Research on Fault Detection for Three Types of Wind Turbine Subsystems Using Machine Learning

Abstract

1. Introduction

2. Data Collection and Processing

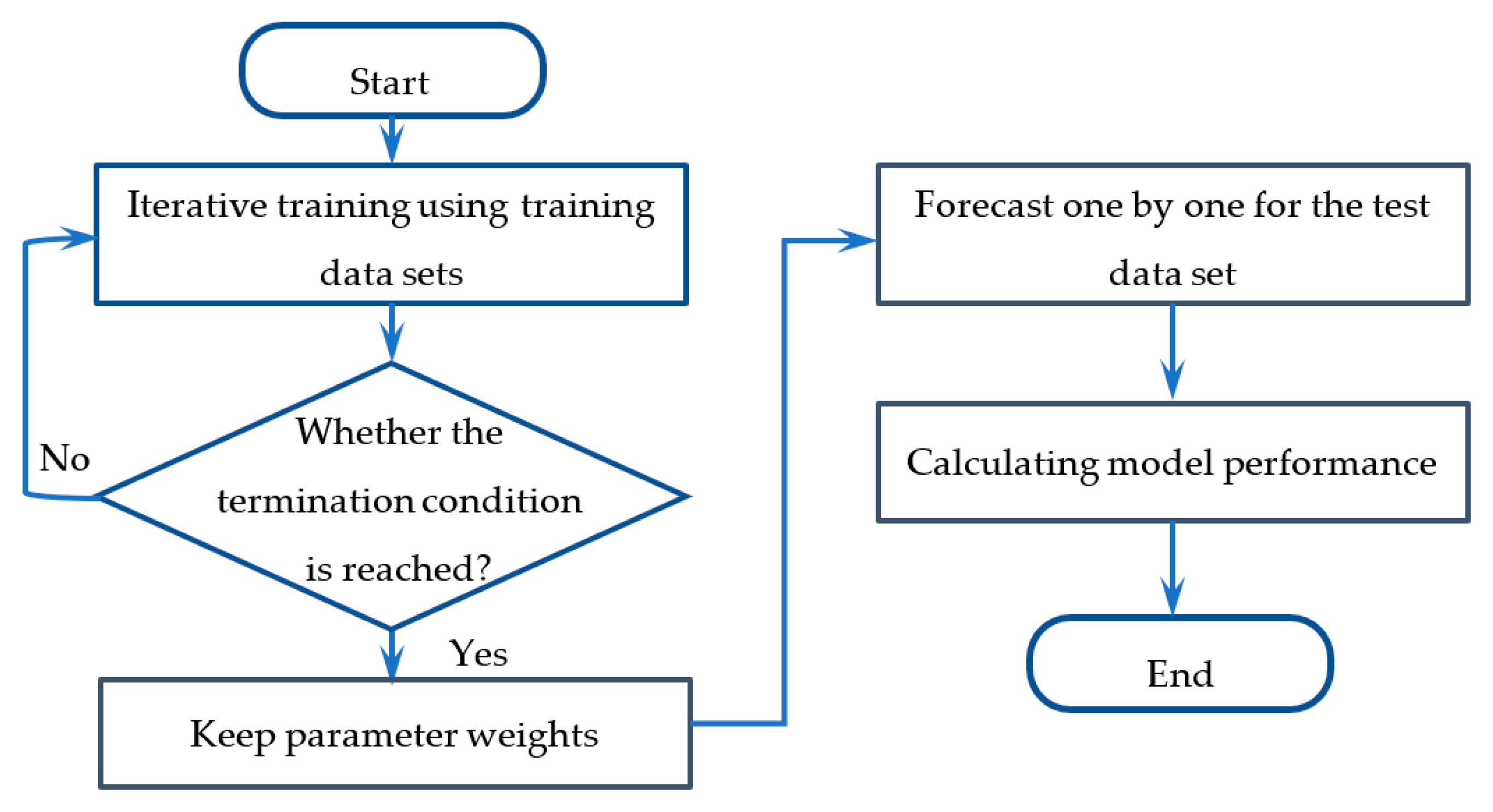

