Effect of Insulation on the Energy Demand of a Standardized Container Facility at Airports in Spain under Different Weather Conditions

Abstract

1. Introduction

- Portability: They are designed to facilitate their mobility and transportation.

- Adaptability: Their weight and load capacity characteristics make them adaptable, with a small base, to any terrain; they also show high structural performance as they allow vertical stacking of other modules.

- Robustness and greater durability: These containers were built to withstand the marine environment and the shocks and movements that occur during maritime transport.

- Effective use of space: The 20 TEU (twenty-foot equivalent unit) container can accommodate approximately 33 m3 in only 15 m2; the 40 FEU (forty-foot equivalent unit) accommodates up to 67 m3 in less than 30 m2.

- Modularity: Due to their design, they are easily stackable. Therefore, with small modifications or adaptations it is an excellent solution for modular architecture, being able to form in-line constructions or increase height by stacking modules. Each container can be, for instance, a room in a house.

- Configurable: They can be configured according to customer needs.

- Cost-effectiveness: The estimated 300 million disused containers in the world could be reused. This means a reduction in overall installation and configuration time, as well as lower costs than a traditional concrete structure. In addition, they could be factory-rebuilt and conditioned and then taken to their destination, further reducing overall cost.

- Recyclability: The reuse of containers is beneficial to the environment as it drastically reduces manufacturing materials, with significant savings in energy and CO2 emissions into the atmosphere. Virtually maintenance free, shipping containers are initially designed to last for many years. They are manufactured with a layer of insulation which, if properly treated, can be totally suitable for use in a home, saving energy in heating and/or cooling [5].

- Expanded polystyrene (EPS): This material derives from polystyrene; it is very versatile and easy to shape. It is widely used in the building sector as it offers great thermal resistance without the need for high thickness.

- Extruded polystyrene (XPS): It is a material with high mechanical performance and very similar properties to those of EPS. The main difference between these two is the ability to be wetted, as it does not rot. Waterproofing is the most characteristic feature of this material, since it facilitates access to the reparation of the constructions. Due to its high density, it is manufactured in very thin plates that allow optimizing the occupied volume.

- Mineral wools, both rock (SW) and glass (GW), are composed of inorganic stone materials that intertwine their filaments to create a very lightweight compound that, in turn, offers great protection and insulation. Due to this stony composition, these materials have a low degree of combustion, which is why they are becoming the great substitute for PUR. In addition to their thermal protection capacity, they also provide acoustic protection, a combination that has made them the most widely used materials nowadays.

