1. Introduction

Piezoelectric materials have a property where, when under mechanical stress, they produce electric potential energy and vice versa. These materials are widely used in various applications, such as sensors, nanopositioners, actuators, ultrasonic motors, fuel injectors, and nanogenerators [

1,

2]. To date, the piezoelectric material Pb(Zr,Ti)O

3 (PZT) has been mostly employed in commercial applications, such as in actuator modules to be mounted on micro-electro-mechanical-system (MEMS) and in cameras/microscope lenses. However, PZT is a lead-based piezoelectric and thereby, causes serious problems in the environment and the human body. Thereby, many studies, searching for the alternatives to PZT, have been in progress. Ferroelectric/piezoelectric materials that have perovskite structure, such as (Bi,Na)TiO

3 (BNT) and (K,Na)NbO

3 (KNN)-based ceramics, have been investigated as possibilities as alternatives for PZT (in specific applications) [

3,

4].

In particular, the characteristic of a large strain induced by an external electric field in BNT-based ceramics has been spotlighted recently [

3,

5]. Since the possible presence of an antiferroelectric phase in (Bi,Na)TiO

3-BaTiO

3 (BNT-BT) systems has been reported [

6], the cause of such a large strain has been suggested as being attributable to an antiferroelectric-to-ferroelectric transition. However, subsequent studies [

7,

8] have identified comprehensively that its paraelectric phase would be ascribable to a relaxor phase, more specifically, the ergodic state of a relaxor ferroelectric (ER). In addition, the large strain of BNT-based ceramics can result in the double polarization hysteresis. The large strain might be due to their structural evolution process induced by an external electric field. In the processes, the initial ER is the paraelectric phase, and it can transit to the ferroelectric phase by an external electric field. After the external electric field is removed, it returns to the initial paraelectric phase. Based on all these processes, a double polarization hysteresis can be observed. Furthermore, the relaxor phase, which is typically counted as a normal ferroelectric, was distinguished as the non-ergodic state of a relaxor ferroelectric (NR).

Looking at the above in further detail [

9], the relaxor ferroelectrics become a paraelectric phase of the cubic crystalline structure at high temperature. As temperature decreases, electrical dipoles are formed at a temperature below the Burns temperature, and consequently becomes an ER showing an increase in electric permittivity. This characteristic of ER results from the interaction between electrical dipoles and thermal energy. As temperature decreases further, the level of thermal energy decreases steadily while the density of electrical dipoles increases continuously, thereby polar nano regions (PNRs) are formed due to an increase in correlation between electrical dipoles. It is well known that a frequency dependence on the dielectric constant apparently appears when PNRs are formed, and an NR is formed below the Vogel–Fulcher temperature. The significant differences between an ER and NR are as follows: (1) one is an NR transition into an irreversible ferroelectric phase with the release of external electric field, (2) the other is an ER easy transition into a ferroelectric phase with the release of external electric field beyond a specific level due to the dynamic characteristics of PNRs, and (3) in contrast to an NR, we note the ER returns to its initial state after the removal of the external electric field [

10]. The ER causes a large strain while under an external electric field, as such previous studies have investigated how to change the characteristics of PNRs by using various dopants [

11,

12]. In this regard, more detailed studies have been conducted on the electric field-induced domain evolutions and phase transitions in BNT-based materials [

13,

14].

In this paper, we investigate how the relaxor phase evolution varies according to changes in composition by fabricating (Bi0.5Na0.5-xKx)TiO3 (BNKT) ceramics, which forms by substituting an A-site ion with a K ion in the BNT structure. We present how the ferro- and piezoelectric characteristics vary according to the composition of x. We also propose and discuss a plausible model on the domain structure of our BNKT ceramics.

2. Materials and Methods

The (Bi

0.5Na

0.5-xK

x)TiO

3 (BNKT) ceramics were fabricated by a conventional solid-solution reaction method [

15]. As starting materials, Bi

2O

3 (99.9%, Sigma–Aldrich, St Louis, USA), Na

2CO

3 (99.9%, Sigma–Aldrich, St Louis, USA), K

2CO

3 (99.9%, Sigma–Aldrich, St Louis, USA) and TiO

2 (99.9%, Sigma–Aldrich, St Louis, USA) were weighted by the stoichiometric ratio of ((Bi

0.5Na

0.5-xK

x)TiO

3. After weighing, the wet milling process was carried out for 20 h in ethanol with zirconia balls, and then the material was dried in an electric oven at 120 °C. The dried powder was calcined in a muffle furnace at 850 °C for 2 h. As a binder, a polyvinyl alcohol (PVA) solution (5 wt%) was added to the crushed fine powder that was prepared in an alumina mortar. The specimens were dried and crushed before they were sieved with a sieve of 100 μm size. The fine powders were then made into pellets with a diameter of 10 mm. After that, they were covered with the calcined powder to prevent bismuth evaporation and to avoid the pellets sticking to the alumina plate before they were finally sintered at 1050–1150 °C for 2 h. During the sintering processes, the melting of the BNKT pellets with various

x components was observed, and we recorded the melting temperature, as shown in

Figure 1. We guessed the cause of this melting might be related to the BKT melting point of 1050 °C. Due to this, we had to find out the optimum sintering temperatures for all the compositions.

