Prediction of Slag Characteristics Based on Artificial Neural Network for Molten Gasification of Hazardous Wastes

Abstract

1. Introduction

2. Materials and Methods

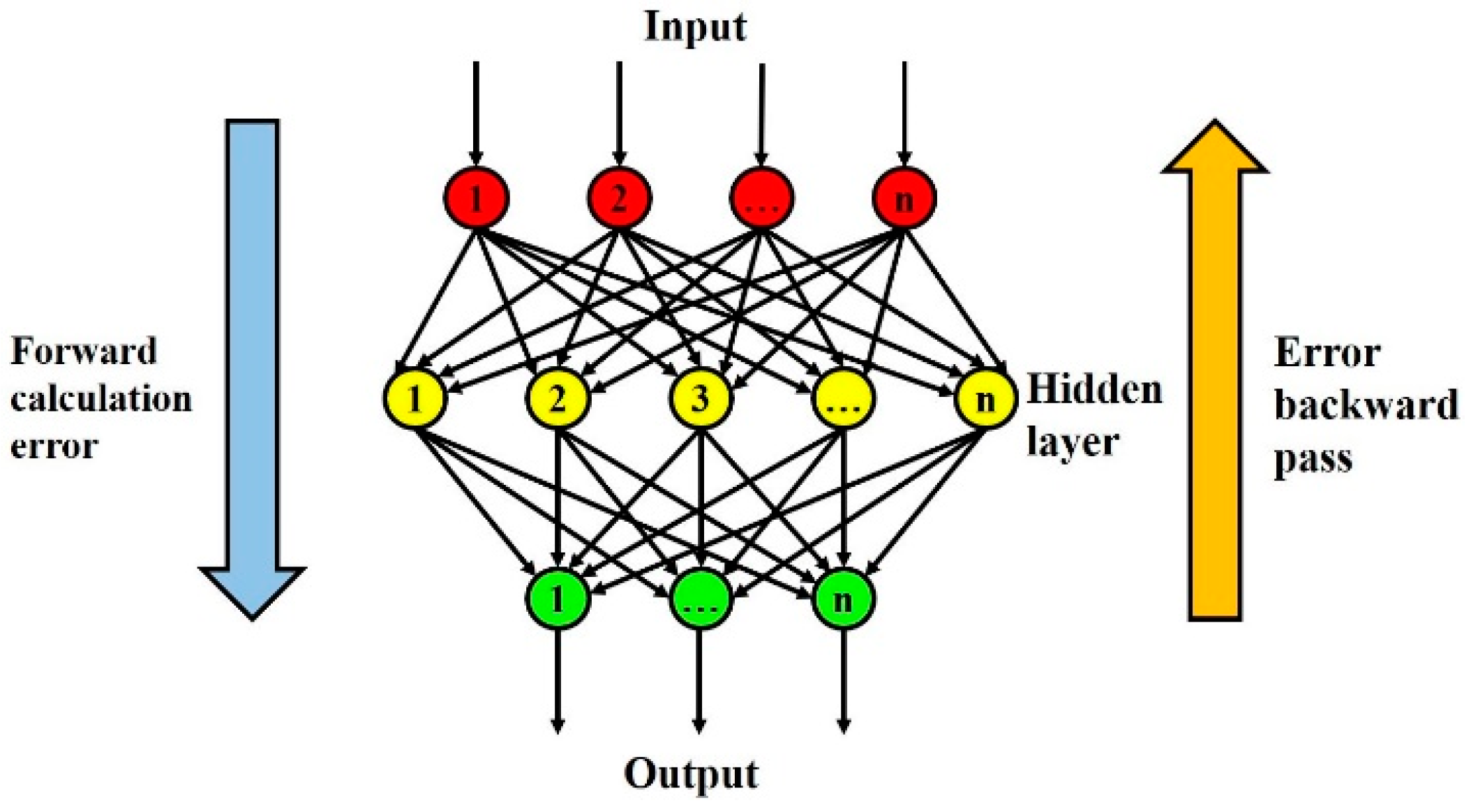

2.1. Topological Structure of Neural Network

2.2. Model Development for the Classification of Slags

- (1)

- Data acquisition and processing

- (2)