2. Methodology

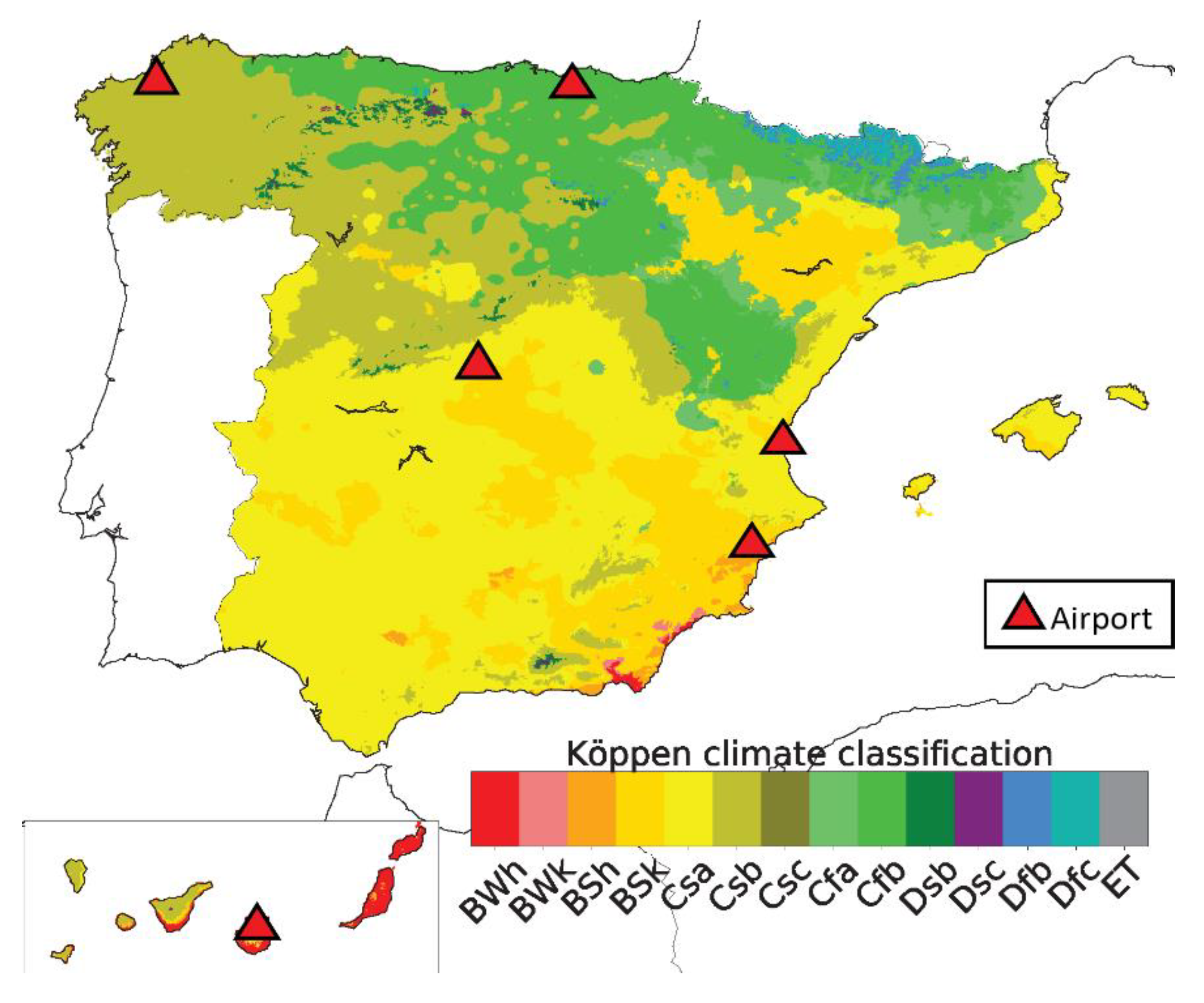

2.1. Locations and Climatic Zones

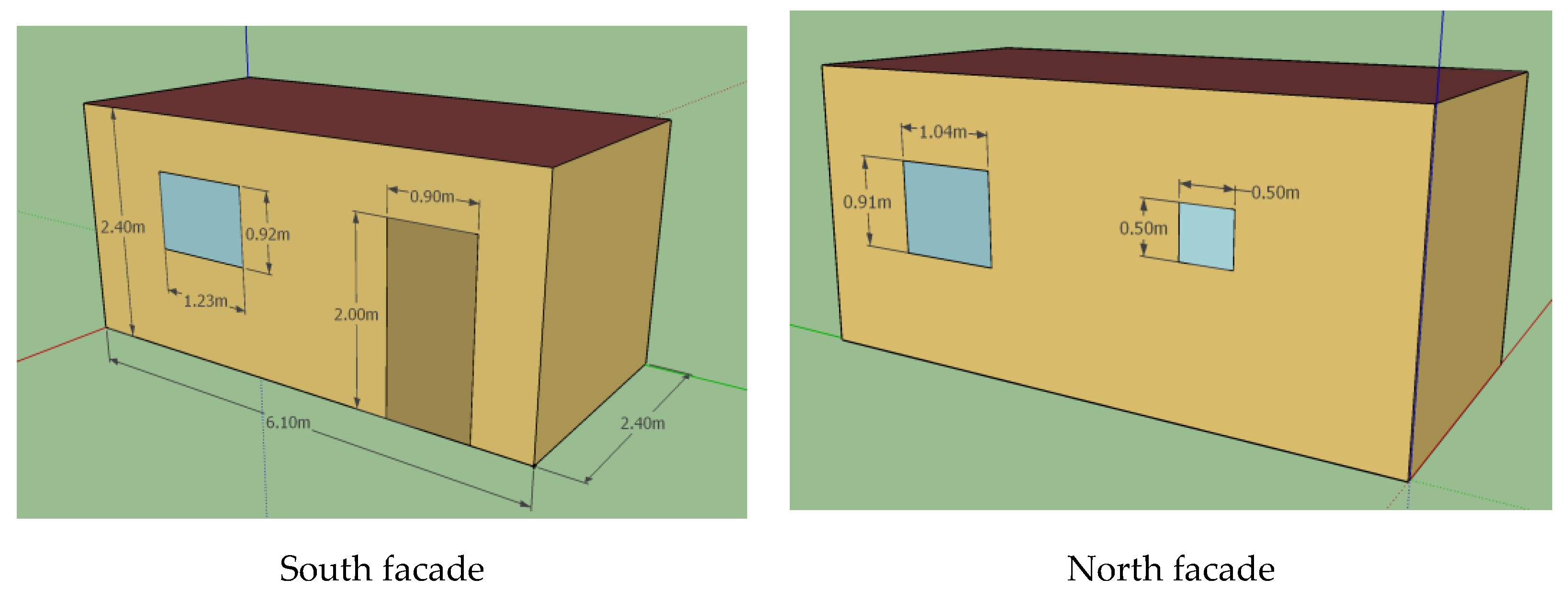

2.2. Building Model

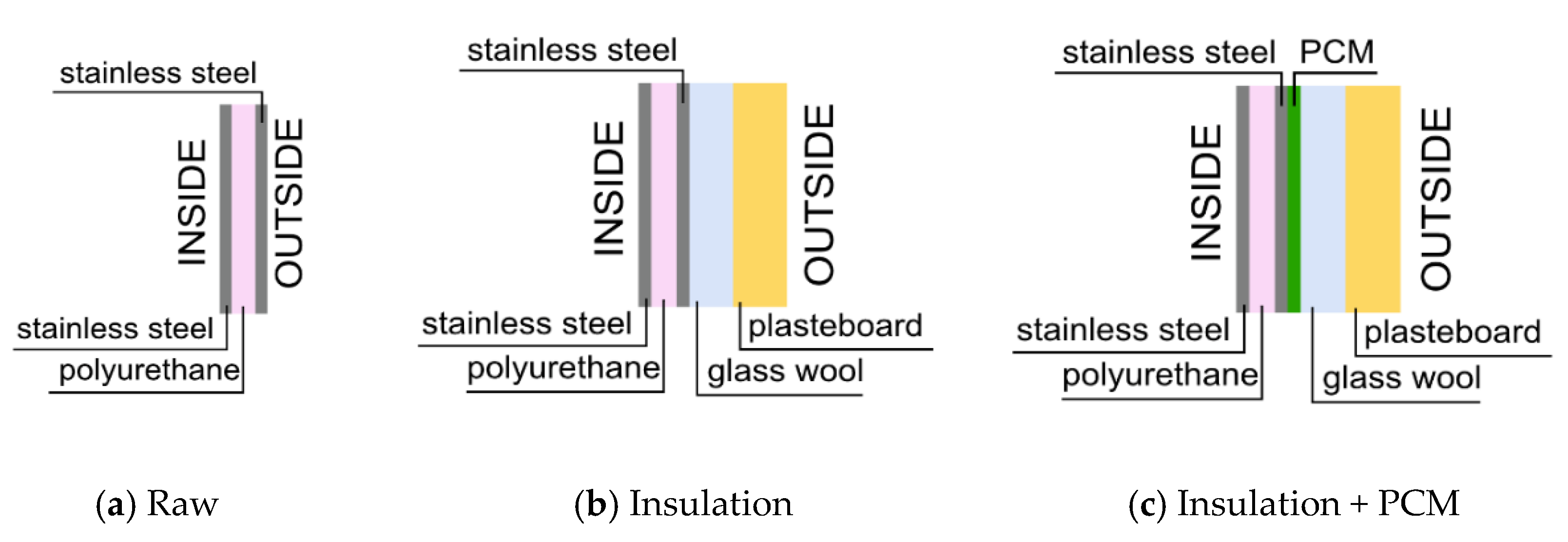

2.3. EnergyPlus Building Simulation