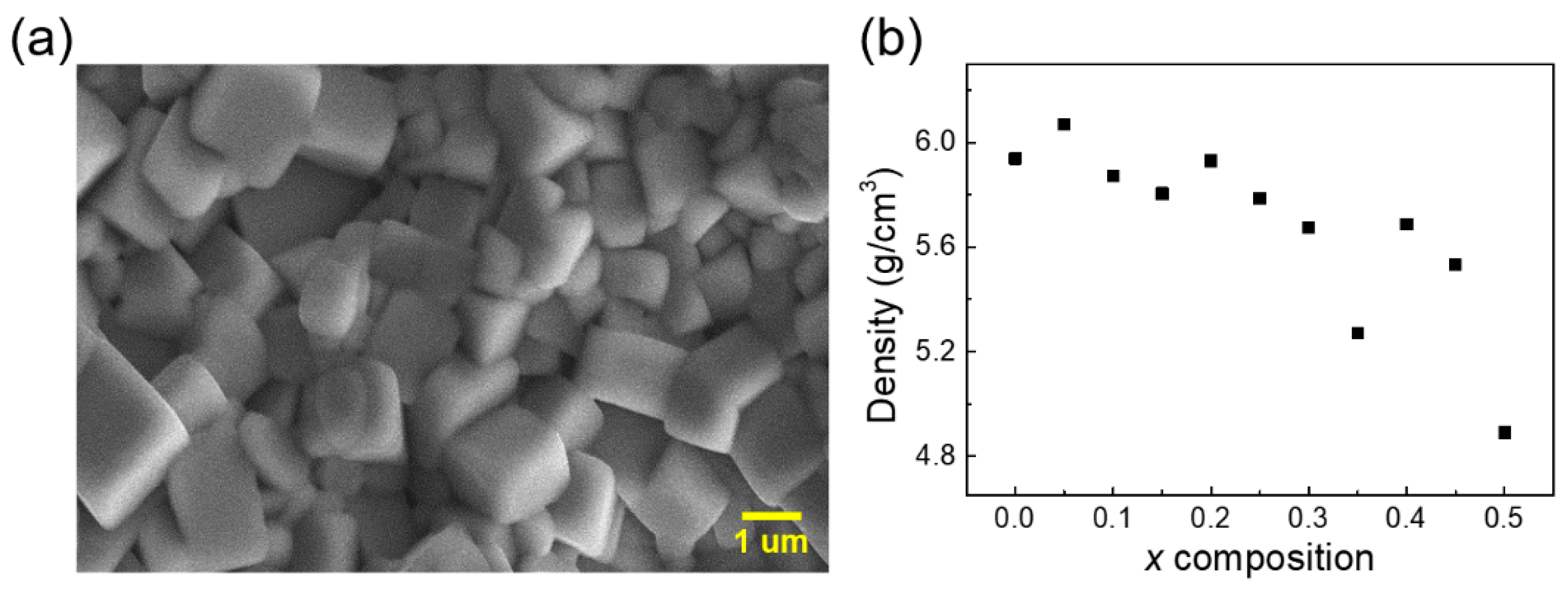

The SEM image of BNKT ceramics shows square-like grains with the size of a few microns (

Figure 2a). The measured density (

) ranges from 4.9 to 6.1 g/cm

3, and it tends to decrease with increasing the

x composition (

Figure 2b). The apparent density was calculated by the following equation:

where

is the weight of dry sample and

Wsat is the weight of saturated sample and

Wsub is the weight of the submerged sample, and

is the density of water. These results are consistent with previous studies [

16].

The sintered specimens were polished to a thickness of 0.5 mm. To make electrodes, both sides of the pellets were covered with silver paste. The crystal structure of the synthesized ceramics was investigated by X-ray Diffraction (XRD) (Rigaku-RINT-2000, Tokyo, Japan) with Cu Kα radiation (X-ray source) using equipment installed in the Center for University Research Facility (CURF) at the Jeonbuk National University. The measurements were made at 40 kV and 30 mA with a step size of 0.01°. The polarization–electric field (P-E), current–electric field (I-E) and strain–electric field (S-E) were measured by using a Piezoelectric Evaluation System (PES) (aixACCT, Aachen, Germany) consisting of a T-F analyzer 2000 (aixACCT, Aachen, Germany) and a high voltage power supply (Trek 610E, New York, NY, USA) at room temperature. The electromechanical measurements were done with a frequency of 10 Hz. Temperature dependence of dielectric constant (εr) and loss tangent (tanδ) was measured at from room temperature to 500 °C with a frequency of 1, 10, and 100 kHz by using an impedance analyzer (Agilent 4294A, Bayan, Malaysia).

3. Results

Figure 3 depicts the XRD measurements of BNKT ceramics taken at room temperature. It shows the (Bi,Na)TiO

3 (BNT) structure (JCPDS no. 00-036-0340) and (Bi,K)TiO

3 (BKT) structure (JCPDS no. 00-036-0339) with compositions in the range of

x = 0.05–0.40 (

Figure 3a) [

17]. The secondary phases, known to be found in the (Bi,Na,K)TiO

3 system, such as BiNaTi

6O

14, K

4Ti

3O

8, K

2Ti

8O

17 and (Na,K)

2Ti

6O

13 [

18,

19], were not observed in our BNKT ceramics.