- The design of BP neural network

2.3. Slag Classification Model for Multiple Atmospheres

2.4. Slag Viscosity Prediction Model for Mild Reducing Atmosphere

2.5. Slag Viscosity Prediction Model for Multiple Atmospheres

3. Results

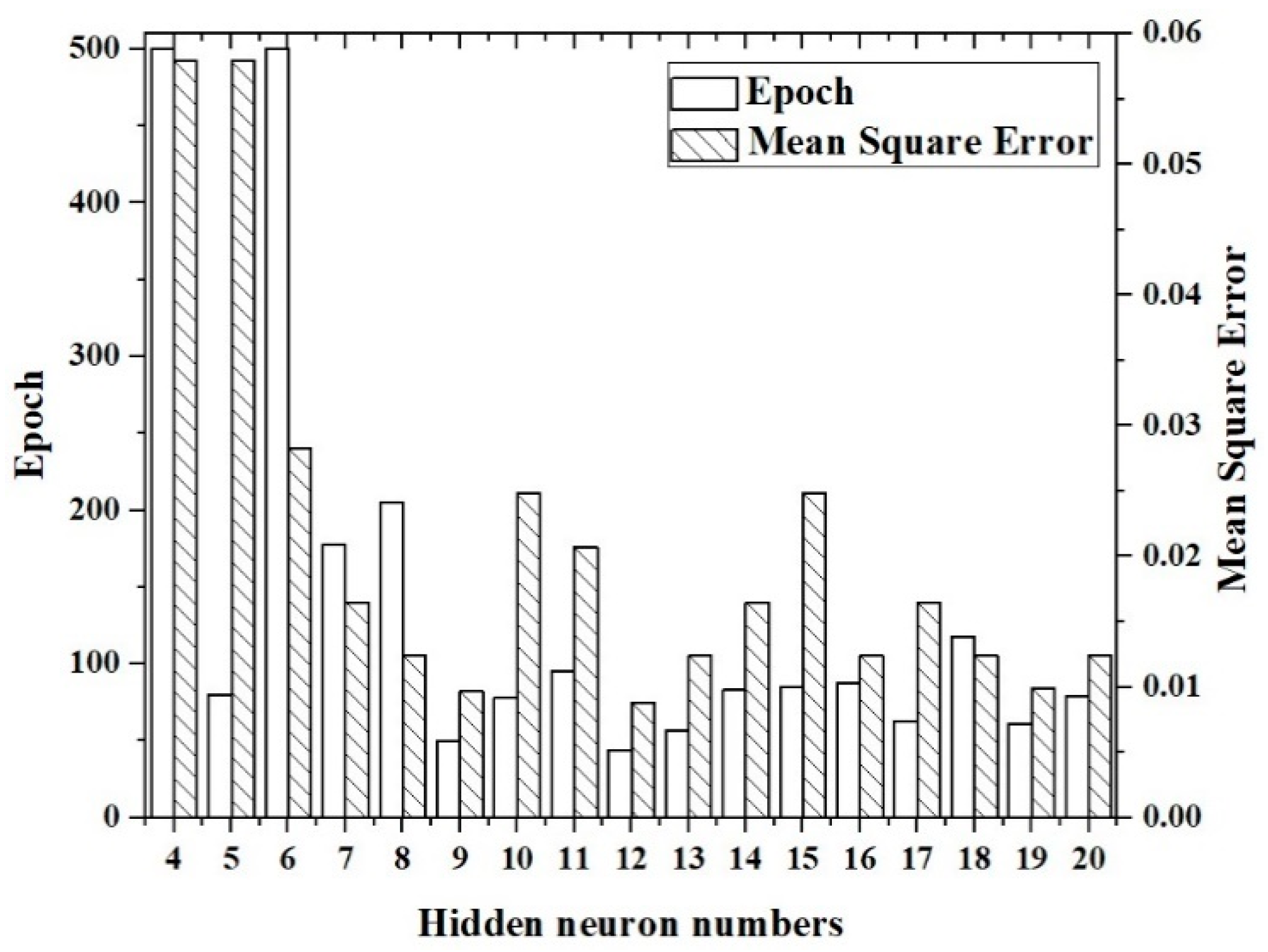

3.1. Optimized Activation Functions, Model Parameters and Algorithm

- (1)

- Slag classification results under a mildly reducing atmosphere (model 1)

- (2)

- Slag classification results under multiple atmospheres (model 2)

- (3)

- Viscosity prediction results under mildly reducing atmosphere (model 3)

- (4)

- Viscosity prediction results under multiple atmospheres (model 4)