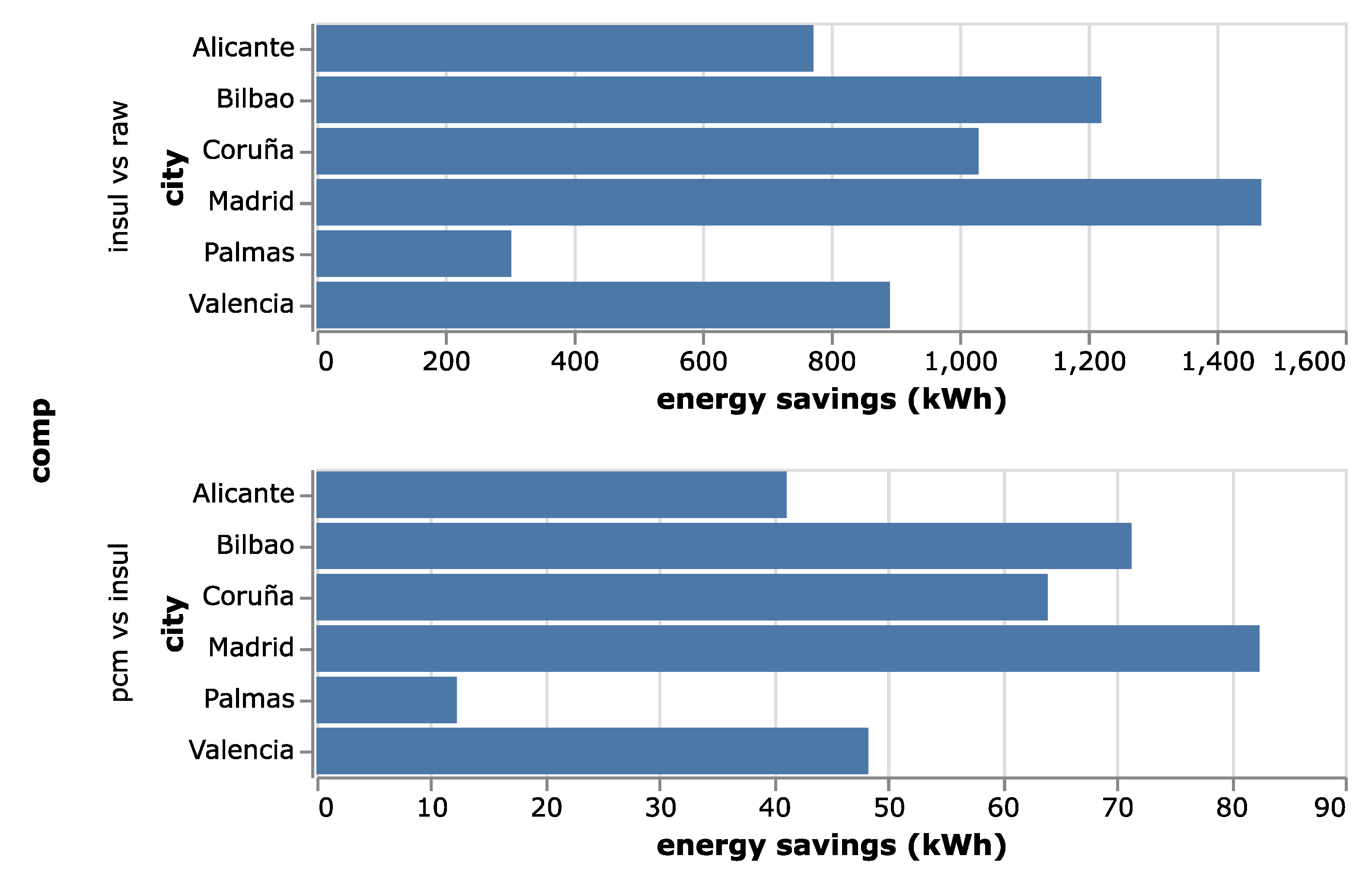

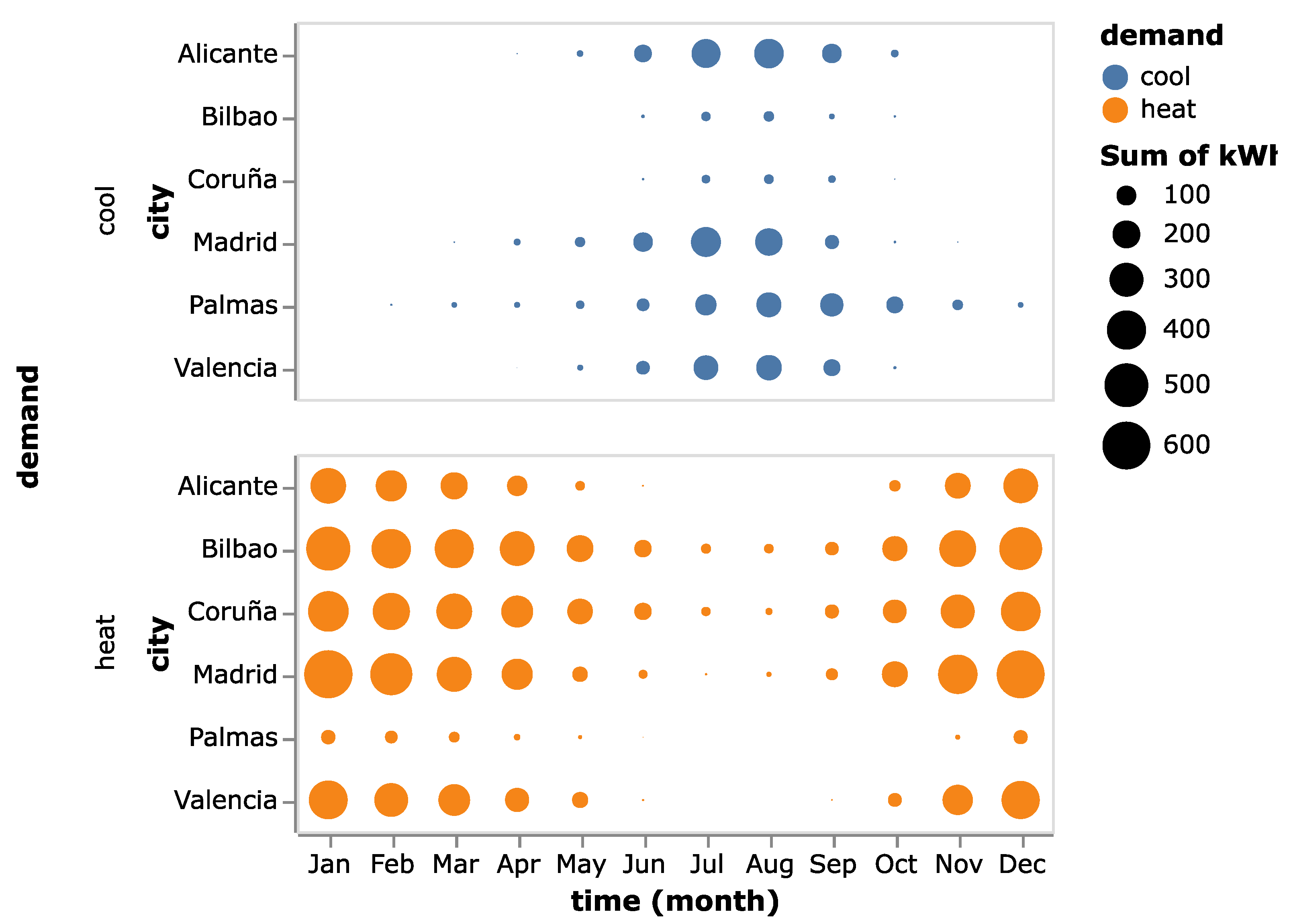

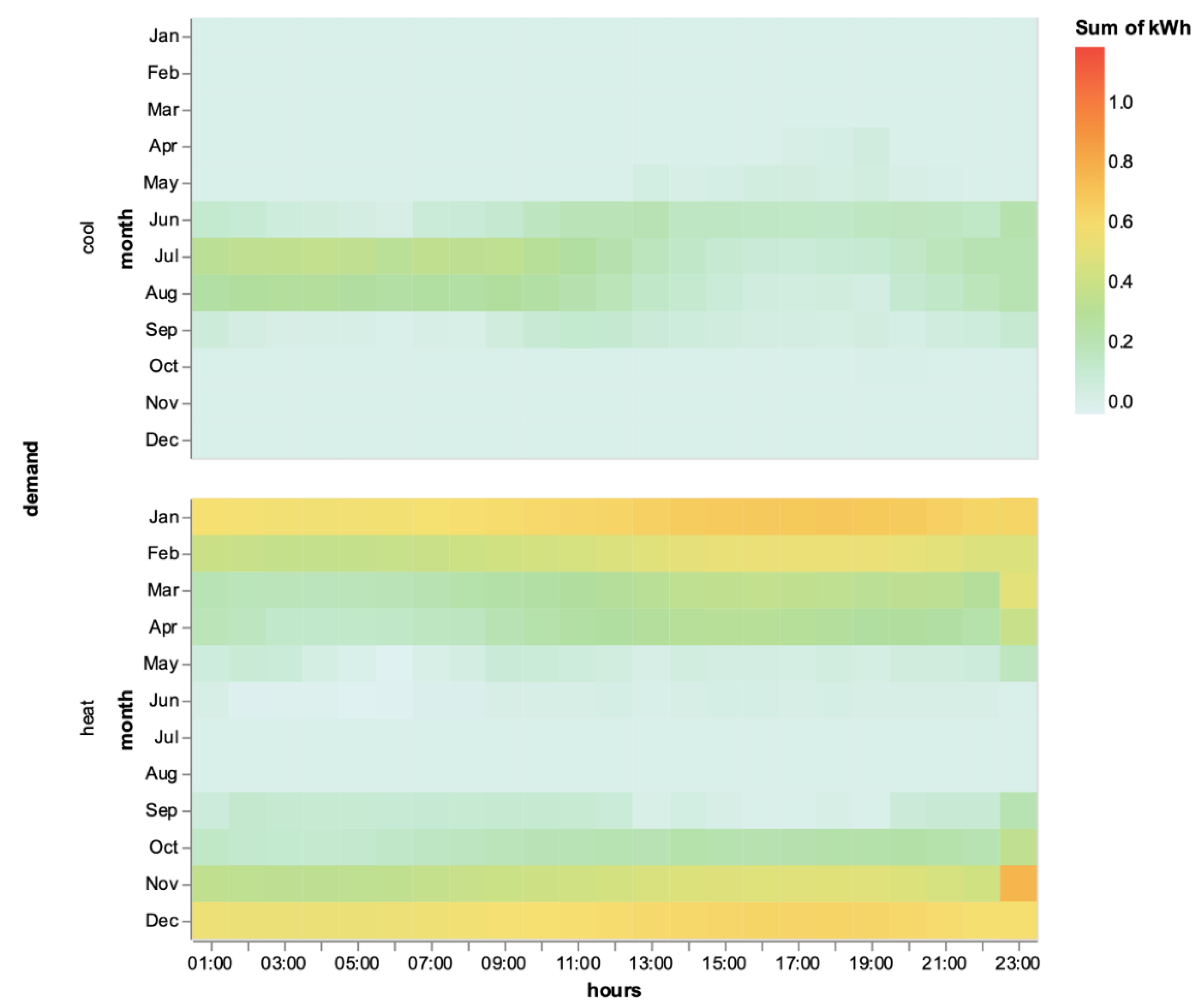

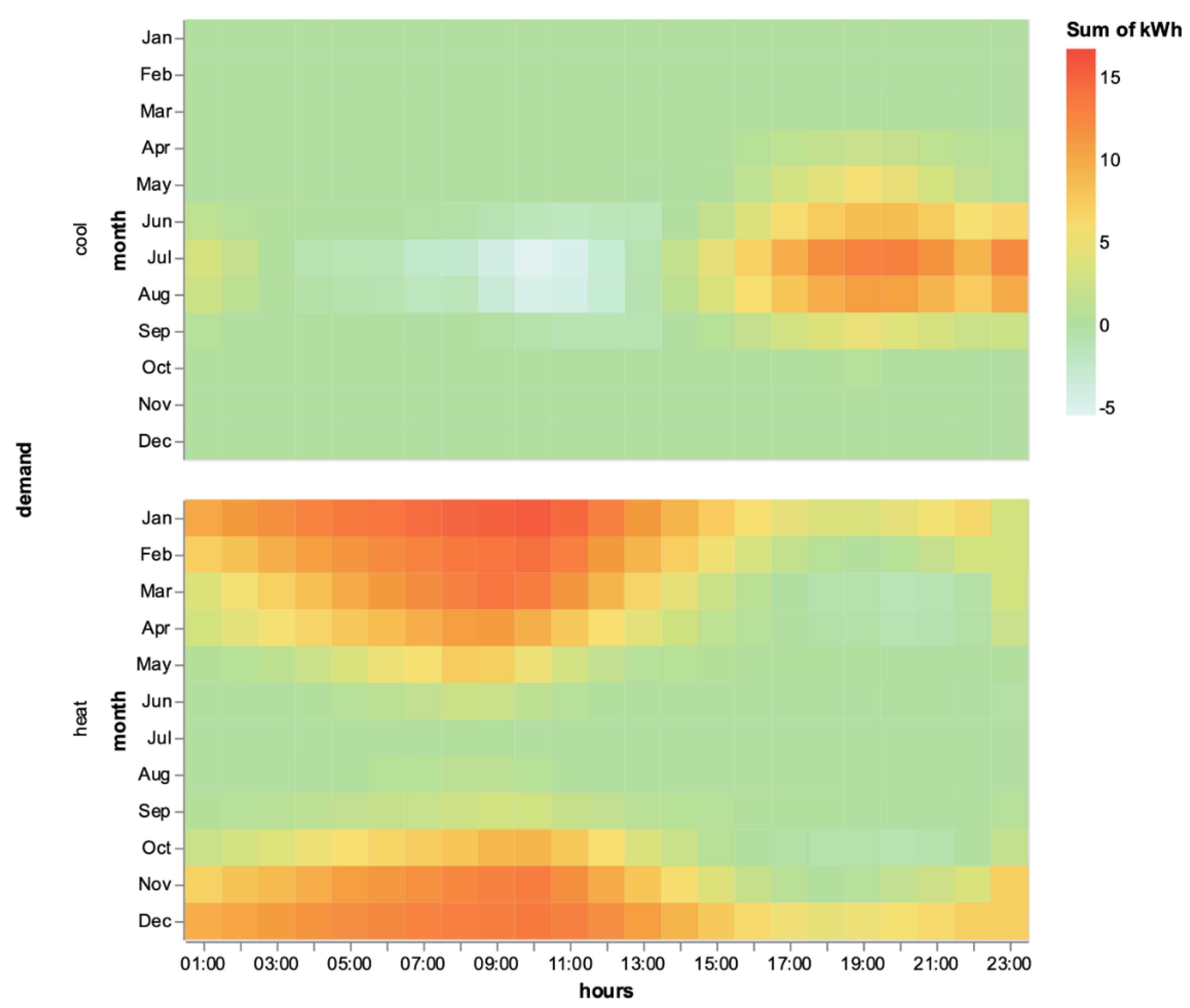

3. Results

Analysis on Temperature inside the Container

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Edwards, B. The Modern Airport Terminal-New Approaches to Airport Architecture, 2nd ed.; Taylor & Francis: New York, NY, USA, 2005; ISBN 10: 0415248124. [Google Scholar]

- Various Applications of Shipping Container Architecture from Around the Globe. Available online: https://www.arch2o.com/applications-shipping-container-architecture (accessed on 20 July 2020).