3. Development of Fault Detection Methods

3.1. Convolutional Neural Network Method for Fault Detection

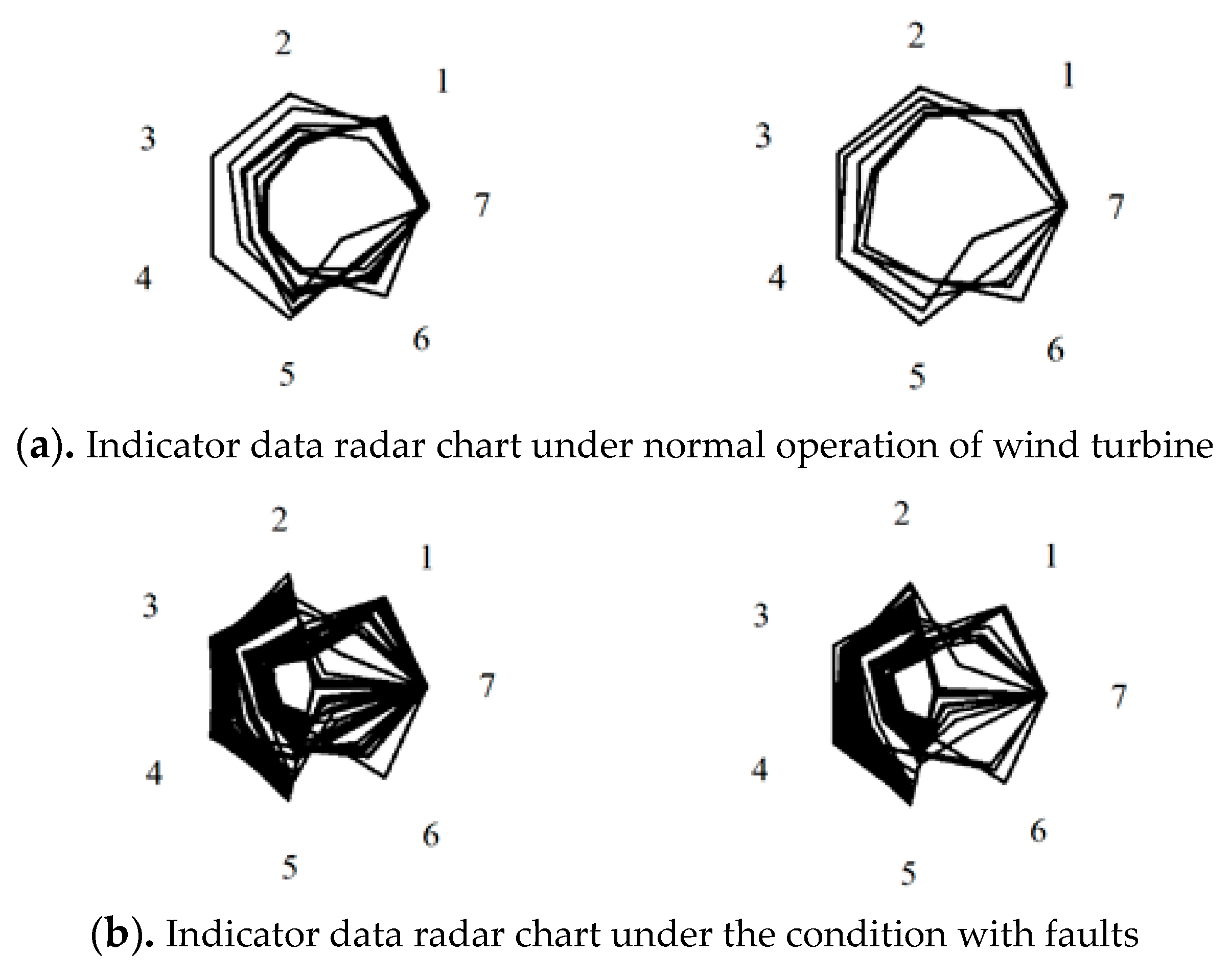

3.1.1. Data Preprocessing and Data Set Construction for Training the Model