The results of the XRD measurements showed a peak change from the (003)

R/(021)

R peak found around 40.0° to a (111)

T peak found around 39.5° as the composition of

x increased (

Figure 3b). In addition, the (202)

R peak identified around 46.5° changed to a (200)

T peak identified around 46.0°, together with the formation of a (002)

T peak identified around 45.0° (

Figure 3c). Such results suggest the rhombohedral (R) structure turns into a tetragonal (T) structure as the composition of

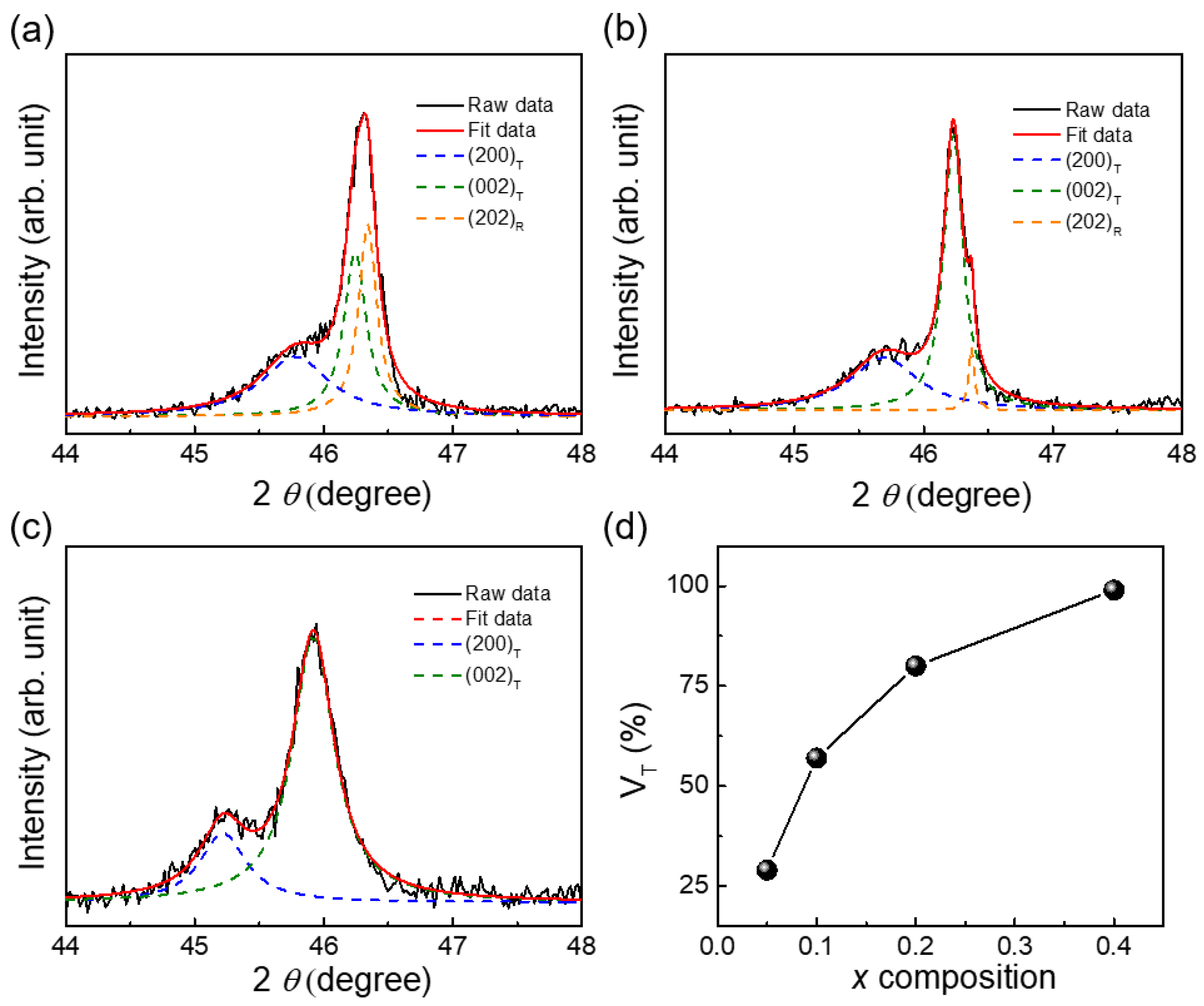

x increases. To identify the structural change in more detail, the (002)

T, (200)

T, and (202)

R peaks in the range of 44° to 48° were separated (

Figure 4a–c). The percentage of tetragonal structure (

VT) in the separated peaks is calculated via the following equation (2) [

20]:

where

I is the peak intensity of the tetragonal or rhombohedral structure.

The results of the calculation of

VT are shown in

Figure 4d. The ratio of the tetragonal structure increased continuously in accordance with increasing composition of

x. What was noticeable was the coexistence of the tetragonal structure and rhombohedral structure in similar ratios when

VT = 57% at

x = 0.10.

