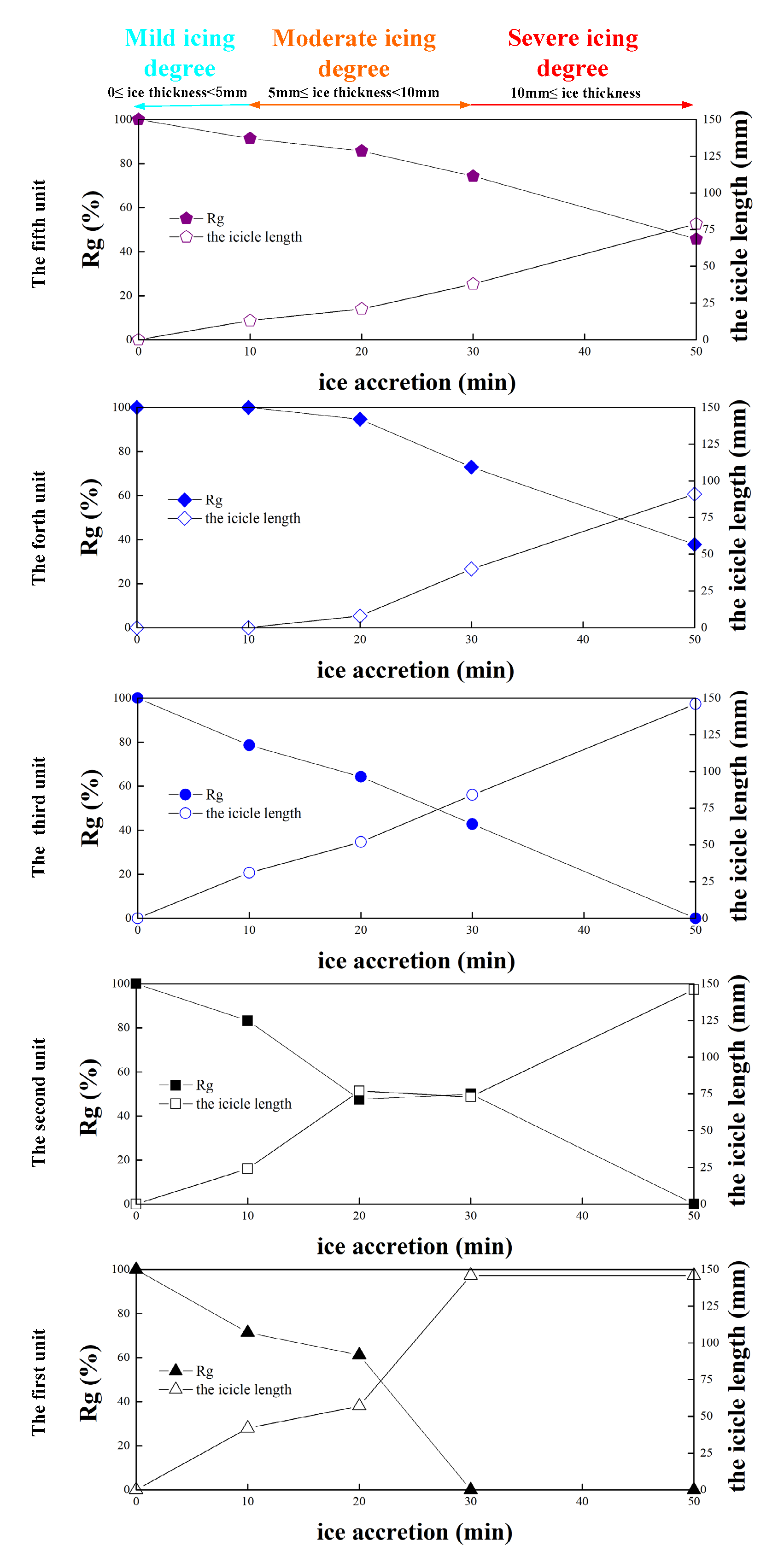

- A regional growing method is proposed to determine the location of icicles, so as to obtain the ice column and air gap in the image of the iced insulator, and then extract the icicle length and RG as the indication value to evaluate the ice bridge state of the insulator string. The analysis results show that once the total length of ice pole exceeds 402 mm and the RG value is lower than 44.9%, the higher the accident probability of iced insulator.