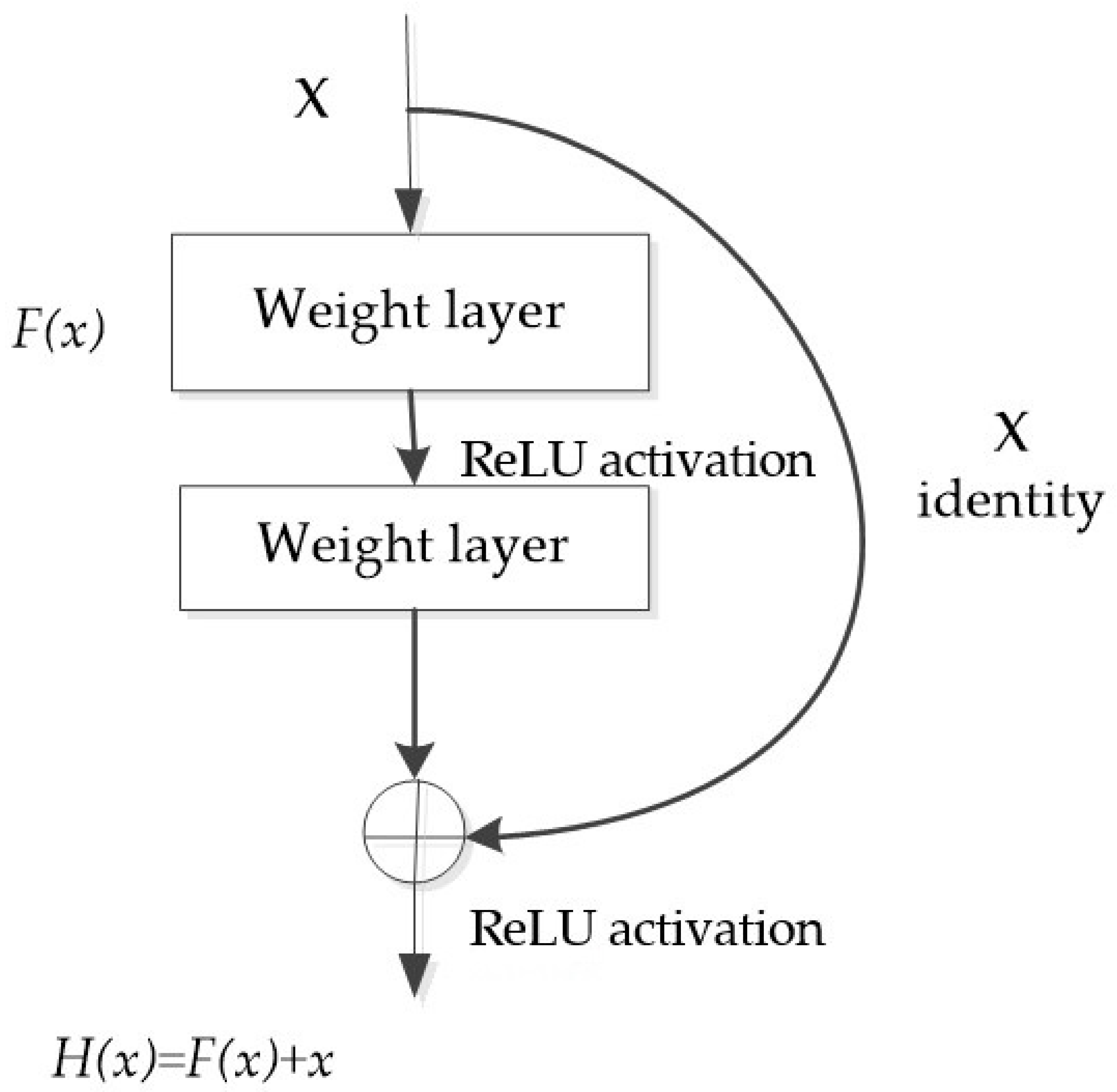

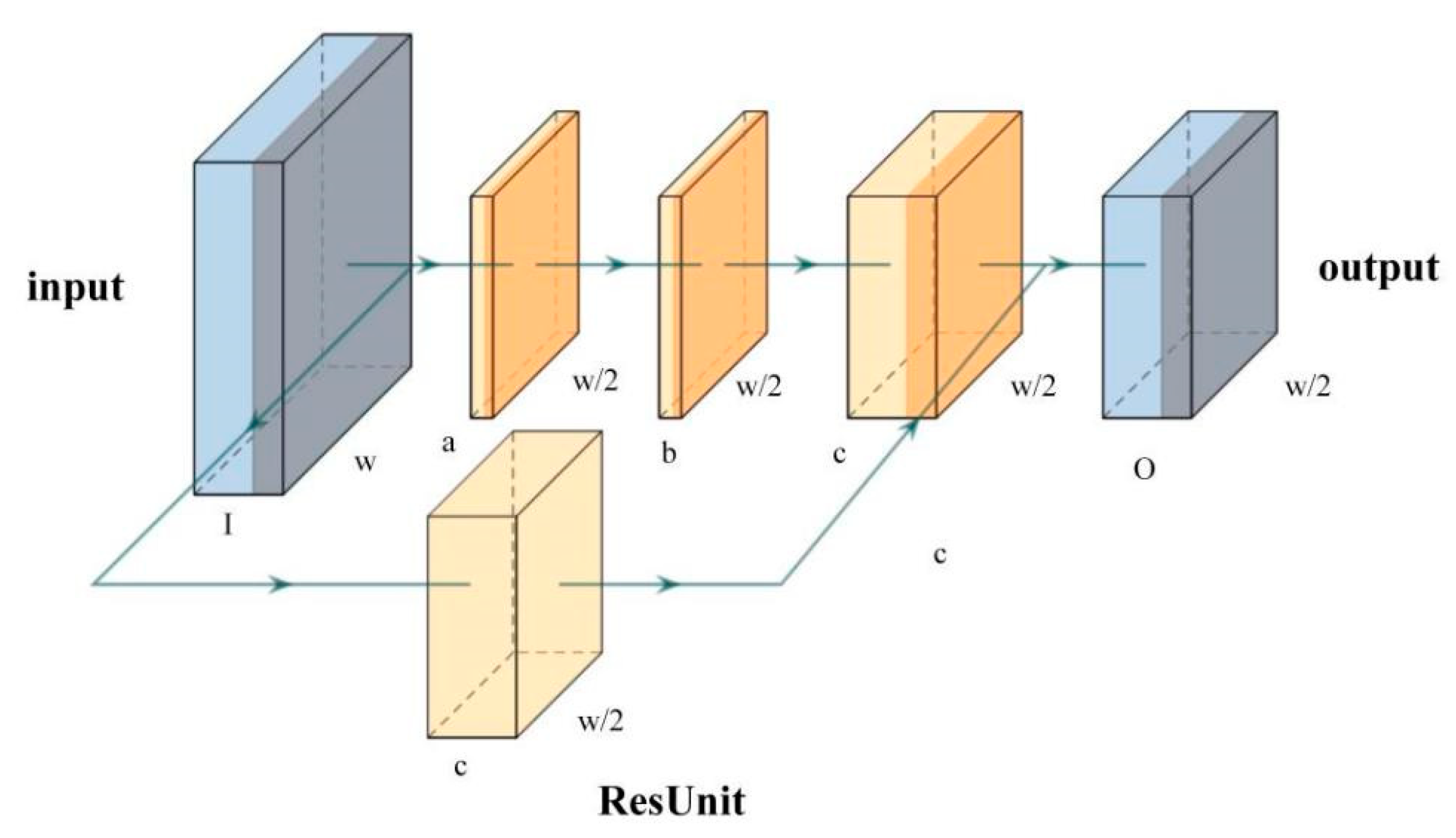

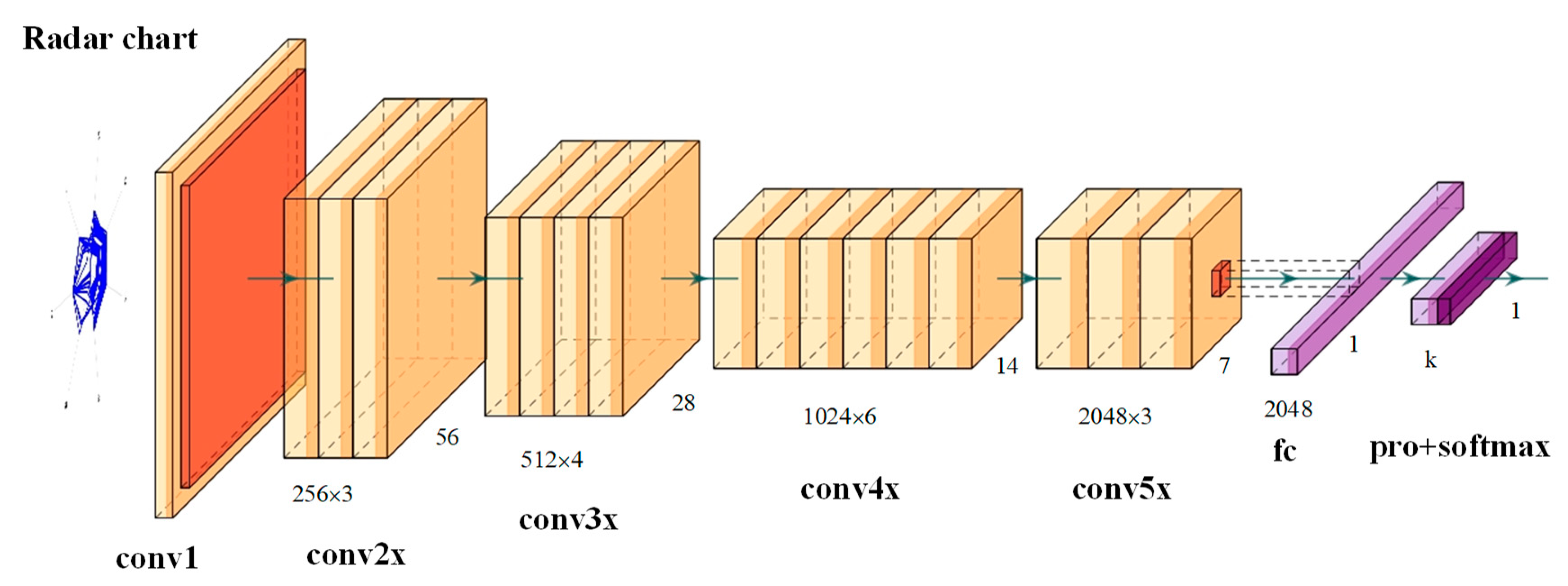

3.1.2. Selection of Network Structure

- a.

- ResNet50 network structure

- b.

- Softmax classifier

- c.