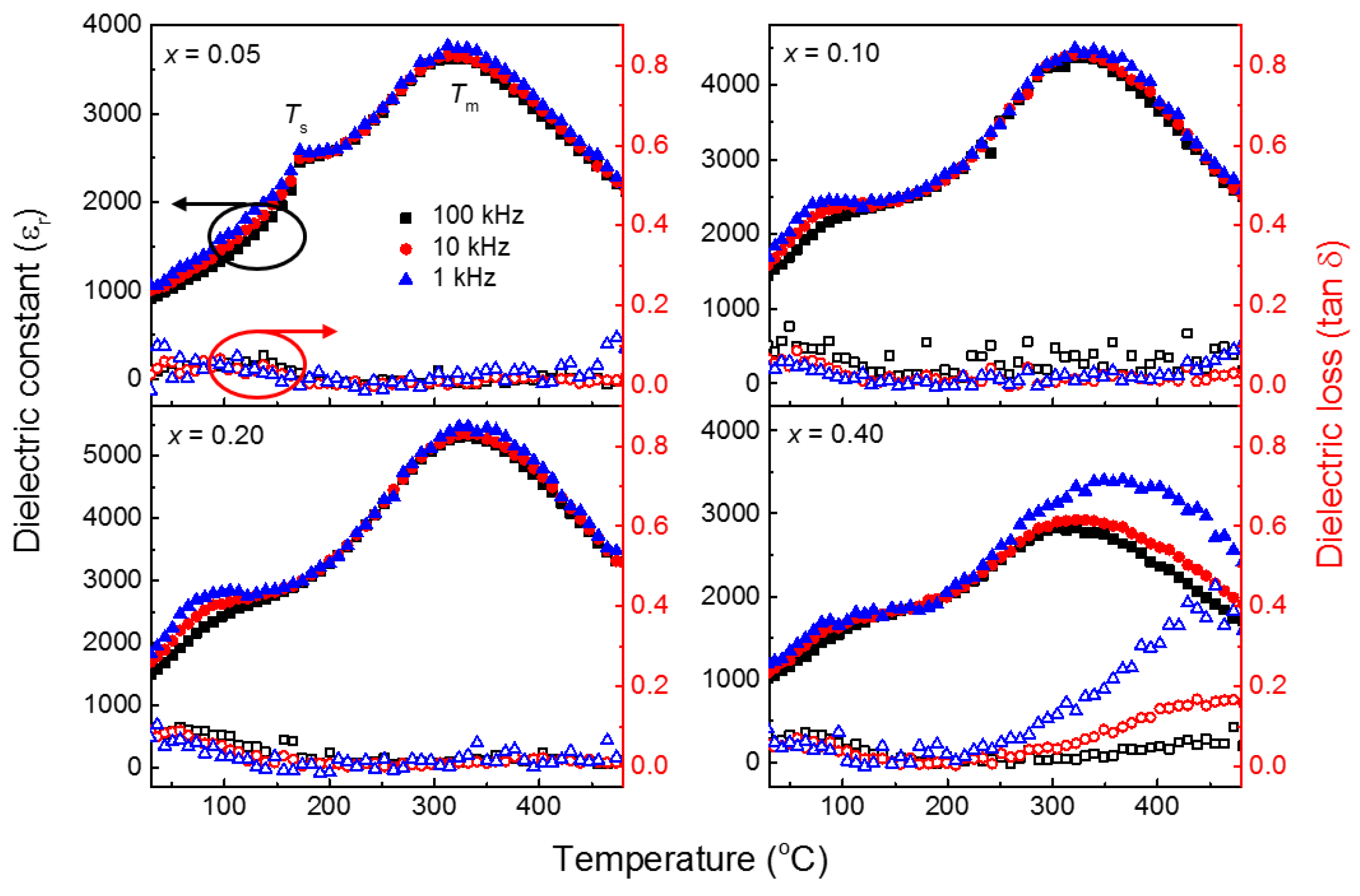

Temperature-dependent dielectric constant (

εr) and loss tangent (

) of the BNKT ceramics for frequencies of 1, 10, and 100 kHz are shown in

Figure 5. Two characteristic peaks could be identified in all specimens; the frequency-dispersive shoulder (

Ts) was seen from a relatively lower temperature, and the diffuse peak (

Tm) was identified from a relatively higher temperature, which are characteristics of relaxor ferroelectrics. The

Ts is known to arise from two events, both the depolarization (

Td) and the ferroelectric-relaxor transition (

Tf–r), which are thermally induced [

21]. In the case of temperature rising further, rhombohedral

R3

c PNRs that change into tetragonal

P4

bm PNRs, a high temperature anomaly at

Tm, have been known to occur [

8,

22]. This phenomena can be explained using a relaxor model assuming a two-phase mixture that is comprises the polar rhombohedral

R3

c clusters dispersed in the weakly polar or tetragonal

P4

bm matrix [

8].