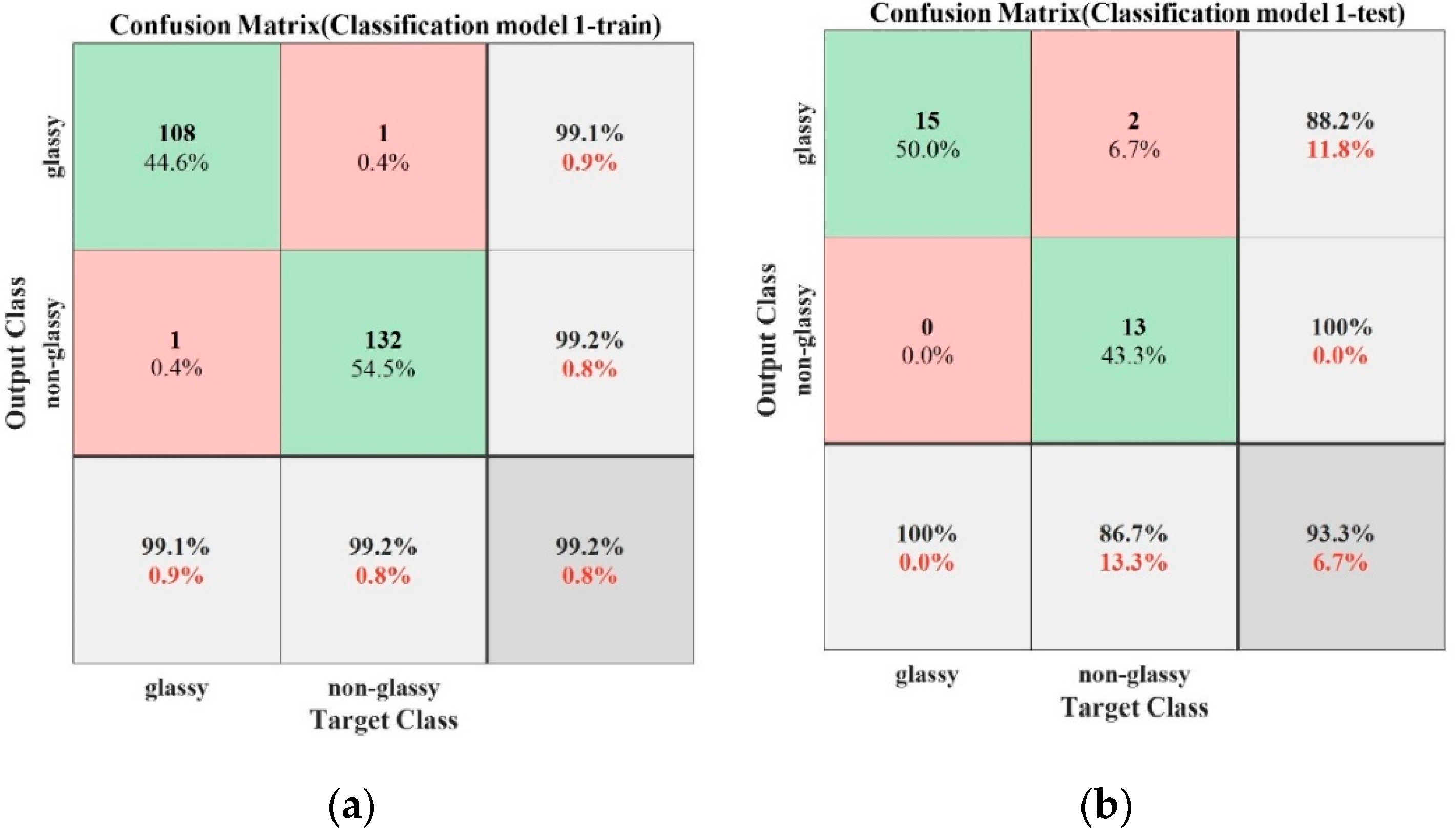

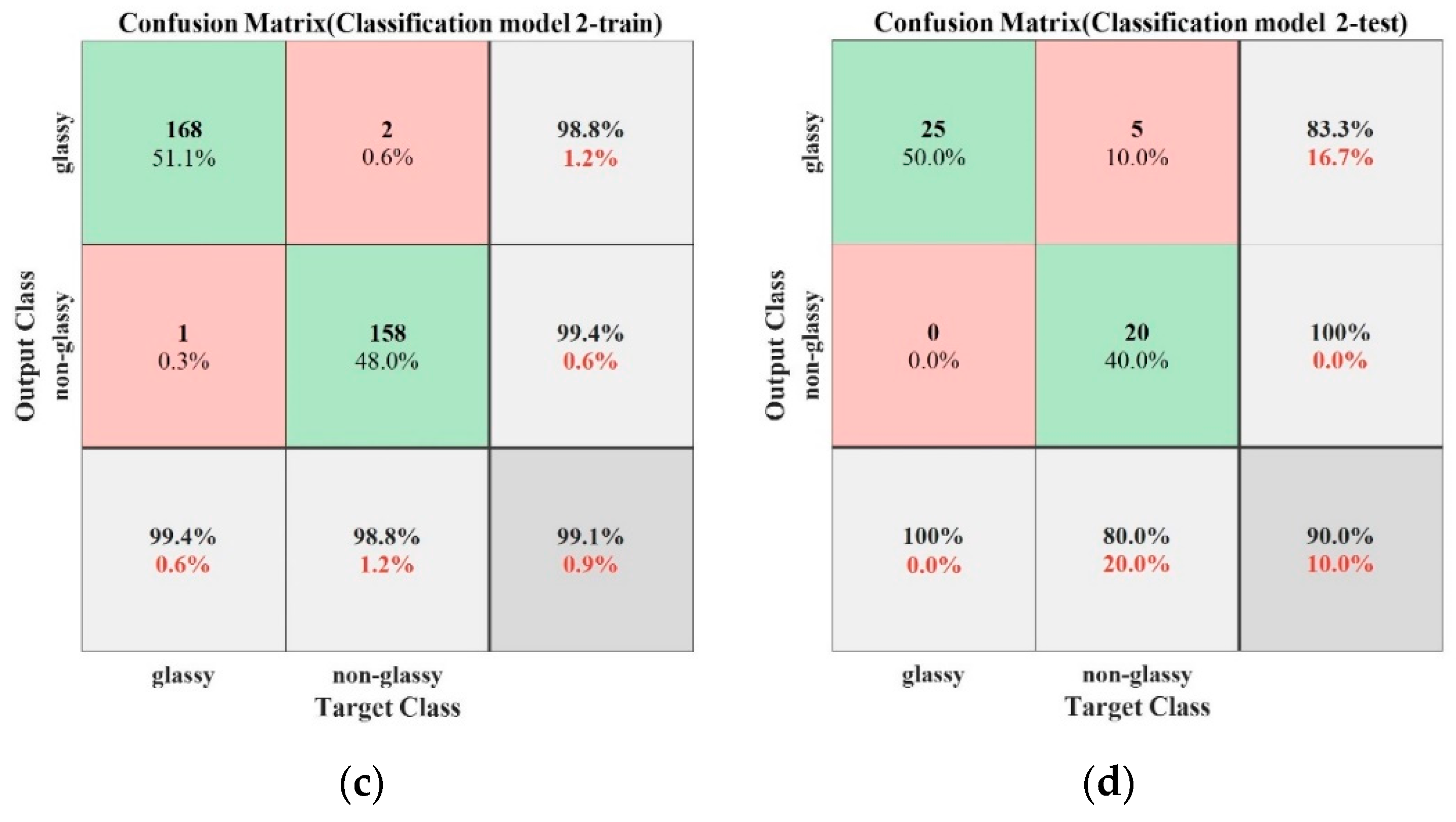

3.2. Slag Classification Results

3.2.1. Slag Classification Results for Mild Reducing Atmosphere (Model 1)

3.2.2. Slag Classification Results under Multiple Atmospheres (Model 2)

3.3. Viscosity Prediction Results

3.3.1. Viscosity Prediction Results for a Mild Reducing Atmosphere (Model 3)

3.3.2. Viscosity Prediction Results under Multiple Atmospheres (Model 4)

4. Discussion

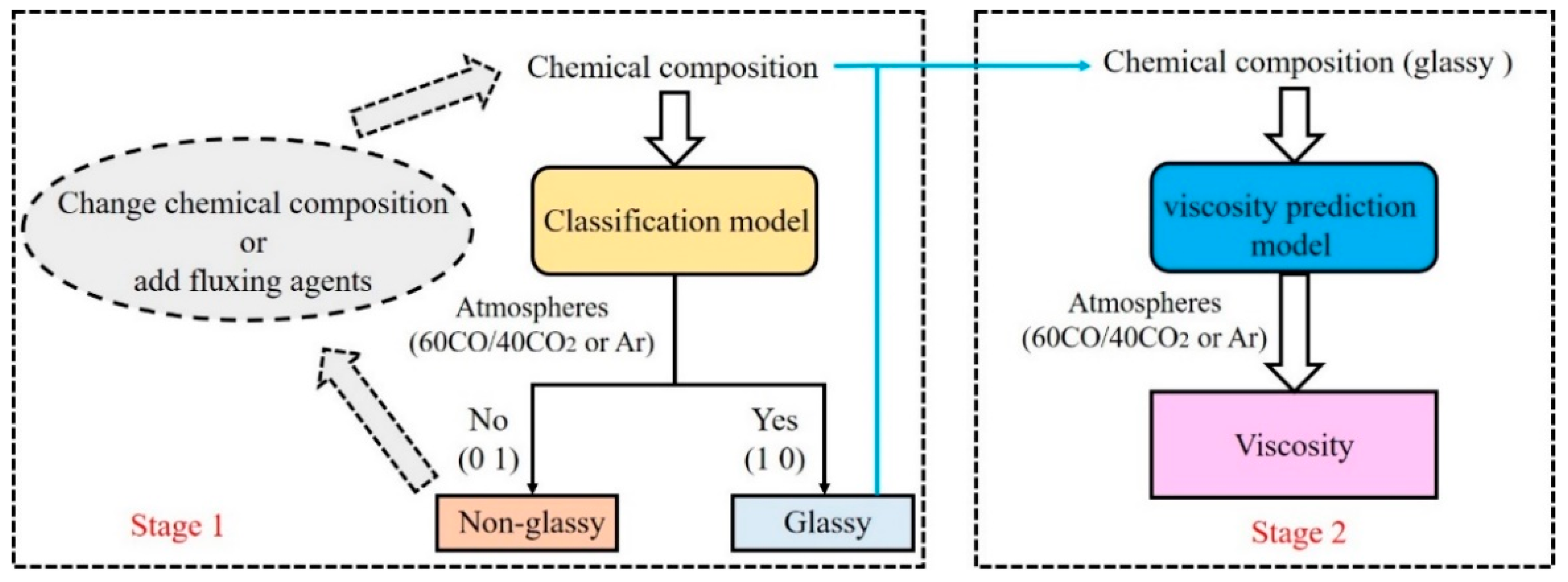

4.1. Technological Usage of Slag Characteristics Prediction Models

4.2. Limitations and Improvement Methods of the Model

5. Conclusions

- (1)

- The slag classification accuracy of the single-atmosphere model is over 93%. Using 1 and 0 as model inputs to represent mildly reducing (60CO/40CO2) and inert (Ar) atmospheres, an effective slag classification neural network model that accounts for different atmospheres was developed. The slag classification accuracy of the multiple-atmosphere model was above 90%. If the influence of the atmosphere is not considered, the classification accuracy based on the same model set-up will be compromised.

- (2)

- A double hidden layer structure enables the neural network to predict the viscosity of glassy slag under a mildly reducing atmosphere. The quality and quantity of data were enough to show the productivities of developed networks. The absolute error of the simulation with 500 test data was generally lower than 4 Pa·s, the maximum absolute error was lower than 9 Pa·s and the average error was 0.86 Pa·s. Using the atmospheric factor data as the input of the neural network, a viscosity prediction model under multiple atmospheres was developed. The absolute error of the simulation with 800 test data was within 10 Pa·s and the average error was 1.60 Pa·s.

- (3)

- The experimental data were used to verify the correlation of the prediction results. The classification model showed that the prepared slags were all glassy. Then, the viscosities of glassy slags were obtained by using the prediction model. The relatively large simulation errors were prone to occur at high temperatures. The model was better at predicting the viscosity of multi-component slag. The simulated viscosity error of slag was within 15%.

- (4)

- It is necessary to narrow the range of chemical composition to obtain a special neural network for predicting the viscosity of a certain molten gasifier or iron-rich slags. There are few experiments on the viscosity tests of hazardous wastes with high salt content (Na2O > 20 wt%), which is a potential challenge. Advanced artificial intelligence, such as deep, learning with more experimental influence factors, needs to be better applied to the viscosity prediction of slag.