- Cross entropy loss

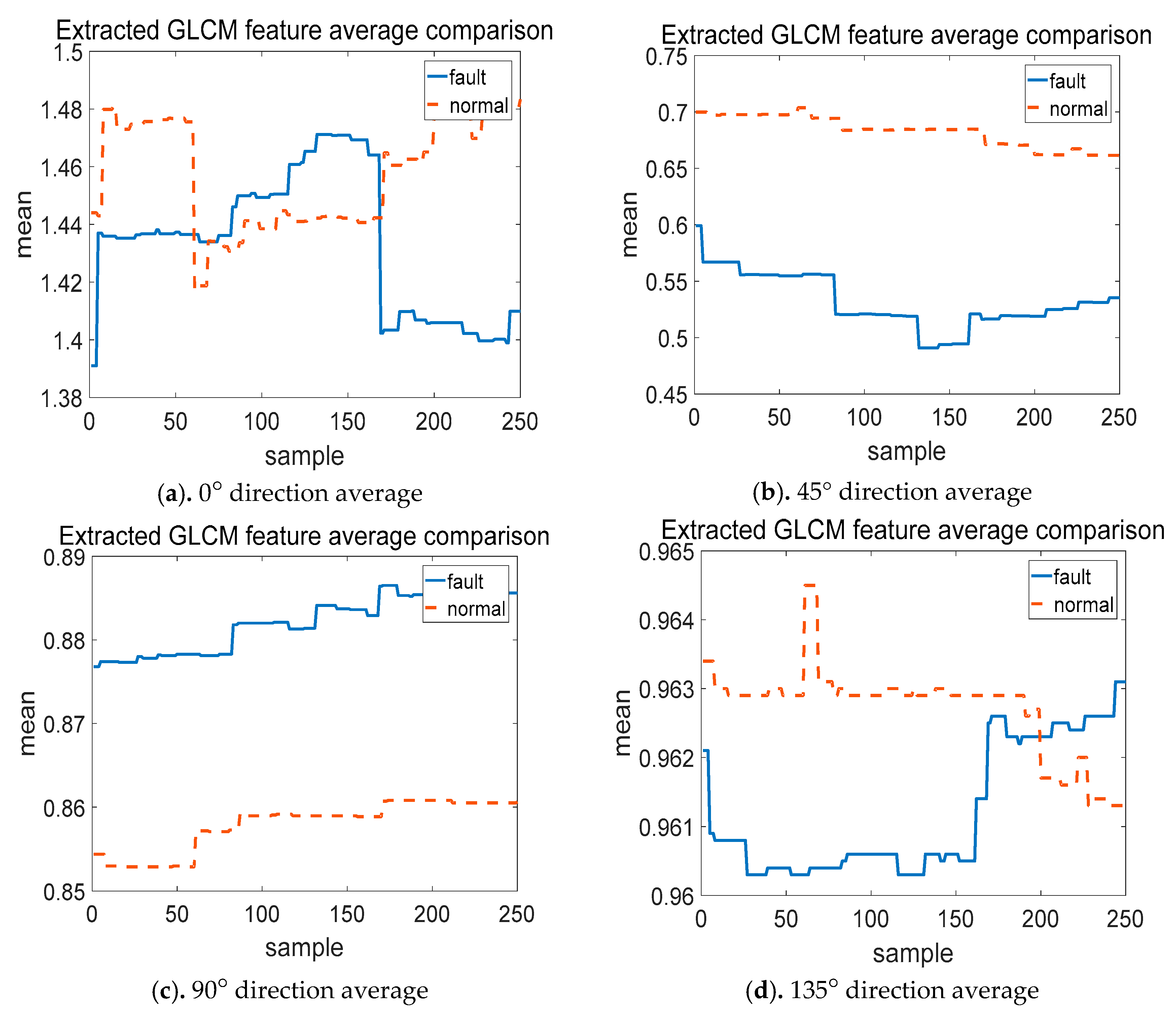

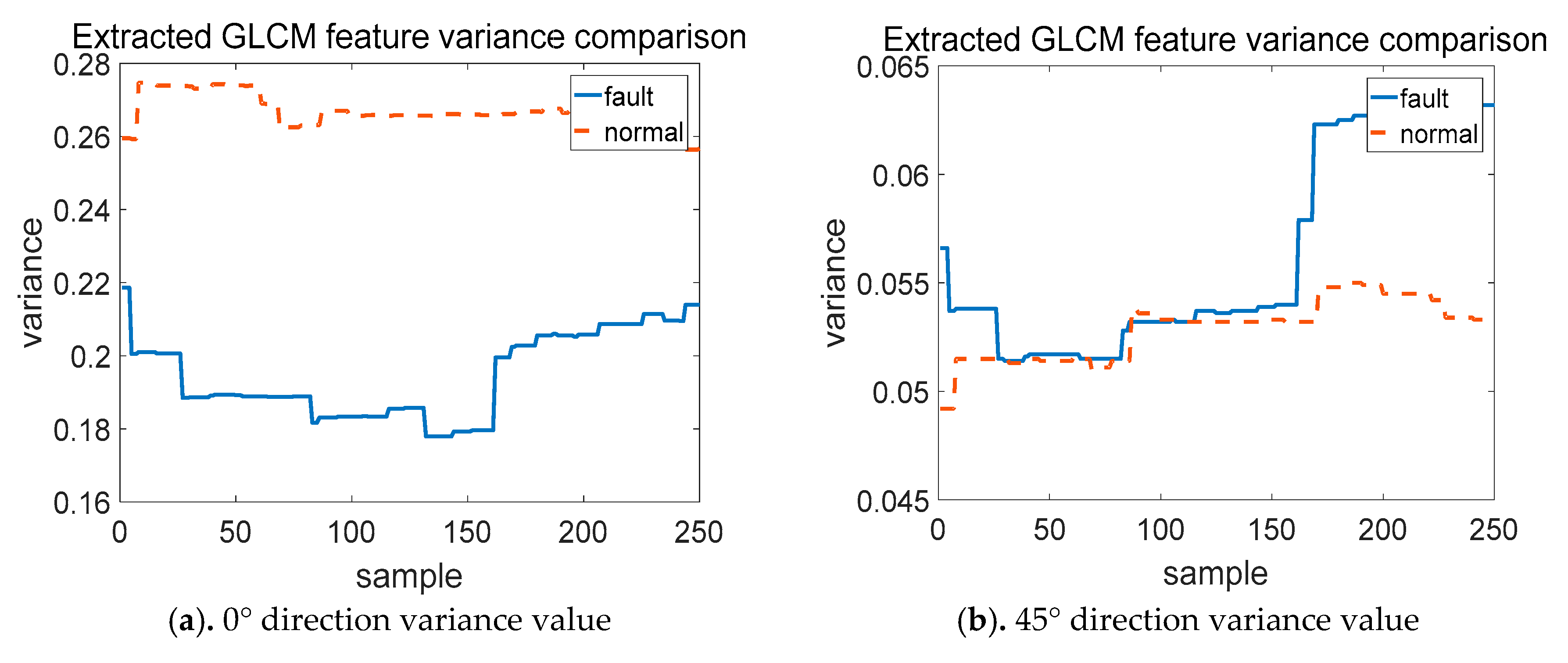

3.1.3. The System Normal and Fault Image Feature Extraction

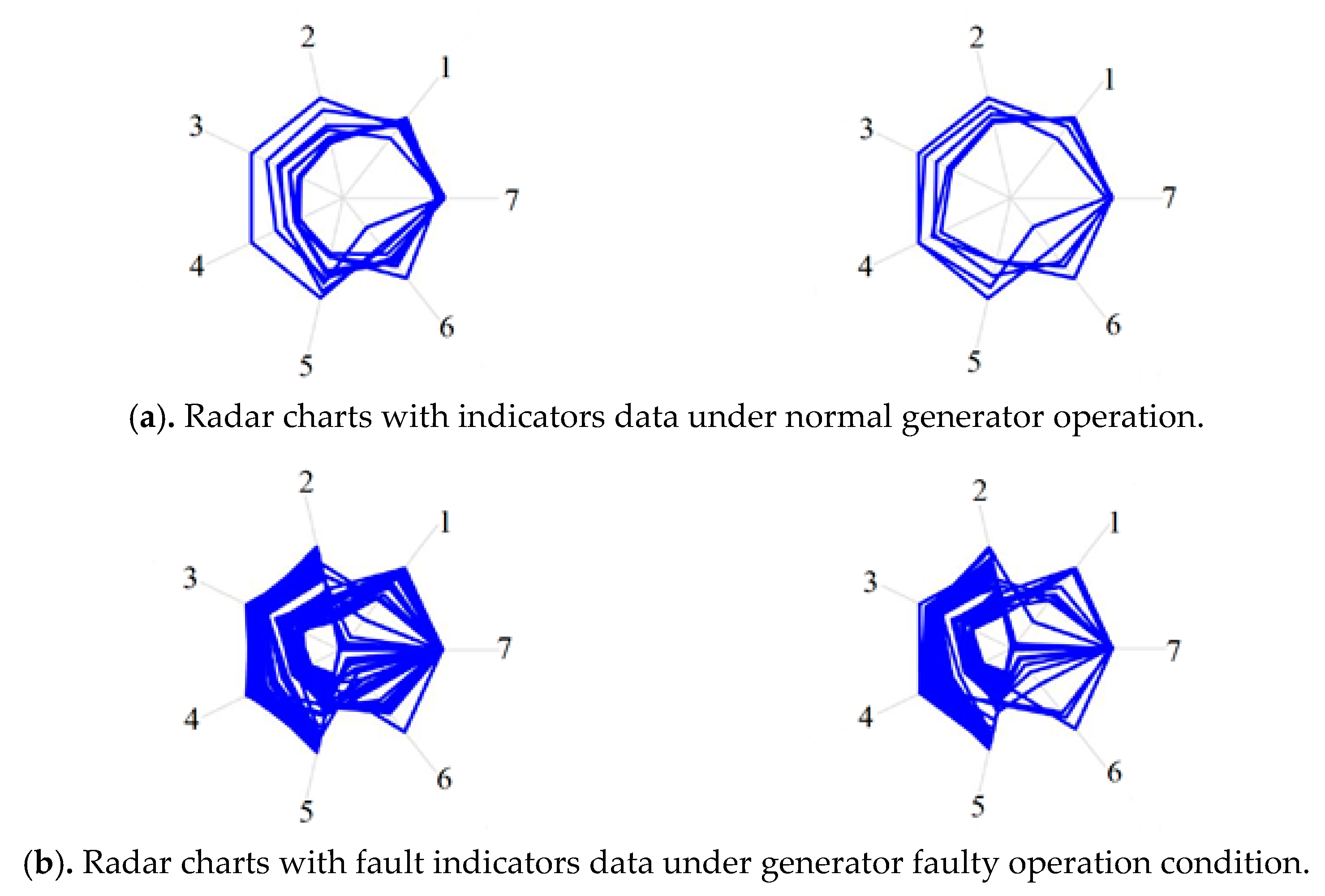

3.2. SVM Detection Using Indicators Data Radar Chart

Construction of Confusion Matrix

- a.

- Accuracy

- b.

- Diagnosed as true accuracy

- c.

- True to true accuracy

- d.

- True to false accuracy

- e.

- Diagnosed as false accuracy

3.3. Support Vector Regression (SVR) Detection Using the Indicator Data

4. Detection Results and Analysis

4.1. Convolutional Neural Network Detection Accuracy Analysis

Calculation of Detection Indices

- a.

- Generator fault detection

- b.

- Converter fault detection

- c.