We here note that, for

x = 0.05, the

Ts peak appeared at around 170 °C, and it tended to shift at around 80 °C as the composition of

x increased (For

x ≥ 0.10, the

Ts points are assumed to be the same as the inflection point of the dielectric dispersion). This suggests that an increase in the composition of

x is closely associated with a decrease in

Ts. Previous studies have identified that the shift of

Tf–r together with the attainment of composition-induced large strain occurs through structural changes, such as changes in composition and/or doping. Therefore, they suggested an electric field-induced ER-to-ferroelectric transition occurring near

Tf–r as the cause of large strain [

5,

23].

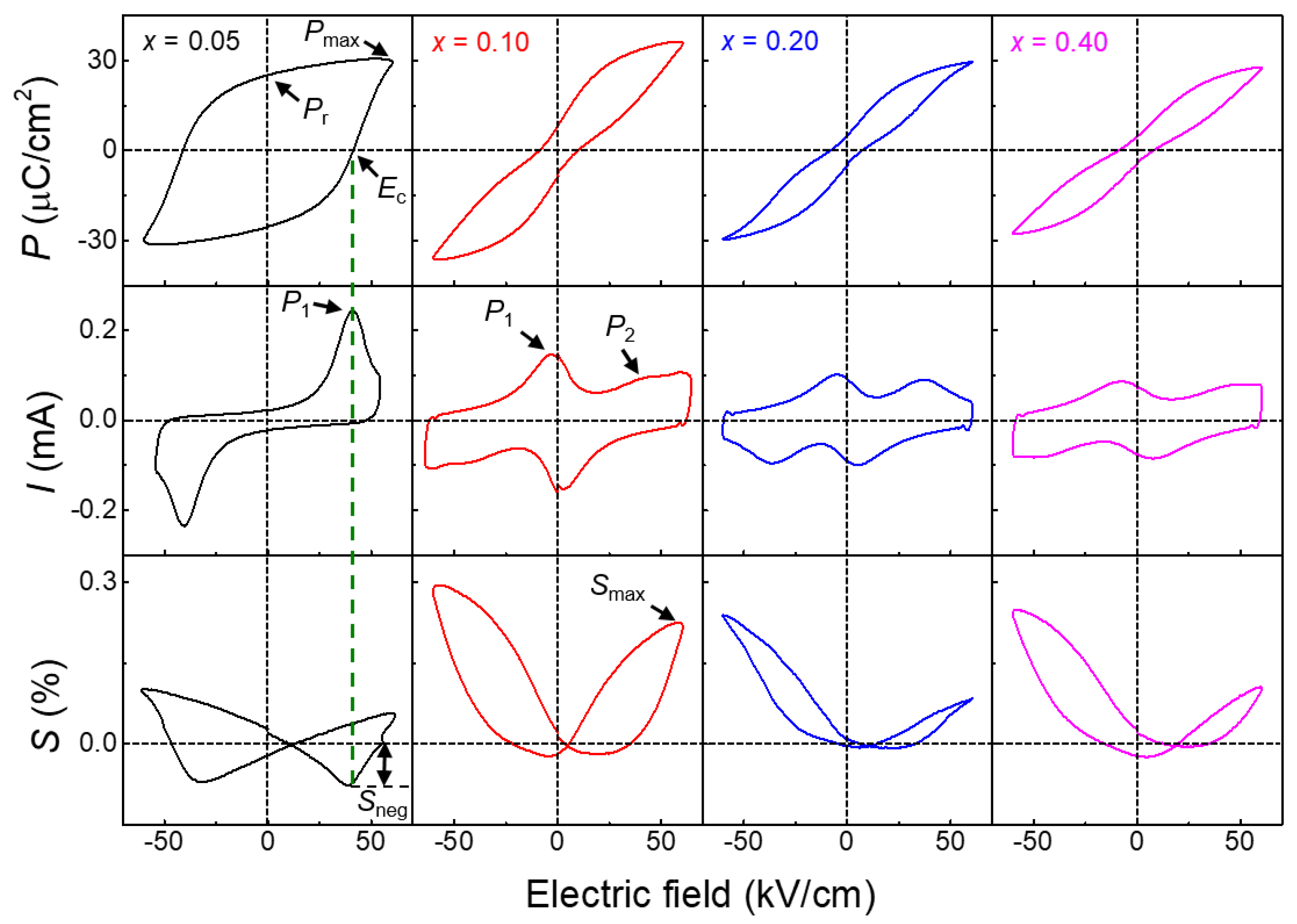

Figure 6 shows the measurements of polarization (

P), current (

I), and strain (

S) for BNKT ceramics under 10 Hz at room temperature. For the specimen of

x = 0.05, the typical shape

P-

E hysteresis loops from ferroelectrics could be seen together with respective values for remnant polarization (

Pr), coercive field (

Ec) and maximum polarization (

Pmax) of 25.3 μC/cm

2, 44 kV/cm, and 29.6 μC/cm

2, respectively. However, the pinch-type

P-

E loops appeared in accordance with increasing

x. Thereby the values of

Pr and

Ec tended to become relatively lower compared to the specimen with

x = 0.05. However,

Pmax remained roughly the same. The decrease in values of

Pr and

Ec is consistent with that reported by Iqbal et al. [

24], which may be a result of a disruption of long-range ferroelectric ordering.