- Ulloa, C.; Arce, M.E.; Rey, G.; Míguez, J.L.; Hernández, J. Recycling COR-TEN® Sea Containers into Service Modules for Military Applications: Thermal Analysis. Energies 2017, 10, 820. [Google Scholar] [CrossRef]

- Bertolini, M.; Guardigli, L. Upcycling shipping containers as building components: An environmental impact assessment. Int. J. Life Cycle Assess. 2020, 25, 947–963. [Google Scholar] [CrossRef]

- Ventajas de Los Contenedores Marítimos Reciclados. Available online: https://www.concienciaeco.com/2015/01/09/10-ventajas-de-los-contenedores-maritimos-reciclados (accessed on 21 July 2020).

- Kotopouleas, A.; Nikolopoulou, M. Thermal comfort conditions in airport terminals: Indoor or transition spaces? Build. Environ. 2016, 99, 184–199. [Google Scholar] [CrossRef]

- Tokbolat, S.; Nazipov, F.; Kim, J.R.; Karaca, F. Evaluation of the environmental performance of residential building envelope components. Energies 2020, 13, 174. [Google Scholar] [CrossRef]

- 5TRB’s Airport Cooperative Research Program (ACRP) Synthesis 21. In Airport Energy Efficiency and Cost Reduction: A Synthesis of Airport Practice; Transportation Research Board: Washington, DC, USA, 2010. [CrossRef]

- Piselli, C.; Romanelli, J.; Di Grazia, M.; Gavagni, A.; Moretti, E.; Nicolini, A.; Cotana, F.; Strangis, F.; Witte, H.J.L.; Pisello, A.L. An Integrated HBIM Simulation Approach for Energy Retrofit of Historical Buildings Implemented in a Case Study of a Medieval Fortress in Italy. Energies 2020, 13, 2601. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A.N.; Cardona, F. Energy saving in airports by trigeneration. Part I: Assessing economic and technical potential. Appl. Therm. Eng. 2006, 26, 1427–1436. [Google Scholar] [CrossRef]

- Kosmela, P.; Hejna, A.; Suchorzewski, J.; Piszczyk, L.; Haponiuk, J.T. Study on the Structure-Property Dependences of Rigid PUR-PIR Foams Obtained from Marine Biomass-Based Biopolyol. Materials 2020, 13, 1257. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A. Experimental study on the performance of insulation materials in Mediterranean construction. Energy Build. 2010, 42, 630–636. [Google Scholar] [CrossRef]

- Ricciu, R.; Besalduch, L.A.; Galatioto, A.; Ciulla, G. Thermal characterization of insulating materials. Renew. Sustain. Energy Rev. 2018, 82, 1765–1773. [Google Scholar] [CrossRef]

- Lakatos, A. Comparison of the Thermal Properties of Different Insulating Materials. Adv. Mater. Res. 2014, 899, 381–386. [Google Scholar] [CrossRef]

- Çengel, Y.A. Heat Transfer, a Practical Approach, 2nd ed.; McGraw-Hill: New York, NY, USA, 1998; ISBN 0-07-011505-2. [Google Scholar]

- European Insulation Manufacturers Association. Available online: https://www.eurima.org/ (accessed on 21 July 2020).

- Bhattacharyya, R.K. Heat transfer model for fibrous insulations. In Thermal Insulation Performance; McElroy, D.L., Tye, R., Eds.; ASTM STP 718; American Society for Testing and Materials: Tampa, FL, USA, 1980; pp. 272–286. [Google Scholar]

- Leang, E.; Tittelein, P.; Zalewski, L.; Lassue, S. Impact of a composite trombe wall incorporating phase change materials on the thermal behavior of an individual house with low energy consumption. Energies 2020, 13, 4872. [Google Scholar] [CrossRef]

- Veiseh, S.; Hakkaki-Fard, A.; Kowsary, F. Determination of the air/fiber conductivity of mineral wool insulations in building applications using nonlinear estimation methods. J. Build. Phys. 2009, 32, 243–260. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R.; Seeniraj, R.V. Phase change material-based building architecture for thermal management in residential and commercial establishments. Renew. Sustain. Energy Rev. 2008, 12, 39–64. [Google Scholar] [CrossRef]

- Al-Saadi, S.N.; Zhai, Z. Modeling phase change materials embedded in building enclosure: A review. Renew. Sustain. Energy Rev. 2013, 21, 659–673. [Google Scholar] [CrossRef]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Jafari, M. Phase change materials (PCM) for solar energy usages and storage: An overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Baek, S.; Kim, S. Analysis of thermal performance and energy saving potential by PCM radiant floor heating system based on wet construction method and hot water. Energies 2019, 12, 828. [Google Scholar] [CrossRef]

- Adeli, M.M.; Farahat, S.; Sarhaddi, F. Increasing thermal comfort of a net-zero energy building inhabitant by optimization of energy consumption. Int. J. Environ. Sci. Technol. 2019, 17, 2819–2834. [Google Scholar] [CrossRef]

- Yun, B.Y.; Park, J.H.; Yang, S.; Wi, S.; Kim, S. Integrated analysis of the energy and economic efficiency of PCM as an indoor decoration element: Application to an apartment building. Sol. Energy 2020, 196, 437–447. [Google Scholar] [CrossRef]

- Kośny, J.; Fallahi, A.; Shukla, N.; Kossecka, E.; Ahbari, R. Thermal load mitigation and passive cooling in residential attics containing PCM-enhanced insulations. Sol. Energy 2014, 108, 164–177. [Google Scholar] [CrossRef]