Author Contributions

Funding

Conflicts of Interest

References

- Farzaneh, M. Insulator Flashover Under Icing Conditions. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1997–2001. [Google Scholar] [CrossRef]

- Farzaneh, M. 50 Years in Icing Performance of Outdoor Insulators. IEEE Electr. Insul. 2014, 30, 14–24. [Google Scholar] [CrossRef]

- Jiang, X.; Meng, Z.; Zhang, Z.; Hu, J. DC Ice-Melting and Temperature Variation of Optical Fibre for Ice-Covered Overhead Ground Wire. IET Gener. Transm. Distrib. 2016, 10, 352–358. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B. Recurrent Plot Analysis of Leakage Current on Flashover Performance of Rime-Iced Composite Insulator. IEEE Trans. Dielectr. Electr. Insul. 2010, 7, 465–472. [Google Scholar] [CrossRef]

- Yang, H.; Pang, L.; Li, Z.; Zhang, Q.; Yang, X.; Tang, Q.; Zhou, J. Characterization of Pre-Flashover Behavior Based on Leakage Current Along Suspension Insulator Strings Covered with Ice. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 941–950. [Google Scholar] [CrossRef]

- Ale-Emran, S.; Farzaneh, M. Experimental Design of Booster Shed Parameters for Post Station Insulators Under Heavy Icing Conditions. IEEE Trans. Power Deliv.. 2015, 30, 488–496. [Google Scholar] [CrossRef]

- Shu, L.; Shang, Y.; Jiang, L.; Hu, Q.; Yuan, Q.; Hu, J.; Zhang, Z.; Zhang, S.; Li, T. Comparison Between AC and DC Flashover Performance and Discharge Process of Ice-Covered Insulators Under the Conditions of Low Air Pressure and Pollution. IET Gener. Transm. Distrib. 2012, 6, 884–892. [Google Scholar] [CrossRef]

- Taheri, S.; Farzaneh, M.; Fofana, I. Empirical Flashover Model of EHV Post Insulators Based on ISP Parameter in Cold Environments. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 403–409. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, S.; Shu, L.; Jiang, X.; Liang, J.; Qiu, G. Comparison of AC Icing Flashover Performances of 220 Kv Composite Insulators With Different Shed Configurations. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 995–1004. [Google Scholar] [CrossRef]

- Farzaneh, M.; Drapeau, J. AC Flashover Performance of Insulators Covered With Artificial Ice. IEEE Trans. Power Deliv. 1995, 10, 1038–1051. [Google Scholar] [CrossRef]

- Yan, B.; Wang, B.; Zhu, L.; Liu, H.; Liu, Y.; Ji, X.; Liu, D. A Novel, Stable, And Economic Power Sharing Scheme for an Autonomous Microgrid in the Energy Internet. Energies 2015, 8, 12741–12764. [Google Scholar] [CrossRef]

- Phan, C.; Hara, M. Leakage Current and Flashover Performance of Iced Insulators. IEEE Trans. Power Appl. Syst. 1979, 98, 849–859. [Google Scholar] [CrossRef]

- Hong, Y.Y.; Wei, Y.H.; Chang, Y.R.; Lee, Y.D.; Liu, P.W. Fault Detection and Location by Static Switches in Microgrids Using Wavelet Transform and Adaptive Network-Based Fuzzy Inference System. Energies 2014, 7, 2658–2675. [Google Scholar] [CrossRef]

- Meghnefi, F.; Volat, C.; Farzaneh, M. Temporal and Frequency Analysis of the Leakage Current of a Station Post Insulator during Ice Accretion. IEEE Trans. Dielectr. Electrl. Insul. 2007, 14, 1381–1389. [Google Scholar] [CrossRef]

- Volat, C.; Meghnefi, F.; Farzaneh, M.; Ezzaidi, H. Monitoring Leakage Current of Ice-Covered Station Post Insulator using Artificial Neural Networks. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 43–450. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, P. Icing Flashover Characteristics and Discharge Process of 500 kV AC Transmission Line Suspension Insulator Strings. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 434–442. [Google Scholar] [CrossRef]

- Liu, Y.; Farzaneh, M.; Du, B. Investigation on Shed Icicle Characteristics and Induced Surface Discharges Along a Suspension Insulator String During Ice Accretion. IET Gener. Transm. Distrib. 2017, 11, 1265–1269. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Farzaneh, M.; Du, B. Image Characteristic Extraction of Surface Phenomena for Flashover Monitoring of Ice-Covered Outdoor Insulator. In Proceedings of the International Conference on Electrical Materials and Power Equipment, Guangzhou, China, 7–10 April 2019; pp. 431–434. [Google Scholar]

- Hao, Y.; Wei, J.; Jiang, X. Icing Condition Assessment of in-Service Glass Insulators Based on Graphical Shed Spacing and Graphical Shed Overhang. Energies 2018, 11, 318. [Google Scholar] [CrossRef]

- Wei, J.; Hao, Y.; Fu, Y. Detection of Glaze Icing Load and Temperature of Composite Insulators Using Fiber Bragg Grating. Sensors 2019, 19, 1321. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Jiang, X.; Hao, Y. Recognition of Natural Ice Types on in-Service Glass Insulators Based on Texture Feature Descriptor. IEEE Trans. Dielect. Elect. Insul. 2017, 24, 535–542. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, C.; Huang, X.; Zhang, X. Research on Image Recognition Method of Icicle Length and Bridge State on Power Insulators. Access 2019, 7, 183524–183531. [Google Scholar] [CrossRef]