Author Contributions

Funding

Conflicts of Interest

References

- Moustakas, K.; Fatta, D.; Malamis, S.; Haralambous, K.; Loizidou, M. Demonstration plasma gasification/vitrification system for effective hazardous waste treatment. J. Hazard. Mater. 2005, 123, 120–126. [Google Scholar] [CrossRef]

- Tanigaki, N.; Manako, K.; Osada, M. Co-gasification of municipal solid waste and material recovery in a large-scale gasification and melting system. Waste Manag. 2012, 32, 667–675. [Google Scholar] [CrossRef] [PubMed]

- Stąsiek, J.; Szkodo, M. Thermochemical Conversion of biomass and municipal waste into useful energy using advanced HiTAG/HiTSG technology. Energies 2020, 13, 4218. [Google Scholar] [CrossRef]

- Zan, R.; Wang, W.; Xu, R.S.; Schenk, J.; Zheng, H.; Wang, H.X. Gasification characteristics and kinetics of unburned pulverized coal in blast furnaces. Energies 2019, 12, 4324. [Google Scholar] [CrossRef]

- Roberts, L.J.; Mason, P.E.; Jones, J.M.; Gale, W.F.; Williams, A.; Hunt, A.; Ashman, J. The impact of aluminosilicate-based additives upon the sintering and melting behavior of biomass ash. Biomass Bioenergy 2019, 127, 105284. [Google Scholar] [CrossRef]

- Indrawan, N.; Simkins, B.; Kumar, A.; Huhnke, R.L. Economics of distributed power generation via gasification of biomass and municipal solid waste. Energies 2020, 13, 3703. [Google Scholar] [CrossRef]

- Kong, L.X.; Bai, J.; Li, W.Q.; Wen, X.D. The internal and external factor on coal ash slag viscosity at high temperatures, Part 3: Effect of CaO on the pattern of viscosity—Temperature curves of slag. Fuel 2016, 179, 10–16. [Google Scholar] [CrossRef]

- Vargas, S.; Frandsen, F.J.; Dam, J.K. Rheological properties of high-temperature melts of coal ashes and other silicates. Prog. Energy Combust. Sci. 2001, 27, 237–429. [Google Scholar] [CrossRef]

- Ilyushechkin, A.Y.; Hla, S.S.; Roberts, D.G.; Kinaev, N.N. The effect of solids and phase compositions on viscosity behavior and TCV of slags from Australian bituminous coals. J. Non Cryst. Solids 2011, 357, 893–902. [Google Scholar] [CrossRef]

- Najser, J.; Buryan, P.; Skoblia, S.; Frantik, J.; Kielar, J.; Peer, V. Problems related to gasification of biomass—Properties of solid pollutants in raw gas. Energies 2019, 12, 963. [Google Scholar] [CrossRef]

- Ramos, A.; Teixeira, C.A.; Rouboa, A. Environmental assessment of municipal solid waste by two-stage plasma gasification. Energies 2019, 12, 137. [Google Scholar] [CrossRef]

- Park, W.; Oh, M.S. Slagging of petroleum coke ash using Korean anthracites. J. Ind. Eng. Chem. 2007, 14, 350–356. [Google Scholar] [CrossRef]

- Schwitalla, D.; Reinmöller, M.; Forman, C.; Wolfersdorf, C.; Gootz, M.; Bai, J.; Guhl, S.; Neuroth, M.; Meyer, B. Ash and slag properties for co-gasification of sewage sludge and coal: An experimentally validated modeling approach. Fuel Process. Technol. 2018, 175, 1–9. [Google Scholar] [CrossRef]

- Arvelakis, S.; Frandsen, F.J.; Folkedahl, B.; Hurley, J. Viscosity of ashes from energy production and municipal solid waste handling: A comparative study between two different experimental setups. Energy Fuels 2008, 22, 2948–2954. [Google Scholar] [CrossRef]

- Reid, W.T. The relation of mineral composition to slagging, fouling and erosion during and after combustion. Prog. Energy Combust. Sci. 1984, 10, 159–169. [Google Scholar] [CrossRef]

- Xuan, W.W.; Wang, H.N.; Xia, D.H. Deep structure analysis on coal slags with increasing silicon content and correlation with melt viscosity. Fuel 2019, 242, 362–367. [Google Scholar] [CrossRef]

- Li, W.; Wang, B.; Nie, J.; Yang, W.; Xu, L.L.; Sun, L.S. Migration and transformation of vanadium and nickel in high sulfur petroleum coke during gasification processes. Energies 2018, 11, 2158. [Google Scholar] [CrossRef]

- Machin, J.S.; Yee, T.B.; Hanna, D.L. Viscosity studies of system CaO–MgO–Al2O3–SiO2: III, 35, 45, and 50% SiO2. J. Am. Ceram. Soc. 2010, 35, 322–325. [Google Scholar] [CrossRef]

- Klein, L.C.; Fasano, B.V.; Wu, J.M. Viscous flow behavior of four iron-containing silicates with alumina, effects of composition and oxidation condition. J. Geophys. Res. 1983, 88, 880–886. [Google Scholar] [CrossRef]

- Mysen, B.O.; Virgo, D.; Seifert, F.A. The structure of silicate melts: Implications for chemical and physical properties of natural magma. Rev. Geophys. Space Phys. 1982, 20, 353–383. [Google Scholar] [CrossRef]

- Jia, R.D.; Deng, L.B.; Yun, F.; Li, H.; Zhang, X.F.; Jia, X.L. Effects of SiO2/CaO ratio on viscosity, structure, and mechanical properties of blast furnace slag glass ceramics. Mater. Chem. Phys. 2019, 233, 155–162. [Google Scholar] [CrossRef]

- Kondratiev, A.; Jak, E. Predicting coal ash slag flow characteristics (viscosity model for the Al2O3–CaO–‘FeO’–SiO2 system). Fuel 2001, 80, 1989–2000. [Google Scholar] [CrossRef]