- Pitch system fault detection

4.2. SVM for Graphics Detection Accuracy Analysis

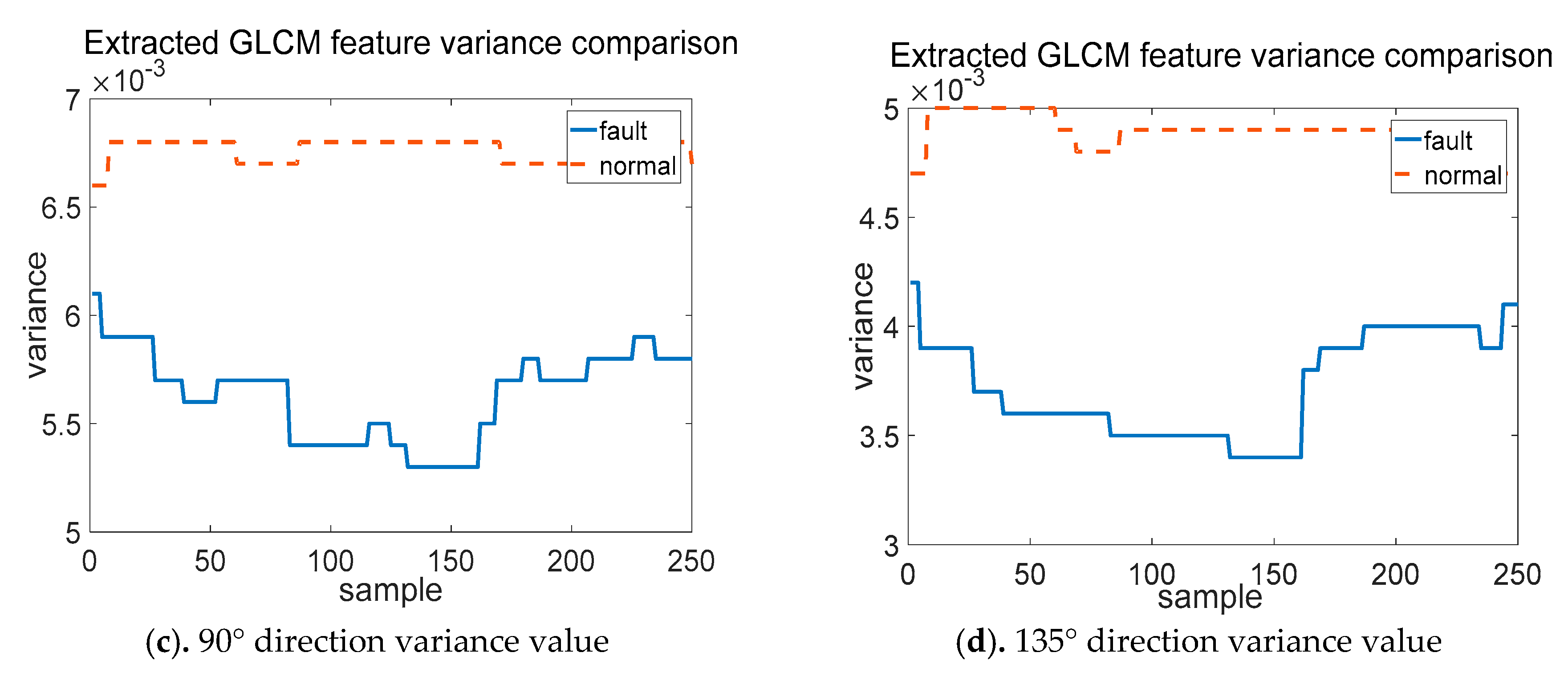

4.2.1. Image Feature Extraction

- a.

- Image preprocessing

- b.

- Image feature extraction

4.2.2. Calculation of Detection Indices

- Generator fault detection

- Converter fault detection

- Pitch system fault detection

4.3. SVR Method for Fault Detection

4.3.1. Data Preprocessing

4.3.2. Calculation of Detection Indices

- a.

- Generator fault detection

- b.

- Converter fault detection

- c.

- Pitch system fault detection

4.4. Comparison Analysis of the Three Fault Detection Methods

- a.

- Comparison of detection evaluation indices for generator failure

- b.

- Comparison of detection evaluation indices for converter failure

- c.

- Comparison of detection evaluation indices for pitch system faults

5. Fault Detection Results and Analysis Using 10-min Data

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martin, B.A.; Bo, R.O.; Ole, W. Flexible non-linear predictive models for large-scale wind turbine diagnostics. Wind Energy 2017, 20, 753–764. [Google Scholar]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the 2009 IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Zhao, Y.Y.; Li, D.S.; Dong, A.; Kang, D.; Lv, Q.; Shang, L. Fault prediction and diagnosis of wind turbine generators using SCADA data. Energies 2017, 10, 1210. [Google Scholar] [CrossRef]

- Dao, P.B.; Staszewski, W.J.; Barszcz, T.; Uhl, T. Condition monitoring and fault detection in wind turbines based on cointegration analysis of SCADA data. Renew. Energy 2018, 116, 107–122. [Google Scholar] [CrossRef]

- Pérez, J.M.P.; Márquez, F.P.G.; Tobias, A.; Papaelias, M. Wind turbine reliability analysis. Renew. Sustain. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Long, H.; Wang, L.; Zhang, Z.; Song, Z.; Xu, J. Data-driven wind turbine power generation performance monitoring. IEEE Trans. Ind. Electron. 2015, 62, 6627–6635. [Google Scholar] [CrossRef]

- Hwas, A.; Katebi, R. Model-based fault detection and isolation for wind turbine. In Proceedings of the 2012 UKACC International Conference on Control, Cardiff, UK, 3–5 September 2012; pp. 876–881. [Google Scholar]

- Ouyang, J.; Zhang, Z.; Tang, T.; Pang, M.; Li, M.; Zheng, D. Fault overload control method for high-proportion wind power transmission systems based on emergency acceleration of doubly-fed induction generator. IEEE Access 2019, 7, 32874–32883. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Zhang, J.; Jiang, G. Frequency-shift multiscale noise tuning stochastic resonance method for fault diagnosis of generator bearing in wind turbine. Measurement 2019, 133, 421–432. [Google Scholar] [CrossRef]

- Dong, H.; Yang, L.; Li, H. Small fault diagnosis of front-end speed controlled wind generator based on deep learning. WSEAS Trans. Circuits Syst. 2016, 15, 64–72. [Google Scholar]

- Hu, Y.; Shi, P.; Li, H.; Yang, C.; Liao, X. Health condition assessment of base-plate solder for multi-chip IGBT module in wind power converter. IEEE Access 2019, 7, 72134–72142. [Google Scholar] [CrossRef]

- Zhao, H.; Cheng, L. Open-circuit faults diagnosis in back-to-back converters of DF wind turbine. IET Renew. Power Gener. 2017, 11, 417–424. [Google Scholar] [CrossRef]

- Baygildina, E.; Smirnova, L.; Juntunen, R.; Murashko, K.; Mityakov, A.V.; Kuisma, M.; Pyrhönen, O.; Peltoniemi, P.; Hynynen, K.; Mityakov, V.Y.; et al. Condition monitoring of wind power converters using heat flux sensor. Int. Rev. Electr. Eng. 2016, 11, 239–246. [Google Scholar] [CrossRef]

- Wu, D.H.; Liu, W. A new fault diagnosis approach for the pitch system of wind turbines. Adv. Mech. Eng. 2017, 9, 1687814017703350. [Google Scholar] [CrossRef]

- Bi, R.; Zhou, C.K.; Hepburn, D.M. Detection and classification of faults in pitch-regulated wind turbine generators using normal behaviour models based on performance curves. Renew. Energy 2017, 105, 674–688. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, K.; Hajizadeh, A.; Soltani, M.; Chen, Z. Fault detection and isolation for wind turbine electric pitch system. In Proceedings of the 2017 IEEE 12th International Conference on Power Electronics and Drive Systems (PEDS), Honolulu, HI, USA, 12–15 December 2017; pp. 618–623. [Google Scholar]

- Wu, D.; Liu, W.; Zhai, Y.; Shen, Y. Fault diagnosis for the pitch system of wind turbines using the observer-based multi-innovation stochastic gradient algorithm. In Theory, Methodology, Tools and Applications for Modeling and Simulation of Complex Systems; Springer: Singapore, 2016; pp. 526–538. [Google Scholar]

- Chen, B.; Matthews, P.C.; Tavner, P.J. Wind turbine pitch faults prognosis using a-priori knowledge-based ANFIS. Expert Syst. Appl. 2013, 40, 6863–6876. [Google Scholar] [CrossRef]

- Xiao, C.; Liu, Z.J.; Zhang, T.L.; Zhang, L. On fault prediction for wind turbine pitch system using radar chart and support vector machine approach. Energies 2019, 12, 2693. [Google Scholar] [CrossRef]