The two peaks, distinguished into

P1 and

P2, are shown in the

I-

E loops of

Figure 6. For

x = 0.05, the strong current peak appeared in the position of

P1, which coincided with the position of

Ec. Thus,

P1 is the peak associated with the switching of ferroelectric polarization that is found in the typical ferroelectrics. By considering the results of temperature-dependent dielectric properties measurement, mentioned above, these results suggest the presence of PNRs inside the ferroelectric domains. In addition, Xu et al. [

25] suggested the supporting results. They showed that the PNRs with [110]-type polarizations could be embedded in the [111]-polarized oriented relaxor Pb(Zn

1/3Nb

2/3)O

3 single crystal. Thereafter, the

P1 peak of the specimen

x = 0.10 shifts to either a low electric field or near zero field and has a value different from

Ec. Together with this, the PNRs can be arranged and can be formed into a long-range ferroelectric order, so

P2 can appear in accordance with increasing the external electric field. That is, it can make a transition from a weakly polar (relaxor ferroelectric phase) to polar phases (ferroelectric phase) by the external electric field [

18]. These results suggest a NR (

x = 0.05) changes into an ER (

x = 0.10) in accordance with increasing composition of

x.

S-

E loops showed the strain according to an electric field (we here measured by using bipolar cycle). The inverse piezoelectric coefficient (

d33* = (

Smax−

Sneg)/

Emax, units of pm/V) can be calculated through this. In the specimen

x = 0.05, the

S–E loop showed a classical butterfly-shaped curve. However, in compositions beyond

x = 0.10, it exhibited a sprout-shaped and asymmetric curves. By taking account of the experimental results mentioned above, for a composition beyond

x = 0.10 suggests the ER, usually found at high temperature, might be induced at room temperature. In this context, studies focusing on the characteristics of PNRs are in progress by many researchers by using various dopants in relaxor ferroelectrics [

8,

12]. From such a standpoint, we can see that BNKT system can be constructed by the substitution of potassium (K) for A-site ions (Bi, Na) in a relaxor ferroelectric BNT, and this line of thinking fits well with the results of studies suggesting that pure BNT is not a typical ferroelectric but a relaxor ferroelectric [

8].

In the meantime, a negative strain (

Sneg) represented the volumetric shrinkage due to an external electric field, and generally, it had the highest value at the point

Ec, whereon the domain switching of ferroelectrics occurred. Thereafter,

Sneg decreased continuously with the decrease in the electric field (without an external electric field in the opposite direction). This suggests that

Sneg originates from remnant polarization. Characteristically, the maximum value of

d33* is observed at the point where the value of

Pr decreases rapidly (

Figure 7). Considering the motion of actuators in connection with this, actuators actually used in practice work on a unipolar cycle. Thereby, the deformation used in actuator applications can be obtained simply from the difference between the maximum strain (

Smax) and

Sneg. Therefore, piezoelectric characteristics are improved with increasing values of

Sneg, whereas the value of strain (the value associated with the value of

d33*) is decreased somewhat. That is, the improvement in strain and piezoelectric characteristics are a trade-off [

26]. The values of

Sneg decreased rapidly from 0.08% (

x = 0.05) to 0.02% (

x = 0.10). After that, it was maintained at about 0.01% (

Figure 7). This reduction in

Sneg may suggest the performance improvement in piezoelectric actuator applications (in other words, in the device wise, the operating performance of the actuator may be estimated by

d33*).