- Xue, Z.C.; Guo, Q.H.; Gong, Y.; Wang, Y.F. In-situ atomization and flame characteristics of coal water slurry in an impinging entrained-flow gasifier. Chem. Eng. Sci. 2018, 190, 248–259. [Google Scholar] [CrossRef]

- Ma, Y.S.; Wu, G.X.; Guo, Q.H.; Liu, X.; Gong, Y.; Yu, G.S. Investigation of fluctuation behavior in viscosity of coal slags used in entrained-flow gasifiers. Fuel Process. Technol. 2018, 181, 133–141. [Google Scholar] [CrossRef]

- He, C.; Bai, J.; Kong, L.X.; Xu, J.; Guhl, S.; Li, X.M.; Ge, Z.F.; Cao, X.; Bai, Z.Q.; Li, W. Effects of atmosphere on the oxidation state of iron and viscosity behavior of coal ash slag. Fuel 2019, 243, 41–51. [Google Scholar] [CrossRef]

- Dahou, T.; Defoort, F.; Thiéry, S.; Grateau, M.; Campargue, M.; Bennici, S.; Jeguirim, M.; Dupont, C. The influence of char preparation and biomass type on char steam gasification kinetics. Energies 2018, 11, 2126. [Google Scholar] [CrossRef]

- Song, L.; Huang, L.J.; Long, B.; Li, F.S. A genetic-algorithm-based dc current minimization scheme for transformless grid-connected photovoltaic inverters. Energies 2020, 13, 746. [Google Scholar] [CrossRef]

- Cheng, J.; Li, Y.C.; Zhou, J.H.; Liu, J.Z.; Cen, K.F. Maximum solid concentrations of coal water slurries predicted by neural network models. Fuel Process. Technol. 2010, 91, 1832–1838. [Google Scholar] [CrossRef]

- Ji, H.C.; Yang, J.Y.; Wang, H.X.; Tian, K.; Okoye, M.O.; Feng, J.W. Electricity consumption prediction of solid electric thermal storage with a cyber–physical approach. Energies 2019, 12, 4744. [Google Scholar] [CrossRef]

- Han, W.; Nan, L.B.; Su, M.; Chen, Y.; Li, R.N.; Zhang, X.J. Research on the prediction method of centrifugal pump performance based on a double hidden layer BP neural network. Energies 2019, 12, 2709. [Google Scholar] [CrossRef]

- Cao, X.; Kong, L.X.; Bai, J.; Zhao, H.L.; Ge, Z.F.; Li, H.Z.; Bai, Z.Q.; Li, W. Effect of water vapor on viscosity behavior of coal slags with high silicon-aluminum level under gasification condition. Fuel 2020, 260, 116351. [Google Scholar] [CrossRef]

- Bai, J.; Li, W.; Li, B.Q. Characterization of low-temperature coal ash behaviors at high temperatures under reducing atmosphere. Fuel 2008, 87, 583–591. [Google Scholar] [CrossRef]

- Bryant, G.W.; Browning, G.J.; Gupta, S.K.; Lucas, J.A.; Gupta, R.P.; Wall, T.F. Thermomechanical analysis of coal ash: The influence of the material for the sample assembly. Energy Fuels 2000, 14, 326–335. [Google Scholar] [CrossRef]

- Meng, Y.H.; Chen, Y.W.; Zhu, F.B.; Tian, E.L. The integration of marine biodiversity information resources based on big data technology. J. Coast. Res. 2020, 103, 806–811. [Google Scholar] [CrossRef]

- Streun, G.L.; Elmiger, M.P.; Dobay, A.; Ebert, L.; Kraemer, T. A machine learning approach for handling big data produced by high resolution mass spectrometry after data independent acquisition of small molecules—Proof of concept study using an artificial neural network for sample classification. Drug Test. Anal. 2020, 12, 836–845. [Google Scholar] [CrossRef]

- Liu, Y.P.; Wu, M.G.; Qian, J.X. Predicting coal ash fusion temperature based on its chemical composition using ACO-BP neural network. Thermochim. Acta 2007, 454, 64–68. [Google Scholar] [CrossRef]

- Huang, A.; Huo, Y.Z.; Yang, J.; Gu, H.Z.; Li, G.Q. Computational modeling and prediction on viscosity of slags by big data mining. Minerals 2020, 10, 257. [Google Scholar] [CrossRef]

- Oh, G.; Ra, H.W.; Yoon, S.M.; Mun, T.Y.; Seo, M.W.; Lee, J.G.; Yoon, S.J. Gasification of coal water mixture in an entrained-flow gasifier: Effect of air and oxygen mixing ratio. Appl. Therm. Eng. 2018, 129, 657–664. [Google Scholar] [CrossRef]

- Wan, L.J.; Li, H.Y.; Chen, Y.W.; Li, C.Y. Rolling bearing fault prediction method based on QPSO-BP neural network and dempster–shafer evidence theory. Energies 2020, 13, 1094. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G.W.; Ning, X.J.; Zhang, J.L.; Li, Y.J.; Zhang, N. Application of BP neural network to the prediction of coal ash melting characteristic temperature. Fuel 2020, 260, 116324. [Google Scholar]

- Liu, P.; Zheng, P.J.; Chen, Z.Y. Deep learning with stacked denoising auto-encoder for short-term electric load forecasting. Energies 2019, 12, 2445. [Google Scholar] [CrossRef]