- Pernebayeva, D.; James, A.; Bagheri, M. Live line snow and ice coverage detection of ceramic insulator using Gabor image features. In Proceedings of the IET International Conference on Resilience of Transmission and Distribution Networks, Birmingham, UK, 26–28 September 2017; pp. 1884–2021. [Google Scholar]

- Vita, V.; Ekonomou, L.; Chatzarakis, G.E. Design of artificial neural network models for the estimation of distribution system voltage insulators’ contamination. In Proceedings of the Wseas International Conference on Mathematical Methods. World Scientific and Engineering Academy and Society (WSEAS), Sousse, Tunisia, 3–6 May 2010; pp. 3–6. [Google Scholar]

- Chen, Y.; Liu, H. Study on the meso-structure image of shale based on the digital image processing technique. In Proceedings of the 2009 International Conference on Image Analysis and Signal Processing, Taizhou, China, 11–12 April 2009; pp. 150–153. [Google Scholar] [CrossRef]

- Gilboa, G.; Sochen, N.; Zeevi, Y.Y. Image Enhancement and Denoising by Complex Diffusion Processes. IEEE Trans. Patt. Anal. Mach. Intel. 2004, 26, 1020–1036. [Google Scholar] [CrossRef] [PubMed]

- IEEE. Standard 1783/2009TM, Guide for Test Methods and Procedures to Evaluate the Electrical Performance of Insulators In Freezing Conditions; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar]

- Farzaneh, M.; Zhang, J.; Chen, X. Modeling of the AC Arc Discharge on Ice Surfaces. IEEE Trans. Power Deliv. 1997, 12, 325–338. [Google Scholar] [CrossRef]

- Farzaneh, M.; Baker, T.; Bernstorf, A.; Brown, K. Insulator Icing Test Methods and Procedures: A Position Paper prepared by the IEEE Task Force on Insulator Icing Test Methods. IEEE Trans. Power Deliv. 2003, 18, 1503–1515. [Google Scholar] [CrossRef]

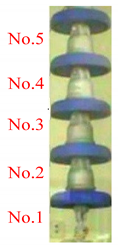

| Main Dimension and Parameters | Configuration |

|---|---|

| Diameter = 254 mm |  |

| Height = 146 mm | |

| Leakage distance = 305 mm | |

| Number of units = 5 units | |

| Arcing distance for 5 units = 809 mm |

| Image of Ice-Covered Insulators |      | |||||

|---|---|---|---|---|---|---|

| Ice accretion time (min) | 0 | 10 | 20 | 30 | 50 | |

| Ice thickness (mm) | 0 | 3 | 7 | 24 | 88 | |

| NO.5 | Icicle length (mm) | 0 | 13 | 21 | 38 | 79 |

| Rg(%) | 100 | 91.4 | 85.7 | 74.3 | 45.7 | |

| NO.4 | Icicle length (mm) | 0 | 0 | 8 | 40 | 91 |

| Rg(%) | 100 | 100 | 94.6 | 72.9 | 37.8 | |

| NO.3 | Icicle length (mm) | 0 | 31 | 52 | 84 | 146 |

| Rg(%) | 100 | 78.6 | 64.3 | 42.8 | 0 | |

| NO.2 | Icicle length (mm) | 0 | 24 | 77 | 73 | 146 |

| Rg(%) | 100 | 83.3 | 47.6 | 50 | 0 | |

| NO.2 | Icicle length (mm) | 0 | 42 | 57 | 146 | 146 |

| Rg(%) | 100 | 71.4 | 61.2 | 0 | 0 | |

| NO.1 | Icicle length (mm) | 0 | 142 | 211 | 402 | 624 |

| Rg(%) | 100 | 80.5 | 71.2 | 44.9 | 14.6 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Li, Q.; Farzaneh, M.; Du, B.X. Image Characteristic Extraction of Ice-Covered Outdoor Insulator for Monitoring Icing Degree. Energies 2020, 13, 5305. https://doi.org/10.3390/en13205305

Liu Y, Li Q, Farzaneh M, Du BX. Image Characteristic Extraction of Ice-Covered Outdoor Insulator for Monitoring Icing Degree. Energies. 2020; 13(20):5305. https://doi.org/10.3390/en13205305

Chicago/Turabian StyleLiu, Yong, Qiran Li, Masoud Farzaneh, and B. X. Du. 2020. "Image Characteristic Extraction of Ice-Covered Outdoor Insulator for Monitoring Icing Degree" Energies 13, no. 20: 5305. https://doi.org/10.3390/en13205305

APA StyleLiu, Y., Li, Q., Farzaneh, M., & Du, B. X. (2020). Image Characteristic Extraction of Ice-Covered Outdoor Insulator for Monitoring Icing Degree. Energies, 13(20), 5305. https://doi.org/10.3390/en13205305