- Yang, Z. Research on Fault Early Warning Method Using Data Analysis for Wind Turbine Pitch System. Master’s Thesis, North China Electric Power University, Beijing, China, 2015. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. In Proceedings of the 32nd International Conference on Machine Learning, Lille, France, 6–11 July 2015. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Zagoruyko, S.; Komodakis, N. Wide residual networks. In Proceedings of the BMVC 2016, York, UK, 19–22 September 2016; pp. 87.1–87.12. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Identity mappings in deep residual networks. In European Conference on Computer Vision; Springer: Cham, Switzerland, 2016; pp. 630–645. [Google Scholar]

- Guo, Y.; Su, P.F.; Wu, Y.F.; Guo, J. Object detection and location of robot based on Faster R-CNN. Huazhong Univ. Sci. Technol. 2018, 46, 55–59. [Google Scholar]

- Wang, H.; Li, X.; Liu, X.F.; Xu, W.L. Classification of breast cancer histopathological images based on ResNet50 Network. J. China Univ. Metrol. 2019, 30, 72–77. [Google Scholar]

- Liao, M.; Zhao, Y.Q.; Zeng, Y.Z.; Huang, Z.C.; Zhang, B.K.; Zou, B.J. Automatic segmentation for cell images bases on support vector machine and ellipse fitting. J. Zhejiang Univ. 2017, 51, 722–728. [Google Scholar]

- Shen, Y.X.; Zhou, W.J.; Ji, Z.C.; Wu, D.H. Fault diagnosis of converter used in wind power generation based on wavelet packet analysis and SVM. Acta Energ. Sol. Sin. 2015, 36, 785–791. [Google Scholar]

| Generator | Converter | Blades/Pitch System | Scheduled Stop | Yaw System | Gearbox | Others |

|---|---|---|---|---|---|---|

| 37% | 19% | 12% | 10% | 4% | 3% | 15% |

| Serial No. | Generator Fault Type |

|---|---|

| 1 | Generator air cooling fan fails |

| 2 | Generator bearing temperature is out of limits |

| 3 | Generator encoder fault |

| 4 | Generator encoder shielded line |

| 5 | Generator winding temperature overrun |

| Serial No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Index | Wind speed | Rotor speed | Generator winding temperature | Generator bearing temperature | Generator cooling air temperature | Grid power | Grid reactive power |

| Serial No. | Main Faults of Converter |

|---|---|

| 1 | The grid side converter voltage is faulty, and the inverter module wiring is loose |

| 2 | Rotor side converter fault |

| 3 | Grid-side converter voltage failure, inverter Hall sensor damage |

| 4 | The grid side converter is ready to be closed, and the CB504 wiring is loose |

| 5 | The grid side converter is ready to be closed and the wiring is faulty |

| Serial No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Index | Wind speed | Rotor speed | Grid power | Generator rotor speed | Converter power | Converter Ctrl torque set point | Generator torque |

| Serial No. | Pitch System Fault Type |

|---|---|

| 1 | Pitch 90° position sensor fault |

| 2 | Pitch safety chain fault |

| 3 | 3° position sensor fault of pitch paddle 1 |

| 4 | Pitch emergency stop fault |

| 5 | Pitch motor high temperature fault |

| Serial No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Index | Wind speed | Wind direction | Rotor speed | Rotor position | Output power | Grid frequency | Pitch angle |

| Serial Number | Wind Speed (m/s) | Rotor Speed (rad/min) | Generator Winding Temperature (°C) | Generator Bearing Temperature (°C) | Generator Cooling Air Temperature (°C) | Grid Power (kW) | Grid Reactive Power (kW) |

|---|---|---|---|---|---|---|---|

| 1 | 5.01 | 10.471 | 50.9 | 37.1 | 31.1 | 124.8 | 184.7 |

| 2 | 5.55 | 10.44 | 50.8 | 37.1 | 31.1 | 138 | 184.1 |

| 3 | 4.89 | 10.45 | 50.8 | 37.1 | 31.1 | 141.6 | 188.8 |

| 4 | 5.88 | 10.51 | 50.8 | 37.1 | 31.1 | 147 | 179.5 |

| 5 | 4.93 | 10.42 | 50.8 | 37.1 | 31.1 | 147 | 182.7 |

| 6 | 5.65 | 10.47 | 50.7 | 37 | 31.1 | 149.4 | 179.3 |

| … | … | … | … | … | |||

| 178 | 1.66 | 0.01 | 41 | 28.9 | 36 | 0 | 0 |

| 179 | 1.51 | 0.01 | 41 | 28.9 | 36 | 0 | 0 |

| 180 | 2.03 | 0.01 | 41 | 29 | 36 | 0 | 0 |

| 181 | 1.96 | 0 | 41 | 28.9 | 36 | 0 | 0 |

| Serial Number | Wind Speed (m/s) | Rotor Speed (rad/min) | Grid Power (kW) | Generator Rotor Speed (rad/min) | Converter Input Power (kW) | Converter Ctrl Torque Set Point (N·m) | Generator Torque (N·m) |

|---|---|---|---|---|---|---|---|

| 1 | 7.61 | 14.33 | 428.4 | 1440.5 | 430.8 | 34.55 | 33.81 |

| 2 | 5.68 | 14.42 | 441.6 | 1448.9 | 450.2 | 34.91 | 35.13 |

| 3 | 4.91 | 14.18 | 414 | 1420 | 419.1 | 33.42 | 33.41 |

| 4 | 5.08 | 13.81 | 387.6 | 1387.6 | 394 | 32.07 | 32.03 |

| 5 | 4.31 | 12.98 | 324 | 1304.3 | 329.6 | 28.28 | 28.55 |

| 6 | 4.85 | 12.54 | 292.2 | 1260.5 | 297.3 | 26.35 | 26.61 |

| … | … | … | … | … | |||

| 178 | 3.22 | 10.38 | 97.8 | 1043.3 | 99.6 | 10.67 | 10.6 |

| 179 | 3.08 | 10.41 | 81.1 | 1045.9 | 85.3 | 8.99 | 8.97 |

| 180 | 3.06 | 10.47 | 69 | 1051.8 | 71.4 | 7.72 | 7.78 |

| 181 | 3.38 | 10.47 | 93 | 1052.3 | 94.3 | 10.54 | 10.29 |

| Serial Number | Wind Speed (m/s) | Wind Direction (°) | Rotor Speed (rad/min) | Rotor Position (°) | Output Power (kW) | Grid Frequency (Hz) | Pitch Angle (°) |