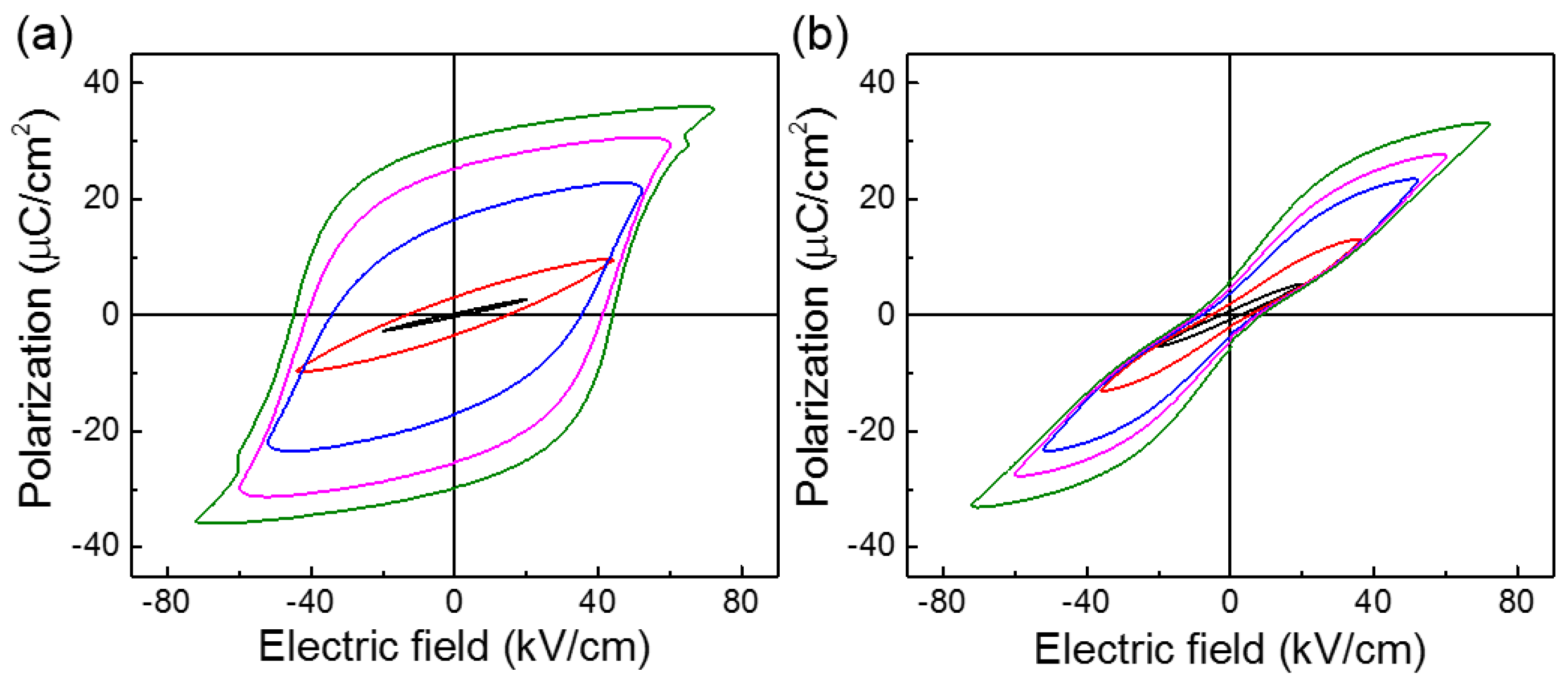

To see the variation of

P-

E hysteresis loops with applied electric fields, we measured the

P-

E hysteresis loops.

Figure 8 shows the

P-

E hysteresis loops according to an external electric field, measured for

x = 0.05 and

x = 0.10.

Figure 8a shows the shape of a typical ferroelectric hysteresis loop with large values of

Pr,

Ec, and

Pmax at 70 kV/cm. It can be seen that wide increasing width in the increasing

Pr and

Ec became narrow at saturation point, which is a similar trend to that reported for BNT-based materials and is close to the characteristics seen for pure BNT [

27]. In

Figure 8b, the loop had low

Pr (5.9 μC/cm

2) and

Ec (8.7 kV/cm) but still had high

Pmax (35.6 μC/cm

2) at 70 kV/cm. In addition, as we can see, the width was narrow.

Based on

Figure 8, the change in

Pmax and

Pr in accordance with the composition of

x can be summarized as follows; the value of

Pr decreased rapidly as

x increased beyond the point of

x = 0.10. On the contrary,

Pmax remained nearly constant in the range 28.0 to 30.2 μC/cm

2 for all compositions except for the

x = 0.10 (35.8 μC/cm

2) that had the highest value of

Pmax. According to the equation

, the difference between

Pmax and

Pr (denoted as

Pmax −

Pr) is related to the energy-storage density (

). It suggests that our sample of

x = 0.10 is a particularly promising material for use in capacitor devices as the value of

Pmax −

Pr was 28.3 µC/cm

2 [

28], even though ER often have high power losses, which limit their use in application, such as the higher electric field. Furthermore, a higher value of

d33* (336 pm/V) was achieved at

x = 0.10. We note that the inverse piezoelectric response was improved about 6.6 times compared with

x = 0.05 (

d33* = 51 pm/V).