- Li, H.B.; Sun, H.; Tian, J.C.; Yang, Q.N.; Wan, Q.Q. Mechanical and ultrasonic testing of self-compacting concrete. Energies 2019, 12, 2187. [Google Scholar] [CrossRef]

- Xiang, M.; Min, J.; Wang, Z.Q.; Gao, P. A novel fault early warning model based on fault gene table for smart distribution grids. Energies 2017, 10, 1963. [Google Scholar] [CrossRef]

- Chen, X.D.; Kong, L.X.; Bai, J.; Dai, X.; Li, H.Z.; Bai, Z.Q.; Li, W. The key for sodium-rich coal utilization in entrained flow gasifier: The role of sodium on slag viscosity-temperature behavior at high temperatures. Appl. Energy 2017, 206, 1241–1249. [Google Scholar] [CrossRef]

- Mukherjee, S.; Srivastava, S.K. Minerals transformations in northeastern region coals of India on heat treatment. Energy Fuels 2006, 20, 1089–1096. [Google Scholar] [CrossRef]

- Kim, M.; Ye, I.; Ryu, C. Effect of slag viscosity model on transient simulations of wall slag flow in an entrained coal gasifier. Korean J. Chem. Eng. 2018, 35, 1065–1072. [Google Scholar] [CrossRef]

- Yun, Y.; Yoo, Y.D.; Chung, S.W. Selection of IGCC candidate coals by pilot-scale gasifier operation. Fuel Process. Technol. 2007, 88, 107–116. [Google Scholar] [CrossRef]

- Lin, X.C.; Liu, J.C.; Ideta, K.; Miyawaki, J.; Wang, Y.G.; Mochida, I.; Yoon, S. Cation induced microstructure and viscosity variation of molten synthetic slag analyzed by solid-state NMR. Fuel 2020, 267, 117310. [Google Scholar] [CrossRef]

- Ge, Z.F.; Kong, L.X.; Bai, J.; Zhao, H.L.; Bai, Z.Q.; Meyer, B.; Guhl, S.; Li, P.; Li, W. Effect of CaO/Fe2O3 ratio on slag viscosity behavior under entrained flow gasification conditions. Fuel 2019, 258, 116129. [Google Scholar] [CrossRef]

- Ge, Z.F.; Kong, L.X.; Bai, J.; Zhao, H.L.; Cao, X.; Li, H.Z.; Bai, Z.Q.; Meyer, B.; Guhl, S.; Li, P.; et al. Effect of CaO/Na2O on slag viscosity behavior under entrained flow gasification conditions. Fuel Process. Technol. 2018, 181, 352–360. [Google Scholar] [CrossRef]

- Liu, X.; Yu, G.S.; Xu, J.L.; Liang, Q.F.; Liu, H.F. Viscosity fluctuation behaviors of coal ash slags with high content of calcium and low content of silicon. Fuel Process. Technol. 2017, 158, 115–122. [Google Scholar] [CrossRef]

- Xuan, W.W.; Zhang, J.S.; Xia, D.H. Crystallization characteristics of a coal slag and influence of crystals on the sharp increase of viscosity. Fuel 2016, 176, 102–109. [Google Scholar] [CrossRef]

- Wang, Z.G.; Bai, J.; Kong, L.X.; Wen, X.D.; Li, X.M.; Bai, Z.Q.; Li, W.; Shi, Y. Viscosity of coal ash slag containing vanadium and nickel. Fuel Process. Technol. 2015, 136, 25–33. [Google Scholar] [CrossRef]

- Xuan, W.W.; Wang, H.N.; Xia, D.H. In-situ observation of crystallization inside coal slags and influence of crystals on flow behavior. Fuel 2019, 251, 242–248. [Google Scholar] [CrossRef]

- Kong, L.X.; Bai, J.; Li, W.; Bai, Z.Q.; Guo, Z.X. Effect of lime addition on slag fluidity of coal ash. J. Fuel Chem. Technol. 2011, 39, 407–411. [Google Scholar] [CrossRef]

- Kim, Y.; Oh, M.S. Effect of cooling rate and alumina dissolution on the determination of temperature of critical viscosity of molten slag. Fuel Process. Technol. 2010, 91, 853–858. [Google Scholar] [CrossRef]

- Wang, D.C.; Liang, Q.F.; Gong, X.; Liu, H.F.; Liu, X. Influence of coal blending on ash fusion property and viscosity. Fuel 2017, 189, 15–22. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, Z.J.; Liang, Q.F.; Xu, L.L.; Liu, H.F. A new prediction method for the viscosity of the molten coal slag. Part 2: The viscosity model of crystalline slag. Fuel 2018, 220, 233–239. [Google Scholar] [CrossRef]

- Lin, X.C.; Ideta, K.; Miyawaki, J.; Takebe, H.; Yoon, S.H. Correlation between fluidity properties and local structures of three typical asian coal ashes. Energy Fuels 2012, 26, 2136–2144. [Google Scholar] [CrossRef]

- Brannon, M.J.; Ollis, G.W.; Shoaf, G.L. Expanding the range of suitable gasification fuels. Fuel Process. Technol. 2012, 99, 1–5. [Google Scholar] [CrossRef]

- Yuan, H.P.; Liang, Q.F.; Gong, X. Crystallization of coal ash slags at high temperatures and effects on the viscosity. Energy Fuels 2012, 26, 3717–3722. [Google Scholar] [CrossRef]

- Liu, M.; Shen, Z.J.; Liang, Q.F.; Xu, J.L.; Liu, H.F. New slag–char interaction mode in the later stage of high ash content coal char gasification. Energy Fuels 2018, 32, 11335–11343. [Google Scholar] [CrossRef]