- Lee, K.O.; Medina, M.A.; Raith, E.; Sun, X. Assessing the integration of a thin phase change material (PCM) layer in a residential building wall for heat transfer reduction and management. Appl. Energy 2015, 137, 699–706. [Google Scholar] [CrossRef]

- Wang, H.; Lu, W.; Wu, Z.; Zhang, G. Parametric analysis of applying PCM wallboards for energy saving in high-rise lightweight buildings in Shanghai. Renew. Energy 2020, 145, 52–64. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Kurz, D.; Mikulski, S.; Wodnicki, G. Analysis of the Impact of Building Integrated Photovoltaics (BIPV) on Reducing the Demand for Electricity and Heat in Buildings Located in Poland. Energies 2020, 13, 2549. [Google Scholar] [CrossRef]

- Wijesuriya, S.; Brandt, M.; Tabares-Velasco, C. Parametric analysis of a residential building with phase change material (PCM)-enhanced drywall, precooling, and variable electric rates in a hot and dry climate. Appl. Energy 2018, 222, 497–514. [Google Scholar] [CrossRef]

- Kong, X.; Wang, L.; Li, H.; Yuan, G.; Yao, C. Experimental study on a novel hybrid system of active composite PCM wall and solar thermal system for clean heating supply in winter. Sol. Energy 2020, 195, 259–270. [Google Scholar] [CrossRef]

- Sang, Y.; Zhao, J.R.; Sun, J.; Chen, B.; Liu, S. Experimental investigation and EnergyPlus-based model prediction of thermal behavior of building containing phase change material. J. Build. Eng. 2017, 12, 259–266. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. Numerical analysis for the optimal location of a thin PCM layer in frame walls. Appl. Therm. Eng. 2016, 103, 1057–1063. [Google Scholar] [CrossRef]

- Arıcı, M.; Bilgin, F.; Nižetić, S.; Karabay, H. PCM integrated to external building walls: An optimization study on maximum activation of latent heat. Appl. Therm. Eng. 2020, 165, 114560. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.; Cui, H.; Yang, L.; Liu, J. Micro-/macro-level optimization of phase change material panel in building envelope. Energy 2020, 195, 116932. [Google Scholar] [CrossRef]

- Khan, R.J.; Bhuiyan, M.Z.H.; Ahmed, D.H. Investigation of heat transfer of a building wall in the presence of phase change material (PCM). Energy Built Environ. 2020, 1, 199–206. [Google Scholar] [CrossRef]

- Prabhakar, M.; Saffari, M.; De Gracia, A.; Cabeza, L.F. Improving the energy efficiency of passive PCM system using controlled natural ventilation. Energy Build. 2020, 110483. [Google Scholar] [CrossRef]

- Bendic, V.; Dobrotă, D. Theoretical and experimental contributions on the use of smart composite materials in the construction of civil buildings with low energy consumption. Energies 2018, 11, 2310. [Google Scholar] [CrossRef]

- Dombaycı, Ö.A. Degree-days maps of Turkey for various base temperatures. Energy 2009, 34, 1807–1812. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; de Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M.; Booten, C. Verification and Validation of EnergyPlus Conduction Finite Difference and Phase Change Material Models for Opaque Wall Assemblies. US Dep. Energy Off. Sci. 2012, 55. [Google Scholar] [CrossRef][Green Version]

- New Thermal Mass Solution for Low Inertia Buildings. Available online: http://www.edsl.myzen.co.uk/downloads/misc/DuPont%20ENERGAIN(r)%20PCM%20Guidebook_December%202010.pdf (accessed on 29 August 2020).

- Energy Plus. U.S. Department of Energy. Available online: https://energyplus.net/documentation (accessed on 30 August 2020).

- De Gracia, A. Dynamic building envelope with PCM for cooling purposes–Proof of concept. Appl. Energy 2019, 235, 1245–1253. [Google Scholar] [CrossRef]

- Kośny, J.; Yarbrough, D.W. Use of PCM enhanced insulation in the building envelope. J. Build. Enclos. Design. 2008, 5, 55–59. [Google Scholar]

- Kośny, J. An Application of Phase Change by Finite Element and Materials in Building Envelopes and Internal Structures. In PCM-Enhanced Building Components; Springer International Publishing: Basel, Switzerland, 2015. [Google Scholar] [CrossRef]

- Shrestha, S.; Miller, W.; Stovall, T.; Desjarlais, A.; Childs, K. Modeling PCM-enhanced insulation system and benchmarking EnergyPlus against controlled field data. In Proceedings of the Building Simulation, Sydney, Australia, 14–16 November 2011; pp. 800–807. [Google Scholar]

- Ministry for Ecological Transition and Demographic Challenge; Institute for Energy Diversification and Saving (IDAE). Energy Guide: Efficient and Responsible Consumption. Available online: http://guiaenergia.idae.es/ (accessed on 5 September 2020).

| Location | Latitude | Longitude | Elevation (m) | Köppen Climate | HDD18 (°C·Days/Year) | CDD18 (°C·Days/Year) |

|---|---|---|---|---|---|---|

| Alicante | 38.28 | −0.56 | 43 | BSh | 841 | 1120 |

| Bilbao | 43.30 | −2.93 | 42 | Cfb | 1505 | 467 |

| La Coruña | 43.30 | −8.38 | 100 | Csb | 1683 | 240 |

| Las Palmas | 27.94 | −15.39 | 23 | BWh | 81 | 1258 |

| Madrid | 40.49 | −3.59 | 610 | Csa | 1932 | 1078 |

| Valencia | 39.49 | −0.48 | 73 | BSk | 1028 | 1142 |

| Thickness | 0.0053 (m) |

|---|---|

| Thermal conductivity: | |

| Solid (T < 21.7 °C) | 0.018 (W/m·K) |

| Liquid (T > 21.7 °C) | 0.014 (W/m·K) |

| Density | 855 (kg/m3) |

| Specific heat | 2500 (J/kg·K) |

| Category | Materials | |||

|---|---|---|---|---|

| Element | Conductivity (W/m·K) | Specific Heat (J/kg·K) | Layer Thickness (mm) | |