|---|---|---|---|---|---|---|---|

| 1 | 5.77 | 196.1 | 10.4 | 193.4 | 168.6 | 50 | 5.02 |

| 2 | 5.96 | 177.1 | 10.5 | 74.9 | 174.6 | 50 | 5.02 |

| 3 | 5.96 | 177.1 | 10.5 | 74.9 | 174.6 | 50 | 5.02 |

| 4 | 5.46 | 173.3 | 10.4 | 235.8 | 152.4 | 50 | 5.02 |

| 5 | 5.46 | 173.3 | 10.4 | 235.8 | 152.4 | 50 | 5.02 |

| 6 | 5.36 | 162.4 | 10.4 | 79.5 | 135.6 | 50 | 5.02 |

| … | … | … | … | … | |||

| 178 | 1.29 | 188.1 | 0.1 | 352.1 | 0 | 49.9 | 88.9 |

| 179 | 0.64 | 152.1 | 0.1 | 354.3 | 0 | 50.1 | 88.9 |

| 180 | 0.79 | 126.7 | 0.1 | 357.1 | 0 | 50.1 | 88.9 |

| 181 | 0.71 | 137.8 | 0.1 | 358.3 | 0 | 50.1 | 88.9 |

| Layer Name | Output Size | 50-Layer |

|---|---|---|

| conv1 | 7 × 7, 64, stride 2 3 × 3 max pool, stride 2 | |

| conv2x | ||

| conv3x | ||

| conv4x | ||

| conv5x | ||

| average pool, 1000-d fc, softmax | ||

| Floating points operations (FLOPs) | ||

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 4807 | 294 | 0 | 5101 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 97.12 | 100 | 94.24 | 100 | 94.55 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 4578 | 523 | 0 | 5101 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 94.87 | 100 | 89.75 | 100 | 90.7 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 5101 | 0 | 90 | 5011 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 99.11 | 98.27 | 100 | 98.24 | 100 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 5057 | 44 | 658 | 4443 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 93.12 | 88.49 | 99.14 | 87.1 | 99.02 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 3379 | 1722 | 226 | 4875 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 80.91 | 93.73 | 66.24 | 95.57 | 73.89 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 4874 | 254 | 111 | 4990 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 96.42 | 97.75 | 95.55 | 97.82 | 95.16 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 8206 | 844 | 955 | 8095 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Numerical value (%) | 89.94 | 89.58 | 90.67 | 89.45 | 90.56 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 3610 | 5440 | 1200 | 7850 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 63.31 | 75.05 | 39.89 | 86.74 | 59.07 |

| Index | TP | FN | FP | TN |

|---|---|---|---|---|

| Numerical value | 5651 | 3399 | 1196 | 7854 |

| Index | Accuracy | Precision | Recall | Specificity | Negative Detection |

|---|---|---|---|---|---|

| Value (%) | 74.61 | 82.53 | 62.44 | 86.78 | 69.79 |

| Approach | Accuracy | Precision | Recall | Specificity | Negative Detection | False Alarm Rate |

|---|---|---|---|---|---|---|

| Convolutional neural network (%) | 97.12 | 100 | 94.24 | 100 | 94.55 | 2.88 |

| SVM method (%) | 93.12 | 88.49 | 99.14 | 87.1 | 99.02 | 6.88 |

| SVR model (%) | 89.94 | 89.58 | 90.67 | 89.45 | 90.56 | 10.06 |

| Approach | Accuracy | Precision | Recall | Specificity | Negative Detection | False Alarm Rate |

|---|---|---|---|---|---|---|

| Convolutional neural network (%) | 94.87 | 100 | 89.75 | 100 | 90.7 | 5.13 |

| SVM method (%) | 80.91 | 93.73 | 66.24 | 95.57 | 73.89 | 19.09 |

| SVR model (%) | 63.31 | 75.05 | 39.89 | 86.74 | 59.07 | 36.69 |

| Approach | Accuracy | Precision | Recall | Specificity | Negative Detection | False Alarm Rate |

|---|---|---|---|---|---|---|

| Convolutional neural network (%) | 99.11 | 98.27 | 100 | 98.24 | 100 | 0.89 |

| SVM method (%) | 96.42 | 97.75 | 95.55 | 97.82 | 95.16 | 3.58 |

| SVR model (%) | 74.61 | 82.53 | 62.44 | 86.78 | 69.79 | 25.39 |

| Approach | Accuracy | Precision | Recall | Specificity | Negative Detection | False Alarm Rate |

|---|---|---|---|---|---|---|

| Convolutional neural network (%) | 97.87 | 98.22 | 97.52 | 98.23 | 97.54 | 2.13 |

| SVM method (%) | 79.03 | 85.96 | 69.38 | 88.67 | 74.33 | 20.97 |

| SVR model (%) | 73.89 | 78.14 | 66.33 | 81.44 | 70.75 | 26.11 |

| Approach | Accuracy | Precision | Recall | Specificity | Negative Detection | False Alarm Rate |

|---|---|---|---|---|---|---|

| Convolutional neural network (%) | 89.03 | 99.1 | 78.76 | 99.29 | 82.38 | 10.97 |

| SVM method (%) | 74.07 | 70.18 | 83.72 | 64.42 | 79.82 | 25.93 |

| SVR model (%) | 64.78 | 74.72 | 44.67 | 84.89 | 60.54 | 35.22 |

| Approach | Accuracy | Precision | Recall | Specificity | Negative Detection | False alarm rate |

|---|---|---|---|---|---|---|

| Convolutional neural network (%) | 98.41 | 96.92 | 100 | 96.82 | 100 | 1.59 |

| SVM method (%) | 89.49 | 82.63 | 100 | 78.98 | 100 | 10.51 |

| SVR model (%) | 80.94 | 78.3 | 90.22 | 71.67 | 87.99 | 19.06 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Xiao, C.; Zhang, T.; Zhang, X. Research on Fault Detection for Three Types of Wind Turbine Subsystems Using Machine Learning. Energies 2020, 13, 460. https://doi.org/10.3390/en13020460

Liu Z, Xiao C, Zhang T, Zhang X. Research on Fault Detection for Three Types of Wind Turbine Subsystems Using Machine Learning. Energies. 2020; 13(2):460. https://doi.org/10.3390/en13020460

Chicago/Turabian StyleLiu, Zuojun, Cheng Xiao, Tieling Zhang, and Xu Zhang. 2020. "Research on Fault Detection for Three Types of Wind Turbine Subsystems Using Machine Learning" Energies 13, no. 2: 460. https://doi.org/10.3390/en13020460

APA StyleLiu, Z., Xiao, C., Zhang, T., & Zhang, X. (2020). Research on Fault Detection for Three Types of Wind Turbine Subsystems Using Machine Learning. Energies, 13(2), 460. https://doi.org/10.3390/en13020460