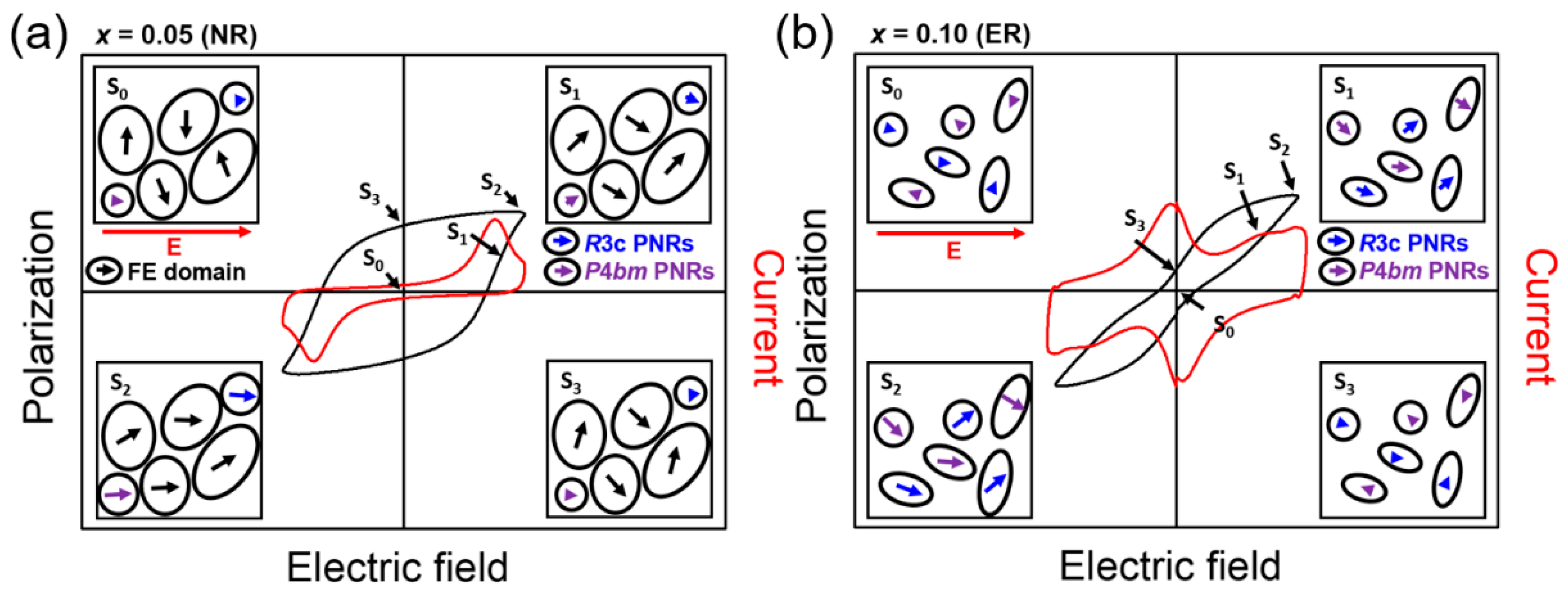

Here we propose a possible mechanism showing the formation of PNRs and their variations with the external applied field.

Figure 9 shows a diagram illustrating the process of the formation of PNRs according to an external electric field for

x = 0.05 (NR) and

x = 0.10 (ER). The formation of PNRs at

x = 0.05 was possible as its phase was an NR at room temperature [

9]. In its initial state (

S0), the directions of polarizations in the ferroelectric (FE) domains mostly cancel each other out, and the total polarization becomes 0, and PNRs are with the FE domains. It is well known that PNRs in BNT-based samples coexist with rhombohedral

R3

c and tetragonal

P4

bm structures [

8,

22]. In addition, the free energy between coexisting

R3

c and

P4

bm PNRs is so small. This makes it relatively easy for the interconversion between them [

8]. In accordance with an increase in external electric field, PNRs, having a weak polarization alignment with coexistence of rhombohedral and tetragonal structure, we denoted

S1 at the point

P1 (see

Figure 6), thereby the total amount of polarization will increase after the initiation of arrangement of the FE domains along the direction of the external electric field. Thereafter, the value of polarization reached its peak (

S2) at the maximum electric field (

Emax) due to the arrangement of the FE domain and PNRs along the directions of the electric field. And then, PNRs were randomly aligned as in the initial state, and the polarization disappeared after the removal of the external electric field, but the residual dielectric polarization (

Pr) of the FE domain remained (

S3). Thus, this material exhibited similar behaviors to those seen in typical ferroelectrics. On the other hand, for

x = 0.10, there was no polarization at the initial state (

S0), and it had an ER at room temperature. Based on the above discussions, we assume that the initial state was a mixed state of paraelectric and PNRs. In other words, the NR had PNRs in the state of the ferroelectric phase, and the ER had PNRs in the state of the paraelectric phase. Along with an increase in the external electric field, there was polarization along the direction of the external electric field (

S1) seen from

P2 (see

Figure 6). Thereafter, PNRs represented the peak value (

S2) at

Emax by their arrangement along the electric field direction. PNRs were randomly aligned, and polarization disappeared after the removal of the external electric field, and the material returned to its initial state (Polarization 0) (

S3).

Let us consider the origin of the PNRs from these results in our ceramics. Ion substitution in relaxor BNT material is one of the most probable causes. That is, the distortion in the lattice structure due to the difference in ionic radius of A-site ions can induce the formation of PNRs. As a result, PNRs are an inherent property of relaxor ferroelectrics. Furthermore, there should exist a sort of lack of sites of A-site ions and oxygens, which can be formed during the sintering process at high temperature. This nonstoichiometric oxygen-deficiency is practically always observed in oxygen-octahedral ferroelectrics. A-site vacancies, caused by the high volatility of Bi

3+, and alkaline earth metal, Na

+ and K

+, have been known to induce the distortion of the lattice structure by diminishing interactions between A-site cations and oxygen-octahedral [

29]. Recently, experimental studies [

28] in acceptor-doped relaxor ferroelectrics have also theorized about the use of complexes of acceptor ions and induced oxygen vacancies, called dipolar defects. It is not clearly established yet.

Thus, we note that it is important to suggest the effects of the interactions between domain motion and space charges, such as vacancies, impurities, and charged defects. Together with this, by taking account of the results of our XRD measurements, we can say that the transition from rhombohedral to tetragonal structure occurs due to the substitution of the K ion. In the process of transition, the ER at room temperature can be induced at the point where ratios of rhombohedral and tetragonal structures become similar. Thus, large strain can manifest itself even at room temperature. Thus, we present the complexes of acceptor ions and induced oxygen vacancies as one of the origins of this large strain seen in our investigated specimen.