| External wall | Stainless steel | 17 | 460 | 0.5 |

| Polyurethane (PUR) | 0.022 | 1400 | 250 | |

| Stainless steel | 17 | 460 | 0.5 | |

| Glass wool | 0.04 | 7955 | 63.5 | |

| Plasteboard | 0.25 | 1000 | 100 | |

| PCM DuPont™ Energain® | 0.018 | 2500 | 53 | |

| Ground | Extruded polystyrene | 0.034 | 1540 | 300 |

| Roof | Stainless steel | 17 | 460 | 0.5 |

| Glass wool | 0.04 | 7955 | 63.5 | |

| Plaster (ceiling) | 0.25 | 1000 | 150 | |

| PCM DuPont™ Energain® | 0.018 | 2500 | 53 | |

| Door | Stainless steel | 17 | 460 | 0.5 |

| Polystyrene | 0.18 | 1500 | 250 | |

| Stainless steel | 17 | 460 | 0.5 | |

| Energy Required | Heating (kWh) | Cooling (kWh) | ||||

|---|---|---|---|---|---|---|

| City | Raw | Insulation | Insulation + PCM | Raw | Insulation | Insulation + PCM |

| Alicante | 1417 | 822 | 788 | 642 | 465 | 457 |

| Bilbao | 2971 | 1777 | 1706 | 61 | 34 | 33 |

| La Coruña | 2566 | 1550 | 1487 | 55 | 43 | 42 |

| Las palmas | 191 | 91 | 83 | 594 | 392 | 387 |

| Madrid | 2933 | 1708 | 1640 | 611 | 366 | 352 |

| Valencia | 1834 | 1083 | 1039 | 453 | 312 | 307 |

| Energy Required | Heating (kWh) | Cooling (kWh) | ||||

|---|---|---|---|---|---|---|

| City | Raw | Insulation | Insulation + PCM | Raw | Insulation | Insulation + PCM |

| Alicante | 0.93 | 0.49 | 0.47 | 1.01 | 0.59 | 0.58 |

| Bilbao | 1.11 | 0.60 | 0.58 | 0.56 | 0.17 | 0.15 |

| Coruña | 0.88 | 0.52 | 0.51 | 0.32 | 0.11 | 0.10 |

| Las Palmas | 0.41 | 0.18 | 0.17 | 0.75 | 0.41 | 0.41 |

| Madrid | 1.46 | 0.73 | 0.71 | 1.24 | 0.60 | 0.58 |

| Valencia | 0.98 | 0.52 | 0.51 | 0.90 | 0.53 | 0.52 |

| Enclosure | Raw (°C) | Insulation (°C) | Insulation + PCM (°C) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| City | M | SD | Max | Min | M | SD | Max | Min | M | SD | Max | Min |

| Alicante | 20.93 | 5.98 | 34.70 | 8.21 | 20.97 | 5.63 | 32.48 | 10.33 | 21.01 | 5.63 | 32.53 | 10.49 |

| Bilbao | 15.64 | 5.08 | 29.38 | 5.31 | 15.96 | 4.68 | 26.24 | 7.77 | 16.01 | 4.66 | 26.01 | 7.96 |

| Coruña | 16.36 | 4.38 | 27.37 | 7.38 | 16.55 | 3.97 | 25.75 | 8.96 | 16.59 | 3.96 | 25.69 | 9.04 |

| Las Palmas | 23.83 | 3.19 | 32.05 | 15.85 | 23.68 | 2.81 | 29.78 | 17.85 | 23.73 | 2.79 | 29.85 | 17.93 |

| Madrid | 17.42 | 8.80 | 38.35 | 0.16 | 17.83 | 8.15 | 35.41 | 4.04 | 17.87 | 8.09 | 35.38 | 4.15 |

| Valencia | 19.43 | 6.08 | 33.71 | 7.07 | 19.63 | 5.71 | 31.61 | 9.70 | 19.68 | 5.70 | 31.63 | 9.83 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Feijoo, M.Á.; Orgeira-Crespo, P.; Arce, E.; Suárez-García, A.; Ribas, J.R. Effect of Insulation on the Energy Demand of a Standardized Container Facility at Airports in Spain under Different Weather Conditions. Energies 2020, 13, 5263. https://doi.org/10.3390/en13205263

Álvarez-Feijoo MÁ, Orgeira-Crespo P, Arce E, Suárez-García A, Ribas JR. Effect of Insulation on the Energy Demand of a Standardized Container Facility at Airports in Spain under Different Weather Conditions. Energies. 2020; 13(20):5263. https://doi.org/10.3390/en13205263

Chicago/Turabian StyleÁlvarez-Feijoo, Miguel Ángel, Pedro Orgeira-Crespo, Elena Arce, Andrés Suárez-García, and José Roberto Ribas. 2020. "Effect of Insulation on the Energy Demand of a Standardized Container Facility at Airports in Spain under Different Weather Conditions" Energies 13, no. 20: 5263. https://doi.org/10.3390/en13205263

APA StyleÁlvarez-Feijoo, M. Á., Orgeira-Crespo, P., Arce, E., Suárez-García, A., & Ribas, J. R. (2020). Effect of Insulation on the Energy Demand of a Standardized Container Facility at Airports in Spain under Different Weather Conditions. Energies, 13(20), 5263. https://doi.org/10.3390/en13205263