- Shen, Z.J.; Liang, Q.F.; Zhang, B.B.; Xu, J.L.; Liu, H.F. Effect of continuous cooling on the crystallization process and crystal compositions of iron-rich coal slag. Energy Fuels 2015, 29, 3640–3648. [Google Scholar] [CrossRef]

- Guo, Q.H.; Zhou, Z.J.; Wang, F.C.; Yu, G.S. Slag properties of blending coal in an industrial OMB coal water slurry entrained-flow gasifier. Energy Convers. Manag. 2014, 86, 683–688. [Google Scholar] [CrossRef]

- Groen, J.C.; Brooker, D.D.; Welch, P.J.; Oh, M.S. Gasification slag rheology and crystallization in titanium-rich, iron–calcium–aluminosilicate glasses. Fuel Process. Technol. 1998, 56, 103–127. [Google Scholar] [CrossRef]

- Zhang, Y.K.; Ren, Q.Q.; Deng, H.X.; Lyu, Q.G. Fusibility characteristic and flow properties of semi-char from industrial circulating fluidized bed gasification. Fuel 2018, 234, 904–913. [Google Scholar] [CrossRef]

- Ma, Z.B.; Tian, X.Q.; Liao, H.Q.; Guo, Y.X.; Cheng, F.Q. Improvement of fly ash fusion characteristics by adding metallurgical slag at high temperature for production of continuous fiber. J. Clean. Prod. 2018, 171, 464–481. [Google Scholar] [CrossRef]

- Xu, J.; Yu, G.S.; Liu, X.; Zhao, F.; Chen, X.L.; Wang, F.C. Investigation on the high-temperature flow behavior of biomass and coal blended ash. Bioresour. Technol. 2014, 166, 494–499. [Google Scholar] [CrossRef]

- Kakietek, S.; Szymczak, J. Artificial neural networks application for solid fuel slagging intensity predictions. E3S Web Conf. 2017, 14, 02004. [Google Scholar] [CrossRef]

- Teruel, E.; Cortés, C.; Díez, L.I.; Arauzo, I. Monitoring and prediction of fouling in coal-fired utility boilers using neural networks. Chem. Eng. Sci. 2005, 60, 5035–5048. [Google Scholar] [CrossRef]

- Romeo, L.M.; Gareta, R. Neural network for evaluating boiler behavior. Appl. Therm. Eng. 2006, 26, 1530–1536. [Google Scholar] [CrossRef]

- Jiang, Y.; Lin, X.C.; Ideta, K.; Takebe, H.; Miyawaki, J.; Yoon, S.H.; Mochida, I. Microstructural transformations of two representative slags at high temperatures and effects on the viscosity. J. Ind. Eng. Chem. 2014, 20, 1338–1345. [Google Scholar] [CrossRef]

| Variable | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | K2O | SO3 | A/B | S/A |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Range | 10.79–64.48 | 3.49–51.14 | ≤40.28 | ≤50.84 | ≤15.71 | ≤27.4 | ≤20 | ≤14.99 | ≤28.36 | 0.27–9.64 | 0.42–7.30 |

| Average | 44.34 | 22.41 | 8.77 | 14.06 | 2.18 | 1.16 | 1.65 | 0.81 | 2.47 | 3.10 | 2.16 |

| Variable | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | K2O | SO3 | A/B | S/A | T (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Range | 20.9–64.5 | 6.3–51.1 | ≤29.2 | ≤50.8 | ≤10.8 | ≤27.4 | ≤20 | ≤15.0 | ≤13.3 | 0.6–6.5 | 0.4–7.3 | 1105–1973 |

| Average | 47.47 | 21.31 | 7.28 | 13.64 | 1.91 | 1.65 | 2.19 | 1.11 | 2.18 | 3.24 | 2.46 | 1381.92 |

| Hidden Layer | Tansig | Logsig | Purelin | Poslin | |

|---|---|---|---|---|---|

| Output Layer | |||||

| tansig | 0.0207 | 0.0124 | 0.1813 | 0.1068 | |

| logsig | 0.1584 | 0.1728 | 0.1949 | 0.1714 | |

| purelin | 0.0576 | 0.0402 | 0.1933 | 0.1311 | |

| poslin | 0.2095 | 0.1934 | 0.2344 | 0.2021 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, X.; Xi, W.; Dai, J.; Wang, C.; Wang, Y. Prediction of Slag Characteristics Based on Artificial Neural Network for Molten Gasification of Hazardous Wastes. Energies 2020, 13, 5115. https://doi.org/10.3390/en13195115

Lin X, Xi W, Dai J, Wang C, Wang Y. Prediction of Slag Characteristics Based on Artificial Neural Network for Molten Gasification of Hazardous Wastes. Energies. 2020; 13(19):5115. https://doi.org/10.3390/en13195115

Chicago/Turabian StyleLin, Xiongchao, Wenshuai Xi, Jinze Dai, Caihong Wang, and Yonggang Wang. 2020. "Prediction of Slag Characteristics Based on Artificial Neural Network for Molten Gasification of Hazardous Wastes" Energies 13, no. 19: 5115. https://doi.org/10.3390/en13195115

APA StyleLin, X., Xi, W., Dai, J., Wang, C., & Wang, Y. (2020). Prediction of Slag Characteristics Based on Artificial Neural Network for Molten Gasification of Hazardous Wastes. Energies, 13(19), 5115. https://doi.org/10.3390/en13195115